Abstract

The circular economy concept needs to be part of the performance management system so that it is in line with a company’s vision and mission. Thus, the circular economy will play an important role at the operational level of companies. The circular economy needs to be internalized, starting by formulating the company’s vision and mission, establishing strategic objectives and performance indicators, and creating resource allocation policies. This research aims to design a sustainable performance management system in the context of a circular economy for state-owned plantation enterprises (SOPEs). This study used a qualitative research coding method that was validated in three SOPEs in Indonesia. Validation was performed by comparing the framework based on the conceptual formulation with the data and information obtained during field assessment. Primary data came from interviews with 15 managers, while secondary data came from official company documents. The research results show that the initial framework that was built is in accordance with the results of the exploration of the circular economy strategic objectives in the three SOPEs. The results of the 100 percent validation and perception test of managers on the range of values are important. Therefore, the proposed framework can be used in SOPE.

1. Introduction

To manage company performance concerning environmental interests, companies can base their performance measurement on the sustainability balanced scorecard (SBSC) approach [1,2,3,4,5]. SBSC is a sustainability performance management approach that aims to guide a company’s long-term strategy by integrating the company’s profit motives with the interests of environmental conservation. The company uses the scorecard measurement results to evaluate the progress of achieving its vision, executing its mission, and implementing the organization’s strategy. SBSC is also an approach for communicating and linking strategic objectives and measures in the form of planning, targeting, and aligning strategic initiatives and enhancing strategic learning feedback [6,7,8,9,10,11,12].

SBSC is a BSC concept enriched by the triple bottom line concept. The triple bottom line concept is the basis for building stakeholder value in the economic, social, and environmental dimensions [13], while the BSC concept is used to formulate strategic objectives [14]. The organization has four strategic objectives in the BSC approach based on financial, consumer, internal business processes, and learning and growth perspectives. Strategic objectives become the benchmark in formulating performance indicators and allocating required resources [15]. Although several previous SBSC studies [4,5,7,9,12,16,17,18,19,20,21,22,23,24,25,26,27,28,29,30] have also formulated sustainability performance indicators on aspects of sustainability performance management, none have included the concept of a circular economy (CE).

The CE concept is built from a society’s production–consumption system and maximizes services generated from linear natural-society-nature material flows and energy output flows [31]. This concept is in line with the idea of sustainable development [32], which adheres to the laws of ecology and efficient use of natural resources to achieve economic development [33], and will ensure economic growth. In addition, CE is a model of economic development that aims to protect the environment and prevent pollution, thereby facilitating sustainable economic development [34]. The CE concept has not been able to fully measure the impact of its performance on the interests of a company and its primary stakeholders. The ability of a business to evaluate its organizational performance in an integrated manner is crucial to its success.

The integrated performance evaluation has been developed to accommodate the interests of a company’s primary stakeholders, including the interests of implementing a CE, especially in the context of state-owned plantation enterprises (SOPEs). SOPEs have a more substantial mission than ordinary business organizations; they carry out national, social, and environmental missions in addition to the basic mission of seeking profit. In this paper, the national mission is defined as the role of an SOPE in carrying out state duties in certain aspects; the social mission is to assist the community in financial and non-financial support. The community in which an SOPE operates grows and supports the achievement of the SOPE’s strategic objectives. In the context of the CE and SOPEs’ mission, SOPEs need to successfully translate the steps in implementing the CE’s interests into SOPE performance. Unfortunately, an assessment of business performance and the importance of the triple bottom line in the context of CE implementation in SOPEs has not been developed. Therefore, it is crucial to create a framework to assess CE performance of long-term and sustainable interests for business organizations, especially SOPEs

2. Literature Review

2.1. Circular Economy and the Concept of Sustainability

The circular economy has been a subject of interest to many researchers. At present, the circular economy is an inseparable part of the concept of sustainable development [32], which adheres to the laws of ecology and efficient use of natural resources to achieve economic development [33] without damaging the environment [35]. Many assumptions and theoretical foundations regarding the concept of a circular economy were proposed by W.R. Stahel (1976) [36]. Furthermore, Stahel and G. Reday (Stahel, Reday 1976, 1981)[37] presented a circular economy vision and its implications for creating jobs, increasing economic competitiveness, saving raw materials and preventing waste generation. A comprehensive circular economy model has been introduced in the world literature by D. Pearce, R. Turner (1990)[38], who was inspired by the views of Kenneth Boulding (1966)[39]. Recently, many scientists from various regions of the world have popularized the idea of a circular economy. Furthermore, the view of Chinese scientists on the circular economy is interesting because of its specificity. The Chinese circular economy model includes additional dimensions and goes beyond the problem of natural resource management, and includes other aspects, such as power efficiency, land management, soil and water protection as well as social and ethical aspects [40,41,42].

The concept of CE is developing dynamically [43]. Muray et al. (2015) [44] defines CE as an economic model in which planning, sourcing, procurement, production, and reprocessing are designed and managed, as both processes and outputs, to maximize ecosystem function and human well-being. According to the Ellen MacArthur Foundation (EMF), CE aims to enable adequate flows of material, energy, labor, and information to rebuild natural and social capital [45]. This is because, basically, the economic system that is present in the community must operate according to the principle of material and energy cycles that can support natural systems [46].

In its development, CE can become a new industrial system that replaces the restoration concept, encourages the use of renewable energy, eliminates the use of toxic chemicals, encourages reuse into the biosphere, and eliminates waste through superior design of materials, products, systems, and business models [44,46,47]. This is in line with Feng, Z. and Ghisellini, P et al. which states that the essence of CE is a closed circular flow of materials and involves the use of raw materials and energy through several phases. The 3R principles, namely reduction, reuse, and recycle are approaches that are realized in practice [48,49,50,51].

Several previous studies on CE only looked at the economic aspect by ignoring the other two pillars of sustainability, namely society and the environment [52]. In addition, the difficulties in implementing CE in industrial societies have not been resolved [44,53]. To answer this gap, in this study, a conceptual framework for a sustainable performance management system was built that can accommodate social and environmental aspects of CE and facilitate its implementation in the industrial world. In the proposed conceptual framework, the CE concept is linked to the company’s performance management system. The SBSC approach is proposed because, in previous studies, the CE concept has not been found related to the company’s performance management system. To strengthen this reason, Table 1 will summarize the results of previous CE studies related to the indicators.

Table 1.

Circular economic performance indicators from previous research.

Table 1 shows the circular economy variables used in manufacturing from previous studies. Variables that appear are reduce [54]; reuse [41,54,55,56]; recycling [41,52,54,55,56]; renovation [54]; remake [41,52]; exile [41,56,57]; added value [56]; and knowledge, behavior, and culture [58]; Integrated resource utilization [66]; restore and redesign [67]; close loop material [68]; composting and landfill [69].

There has been no circular economy research related to sustainable performance management systems from this study. Companies that implement a sustainable performance management system with a CE approach are expected to be more effective in achieving the company’s circular economy goals. According to Kaplan and Norton (2006), the sustainable performance management system approach will be able to link the company’s performance in terms of strategy—vision, mission, and strategic objectives—with operations, so it is hoped that it will make it easier for companies to implement CE in his company [55,70,71].

2.2. Balanced Scorecard

The balanced scorecard (BSC) concept released by Kaplan and Norton in 1992 was born from the necessity to build long-term company capabilities with the unwavering goal of a historically based cost financial accounting model. Unfortunately, financial measures only explain past events where long-term capabilities and customer relations were not crucial to the success of industrial era companies. These measures are inadequate to guide and evaluate companies in the information age in creating future value through investments made in customers, suppliers, workers, processes, technology, and information [15,67,72,73].

The BSC has become a measurement system that manages long-term strategies. Companies use the results of the scorecard measurement to produce various essential management processes, namely, clarifying the organization’s vision and strategy, communicating and linking various strategic objectives and measures, planning, setting goals, aligning various strategic initiatives, and improving strategic learning feedback [66,72]. Table 2 shows a list of strategic goals for BSC perspective summarized from various references.

Table 2.

Strategic goals for perspective summarized from various references.

2.3. Triple Bottom Line

Triple bottom line (TBL) is defined as an accounting framework that connects three performance dimensions: economic, social, and environmental. The TBL dimension is also called the 3P, for people, planet, and profit [68,74]. The TBL was popularized by Elkington (1997) [13], who think that companies need dramatic changes in performance for sustainability. The basic concept of TBL is encompassed in three “sliding zones”: economic and environmental zones, environmental and focus zones, and social and economic zones. Table 3 shows a list of strategic goals for TBL dimension summarized from various references.

Table 3.

Strategic goals for TBL dimension summarized from various references.

2.4. Sustainability Balanced Scorecard

The sustainability balanced scorecard (SBSC) is a term for a performance management system that combines the perspective of the balanced scorecard (BSC) and the triple bottom line (TBL) concept, which aims to integrate social and environmental dimensions in a structured way [1,2,3,6,9,11,19,30,68,75,76]. Govindan (2016) said that a balance between SBSC dimensions is needed to realize shareholder satisfaction in profits while still paying attention to community welfare and environmental sustainability. Furthermore, conceptually, it provides opportunities for companies to contribute to sustainable development in an integrative way [7,41,77,78].

SBSC is a strategic management system that enables the translation of strategic goals into sustainable corporate actions [1,2,3,4,5,7,8,9,16,79]. Several previous studies on SBSC have been developed by adding additional perspectives to the four BSC perspectives, and the three TBL dimensions. Table 4 shows that, based on previous studies, the circular economy as a sustainable performance measurement perspective has not been considered as an indicator of performance management.

Table 4.

Contribution of additional perspectives in the framework of the concept of sustainable performance management.

3. Methodology

3.1. Framework Design Stages

The framework was designed with sustainability performance management based on circular economy. The CE concept developed from 3Rs (reduce, reuse, recycle), which is more strategic. The framework developed must be formulated as part of SOPEs’ mission and strategy for the CE to be more valuable operationally, then integrated with SBSC-based sustainability performance management [67,70,71]. For this reason, it is necessary to formulate a conceptual framework through the following stages.

3.1.1. Stakeholder Value Formulation Using SBSC Approach

The SBSC concept is a strategic management concept that was developed by covering the formulation of the vision, mission, strategy, and strategy implementation in setting strategic goals on the four BSC perspectives that also address stakeholder values on the social and environmental dimensions. Value stakeholders consist of shareholders, consumers, community, business partners, employees, and management. Stakeholder values are then translated into a company’s strategic objectives [72,87]. The mapping of stakeholder values can be seen in Table 5.

Table 5.

Stakeholder values using SBSC approach and circular economy.

3.1.2. Formulate Organizational Strategic Goals Based on Stakeholder Values

A company’s strategic goals are based on the BSC concept with four perspectives: financial, consumer, internal business processes, and learning and growth perspectives. According to Kaplan and Norton, 2006; David, 2011; Parnell, 1964 states that strategic goals are used to describe the mission to be achieved within a certain period of time. Strategic objectives will drive the design of different performance metrics for companies with different strategies. This strategic objective is aimed at addressing stakeholder values [91,92], and both have a positive relationship with the concept of sustainability [74]. Stakeholder values can be seen in Table 5.

From a financial perspective, according to Elkington (1997) and Govindan et al. (2016), regarding sustainability, the company’s goal of profit must be obtained without neglecting the social aspects of society and environmental sustainability. Thus, the company’s profits are an achievement of success in increasing the fulfillment of consumer needs [1,9,15,16,22] and providing added value from waste treatment [4] as a public demand that will increase company profits in the long term [4,13,67,88,89,90,91].

The customer perspective has a strategic goal that answers consumer demand for customer satisfaction [1,4,9,15,16,22,89,90], healthy and safe product quality [22], corporate image or green image [1,9,22], and continuous innovation [1,3,15,76]. Green image and innovation in the circular economy context will emphasize the fulfillment of community needs [28,35,41,45,47] with the strategic objectives of creating environmental sustainability [13,68] and utilizing waste as a source of energy and industrial raw materials [17,89,91,93].

The strategic goal of the internal business process perspective is to emphasize processes that significantly impact customer and community satisfaction [55]. The internal strategic objectives of the proposed business process are environmentally friendly operation management process [13,17,22,88], customer management process [15,91,94,95,96], green product and waste treatment innovation process [3,15,35], and value-added waste treatment recycle process [4,20,25,89].

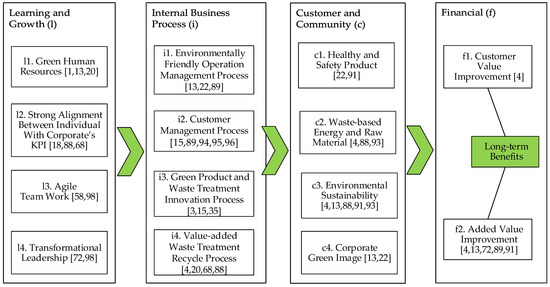

The success of the internal business process strategic goals perspective depends heavily upon the learning and growth strategies [67]. These strategic goals address the needs of employees and business partners and are in HR systems, infrastructure, and information management [66]. An HR support system will be successful in supporting performance if HR has sufficient competence [1,4,20,22,67,76,88,89,90,91] in building systems and implementing standard operating procedures (SOPs) that will encourage the realization of reliable internal business processes [67]. This requires a strong employee awareness of the importance of sustainability and a circular economy for the company and society. Human resources who care about human resources are known as green human resources [1,13,20,73,97], and strong alignment between an individual with corporate’s key performance indicator (KPI) [18,68,89]. The success of these strategic goals can only be achieved with an agile and responsive work team [53,78], as well as leadership that cares about sustainability [22,72,98]. High awareness of the concept of sustainability and circular economy, an agile and responsive work team, and caring leadership will build a strong culture in realizing green performance. These strategic goals are then compiled in a sustainability performance management framework based on the CE and can be seen in Figure 1.

Figure 1.

Framework sustainability performance management for implementing a circular economy based on strategic goals of SBSC.

3.1.3. Validation

Validation was carried out using exploratory research with a case study by Yin (2018) [99] on three SOPEs companies in Indonesia and data analysis used coding qualitative research by Saldana (2013) [100]. The selection of companies was based on different types of superior commodities, namely, palm oil, tobacco, and sugar cane, which perform higher than others. Exploration was carried out through a study of the extent to which the company has a robust circular economy such as SOPEs. It can support the SBSC-based conceptual framework that is integrated with the circular economy as the company’s strategic goals.

The study was conducted from January to August 2020. Data were collected in the form of primary and secondary data [101]. Primary data were obtained from interviews and observations, while secondary data came from company documents in the form of hard and soft copies or on the company’s website. Interviews were conducted with five types of managers: at each SOPE with scope area were HR managers, performance evaluation managers, processing managers, plant managers, and sustainability managers. Therefore, the total number of managers interviewed was 15 people. A list of interview questions (Table 6) was compiled to provide guidance on the interview process so that an overview of the suitability of strategic objectives in the framework (Figure 1) could be obtained and compared to phenomena in the field. Primary data were conducted with structure and semi-structured interviews [99,101].

Table 6.

List of questions for the interview.

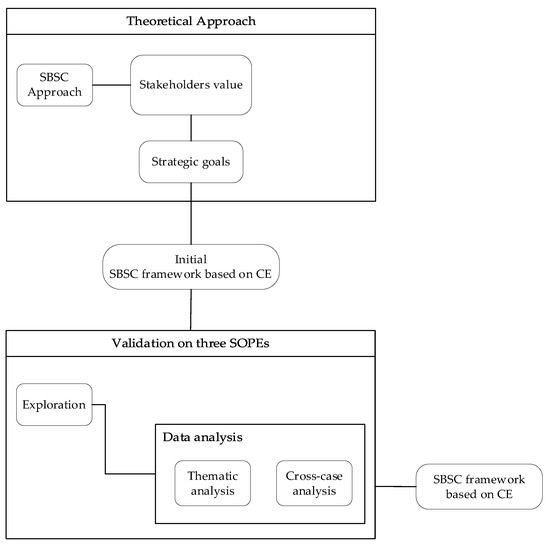

Primary and secondary data were converted using formal coding, which became the basis for defining categories and concepts in qualitative research coding analysis [80]. The validation process was carried out by comparing the theoretically generated framework with the framework explored in the field. Then, a cross-case analysis was carried out to conclude the appropriateness of the proposed framework. Figure 2 illustrates the flow mechanism of the framework comparison based on theory and empirical evidence.

Figure 2.

Stages of forming a conceptual framework for sustainability performance management for implementing a circular economy based on strategic goals of SBSC.

The results of conceptual frameworks’ sustainability performance management for circular economy were then tested on perceptions of 15 managers across three SOPEs with a Likert scale ranging from 1 to 5 (1 = very unimportant, 2 = not important, 3 = moderately important, 4 = important, and 5 = very important) [101].

4. Results and Discussion

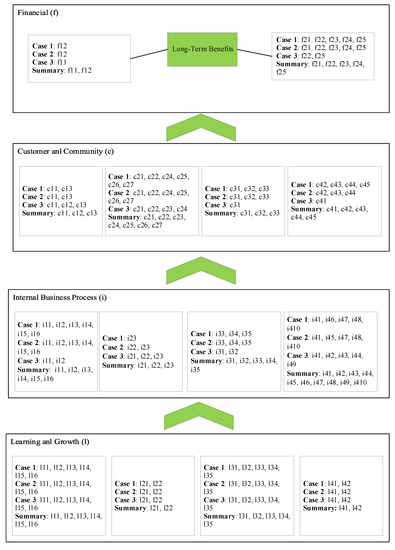

The results of the exploration of the conceptual framework, as presented in Figure 2, were cross-analyzed, which synthesizes the similarities and differences between the three SOPEs or complements each other. SOPEs have developed strategic objectives concerning four perspectives: financial, consumer, internal business processes, and learning and growth. However, the formulation of strategic objectives and performance indicators needs to be further adjusted for the concept of SBSC and circular economy. A phenomenon was found in the sustainability performance management for implementing CE in SOPEs, as shown in Figure 3. Appendix A shows a detailed description of the code, summarized based on the results of interviews and company documents.

Figure 3.

The results of the exploration of the strategic map of sustainability performance management in the CE context.

Figure 3 shows the results of an exploratory study on three SOPEs. The codes (f, c, i, and l) are codes for SBSC perspectives. In contrast, the numeric codes in the first digit indicate strategic goals, and the numeric codes in the second digit indicate phenomena. For example: f11 is phenomena 1 (High product quality standards, for example: sugar products) in financial perspective and strategic goal 1 (Customer value improvement). The summary shows the perspectives, strategic objectives, and phenomena that emerged in the three cases.

From the financial perspective, the results of the case study exploration showed that the summary of strategic objectives of the three SOPEs corresponds to the initial review component with a validation level of 100 percent, namely increasing profits for shareholders. This increase in profits is achieved through the strategic objectives of increasing consumer value and providing added value. The case study results showed that the strategic objectives of consumer value are met through product yield indicators with high-quality standards, such as premium sugar products for sugarcane plantations and golden crude palm oil (CPO) for oil palm plantations. Meanwhile, the company’s strategic purpose of added value is indicated by the process of waste into products of economic value such as biogas, bioethanol, briquettes, animal feed raw materials, and organic fertilizers from industrial waste processing.

From a consumer perspective, the results of the exploration of three case studies showed that the strategic objectives consist of healthy and safe products, a green image, environmental sustainability, and the use of waste as a source of energy and raw materials with a validation level of 100 percent. The results of the cross-case analysis showed the results of exploring the strategic goals of healthy and safe products supported by quality indicators of environmentally friendly products such as products that do not contain harmful additives and are safe for consumption for people with certain diseases. In addition, high product standards such as Golden CPO are needed whose marketing is aimed at the European market by applying the ISCC process standard. The strategic goal of a green image is achieved by obtaining green-worthy certification from the Ministry of Environment, Indonesian Sustainable Palm Oil (ISPO), Roundtable on Sustainable Palm Oil (RSPO), International Sustainability and Carbon Certification (ISCC), and Rainforest Alliance (UTZ). The strategic objectives of environmental sustainability in the three SOPEs are marked by maintaining land fertility through crop rotation, planting legumes, organic fertilization from liquid and solid waste from sugarcane, CPO, and PKO factories, integrated pest control using natural predators and host plants, and reforestation.

The strategic objective of making waste as a source of energy and the industrial raw material is carried out through the conversion of bamboo shoots and oil palm meal for animal feed; bagasse, coconut shell, and palm fiber for boiler fuel; molasses as raw material for bioethanol production; and sugarcane leaves, palm fronds, oil palm empty fruit bunches, and oil palm waste for soil organic fertilizer. Palm shells are used as paving materials. Sludge solids are used for animal feed and organic fertilizers. Timber from land clearing can be used as smoked wood in rubber factories.

From the internal business process perspective, the company’s strategic objectives in case studies 1, 2, and 3 appear with the same phenomenon so that the validation rate is 100 percent. The strategic objectives include environmentally friendly operations management processes, customer management processes, green products, waste treatment innovation processes, and value-added waste processing processes. The strategic target of environmentally friendly operations management processes is carried out through the application of standardization of quality control processes using ISO 9000:2015 and standardization of environmental management using ISO 14001 and the right ISPO to reduce greenhouse gas emissions, RSPO to control best practices by paying attention to social and environmental issues, ISCC for the concept of sustainability and greenhouse gas emissions, and compliance with the requirements of the Renewable Energy Directive (RED) in the European Union. ISCC certification can be applied to meet legal requirements in the bioenergy market and demonstrate the sustainability and traceability of raw materials in the food, feed, and chemical industries.

The strategic objectives of service to consumers can be seen from the case of tobacco products exported to other countries. Services to consumers of CPO and sugar are carried out through direct sales, where consumers visit product warehouses. This service to consumers is carried out through the principles of efficiency and quality. For sugarcane, the green product innovation process and waste treatment are carried out by manufacturing low-glycemic sugar. The innovation of the waste treatment process is implemented by utilizing sugarcane waste as a raw material for making bioethanol, which previously used molasses as a raw material. In addition, also develop product innovations biogas to obtain biogas with a higher methane gas content. In addition, machine maintenance is carried out regularly to not cause excessive smoke and noise. Thorny plants are planted around the factory to reduce dust pollution from the sugar factory and as a buffer plant to reduce noise from the sugar factory area. For palm oil, waste treatment innovation is carried out by using liquid waste containers in holding ponds that are channeled to oil palm fields using pumps. Innovations in handling gas waste include building chimneys high above the ground and treating factory waste directly channeled to the ground through ditches. Regular maintenance of dust collectors demonstrates the strategic objective of waste management to reduce air pollution. This is in line with [3,13,15].

The strategic objectives of the value-added waste treatment process based on cross-case analysis in the three SOPEs are demonstrated through the successful processing of sugarcane shoots and oil palm meal used for animal feed, bagasse for boiler fuel, molasses as raw material for bioethanol production, or sold to other factories, and sugarcane waste for compost. Palm oil is used as briquettes, empty fruit bunches are used as raw material for paper pulp, and palm oil waste is used as biogas and organic fertilizer. Another recycling process is using hot steam from boilers for power generation, both in sugarcane and palm oil mills. Added value is also obtained by selling this electric power in collaboration with the State Electricity Company, a government-owned enterprise that produces most of Indonesia’s electricity. It can directly sell the utilization of waste from oil palm. It can develop product innovation rubber plantations in plant roots, and it can use directly wood from land clearing to consumers. This strengthens the opinion [4,20,68,89].

In the perspective of learning and growth, the results of exploratory studies in case studies 1, 2, and 3 showed the same phenomenon, so the validation rate is 100 percent. The strategic objectives consist of green human resources, aligning individual key performance indicators (KPIs) with corporate ones, agile teamwork, and transformational leadership. The strategic objectives of green human resources are demonstrated by increasing the competence of skilled human resources in managing environmentally friendly production processes, having a sustainability paradigm, and the awareness to implement it. Some employees have ISO 14001 certification. Employees run the Occupational Health and Safety Principles program, Reuse, Reduce and Recycle (3R), and the ISO 14001 program to protect the environment and internalize organizational culture through morning briefings to discuss and evaluate past activities and delivery of targets for the day. That. This is following the opinion of [1,13,20].

The strategic target of aligning individual KPIs with corporate KPIs is achieved through sustainability performance targets. The circular economy and company work units are aligned with individual KPIs so that employees’ work will be focused and aligned with the company’s vision of sustainability. The work unit operationalizes the company’s vision to care for the environment as follows [18,68,89]. Its success can determine the strategic goals of agile teamwork through an investment committee consisting of various units to discuss corporate budgeting. This committee accommodates requests for budget allocations based on performance targets and aggressive cross-organizational teamwork when new policies or systems are implemented. Teamwork is also encouraged when companies adopt certain technologies, such as crowdfunding and e-farming, and teamwork competence is one of the assessment elements considered for promotion. This supports the opinion [72,98].

The strategic goals of transformational leadership are indicated by the success of the leadership in setting targets and the commitment of managers to achieve circular economy targets [72,98]. Based on a cross-case analysis across three SOPEs, these targets were conveyed through a meeting of all factory employees, signed an agreement between the general manager, assistant general manager, and supervisor, and then communicated to each.

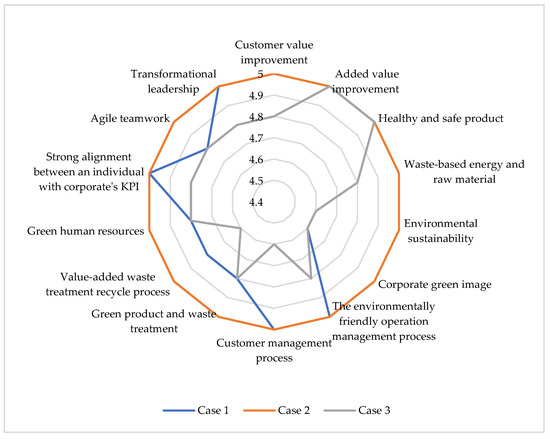

Variable conceptual framework strategic goals SBSC based on CE were validated in the cross-case analysis above; then, the level of importance is assessed by 15 managers in three SOPEs. The results of the perception test can be seen in Figure 4. Based on Figure 4, it can be seen that managers assess importance and importance. Thus, the SBSC conceptual framework based on CE is considered important to companies.

Figure 4.

Average scores of managers’ importance level test results in case study 1, 2, and 3.

Based on the explanation of the exploration results above, it is found that the formulation of the conceptual framework of sustainable performance management for the circular economy in Figure 4 can be applied to SOPEs companies in Indonesia. The field study results show that the CE concept has been implemented. The reason is that SOPE has a mandate as an agent of development bound to the Indonesian government’s agenda concerned with the environment. This is evident from the many phenomena in the field that support the conceptual framework. Thus, companies can be encouraged to make the circular economy a part of sustainability performance management.

The implication of the research is that the conceptual framework of the sustainability performance management for CE can be used as a guideline for the formulation of the company’s strategic objectives. Furthermore, the strategic goals of the organization are used as a reference or guideline in compiling organizational performance indicators and allocating resources; this is reinforced by the explanations in [67,70,71]. The key to the success of organizational performance is based on the organization’s ability to allocate organizational resources effectively and efficiently to achieve company goals [102]. A further implication of implementing this framework is that if many companies around the world make CE a part of their sustainable performance management, it will be able to encourage many companies to continue to generate economic growth by maintaining the value of products, materials, and resources in the economy for as long as possible, minimizing social and environmental damage.

5. Conclusions

Several previous sustainability balanced scorecard (SBSC) studies have formulated sustainable performance indicators in sustainability performance management, but have not considered the circular economy (CE) concept. Therefore, a CE conceptualization was carried out in this study by developing sustainable performance management in state-owned plantation enterprises (SOPEs).

Increasing a company’s performance by implementing a circular economy will be easier to achieve if the company applies the concept of a CE to the company’s mission and strategy. The company experience is often difficult in operationalizing their strategies.

A framework of sustainability performance management based on CE includes the following stages of formulating stakeholder values: using the SBSC approach, formulating company strategic goals, and formulating strategic goals in the conceptual framework of SBSC-based sustainable management integrated with the CE.

The exploration of the strategic objectives of the circular economy in the three SOPEs revealed optimal practices in the form of an environmentally friendly operation management process, customer management process, green product and waste treatment innovation process, value-added waste treatment recycle process, waste-based energy and raw materials, environmental sustainability, corporate green image, and added value improvement. The validation results showed that the phenomenon in the field indicates that the strategic goal’s theme that appears in the three cases has a validation value of 100 percent. Then, also, based on the perception test by managers on the importance of the strategic goals of SBSC on CE, it shows that the values range from important to very important values.

The results of this research imply that the CE sustainability performance management framework based on the SBSC perspective can be synthesized and implemented as a sustainability performance management framework for SOPE. It is hoped that in the future, this conceptual framework using CE can develop a paradigm used by company leaders from what was originally limited to a more strategic operational level. Future research is expected to measure CE performance for reduction, reuse, and recycling.

Author Contributions

Conceptualization, E.T., K.S., B.P. and M.A.; methodology, M.A.; validation, E.T.; formal analysis, E.T. and M.A.; writing—original draft preparation, E.T.; writing—review and editing, K.S., B.P. and M.A.; visualization, E.T.; supervision, K.S.; project administration, E.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors’ gratitude goes to the Board of Directors, top management, middle management, and lower management SOPE, as well as the staff who have been pleased to provide information, discuss and fill out questionnaires during field visits and online communication.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

Description of the code in Figure 3.

Table A1.

Description code of Figure 3.

Table A1.

Description code of Figure 3.

| Initial Framework | Interviews Results and Document Analysis | Code | Theme Strategic Goals | Validation |

|---|---|---|---|---|

| f1 | High product quality standards, for example: sugar products. | f11 | Customer value improvement | 100% |

| High product quality standards, for example: golden CPO. | f12 | |||

| f2 | Processing of PKS liquid waste into biogas | f21 | Added value Improvement | 100% |

| Processing molasses liquid waste into bioethanol | f22 | |||

| Palm kernel shell waste processed into briquettes | f23 | |||

| Processing forage waste and cakes into animal feed ingredients | f24 | |||

| Processing of solid and liquid waste into organic fertilizer | f25 | |||

| c1 | Do not use harmful additives | c11 | Healthy and Safety Product | 100% |

| Low glycaemic sugar products that are safe to use for diabetics | c12 | |||

| Golden CPO produced with an excellent production process. | c13 | |||

| c2 | Conversion of sugarcane shoots, oil palm meal, and palm oil mill sludge solids for animal feed | c21 | Waste-based Energy and Raw Material | 100% |

| Conversion of sugarcane bagasse, palm shell, and palm fibre for boiler fuel | c22 | |||

| Conversion of molasses for raw material for the manufacture of bioethanol | c23 | |||

| Conversion of sugarcane fronds, palm fronds, oil palm empty fruit bunches, palm oil effluent, and palm oil mill sludge solids to organic fertilizer for land | c24 | |||

| Palm shells are used as paving materials. | c25 | |||

| The wood from the land clearing will be used as smoked wood in the rubber factory. | c26 | |||

| Converting PKS liquid waste into biogas | c27 | |||

| c3 | Crop rotation, planting legumes, organic fertilization from liquid and solid waste from sugarcane, CPO, and PKO mills to maintain soil fertility. | c31 | environmental sustainability | 100% |

| Integrated pest control using natural predators and host plants | c32 | |||

| Planting perennials in watersheds to prevent erosion | c33 | |||

| c4 | Obtaining the proper green predicate from the Ministry of the Environment | c41 | Corporate Green Image | 100% |

| ISPO certification | c42 | |||

| RSPO certification | c43 | |||

| ISCC certification | c44 | |||

| UTZ certification | c45 | |||

| i1 | Implementation of standardization of quality control processes using ISO 9000:2015 | i11 | The environmentally friendly Operation management process | 100% |

| Implementation of environmental management standardization using ISO 14001 and proper | i12 | |||

| Implementation of ISPO certification to reduce greenhouse gas emissions | i13 | |||

| Implementation of RSPO certification for best practice control with social and environmental considerations | i14 | |||

| Implementation of ISCC certification for the concept of sustainability and greenhouse gas emissions | i15 | |||

| Compliance with renewable energy directive’s (RED) requirements in the European Union | i16 | |||

| i2 | Services to consumers of sugar sold to wholesalers, and buyers take it to the location so that it is more efficient and energy-efficient | i21 | Customer Management Process | 100% |

| Services for tobacco consumers are carried out through exports to other countries. | i22 | |||

| Services for consumers of CPO and sugar are carried out through direct selling, where consumers visit the product warehouse. | i23 | |||

| i3 | Process innovation for low glycaemic sugar | i31 | Green Product and Waste Treatment Innovation Process | 100% |

| The innovation of the waste treatment process is carried out, among others, through the manufacture of bioethanol using raw materials derived from sugarcane litter which previously used molasses as raw material. | i32 | |||

| Innovation of biogas products to obtain biogas with higher methane gas content | i33 | |||

| Waste treatment innovations are carried out, among others, through liquid waste containers in holding ponds that are channeled to palm oil fields using pumps. | i34 | |||

| Innovations in handling gas waste are carried out, among others, by making chimneys high above the ground and processing factory waste directly applied to the ground through ditches. | i35 | |||

| i4 | The success of processing sugarcane shoots and palm oil meal waste is used for animal feed. | i41 | Value-added waste treatment Recycle process | 100% |

| Successful treatment of waste bagasse for boiler fuel | i42 | |||

| The success of processing molasses waste for raw material for making bioethanol or selling it to other factories | i43 | |||

| The success of processing sugarcane litter for compost | i44 | |||

| The success of processing palm oil shell waste into briquettes using palm oil shell waste into briquettes | i45 | |||

| The success of processing waste from empty fruit bunches is used as raw material for paper pulp. | i46 | |||

| The success of processing palm oil waste into biogas | i47 | |||

| The success of processing palm oil waste into organic fertilizer | i48 | |||

| Successful treatment of waste hot steam from boilers for power generation | i49 | |||

| Utilization of waste from oil palm and rubber plantations in the form of plant roots and wood from land clearing, which will be sold directly | i410 | |||

| l1 | Increasing the competence of skilled human resources in managing environmentally friendly production processes | l11 | Green Human resources | 100% |

| Have a sustainability paradigm, and have the awareness to implement it | l12 | |||

| An employee that runs ISO 14001 is certified. | l13 | |||

| Employees run Occupational Health and Safety (K3), Reuse, Reduce and Recycle (3R), and ISO 14001 programs to protect the environment. | l14 | |||

| All employees are committed to achieving the highest predicate in managing the environment. | l15 | |||

| Internalization of organizational culture is carried out through a morning briefing to discuss the evaluation of past activities and the delivery of targets for the day. | l16 | |||

| l2 | The company’s and work unit’s sustainability and circular economic performance targets are aligned with individual KPIs so that employees’ work will be focused and aligned with the company’s vision of sustainability. | l21 | Strong Alignment between an individual with Corporate’s KPI | 100% |

| The unit operationalizes the company’s vision to care for the environment. | l22 | |||

| l3 | The existence of an investment committee consisting of various units to discuss the company’s budgeting that accommodates requests for budget allocations based on performance targets and unit potentials | l31 | Agile Teamwork | 100% |

| Building aggressive cross-organizational teamwork for organizational change, when some new policies or systems will be implemented | l32 | |||

| Forming teamwork to adopt certain technologies such as crowdfunding and e-farming that the company has implemented | l33 | |||

| Teamwork competence is one of the assessment elements considered for promotion. | l34 | |||

| l4 | The success of the leadership set targets in line with GM’s commitment to headquarters. This target was conveyed through a meeting of all factory employees and signed the agreement between GM, Supervisor, and the coordinator, cascading to each department. | l41 | Transformational leadership | 100% |

| The individual targets stated in the Work Target Agreement (KSK) are determined top-down by considering fairness for each unit and division following the directors’ targets. | l42 |

References

- Agrawala, S.; Singh, R.K.; Murtaza, Q. Outsourcing decisions in reverse logistics: Sustainable balanced scorecard and graph theoretic approach. J. Resour. Conserv. Recycl. 2016, 108, 41–53. [Google Scholar] [CrossRef]

- Amrina, E.; Ramadhani, C.; Vilsi, A.F. Fuzzy multi criteria approach for sustainable manufacturing evaluation in cement industry. Procedia CIRP 2016, 40, 619–624. [Google Scholar] [CrossRef] [Green Version]

- Baumgartner, R.J.; Rauter, R. Strategic perspectives of corporate sustainability management to develop a sustainable organization. J. Clean. Prod. 2017, 140, 81–92. [Google Scholar] [CrossRef]

- Dočekalová, M.P.; Kocmanová, A. Composite indicator for measuring corporate sustainability. Ecol. Indic. 2016, 61, 612–623. [Google Scholar] [CrossRef]

- Edgeman, R.; Eskildsen, J. Modeling and assessing sustainable enterprise excellence. Bus. Strateg. Environ. 2014, 23, 173–187. [Google Scholar] [CrossRef]

- Ahmed, M.D.; Sundaram, D. Sustainability modelling and reporting: From roadmap to implementation. J. Decis. Support Syst. 2012, 53, 611–624. [Google Scholar] [CrossRef]

- Figge, F.; Hahn, T.; Schaltegger, S.; Wagner, M. The sustainability balanced scorecard linking sustainability management to business strategy. Bus. Strateg. Environ. 2002, 11, 269–284. [Google Scholar] [CrossRef]

- Fulop, G.; Hernadi, B.; Jalali, M.; Kavaliauskiene, L.M.; Ferreira, F. Developing of sustainability balanced scorecard for the chemical industry: Preliminary evidence from a case analysis. Inz. Ekon.-Eng. Econ. 2014, 25, 341–349. [Google Scholar] [CrossRef] [Green Version]

- Journeault, M. The Integrated Scorecard in support of corporate sustainability strategies. J. Clean. Prod. 2016, 182, 214–229. [Google Scholar] [CrossRef]

- Junior, N.A.J.; Oliveira, M.C.; Helleno, A.L. Sustainability evaluation model for manufacturing sistems based on the correlation between triple bottom line dimensions and balanced scorecard perspectives. J. Clean. Prod. 2018, 190, 84–93. [Google Scholar] [CrossRef]

- Kalender, Z.T.; Vayvay, O. The fifth pillar of the balanced scorecard: Sustainability. Procedia Soc. Behav. Sci. 2016, 235, 76–83. [Google Scholar] [CrossRef]

- Nikolaou, I.E.; Tsalis, T.A. Development of a sustainable balanced scorecard framework. Ecol. Indic. 2013, 34, 76–86. [Google Scholar] [CrossRef]

- Elkington, J. Cannibals with Forks: The Triple Bottom Line of 21st Century Business; Capstone: Oxford, UK, 1997. [Google Scholar]

- Kaplan, R.S.; Norton, D.P. The Balanced Scorecard: Measures That Drive Performance; Harvard Business Review: Boston, MA, USA, 1992; pp. 71–79. [Google Scholar]

- Kaplan, R.S.; Norton, D. The Strategy-Focused Organization: How Balanced Scorecard Companies Thrive in the New Business Environment, 1st ed.; Harvard Business Review Press: Boston, MA, USA, 2000. [Google Scholar]

- Asiaei, K.; Jusoh, R. Using a robust performance measurement system to illuminate intellectual capital. Int. J. Account. Inf. Syst. 2017, 26, 1–19. [Google Scholar] [CrossRef]

- Bautista, S.; Enjolras, M.; Narvaez, P.; Camargo, M.; Morel, L. Biodiesel-triple bottom line (TBL): A new hierarchical sustainability assessment framework of principles criteria and indicators (PC dan I) for biodiesel production. Part II-validation. Ecol. Indic. 2016, 69, 803–817. [Google Scholar] [CrossRef]

- Campos, L.M.S.; Heizen, D.A.M.; Verdinelli, M.A.; Miguel, C. Environmental performance indicators: A study on ISO 14001 certified companies. J. Clean. Prod. 2015, 99, 286–296. [Google Scholar] [CrossRef]

- Chalmeta, R.; Palomero, S. Methodological proposal for business sustainability management by means of the Balanced Scorecard. J. Oper. Res. Soc. 2011, 62, 1344–1356. [Google Scholar] [CrossRef]

- Helleno, A.L.; Moraes, A.J.M.; Simon, A.T. Integrating sustainability indicators and lean manufacturing to assess manufacturing processes: Application case studies in Brazilian industry. J. Clean. Prod. 2017, 153, 405–416. [Google Scholar] [CrossRef]

- Hristov, I.; Chirico, A.; Appolloni, A. Sustainability value creation, survival, and growth of the company: A critical perspective in the Sustainability Balanced Scorecard (SBSC). J. Sustain. 2019, 11, 2119. [Google Scholar] [CrossRef] [Green Version]

- Hsu, C.-W.; Hu, A.H.; Chiou, C.-Y.; Chen, T.-C. Using the FDM and ANP to construct a sustainability balanced scorecard for the semiconductor industry. J. Clean. Prod. 2011, 38, 12881–12889. [Google Scholar] [CrossRef]

- Isaksson, R.B.; Garvare, R.; Johnson, M. The crippled bottom line—Measuring and managing sustainability. Int. J. Product. Perform. Manag. 2015, 64, 334–355. [Google Scholar] [CrossRef]

- Nouri, F.A.; Nikabadi, M.S. Developing the framework of sustainable service supply chain balanced scorecard (SSSC BSC). Int. J. Product. Perform. Manag. 2018, 68, 148–170. [Google Scholar] [CrossRef]

- Rimppi, H.; Uusitalo, V.; Väisänen, S.; Soukka, R. Sustainability criteria and indicators of bioenergy systems from steering, research and Finnish bioenergy business operators’ perspectives. Ecol. Indic. 2016, 66, 357–368. [Google Scholar] [CrossRef]

- Soriano, R.L.; Torres, M.J.; Chalmeta, R.R. Methodology for sustainability strategic planning and management. Ind. Manag. Data Syst. 2009, 110, 249–268. [Google Scholar] [CrossRef]

- Tai, X.; Xiao, W.; Tang, Y. A quantitative assessment of vulnerability using social-economic natural compound ecosystem framework in coal mining cities. J. Clean. Prod. 2020, 258, 120969. [Google Scholar] [CrossRef]

- Trisyulianti, E.; Suryadi, K.; Prihantoro, B. A conceptual framework of sustainability balanced scorecard for stated-own plantation enterprises. In Proceedings of the 7th International Conference on Frontiers of Industrial Engineering (ICFIE 2020), Singapore, 18–20 September 2020. [Google Scholar]

- Tsai, F.M.; Bui, T.D.; Tseng, M.L.; Wu, K.J.; Chiu, A.S.F. A performance assessment approach for integrated solid waste management using a sustainable balanced scorecard approach. J. Clean. Prod. 2019, 251, 119740. [Google Scholar] [CrossRef]

- Wilburn, K.; Wilburn, R. The double bottom line: Profit and social benefit. Bus. Horiz. 2014, 57, 11–20. [Google Scholar] [CrossRef]

- Korhonen, J.; Honkasalo, A.; Seppala, J. Circular Economy: The Concept and its Limitations. Ecol. Econ. 2018, 143, 37–46. [Google Scholar] [CrossRef]

- Wang, P.; Che, F.; Fan, S.; Gu, C. Ownership governance, institutional pressures and circular economy accounting information disclosure: An institutional theory and corporate governance theory perspective. Chin. Manag. Stud. 2014, 8, 487–501. [Google Scholar] [CrossRef]

- Zhijun, F.; Nailing, Y. Putting a circular economy into practice in China. Sustain. Sci. 2007, 2, 95–101. [Google Scholar] [CrossRef]

- Ma, S.; Hu, S.; Chen, D.; Zhu, B. A case study of a phosphorus chemical firm’s application of resource efficiency and eco-efficiency in industrial metabolism under circular economy. J. Clean. Prod. 2015, 87, 839–849. [Google Scholar] [CrossRef]

- Dajian, Z. Background, pattern and policy of China for developing circular economy. Chin. J. Popul. Resour. Environ. 2008, 6, 3–8. [Google Scholar] [CrossRef]

- Stahel, W.R.; Reday, G. The Potential for Substituting Manpower for Energy; European Communities: Brussels, Belgium, 1976. [Google Scholar]

- Stahel, W.R.; Reday, G. Jobs for Tomorrow, the Potential for Substituting Manpower for Energy; Vantage Press: New York, NY, USA, 1981. [Google Scholar]

- Pearce, D.W.; Turner, R.K. Economics of Natural Resources and the Environment; The Johns Hopkins University Press: Baltimore, MD, USA, 1990; pp. 35–42. [Google Scholar]

- Boulding, K.E. The Economics of the Coming Spaceship Earth. In Environmental Quality in a Growing Economy; Jarrett, H., Ed.; Johns Hopkins University Press: Baltimore, MD, USA, 1966; pp. 3–14. [Google Scholar]

- Su, Y.; Zhou, H. Promoting circular economy development a basic national policy. North. Econ. 2005, 1, 8–10. [Google Scholar]

- Kumar, V.; Sezersan, I.; Garza-Reyes, J.A.; Gonzalez, E.D.R.S.; Al-Shboul, M.A. Circular economy in the manufacturing sector: Benefits, opportunities and barriers. Manag. Decis. 2019, 57, 1067–1086. [Google Scholar] [CrossRef] [Green Version]

- Peters, G.P.; Weber, C.L.; Guan, D.; Hubacek, K. China’s growing CO2 emissions: A race between increasing consumption and efficiency gains. Environ. Sci. Technol. 2007, 41, 5939–5944. [Google Scholar] [CrossRef] [Green Version]

- Beckmann, A.; Sivarajah, U.; Irani, Z. Circular economy versus planetary limits: A Slovak forestry sector case study. J. Enterp. Inf. Manag. 2020, 34, 1673–1698. [Google Scholar] [CrossRef]

- Murray, A.; Skene, K.; Haynes, K. The circular economy: An interdisciplinary exploration of the concept and application in a global context. J. Bus. Ethics 2015, 140, 369–380. [Google Scholar] [CrossRef] [Green Version]

- Ellen MacArthur Foundation (EMF). Towards the Circular Economy: Economic and Business Rationale for an Accelerated Transition; Ellen MacArthur Foundation: Cowles, UK, 2013; p. 26. [Google Scholar]

- Zhu, Q.; Geng, Y.; Lai, K.H. Environmental supply chain cooperation and its effect on the circular economy practice-performance relationship among Chinese manufacturers. J. Ind. Ecol. 2011, 15, 405–419. [Google Scholar] [CrossRef]

- MacArthur, E. Towards a Circular Economy—Opportunities for the Consumer Goods Sector; Ellen MacArthur Foundation: Bristol, UK, 2013; Available online: www.ellenmacarthurfoundation.org/assets/downloads/publications/TCE_Report-2013.pdf (accessed on 25 October 2021).

- Feng, Z. Circular Economy Overview; People’s Publishing House: Beijing, China, 2004. (In Chinese) [Google Scholar]

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A review on circular economy: The expected transition to a balanced interplay of environmental and economic systems. J. Clean. Prod. 2016, 114, 11–32. [Google Scholar] [CrossRef]

- Stahel, W.R. Circular economy. Nature 2016, 531, 435–438. [Google Scholar] [CrossRef] [Green Version]

- Ripanti, E.F.; Tjahjono, B. Unveiling the potentials of circular economy values in logistics and supply chain management. Int. J. Logist. Manag. 2019, 30, 723–742. [Google Scholar] [CrossRef] [Green Version]

- Jawahir, I.S.; Bradley, R. Technological Elements of Circular Economy and the Principles of 6R-Based Closed-loop Material Flow in Sustainable Manufacturing. Procedia CIRP 2016, 40, 103–108. [Google Scholar] [CrossRef] [Green Version]

- Winans, K.; Kendall, A.; Deng, H. The history and current applications of the circular economy concept. Renew. Sustain. Energy Rev. 2017, 68, 825–833. [Google Scholar] [CrossRef]

- De Vasconcelos, D.C.; Viana, F.L.E.; De Souza, A.L. Circular Economy and Sustainability in the Fresh Fruit Supply Chain: A Study across Brazil and the UK. Lat. Am. Bus. Rev. 2021, 22, 393–421. [Google Scholar] [CrossRef]

- Ferronato, N.; Rada, E.C.; Portillo, M.A.G.; Cioca, L.I.; Ragazzi, M.; Torretta, V. Introduction of the circular economy within developing regions: A comparative analysis of advantages and opportunities for waste valorization. J. Environ. Manag. 2019, 230, 366–378. [Google Scholar] [CrossRef]

- Geng, Y.; Fu, J.; Sarkis, J.; Xue, B. Towards a national circular economy indicator system in China: An evaluation and critical analysis. J. Clean. Prod. 2012, 23, 216–224. [Google Scholar] [CrossRef]

- Rada, E.C.; Cioca, L.I.; Ionescu, G. Energy recovery from Municipal Solid Waste in EU: Proposals to assess the management performance under a circular economy perspective. MATEC Web Conf. 2017, 121, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Sehnem, S.; Jabbour, C.J.C.; Pereira, S.C.F.; Jabbour, A.B.L. Improving sustainable supply chains performance through operational excellence: Circular economy approach. Resour. Conserv. Recycl. 2019, 149, 236–248. [Google Scholar] [CrossRef]

- Su, C.; Urban, F. Circular economy for clean energy transitions: A new opportunity under the COVID-19 pandemic. Appl. Energy 2021, 288, 116666. [Google Scholar] [CrossRef]

- Su, B.; Heshmati, A.; Geng, Y.; Yu, X. A review of the circular economy in China: Moving from rethoric to implementation. J. Clean. Prod. 2013, 42, 215–277. [Google Scholar] [CrossRef]

- Stumpf, L.; Schoggl, J.; Baumgartner, R.J. Climbing up the circularity ladder?—A mixed-methods analysis of circular economy in business practice. J. Clean. Prod. 2021, 316, 128158. [Google Scholar] [CrossRef]

- Maldonado-Guzman, G.; Garza-Reyes, J.A.; Pinzón-Castro, Y. Eco-innovation and the circular economy in the automotive industry. Benchmarking Int. J. 2021, 28, 621–635. [Google Scholar] [CrossRef]

- Zaman, A.U.; Lehmann, S. The zero-waste index: A performance measurement tool for waste management systems in a “zero waste city”. J. Clean. Prod. 2013, 50, 123–132. [Google Scholar] [CrossRef]

- Golinska, P.; Kosacka, M.; Mierzwiak, R.; Werner-Lewandowska, K. Grey decision making as a tool for the classification of the sustainability level of remanufacturing companies. J. Clean. Prod. 2015, 105, 28–40. [Google Scholar] [CrossRef]

- Park, J.J.; Chertow, M. Establishing and testing the “reuse potential” indicator for managing waste as resources. J. Environ. Manag. 2014, 137, 45–53. [Google Scholar] [CrossRef]

- Kaplan, R.S. Conceptual foundations of the balanced scorecard. In Handbook of Management Accounting Research; Working Paper 10-074; Elsevier: Amsterdam, The Netherlands, 2010; Volume 3, pp. 1–36. [Google Scholar]

- Kaplan, R.S.; Norton, D. Alignment: Using the Balanced Scorecard to Create Corporate Synergies; HBS Press: Boston, MA, USA, 2006. [Google Scholar]

- Slaper, T. The triple bottom line: What is it and how does it work? Indiana University Kelley School of Business. Indiana Bus. Res. Cent. 2011, 86, 4–8. [Google Scholar]

- Govindan, K.; Seuring, S.; Zhu, Q.; Azevedo, S.G. Accelerating the transition towards sustainability dynamics into supply chain relationship management and governance structures. J. Clean. Prod. 2016, 112, 1813–1823. [Google Scholar] [CrossRef]

- Parnell, J.A. Strategic Management: Theory and Practice, 4th ed.; SAGE: Newcastle upon Tyne, UK, 1964. [Google Scholar]

- David, F.R. Strategic Management Concepts and Cases; Pearson: London, UK, 2011. [Google Scholar]

- Kaplan, R.S.; Norton, D. The Balanced Scorecard: Translating Strategy into Action; HBS Press: Boston, MA, USA, 1996. [Google Scholar]

- Ahmad, S.; Nisar, T. Green Human Resource Management: Policies and practices. Cogent Bus. Manag. 2015, 2, 1030817. [Google Scholar] [CrossRef]

- Senechal, O. Research directions for integrating the triple bottom line in maintenance dashboards. J. Clean. Prod. 2017, 142, 331–342. [Google Scholar] [CrossRef]

- Hansen, E.G.; Schaltegger, S. The sustainability balanced scorecard: A systematic review of architectures. J. Bus. Ethics 2014, 133, 193–221. [Google Scholar] [CrossRef]

- Zarte, M.; Pechman, A.; Nunes, I.L. Decision support systems for sustainable manufacturing surrounding the product and production life cycle, A literature review. J. Clean. Prod. 2019, 219, 336–349. [Google Scholar] [CrossRef]

- Jamaludin, N.F.; Hashim, H.; Muis, Z.A.; Zakaria, Z.Y.; Jusoh, M.; Yunus, A.; Murad, S.M.A. A sustainability performance assessment framework for palm oil mills. J. Clean. Prod. 2018, 174, 1679–1693. [Google Scholar] [CrossRef]

- Kumar, A.; Anbanandam, R. Assessment of environmental and social sustainability performance of the freight transportation industry: An index-based approach. Transp. Policy 2020. [Google Scholar] [CrossRef]

- Gohar, E.A.A. Sustainable Balanced Scorecard: A new approach to vision and implementation of a sustainable strategy in Egyptian travel agencies. Int. J. Tour. Hosp. Manag. 2019, 2, 98–126. [Google Scholar]

- Hansen, E.G.; Schaltegger, S. Sustainability balanced scorecards and their architectures: Irrelevant or misunderstood? . J. Bus. Ethics. 2017, 150, 937–952. [Google Scholar] [CrossRef] [Green Version]

- Huang, T.; Pepper, M.; Bowrey, G. Implementing a sustainability balanced scorecard to contribute to the process of organizational, Australasian Accounting. J. Legitimacy Assess. Bus. Financ. 2014, 8, 15–34. [Google Scholar]

- Lee, S.; Geuma, Y.; Lee, H.; Park, Y. Dynamic and multidimensional measurement of product-service system (PSS) sustainability: A triple bottom line (TBL) based sistem dynamics approach. J. Clean. Prod. 2012, 32, 173–182. [Google Scholar] [CrossRef]

- Lu, M.T.; Hsu, C.C.; Liou, J.J.H.; Loc, H.W. A hybrid MCDM and sustainability-balanced scorecard model to establish sustainable performance evaluation for international airports. J. Air Transp. Manag. 2018, 71, 9–19. [Google Scholar] [CrossRef]

- Petrini, M.; Pozzebon, M. Managing sustainability with the support of business intelligence: Integrating socio-environmental indicators and organizational context. J. Strateg. Inf. Syst. 2009, 18, 178–191. [Google Scholar] [CrossRef]

- Pislaru, M.; Herghiligiu, I.V.; Robu, I.B. Corporate sustainable performance assessment based on fuzzy logic. J. Clean. Prod. 2019, 223, 998–1013. [Google Scholar] [CrossRef]

- Wicher, P.; Zapletal, F.; Lenort, R. Sustainability performance assessment of industrial corporation using Fuzzy Analytic Network Process. J. Clean. Prod. 2019, 241, 118132. [Google Scholar] [CrossRef]

- Freeman, E. Stakeholder Management: Framework and Philosophy; Pitman: Boston, MA, USA, 1984. [Google Scholar]

- Munteanu, V.; Danaiata, D.; Hurbean, L.; Bergler, A. The value-based management approach: From the shareholder value to the stakeholder value. In Proceedings of the 6th International Management Conference, Approaches in Organizational Management, Bucharest, Romania, 15–16 November 2012. [Google Scholar]

- Freudenreich, B.; Freund, F.L.; Schaltegger, S. A stakeholder theory perspective on business models: Value creation for sustainability. J. Bus. Ethics 2019, 166, 3–18. [Google Scholar] [CrossRef]

- Bohari, A.A.M.; Skitmore, M.; Xia, B.; Teo, M.; Khalil, N. Key stakeholder values in encouraging green orientation of construction procurement. J. Clean. Prod. 2020, 20, 122246. [Google Scholar] [CrossRef]

- Chang, A.-Y.; Cheng, Y.-T. Analysis model of the sustainability development of manufacturing small and medium sized enterprises in Taiwan. J. Clean. Prod. 2019, 207, 458–473. [Google Scholar] [CrossRef]

- Kamali, M.; Hewage, K. Development of performance criteria for sustainability evaluation of modular versus conventional construction methods. Int. J. Clean. Prod. 2017, 142, 3592–3606. [Google Scholar] [CrossRef]

- Huang, A.; Badurdeen, F. Sustainable manufacturing performance evaluation: Integrating product and process metrics for systems level assessment. Procedia Manuf. 2017, 8, 563–570. [Google Scholar] [CrossRef]

- Franz, P.H.; Krichmer, M.; Rosemann, M. Value-Driven Business Process Management, Impact and Benefits; Accenture: Dublin, Ireland; Queensland University of Technology: Brisbane, Australia, 2012. [Google Scholar]

- Mohammadfam, I.; Kamalinia, M.; Momeni, M.; Golmohammadi, R.; Hamidi, Y.; Soltanian, A. Evaluation of the quality of occupational health and safety management systems based on key performance indicators in certified organizations. Saf. Health Work 2017, 8, 156–161. [Google Scholar] [CrossRef] [PubMed]

- Neely, A.; Gregory, M.; Platts, K. Performance measurement system design a literature review and research agenda. Int. J. Oper. Prod. Manag. 2005, 25, 1228–1263. [Google Scholar]

- Harmon, J.; Fairfield, K.D.; Wirtenberg, J. Missing an opportunity: HR leadership and sustainability. People Strategy 2010, 33, 16–21. [Google Scholar]

- Perkin, N.; Abraham, P. Building the Agile Business through Digital Transformation, 1st ed.; Kogan Page: New York, NY, USA, 2017. [Google Scholar]

- Yin, R.k. Case Study Research Design and Methods, 5th ed.; SAGE Publications Inc.: New York, NY, USA, 2014. [Google Scholar]

- Sladana, J. The Coding Manual for Qualitative Researchers, 2nd ed.; Sage: London, UK, 2013. [Google Scholar]

- Sekaran, U.; Bougie, R. Research Methods for Business—A Skill-Building Approach; John Wiley and Sons Ltd.: Hoboken, NJ, USA, 2016. [Google Scholar]

- Anthony Robert N. Planning and Control Systems: A Framework for Analysis; Division of Research, Graduate School of Business Administration, Harvard University: Boston, MA, USA, 1965. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).