Environmental Impact Evaluation of University Integrated Waste Management System in India Using Life Cycle Analysis

Abstract

:1. Introduction

2. Materials and Methods

2.1. Study Area

2.2. Physical Characterization of Municipal Solid Waste

2.3. Waste Management Scenarios

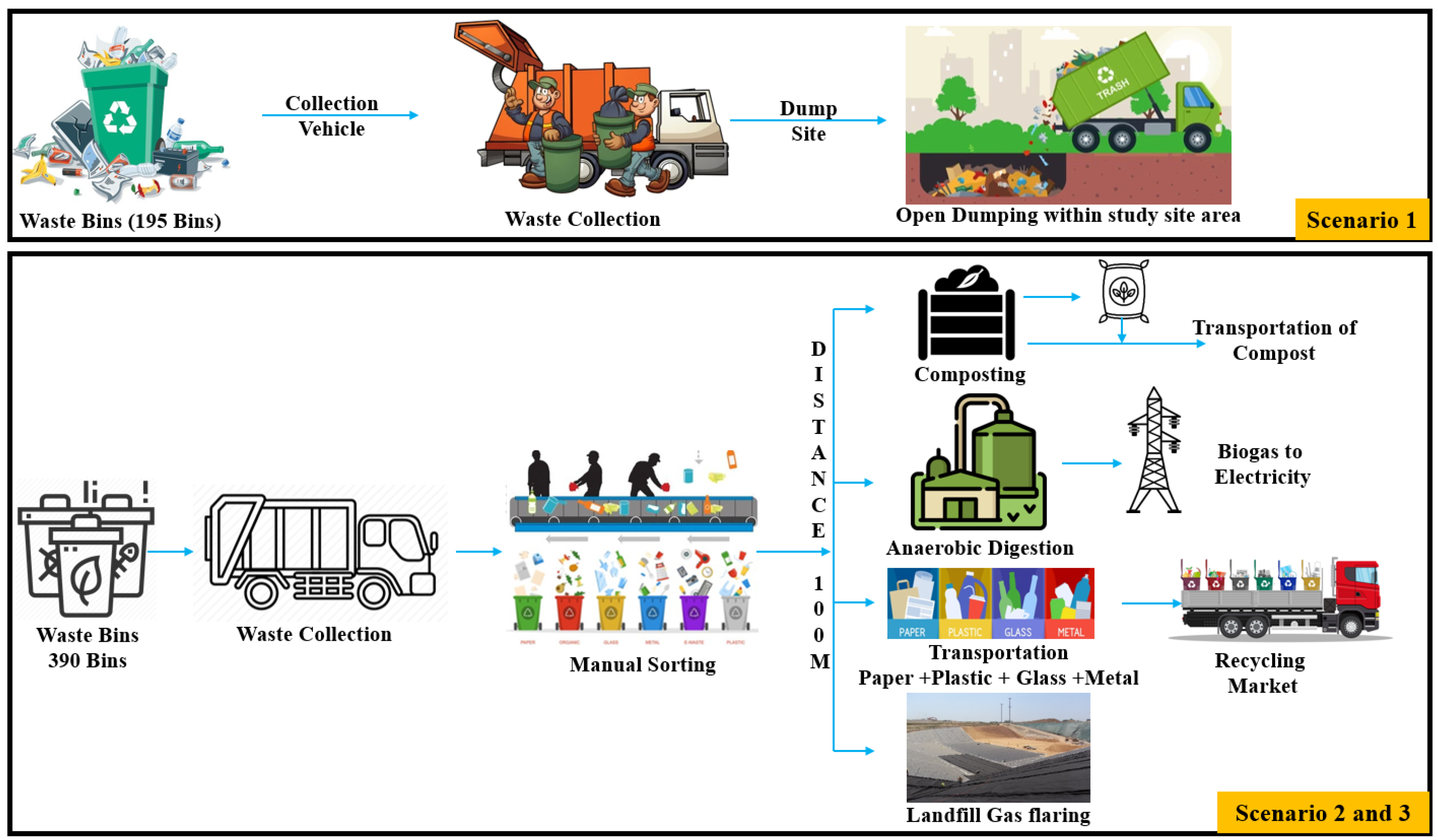

2.3.1. Scenario (S1)—Business-As-Usual (BAU): Open Dumping

2.3.2. Scenario (S2 & S3)—Integrated Waste Treatment Facility with 50 & 90% Waste Sorting

2.4. Life Cycle Assessment

2.4.1. Goal and Scope Definition

2.4.2. Life Cycle Inventory Data

- Anaerobic Digestion

- Windrow composting

2.4.3. Life Cycle Impact Assessment

3. Results

3.1. Physicochemical Characteristics of MSW

3.2. Life Cycle Impact Assessment Results

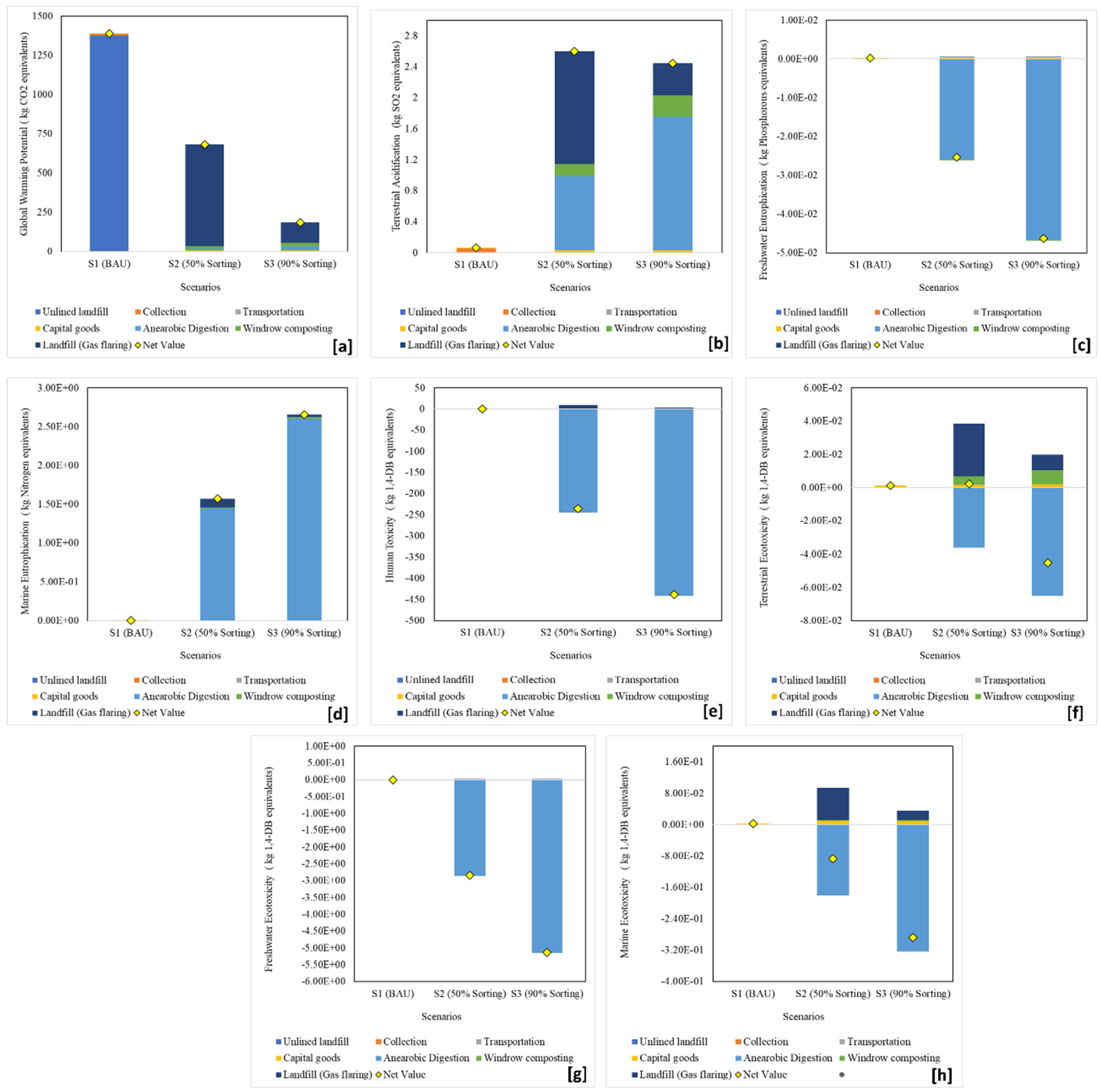

3.2.1. Global Warming Potential

3.2.2. Terrestrial Acidification

3.2.3. Freshwater Eutrophication

3.2.4. Marine Eutrophication

3.2.5. Human Toxicity Potential

3.2.6. Terrestrial Ecotoxicity Potential

3.2.7. Freshwater Ecotoxicity

3.2.8. Marine Ecotoxicity

4. Discussion

4.1. Bioeconomy Fertilizers

4.2. Bio-Methanation

4.3. Bioethanol

4.4. Biohydrogen

4.5. Implementation of Waste Systems across the University Campus

4.6. Recommendations for Future Studies

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Abdul-Azeez, I.A.; Ho, C.S. Realizing Low Carbon Emission in the University Campus towards Energy Sustainability. Open J. Energy Effic. 2015, 4, 15–27. [Google Scholar] [CrossRef] [Green Version]

- Adeniran, A.E.; Nubi, A.T.; Adelopo, A.O. Solid waste generation and characterization in the University of Lagos for a sustainable waste management. Waste Manag. 2017, 67, 3–10. [Google Scholar] [CrossRef]

- AICTE. Government of India, All India Council for Technical Education. 2016. Available online: https://facilities.aicte-india.org/dashboard/pages/dashboardaicte.php (accessed on 28 August 2021).

- Andrianisa, H.A.; Brou, Y.O. Role and importance of informal collectors in the municipal waste pre-collection system in Abidjan, Côte d’Ivoire. Habitat Int. 2016, 53, 265–273. [Google Scholar] [CrossRef]

- Angelo, A.C.M.; Saraiva, A.B.; Clímaco, J.C.N.; Infante, C.E.; Valle, R. Life Cycle Assessment and Multi-criteria Decision Analysis: Selection of a strategy for domestic food waste management in Rio de Janeiro. J. Clean. Prod. 2017, 143, 744–756. [Google Scholar] [CrossRef]

- Armijo de Vega, C.; Ojeda-Benítez, S.; Ramírez-Barreto, M.E. Mexican educational institutions and waste management programmes: A University case study. Resour. Conserv. Recycl. 2003, 39, 283–296. [Google Scholar] [CrossRef]

- Bahçelioğlu, E.; Buğdaycı, E.S.; Doğan, N.B.; Şimşek, N.; Kaya, S.; Alp, E. Integrated solid waste management strategy of a large campus: A comprehensive study on METU campus, Turkey. J. Clean. Prod. 2020, 265, 121715. [Google Scholar] [CrossRef]

- Zen, I.S.; Subramaniam, D.; Sulaiman, H.; Saleh, A.L.; Omar, W.; Salim, M.R. Institutionalize waste minimization governance towards campus sustainability: A case study of Green Office initiatives in Universiti Teknologi Malaysia. J. Clean. Prod. 2016, 135, 1407–1422. [Google Scholar] [CrossRef]

- Armijo de Vega, C.; Ojeda Benítez, S.; Ramírez Barreto, M.E. Solid waste characterization and recycling potential for a university campus. Waste Manag. 2008, 28 (Supp. 1), S21–S26. [Google Scholar] [CrossRef]

- Fagnani, E.; Guimarães, J.R. Waste management plan for higher education institutions in developing countries: The Continuous Improvement Cycle model. J. Clean. Prod. 2017, 147, 108–118. [Google Scholar] [CrossRef]

- Smyth, D.P.; Fredeen, A.L.; Booth, A.L. Reducing solid waste in higher education: The first step towards ‘greening’ a university campus. Resour. Conserv. Recycl. 2010, 54, 1007–1016. [Google Scholar] [CrossRef]

- Malakahmad, A.; Kutty, S.; Hasnain Isa, M. Solid Waste Characterization and Recycling Potential for University Technology PETRONAS Academic Buildings USM-MOSTI Project View project Detection Methods of Carcinogens in Estuaries View project. Am. J. Environ. Sci. 2014, 6, 422–427. [Google Scholar] [CrossRef]

- Berchin, I.I.; Grando, V.D.S.; Marcon, G.A.; Corseuil, L.; Guerra, J.B.S.O.D.A. Strategies to promote sustainability in higher education institutions: A case study of a federal institute of higher education in Brazil. Int. J. Sustain. High. Educ. 2017, 18, 1018–1038. [Google Scholar] [CrossRef]

- Tangwanichagapong, S.; Nitivattananon, V.; Mohanty, B.; Visvanathan, C. Greening of a campus through waste management initiatives: Experience from a higher education institution in Thailand. Int. J. Sustain. High. Educ. 2017, 18, 203–217. [Google Scholar] [CrossRef]

- Clabeaux, R.; Carbajales-Dale, M.; Ladner, D.; Walker, T. Assessing the carbon footprint of a university campus using a life cycle assessment approach. J. Clean. Prod. 2020, 273, 122600. [Google Scholar] [CrossRef]

- Sammalisto, K.; Brorson, T. Training and communication in the implementation of environmental management systems (ISO 14001): A case study at the University of Gävle, Sweden. J. Clean. Prod. 2008, 16, 299–309. [Google Scholar] [CrossRef]

- Lukman, R.; Tiwary, A.; Azapagic, A. Towards greening a university campus: The case of the University of Maribor, Slovenia. Resour. Conserv. Recycl. 2009, 53, 639–644. [Google Scholar] [CrossRef]

- Geng, Y.; Liu, K.; Xue, B.; Fujita, T. Creating a “green university” in China: A case of Shenyang University. J. Clean. Prod. 2013, 61, 13–19. [Google Scholar] [CrossRef]

- Ozawa-Meida, L.; Brockway, P.; Letten, K.; Davies, J.; Fleming, P. Measuring carbon performance in a UK University through a consumption-based carbon footprint: De Montfort University case study. J. Clean. Prod. 2013, 56, 185–198. [Google Scholar] [CrossRef]

- Dong, J.; Ni, M.; Chi, Y.; Zou, D.; Fu, C. Life cycle and economic assessment of source-separated MSW collection with regard to greenhouse gas emissions: A case study in China. Environ. Sci. Pollut. Res. 2013, 20, 5512–5524. [Google Scholar] [CrossRef]

- Wang, M.Q.; Han, J.; Haq, Z.; Tyner, W.E.; Wu, M.; Elgowainy, A. Energy and greenhouse gas emission effects of corn and cellulosic ethanol with technology improvements and land use changes. Biomass Bioenergy 2011, 35, 1885–1896. [Google Scholar] [CrossRef] [Green Version]

- Mandpe, A.; Bhattacharya, A.; Paliya, S.; Pratap, V.; Hussain, A.; Kumar, S. Life-cycle assessment approach for municipal solid waste management system of Delhi city. Environ. Res. 2022, 212, 113424. [Google Scholar] [CrossRef] [PubMed]

- Cheela, V.R.S.; Dubey, B. Review of Application of Systems Engineering Approaches in Development of Integrated Solid Waste Management for a Smart City. In Water Resources and Environmental Engineering II; Rathinasamy, M., Chandramouli, S., Phanindra, K., Mahesh, U., Eds.; Springer: Berlin/Heidelberg, Germany, 2019; pp. 159–177. [Google Scholar]

- Liikanen, M.; Havukainen, J.; Viana, E.; Horttanainen, M. Steps towards more environmentally sustainable municipal solid waste management—A life cycle assessment study of São Paulo, Brazil. J. Clean. Prod. 2018, 196, 150–162. [Google Scholar] [CrossRef]

- Oliveira, L.S.; Oliveira, D.S.; Bezerra, B.S.; Pereira, B.S.; Battistelle, R.A.G. Environmental analysis of organic waste treatment focusing on composting scenarios. J. Clean. Prod. 2017, 155, 229–237. [Google Scholar] [CrossRef] [Green Version]

- Sharp, L. Green campuses: The road from little victories to systemic transformation. Int. J. Sustain. High. Educ. 2002, 3, 128–145. [Google Scholar] [CrossRef]

- Institute, U.S. Climate & Emissions Sustainability. 2018. Available online: https://www.unh.edu/sustainability/operations/air-climate (accessed on 28 August 2021).

- ASTM E1756-08; Standard Test Method for Determination of Total Solids in Biomass. American Society for Testing and Materials: West Conshohocken, PA, USA, 2008. Available online: https://www.astm.org/Database.cart/historical/e1756-08.htm (accessed on 24 August 2021).

- ASTM E711-87; Standard Test Method for Gross Calorific Value of Refuse-Derived Fuel by the Bomb Calorimeter (Withdrawn 2004). American Society for Testing and Materials: West Conshohocken, PA, USA, 2004. Available online: https://www.astm.org/Standards/E711.htm (accessed on 24 August 2021).

- ASTM E777-87; Standard Test Method for Carbon and Hydrogen in the Analysis Sample of Refuse-Derived Fuel. American Society for Testing and Materials: West Conshohocken, PA, USA, 2004. Available online: https://www.astm.org/DATABASE.CART/HISTORICAL/E777-87R04.htm (accessed on 24 August 2021).

- ASTM E872-82; Standard Test Method for Volatile Matter in the Analysis of Particulate Wood Fuels. American Society for Testing and Materials: West Conshohocken, PA, USA, 2019. Available online: https://www.astm.org/Standards/E872.htm (accessed on 24 August 2021).

- Barlaz, M.A.; Chanton, J.P.; Green, R.B. Controls on landfill gas collection efficiency: Instantaneous and lifetime performance. J. Air Waste Manag. Assoc. 2009, 59, 1399–1404. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, Y.; Sun, W.; Liu, J. Greenhouse gas emissions from different municipal solid waste management scenarios in China: Based on carbon and energy flow analysis. Waste Manag. 2017, 68, 653–661. [Google Scholar] [CrossRef]

- Bhupednra Kumar, S.; Munish, K. Life cycle assessment of potential municipal solid waste management strategies for Mumbai, India. Waste Manag. Res. J. Sustain. Circ. Econ. 2017, 35, 79–91. [Google Scholar] [CrossRef]

- Biswas, W.K. Life cycle assessment of seawater desalinization in Western Australia. World Acad. Sci. Eng. Technol. 2009, 56, 369–375. [Google Scholar] [CrossRef]

- Silva, F.B.; Yoshida, O.S.; Diestelkamp, E.D.; De Oliveira, L.A. Relevance of including capital goods in the life cycle assessment of construction products. LALCA Rev. Lat.-Am. Em Avaliação Do Ciclo De Vida 2018, 2, 7–22. [Google Scholar] [CrossRef]

- CPHEEO. CPHEEO:Central Public Health & Environmental Engineering Organisation (CPHEEO), Govt of India. 2020. Available online: http://cpheeo.gov.in/cms/about-cpheeo.php (accessed on 28 August 2021).

- Environmental Protection Agency (EPA). Report on “LFG Energy Project Development Handbook”. 2020. Available online: https://www.epa.gov/sites/production/files/2016-11/documents/pdh_full.pdf (accessed on 15 April 2021).

- Bassi, A.; Højlund, T. Environmental performance of household waste management in Europe—An example of 7 countries. Waste Manag. 2021, 69, 545–557. [Google Scholar] [CrossRef] [Green Version]

- Babu, G.L.S.; Lakshmikanthan, P.; Santhosh, L.G. Life Cycle Analysis of Municipal Solid Waste (MSW) Land Disposal Options in Bangalore City. In ICSI 2014: Creating Infrastructure for a Sustainable World—Proceedings of the 2014 International Conference on Sustainable Infrastructure; American Society for Civil Engineers: Pomona, CA, USA, 2014; pp. 795–806. [Google Scholar] [CrossRef]

- Bogner, J.E.; Chanton, J.P.; Blake, D.; Abichou, T.; Powelson, D. Effectiveness of a Florida Landfill Biocover for Reduction of CH4 and NMHC Emissions. Environ. Sci. Technol. 2010, 44, 1197–1203. [Google Scholar] [CrossRef] [PubMed]

- Turner, D.A.; Williams, I.D.; Kemp, S. Combined material flow analysis and life cycle assessment as a support tool for solid waste management decision making. J. Clean. Prod. 2016, 129, 234–248. [Google Scholar] [CrossRef] [Green Version]

- Mistri, A.; Dhami, N.; Bhattacharyya, S.K.; Barai, S.V.; Mukherjee, A.; Biswas, W.K. Environmental implications of the use of bio-cement treated recycled aggregate in concrete. Resour. Conserv. Recycl. 2021, 167, 105436. [Google Scholar] [CrossRef]

- European Commission. Committee and the Committee of the Regions a European Agenda on Migration 2. 2015. Available online: http://www.europarl.europa.eu/oeil/popups/ficheprocedure.do?lang=en&reference=2015/2660 (accessed on 25 August 2021).

- Pooja, Y.; Sukha, R. Environmental impact assessment of municipal solid waste management options using life cycle assessment: A case study. Environ. Sci. Pollut. Res. 2018, 25, 838–854. [Google Scholar] [CrossRef]

- Chatterjee, B.; Mazumder, D. Role of stage-separation in the ubiquitous development of Anaerobic Digestion of Organic Fraction of Municipal Solid Waste: A critical review. Renew. Sustain. Energy Rev. 2019, 104, 439–469. [Google Scholar] [CrossRef]

- CPHEEO. Manual on Municipal Solid Waste Management—2016:Central Public Health & Environmental Engineering Organisation (CPHEEO), Govt of India. 2016. Available online: http://cpheeo.gov.in/cms/manual-on-municipal-solid-waste-management-2016.php (accessed on 28 August 2021).

- Seruga, P.; Krzywonos, M.; Seruga, A.; Niedźwiecki, Ł.; Pawlak-Kruczek, H.; Urbanowska, A. Anaerobic Digestion Performance: Separate Collected vs. Mechanical Segregated Organic Fractions of Municipal Solid Waste as Feedstock. Energies 2020, 13, 3768. [Google Scholar] [CrossRef]

- Goedkoop, M.; Oele, M.; Leijting, J.; Ponsioen, T.; Meijer, E. Introduction to LCA with SimaPro Title: Introduction to LCA with SimaPro. 2016. Available online: www.pre-sustainability.com (accessed on 25 August 2021).

- El Hanandeh, A.; El-Zein, A. Life-cycle assessment of municipal solid waste management alternatives with consideration of uncertainty: SIWMS development and application. Waste Manag. 2010, 30, 902–911. [Google Scholar] [CrossRef] [Green Version]

- Ingrao, C.; Faccilongo, N.; Di Gioia, L.; Messineo, A. Food waste recovery into energy in a circular economy perspective: A comprehensive review of aspects related to plant operation and environmental assessment. J. Clean. Prod. 2018, 184, 869–892. [Google Scholar] [CrossRef]

- Styles, D.; Dominguez, E.M.; Chadwick, D. Environmental balance of the UK biogas sector: An evaluation by consequential life cycle assessment. Sci. Total Environ. 2016, 560–561, 241–253. [Google Scholar] [CrossRef] [Green Version]

- National Research Council. Waste Incineration and Public Health; National Academies Press: Washington, DC, USA, 2000. [Google Scholar]

- Kanhar, A.H.; Chen, S.; Wang, F. Incineration Fly Ash and Its Treatment to Possible Utilization: A Review. Energies 2020, 13, 6681. [Google Scholar] [CrossRef]

- Cheela, V.R.S.; John, M.; Biswas, W.; Dubey, B. Environmental Impact Evaluation of Current Municipal Solid Waste Treatments in India Using Life Cycle Assessment. Energies 2021, 14, 3133. [Google Scholar] [CrossRef]

- Zhou, H.; Yang, Q.; Gul, E.; Shi, M.; Li, J.; Yang, M.; Yang, H.; Chen, B.; Zhao, H.; Yan, Y.; et al. Decarbonizing university campuses through the production of biogas from food waste: An LCA analysis. Renew. Energy 2021, 176, 565–578. [Google Scholar] [CrossRef]

| Parameter | Value | Unit | Reference |

|---|---|---|---|

| Landfill | |||

| Diesel consumption | 2 | L·t−1 | [40] |

| Methane generation | 55 | % | [38] |

| LFG Collection efficiency | 90 | % | [38] |

| LFG collected (Years 0–55) | 95 | % | [39] |

| LFG collected (Years 55–100) | % | [39] | |

| LFG Top cover oxidation | 36 | % CH4 | [41] |

| Anaerobic digestion | |||

| Electricity (pre-treatment) | 12.6 | kWh | [5] |

| Electricity (Reactor) | 14 | kWh | [39] |

| Methane emissions | 0.5% | % of CH4 | [39] |

| Transport of compost | 3 | L·t−1 | [40] |

| Electricityrecovery (biogas) | 35 | % | [40] |

| Land application | |||

| N2O-N emissions (direct) | 1.25 | % of N-tot | [5] |

| NH3-N emissions | 15 | % of N-tot | [5] |

| NO3−-N emissions | 20 | % of N-tot | [5] |

| Incoming N content | 4.85 | kg N-tot | [5] |

| Incoming P content | 0.65 | kg P-tot | [5] |

| Incoming K content | 1.48 | kg K-tot | [5] |

| Application of digestate | 20 | MJ/t digestate | [5] |

| Application of mineral fertilizers | 0.36 | MJ/kg N-tot | [5] |

| Incineration | |||

| Sodium hydroxide | 0.24 | kg | [42] |

| Hydrated lime | 10 | kg | [42] |

| Activated carbon | 0.25 | kg | [42] |

| Ammonia (NH3) | 0.5 | kg | [42] |

| Electricity consumption | 0.27 | MWh | [5] |

| Impact Category | Unit |

|---|---|

| Global warming potential | kg CO2 equivalent |

| Terrestrial acidification | kg SO2 equivalent |

| Freshwater eutrophication | kg-phosphorus equivalent |

| Marine water eutrophication | kg-nitrogen equivalent |

| Human toxicity | kg 1,4-dichlorobenzene equivalent |

| Terrestrial ecotoxicity | kg 1,4-dichlorobenzene equivalent |

| Freshwater ecotoxicity | kg 1,4-dichlorobenzene equivalent |

| Marine ecotoxicity | kg 1,4-dichlorobenzene equivalent |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jaglan, A.K.; Cheela, V.R.S.; Vinaik, M.; Dubey, B. Environmental Impact Evaluation of University Integrated Waste Management System in India Using Life Cycle Analysis. Sustainability 2022, 14, 8361. https://doi.org/10.3390/su14148361

Jaglan AK, Cheela VRS, Vinaik M, Dubey B. Environmental Impact Evaluation of University Integrated Waste Management System in India Using Life Cycle Analysis. Sustainability. 2022; 14(14):8361. https://doi.org/10.3390/su14148361

Chicago/Turabian StyleJaglan, Amit Kumar, Venkata Ravi Sankar Cheela, Mansi Vinaik, and Brajesh Dubey. 2022. "Environmental Impact Evaluation of University Integrated Waste Management System in India Using Life Cycle Analysis" Sustainability 14, no. 14: 8361. https://doi.org/10.3390/su14148361

APA StyleJaglan, A. K., Cheela, V. R. S., Vinaik, M., & Dubey, B. (2022). Environmental Impact Evaluation of University Integrated Waste Management System in India Using Life Cycle Analysis. Sustainability, 14(14), 8361. https://doi.org/10.3390/su14148361