This section discusses SSCM, digitalization in SC, the proposed methodology, and the measurement attribute set.

2.1. Sustainable Supply Chain Management

SSCM has grown exponentially and plays a vital role in SC management by addressing competitive markets and various environmental and social issues [

1,

3]. SSCM is defined as the strategies, transparent incorporation, and organizational goal achievement in the interorganizational occupational process coordinated to improve the long-term economic, social, and environmental performance of specific firms and their SCs [

5]. SSCM contributes to linking business development and sustainability issues. Hong et al. [

1] claimed that SSCM combined elements of business sustainability development and characteristics of SC management. Tseng et al. [

20] and Khan et al. [

2] argued that SSCM activities are triggered by external pressures, the government, customers, and NGOs and pursue good economic performance by ensuring the effectiveness and efficiency of product consumption and waste generation in operational functions. In sum, SSCM supervises SC activities, operations, information, and resources with the aims of refining economic benefits and social welfare and of reducing harmful environmental effects simultaneously for sustainable development.

However, increasing environmental issues and numerous pressures to balance SSCM and stakeholder benefits in conventional activities still exist, although the literature suggests that firms need to adopt sustainable dimensions in SC management. Tsai et al. [

4] argued that firms need to focus on the integration of social development, environmental issues, and economic consequences in the SSCM process. Hu et al. [

21] debated that by adopting SSCM, firms can also improve profitability, operational effectiveness, and competitive advantage by reducing waste and achieving socioenvironmental performance. Genovese et al. [

22] claimed that the practices of SSCM result in the principles of a circular economy by disclosing a compromising drive to promote the SC loop cycle border. However, the changeover to sustainability is a challenging process, as a wide range of limitations, including cultural, political, and economic structures, as well as human and technological confines, arise [

22]. Hence, SSCM still has many gaps to be addressed to achieve long-term sustainability performance [

3].

2.2. Digitalization in Supply Chain

Digitalization in SSCM is defined as connecting activities involved in the SC process between suppliers and consumers by means of novel technologies [

6]. Digitalization in SC (DSC) and its impacts have been discussed in prior studies. However, it is considered an emerging term [

14,

23]. Bhargava et al. [

23] specified that the DSC was systematically composed of hardware, software, and global communication networks supporting organizational interaction and orchestrating SC stakeholder activity. However, as an emergent term, digitalization is still in the early conceptualization stage, which is under similar theoretical underpinnings [

14]. Queiroz et al. [

24] proposed that digitalization is based on the growth of data and communication technologies. Nasiri et al. [

25] argued that digitalization is a transformation of business aspects (process, organizational, and culture) as required by the market. This perspective connects the existing processes at the societal, organizational, and individual levels, thus fostering the transformation of traditional SC into an interconnected system that runs flawlessly [

26].

DSC has the potential to transform the SC to make it more valuable, accessible, and affordable. DSC provides information sharing, collaboration, and communication through digital platforms, resulting in advanced reliability, agility, and effectiveness [

6]. Firms are starting to consider digitality because of the huge number of benefits digitality can bring for firms by utilizing it in SC. Nasiri et al. [

25] proposed that digitality changes the ways companies and individuals communicate and interact with their surroundings in an extreme manner. Fettermann et al. [

27] claimed that the interconnectedness within SC needs collaboration among diverse technologies, such as sensors, cloud processing, and cyber–physical practices, to encourage management transformation towards Industry 4.0. Annosi et al. [

13] argued that high-performance DSC integration allows an increase in financial performance and is beneficial for sustainability. Kianpour et al. [

28] proposed integrating digital technology with real-time information on processing times and due date rescheduling decisions to adapt to dynamic situations. Nevertheless, challenges exist in building DSCs due to the accuracy of the information, but the required data need to be collected from various sources. Therefore, to achieve sustainable development, a well-established SC should be extended to the application of digital technology and integrated into a firm’s SC [

15,

17,

25]. Hence, there is a need for firms to reimagine their SC process as a DSC network to reach development goals.

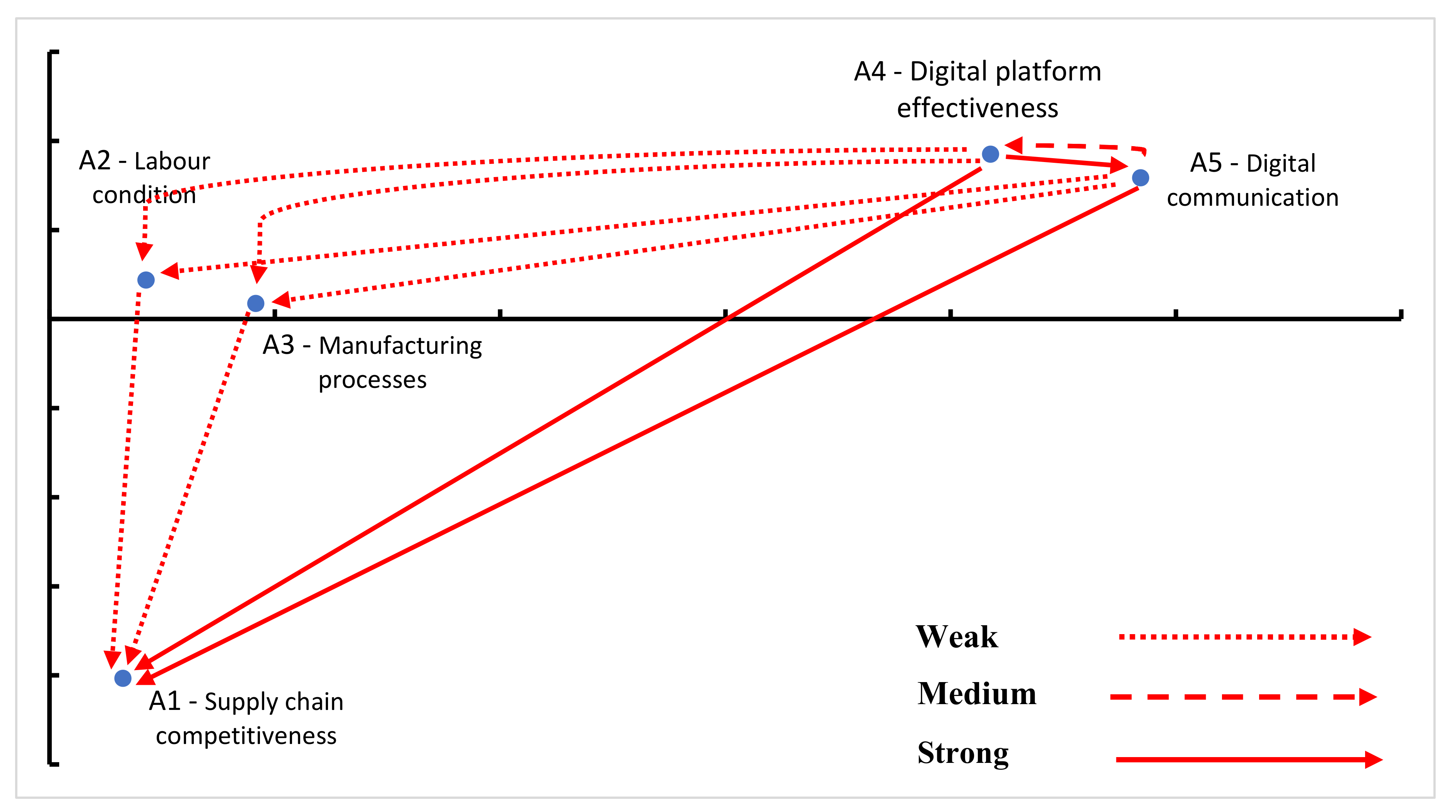

2.4. Proposed Measure

The SSCM literature has addressed various attributes. These attributes have a significant role that helps decision makers focus their effort on achieving more efficient performance. This study identifies 35 criteria and 8 aspects from 4 perspectives, namely, the economic dimension, the social dimension, the environmental dimension, and SC digitalization, for measuring processes (See

Table 1).

The economic dimension is still the priority, and firms may initially emphasize an SC process that minimizes waste and yields economic gains [

3,

35].

Economic benefits (A1) are a basic condition that firms must pursue to achieve economic performance and development [

11].

SC competitiveness (A2) is an economic concern [

35]. Previous studies have proposed

investment recovery (C1), which means recoupling the surplus assets value and reducing the waste of initial capital, which results in efficiency. The

production stage (C2) refers to ensuring process feasibility based on the efficiency of manufacturing processes and material costs.

Operation practices (C3) are related to economics of scale in transportation, both outbound and inbound, scientific inventory control, or just-in-time and lean production.

Strategic supplier collaboration (C4) refers to collaboration between firms and their suppliers in the SC that applies innovative technologies [

19].

Product quality (C5) refers to creating a high-value product.

Logistic integration (C6) is the coordination of the material flow from suppliers to customers.

Logistic optimization (C7) optimizes the logistic process in SC, including the pace, path, load, and character of transportation.

Sourcing flexibility (C8) refers to the ability to respond to market uncertainties and changes [

2].

Although social sustainability is deemed an intricate aspect, it is relatively neglected and infrequently accounted for in SSCM models [

10,

36]. There are two aspects with eight criteria that are proposed in this study.

Social benefit (A3) represents social activities that seek to benefit employees, customers, and local communities.

Labour condition (A4) is related to issues such as labour rights, child labour, and exploitative labour practices [

35].

Social collaboration (C9) is collaboration that involves SC stakeholders to improve social outcomes.

Corporate practice transparency (C10) concerns internal and external stakeholders that are becoming demanding for visible and transparent corporate practices.

Social responsibility (C11) refers to the social awareness and activities in the SC process to support humanity and do no harm to communities.

Top management commitment (C12) ensures the initiation of action and the dedication of resources to implement a social sustainability SC [

10].

Working condition (C13) ensures a higher living level and provides clear terms of employment, including salaries and benefits, full and stable employment, vacation, disciplinary regulations, and parenthood and dismissal fortifications.

Worker safety (C14) complies with governments’ regulations regarding working safety.

Labour rights (C15) refer to respect for the rights of labourers to form unions and groups [

37]. Child labour or forced labour (C16) is any kind of forced labour, including underage labour.

Environmental sustainability encompasses the management of resources, so waste from processes does not harm the natural environment or humankind [

38]. This perspective is apprehensive with finding and unravelling difficulties associated with pollution and damage related to the flow of resources and production stability [

25]. In this context, an approach that emphasizes a circular economy as a green and closed system is suggested in alignment with SSCM strategies, as resources are depleted and waste reduction becomes important once environmental sustainability constraints are imposed [

16,

23]. This study proposes two aspects from the environmental sustainability perspective.

Material sourcing (A5) consists of supplier selection and collaboration.

Manufacturing processes (A6) is a concept of administrating consumption and production activities.

Green purchasing (C17) relates to environmentally preferable purchasing items, such as non-hazardous items, reusability, and recyclability.

Eco collaboration (C18) means collaboration between SC stakeholders to reduce waste, lessen the carbon footprint, and conserve resources [

38].

Supplier green management (C19) is a collaboration between firms and their suppliers to be environmentally responsible, have a green certification, and evaluate suppliers’ environmental performance [

39].

Recycling or reverse logistics (C20) is related to the efficient processing, from the end user back to the point of origin, of material and information that can be disposed of or have its value regenerated.

Cleaner production (C21) efficiently reduces hazardous material and toxic emissions from the process.

Waste minimization and recovery (C22) means waste management that minimizes waste, prevents waste from being generated, and attempts to make waste recoverable.

Green packaging (C23) includes adopting renewable materials and minimizing the usage of resources.

Eco-design (C24) represents product or service design that embeds green value [

39].

In SC digitalization, Büyüközkan and Göçer [

6] proposed the features of DSC. For example,

digital platform effectiveness (A7) is related to the ability to enhance reliability, agility, and effectiveness in the SSCM process by using digital platforms.

Digital communication (A8) refers to SC interactions and stakeholder activities.

Delivery speed (C25) means the ability to quickly transfer extra material within a specified amount of time.

Adaption flexibility (C26) refers to the ability to adapt to changing circumstances and respond to problems in SC.

Autonomous decision making (C27) is related to the ability of digital technology that provides smart products that can self-learn and make decisions autonomously based on defined algorithms.

Process scalability (C28) means facilitating process duplication and growth by utilizing digital technology.

The innovative approach (C29) is related to the DSC distinction as a key characteristic of continuously being open for changes.

Proactive action (C30) means that DSCs gain abilities to mitigate potential disruptions.

Eco-friendliness (C31) relates to digital technology that can extend the traditional SC process to make it cleaner with respect to the environment.

Global connectivity (C32) enables firms to efficiently supply products locally across the world.

Real-time inventory (C33) means that DSC helps firms efficiently meet demand by ensuring that the supply is not disproportionately in surplus or shortage.

Information transparency (C34) ensures that the orderly flow within SC is visible to stakeholders and is not disrupted.

Relationship performance (C35) refers to collaborations built for conducting business, both internally and externally, between companies and their stakeholders.