Ensuring Sustainability via Application of Root Zone Technology in a Rubber Product Industry: A Circular Economy Approach

Abstract

:1. Introduction

- Limited availability of raw materials and resources.

- The dependence on imported raw materials (i.e., high prices, volatile markets, and uncertain political situations in some countries).

- Decreasing competitiveness of the global economy.

2. Materials and Methods

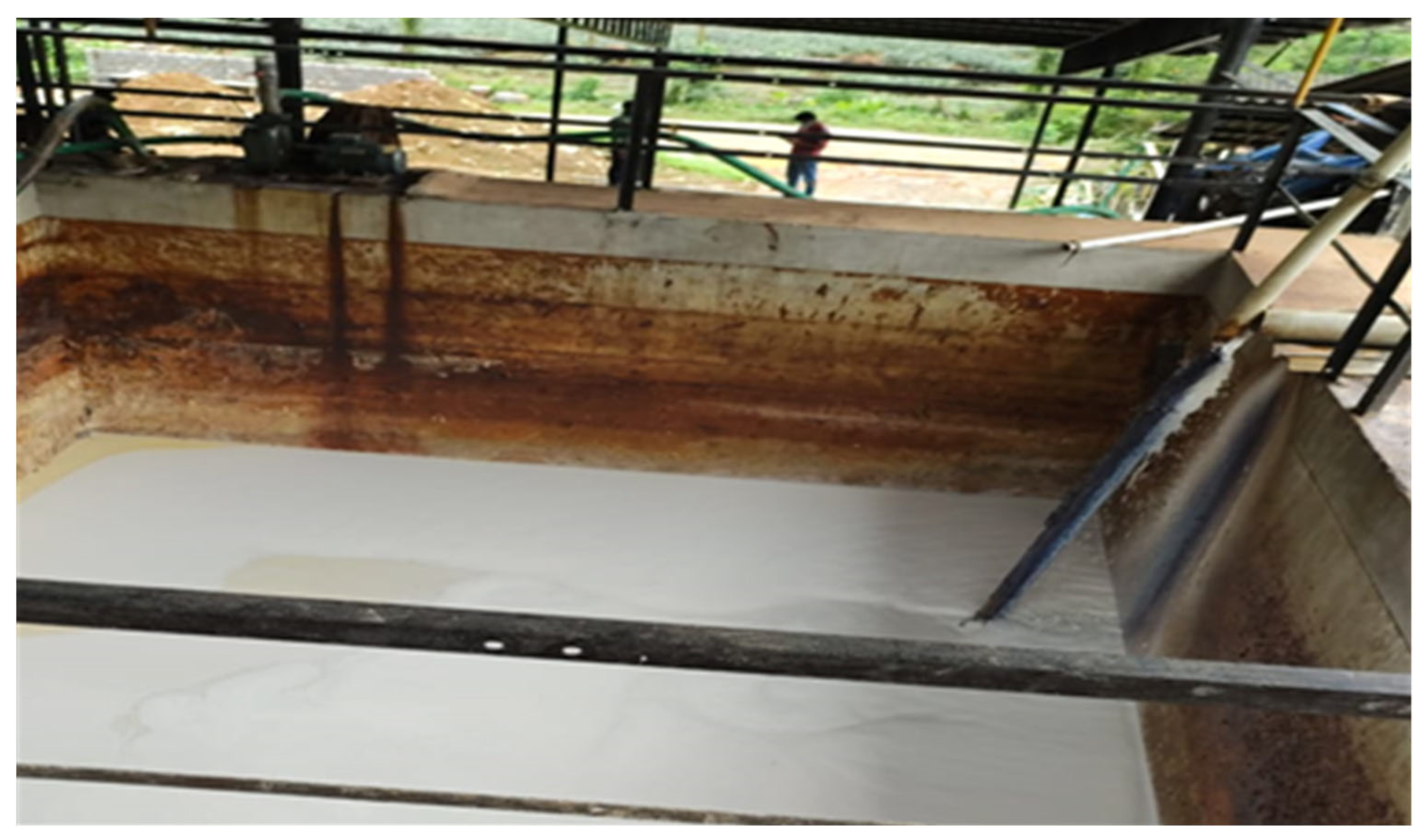

Steps of Construction and Procedure of RZT

3. Results and Discussion

3.1. Changes Observed in Characteristics of Colocasia and Vetiver Plants in Root Zone Technology

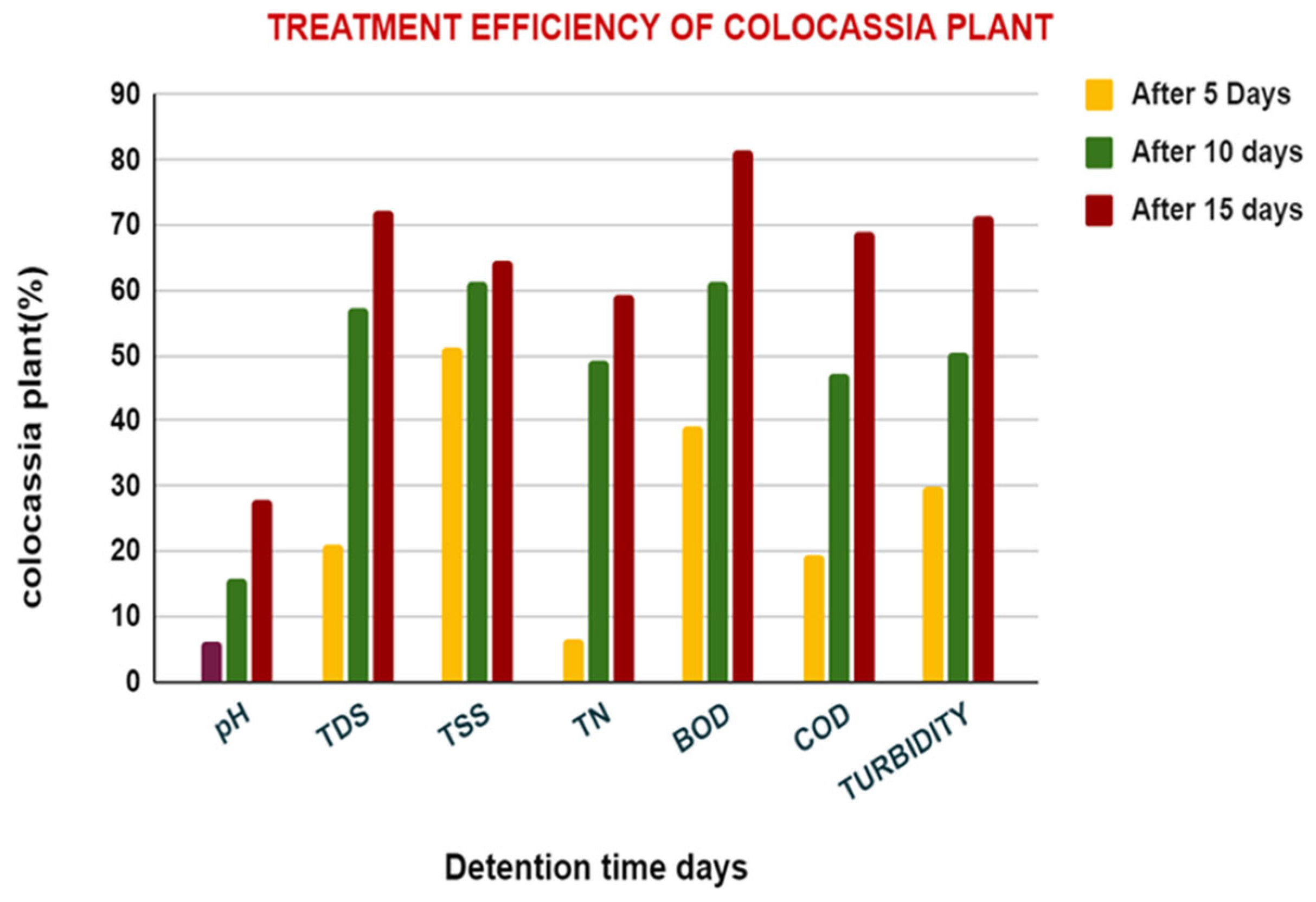

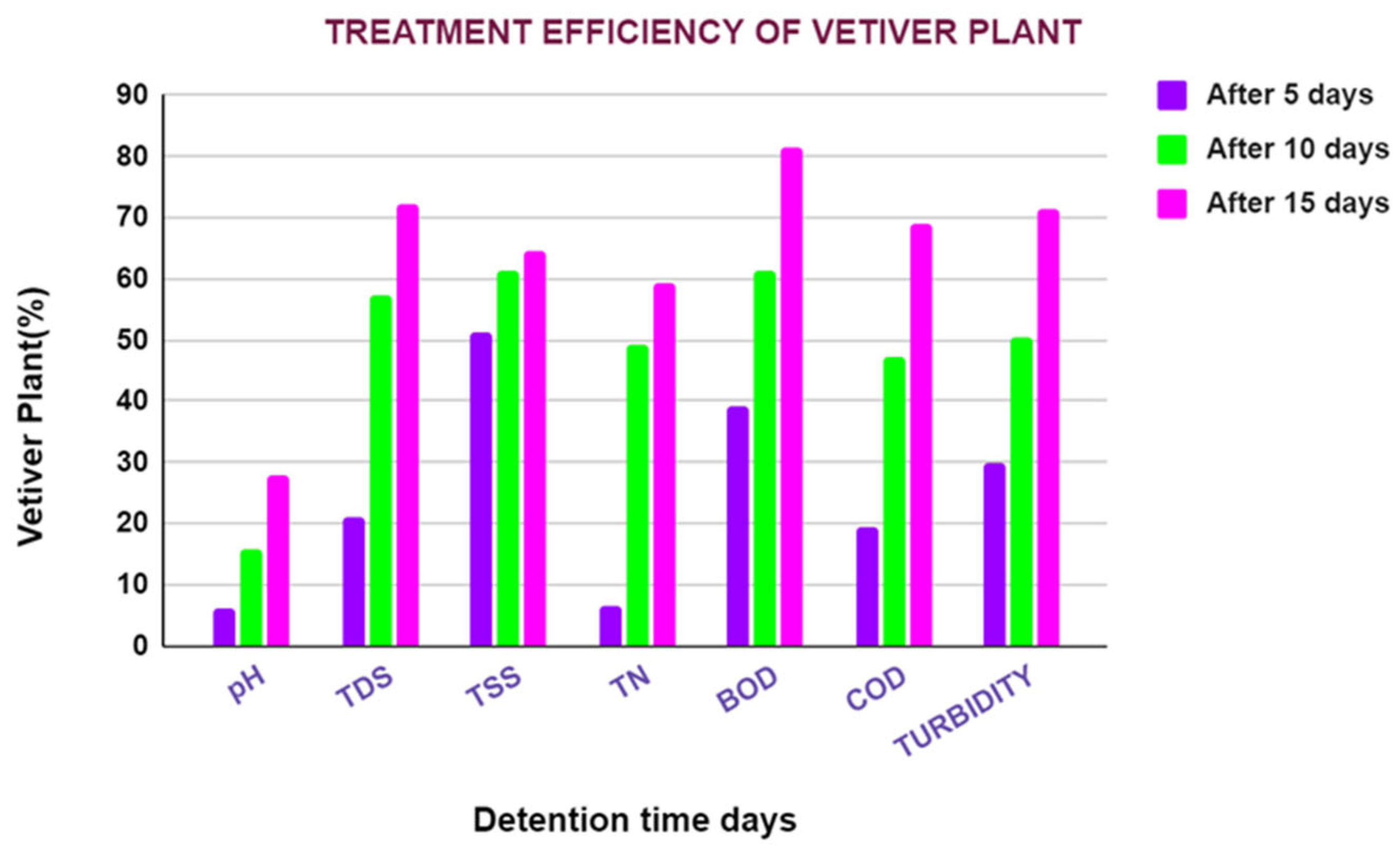

3.2. Treatment Efficiency of Colocasia and Vetiver

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ranjbari, M.; Saidani, M.; Esfandabadi, Z.S.; Peng, W.; Lam, S.S.; Aghbashlo, M.; Quatraro, F.; Tabatabaei, M. Two decades of research on waste management in the circular economy: Insights from bibliometric, text mining, and content analyses. J. Clean. Prod. 2021, 314, 128009. [Google Scholar] [CrossRef]

- Ranjbari, M.; Esfandabadi, Z.S.; Shevchenko, T.; Chassagnon-Haned, N.; Peng, W.; Tabatabaei, M.; Aghbashlo, M. Mapping healthcare waste management research: Past evolution, current challenges, and future perspectives towards a circular economy transition. J. Hazard. Mater. 2022, 422, 126724. [Google Scholar] [CrossRef]

- Gautam, S.; Makitha, L.M.; Gupta, A.; Brema, J.; James, E.J.; Chellaiah, G. Treatment and Effective Utilization of Greywater: A Preliminary Case Study. Appl. Innov. Syst. 2020, 4, 16. [Google Scholar] [CrossRef]

- Raval, A.A.; Desai, P.B. Root Zone Technology: Reviewing its past and present. Int. J. Curr. Microbiol. Appl. Sci. 2015, 4, 238–247. [Google Scholar]

- Thorat, P.; Saniya, S.; Shaikh, S.; Shaikh, R.; Sonawane, A. Domestic wastewater treatment by root zone technology option: Colacassia plant. Int. J. Eng. Manag. Res. 2019, 9, 55–60. [Google Scholar] [CrossRef]

- Bastion, R.K.; Hammer, D.A. The Use of Constructed Wetlands for Wastewater Treatment and Recycling. In Constructed Wetlands for Water Quality Improvement; CRC Press: Boca Raton, FL, USA, 1992; pp. 59–68. [Google Scholar]

- Gupta, R.; Sharma, S.; Sharma, A.K.; Verma, S. Treatment of waste water by using root zone technology. Pollut. Res. 2013, 32, 317–320. [Google Scholar]

- Singh, N.; Kazmi, N.; Singh, R.P.; Pandey, S.; Gautam, S.; Dahiya, S. Effect of Intermittent Aeration Cycles on EPS Production and Sludge Characteristics in a Field Scale IFAS Reactor. J. Water Process. Eng. 2018, 23, 230–238. [Google Scholar] [CrossRef]

- Tiwari, K.; Jha, S.; Vyas, K.; Patel, K.; Patel, M. Reed bed technology: A Review. Int. J. Eng. 2017, 3, 2349–6185. [Google Scholar]

- Brix, H. Treatment of wastewater in the rhizosphere of wetland plants-the root-zone method. Water Sci. Technol. 1987, 19, 107–118. [Google Scholar]

- Almuktar, S.A.; Abed, S.N.; Scholz, M. Wetlands for wastewater treatment and subsequent recycling of treated effluent: A review. Environ. Sci. Pollut. Res. 2018, 25, 23595–23623. [Google Scholar] [CrossRef]

- Choudhary, A.; Kumar, S.; Sharma, C. Constructed wetlands: An approach for wastewater treatment. Elixir Pollut. 2011, 37, 3666–3672. [Google Scholar]

- Clothier, B.E.; Green, S.R. Rootzone processes and the efficient use of irrigation water. Agric. Water Manag. 1994, 25, 1–12. [Google Scholar] [CrossRef]

- Varne, A.L.; Wagh, K.K. Low cost treatment of sewage using root zone technology. J. Environ. Res. Dev. 2014, 9, 411–420. [Google Scholar]

- Dange, P.S.; Lad, R.K. Upgrading conventional sewage treatment process by using Mangifera Indica. Int. J. Sci. Res. 2015, 3, 1584–1588. [Google Scholar]

- Ranjbari, M.; Esfandabadi, Z.S.; Quatraro, F.; Vatanparast, H.; Lam, S.S.; Aghbashlo, M.; Tabatabaei, M. Biomass and organic waste potentials towards implementing circular bioeconomy platforms: A systematic bibliometric analysis. Fuel 2022, 318, 123585. [Google Scholar] [CrossRef]

- Ranjbari, M.; Esfandabadi, Z.S.; Gautam, S.; Ferraris, A.; Scagnelli, S.D. Waste management beyond the COVID-19 pandemic: Bibliometric and text mining analyses. Gondwana Res. 2022; in press. [Google Scholar] [CrossRef]

- Vymazal, J. Horizontal sub-surface flow and hybrid constructed wetlands systems for wastewater treatment. Ecol. Eng. 2005, 25, 478–490. [Google Scholar] [CrossRef]

- Meshram, P.G.; Raut, R.J.; Bokse, P.G.; Rathod, A.W. Waste water treatment by using Root Zone Technology: Using Colocassia Plant. Int. J. Engg. Res. 2020, 7, 3575–3578. [Google Scholar]

- Smol, M.; Adam, C.; Preisner, M. Circular economy model framework in the European water and wastewater sector. J. Mater. Cycles Waste Manag. 2020, 22, 682–697. [Google Scholar] [CrossRef]

- Zhu, Q.; Geng, Y.; Lai, K.H. Circular economy practices among Chinese manufacturers varying in environmental-oriented supply chain cooperation and the performance implications. J. Environ. Manag. 2010, 91, 1324–1331. [Google Scholar] [CrossRef]

- Imbert, E.; Ladu, L.; Tani, A.; Morone, P. The transition towards a bio-based economy: A comparative study based on social network analysis. J. Environ. Manag. 2019, 230, 255–265. [Google Scholar] [CrossRef]

- Li, J.; Song, X.; Guo, Y.; Yang, Q.; Feng, K. The determinants of China’s national and regional energy-related mercury emission changes. J. Environ Manag. 2019, 246, 505–513. [Google Scholar] [CrossRef]

- Rathinasamy, M.; Monica, G.K.; Ramasamy, D.; Nithila, R. Root Zone Treatment for Periyakulam Pond in Coimbatore. Asian J. Appl. Sci. 2018, 2, 63–70. [Google Scholar]

- Abidi, S.; Kallali, H.; Jedidi, N.; Bouzaiane, O.; Hassen, A. Comparative pilot study of the performances of two constructed wetland wastewater treatment hybrid systems. Desalination. 2009, 246, 370–377. [Google Scholar] [CrossRef]

- IS 3025; (Part 1): Method of Sampling and Test (Physical and Chemical) for Water and Wastewater, Hardness (Second Revision). Bureau Of Indian Standards (BIS): New Delhi, India, 1987.

- Dhanya, G.; Jaya, D.S. Waste water treatment efficiency of vetiver grass in constructed wetlands. Aquat. Biol. 2013, 2, 119–125. [Google Scholar]

- Parmar, J.P.; Vyas, D.S.; Christian, R.A. Experimental study on post treatment of dairy wastewater using hybrid reed bed technology. Int. J. Adv. Res. Innov. Ideas Educ. 2016, 2, 618–628. [Google Scholar]

| Parameter Analyzed | Detention Time (d) | Colocasia Plants | Vetiver Plants | Desirable Limit |

|---|---|---|---|---|

| pH | 5 10 15 | 4.5 5.4 6.1 | 5 5.8 7.2 | 6–8 |

| TDS (mg/L) | 5 10 15 | 1790 960 630 | 1750 950 620 | 2100 |

| TSS (mg/L) | 5 10 15 | 1070 850 786 | 1050 837 765 | 100 |

| TN (mg/L) | 5 10 15 | 96 53 38 | 83 45 36 | 50 |

| Turbidity (NTU) | 5 10 15 | 23.5 15 12.2 | 21 14.8 8.5 | 1–5 |

| BOD (mg/L) | 5 10 15 | 3000 1950 920 | 3020 1932 910 | 30–100 |

| COD (mg/L) | 5 10 15 | 6985 4525 2655 | 6875 4498 2640 | 250 |

| Parameters Analyzed | Detention Time (d) | Colocasia | Vetiver |

|---|---|---|---|

| pH | 5 10 15 | 12.5 35 52.5 | 25 45 80 |

| TDS (mg/L) | 5 10 15 | 19.7 56.9 71.7 | 20.86 57.3 72.1 |

| TSS (mg/L) | 5 10 15 | 50.46 60.6 63.6 | 51.3 61.2 64.5 |

| TN (mg/L) | 5 10 15 | 7.8 40.4 57.3 | 6.7 49.4 59.5 |

| Turbidity | 5 10 15 | 21.6 50 59.3 | 30 50.6 71.6 |

| (NTU) | 5 10 15 | 39.7 60.8 81.5 | 39.3 61.2 81.7 |

| BOD (mg/L) | 5 10 15 | 18.3 47.1 68.9 | 19.6 47.4 69.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

C, G.; Jacob, L.; Gautam, S.; Singh, N.K.; Kumar, R.P. Ensuring Sustainability via Application of Root Zone Technology in a Rubber Product Industry: A Circular Economy Approach. Sustainability 2022, 14, 12141. https://doi.org/10.3390/su141912141

C G, Jacob L, Gautam S, Singh NK, Kumar RP. Ensuring Sustainability via Application of Root Zone Technology in a Rubber Product Industry: A Circular Economy Approach. Sustainability. 2022; 14(19):12141. https://doi.org/10.3390/su141912141

Chicago/Turabian StyleC, Gajendran, Lydia Jacob, Sneha Gautam, Nitin Kumar Singh, and Roshini Praveen Kumar. 2022. "Ensuring Sustainability via Application of Root Zone Technology in a Rubber Product Industry: A Circular Economy Approach" Sustainability 14, no. 19: 12141. https://doi.org/10.3390/su141912141

APA StyleC, G., Jacob, L., Gautam, S., Singh, N. K., & Kumar, R. P. (2022). Ensuring Sustainability via Application of Root Zone Technology in a Rubber Product Industry: A Circular Economy Approach. Sustainability, 14(19), 12141. https://doi.org/10.3390/su141912141