Sensory Characteristics of Dairy By-Products as Potential Milk Replacers in Ice Cream

Abstract

1. Introduction

2. Materials and Methods

2.1. Dairy By-Product Samples

2.2. Ice Cream Production

2.3. Bacteriological Analysis

2.4. Sensory Analysis

2.4.1. Participants

2.4.2. Experimental Procedure

2.4.3. Consumer Acceptance Testing

2.4.4. Just-about-Right (JAR) Analysis

2.4.5. Survival-Analysis

2.5. Statistical Analyses

3. Results and Discussion

3.1. Bacteriological Analysis

3.2. Consumer Acceptance

3.3. Just-About-Right (JAR) and Penalty Analysis

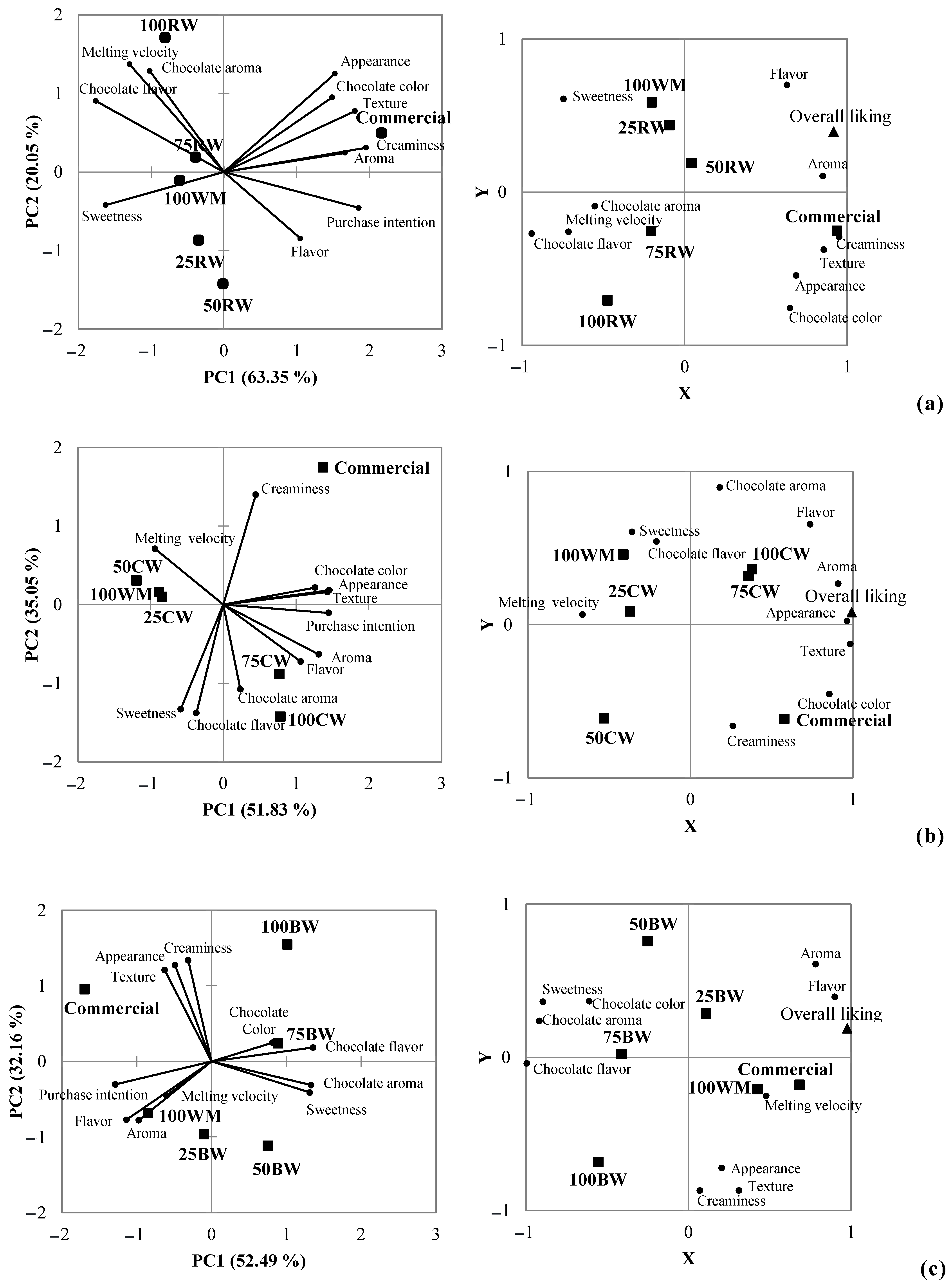

3.4. Principal Component Analysis and Partial Least Square Regression (PLSR)

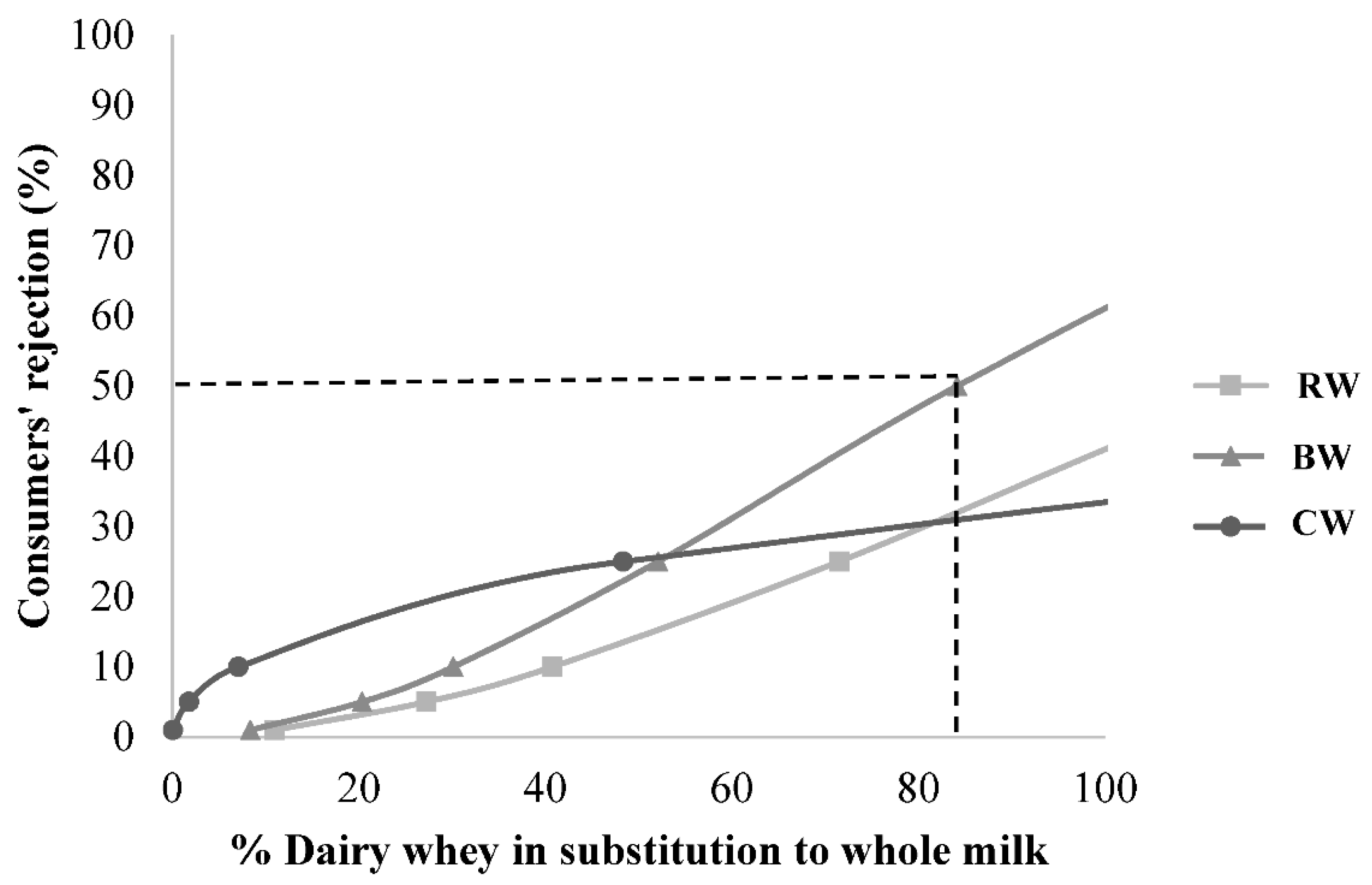

3.5. Survival-Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Agrawal, A.K. Effect of variation of ginger juice on some physical and sensory properties of ice cream. Indian J. Dairy Sci. 2016, 69, 17–23. [Google Scholar] [CrossRef]

- Euroglaces—European Ice Cream Association. Available online: http://www.euroglaces.eu/en/ (accessed on 15 November 2020).

- FAO. Milk and Dairy Products in Human Nutrition; Food and Agriculture Organization of the United Nations: Rome, Italy, 2013. [Google Scholar]

- Panesar, P.S.; Kennedy, J.F. Biotechnological approaches for the value addition of whey. Crit. Rev. Biotechnol. 2012, 32, 327–348. [Google Scholar] [CrossRef]

- Parashar, A.; Jin, Y.; Mason, B.; Chae, M.; Bressler, D.C. Incorporation of whey permeate, a dairy effluent, in ethanol fermentation to provide a zero waste solution for the dairy industry. J. Dairy Sci. 2016, 99, 1859–1867. [Google Scholar] [CrossRef]

- Kushwaha, J.P.; Srivastava, V.C.; Mall, I.D. An overview of various technologies for the treatment of dairy wastewaters. Crit. Rev. Food. Sci. Nutr. 2011, 51, 442–452. [Google Scholar] [CrossRef]

- Morin, P.; Pouliot, Y.; Jiménez-Flores, R. A comparative study of the fractionation of regular buttermilk and whey buttermilk by microfiltration. J. Food Eng. 2006, 77, 521–528. [Google Scholar] [CrossRef]

- Bald, J.A.; Vincenzi, A.; Gennari, A.; Lehn, D.N.; de Souza, C.F.V. Características físico-químicas de soros de queijo e ricota produzidos no Vale do Taquari, RS. Rev. Jovens Pesq. 2014, 4, 90–99. [Google Scholar] [CrossRef][Green Version]

- Cortellino, G.; Rizzolo, A. Storage stability of novel functional drinks based on ricotta cheese whey and fruit juices. Beverages 2018, 4, 67. [Google Scholar] [CrossRef]

- Martins, Z.E.; Pinho, O.; Ferreira, I.M.P.L.V.O. Food industry by-products used as functional ingredients of bakery products. Trends Food Sci. Technol. 2017, 67, 106–128. [Google Scholar] [CrossRef]

- Parrón, J.A.; Ripollés, D.; Navarro, F.; Ramos, S.J.; Pérez, M.D.; Calvo, M.; Sánchez, L. Effect of high pressure treatment on the antirotaviral activity of bovine and ovine dairy by-products and bioactive milk proteins. Innov. Food Sci. Emerg. Technol. 2018, 48, 265–273. [Google Scholar] [CrossRef]

- Haque, Z.U.; Ji, T. Cheddar whey processing and source: II. Effect on non-fat ice cream and yoghurt. Int. J. Food Sci. Technol. 2003, 38, 463–473. [Google Scholar] [CrossRef]

- Rodríguez, T.; M’Boumba, A. Utilización del suero de queso en helado. RVCTA 2011, 21, 9–12. [Google Scholar]

- Gerhardt, Â.; Monteiro, B.W.; Gennari, A.; Lehn, D.N.; de Souza, C.F.V. Características físico-químicas e sensoriais de bebidas lácteas fermentadas utilizando soro de ricota e colágeno hidrolisado. Rev. Ilct. 2013, 68, 41–50. [Google Scholar] [CrossRef]

- Hickey, C.D.; O’Sullivan, M.G.; Davis, J.; Scholz, D.; Kilcawley, K.N.; Wilkinson, M.G.; Sheehan, J.J. The effect of buttermilk or buttermilk powder addition on functionality, textural, sensory and volatile characteristics of Cheddar-style cheese. Food Res. Int. 2018, 103, 468–477. [Google Scholar] [CrossRef] [PubMed]

- Sakhale, B.K.; Pawar, V.N.; Ranveer, R.C. Studies on the development and storage of whey based RTS beverage from mango cv. Kesar. J. Food Process. Technol. 2012, 3, 1–4. [Google Scholar] [CrossRef]

- Castro, W.F.; Cruz, A.G.; Bisinotto, M.S.; Guerreiro, L.M.R.; Faria, J.A.F.; Bolini, H.M.A.; Cunha, R.L.; Deliza, R. Development of probiotic dairy beverages: Rheological properties and application of mathematical models in sensory evaluation. J. Dairy Sci. 2013, 96, 16–25. [Google Scholar] [CrossRef]

- Ozdemir, C.; Arslaner, A.; Ozdemir, S.; Allahyari, M. The production of ice cream using stevia as a sweetener. J. Food Sci. Technol. 2015, 52, 7545–7548. [Google Scholar] [CrossRef]

- American Public Health Association (APHA). Compendium of Methods for the Microbiological Examination of Foods, 4th ed.; APHA: Washington, DC, USA, 2001. [Google Scholar]

- ANVISA—Agência Nacional de Vigilância Sanitária. Regulamento Técnico Sobre os Padrões Microbiológicos para Alimentos (Resolução nº 12, de 02 de Janeiro de 2001). Available online: http://portal.anvisa.gov.br/documents/33880/2568070/RDC_12_2001.pdf/15ffddf6-3767-4527-bfac-740a0400829b (accessed on 5 November 2020).

- World Health Organization (WHO). Microbiological Criteria for Foods: Summary of Recommendations of FAO/OMS; WHO: Geneva, Switzerland, 1983. [Google Scholar]

- Dornelles, A.S.; Rodrigues, S.; Garruti, D.S. Acceptance and sensory profile of cachaça produced using Kefir and Saccharomyces cerevisae. J. Food Sci. Technol. 2009, 29, 518–522. [Google Scholar] [CrossRef]

- Stone, H.; Sidel, J.L. Quantitative descriptive analysis: Developments, applications, and the future. Food Technol. 1998, 52, 48–52. [Google Scholar]

- Lawless, H.T.; Heymann, H. Sensory Evaluation of Food: Principles and Practices, 2nd ed.; Springer: New York, NY, USA, 2010; pp. 1–56. [Google Scholar]

- Cervantes, B.G.; Aoki, N.A.; Almeida, C.P.M. Sensory acceptance of fermented cassava starch biscuit prepared with flour okara and data analysis with penalty analysis methodology. Braz. J. Food Technol. 2010, 19, 3–10. [Google Scholar] [CrossRef]

- Palazzo, A.B.; Bolini, H.M.A. Sweeteners in diet chocolate ice cream: Penalty analysis and acceptance evaluation. J. Food Stud. 2017, 6, 1–13. [Google Scholar] [CrossRef][Green Version]

- Hough, G.; Garitta, L. Methodology for sensory shelf-life estimation: A review. J. Sens. Stud. 2012, 27, 137–147. [Google Scholar] [CrossRef]

- Hough, G. Sensory Shelf Life Estimation of Food Products, 1st ed.; CRC Press: Boca Raton, FL, USA, 2010; pp. 83–111. [Google Scholar]

- Wold, S.; Sjostrom, M.; Eriksson, L. PLS-regression: A basic tool of chemometrics. Chemom. Intell. Lab. Syst. 2001, 58, 109–130. [Google Scholar] [CrossRef]

- Pereira, C.; Andrejewski, A.; Mattana, A.; Schmidt, C.A.P.; Barreto, P.L.M.; Sant Ánna, E.S. Processing and microbiological characterization of diet strawberry ice cream with addition of whey protein concentrate, whole milk powder and sweeteners. Int. J. Nutr. Food Sci. 2014, 3, 97–103. [Google Scholar] [CrossRef]

- Tsuchiya, A.C.; Silva, A.G.M.; Brandt, D.; Kalschne, D.L.; Drunkler, D.A.; Colla, E. Lactose-reduced ice cream enriched with whey powder. Semin. Ciências Agrárias 2017, 38, 749–758. [Google Scholar] [CrossRef]

- Foegeding, E.A.; Çakır, E.; Koç, H. Using dairy ingredients to alter texture of foods: Implications based on oral processing considerations. Int. Dairy J. 2010, 20, 562–570. [Google Scholar] [CrossRef]

- Meneses, R.B.; Silva, M.S.; Monteiro, M.L.G.; Rocha-Leão, M.H.M.; Conte-Junior, C.A. Effect of dairy by-products as milk replacers on quality attributes of ice cream. J. Dairy Sci. 2020, 103, 10022–10035. [Google Scholar] [CrossRef]

- Prindiville, E.A.; Marshall, R.T.; Heymann, H. Effect of milk fat, cocoa butter, and whey protein fat replacers on the sensory properties of low fat and nonfat chocolate ice cream. J. Dairy Sci. 2000, 83, 2216–2223. [Google Scholar] [CrossRef]

- El-Zeini, H.M.; El-Abd, M.M.; Metwaly, F.A.; Zeidan, M.A.; Hassan, Y.F. Using whey protein isolate as a substitute of milk solid not fat on chemical and physico-chemical properties of ice cream. J. Food Dairy Sci. 2016, 7, 133–137. [Google Scholar] [CrossRef]

- Silveira, E.O.; Lopes Neto, J.H.; Silva, L.A.; Raposo, A.E.S.; Magnani, M.; Cardarelli, H.R. The effects of inulin combined with oligofructose and goat cheese whey on the physicochemical properties and sensory acceptance of a probiotic chocolate goat dairy beverage. LWT Food Sci. Technol. 2015, 62, 445–451. [Google Scholar] [CrossRef]

- Crippen, K.L.; Jeon, I.J. Direct-acid-set cottage cheese whey as a base for a shelf-stable athletic-type drink. J. Food Prot. 1984, 47, 53–57. [Google Scholar] [CrossRef]

- Meneses, R.B.; Maciel, L.F.; Rocha-Leão, M.H.M.; Conte-Junior, C.A. Physicochemical characteristics of milk by-products. Chem. Eng. Trans. 2020, 79, 37–42. [Google Scholar] [CrossRef]

- Tharp, B.W.; Forrest, B.; Swan, C.; Dunning, L.; Hilmoe, M. Basic factors affecting ice cream meltdown. In Ice Cream, 1st ed.; Buchheim, W., Ed.; International Dairy Federation: Brussels, Belgium, 1998; pp. 54–64. [Google Scholar]

- Granger, C.; Leger, A.; Bareyb, P.; Langendorff, V.; Cansella, M. Influence of formulation on the structural networks in ice cream. Int. Dairy J. 2005, 15, 255–262. [Google Scholar] [CrossRef]

- Janiaski, D.R.; Pimentel, T.C.; Cruz, A.G.; Prudencio, S.H. Strawberry-flavored yogurts and whey beverages: What is the sensory profile of the ideal product? J. Dairy Sci. 2016, 99, 5273–5283. [Google Scholar] [CrossRef] [PubMed]

| Ingredients (%) ¥ | Formulations | ||||

|---|---|---|---|---|---|

| 0% (100WM) | 25% (25RW or 25CW or 25BW) | 50% (50RW or 50CW or 50BW) | 75% (75RW or 75CW or 75BW) | 100% (100RW or 100CW or 100BW) | |

| Whole Milk | 58.14 | 43.61 | 29.07 | 14.53 | - |

| Ricotta whey or Cheese whey or Butter whey | - * | 14.53 | 29.07 | 43.61 | 58.14 |

| Formulation | Appearance x | Aroma x | Flavor x | Texture x | Overall Liking x | Purchase Intention y |

|---|---|---|---|---|---|---|

| Ricotta Whey | ||||||

| Commercial (Kibon®) | 5.80 ± 1.63 a | 5.34 ± 1.27 a | 5.61 ± 1.68 a | 5.47 ± 1.79 a | 5.71 ± 1.58 a | 3.53 ± 1.25 a |

| 100WM r | 5.12 ± 1.20 b | 5.13 ± 1.28 a | 5.60 ± 1.21 a | 5.09 ± 1.30 a | 5.37 ± 1.24 ab | 3.25 ± 1.18 a |

| 25RW r | 5.00 ± 1.10 b | 5.04 ± 1.01 a | 5.50 ± 1.11 a | 5.02 ± 1.18 a | 5.35 ± 1.11 ab | 3.26 ± 0.85 a |

| 50RW r | 4.93 ± 1.60 b | 4.96 ± 1.34 a | 5.33 ± 1.50 a | 5.04 ± 1.73 a | 5.37 ± 1.60 ab | 3.26 ± 1.21 a |

| 75RW r | 5.14 ± 1.29 b | 4.96 ± 0.99 a | 5.21 ± 1.26 a | 5.10 ± 1.29 a | 5.18 ± 1.23 ab | 3.17 ± 0.93 a |

| 100RW r | 5.34 ± 1.54 ab | 4.96 ± 1.11 a | 5.06 ± 1.65 a | 5.11 ± 1.53 a | 4.97 ± 1.54 b | 3.08 ± 1.24 a |

| Cheese Whey | ||||||

| Commercial (Kibon®) | 5.76 ± 1.70 a | 5.31 ± 1.33 a | 5.56 ± 1.74 a | 5.42 ± 1.84 a | 5.67 ± 1.65 a | 3.53 ± 1.25 a |

| 100WM s | 5.06 ± 1.25 bc | 5.07 ± 1.33 a | 5.54 ± 1.28 a | 5.03 ± 1.34 a | 5.31 ± 1.30 a | 3.21 ± 1.19 a |

| 25CW s | 4.91 ± 1.16 bc | 5.11 ± 1.04 a | 5.52 ± 1.10 a | 5.05 ± 1.10 a | 5.30 ± 1.10 a | 3.16 ± 0.87 a |

| 50CW s | 4.72 ± 1.65 c | 5.05 ± 1.34 a | 5.34 ± 1.48 a | 5.00 ± 1.39 a | 5.21 ± 1.48 a | 3.06 ± 1.22 a |

| 75CW s | 5.45 ± 1.32 ab | 5.45 ± 1.34 a | 5.70 ± 1.15 a | 5.29 ± 1.13 a | 5.62 ± 1.11 a | 3.47 ± 1.19 a |

| 100CW s | 5.43 ± 1.37 ab | 5.43 ± 1.39 a | 5.66 ± 1.24 a | 5.26 ± 1.20 a | 5.59 ± 1.19 a | 3.46 ± 1.21 a |

| Butter Whey | ||||||

| Commercial (Kibon®) | 5.73 ± 1.76 a | 5.28 ± 1.39 a | 5.52 ± 1.79 a | 5.39 ± 1.89 a | 5.62 ± 1.72 a | 3.51 ± 1.28 a |

| 100WM t | 5.03 ± 1.31 bc | 5.04 ± 1.38 a | 5.51 ± 1.35 a | 5.00 ± 1.40 abc | 5.28 ± 1.36 ab | 3.19 ± 1.21 ab |

| 25BW t | 4.96 ± 1.12 bc | 5.15 ± 0.99 a | 5.37 ± 1.19 a | 4.77 ± 1.13 bc | 5.12 ± 1.07 abc | 3.15 ± 0.88 abc |

| 50BW t | 4.86 ± 1.53 c | 5.14 ± 1.36 a | 5.08 ± 1.53 ab | 4.55 ± 1.59 c | 4.91 ± 1.52 bcd | 3.04 ± 1.21 bc |

| 75BW t | 5.20 ± 1.20 abc | 4.79 ± 1.05 ab | 4.64 ± 1.25 bc | 4.92 ± 1.15 abc | 4.65 ± 1.15 cd | 2.87 ± 0.88 bc |

| 100BW t | 5.52 ± 1.49 ab | 4.49 ± 1.42 b | 4.17 ± 1.76 c | 5.27 ± 1.72 ab | 4.39 ± 1.53 d | 2.69 ± 1.22 c |

| Formulation | Chocolate Color x | Chocolate Aroma x | Chocolate Flavor x | Sweetness x | Creaminess x | Melting Velocity x |

|---|---|---|---|---|---|---|

| Ricotta Whey | ||||||

| Commercial (Kibon®) | 3.88 ± 0.69 a | 3.08 ± 0.97 a | 3.61 ± 1.02 b | 3.86 ± 0.86 a | 4.00 ± 1.50 a | 3.10 ± 1.33 bc |

| 100WM r | 3.16 ± 0.94 c | 3.30 ± 1.01 a | 3.99 ± 1.18 ab | 4.24 ± 1.05 a | 3.50 ± 1.29 a | 3.50 ± 1.24 ab |

| 25RW r | 3.30 ± 0.64 bc | 3.14 ± 0.72 a | 3.91 ± 0.76 ab | 4.14 ± 0.74 a | 3.55 ± 0.97 a | 3.27 ± 0.90 abc |

| 50RW r | 3.43 ± 0.79 bc | 2.98 ± 1.12 a | 3.82 ± 1.07 ab | 4.03 ± 1.08 a | 3.59 ± 1.38 a | 3.03 ± 1.23 c |

| 75RW r | 3.51 ± 0.60 b | 3.14 ± 0.93 a | 4.02 ± 0.78 ab | 4.05 ± 0.88 a | 3.57 ± 1.03 a | 3.34 ± 0.92 abc |

| 100RW r | 3.59 ± 0.74 ab | 3.29 ± 1.14 a | 4.21 ± 1.17 a | 4.06 ± 1.16 a | 3.54 ± 1.27 a | 3.64 ± 1.07 a |

| Cheese Whey | ||||||

| Commercial (Kibon®) | 3.86 ± 0.74 a | 3.06 ± 0.99 a | 3.60 ± 1.04 b | 3.83 ± 0.91 b | 3.97 ± 1.53 a | 3.08 ± 1.35 abc |

| 100WM s | 3.15 ± 0.96 d | 3.29 ± 1.03 a | 3.97 ± 1.22 ab | 4.21 ± 1.09 ab | 3.48 ± 1.31 ab | 3.47 ± 1.26 a |

| 25CW s | 3.32 ± 0.55 cd | 3.16 ± 0.74 a | 4.07 ± 0.76 a | 4.26 ± 0.78 a | 3.47 ± 0.99 ab | 3.29 ± 0.97 ab |

| 50CW s | 3.47 ± 0.80 bc | 3.02 ± 0.99 a | 4.14 ± 1.21 a | 4.28 ± 1.17 a | 3.44 ± 1.39 b | 3.07 ± 1.38 abc |

| 75CW s | 3.58 ± 0.59 abc | 3.20 ± 0.81 a | 4.22 ± 0.79 a | 4.33 ± 0.91 a | 3.34 ± 1.04 b | 2.92 ± 0.91 bc |

| 100CW s | 3.69 ± 0.77 ab | 3.38 ± 1.25 a | 4.30 ± 1.00 a | 4.37 ± 1.06 a | 3.23 ± 1.34 b | 2.77 ± 1.17 c |

| Butter Whey | ||||||

| Commercial (Kibon®) | 3.84 ± 0.79 bc | 3.04 ± 1.01 b | 3.58 ± 1.07 d | 3.81 ± 0.95 b | 3.96 ± 1.55 a | 3.09 ± 1.33 a |

| 100WM t | 3.13 ± 0.98 d | 3.28 ± 1.05 ab | 3.95 ± 1.25 cd | 4.18 ± 1.14 ab | 3.44 ± 1.33 b | 3.44 ± 1.28 a |

| 25BW t | 3.71 ± 0.65 c | 3.39 ± 0.70 ab | 4.24 ± 0.85 bc | 4.45 ± 0.84 a | 3.31 ± 0.88 b | 3.26 ± 0.83 a |

| 50BW t | 4.25 ± 0.94 a | 3.48 ± 1.14 a | 4.48 ± 1.13 ab | 4.66 ± 1.30 a | 3.12 ± 1.27 b | 3.01 ± 1.37 a |

| 75BW t | 4.10 ± 0.60 ab | 3.48 ± 1.00 ab | 4.67 ± 0.96 ab | 4.59 ± 1.13 a | 3.56 ± 0.98 ab | 3.06 ± 0.92 a |

| 100BW t | 3.95 ± 0.61 abc | 3.47 ± 1.45 ab | 4.85 ± 1.45 a | 4.52 ± 1.71 a | 4.00 ± 1.45 a | 3.11 ± 1.29 a |

| Formulation | Chocolate Color x | Chocolate Aroma x | Chocolate Flavor x | Sweetness x | Creaminess x | Melting Velocity x | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Too Little | Too Much | Too Little | Too Much | Too Little | Too Much | Too Little | Too Much | Too Little | Too Much | Too Little | Too Much | |

| Ricotta Whey | ||||||||||||

| Commercial (Kibon®) | - | - | 60 y (0.50) z | - | 41 (0.81) | - | 25 (0.61) | - | 35 (0.66) | - | 60 (1.47) | - |

| 100WM r | 64 (1.25) | - | 54 (0.86) | - | 37 (1.28) | - | - | 30 (1.67) | 64 (1.34) | - | - | - |

| 25RW r | 44 (0.64) | - | - | - | - | - | - | 42 (0.56) | - | - | - | - |

| 50RW r | - | - | - | - | - | - | - | - | 51 (0.63) | - | - | - |

| 75RW r | - | - | - | - | - | - | - | - | - | - | 51 (0.61) | - |

| 100RW r | 41 (0.56) | - | - | - | - | 39 (1.46) | - | 30 (1.69) | 52 (1.38) | - | - | - |

| Cheese Whey | ||||||||||||

| Commercial (Kibon®) | - | - | 60 (0.52) | - | 41 (0.83) | - | 25 (0.65) | - | 35 (0.69) | - | 60 (1.38) | - |

| 100WM s | 64 (1.28) | - | 54 (0.89) | - | 38 (1.390 | - | - | 29 (1.62) | 64 (1.37) | - | - | - |

| 25CW s | - | - | - | - | - | - | - | - | 48 (0.43) | - | - | - |

| 50CW s | - | - | - | - | 32 (0.70) | - | - | - | - | - | - | - |

| 75CW s | - | - | - | - | - | - | - | 51 (0.70) | - | - | - | - |

| 100CW s | - | - | 44 (0.68) | - | - | 37 (1.21) | - | 36 (1.02) | 59 (1.35) | - | 73 (1.08) | - |

| Butter Whey | ||||||||||||

| Commercial (Kibon®) | - | - | 60 (0.50) | - | 41 (0.81) | - | 26 (0.78) | - | 35 (0.66) | - | 60 (1.37) | - |

| 100WM t | 63 (1.33) | - | 55 (1.02) | - | 38 (1.47) | - | - | 29 (1.62) | 64 (1.42) | - | - | - |

| 25BW t | 23 (0.73) | - | 45 (0.54) | - | - | 41 (0.70) | - | 54 (0.60) | 53 (0.50 | - | - | - |

| 50BW t | - | - | 49 (0.51) | - | - | 45 (1.51) | - | 50 (0.89) | 71 (0.74) | - | - | - |

| 75BW t | - | - | - | - | - | 70 (0.69) | - | - | - | - | - | - |

| 100BW t | - | - | - | - | - | 62 (1.19) | - | 56 (1.12) | 35 (0.58) | - | 63 (0.68) | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meneses, R.B.d.; Monteiro, M.L.G.; Santos, F.F.d.; Leão, M.H.M.d.R.; Conte-Junior, C.A. Sensory Characteristics of Dairy By-Products as Potential Milk Replacers in Ice Cream. Sustainability 2021, 13, 1531. https://doi.org/10.3390/su13031531

Meneses RBd, Monteiro MLG, Santos FFd, Leão MHMdR, Conte-Junior CA. Sensory Characteristics of Dairy By-Products as Potential Milk Replacers in Ice Cream. Sustainability. 2021; 13(3):1531. https://doi.org/10.3390/su13031531

Chicago/Turabian StyleMeneses, Roberta Barbosa de, Maria Lúcia Guerra Monteiro, Fabiane Ferreira dos Santos, Maria Helena Miguez da Rocha Leão, and Carlos Adam Conte-Junior. 2021. "Sensory Characteristics of Dairy By-Products as Potential Milk Replacers in Ice Cream" Sustainability 13, no. 3: 1531. https://doi.org/10.3390/su13031531

APA StyleMeneses, R. B. d., Monteiro, M. L. G., Santos, F. F. d., Leão, M. H. M. d. R., & Conte-Junior, C. A. (2021). Sensory Characteristics of Dairy By-Products as Potential Milk Replacers in Ice Cream. Sustainability, 13(3), 1531. https://doi.org/10.3390/su13031531