Twin Transition through the Implementation of Industry 4.0 Technologies: Desk-Research Analysis and Practical Use Cases in Europe

Abstract

:1. Introduction

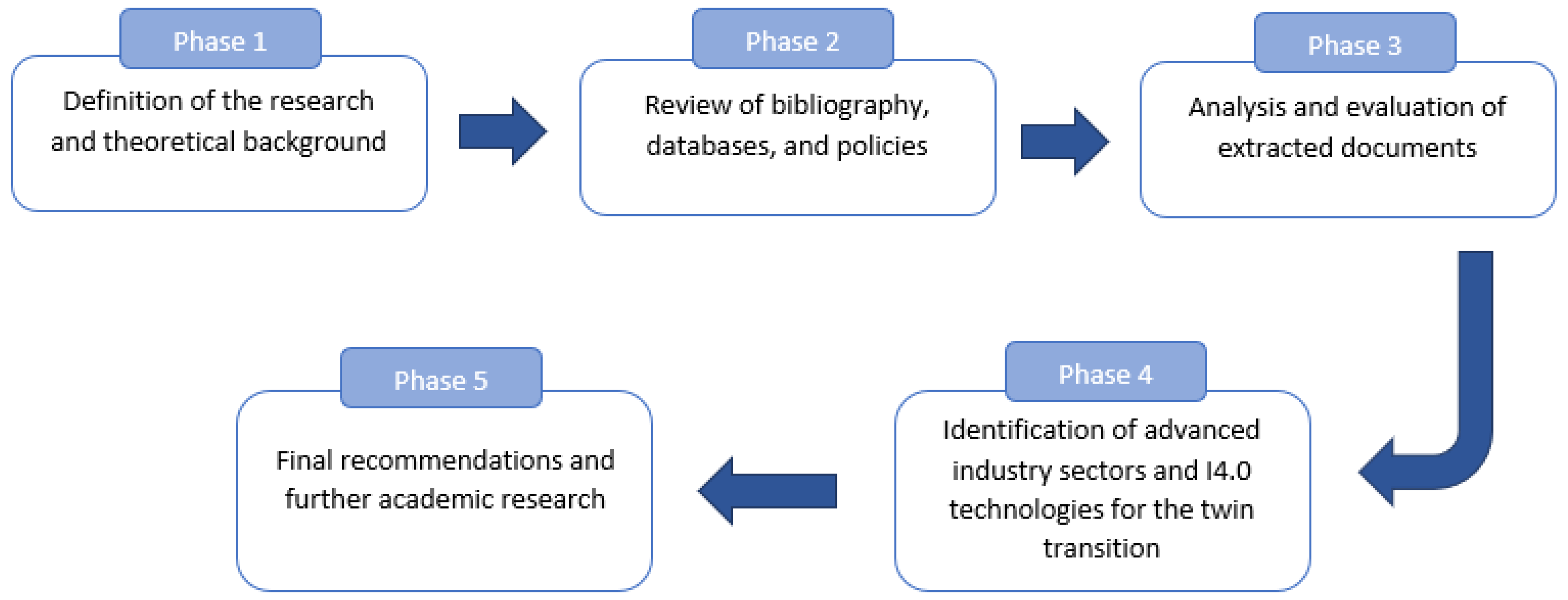

2. Materials and Methods

- Multidisciplinary databases for the scientific papers research such as Web of Science [19] and Scopus [20] at an international level, and the databases of CSIC [21] and Dialnet Plus [22] in Spain. The keywords predefined for the systematic review of the state of the art are the combined parameters entered in those sources of information to perform our research; the following terms are included among those keywords: Key Enabling Technologies (KET); Circular Economy; Industry 4.0; Twin Transition; Artificial intelligence (AI); Big Data; Blockchain; Cloud computing; Dematerialisation; Circular economy; Digitalisation; Digitally-enabled solutions; Digital twins; Lifecycle assessments (LCAs); Internet of things (IoT) and connected devices; Machine Learning (ML); Online platforms; Radio-frequency identification (RFID); Sensors; 3D printing or additive manufacturing. Additionally, other scholar search tools have been consulted such as Google Scholar [23] or Academia.edu [24] to supplement the search and identify possible information gaps.

- Patent databases. At the level of technological innovation, the following databases have been determined as sources of information: The Spanish Patent Office, at a European level Espacenet [25], USPTO database in the US [26], the Japanese Patent Office JPO [27] and WIPO [28] at a global level. Apart from the predefined keywords, the International Patent Code has been used, with the focus on the following codes: B25J Manipulators; chambers provided with manipulation devices; B25J9/00 Programme-controlled manipulators; G06N 20/00 Machine Learning; B33 Additive manufacturing technology. Likewise, other open patent databases were consulted such as Google Patents [29] or Lens [30].

- Research projects databases: a compilation of the European projects facing the twin transition has been carried out, especially at the industry level. For this purpose, the most relevant project databases at a global level have been used such as: CORDIS [31], which provides information on all EU-supported R&D activities; Interreg Europe [32], which helps regional and local governments across Europe to develop and deliver better policy; Keep: a source for Interreg, Interreg-IPA cross-border [33], ENI-CBC and IPA-IPA cross-border since 2000 [34], updated on a daily basis; European Investment Project Portal (EIPP) [35]: The EU Matchmaking Portal; LIFE [36]; ERASMUS+ PROJECT RESULTS [37]; European Circular Economy Stakeholder Platform [38].

- Policies and current solutions databases: a search for information on the policies framework, directives, and regulations related to the twin transition in manufacturing and traditional industries in Europe. For this purpose, the most important databases at a European level have been consulted such as Eurostat [39], the official data base of the European Commission [40], EUR-Lex [41], and the official site of the Advanced Technologies for Industry [42].

3. Results

3.1. European Policies for the Twin Digital and Green Transition

Funding Instruments

3.2. Twin Transition in the Industry: Practical Cases

3.2.1. R&D Projects

3.2.2. Patents

3.2.3. Commercial Solutions

4. Discussion

5. Conclusions

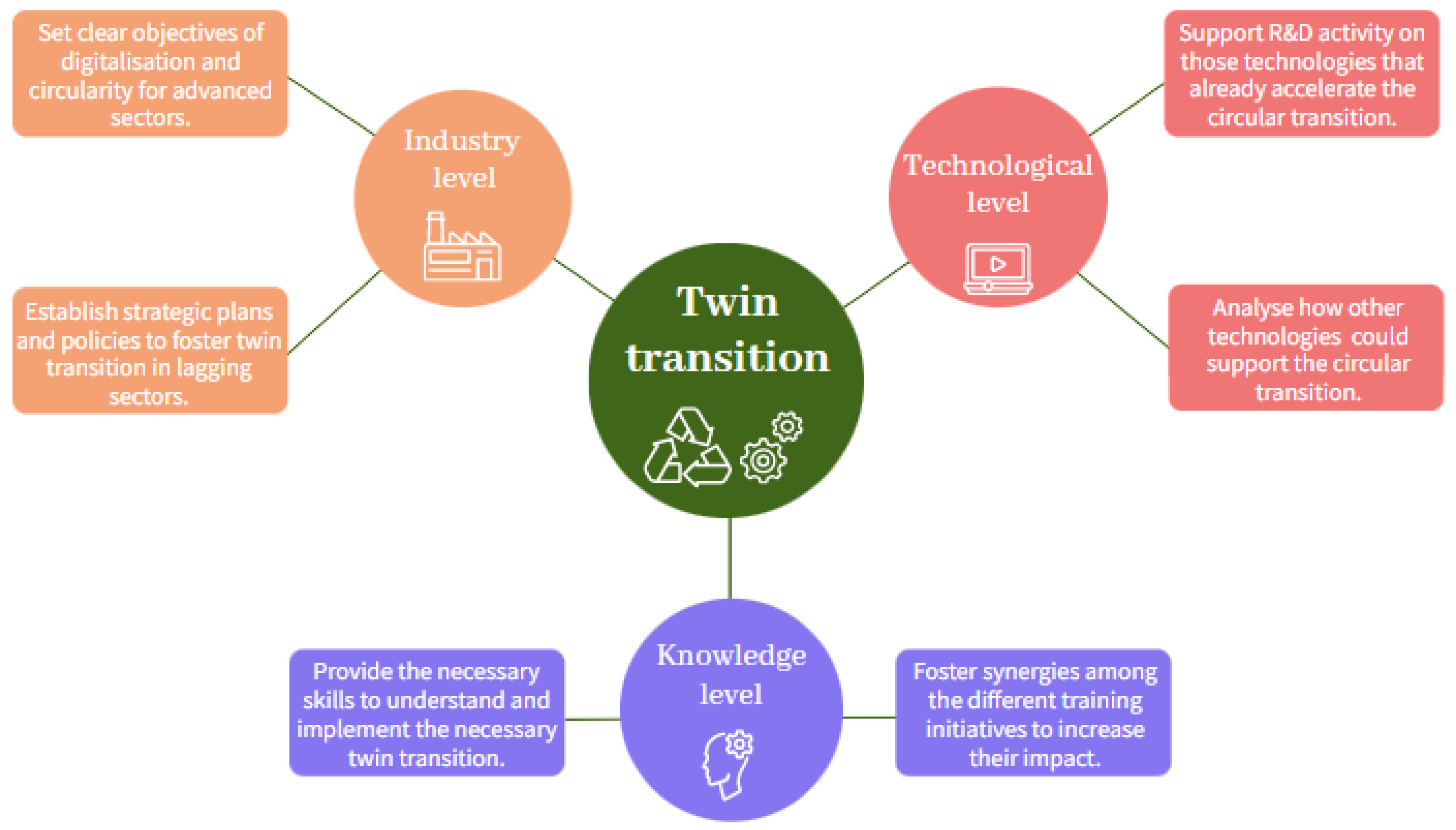

- Set clear objectives of digitalisation and circularity for those advanced sectors (waste management, automotive and aviation, construction) to spread this process, and extend to the whole European system the already achievements.

- Establish new strategic plans and policies to foster the twin transition in manufacturing, energy, electrical and electronic, and mobility industry sectors, and set new specific funding programs for these sectors.

- Support R&D activity on those technologies that already accelerate the circular transition (Big Data, AI, IoT, Robotic, and AM) with the aim to continue fostering the digitalisation of the industry while achieving sustainable goals.

- Analyse how other technologies currently not or less applied could support the circular transition in different industry sectors and foster them through strategic and funding plans.

- Launch new initiatives to provide the necessary skills and competencies to workers and managers of different industry sectors to understand and implement the necessary twin transition, through the application of I4.0 technologies and CE strategies.

- Foster synergies among the different training initiatives to increase their impact, for instance through a Centres of Vocational Excellence (CoVE) [77] focused on the twin transition.

Author Contributions

Funding

Conflicts of Interest

References

- European Commission. Communication from the Commission to the European Parliament, the European Council, the Council, the European Economic and Social Committee and the Committee of the Regions-The European Green Deal; COM(2019) 640 Final; European Commission: Brussels, Belgium, 2019; Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?qid=1588580774040&uri=CELEX%3A52019DC0640 (accessed on 20 May 2021).

- Ellen MacArthur Foundation. Towards a Circular Economy: Business Rationale for an Accelerated Transition; Ellen MacArthur Foundation: Cowes, UK, 2015. [Google Scholar]

- Bag, S.; Yadav, G.; Dhamija, P.; Kataria, K.K. Key resources for industry 4.0 adoption and its effect on sustainable production and circular economy: An empirical study. J. Clean. Prod. 2020, 281, 125233. [Google Scholar] [CrossRef]

- Romero-Gazquez, J.L.; Canavate-Cruzado, G.; Bueno-Delgado, M.-V. IN4WOOD: A Successful European Training Action of Industry 4.0 for Academia and Business. IEEE Trans. Educ. 2021, 1–10. [Google Scholar] [CrossRef]

- European Commission. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions—A European Strategy for Key Enabling Technologies—A Bridge to Growth and Jobs; COM(2012)341 Final; European Commission: Brussels, Belgium, 2012; Available online: https://eur-lex.europa.eu/legal-content/EN/ALL/?uri=celex:52012DC0341 (accessed on 15 May 2021).

- Cañavate, G.; Moreno, F.; Bueno, M. Modernizing the Vocational Educational Training in the field social sciences and humanities towards the Key Enabling Technologies in the digital transformation. In Proceedings of the 12th International Conference on Education and New Learning Technologies (EDULEARN20), Online Conference, 6–7 July 2020; pp. 8125–8132. [Google Scholar] [CrossRef]

- Martinelli, A.; Mina, A.; Moggi, M. The enabling technologies of industry 4.0: Examining the seeds of the fourth industrial revolution. Ind. Corp. Chang. 2021, 30, 162–188. [Google Scholar] [CrossRef]

- Mabkhot, M.M.; Ferreira, P.; Maffei, A.; Podržaj, P.; Mądziel, M.; Antonelli, D.; Lanzetta, M.; Barata, J.; Boffa, E.; Finžgar, M.; et al. Mapping Industry 4.0 Enabling Technologies into United Nations Sustainability Development Goals. Sustainability 2021, 13, 2560. [Google Scholar] [CrossRef]

- Mubarok, K. Redefining Industry 4.0 and its Enabling Technologies. In Proceedings of the International Conference on Science and Technology, Surabaya, Indonesia, 17–18 October 2019; Volume 1569. [Google Scholar] [CrossRef]

- Rocca, R.; Costa, P.; Sassanelli, C.; Fumagalli, L.; Terzi, S. Industry 4.0 solutions supporting Circular Economy. In Proceedings of the International Conference on Engineering Technology and Innovation (ICE/ITMC), Cardiff, UK, 15–17 June 2020. [Google Scholar] [CrossRef]

- Tronchoni, D.; Brennan, G. Industry 4.0: A Key Enabler of the Circular Economy, Climate Innovation Insights, Series 2, No. 7, EIT-Climate KIC. Available online: https://www.climate-kic.org/insights/industry-4-0-a-key-enabler-of-the-circular-economy/ (accessed on 13 November 2021).

- Berg, H.; Bendix, P.; Jansen, M.; Le Blévennec, K.; Botterman, P.; Magnus-Melgar, M.; Pohjalainen, E.; Wahlström, M. Unlocking the Potential of Industry 4.0 to Reduce the Environmental Impact of Production; European Environment Agency, European Topic Centre on Waste and Materials in a Green Economy: Mol, Belgium, 2021. [Google Scholar]

- Blunck, E.; Werthmann, H. Industry 4.0—An Opportunity to Realize Sustainable Manufacturing and its Potential for a Circular Economy. In Proceedings of the 3rd Dubrovnik International Economic Meeting (DIEM), Dubrovnik, Croatia, 12–14 October 2017; pp. 644–666. [Google Scholar]

- Le Moigne, R. The Power of Digital Technologies to Enable the Circular Economy. 2021. Available online: https://medium.com/circulatenews/the-power-of-digital-technologies-to-enable-the-circular-economy-5471d097ee7f (accessed on 10 October 2021).

- Rosa, P.; Sassanelli, C.; Urbinati, A.; Chiaroni, D.; Terzi, S. Assessing relations between Circular Economy and Industry 4.0: A systematic literature review. Int. J. Prod. Res. 2019, 58, 1662–1687. [Google Scholar] [CrossRef] [Green Version]

- European Commission. Communication from the Commission to the European Parliament, the European Council, the Council, the European Economic and Social Committee and the Committee of the Regions—A New Industrial Strategy for Europe; COM(2020) 102 Final; European Commission: Brussels, Belgium, 2020; Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A52020DC0102 (accessed on 18 May 2021).

- Ortega Gras, J.J.; Garrido Lova, J.; Muñoz Puche, A.; Mouazan, E.; Gómez Gómez, M.V.; Rodriguez Fuentes, J.; Rajala, A. Joint Curriculum Design on Circular Economy Practices Within the Furniture Industry for a Vocational Education Training. In Proceedings of the 15th International Technology, Education and Development Conference, Online Conference, 8–9 March 2021; pp. 1227–1237. [Google Scholar]

- Spanish Association for Standardisation (UNE). R&D&i Management: Technological Watch and Competitive Intelligence System. 2011. Available online: https://www.une.org/encuentra-tu-norma/busca-tu-norma/norma?c=N0046930 (accessed on 25 May 2021).

- Web of Science Home Page. Available online: https://www.webofscience.com/wos/woscc/basic-search (accessed on 2 June 2021).

- Scopus Home Page. Available online: https://www.scopus.com/home.uri (accessed on 6 June 2021).

- CSIC Database Home Page. Available online: https://indices.csic.es/ (accessed on 18 May 2021).

- Dialnet Plus Home Page. Available online: https://dialnet.unirioja.es/ (accessed on 25 May 2021).

- Google Scholar Home Page. Available online: https://scholar.google.es/schhp?hl=es (accessed on 14 June 2021).

- Academia Home Page. Available online: https://www.academia.edu/ (accessed on 16 June 2021).

- Espacenet Home Page. Available online: https://worldwide.espacenet.com/ (accessed on 21 June 2021).

- United States Patent and Trademark Office (USPTO) Home Page. Available online: https://www.uspto.gov/ (accessed on 22 June 2021).

- Japan Patent Office Home Page. Available online: https://www.jpo.go.jp/e/ (accessed on 23 June 2021).

- World Intellectual Property Organization (WIPO) Home Page. Available online: https://www.wipo.int/portal/en/index.html (accessed on 23 June 2021).

- Google Patents Home Page. Available online: https://patents.google.com/ (accessed on 19 June 2021).

- The Lens Home Page. Available online: https://www.lens.org/ (accessed on 25 June 2021).

- Cordis Europa Home Page. Available online: https://cordis.europa.eu/es (accessed on 28 June 2021).

- Interreg Europe Home Page. Available online: https://www.interregeurope.eu/ (accessed on 30 June 2021).

- European Commission. IPA Cross-Border Cooperation Programmes. Available online: https://ec.europa.eu/regional_policy/en/funding/ipa/cross-border/ (accessed on 30 June 2021).

- Keep. Interreg, Interreg-IPA, ENI, and IPA-IPA Cross-Border. Available online: https://keep.eu/home/ (accessed on 1 July 2021).

- European Commission. European Investment Project Portal (EIPP): Using the Portal is now Easier than Ever. Available online: https://ec.europa.eu/investeuportal/desktop/en/index.html (accessed on 2 July 2021).

- LIFE Public Database. Available online: https://webgate.ec.europa.eu/life/publicWebsite/index.cfm (accessed on 2 July 2021).

- ERASMUS+ Project Results. Available online: https://ec.europa.eu/programmes/erasmus-plus/projects_en (accessed on 3 July 2021).

- European Circular Economy Stakeholder Platform. Available online: https://circulareconomy.europa.eu/platform/ (accessed on 2 July 2021).

- Eurostat Database. Available online: https://ec.europa.eu/eurostat/data/database (accessed on 5 July 2021).

- AMECO Database. Available online: https://ec.europa.eu/info/business-economy-euro/indicators-statistics/economic-databases/macro-economic-database-ameco/ameco-database_en (accessed on 4 July 2021).

- EUR-Lex Home Page: EU Law. Available online: https://eur-lex.europa.eu/homepage.html?locale=en (accessed on 8 July 2021).

- Advanced Technologies for Industry. Available online: https://ati.ec.europa.eu/ (accessed on 10 July 2021).

- European Commission. Annex to the Communication to the European Parliament, the European Council, the Council, the European Economic and Social Committee and the Committee of the Regions—The European Green Deal. Roadmap—Key Actions; COM(2019) 640 Final; European Commission: Brussels, Belgium, 2019; Available online: https://ec.europa.eu/info/sites/default/files/european-green-deal-communication-annex-roadmap_en.pdf (accessed on 25 May 2021).

- European Commission. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee of the Regions—Shaping Europe’s Digital Future; COM(2020) 67 Final; European Commission: Brussels, Belgium, 2020; Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A52020DC0067 (accessed on 7 July 2021).

- European Commission. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee of the Regions—A New Circular Economy Action Plan—For a Cleaner and More Competitive Europe; COM(2020) 98 Final; European Commission: Brussels, Belgium, 2020; Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?qid=1583933814386&uri=COM:2020:98:FIN (accessed on 14 May 2021).

- European Commission. European Commission Decision-Horizon Europe. Work Programme 2021–2022. 7 Digital, Industry and Space; C(2021) 7804; European Commission: Brussels, Belgium, 2021; Available online: https://ec.europa.eu/info/funding-tenders/opportunities/docs/2021-2027/horizon/wp-call/2021-2022/wp-7-digital-industry-and-space_horizon-2021-2022_en.pdf (accessed on 30 October 2021).

- European Parliament and the Council of the European Union. Regulation (EU) 2021/783 of the European Parliament and of the Council of 29 April 2021 Establishing a Programme for the Environment and Climate Action (LIFE) and Repealing Regulation (EU) No 1293/2013. Official Journal of the European Union L 172/53, 2021. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32021R0783&from=EN (accessed on 14 May 2021).

- European Commission. Annex to the Commission Implementing Decision on the Adoption of the Multiannual Work Programme for the Years 2021–2024 for the LIFE Programme; C(2021) 4997 Final; European Commission: Brussels, Belgium, 2021; Available online: https://ec.europa.eu/info/funding-tenders/opportunities/docs/2021-2027/life/wp-call/2021-2024/wp_life-2021-2024_en.pdf (accessed on 12 September 2021).

- European Commission. Commission Delegated Regulation 2019/856 of Supplementing Directive 2003/87/EC of the European Parliament and of the Council with Regard to the Operation of the Innovation Fund. Official Journal of the European Union L 140/6, 2019. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32019R0856&from=EN (accessed on 12 September 2021).

- DigiCirc Project. Available online: https://digicirc.eu (accessed on 6 September 2021).

- DigiVIP Project. Available online: https://ec.europa.eu/programmes/erasmus-plus/projects/eplus-project-details/#project/2020-1-TR01-KA226-HE-098393 (accessed on 11 July 2021).

- SUSTAINair Project. Available online: https://www.sustainair.eu (accessed on 6 September 2021).

- Single Market & Competition Law in the Digital and Ecological Transition Era Project. Available online: https://ec.europa.eu/programmes/erasmus-plus/projects/eplus-project-details/#project/620517-epp-1-2020-1-es-eppjmo-chair (accessed on 6 September 2021).

- Circular4.0 Project. Available online: https://www.alpine-space.eu/projects/circular4_0/en/home (accessed on 6 September 2021).

- SAWYER. Available online: https://circularfurniture-sawyer.eu (accessed on 6 September 2021).

- C-SERVEES. Available online: https://c-serveesproject.eu (accessed on 6 September 2021).

- SABINA Project. Available online: https://sabina-project.eu (accessed on 6 September 2021).

- BIM2TWIN Project. Available online: https://bim2twin.eu (accessed on 6 September 2021).

- WASTE4think Project. Available online: https://waste4think.eu (accessed on 6 September 2021).

- BURBA Project. Available online: https://cordis.europa.eu/project/id/265177 (accessed on 6 September 2021).

- RoCycle Project. Available online: https://www.csail.mit.edu/news/robots-can-sort-recycling (accessed on 6 September 2021).

- Bradley, R.; Jawahir, I. Innovative Manufacturing Methods for Next-Generation Products, Processes, and Systems. U.S. Patent 16/998366, 25 February 2021. [Google Scholar]

- Zhijun, P.; Bo, P.; Weiguo, H.; Jianzhong, S.; Bangpeng, X.; Wenkai, Z.; Jialin, W.; Xiaopeng, L.; Jing, G.; Yang, W.; et al. Energy monitoring method based on big data intelligent analysis technology and energy cloud platform. Patent CN 110138877A, 16 August 2019. Available online: https://worldwide.espacenet.com/patent/search/family/067583244/publication/CN110138877A?q=pn%3DCN110138877A (accessed on 11 August 2021).

- Dingqi, T.; Duozhang, Y.; Yinbin, W.; Guibao, Z.; Xuewu, Z. Wallboard assembling robot. Patent CN 103276910A, 20 May 2013. Available online: https://worldwide.espacenet.com/patent/search/family/049059516/publication/CN103276910A?q=pn%3DCN103276910A (accessed on 11 August 2021).

- Priyanka, D.; Bhawana, P.; Arundhati, A.; Uday, C.; Kavita, C. A Machine Learning and IOT Based System for Intelligent Routing. Patent AU 2021101897A4, 3 June 2021. Available online: https://worldwide.espacenet.com/patent/search/family/076132922/publication/AU2021101897A4?q=pn%3DAU2021101897A4 (accessed on 11 August 2021).

- Yingchen, Z.; Hongyan, W.; Xianan, Z.; Ruonan, Y.; Li, X.; Tian, W.; Luning, T.; Yan, J. Internet of Things System and Method for Waste Selvage. Patent CN 109981791A, 5 July 2019. Available online: https://worldwide.espacenet.com/patent/search/family/067083408/publication/CN109981791A?q=pn%3DCN109981791A (accessed on 11 August 2021).

- GE Digital. Available online: https://www.ge.com/digital/applications/digital-twin (accessed on 11 August 2021).

- Circulor. Available online: https://www.circulor.com (accessed on 11 August 2021).

- Circular Economy Stakeholder Platform, Good Practices. Available online: https://circulareconomy.europa.eu/platform/en/good-practices/volvo-cars-ev-battery-materials-traceability (accessed on 11 August 2021).

- Ohmie. Available online: https://www.ohmie-krilldesign.net (accessed on 11 August 2021).

- RetourMatras. Available online: https://www.retourmatras.nl (accessed on 11 August 2021).

- Bollegraaf. Available online: https://www.bollegraaf.com (accessed on 11 August 2021).

- Optimitive. Available online: https://optimitive.com/solutions (accessed on 11 August 2021).

- Segara. Available online: https://segara.io/es (accessed on 11 August 2021).

- AEVAE. Available online: https://www.aevae.net/tecnologia-blockchain-en-aevae (accessed on 11 August 2021).

- Recircula Solutions. Available online: https://recirculasolutions.com (accessed on 11 August 2021).

- European Commission, Centres of Vocational Excellence. Available online: https://ec.europa.eu/social/main.jsp?catId=1501 (accessed on 6 September 2021).

| Key Enablign Technology | Definition |

|---|---|

| Internet of Things (IoT) | It refers to the connection of physical objects from the real world with a representative in the virtual world. |

| Big Data & Analytics | It is the use of large amounts of data characterised by their volume, velocity, namely the speed at which they are generated, accessed, processed and analysed, and variety such as unstructured and structured data. |

| Cloud Computing (CC) | A network of remote servers to store, manage and process data |

| Simulation | A close imitation of a process or system operation, considering its characteristics, behaviour and/or physical properties. It can be used to reduce costs of production line processes and reduce the impact of modifications applied to it. |

| Virtual Reality (VR) & Augmented Reality (AR) | While Virtual Reality (VR) immerses users into a completely virtual world where they can interact with the environment, Augmented Reality (AR) adds virtual entities and information to a user viewport, combined with images of the real world. |

| Artifical Intelligence (AI) | Software that exhibits a behaviour traditionally identified as human intelligence that goes beyond what computers and machines are expected to do with conventional programming. |

| Additive Manufacturing (AM) | Additive Manufacturing (AM), also called 3D printing, is a process that creates a physical object from a digital design. |

| System Integration | To be a fully connected I4.0 factory, both horizontal and vertical systems need to be integrated together. Standard protocols and specific software packages should be used to achieve this integration among the disparate information technology systems used in the company. |

| Robotic | A mechanical system which executes various remote simple tasks with good accuracy. Autonomous and advanced robots are even able to adapt themselves to changes without any kind of human assistance. |

| Cybersecurity | It pursues the goal of preventing threats in the use of information technologies, such as confidential information, business secrets, know-how, employee and customer data, IT systems, software, networks, operational processes and operating facilities. |

| Process | Policy Framework | Directive | Regulation |

|---|---|---|---|

| Raw material |

|

| |

| Product design and production |

|

|

|

| Use and/or consumption |

|

|

|

| Waste management |

|

|

|

| Project Title | Programme | Goal | Reference |

|---|---|---|---|

| DigiCirc—European cluster-led accelerator for digitisation of the circular economy across key emerging sectors | H2020 (873468) | Empower SMEs to leverage digital technology as a key enabler for innovative circular products/services, processes and business models. | [50] |

| DigiVIP—Building Virtual Learning Platform for Environmentally-Friendly Digital Transformation Management | Erasmus+ (2020–1-TR01-KA226-HE-098393) | The project aims to develop a digital transformation management curriculum and learning materials with a focus on “environmental sustainability” standards. | [51] |

| SUSTAINair—Bringing the aerospace and aviation sectors in line with circular principles | Horizon 2020 (Nº 101006952) | The project aims to research and develop solutions to increase resource efficiency and aircraft performance while cutting down on waste and material costs throughout the aircraft life cycle | [52] |

| Single Market & Competition Law in the Digital and Ecological Transition Era | Erasmus+ (620517-EPP-1-2020-1-ES-EPPJMO-CHAIR) | Offering an EU Economic Law Specialisation through two courses on “Single European Market” and “EU Competition Law” | [53] |

| Circular4.0—Strengthening the transition to the circular economy in the Alpine Space thanks to the SMEs digitalization | Interreg Alpine Space | Improving the Alpine eco-system of innovation and its contribution to the transition to Circular Economy in the Alpine Area by SMEs and economic operators, exploiting the potential and the added value of the digitalisation processes by SMEs. | [54] |

| SAWYER—Holistic approach for the identification of skills and safety needs towards a growing sustainability & circularity of furniture sector | EU Support for Social Dialogue (VS/2019/0027) | Facilitating the transition of European furniture companies to a more circular economy. | [55] |

| C-SERVEES—Activating Circular Services in the Electrical and Electronic Sector | Horizon 2020 (Nº 776714) | Boosting a resource-efficient circular economy in the electrical and electronic (E&E) sector through the development, testing, validation and transfer of new circular economic business models based on systemic eco-innovative services that include: eco-leasing, product customisation, improved E&E equipment waste management, and ICT services to support the other eco-services | [56] |

| SABINA—Smart bi-directional multi energy gateway | Horizon 2020 (Nº 731211) | Developing new technology and financial models to connect, control and actively manage generation and storage assets to exploit synergies between electrical flexibility and the thermal inertia of buildings. | [57] |

| BIM2TWIN—Optimal Construction Management & Production Control | Horizon 2020 (Nº 958398) | Designing, implementing and testing a construction management platform able to make managers aware of real-time status of everything happening on site and throughout the whole supply chain. | [58] |

| WASTE4think—Moving towards Life Cycle Thinking by integrating Advanced Waste Management Systems | Horizon 2020 (Nº 688995) | Designing solutions based on the use of ICT that would enable the improvement of all waste management stages, adopting a global approach and particularly focusing on citizen participation in order to build more sustainable, eco-friendly cities. | [59] |

| BURBA—Bottom-Up selection, collection and management of urban waste | Horizon 2020 (Nº 265177) | Developing an automatic system to be used for intelligent waste management. | [60] |

| RoCycle | N.A. | Developing a robotic system that can detect if an object is paper, metal, or plastic. | [61] |

| Title | Nº Patent | Abstract | Reference |

|---|---|---|---|

| Innovative manufacturing methods for next-generation products, processes, and systems | 16/998366 | A method for managing a modular product life cycle is described. A central computing device or system receives inputs representative of one or more of: an expected product life cycle, a market demand for the product, a manufacturing process for the product, a reverse manufacturing process for the product, and one or more technical engineering constraints associated with the product. From this information, a first modular product design is determined. Later in the life cycle of the modular product a second plurality of inputs representative of one or more of: a market demand, a manufacturing process, a reverse manufacturing process, and one or more technical engineering constraints are retrieved. From this information, a second modular product design is determined. | [62] |

| Energy monitoring method based on big data intelligent analysis technology and energy cloud platform | CN110138877A | The invention discloses an energy monitoring method based on a big data intelligent analysis technology and an energy cloud platform. The method comprises the following steps: S1, obtaining related index data from the energy cloud platform; S2, providing real-time monitoring of regional energy supply and consumption conditions from three dimensions of a whole region, partition and industry division; S3, performing statistics and analysis on the energy use condition data of the set area to obtain a statistics and analysis result; and S4, on the basis of the statistics and analysis result in the step S3, adopting a big data analysis method, and providing a regional energy analysis report for the target object through an energy cloud platform semi-automatic generation report function. According to the invention, online monitoring and dynamic analysis of energy consumption can be realised, regional energy development planning and multi-energy regulation are supported, diversified government supervision is realised, and CE and low-carbon economy of regional energy are realised. | [63] |

| Wallboard assembling robot | CN103276910A | The invention discloses a wallboard assembling robot which comprises a vehicle frame. A lifting frame is arranged in a guide rail A of the vehicle frame, and a piston rod of a lifting hydraulic cylinder is fixedly connected with the lifting frame. A sliding frame is arranged in a guide rail B of the lifting frame, and a lifting chain A which is fixedly connected to a stand column is fixedly connected with the sliding frame by winding around a guiding chain wheel A of the lifting frame. A lifting seat is arranged in a guide rail C of the sliding frame in a sliding mode, and a lifting chain B which is fixedly connected with the stand column is fixedly connected with the lifting seat by winding around a guiding chain wheel B of the sliding frame. A hanging basket is connected with the lifting seat. The wallboard assembling robot has the advantages of being capable of improving installation efficiency and degree of labour safety and reducing labour intensity, simple in structure, easy to maintain, convenient to operate, safe, reliable, and capable of achieving high lifting. | [64] |

| A machine learning and IOT based system for intelligent routing | AU2021101897A4 | The present invention relates to a machine learning and IoT based system for intelligent routing. In order to improve the reliability and efficacy of public transport, many IoT attempts have been made. Many problems, such as car traffic congestion, road safety and improper use of parking spaces for vehicles, have been handled and controlled by the IoT. The present invention provides an intelligent routing based on a distributed cloud architecture of IoT for managing the traffic system combined with a machine learning to improve the process of finding the optimised route in the minimum time based on the state of traffic on the road. | [65] |

| Internet of Things system and method for waste selvage | CN109981791A | The invention provides an IoT system and method for waste selvage. The system comprises an internet platform, a monitoring computer and a waste cloth edge printing and weaving integrated unit, a processing state monitoring module is arranged on the waste cloth edge printing and weaving integrated unit; the monitoring computer is connected with the processing state monitoring module and the waste selvage data acquisition system, the waste selvage printing and weaving integrated unit and the monitoring computer are both connected with the router, the router is connected with the web server and the database server, and the database server and the web server are both connected with the Internet platform. According to the invention, centralised monitoring, online remote monitoring and real-time allocation can be carried out on the waste selvedge data acquisition and waste selvedge printing and weaving integrated unit of an enterprise, a basis is provided for decision making of an enterprise management layer, and meanwhile, the management level of waste selvedge’s and related solid wastes of the enterprise and the additional value of solid wastes of textile, printing, dyeing and clothing production and processing enterprises are also improved. | [66] |

| Product Name | Company | Description | Reference |

|---|---|---|---|

| Digital twins & Csense | General Electric (GE) Company | Digital Twin is most commonly defined as a software representation of a physical asset, system or process designed to detect, prevent, predict, and optimise through real time analytics to deliver business value. It has been tested in aviation and automotive sectors. Digital Twin integrates data from multiple sources and uses analytics to monitor, predict, and prevent generation of waste from production operations. Process Digital Twins create models of ‘the best way’ to run a process in a given environment—often referred to as ‘the golden batch’. By identifying the most optimal process to manufacture a given product, plant operators can ensure they are consistently delivering against quality, cost, and volume objectives. In addition, through CSense Operations Performance Management solutions, Process Digital Twins help manufacturers meet the challenges of fast-changing consumer demand, regulatory requirements, and looming generation knowledge gap with results like reduced product waste by up to 75%, quality complaints reduced by 38%. | [67] |

| Circulor | Circulor Ltd. | Circulor tracks raw materials from source, into components and finally to finished products, helping manufacturers and their suppliers build a sustainable future. Companies can secure deliveries, manage payments, and check provenance of their raw materials, as well as a host of other features, making Circulor designed for real world complexity. The solution is based on different technological applications, where traceability-as-a-service includes supply chain mapping, verification, specialist responsible sourcing expertise, and implementation know-how. It could be applied to different sectors, such as plastics, electronic waste, agriculture, or extractive industries. For instance, Volvo Cars commissioned Circulor to implement a technology-enabled traceability solution, to enable an end-to-end chain of custody to be constructed, initially for Cobalt and subsequently for Mica, with other materials being planned. | [68,69] |

| Ohmie | Krill design | Orange peels certainly are compostable, but Milan-based start-up Krill Design has come up with an interesting alternative use for them. The company is incorporating orange waste into its 3D-printed Ohmie lamp. Obtained as waste from the food industry, the peels are dried, ground into a powder, mixed with a plant-derived biopolymer, and extruded into the form of a filament. The filament is then used in a conventional FDM (fused deposition modelling) 3D printer to build the main body of the lamp. In that way, Krill design transform waste from the food supply chain through a CE process that enhances the resources of nature, enhancing waste by giving it new life and a renewed meaning in a product with a green soul, with a unique design and made with new generation biopolymers. | [70] |

| RetourMatras | RetourMatras B.V. | RetoruMatras has created a complete recycling system for mattresses, taking into account two key points: to be as much automatised as possible, and to maximizes dust extraction. They have implemented several technologies, as sensors, robotics, etc. to create their own equipment for the complete process of sorting, dissembling, classification, and even to produce a new foam from the processes foam waste: Aslon Refoam. Aslon Refoam have resulted in a high-quality solution for the secondary raw material flow foam that results from recycling discarded mattresses. Currently, it is used as underlayment for falling surfaces in parks, playgrounds, and sports fields. | [71] |

| Bollegraaf | Bollegraaf Recycling Machinery BV | Decades of experience with household waste and plastic recycling have made Bollegraaf Recycling Solutions. The company is a leader in process, technology & automation and robotics; developments in which it invests continuously and intensively. Bollegraaf is increasingly adding a new dimension to their globally recognised pioneering role in recycling. The recycling company created a world of difference for and with their clients. The machines are not only manufactures to do sustainable work, they are ‘green’ themselves. The devices are painted with water-based paint and have the lowest power consumption possible. | [72] |

| Optibat RTO | Optimitive SL | OPTIBAT is a product based on AI that, connected to the control system of an industrial process (cement, chemist, paper, or energy sectors), reads the process data, learns from them and makes optimal adjustments to it on automatic pilot, achieving maximum efficiency in the operation of the process. Its objective is to optimise the efficiency and sustainability of the process, maximising production and quality, minimising energy consumption, and ensuring the stability and availability of the process. | [73] |

| SEGARA | Segara Environmental Consulting, SL | SEGARA automates the management of the carbon footprint through 4.0 technologies, such as Big Data. The developed software performs the integral calculation of the carbon footprint with scopes 1 and 2 according to the GHG Protocol and the ISO 14064 standard. | [74] |

| AEVAE | Spanish Association for the Valorisation of Containers, AEVAE | AEVAE has developed an innovative system to trace the full circle of the plastic material (HPDE and LPDE) to re-manufacture new packaging for the agricultural sector. In collaboration with a Blockchain-based asset traceability platform, a new system has been developed that allows, not only to uniquely identify the waste, but to incorporate its characteristics and geolocation into the Blockchain, allowing its monitoring in an agile, secure, and unalterable way by all agents, whether they are manufacturers, packers or distributors, involved in the management of waste originated in production processes. The new system allows manufacturers to incorporate the benefits of this technology into these environmental management processes and thus promote the impact of the systems that seek to guarantee compliance with the responsibility associated with the manufacture of fertilizers and associated products. The traceability and transparency offered by Blockchain, together with the fact that it is a PaaS (Platform as a Service) solution accessible by all actors, helps to know exactly the entire process through which a waste passes, ensuring that it complies with the international regulations and facilitating its traceability by all parties involved in the process. | [75] |

| RecySmart | Recircula Solutions S.L. | RecySmart is the IoT technology that allows citizens to recognise recycled packaging through AI. Citizens will use the RecySmart Citizen app or RFID cards to log in to RecySmart and begin the recycling process. Once logged in, they can deposit the items one by one (glass, plastic bottles, metal cans, and cardboard containers) in the corresponding container. The RecySmart device identifies each container using techniques with artificial intelligence algorithms in real time. For each container, citizens accumulate points that can be exchanged for money refunds, vouchers, or any other form of incentive managed by the local authority or third parties such as large brands, local businesses, etc. All information is sent to a server so that it is reflected in the Waste Platform Management, including the filling level of the containers. Thanks to this, third parties—city authorities, brands, businesses—can offer incentives motivating citizens’ behaviour to increase recycling rates up to 20–30% and meet EU recycling targets. | [76] |

| Robotic | Big Data | AI | IoT | AM | Training | |

|---|---|---|---|---|---|---|

| Energy | CN110138877A | CN110138877A | ||||

| Automotive & aviation | SUSTAINair | Digital twins & Csense | Digital twins & Csense | SUSTAINair | ||

| Waste management | RoCycle RetourMatras | WASTE4think BURBA RecySmart | WASTE4think RoCycle AEVAE | WASTE4think BURBA RetourMatras RecySmart | ||

| Construction | CN103276910A | SABINA | BIM2TWIN | SABINA | ||

| Electrical and Electronic | C-SERVEES | C-SERVEES | ||||

| Multisectorial | Bollegraaf | Circulor SEGARA | 16/998366 Optibat RTO SEGARA | 16/998366 Circulor | DigiCirc DigiVIP Single Market & Competition Circular4.0 | |

| Mobility | AU2021101897A4 | AU2021101897A4 | ||||

| Furniture | Ohmie | SAWYER | ||||

| Textile | CN109981791A |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ortega-Gras, J.-J.; Bueno-Delgado, M.-V.; Cañavate-Cruzado, G.; Garrido-Lova, J. Twin Transition through the Implementation of Industry 4.0 Technologies: Desk-Research Analysis and Practical Use Cases in Europe. Sustainability 2021, 13, 13601. https://doi.org/10.3390/su132413601

Ortega-Gras J-J, Bueno-Delgado M-V, Cañavate-Cruzado G, Garrido-Lova J. Twin Transition through the Implementation of Industry 4.0 Technologies: Desk-Research Analysis and Practical Use Cases in Europe. Sustainability. 2021; 13(24):13601. https://doi.org/10.3390/su132413601

Chicago/Turabian StyleOrtega-Gras, Juan-José, María-Victoria Bueno-Delgado, Gregorio Cañavate-Cruzado, and Josefina Garrido-Lova. 2021. "Twin Transition through the Implementation of Industry 4.0 Technologies: Desk-Research Analysis and Practical Use Cases in Europe" Sustainability 13, no. 24: 13601. https://doi.org/10.3390/su132413601

APA StyleOrtega-Gras, J.-J., Bueno-Delgado, M.-V., Cañavate-Cruzado, G., & Garrido-Lova, J. (2021). Twin Transition through the Implementation of Industry 4.0 Technologies: Desk-Research Analysis and Practical Use Cases in Europe. Sustainability, 13(24), 13601. https://doi.org/10.3390/su132413601