Environmental Performance Reporting and Assessment of the Biodegradable Waste Treatment Plants Registered to EMAS in Italy

Abstract

1. Introduction

2. Methodology

2.1. Inventory

2.2. Data analysis

2.2.1. Technical Features of the Plants

2.2.2. Reporting on Key Aspects

- Identification of the relevance of each aspect as assessed by each company, leading to a classification as “significant” or “non-significant”;

- Identification of the specific metrics and indicators used for the quantification of each aspect (with a specific insight devoted to the reporting of greenhouse gas (GHG) emissions);

- Identification of the improvement objectives set for each aspect in 2017–2020, including related actions, metrics, and allocated budget.

2.2.3. Environmental Performance Analysis

3. Results and Discussion

3.1. Technical Features of the Plants

3.2. Reporting on Key Aspects (Significance, Indicators, and Improvement Objectives)

3.2.1. Metrics and Indicators Used to Quantify the Aspects

3.2.2. GHG Emissions

3.2.3. Improvement Objectives

3.3. Environmental Performances’ Analysis

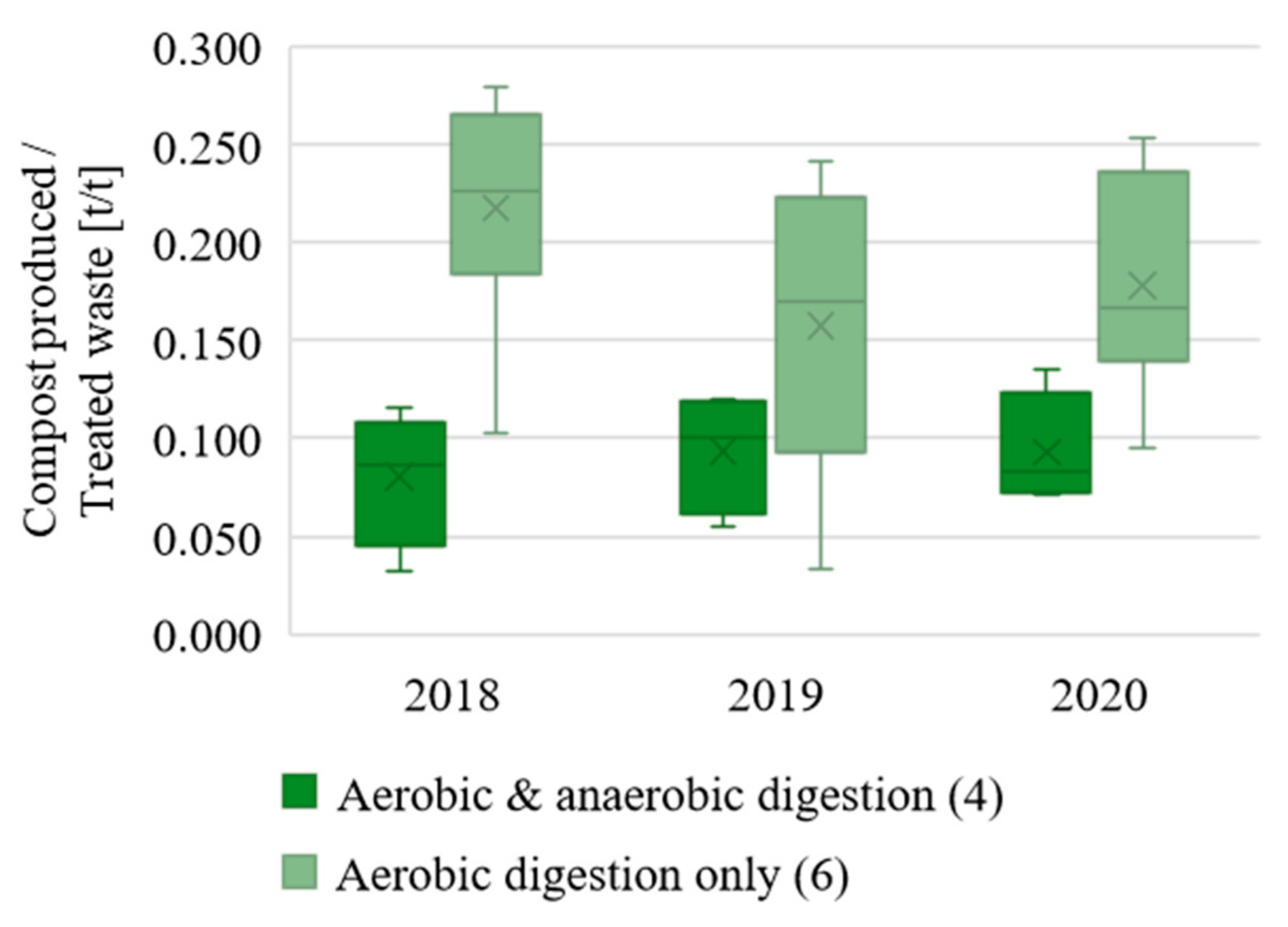

3.3.1. Compost and Biogas Specific Production

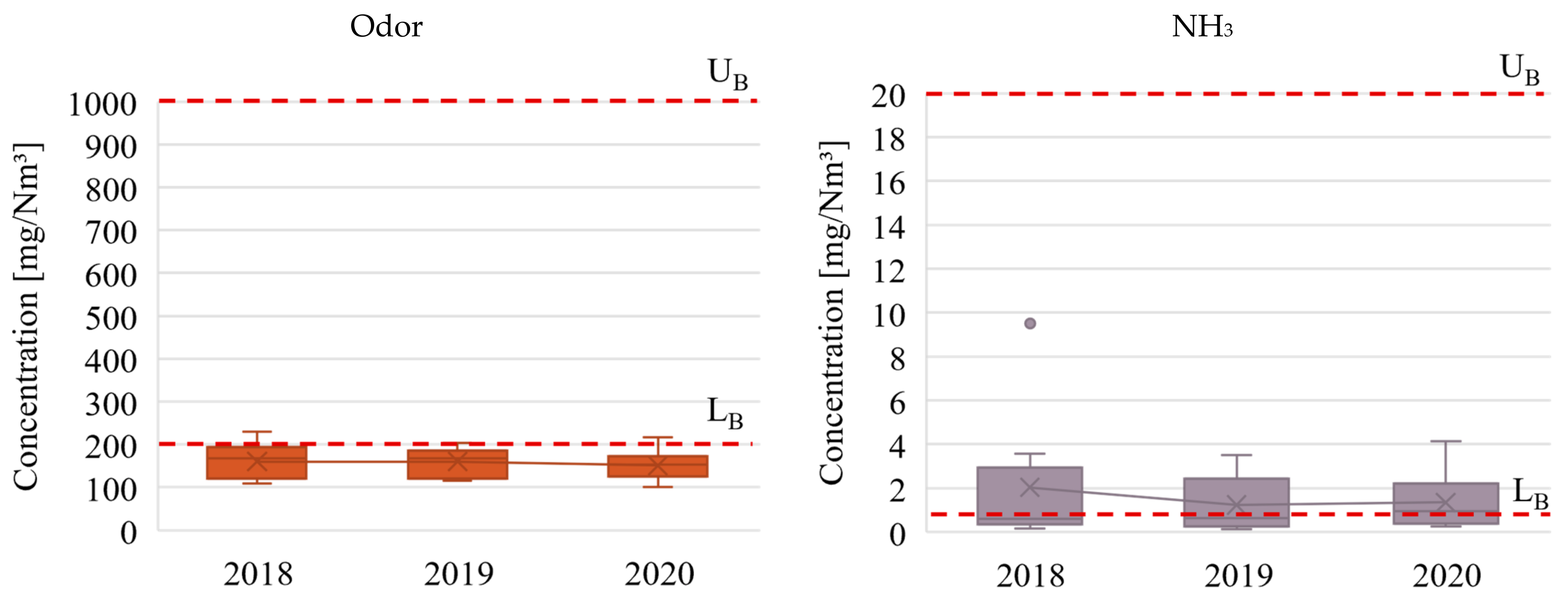

3.3.2. Odor Emissions and Emissions to Air

4. Conclusions

- (i)

- Identification of the performance indicators and metrics used by the companies to describe the environmental impacts of their plants: The key aspects considered significant and quantified in the ESs by at least 50% of the organizations were emissions to air, odor emissions, energy consumption, and waste production. A strong positive correlation linked the significance of specific key aspects and the number of related indicators. Produced and avoided GHG emissions were reported in 69% and 38% of the ESs, respectively, but crucial contributions ,such as waste transportation and disposal of the originated waste, were neglected.

- (ii)

- Analysis of which aspects, how and to what extent are companies committed to improving their environmental performances: Overall, the analyzed ESs declared 44 improvement objectives: 11 related to process management, and 19 related to odor emissions, emission to air, energy/water consumption, and waste production. Over 90% of the allocated budget was associated with improvements related to process management and to emissions to air, and no correlation was found between the significance of specific key aspects and the budget allocated for their improvement.

- (iii)

- Comparison of the environmental performances of the plants to the BAT-AELs defined for odor and NH3 concentration: Odor emissions (151 ± 35 OUE/Nm3 in 2020) were mostly below the lower BAT-AEL (200 OUE/Nm3), with lower (−17%) values for anaerobic/aerobic combined processes compared with aerobic processes. NH3 concentrations in the exhaust air (1.35 ± 1.36 mg/Nm3 in 2020) were slightly above the lower (0.3 mg/Nm3) and significantly below the upper BAT-AEL (20 mg/Nm3).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Eurostat Municipal Waste by Waste Management Operations. Available online: https://ec.europa.eu/eurostat/databrowser/view/ENV_WASMUN__custom_1977762/default/table?lang=en (accessed on 26 January 2022).

- European Commission. A Sustainable Bioeconomy for Europe: Strengthening the Connection between Economy, Society and the Environment: Updated Bioeconomy Strategy; Publications Office: Brussels, Belgium, 2018. [Google Scholar]

- Eurostat Management of Waste by Waste Management Operations and Type of Material-Sankey Diagram Data. Available online: https://ec.europa.eu/eurostat/databrowser/view/env_wassd/default/table?lang=en (accessed on 26 January 2022).

- European Commission. Council Directive 1999/31/EC of 26 April 1999 on the Landfill of Waste; European Commission: Brussels, Belgium, 1999. [Google Scholar]

- European Commission. Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on Waste and Repealing Certain Directives (Text with EEA Relevance); European Commission: Brussels, Belgium, 2008. [Google Scholar]

- Scherhaufer, S.; Moates, G.; Hartikainen, H.; Waldron, K.; Obersteiner, G. Environmental Impacts of Food Waste in Europe. Waste Manag. 2018, 77, 98–113. [Google Scholar] [CrossRef]

- Pujara, Y.; Pathak, P.; Sharma, A.; Govani, J. Review on Indian Municipal Solid Waste Management Practices for Reduction of Environmental Impacts to Achieve Sustainable Development Goals. J. Environ. Manag. 2019, 248, 109238. [Google Scholar] [CrossRef] [PubMed]

- Sharma, H.B.; Vanapalli, K.R.; Samal, B.; Cheela, V.R.S.; Dubey, B.K.; Bhattacharya, J. Circular Economy Approach in Solid Waste Management System to Achieve UN-SDGs: Solutions for Post-COVID Recovery. Sci. Total Environ. 2021, 800, 149605. [Google Scholar] [CrossRef] [PubMed]

- AlQattan, N.; Acheampong, M.; Jaward, F.M.; Ertem, F.C.; Vijayakumar, N.; Bello, T. Reviewing the Potential of Waste-to-Energy (WTE) Technologies for Sustainable Development Goal (SDG) Numbers Seven and Eleven. Renew. Energy Focus 2018, 27, 97–110. [Google Scholar] [CrossRef]

- European Commission. Decision (EU) 2022/591 of the European Parliament and of the Council of 6 April 2022 on a General Union Environment Action Programme to 2030; European Commission: Brussels, Belgium, 2022. [Google Scholar]

- Schroeder, P.; Anggraeni, K.; Weber, U. The Relevance of Circular Economy Practices to the Sustainable Development Goals. J. Ind. Ecol. 2019, 23, 77–95. [Google Scholar] [CrossRef]

- Demichelis, F.; Piovano, F.; Fiore, S. Biowaste management in Italy: Challenges and perspectives. Sustainability 2019, 11, 4213. [Google Scholar] [CrossRef]

- Demichelis, F.; Laghezza, M.; Chiappero, M.; Fiore, S. Technical, Economic and Environmental Assessement of Bioethanol Biorefinery from Waste Biomass. J. Clean. Prod. 2020, 277, 124111. [Google Scholar] [CrossRef]

- Osman, A.I.; Mehta, N.; Elgarahy, A.M.; Al-Hinai, A.; Al-Muhtaseb, A.H.; Rooney, D.W. Conversion of Biomass to Biofuels and Life Cycle Assessment: A Review. Environ. Chem. Lett. 2021, 19, 4075–4118. [Google Scholar] [CrossRef]

- Barjoveanu, G.; Pătrăuțanu, O.-A.; Teodosiu, C.; Volf, I. Life Cycle Assessment of Polyphenols Extraction Processes from Waste Biomass. Sci. Rep. 2020, 10, 13632. [Google Scholar] [CrossRef]

- Da Costa, T.P.; Quinteiro, P.; Tarelho, L.A.C.; Arroja, L.; Dias, A.C. Life Cycle Assessment of Woody Biomass Ash for Soil Amelioration. Waste Manag. 2020, 101, 126–140. [Google Scholar] [CrossRef]

- Cusenza, M.A.; Longo, S.; Guarino, F.; Cellura, M. Energy and Environmental Assessment of Residual Bio-Wastes Management Strategies. J. Clean. Prod. 2021, 285, 124815. [Google Scholar] [CrossRef]

- Komakech, A.J.; Sundberg, C.; Jönsson, H.; Vinnerås, B. Life Cycle Assessment of Biodegradable Waste Treatment Systems for Sub-Saharan African Cities. Resour. Conserv. Recycl. 2015, 99, 100–110. [Google Scholar] [CrossRef]

- Sonesson, U.; Björklund, A.; Carlsson, M.; Dalemo, M. Environmental and Economic Analysis of Management Systems for Biodegradable Waste. Resour. Conserv. Recycl. 2000, 28, 29–53. [Google Scholar] [CrossRef]

- Lei, H.; Li, L.; Yang, W.; Bian, Y.; Li, C.-Q. An Analytical Review on Application of Life Cycle Assessment in Circular Economy for Built Environment. J. Build. Eng. 2021, 44, 103374. [Google Scholar] [CrossRef]

- Zhang, J.; Qin, Q.; Li, G.; Tseng, C.-H. Sustainable Municipal Waste Management Strategies through Life Cycle Assessment Method: A Review. J. Environ. Manag. 2021, 287, 112238. [Google Scholar] [CrossRef]

- Seber, G.; Malina, R.; Pearlson, M.N.; Olcay, H.; Hileman, J.I.; Barrett, S.R.H. Environmental and Economic Assessment of Producing Hydroprocessed Jet and Diesel Fuel from Waste Oils and Tallow. Biomass Bioenergy 2014, 67, 108–118. [Google Scholar] [CrossRef]

- Olofsson, J.; Börjesson, P. Residual Biomass as Resource–Life-Cycle Environmental Impact of Wastes in Circular Resource Systems. J. Clean. Prod. 2018, 196, 997–1006. [Google Scholar] [CrossRef]

- European Commission. Council of the EU Regulation (EC) No 1221/2009 of the European Parliament and of the Council of 25 November 2009 on the Voluntary Participation by Organisations in a Community Eco-Management and Audit Scheme (EMAS); European Commission: Brussels, Belgium, 2009. [Google Scholar]

- ISO 14001:2015; Environmental Management Systems. Requirements with Guidance for Use. 3rd ed. ISO: Geneva, Switzerland, 2015.

- Comoglio, C.; Botta, S. The Use of Indicators and the Role of Environmental Management Systems for Environmental Performances Improvement: A Survey on ISO 14001 Certified Companies in the Automotive Sector. J. Clean. Prod. 2012, 20, 92–102. [Google Scholar] [CrossRef]

- Petrosillo, I.; De Marco, A.; Botta, S.; Comoglio, C. EMAS in Local Authorities: Suitable Indicators in Adopting Environmental Management Systems. Ecol. Indic. 2012, 13, 263–274. [Google Scholar] [CrossRef]

- Pinasseau, A.; Zerger, B.; Roth, J.; Canova, M.; Roudier, S. Best Available Techniques (BAT) Reference Document for Waste Treatment Industrial Emissions Directive 2010/75/EU (Integrated Pollution Prevention and Control); Publications Office of the European Union: Luxembourg, 2018. [Google Scholar]

- ISPRA. Catasto Nazionale Rifiuti: Search of the Authorizations Contained in the MUD Databases. Available online: https://www.catasto-rifiuti.isprambiente.it/index.php?pg=comautmudoperazione®id=01&nomereg=Piemonte&provid=004&nomeprov=Cuneo&comid=01004113&nomecom=Magliano%20Alfieri&ta=&cerca=cerca&p=1&opr=&opd=&rv=&tipogest=&tipogest1=&attivata=si&width=1536&height=864&advice=si (accessed on 16 February 2022).

- ISPRA. Catasto Nazionale Rifiuti: Localization of Municipal Waste Treatment Plants-Composting, Composting/Anaerobic Digestion, Anaerobic Digestion Plants, Year. 2020. Available online: https://www.catasto-rifiuti.isprambiente.it/index.php?pg=gestnazione&aa=2019®id=&mappa=4&width=1280&height=720&advice=si (accessed on 16 February 2022).

- ISPRA. List of Organizations Registered to EMAS. Available online: https://www.isprambiente.gov.it/it/attivita/certificazioni/emas/elenco-organizzazioni-registrate-emas (accessed on 1 November 2021).

- Wang, A.; Tu, R.; Gai, Y.; Pereira, L.G.; Vaughan, J.; Posen, I.D.; Miller, E.J.; Hatzopoulou, M. Capturing Uncertainty in Emission Estimates Related to Vehicle Electrification and Implications for Metropolitan Greenhouse Gas Emission Inventories. Appl. Energy 2020, 265, 114798. [Google Scholar] [CrossRef]

- European Commission; Joint Research Centre; Dri, M.; Canfora, P.; Antonopoulos, I.; Gaudillat, P. Best Environmental Management Practice for the Waste Management Sector: Learning from Frontrunners; Publications Office: Brussels, Belgium, 2018. [Google Scholar]

- Comoglio, C.; Castelluccio, S.; Scarrone, A.; Fiore, S. Environmental Sustainability Reporting in the Waste-to-Energy Sector: Performance Indicators and Improvement Targets of the EMAS-Registered Waste Incineration Plants in Italy. 2022; in preparation. [Google Scholar]

- Álvarez-García, J.; Del RíoRama, M.D.L.C. Sustainability and EMAS: Impact of Motivations and Barriers on the Perceived Benefits from the Adoption of Standards. Sustainability 2016, 8, 1057. [Google Scholar] [CrossRef]

- Tourais, P.; Videira, N. Why, How and What Do Organizations Achieve with the Implementation of Environmental Management Systems?—Lessons from a Comprehensive Review on the Eco-Management and Audit Scheme. Sustainability 2016, 8, 283. [Google Scholar] [CrossRef]

- Carnevale, E.; Lombardi, L. Comparison of Different Possibilities for Biogas Use by Life Cycle Assessment. Energy Procedia 2015, 81, 215–226. [Google Scholar] [CrossRef][Green Version]

- Chen, T.-C.; Lin, C.-F. Greenhouse Gases Emissions from Waste Management Practices Using Life Cycle Inventory Model. J. Hazard. Mater. 2008, 155, 23–31. [Google Scholar] [CrossRef] [PubMed]

- Campuzano, R.; González-Martínez, S. Characteristics of the Organic Fraction of Municipal Solid Waste and Methane Production: A Review. Waste Manag. 2016, 54, 3–12. [Google Scholar] [CrossRef]

- Sosnowski, P.; Wieczorek, A.; Ledakowicz, S. Anaerobic Co-Digestion of Sewage Sludge and Organic Fraction of Municipal Solid Wastes. Adv. Environ. Res. 2003, 7, 609–616. [Google Scholar] [CrossRef]

- Orzi, V.; Cadena, E.; D’Imporzano, G.; Artola, A.; Davoli, E.; Crivelli, M.; Adani, F. Potential Odour Emission Measurement in Organic Fraction of Municipal Solid Waste during Anaerobic Digestion: Relationship with Process and Biological Stability Parameters. Bioresour. Technol. 2010, 101, 7330–7337. [Google Scholar] [CrossRef]

- Nowicki, P.; Ćwiklicki, M.; Kafel, P.; Wojnarowska, M. Credibility of Certified Environmental Management Systems: Results from Focus Group Interviews. Environ. Impact Assess. Rev. 2021, 88, 106556. [Google Scholar] [CrossRef]

| Operational Data | Process | Exhaust Air Treatment | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Site | Feedstock | Annual Treated Waste | Aerobic | Anaerobic | Bio-Filter | Wet Scrubber | Bag Filter | Cyclone | Water Spray | ||||||

| OFMSW | Green | Ag&Li | Sew. Sludge | Wood&Paper | Others | Type | Type | Energy Recovery | |||||||

| % | % | % | % | % | % | K Tons | - | - | - | - | - | - | - | - | |

| Pa | 48 | 14 | 38 | 51.4 | St | We | E | x | |||||||

| Or | - | - | - | - | - | - | 40.5 | St | Dr | E | x | x | |||

| Fa | 13 | 32 | 12 | 9 | 32 | 2 | 47.4 | St | x | ||||||

| Fm | - | - | - | - | - | - | 25.6 | Dy | x | x | |||||

| Sd | - | - | - | - | - | - | 17.3 | St | x | ||||||

| Lu | 77 | 19 | 2 | 1 | <1 | 59.9 | Dy | Dr | EH | x | |||||

| Ce | 86 | 14 | 1 | 45.2 | Dy | Dr | EH | x | |||||||

| Ca | 80 | 20 | <1 | 55.9 | Dy | Dr | EH | x | x | x | |||||

| La | 87 | 12 | 1 | <1 | 67.5 | St | x | x | x | ||||||

| Es | - | - | - | - | - | - | 490.1 | St | We | EH | x | x | |||

| Sc | 100 | 6.1 | ns | x | |||||||||||

| As | 84 | 16 | 12.0 | St | x | x | |||||||||

| Ab | 73 | 27 | 26.4 | ns | x | x | |||||||||

| Sr | 93 | 7 | 39.9 | ns | ns | E | x | ||||||||

| Bm | 93 | 7 | <1 | 28.5 | St | x | x | ||||||||

| Tc | 81 | 19 | 1 | 7.8 | St | x | |||||||||

| Aspect | Significant | Described by Indicators | No. of Indicators | ESs with Objectives | No. of Objectives | Tot Budget | Budget Per Objective |

|---|---|---|---|---|---|---|---|

| % | % | - | % | - | k€ | k€ | |

| Emissions to Air | 75.0 | 84.6 | 29 | 23.1 | 4 | 5600 | 1867 |

| Odor Emissions | 75.0 | 69.2 | 9 | 30.8 | 4 | 750 | 375 |

| Energy Consumption | 75.0 | 61.5 | 25 | 30.8 | 5 | 438 | 146 |

| Waste Production | 62.5 | 69.2 | 18 | 30.8 | 5 | 100 | 100 |

| Water Consumption | 50.0 | 46.2 | 10 | 7.7 | 1 | 570 | 570 |

| Noise Emissions | 37.5 | 30.8 | 8 | 0.0 | 0 | 0 | |

| Soil Contamination | 37.5 | 0.0 | 0 | 0.0 | 0 | 0 | |

| Biodiversity | 25.0 | 30.8 | 11 | 0.0 | 0 | 0 | |

| Raw Materials Consumption | 25.0 | 23.1 | 6 | 0.0 | 0 | 0 | |

| Transport | 25.0 | 7.7 | 2 | 7.7 | 1 | 0 | |

| Risk of Env. Accidents | 25.0 | 0.0 | 0 | 23.1 | 3 | 10 | 10 |

| Energy Production | 12.5 | 46.2 | 11 | 23.1 | 3 | 335 | 112 |

| Releases to Water | 12.5 | 15.4 | 2 | 30.8 | 5 | 200 | 100 |

| Process Management | 0.0 | 0.0 | 0 | 61.5 | 11 | 17,180 | 2148 |

| Stakeholder Engagement | 0.0 | 0.0 | 0 | 15.4 | 2 | 12 | 6 |

| Aspect | Indicator | Unit | No. of ESs |

|---|---|---|---|

| Emissions to Air | Mean annual concentrations of pollutants emitted to air | mg/Nm3 | 5 |

| Concentration of contaminants emitted to air from grab sampling | mg/Nm3 | 4 | |

| Total annual CO2 mass emitted to air | t | 3 | |

| Total annual CO2 mass avoided to air | t | 3 | |

| Total annual CO2 mass emitted to air per treated waste | t/t | 3 | |

| Emissions flow rate | Nm3/h | 3 | |

| Total annual greenhouse gas mass emitted to air | t | 2 | |

| Total annual greenhouse gas mass emitted to air by source | t | 2 | |

| Releases to Water | Mean annual concentrations of pollutants released to water | Various | 2 |

| Waste Production | Total annual mass of waste produced | t | 8 |

| Total annual mass of waste produced per typology | t | 6 | |

| Total annual mass of waste produced per treated waste | t/t | 2 | |

| Energy Consumption | Total annual electricity consumption | MWh | 6 |

| Total annual oil consumption | t | 5 | |

| Total annual electricity consumption per treated waste | MWh/t | 4 | |

| Total annual energy consumption | MWh | 3 | |

| Total annual methane consumption | t, Sm3 | 2 | |

| Water Consumption | Total annual water consumption | m3 | 5 |

| Total annual water consumption per treated waste | m3/t | 4 | |

| Raw Material Consumption | Total annual reagents consumption | t | 2 |

| Odor Emissions | Mean annual concentrations of odors emitted to air | OUE/m3 | 5 |

| Concentration of odors emitted to air from grab sampling | OUE/m3 | 4 | |

| Noise Emissions | Maximum noise levels at the plant’s boundaries | dB | 4 |

| Maximum noise levels at sensitive receptors | dB | 4 | |

| Energy Production | Total annual electricity production | MWh | 6 |

| Total annual heat production | MWh | 2 | |

| Total annual energy production | MWh | 2 | |

| Biodiversity | Total site area | m2 | 4 |

| Site | Produced Emissions | Avoided Emissions | |||||

|---|---|---|---|---|---|---|---|

| Considered | Process Emissions | Energy Consumed | Fuels | Considered | Energy Produced | Fertilizers Produced | |

| Pa | N | Y | x | ||||

| Or | Y | x | Y | x | |||

| Fa | N | N | |||||

| Fm | Y | x | N | ||||

| Sd | Y | N | |||||

| Lu | Y | x | x | x | Y | x | x |

| Ce | Y | x | x | x | Y | x | x |

| Ca | Y | x | x | x | Y | x | x |

| La | N | N | |||||

| Es | Y | x | Y | x | |||

| Sc | Y | N | |||||

| As | N | N | |||||

| Ab | Y | x | N | ||||

| Sr | Y | N | |||||

| Bm | Y | x | N | ||||

| Tc | N | N | |||||

| Aspect | Objective | Action | No. of ESs |

|---|---|---|---|

| Emissions to Air | Reduction of GHG emissions | Increased biogas recovery | 1 |

| Equipment conversion to biomethane | 1 | ||

| Installation of photovoltaic panels | 1 | ||

| Reduction of emissions | Improved suction system | 1 | |

| Releases to Water | Reduction of discharges to be purified | Realization of a coverage | 2 |

| Improvement of the management of water discharges | Construction of new tanks | 2 | |

| Realization of a purifier | 1 | ||

| Waste Production | Reduction of waste produced | Increased compost recovery during refining | 2 |

| Exclusion of the biotrickling system from the emission treatment system | 1 | ||

| Raising the awareness of waste donors | 1 | ||

| Improvement of waste management | Mapping of the waste produced | 1 | |

| Energy Consumption | Reduction of electricity consumption | Component replacement | 2 |

| Energy efficiency improvement | Biomethane production from new anaerobic composting line | 1 | |

| Staff training | 1 | ||

| Reduction of the consumption of oil | Equipment replacement | 1 | |

| Water Consumption | Reduction in consumption of water drawn | Use of wastewater | 1 |

| Odor Emissions | Reduction of odor emissions | Installation of a new scrubber | 1 |

| Closure of the compost storage area | 1 | ||

| Increase of windrows irrigation | 1 | ||

| Improvement of odor management | Installation of continuous monitoring | 1 | |

| Transport | Improvement of the viability | Reorganization of the access node | 1 |

| Stakeholder Engagement | Increased awareness | External initiatives | 1 |

| Improvement of relations with stakeholders | Guided tours | 1 | |

| Process Management | Performance improvement | Renovation | 6 |

| Maintenance event prevention | Improvement of the water network | 1 | |

| Internal waste handling improvement | Renovation | 1 | |

| Realization of a sludge drying plant | - | 1 | |

| Construction of a green waste processing plant | - | 1 | |

| Installation of a compost pellet plant | - | 1 | |

| Energy Production | Increase in the electricity produced | Component replacement | 1 |

| Optimization of biogas production | 2 | ||

| Risk of Environmental Accidents | Prevention of emergencies | Expansion of the storage capacity of the leachate | 1 |

| Pollution prevention | Construction of a compost packaging plant | 1 | |

| Fire management improvement | Formation of a fire team | 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Castelluccio, S.; Comoglio, C.; Fiore, S. Environmental Performance Reporting and Assessment of the Biodegradable Waste Treatment Plants Registered to EMAS in Italy. Sustainability 2022, 14, 7438. https://doi.org/10.3390/su14127438

Castelluccio S, Comoglio C, Fiore S. Environmental Performance Reporting and Assessment of the Biodegradable Waste Treatment Plants Registered to EMAS in Italy. Sustainability. 2022; 14(12):7438. https://doi.org/10.3390/su14127438

Chicago/Turabian StyleCastelluccio, Stefano, Claudio Comoglio, and Silvia Fiore. 2022. "Environmental Performance Reporting and Assessment of the Biodegradable Waste Treatment Plants Registered to EMAS in Italy" Sustainability 14, no. 12: 7438. https://doi.org/10.3390/su14127438

APA StyleCastelluccio, S., Comoglio, C., & Fiore, S. (2022). Environmental Performance Reporting and Assessment of the Biodegradable Waste Treatment Plants Registered to EMAS in Italy. Sustainability, 14(12), 7438. https://doi.org/10.3390/su14127438