Theoretical Study on the Effect of Parallel Air Chambers Embedded in Rockwool Panels on the Energy Consumption of a Low-Energy High School

Abstract

1. Introduction

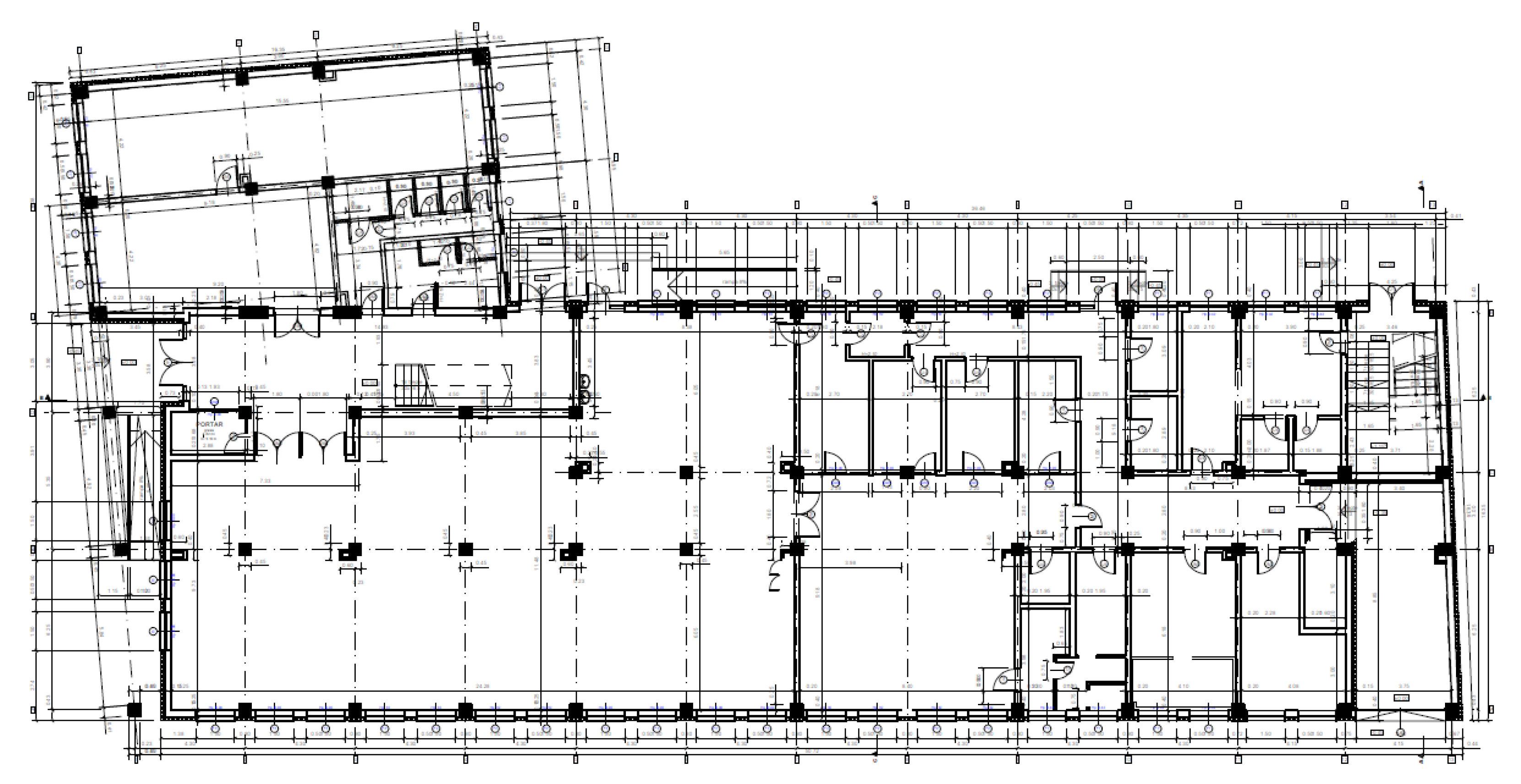

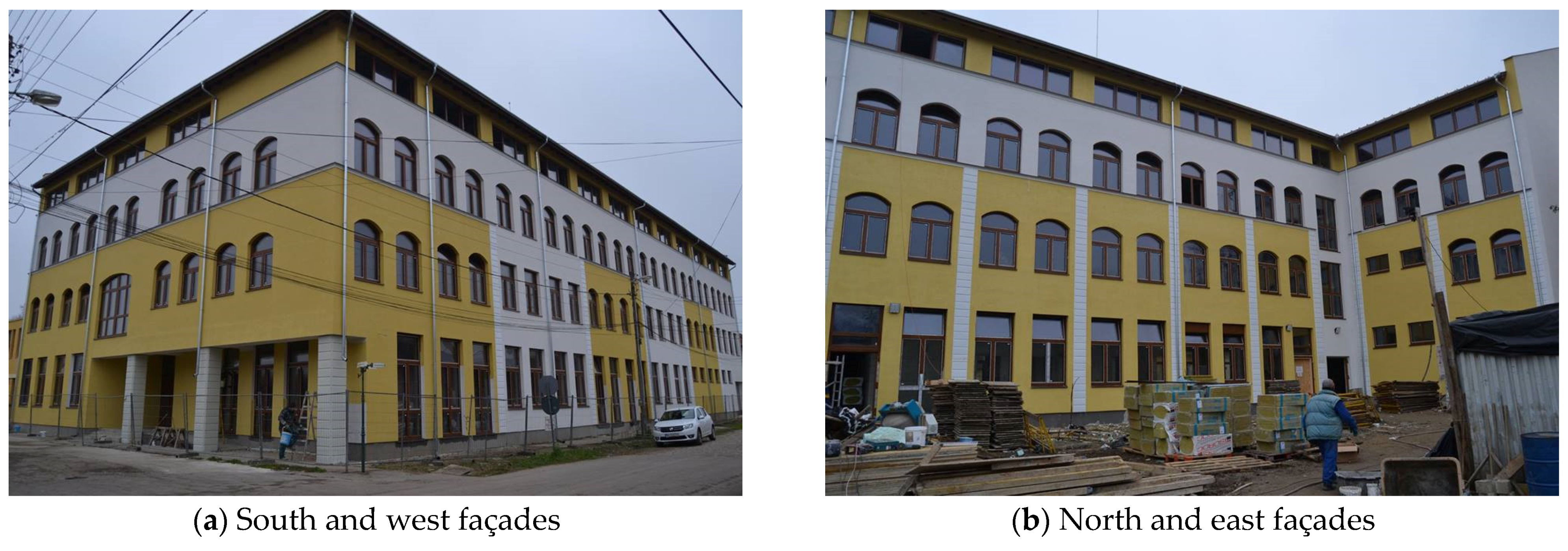

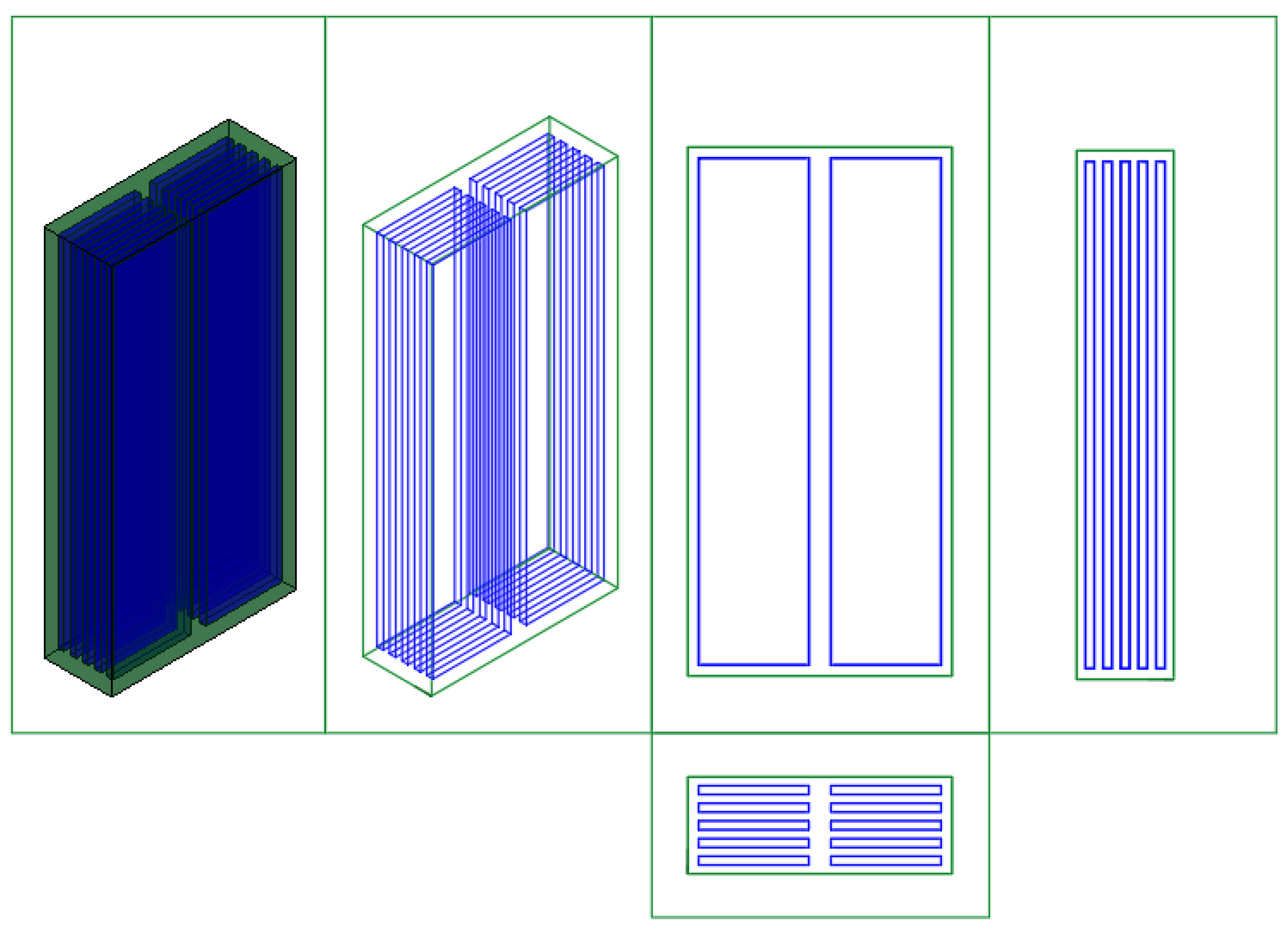

2. Materials and Methods

- Solid rockwool layers having a thickness of 23.0 mm (exterior walls) and 30.0 mm (upper slab);

- Air layers that consist of two air cavities surrounded by a solid perimetral frame and that are separated by an intermediary section of solid material having a width of 5 cm.

3. Results

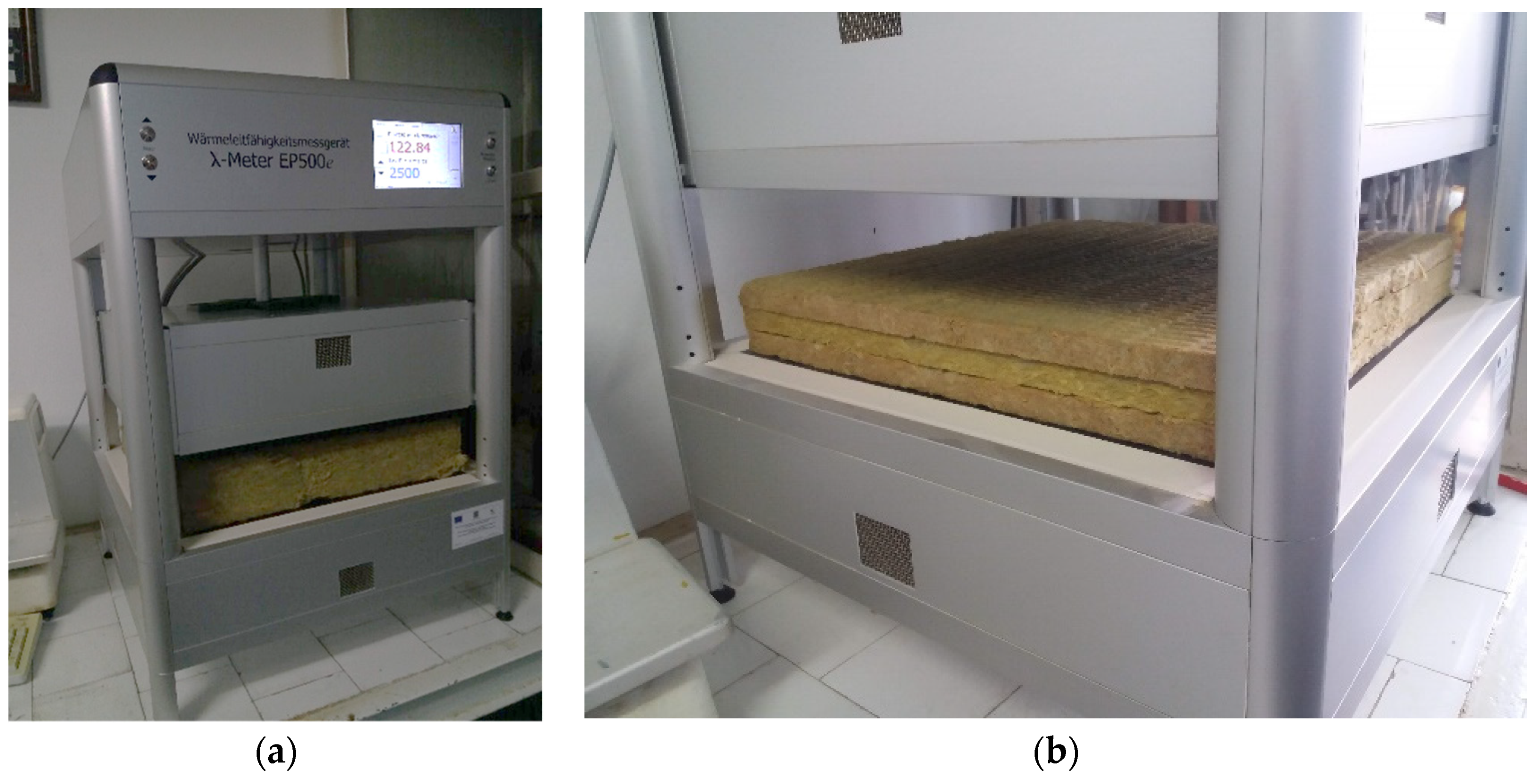

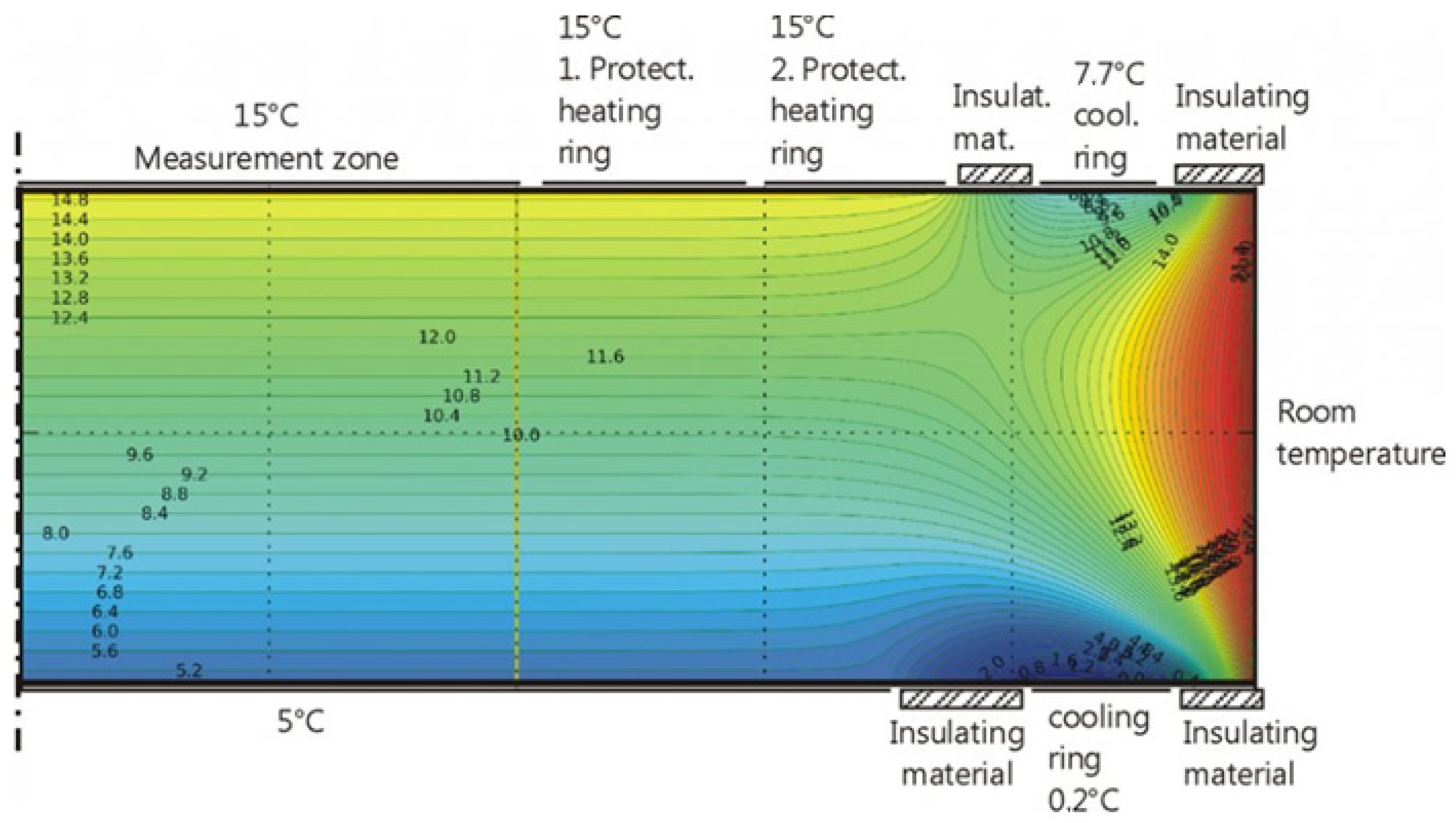

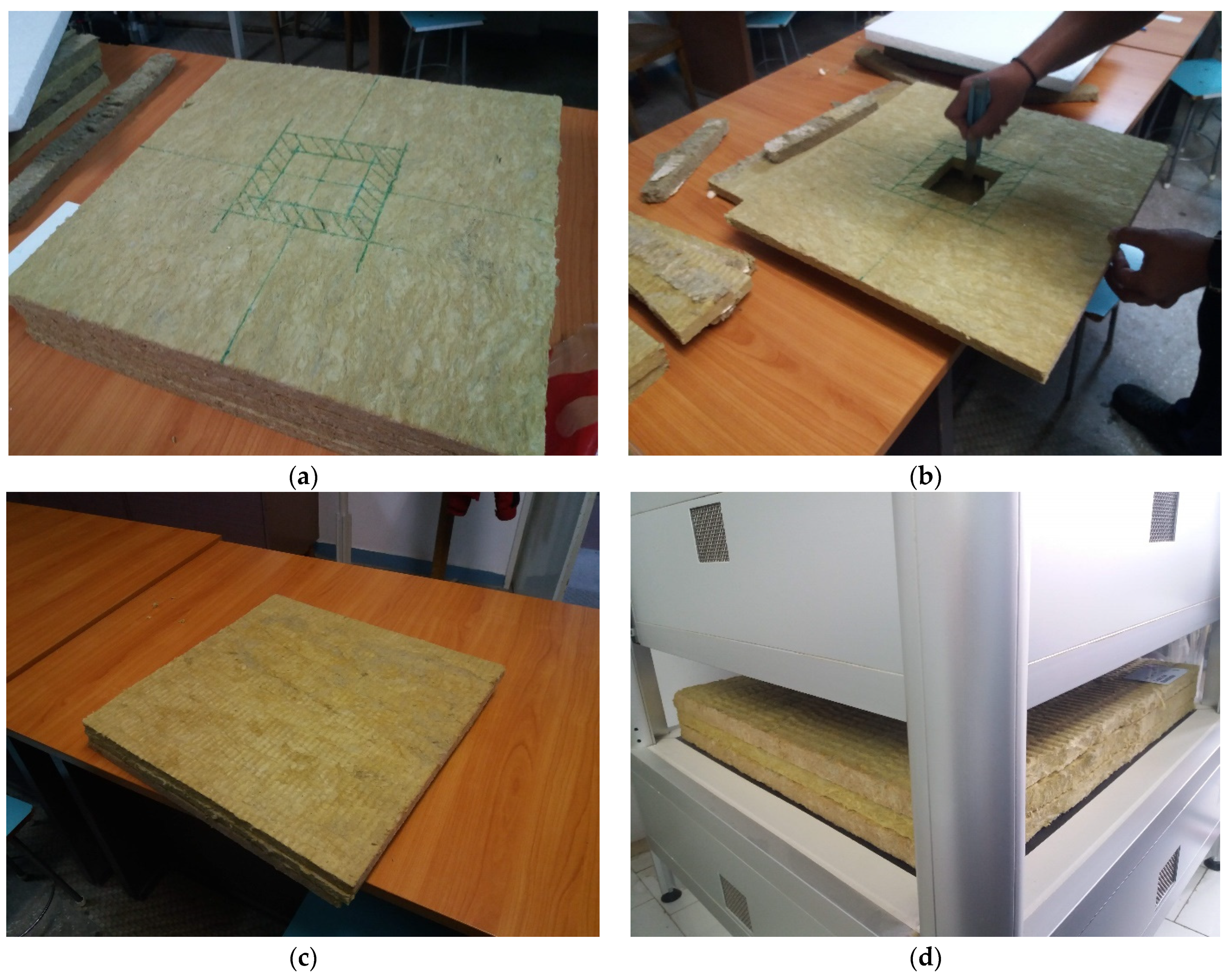

3.1. Laboratory Investigations on Insulation Systems

3.2. Evaluation of Thermal Properties

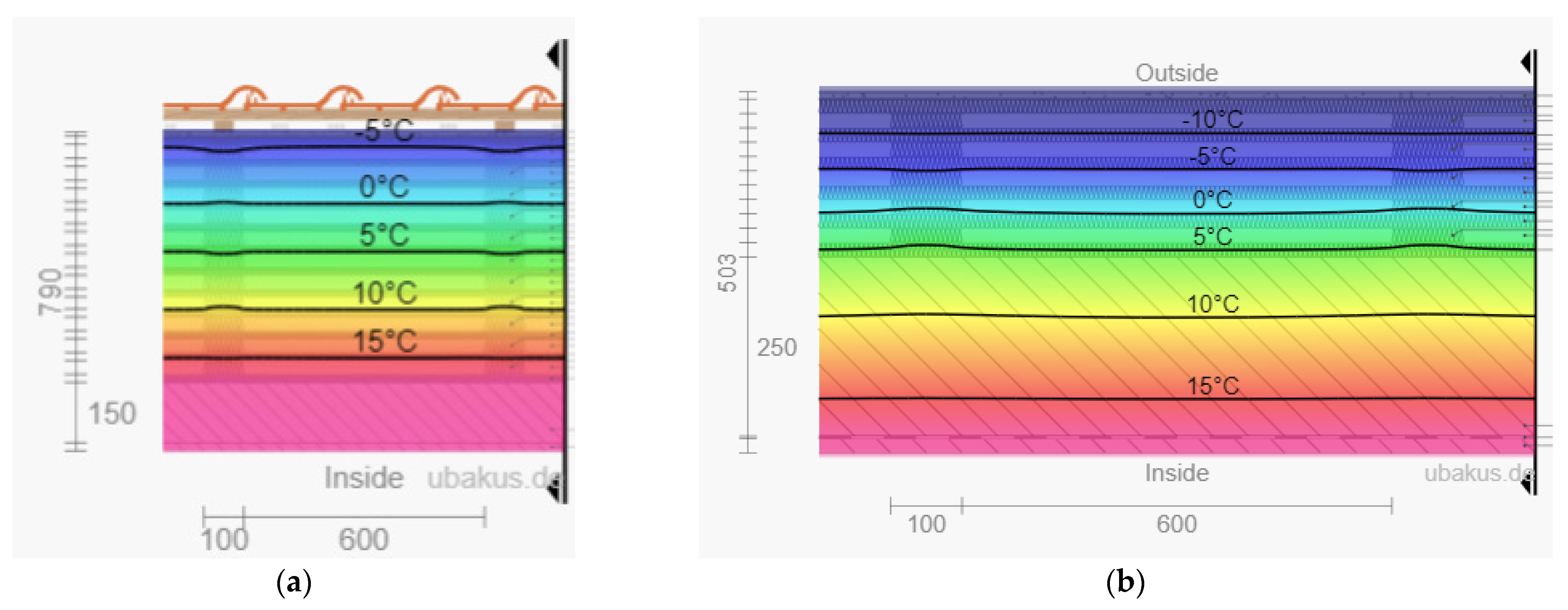

3.3. Temperature Gradient Inside the Cross-Section of the Envelope Elements

- The inner surface temperature of the envelope element was determined at 17.42 °C;

- The outer surface temperature was mainly affected by the exterior temperature. This was determined at −7.10 °C for the upper slab, and −14.95 °C for the exterior walls;

- The temperature of the concrete layer fluctuated between 17.7 °C and 17.4 °C in the case of the upper slab; in case of the exterior walls, the temperature of the AAC masonry fluctuated between 7.5 °C and 17.4 °C;

- We considered that the mean exterior humidity of the air, measured during the winter season in Salonta was 68%, and that the interior humidity of the air was kept at a constant 50%. The temperature of the dew point for a relative humidity of between 50 and 65% was assessed according to the national standards as being between 7.0 °C and 10.1 °C. In the case of both the slab and the exterior walls, the dew point was placed outside the structural layers of the wall.

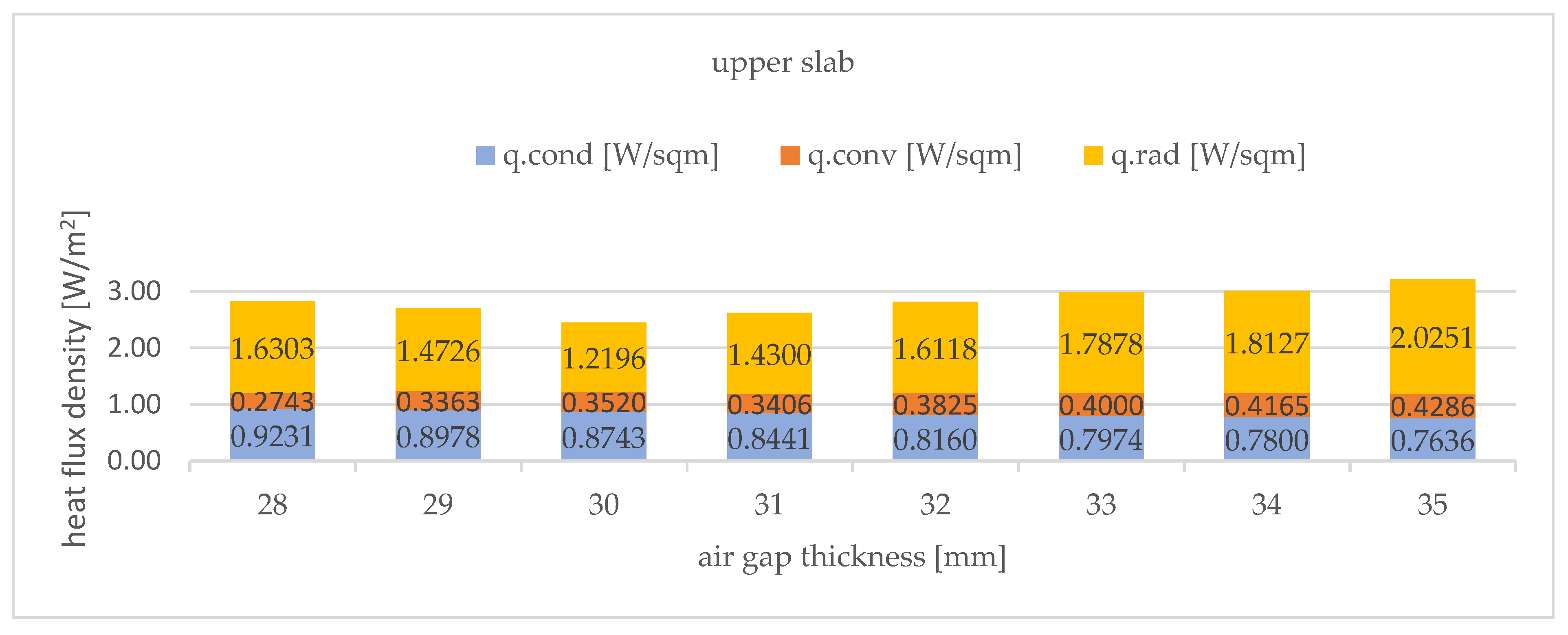

3.4. Heat Flux Density Analysis

3.5. Embedded Emissions during the Produciton Stage of Insulation Systems

3.6. Energy Consumption during the Operating Phase

- Electric power source. Electric energy consumed by the kitchen facilities was measured to increase to 0.272 kWh/(m2∙month). Because the kitchen was fully operational for only 10 months of the measurement period, it was estimated that the consumption would increase by no more than 0.25 kWh/(m2∙month).

- Gas power source. During the first 10 months of operation, gas consumption was 118 m3/month, i.e., an annual consumption of 4.2 kWh/year or 0.35 kWh/(m2∙month). As the rate of use increased, the average energy consumption of the kitchen was expected to increase by 0.2 kWh/(m2∙month).

- Since the accommodation rooms were only used periodically, the heating systems did not operate continuously on the upper level. However, without continuous heating sources, the average interior temperature of the accommodation rooms was only provided by ventilation systems at 17 °C.

- A more intense use of accommodation rooms was estimated to increase inconsequential energy consumption due to higher internal heat gains. In return, a more intense use of accommodation rooms was expected to increase the consumption of electrical energy from household appliances by 0.2 kWh/month, resulting in 2.4 kWh/(m2∙year).

3.7. Temperature Gradient within the Envelope Elements Determined According to Each of the Five National Climate Zones

- The inner surface temperature of the envelope element was between 17.2 °C and 17.9 °C, depending on the temperature difference between the interior and exterior environments. The specific climate zone in which the simulation was performed had little to no effect on the interior surface temperature in the case of highly efficient envelope elements: the maximum temperature difference between the interior temperatures of the surface elements did not exceed 0.5 °C (2.9%).

- The outer surface temperature was affected mainly by the exterior temperature. This ranged between −6.7 °C and 15.2 °C for the upper slab, and from −14.8 °C to −24.6 °C for the exterior walls.

- The temperature of the concrete layer fluctuated between 17.7 °C and 17.4 °C in the case of the upper slab, and in the case of the exterior walls, the temperature of the AAC masonry fluctuated between 7.5 °C and 17.4 °C.

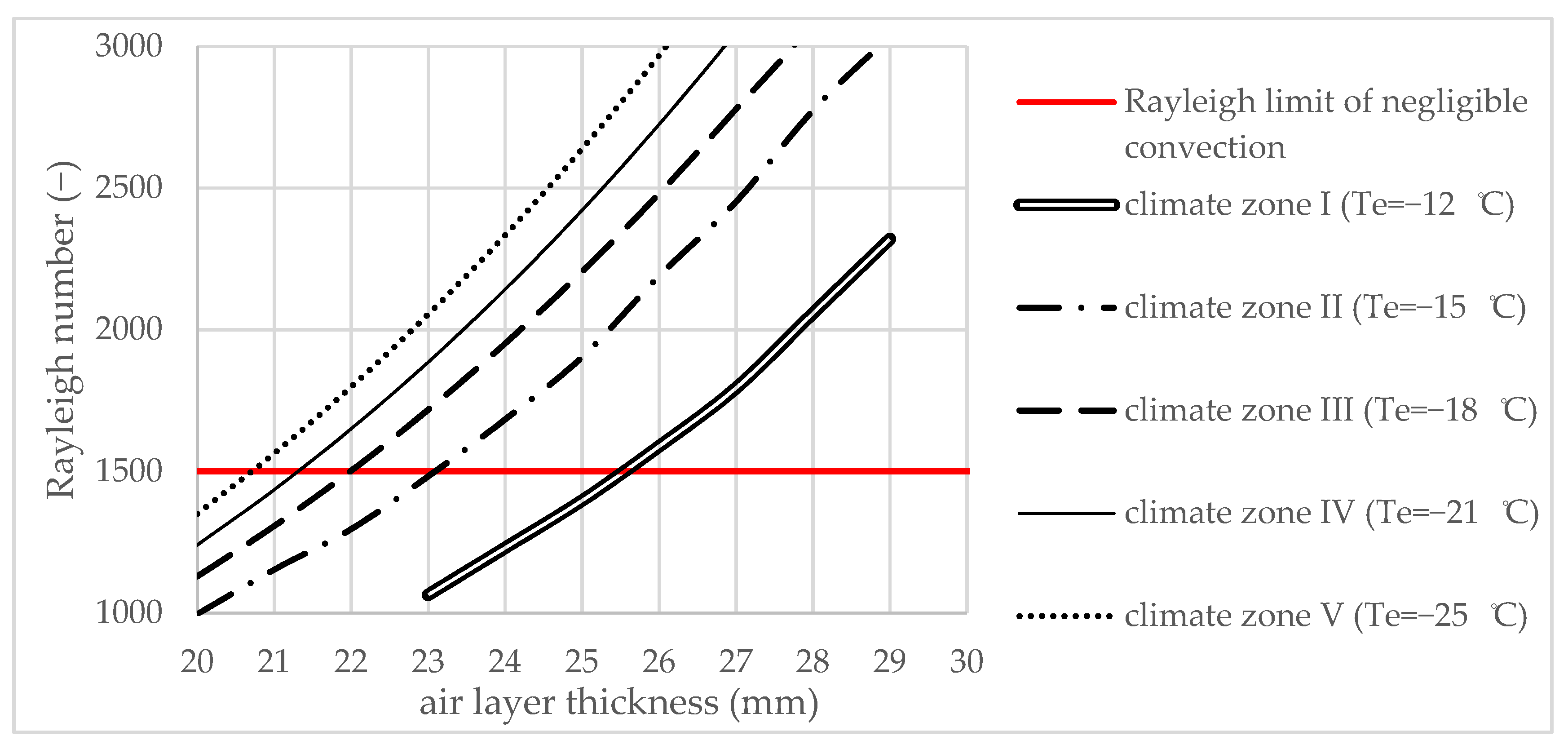

3.8. Confirmation of Optimum Air Layer Thicknesses according to the Rayleigh and Nusselt Numbers

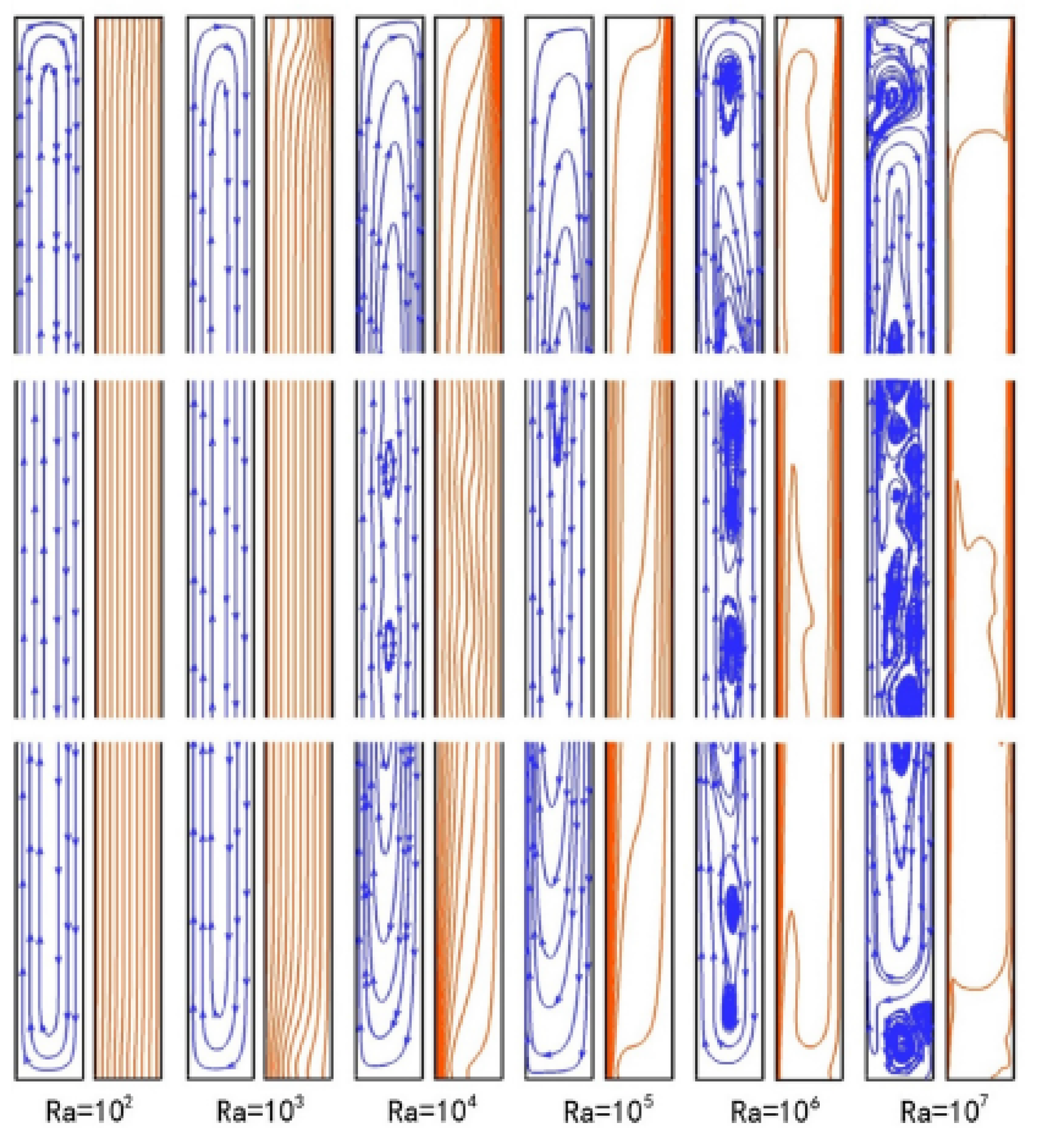

- When the Rayleigh number exceeds 102, the streamlines and isotherms show parallel distributions, indicating that the heat flux caused by the convection mechanism is negligible.

- The airflow pattern has a pure conductive character when Ra < 1.2 × 103 in the case of horizontal displacement of the air layer, and when Ra < 1.5 × 103, in the case of vertical displacement of the air layer.

- When the Rayleigh number exceeds 1.2 × 103 in the case of horizontal air layers, and 1.5 × 103 in the case of vertical air layers, the airflow gains a laminar aspect.

- The laminar flow is noticeable when Ra overcomes 3.5 × 104 for the slab, and 1.4 × 105 for the walls.

- Nu ≤ 1.0;

- Ra ≤ 1200 for the upper slab (horizontal air chamber);

- Ra ≤ 1500 for the exterior walls (vertical air chambers).

- The ratio between the height and the thickness of the air layer;

- The temperature difference between the interior and exterior temperatures. The calculations comprised in this work were performed according to the conventional interior temperatures of school buildings, and according to the conventional exterior temperatures of the five climate zones in Romania.

4. Discussion

5. Conclusions

- (1)

- A significant positive correlation was found between the limits established by previous research using the Rayleigh equation and the thermal flux variation inside the air layers determined for the second climate zone of Romania. In other words, the optimum insulation thickness is reached when the Rayleigh number approaches but succeeds the 1200 limit for vertical air layers, and 1500 for horizontal air layers. These values overlap the minimum heat flow measured for the high school building, i.e., 0.0695 W/(m∙K) for the upper slab and 1.695 W/(m∙K) for the exterior walls.

- (2)

- As expected, the test results show a slightly higher combined thermal conductivity of the ISPA, compared to the existing insulation system, with approximately 6.9%, from 0.03907 W/(m∙K) to 0.04196 W/(m∙K).

- (3)

- The thermal resistance of the exterior walls is improved, from 3.839 to 5.243 (m2∙K)/W, and in the case of the upper slab, from 6.399 to 8.817 m2∙K/W. Improvements in thermal properties were achieved with similar insulation consumption; that is, 606.63 m3 in the case of the existing insulation system, and 602.38 m3 in the case of the experimental system. Consequently, the embedded CO2 emissions generated during the manufacturing stage are also similar; that is, 14,010.79 kgCO2eq for the existing insulation and 13,914.97 kgCO2eq for the experimental insulation system.

- (4)

- Compared to the standard rockwool-based insulation system of a high school building built to passive house standards, by using the insulation system based on parallel air layers, energy consumption is reduced by approximately 11%, from 81.725 kWh/year to 73.675 kWh/year.

- (5)

- The energy savings resulting from the use of the experimental insulation system are achieved with similar volumes and emissions of insulating material generated during the manufacturing stage. Taking into account the embedded emission of rockwool material, the experimental system generates approximately 0.69% less CO2. However, the more complex manufacturing process is expected to produce additional emissions.

- (6)

- The improvements in thermal performance are undeniable, but it should be remembered that the use of the new insulating system (with parallel air layers) requires an increase in insulation thicknesses of between 35 and 40%, compared to the standard insulation system.

Author Contributions

Funding

Institutional Review Board Statement

Conflicts of Interest

References

- Roman, K. Carbon footprint of thermal insulation materials in building. Energy Effic. 2017, 10, 1511–1528. [Google Scholar]

- Muhammad, M.; Muzaffar, A.; Hassan, R. Assessment of embodied energy and environmental impact of sustainable building materials and technologies for residential sector. Eng. Proc. 2021, 12, 62. [Google Scholar]

- Friederike, S.; Johannes, G.; René, T.; Stefan, A.; Philip, L. LCA of buildings in Germany: Proposal for a future benchmark based on existing databases. Energy Build. 2019, 194, 342–350. [Google Scholar]

- Mateja, D.; Jernej, M.; Roman, K. Embodied global warming potential of different thermal insulation materials for industrial products. J. Eng. Appl. Sci. 2018, 13, 2242–2249. [Google Scholar]

- Galan-Marin, C.; Rivera-Gomez, C.; Garcia-Martinez, A. Use of natural-fiber bio-composites in construction versus traditional solutions: Operational and embodied energy assessment. Materials 2016, 9, 465. [Google Scholar] [CrossRef]

- Ministerul Dezvoltării Regionale și Administrației Publice. Methodology for Calculating the Thermal Performances of Buildings. Mc001/2006. Available online: https://aaecr.ro/wp-content/uploads/2020/01/Metodologie-de-calcul.pdf (accessed on 14 June 2022).

- Ministerul Dezvoltării Regionale și Administrației Publice. Order 2641/2017 Concerning the Modification and Addition of the Methodology for Calculation for Calculating of the Thermal Performances of Buildings, Mc001/2006, Aproved by Order of the Minister no. 157/2007. Available online: https://aaecr.ro/wp-content/uploads/2017/04/normele-privind-calculul-performantei-energetice-a-cladirilor.pdf (accessed on 14 June 2022).

- Ministerul Dezvoltării Regionale și Administrației Publice. The National Methodology According to the European Standards Including nZEB Buildings. Available online: https://oer.ro/wp-content/uploads/3.-REHVA-OAER-C%c4%83t%c4%83lin-LUNGU.pdf (accessed on 14 June 2022).

- Ene, R.C.; Brata, S.; Boros, I.; Dan, D. Effect of inserted parallel air chambers in rockwool and polystyren insulation panels. J. Environ. Prot. Ecol. 2020, 21, 202–210. [Google Scholar]

- Al-Hazmy, M.M. Analysis of coupled natural convection–conduction effects on the heat transport through hollow building blocks. Energy Build. 2006, 38, 515–521. [Google Scholar] [CrossRef]

- Boukendil, M.; Abdelbaki, A.; Zrikem, Z. Detailed numerical simulation of coupled heat transfer by conduction, natural convection and radiation through double honeycomb walls. Build. Simul. 2012, 5, 337–344. [Google Scholar] [CrossRef]

- Arıcı, M.; Karabay, H. Determination of optimum thickness of double-glazed windows for the climatic regions of Turkey. Energy Build. 2010, 42, 1773–1778. [Google Scholar] [CrossRef]

- Arıcı, M.; Karabay, H.; Kan, M. Flow and heat transfer in double, triple and quadruple pane windows. Energy Build. 2015, 86, 394–402. [Google Scholar] [CrossRef]

- Sun, W.; Ji, J.; Luo, C.; He, W. Performance of PV-Trombe wall in winter correlated with south façade design. Appl. Energy 2011, 88, 224–231. [Google Scholar] [CrossRef]

- Hu, Z.; He, W.; Ji, J.; Hu, D.; Lv, S.; Chen, H.; Shen, Z. Comparative study on the annual performance of three types of building integrated photovoltaic (BIPV) Trombe wall system. Appl. Energy 2017, 194, 81–93. [Google Scholar] [CrossRef]

- Suárez-López, M.J.; Blanco-Marigorta, A.M.; Gutiérrez-Trashorras, A.J.; Pistono-Favero, J.; Blanco-Marigorta, E. Numerical simulation and exergetic analysis of building ventilation solar chimneys. Energy Convers. Manag. 2015, 96, 1–11. [Google Scholar] [CrossRef]

- Harris, D.J.; Helwig, N. Solar chimney and building ventilation. Appl. Energy 2007, 84, 135–146. [Google Scholar] [CrossRef]

- Peng, J.; Curcija, D.C.; Lu, L.; Selkowitz, S.E.; Yang, H.; Zhang, W. Numerical investigation of the energy saving potential of a semi-transparent photovoltaic double-skin facade in a cool-summer Mediterranean climate. Appl. Energy 2016, 165, 345–356. [Google Scholar] [CrossRef]

- Han, J.; Lu, L.; Yang, H. Numerical evaluation of the mixed convective heat transfer in a double-pane window integrated with see-through a-Si PV cells with low-e coatings. Appl. Energy 2010, 87, 3431–3437. [Google Scholar] [CrossRef]

- Wang, M.; Peng, J.; Li, N.; Yang, H.; Wang, C.; Li, X.; Lu, T. Comparison of energy performance between PV double skin facades and PV insulating glass units. Appl. Energy 2017, 194, 148–160. [Google Scholar] [CrossRef]

- Cheng, Y.; Gao, M.; Dong, J.; Jia, J.; Zhao, X.; Li, G. Investigation on the daylight and overall energy performance of semi-transparent photovoltaic facades in cold climatic regions of China. Appl. Energy 2018, 232, 517–526. [Google Scholar] [CrossRef]

- Zhang, T.; Tan, Y.; Yang, H.; Zhang, X. The application of air layers in building envelopes: A review. Appl. Energy 2016, 165, 707–734. [Google Scholar] [CrossRef]

- Juanicó, L.E.; González, A.D. Thermal insulators with multiple air gaps: Performance, cost and embodied impacts. J. Build. Eng. 2017, 12, 188–195. [Google Scholar] [CrossRef]

- Zhang, T.; Yang, H. Heat transfer pattern judgment and thermal performance enhancement of insulation air layers in building envelopes. Appl. Energy 2019, 250, 834–845. [Google Scholar] [CrossRef]

- Juanico, L.E. Thermal insulation of roofs by using multiple air gaps separated by insulating layers of low infrared emissivity. Constr. Build. Mater. 2020, 230, 116931. [Google Scholar] [CrossRef]

- Zhang, T.; Yang, H. Optimal thickness determination of insulating air layers in building envelopes. Energy Procedia 2018, 152, 444–449. [Google Scholar] [CrossRef]

- Building Physics. Available online: https://www.lambda-messtechnik.de/en/thermal-conductivity-test-tool-ep500e/lambda-meter-ep500-characteristics (accessed on 2 February 2020).

- European Committee for Standardization (CEN). EN13162. Thermal Insulation Products for Buildings—Factory-Made Mineral Wool (MW) Products. Available online: https://www.en-standard.eu/bs-en-13162-2012-a1-2015-thermal-insulation-products-for-buildings-factory-made-mineral-wool-mw-products-specification/?gclid=CjwKCAjwqauVBhBGEiwAXOepkZeYAELORVN8YHALj9EDZQy9bM4hPQAY4EBL88qJc8N6vcqrmN19DxoC7m4QAvD_BwE (accessed on 14 June 2022).

- WUFI, Frauenhofer IBP. Available online: https://wufi.de/en/software/what-is-wufi/ (accessed on 15 February 2020).

- Test Tool ep500e. Available online: http://www.lambda-messtechnik.de/en/thermal-conductivity-test-tool-ep500e/lambda-meter-ep500-characteristics.html (accessed on 15 February 2020).

- Boros, I.; Nagy-György, T.; Dan, D. Energy efficient school building concept and constructive solutions. Int. Rev. Appl. Sci. Eng. 2015, 6, 101–110. [Google Scholar] [CrossRef][Green Version]

- Brata, S.; Ene, R.C.; Dan, D.; Boros, I. Life Cycle Assessment, an Integrated Vision to Energy Efficiency in the Building Industry. In Book Environmental and Human Impact of Buildings; Moga, L., Șoimoșan, T.M., Eds.; Springer Tracts in Civil Engineering; Springer: Berlin/Heidelberg, Germany, 2021; pp. 313–340. [Google Scholar]

- Parlamentul României. Legea 372/2005—National Regulation on Energy Efficiency in the Construction Industry. Available online: https://legislatie.just.ro/Public/DetaliiDocument/66970 (accessed on 14 June 2022).

- Directive EC 91/2002 of the European Parliament and of the Council Adopted on 16.12.2002 on the Energy Performance of Buildings. Available online: https://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:L:2003:001:0065:0071:EN:PDF (accessed on 14 June 2022).

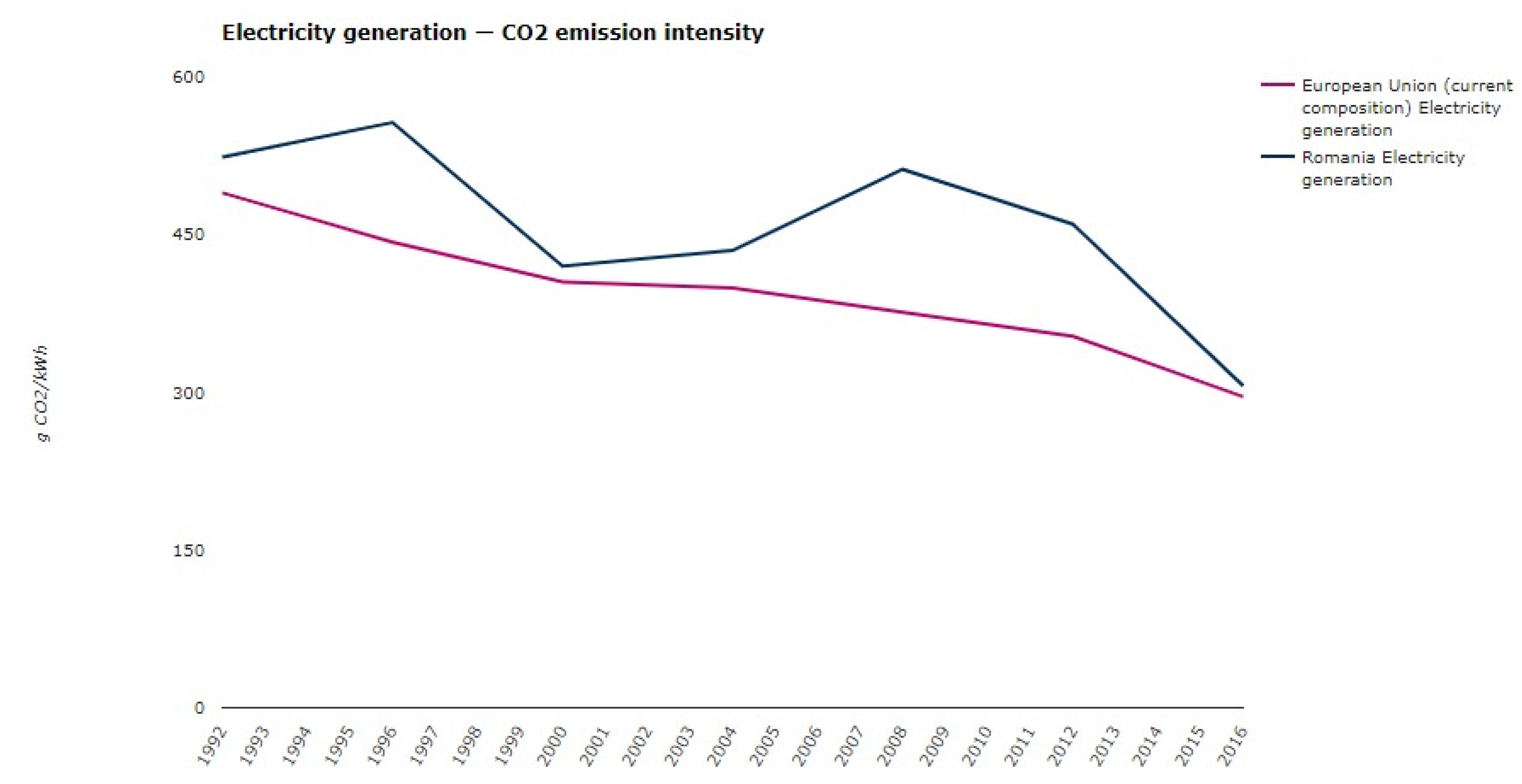

- European Environmental Agency. Overview of Electricity Production and Use in Europe. Available online: https://www.eea.europa.eu/data-and-maps/indicators/overview-of-the-electricity-production-2/assessment-4 (accessed on 1 February 2020).

- Azari, R.; Abbasabadi, N. Embodied energy of buildings: A review of data, methods, challenges, and research trends. Energy Build. 2018, 168, 225–235. [Google Scholar] [CrossRef]

- Dixit, M.K.; Culp, C.H.; Fernández-Solís, J.L. System boundary for embodied energy in buildings: A conceptual model for definition. Renew. Sustain. Energy Rev. 2013, 21, 153–164. [Google Scholar] [CrossRef]

- Owerczuk, J. Towards Modern Technology and Traditional Form—Evolution of the Form of Energy-Efficient Houses in Poland over the Last Decades. Multidiscip. Digit. Publ. Inst. Proc. 2020, 51, 30. [Google Scholar]

- Kamara, J.M.; Heidrich, O.; Tafaro, V.E.; Maltese, S.; Dejaco, M.C.; Re Cecconi, F. Change Factors and the Adaptability of Buildings. Sustainability 2020, 12, 6585. [Google Scholar] [CrossRef]

- Musarat, M.A.; Alaloul, W.S.; Liew, M.S.; Maqsoom, A.; Qureshi, A.H. The Effect of Inflation Rate on CO2 Emission: A Framework for Malaysian Construction Industry. Sustainability 2021, 13, 1562. [Google Scholar] [CrossRef]

- Atanas Petrovski, A.; Pauwels, E.; González, A.G. Implementing Regenerative Design Principles: A Refurbishment Case Study of the First Regenerative Building in Spain. Sustainability 2021, 13, 2411. [Google Scholar] [CrossRef]

- Asociația de Standardizare din România. SR1907-2; Heatying Systems. Calculation of the Heating Demand. Indoor Calculation Temperatures. 2014. Available online: https://kupdf.net/download/sr-1907-2-2014_58a49bc86454a7120bb1e8fb_pdf (accessed on 14 June 2022).

| Envelope Element | Mc001/2006 | Order 2641/2017 | National Methodology (Including nZEB 1) |

|---|---|---|---|

| Thermal Transmittance U′max, W/(m2∙K) | |||

| Exterior walls | 0.80 | 0.57 | 0.33 |

| Upper slab | 0.34 | 0.22 | 0.17 |

| Slab on the ground | 0.95 | 0.40 | 0.20 |

| Glazing | 2.56 | 1.45 | 1.10 |

| Ground facing walls | 0.91 | 0.71 | 0.29 |

| Room Destination | Interior Design Temperature °C |

|---|---|

| Classroom | 18.0 |

| Offices | 20.0 |

| Laboratories | 18.0 |

| Libraries, reading rooms | 20.0 |

| Halls, corridors, stairwells | 18.0 |

| Wind fang | 12.0 |

| Toilets | 15.0 |

| Medical offices | 22.0 |

| Cafeteria | 18.0 |

| Kitchen | 15.0 |

| Car garage | 15.0 |

| Building Material | Mean Thermal Conductivity λ, W/(m∙K) W/(m∙K) |

|---|---|

| Solid rockwool panel (d = 100 mm) | 0.03907 |

| Rockwool panel with air layers (d ≤ 25 mm) | 0.04196 |

| Insulation System | Layer | dins (mm) | Volume per Unit Envelope Area (cm3/m2) | R (m2∙K/W) | |

|---|---|---|---|---|---|

| Description | Amounts in Cross-Section | ||||

| Exterior walls | |||||

| EIS (150 mm) | solid | 1 | 150 | 0.208 | 3.839 |

| ISPA (235 mm) | solid layers | 6 | 20 | 0.167 | 5.243 |

| supporting frame | 5 | 23 | 0.040 | ||

| Upper slab | |||||

| EIS (250 mm) | solid | 1 | 250 | 0.347 | 6.399 |

| ISPA (586.5 mm) | solid layers | 12 | 20 | 0.333 | 8.817 |

| supporting frame | 11 | 31.0 | 0.012 | ||

| Climate Zone | Envelope Element | Layer | Air Layer Thickness, mm | |||

|---|---|---|---|---|---|---|

| 20 | 25 | 30 | 35 | |||

| II | Exterior walls | Air layer | 0.99 | 1.05 | 1.09 | - |

| Rockwool | 2.59 | 2.61 | 2.56 | - | ||

| Upper slab | Air layer | - | 0.74 | 0.80 | 0.80 | |

| Rockwool | - | 1.33 | 1.38 | 1.27 | ||

| Envelope Element | Assessment Unit | EIS | ISPA | |

|---|---|---|---|---|

| - | Density of Solid Insulation Material (kg/m3) | 22 | ||

| - | Rockwool GWP (kg CO2eq/kg) | (kgCO2eq/kg) | 1.05 | |

| Outer walls | Volume per unit envelope area | (cm3/m2) | 0.208 | 0.2074 |

| Insulated area | m2 | 1453 | ||

| Insulation volume | m3 | 302.71 | 300.19 | |

| Weight of the insulation system | kg | 6659.58 | 6604.09 | |

| Embedded CO2 emissions | kgCO2eq | 6992.56 | 6934.29 | |

| Upper slab | Embedded CO2 emissions | kgCO2eq | 0.347 | 0.345 |

| Surface area | cm3/m2 | 875 | ||

| Insulation volume | m3 | 303.82 | 302.19 | |

| Weight of the insulation system | kg | 6684.03 | 6648.27 | |

| Embedded CO2 emissions | kgCO2eq | 7018.23 | 6980.68 | |

| Generated Emissions during Operation Phase | ||||

|---|---|---|---|---|

| Type of Insulation | EIS | EIS | ISPA | |

| Determination Type | Real Time Measurement | Theoretically Determined | ||

| Energy consumption | kWh/m2∙year | 21.24 | 23.35 | 21.05 |

| kWh/year | 74,340.00 | 81,725.00 | 73,675.00 | |

| CO2 emissions | kgCO2eq/m2∙year | 6.29 | 6.91 | 6.22 |

| kgCO2eq/year | 22,007.00 | 24,193.30 | 21,793.00 | |

| Unit | Real-Time Measurements | Estimated Increase Value |

|---|---|---|

| Total energy consumption, kWh/(m2∙year) | 74,340.00 | 107,940.00 |

| Embedded emissions during the operating stage, (kg CO2eq)/ m2∙year | 78,057.00 | 113,337.00 |

| Area, m2 | 3500.00 | 3500.00 |

| Annual consumption, kWh/(m2∙year) | 21.24 | 30.84 |

| Annual consumption of the kitchen—electric energy, kWh/(m2∙year) | 3.26 | 3.51 |

| Monthly consumption of the kitchen—gas consumption, m3/month | 118.00 | 120.20 |

| Yearly consumption of the kitchen—gas consumption, kWh/(m2∙year) | 4.20 | 4.55 |

| Accommodation rooms, kWh/(m2∙year) | 0 1 | 2.40 |

| Layer | Climate Zone | Air Layer Thickness, mm | ||

|---|---|---|---|---|

| 20 | 25 | 30 | ||

| Air layer | I | 0.84 | 0.93 | 0.86 |

| Rockwool | 2.42 | 2.34 | 2.42 | |

| Air layer | II | 0.99 | 1.05 | 1.09 |

| Rockwool | 2.59 | 2.61 | 2.56 | |

| Air layer | III | 1.02 | 0.86 | 1.17 |

| Rockwool | 2.87 | 2.88 | 2.76 | |

| Air layer | IV | 1.12 | 1.10 | 1.23 |

| Rockwool | 3.15 | 3.12 | 3.04 | |

| Air layer | V | 1.22 | 1.23 | 1.23 |

| Rockwool | 2.92 | 3.47 | 3.44 | |

| Layer | Climate Zone | Air Layer Thickness, mm | ||

|---|---|---|---|---|

| 25 | 30 | 35 | ||

| Air layer | I | 0.78 | 0.80 | 0.80 |

| Rockwool | 1.35 | 1.29 | 1.25 | |

| Air layer | II | 0.74 | 0.80 | 0.80 |

| Rockwool | 1.33 | 1.38 | 1.27 | |

| Air layer | III | 0.92 | 0.98 | 0.98 |

| Rockwool | 1.48 | 1.47 | 1.42 | |

| Air layer | IV | 0.94 | 1.01 | 1.00 |

| Rockwool | 1.62 | 1.60 | 1.55 | |

| Air layer | V | 0.95 | 1.01 | 1.01 |

| Rockwool | 1.73 | 1.72 | 1.67 | |

| Exterior Walls | |||||

|---|---|---|---|---|---|

| Climate Zone | Temperature [°C] | Nu - | Ra - | Optimal Thickness mm | |

| Exterior (Te) | Interior (Ti) | ||||

| I | −12.0 | 18.4 | 0.809 | 1498 | 23.5 |

| II | −15.0 | 18.4 | 0.798 | 1482 | 23.0 |

| III | −18.0 | 18.4 | 0.789 | 1498 | 22.0 |

| IV | −21.0 | 18.4 | 0.787 | 1492 | 21.5 |

| V | −25.0 | 18.4 | 0.767 | 1490 | 20.5 |

| Upper Slab | ||||||

|---|---|---|---|---|---|---|

| Climate Zone | Temperature [°C] | Nu - | Ra - | Optimal Thickness mm | ||

| Exterior (Te) | Unheated Attic (Tattc) | Interior (Ti) | ||||

| I | −12.0 | −6.8 | 18.4 | 0.845 | 1196 | 30.3 |

| II | −15.0 | −7.2 | 18.4 | 0.826 | 1187 | 30.0 |

| III | −18.0 | −10.6 | 18.4 | 0.821 | 1195 | 29.8 |

| IV | −21.0 | −12.5 | 18.4 | 0.813 | 1196 | 29.5 |

| V | −25.0 | −15.1 | 18.4 | 0.803 | 1181 | 29.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ene, R.C.; Brata, S.; Boros, I.; Chendes, R.; Dan, D. Theoretical Study on the Effect of Parallel Air Chambers Embedded in Rockwool Panels on the Energy Consumption of a Low-Energy High School. Sustainability 2022, 14, 7425. https://doi.org/10.3390/su14127425

Ene RC, Brata S, Boros I, Chendes R, Dan D. Theoretical Study on the Effect of Parallel Air Chambers Embedded in Rockwool Panels on the Energy Consumption of a Low-Energy High School. Sustainability. 2022; 14(12):7425. https://doi.org/10.3390/su14127425

Chicago/Turabian StyleEne, Raul C., Silviana Brata, Iosif Boros, Remus Chendes, and Daniel Dan. 2022. "Theoretical Study on the Effect of Parallel Air Chambers Embedded in Rockwool Panels on the Energy Consumption of a Low-Energy High School" Sustainability 14, no. 12: 7425. https://doi.org/10.3390/su14127425

APA StyleEne, R. C., Brata, S., Boros, I., Chendes, R., & Dan, D. (2022). Theoretical Study on the Effect of Parallel Air Chambers Embedded in Rockwool Panels on the Energy Consumption of a Low-Energy High School. Sustainability, 14(12), 7425. https://doi.org/10.3390/su14127425