Assessing Urban Metabolism through MSW Carbon Footprint and Conceptualizing Municipal-Industrial Symbiosis—The Case of Zaragoza City, Spain

Abstract

:1. Introduction

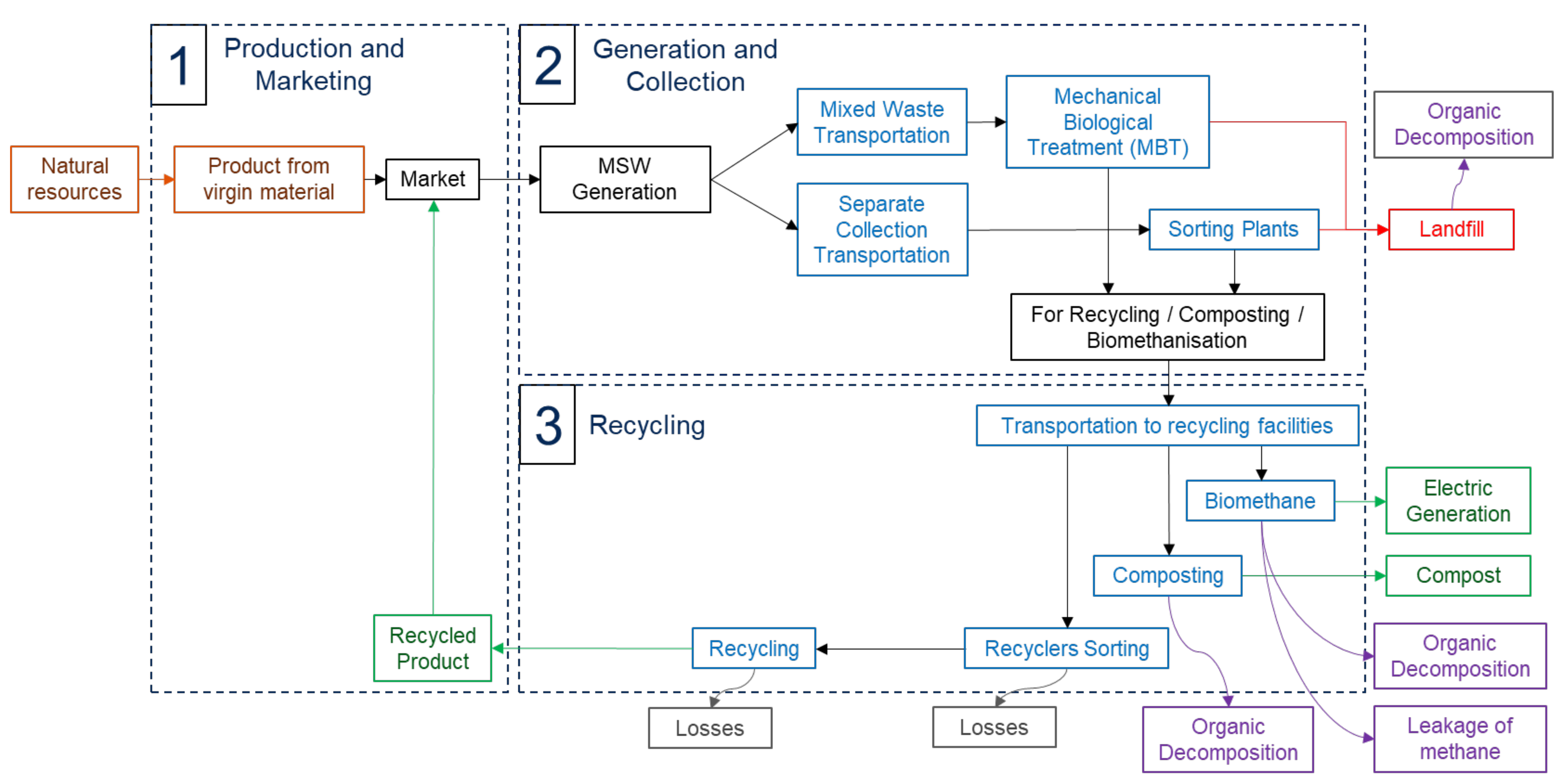

- Design, production and marketing (1): conception, manufacturing industry and advertising.

- Generation and collection (2): local authorities and H&B.

- Recycling (3): recyclers.

2. Materials and Methods

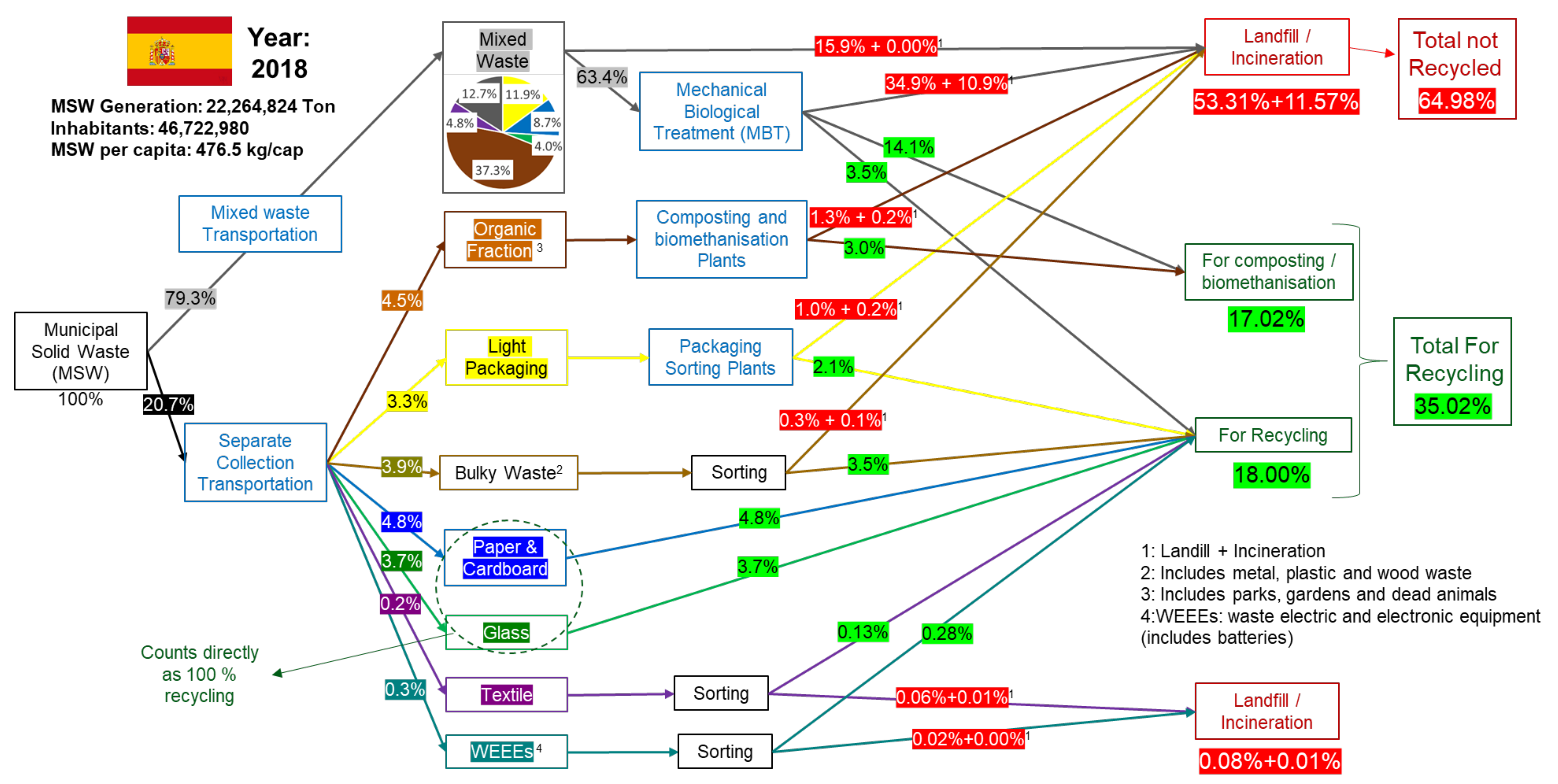

2.1. MSW Data Sources for Zaragoza and Spain

2.2. CO2 Footprint Method Data

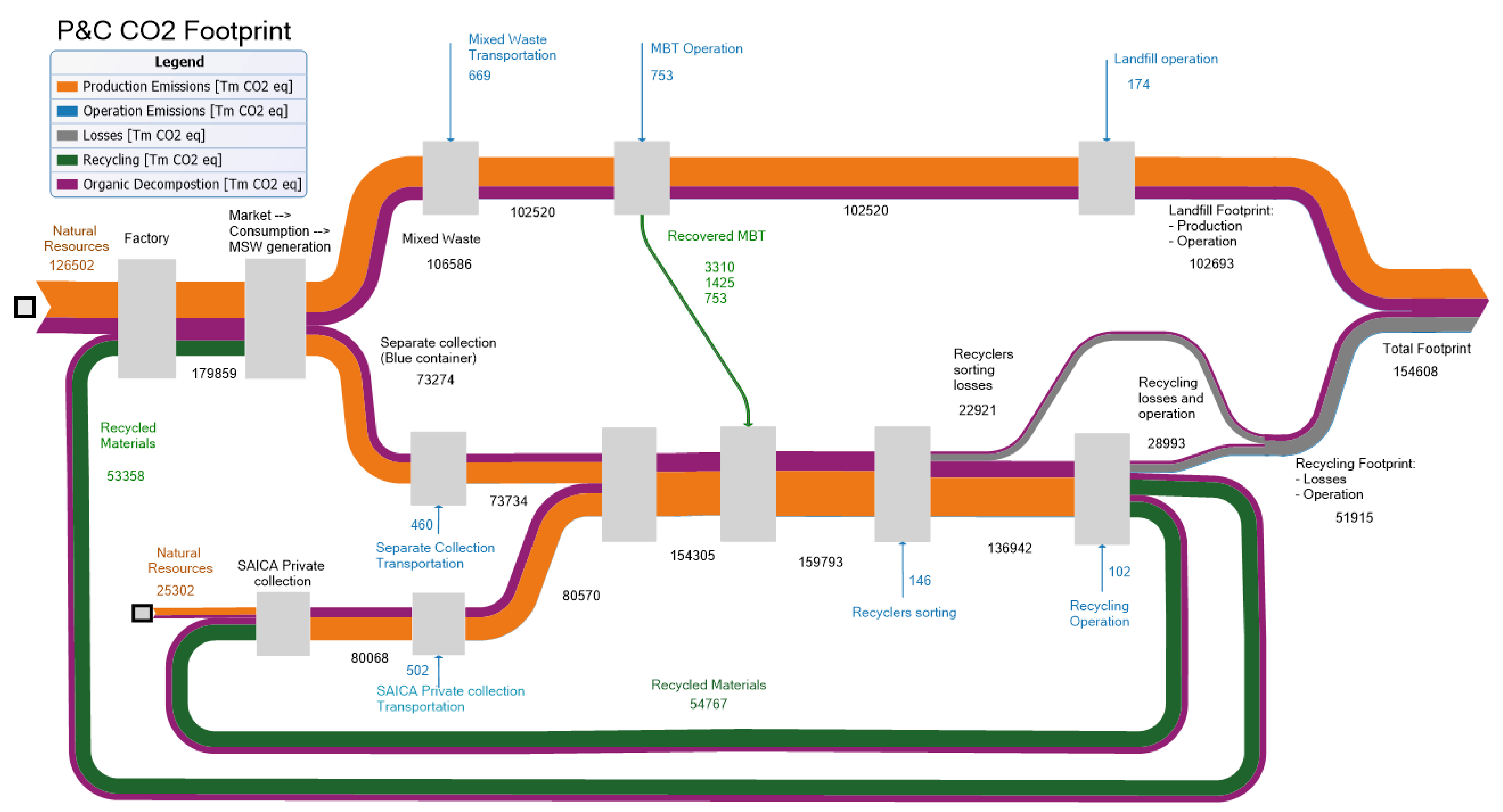

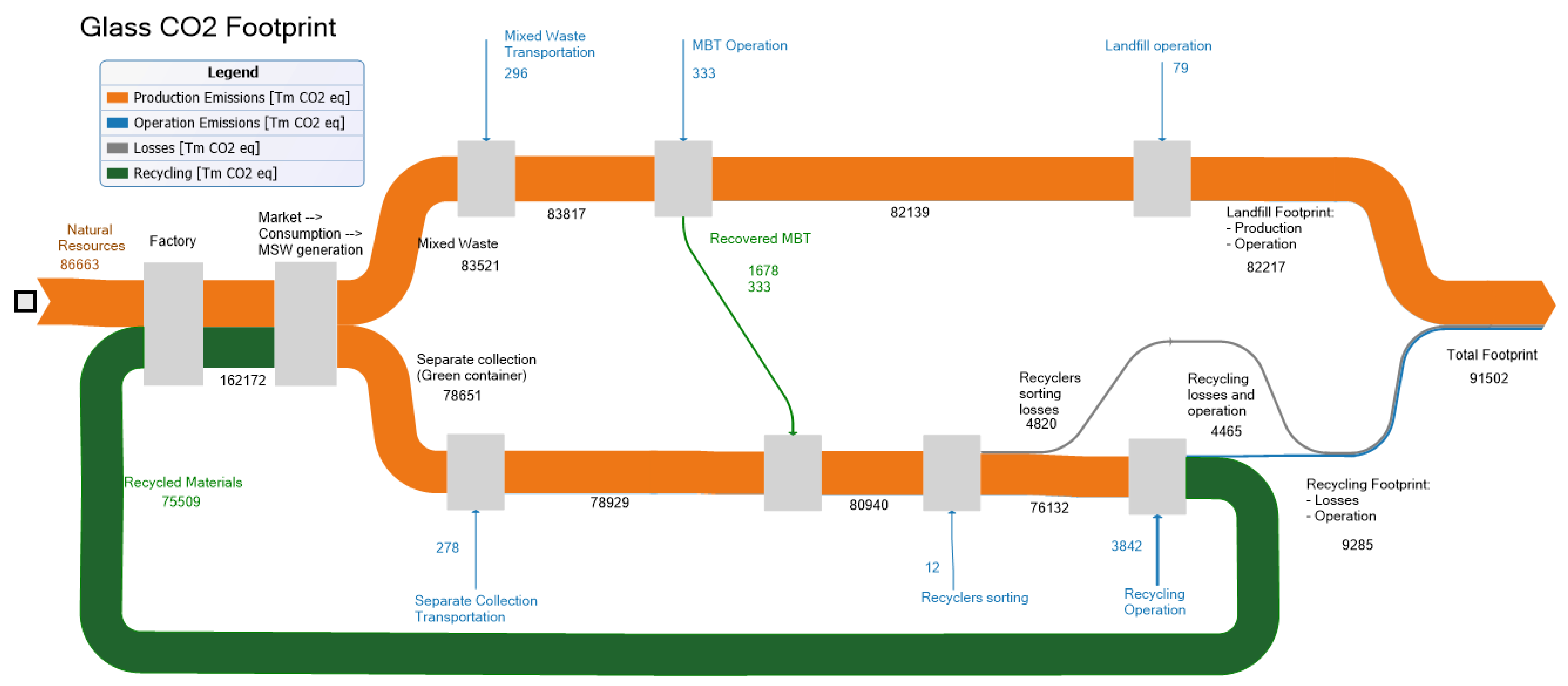

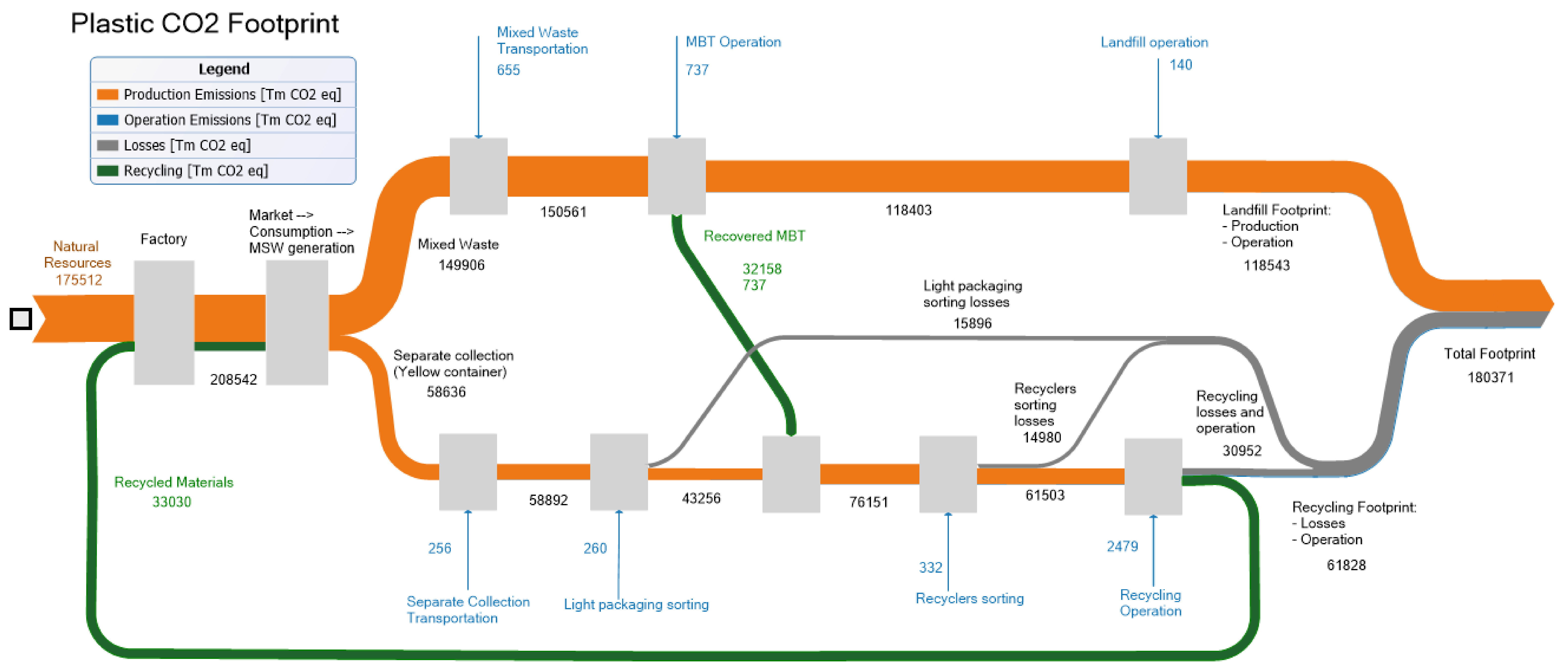

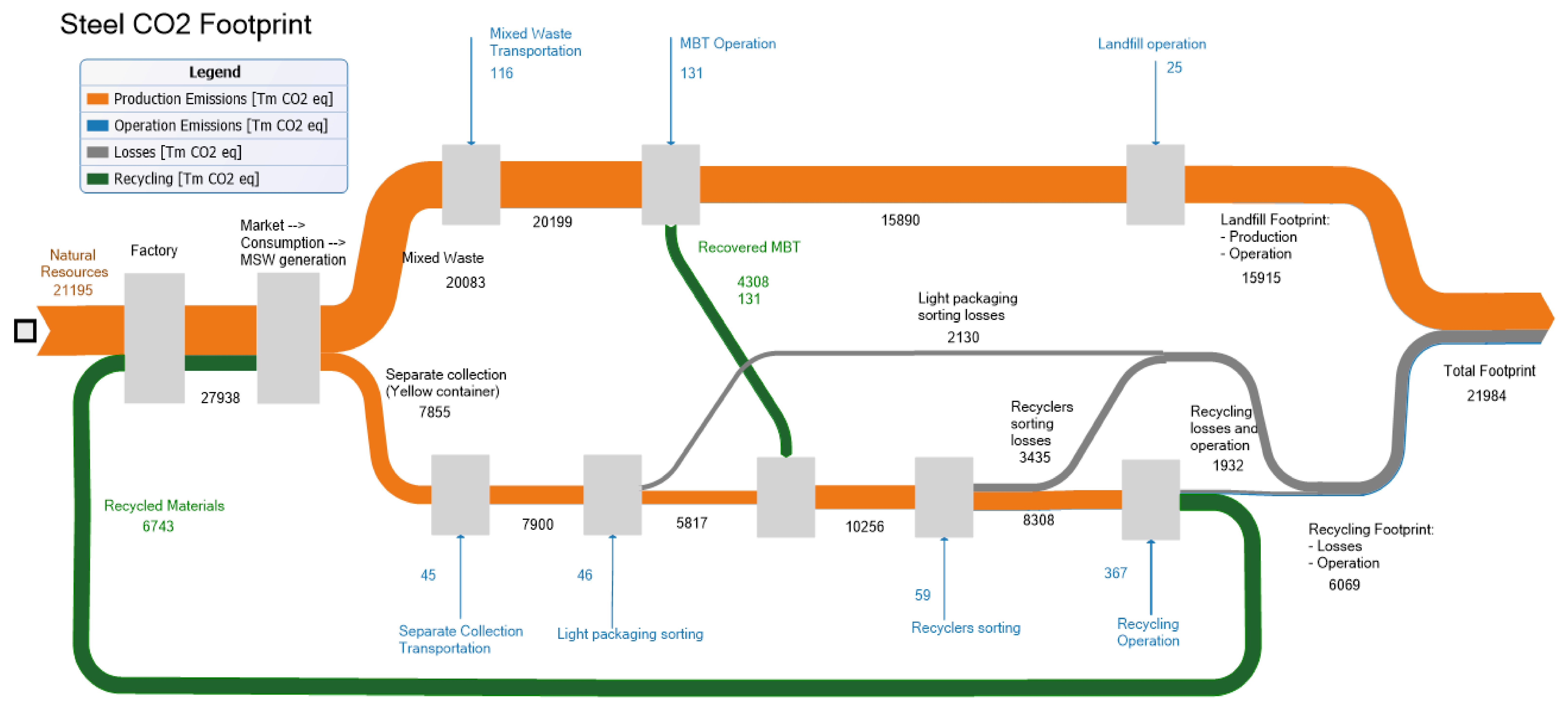

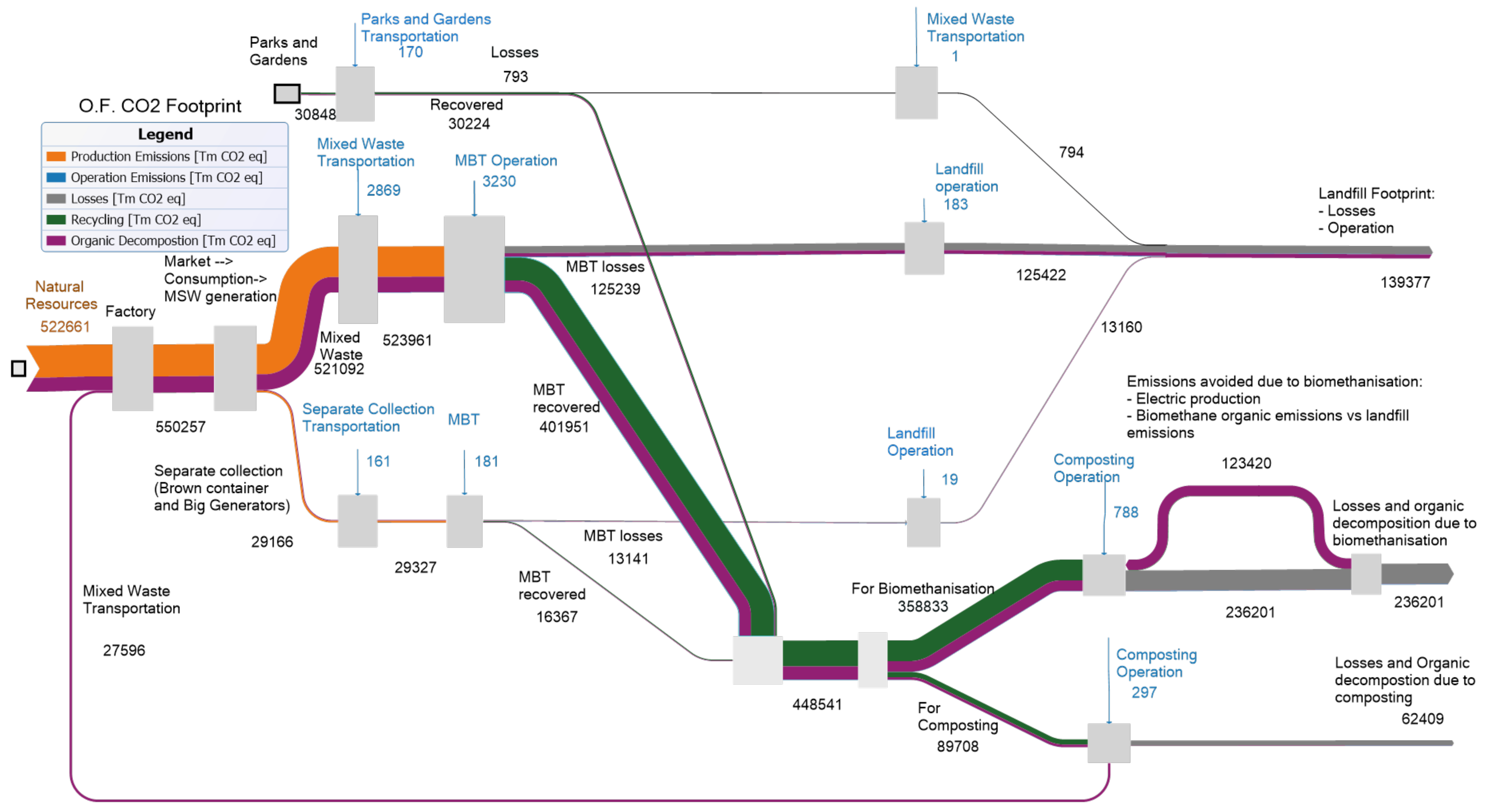

- Orange (initial Carbon Footprint (CF)): represents all the previous CO2 footprint produced in stage 1 by crops, manufacturing, transport… from the time the raw material is extracted from nature until it reaches the market and can be purchased by the consumer.

- Blue (operations): represents emissions produced by operations that emit CO2, mainly due to energy consumption. These operations are waste transport, sorting, biomethanization, composting or recycling operations.

- Red (landfill): indicates that once a waste reaches the landfill, it can no longer be reintroduced into the economy, so its “CO2 backpack” is not recoverable either. In addition, emissions due to the operation of the landfill are also considered.

- Green (avoided emissions): covers processes that manage to avoid CO2 emissions. These include the production of biomethane, which is used to generate electricity, compost, and recycling processes that reduce the amount of natural resources required.

- Purple (organic decomposition): This color highlights processes related to organic decomposition. Organic decomposition only occurs if the material comes from living matter, which generates methane with its decomposition. It only affects the organic and P&C fractions as they are of organic origin [36].

2.2.1. Packaging Fraction Data

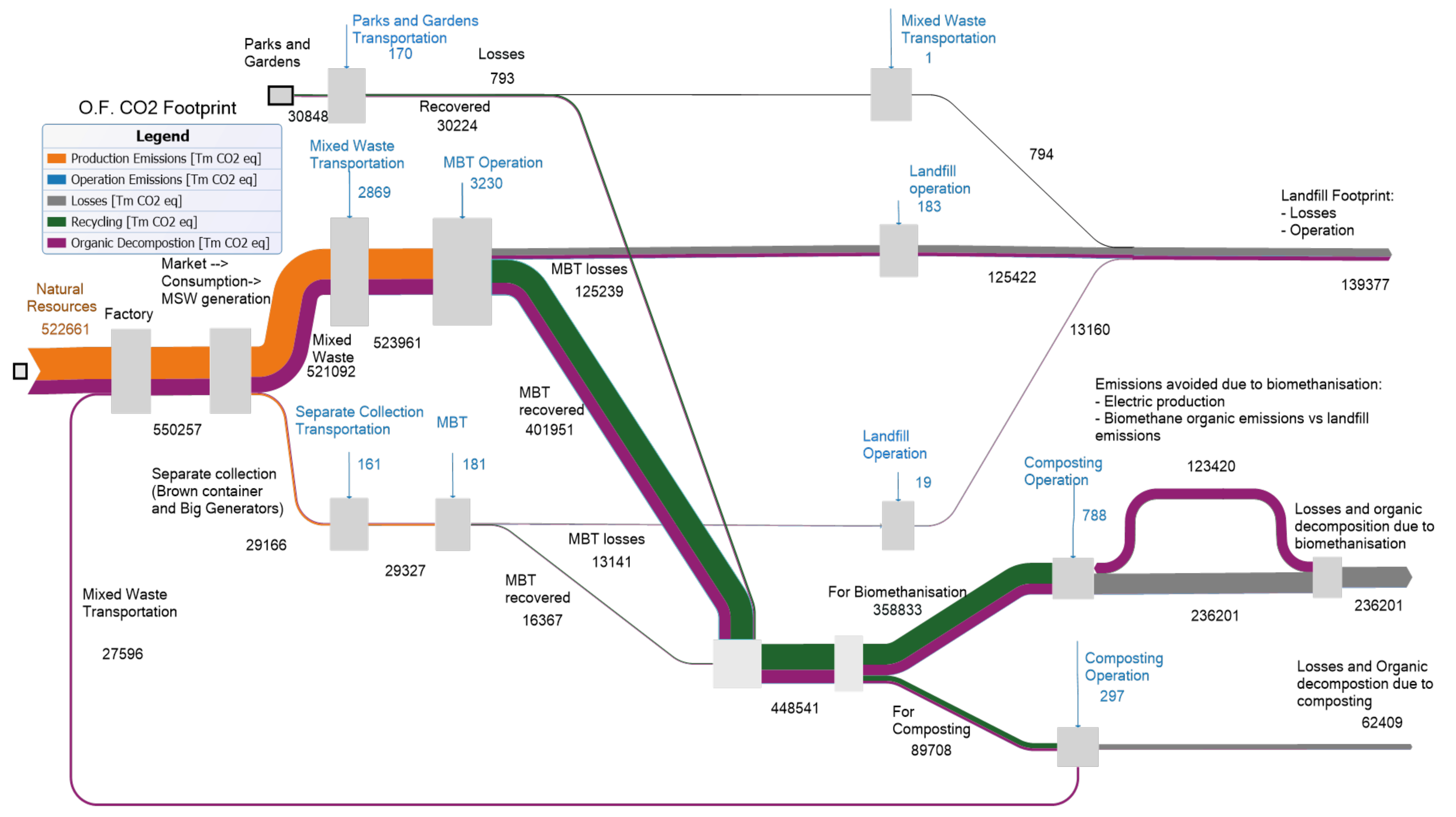

2.2.2. Organic Fraction Data

2.3. City Council Strategies Data

- Deposit Return System (DRS) implementation: According to the What We Waste report published by Reloop [44], the country’s typical DRS has an average return rates of 89% for cans and 87% for glass. However, in the case of Zaragoza there are some legislative barriers in this respect (see Appendix A).

- Door-to-door commercial collection with identification code. The Spanish city of Lleida uses the door-to-door commercial collection system, using personalized bags incorporating a TAG [45]. Thanks to this system, the city increased selective collection by 4.8 percentage points (pp) between 2016 and 2017.

- Improved collection and quality of the organic fraction: the implementation of electronic card-opening locks on the organic fraction containers makes it possible to verify the effective use of the containers, applying a reduced rate to all those families who deposit the organic fraction in the container. As a result, the Mancomunidad del Txingudi (Basque Country, Spain) increased selective collection in 10.8% [46].

3. MSW Analysis Results

3.1. Analysis of the MSW Flow in Zaragoza

3.1.1. Temporal Evolution of Zaragoza’s MSW

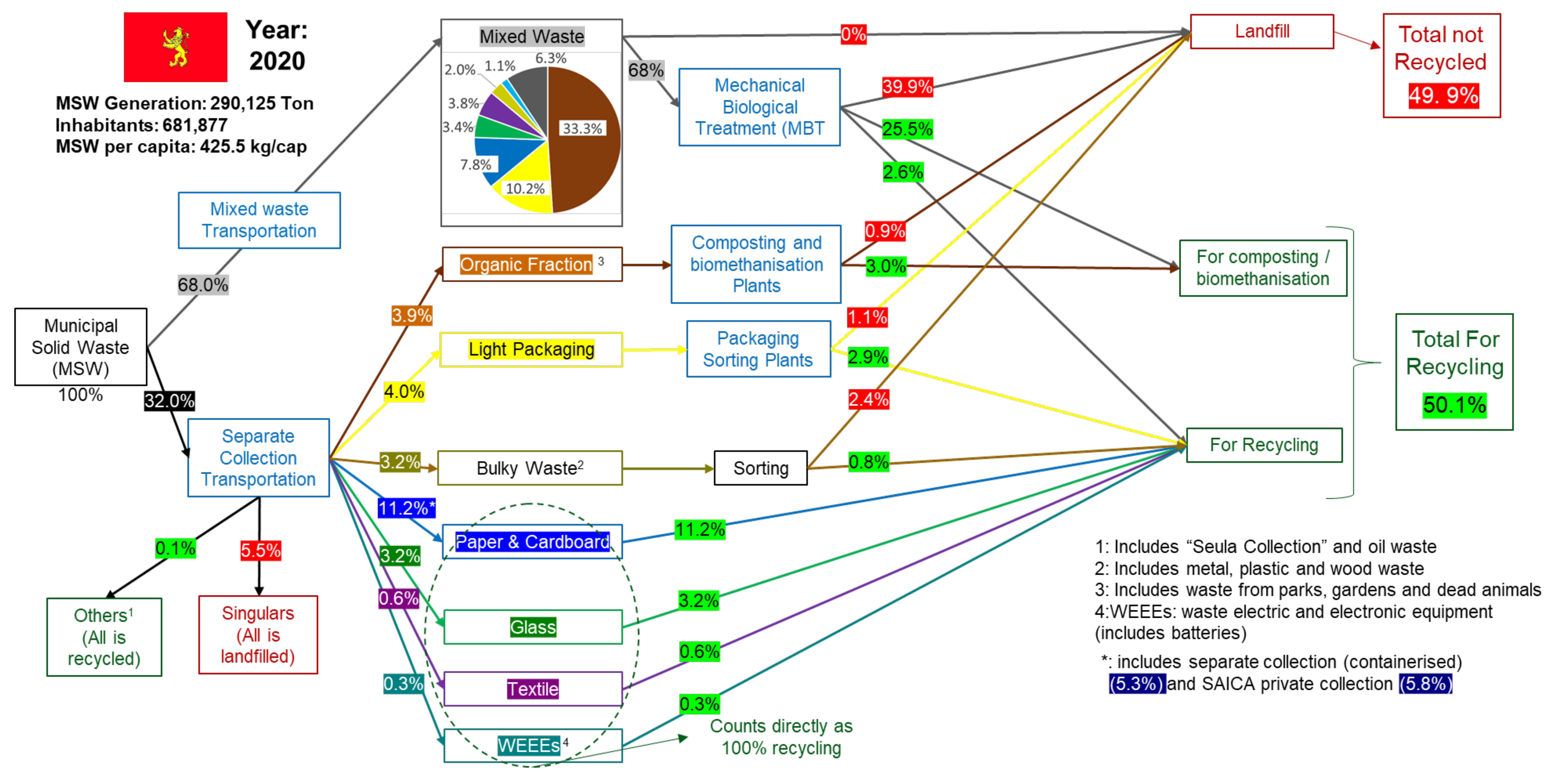

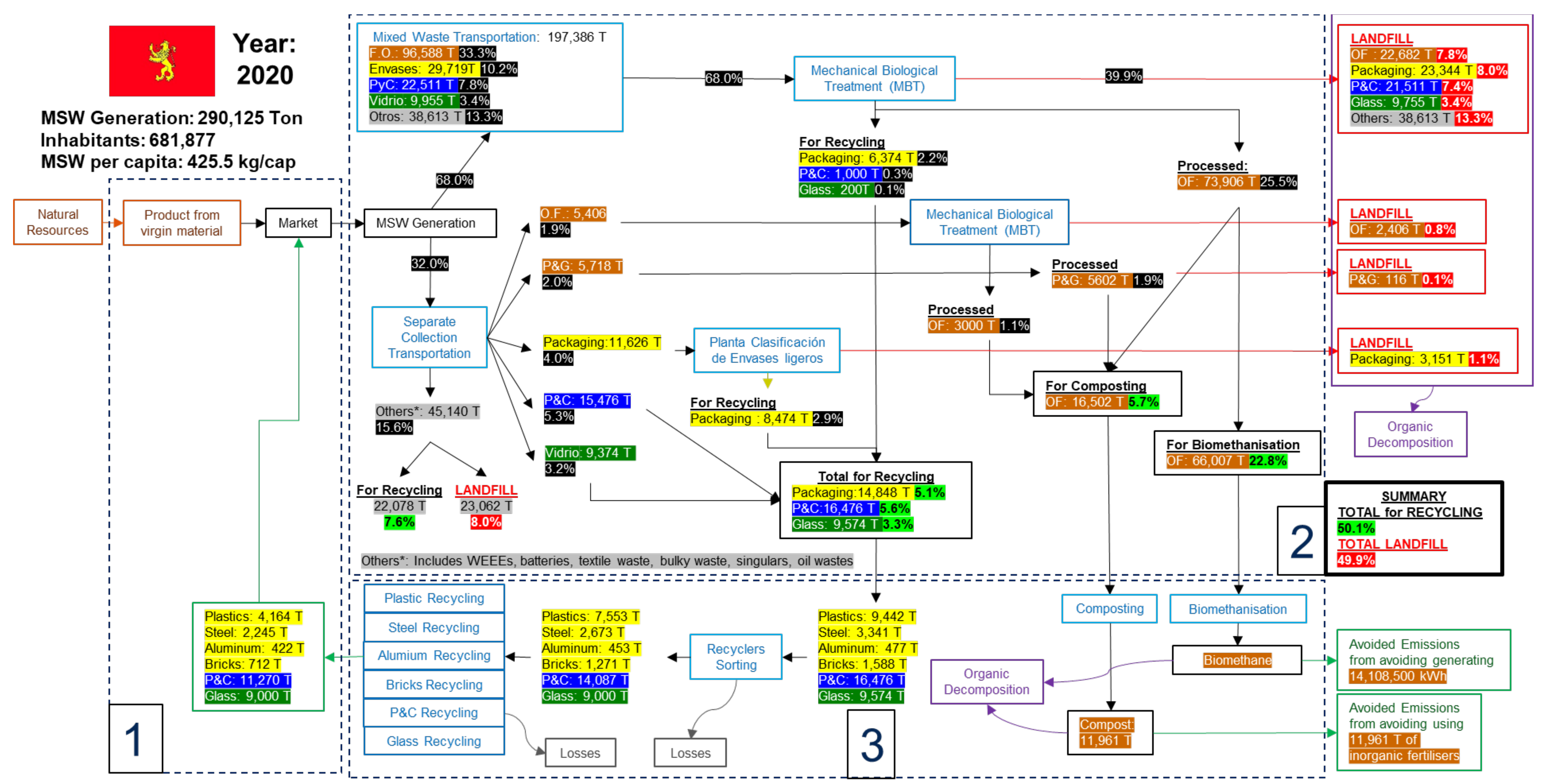

3.1.2. MSW Fraction Flows in 2020

- Mixed waste: It is the main waste fraction (68%). However, up to 85% of waste should be collected selectively, highlighting the low collection efficiency of the city’s current method based on containers placed on the street. Nevertheless, if citizens separate MSW correctly and deposit it in the appropriate container, this percentage could be considerably reduced. For the treatment of this fraction, Zaragoza has a Mechanical-Biological Treatment (MBT) plant at the CTRUZ (see Appendix B) where the entire fraction (197,000 tons) is treated. Here, 41.3% of mixed waste is recovered (28.1% of total MSW, see Figure 2), corresponding to more than half of the total recycling (50.1%). On the other hand, 58.7% (39.9% of total MSW, see Figure 2) is rejected and sent to landfills—which shows the low efficiency of this process—selective collection being preferable.

- Organic fraction: The majority of MSW belongs to this fraction: 33.3% of total MSW ends up in mixed waste, and 3.9% of total MSW is in the selective collection. The big difference between them is that this fraction’s selective collection is only carried out in some neighborhoods, but it is expected to reach the whole city in 2023.

- Light packaging: This fraction is transported to a packaging sorting plant. In 2020, some 11,600 tons of light packaging (4% of total MSW) were collected separately; however, as much as 29,600 tons (10.2% of total MSW) ended up in the mixed waste fraction, making it the most abundant fraction after organic fraction. Given that only 28% of light packaging is collected selectively, urgent measures are needed to increase the selective collection with alternative and/or complementary collection systems such as the DRS. In addition, future sensorization projects in Zaragoza city could help to improve collection efficiency (see Appendix C). On the other hand, only 72.5% of the fraction is recovered for recycling at the packaging sorting plant (2.9% of the 4% collected selectively), which contrasts with the recyclability of P&C or glass, which have 100% recycling. However, research projects are being carried out in facilities close to Zaragoza city that promise to recover 100% of the plastic (see Appendix C).

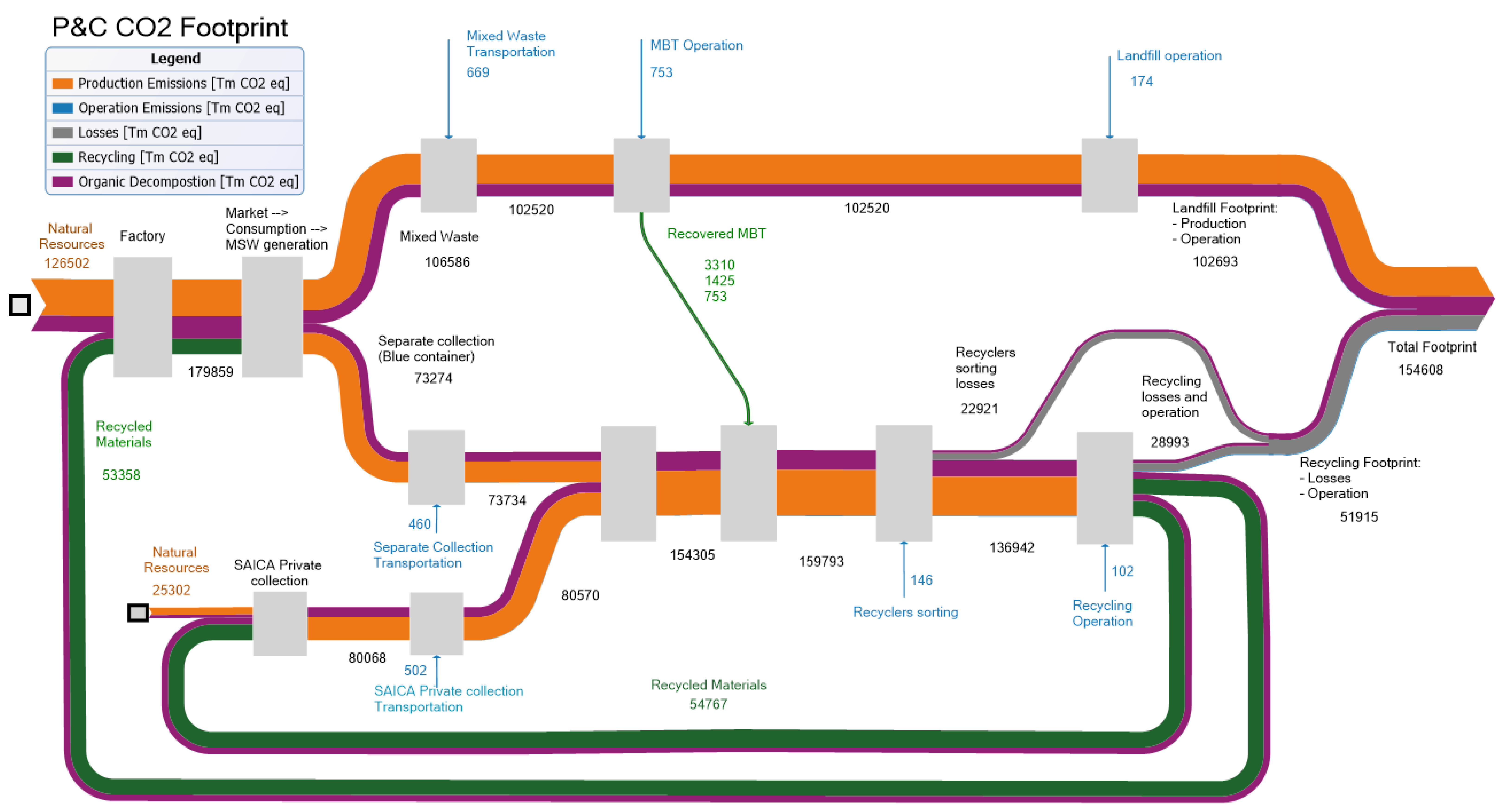

- Paper & Cardboard: This fraction shows recycling rates of 100% of what is collected separately, since it is not sorted but sent directly to recyclers. This fraction is the third most important (11.2% of the total, collected selectively), as it has to be divided in two: on the one hand, 5.3% is collected in street containers and, on the other hand, 5.8% is collected by Aragonese cellulose industry Inc. (SAICA for its Spanish acronym), through containers placed in industries near Zaragoza (see Appendix B). However, a significant part of this waste ends up in the mixed fraction, around 7.8% (of total MSW), which means that approximately 60% of P&C ends up in the mixed waste fraction, and it is necessary to improve selective collection.

- Glass: This fraction has recycling rates of 100% of what is collected separately, as in the previous one. It also has the highest rate of selective packaging collection (light packaging and P&C). 3.2% is collected separately versus 3.4%, which ends up in the mixed waste fraction. Therefore, despite this, there is still much potential for improvement because 51.5% still ends up in the mixed waste fraction.

3.2. Analysis of Zaragoza’s MSW Metabolism and Household Behavior with the CO2 Footprint Method

- Maximum footprint: In this scenario, it is assumed that nothing is recycled, and therefore 100% of the fractions end up in the landfill.

- Current footprint: It is the current scenario

- Minimum footprint: Everything is supposed to be recycled while maintaining the current market mass. This scenario shows the minimum carbon footprint that would be generated if every citizen separated 100% of their waste correctly, i.e., if their behavior was perfect.

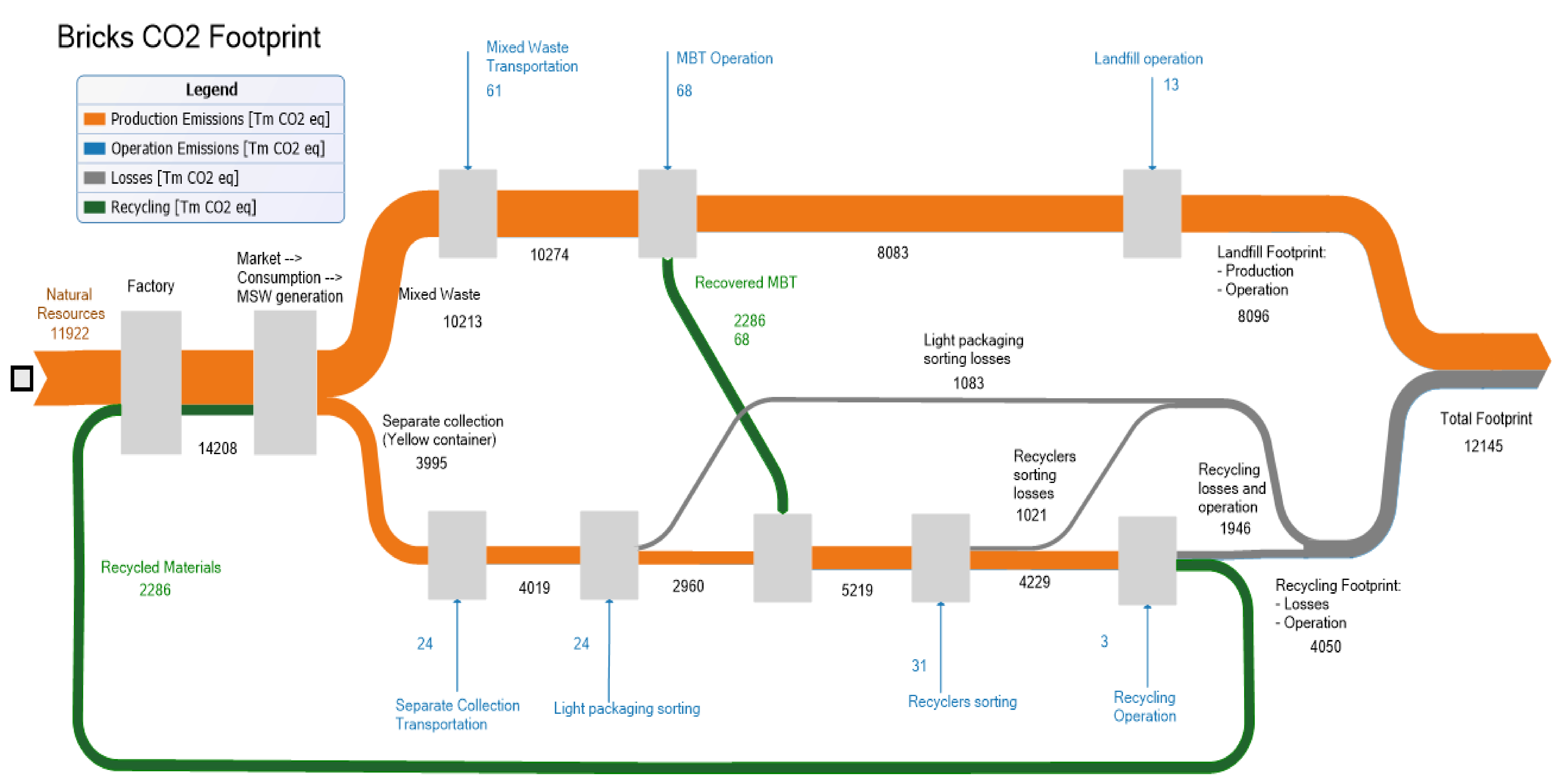

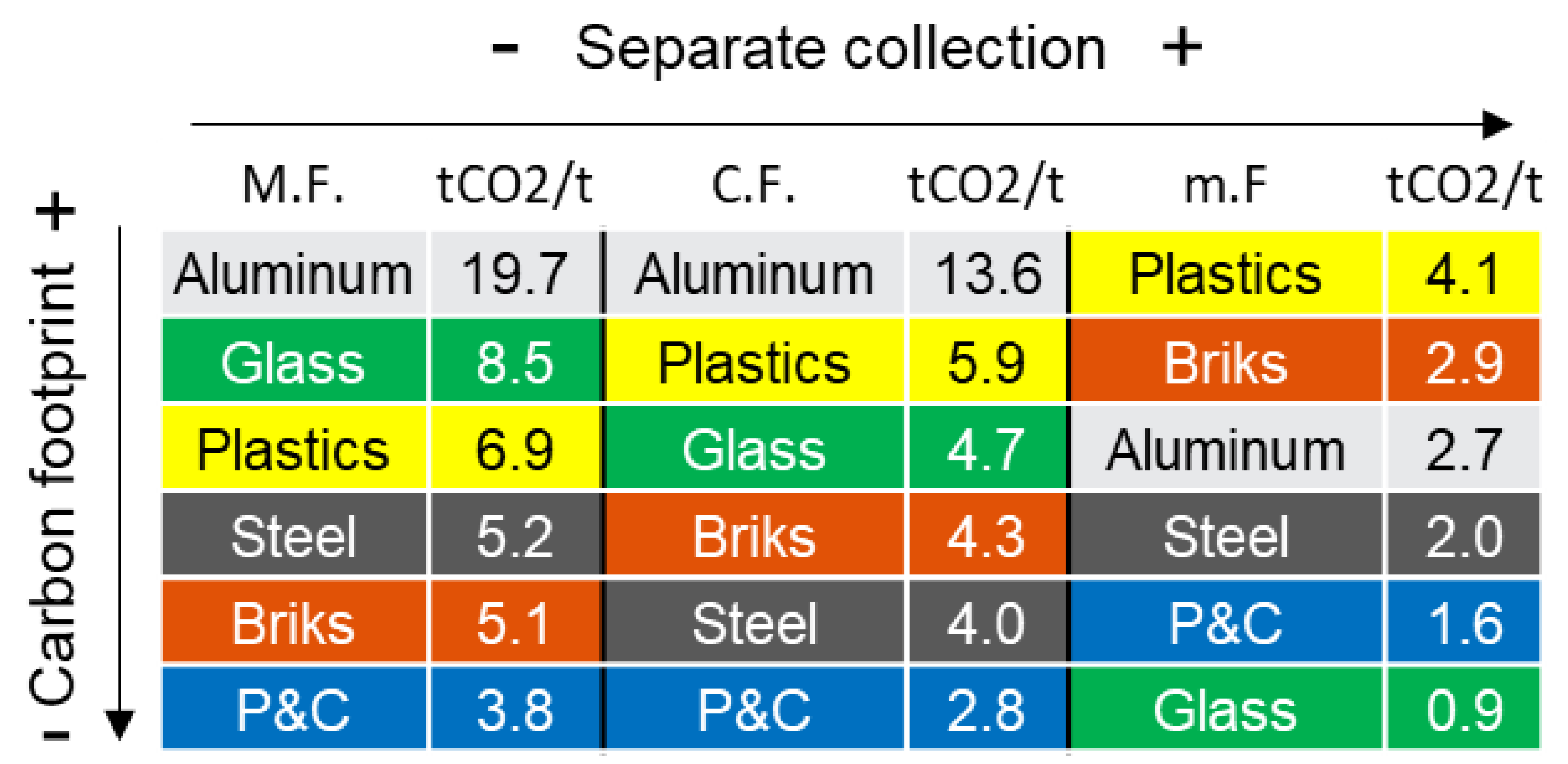

3.2.1. Analysis of the Packaging Fraction

- Results for each scenario (columns A, B, C), with their separate collection rates (columns SC.)

- Current avoided emissions are the difference between the maximum footprint scenario and the current footprint scenario and the potential avoided emissions, which are the difference between the current and minimum footprint.

- Total market mass and the relative results are obtained by dividing columns A, B, and C (D).

| Maximum Footprint | Current Footprint | Minimum Footprint | Current Avoided Emissions | Potential Avoided Emissions | Market Mass | Relative MF. | Relative CF. | Relative m.F. | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| S.C. | A | S.C. | B | S.C. | C | A-B | B-C | D | A/D | B/D | C/D | |

| Units | % | t CO2 | % | t CO2 | % | t CO2 | t CO2 | t CO2 | t | t CO2/t | t CO2/t | t CO2/t |

| P&C | 0% | 208,494 | 40.7% | 154,607 | 100% | 87,174 | 53,887 | 67,433 | 54,897 | 3.8 | 2.8 | 1.6 |

| Glass | 0% | 163,549 | 48.5% | 91,502 | 100% | 18,084 | 72,047 | 73,418 | 19,329 | 8.5 | 4.7 | 0.9 |

| Plastics | 0% | 210,726 | 28.1% | 180,371 | 100% | 126,237 | 30,355 | 54,134 | 30,668 | 6.9 | 5.9 | 4.1 |

| Steel | 0% | 28,325 | 28.1% | 21,984 | 100% | 10,674 | 6341 | 11,310 | 5435 | 5.2 | 4.0 | 2.0 |

| Aluminum | 0% | 47,360 | 28.1% | 32,649 | 100% | 6400 | 14,711 | 26,249 | 2399 | 19.7 | 13.6 | 2.7 |

| Briks | 0% | 14,411 | 28.1% | 12,146 | 100% | 8107 | 2265 | 4039 | 2841 | 5.1 | 4.3 | 2.9 |

| Total | 672,865 | 493,259 | 256,676 | 179,606 | 236,583 | |||||||

3.2.2. Analysis of the Organic Fraction

3.2.3. Summary of Results of the Metabolism of Zaragoza in CO2 and Monetary Terms

3.3. Analysis of the City Council Strategies

4. Discussion and Conclusions

5. Beyond Conclusions: The Concept of “Liver-Industries” and “Brain-Management”

Author Contributions

Funding

Conflicts of Interest

Appendix A

Appendix B

- CTRUZ: Zaragoza City Council has the Zaragoza Urban Waste Treatment Complex (CTRUZ, acronym in Spanish), in operation since 2009. This facility serves more than 750,000 citizens of Zaragoza city and 61 nearby municipalities. Its construction and operation were assigned to UTE Ebro, composed of the companies Urbaser and Vertresa. Its commissioning has allowed [51]:

- ○

- The recovery of materials for subsequent recycling (MBT process).

- ○

- The use of organic matter for biogas and compost production.

- ○

- The generation of electrical energy: the biogas obtained is transformed into electrical energy through a cogeneration installation that allows the Complex’s consumption to be covered and the surplus to be exported to the electricity grid.

- ○

- Water treatment, where the leachate produced is treated.

- ○

- Controlled landfill

- SAICA (Sociedad Anónima Industrias Celulosa Aragonesa): was founded in 1943 in Zaragoza to produce paper. It is currently the most important paper and cardboard producer and recycler in Spain, with an international presence. All the briks in Spain are recycled in the Zaragoza plants. Nevertheless, only 75% of the cardboard is extracted, while the other 25%, made up of plastic and aluminium, is deposited for the moment in an industrial waste landfill pending the implementation of a technology that can separate them [52]. In addition, these plants also recycle the paper and cardboard fraction of Zaragoza city.

- Verallia: the glass separated from the MSW of Zaragoza city is used as raw material in the nearby Verallia factory in Cuarte de Huerva, where new glass is manufactured using the previous waste. Verallia is the world’s third-largest producer of glass containers for food and beverage and in the Iberian Peninsula has 6 factories located in Azuqueca de Henares, Burgos, Montblanc, Sevilla, Zaragoza and Mondego (Portugal) [53].

- CEMEX (Morata de Jalón): About 65 km from Zaragoza in the town of Morata de Jalón is the Cemex factory with a production capacity of 970,000 tons of clinker and 1,400,000 tons of cement per year [54]. MSW organic fraction with sufficient calorific value could be used as secondary fuel for clinker production.

- Parque Tecnológico de Reciclado López Soriano (PTR): is an industrial estate located on 835 hectares in the district of Torrero-La Paz in the municipality of Zaragoza. It is promoted by the López Soriano business group and is mainly dedicated to recycling. The previously named CTRUZ is located within the estate. In addition, many other SMEs dedicated to recycling are located there [55].

- Mercazaragoza: is the most important logistics platform specializing in agrifood in the Ebro Valley. A distribution, commercialization, transformation and logistics platform that operates 24 h a day to guarantee the supply of foodstuffs in its area of influence. It contains more than 150 companies specializing in fresh and frozen products. These companies market around 200,000 tonnes of food a year, concentrating on one of Spain’s most important fresh food offers. Although Mercazaragoza is not an industry or company dedicated to recycling, it should be mentioned as a significant food waste generator, which will be used to generate the compost necessary for the Bosque de los Zaragozanos Project [56].

Appendix C

- Sensorization project: From 2022–2023, Zaragoza City Council is going to implement a system of sensors installed in the city’s waste collection vehicles, containers and cleaning vehicles, as well as software that will allow real-time data to be obtained on waste collection in the city. In addition to providing more reliable data in the medium and long term to have a more accurate knowledge of the city’s MSW flows, this system will enable energy and time costs to be reduced through the optimization of operations with the acquisition of real-time data on dynamic collection routes. Along with this system, a specific container for the organic matter will be implemented throughout the city, making use of electronic card-opening locks, allowing for the collection of more data on the separation of this fraction.

- Project to transform plastic into fuel: The R&D project “3R2020+. From waste to resource through recycling” was funded by the Ministry of Science, Innovation and University and framed in the Collaboration Agreement signed between Urbaser, CTRUZ, and Zaragoza City Council ended in October 2020. This project was developed in Urbaser’s R&D centre, located in Zaragoza, and investigated the transformation of plastic film from MSW into diesel fuel by distilling the pyrolysis liquids produced. It is still in the pilot phase, but a functional plant will be built soon [57].

- “Bosque de los Zaragozanos” project foresees the planting of a forest of 700,000 trees in the vicinity of Zaragoza, using compost recovered from the MBT and covering an area of 1200 hectares [58].

- Circular Biocarbon project: it is a first-of-its-kind flagship biorefinery designed to turn the organic fraction of municipal solid waste and sewage sludge into high added-value end products, including plastic molding tools, mechanical moving parts, direct consumer products, night vision cameras, devices for 5G telecommunications, bags for biowaste collection, biodegradable in soil mulch films, liquid microalgae biostimulant fertilizer or solid organ-mineral fertilizer with biostimulant properties. The project will set the basis for the commercial demonstration of the feasibility of a biorefinery as a new waste treatment model for cities. It will open up the market for new products and business frameworks based on a circular vision of waste treatment in cities and help pave the way towards a sustainable bioeconomy [59]. This project, led by Urbaser, will lead to the construction of Europe’s first biorefinery for solid urban waste and sewage sludge in Zaragoza.

Appendix D

References

- Kaza, S.; Yao, L.; Bhada-Tata, P.; van Woerden, F. What a Waste 2.0 A Global Snapshot of Solid Waste Management to 2050; World Bank Group: Washington, DC, USA, 2018. [Google Scholar]

- Bourguignon, D. European Circular Economy Package: Four Legislative Proposals on Waste. Available online: https://www.europarl.europa.eu/RegData/etudes/BRIE/2017/599288/EPRS_BRI%282017%29599288_EN.pdf (accessed on 2 November 2021).

- Girardet, H. Creating Regenerative Cities. Available online: https://www.taylorfrancis.com/books/mono/10.4324/9781315764375/creating-regenerative-cities-herbert-girardet (accessed on 2 November 2021).

- Valero, A.; Valero, A. Thermodynamic Rarity and Recyclability of Raw Materials in the Energy Transition: The Need for an In-Spiral Economy. Entropy 2019, 21, 873. [Google Scholar] [CrossRef] [Green Version]

- Kennedy, C.; Pincetl, S.; Bunje, P. The Study of Urban Metabolism and Its Applications to Urban Planning and Design. Environ. Pollut. 2011, 159, 1965–1973. [Google Scholar] [CrossRef] [PubMed]

- Neves, A.; Godina, R.; Azevedo, S.G.; Matias, J.C.O. A Comprehensive Review of Industrial Symbiosis. J. Clean. Prod. 2020, 247, 119113. [Google Scholar] [CrossRef]

- Chertow, M.R. Industrial Symbiosis: Literature and Taxonomy. Annu. Rev. Energy Environ. 2000, 25, 313–337. [Google Scholar] [CrossRef] [Green Version]

- Ulhøi, J.P. Industrial Symbiosis in an Extended Perspective; ResearchGate: Berlin, Germany, 2002. [Google Scholar]

- Neves, A.; Godina, R.; Azevedo, S.G.; Pimentel, C.; Matias, J.C.O. The Potential of Industrial Symbiosis: Case Analysis and Main Drivers and Barriers to Its Implementation. Sustainability 2019, 11, 7095. [Google Scholar] [CrossRef] [Green Version]

- Christensen, T.H.; Damgaard, A.; Levis, J.; Zhao, Y.; Björklund, A.; Arena, U.; Barlaz, M.A.; Starostina, V.; Boldrin, A.; Astrup, T.F.; et al. Application of LCA Modelling in Integrated Waste Management. Waste Manag. 2020, 118, 313–322. [Google Scholar] [CrossRef] [PubMed]

- Pérez, J.; de Andrés, J.M.; Lumbreras, J.; Rodríguez, E. Evaluating Carbon Footprint of Municipal Solid Waste Treatment: Methodological Proposal and Application to a Case Study. J. Clean. Prod. 2018, 205, 419–431. [Google Scholar] [CrossRef]

- Fernández-Braña, A.; Feijoo, G.; Dias-Ferreira, C. Turning Waste Management into a Carbon Neutral Activity: Practical Demonstration in a Medium-Sized European City. Sci. Total Environ. 2020, 728, 138843. [Google Scholar] [CrossRef] [PubMed]

- Bovea, M.D.; Ibáñez-Forés, V.; Gallardo, A.; Colomer-Mendoza, F.J. Environmental Assessment of Alternative Municipal Solid Waste Management Strategies. A Spanish Case Study. Waste Manag. 2010, 30, 2383–2395. [Google Scholar] [CrossRef]

- Herva, M.; Neto, B.; Roca, E. Environmental Assessment of the Integrated Municipal Solid Waste Management System in Porto (Portugal). J. Clean. Prod. 2014, 70, 183–193. [Google Scholar] [CrossRef]

- Fernández-Nava, Y.; del Río, J.; Rodríguez-Iglesias, J.; Castrillón, L.; Marañón, E. Life Cycle Assessment of Different Municipal Solid Waste Management Options: A Case Study of Asturias (Spain). J. Clean. Prod. 2014, 81, 178–189. [Google Scholar] [CrossRef] [Green Version]

- Habib, K.; Schmidt, J.H.; Christensen, P. A Historical Perspective of Global Warming Potential from Municipal Solid Waste Management. Waste Manag. 2013, 33, 1926–1933. [Google Scholar] [CrossRef] [PubMed]

- Arushanyan, Y.; Björklund, A.; Eriksson, O.; Finnveden, G.; Söderman, M.L.; Sundqvist, J.O.; Stenmarck, Å. Environmental Assessment of Possible Future Waste Management Scenarios. Energies 2017, 10, 247. [Google Scholar] [CrossRef] [Green Version]

- Banias, G.; Batsioula, M.; Achillas, C.; Patsios, S.I.; Kontogiannopoulos, K.N.; Bochtis, D.; Moussiopoulos, N. A Life Cycle Analysis Approach for the Evaluation of Municipal Solid Waste Management Practices: The Case Study of the Region of Central Macedonia, Greece. Sustainability 2020, 12, 8221. [Google Scholar] [CrossRef]

- Jeswani, H.K.; Azapagic, A. Assessing the Environmental Sustainability of Energy Recovery from Municipal Solid Waste in the UK. Waste Manag. 2016, 50, 346–363. [Google Scholar] [CrossRef]

- Wittmaier, M.; Langer, S.; Sawilla, B. Possibilities and Limitations of Life Cycle Assessment (LCA) in the Development of Waste Utilization Systems—Applied Examples for a Region in Northern Germany. Waste Manag. 2009, 29, 1732–1738. [Google Scholar] [CrossRef]

- Ripa, M.; Fiorentino, G.; Vacca, V.; Ulgiati, S. The Relevance of Site-Specific Data in Life Cycle Assessment (LCA). The Case of the Municipal Solid Waste Management in the Metropolitan City of Naples (Italy). J. Clean. Prod. 2017, 142, 445–460. [Google Scholar] [CrossRef]

- Zhang, J.; Qin, Q.; Li, G.; Tseng, C.H. Sustainable Municipal Waste Management Strategies through Life Cycle Assessment Method: A Review. J. Environ. Manag. 2021, 287, 112238. [Google Scholar] [CrossRef] [PubMed]

- Moffatt, S.; Kohler, N. Conceptualizing the Built Environment as a Social-Ecological System. Build. Res. Inf. 2008, 36, 248–268. [Google Scholar] [CrossRef]

- Zhang, Y. Urban Metabolism: A Review of Research Methodologies. Environ. Pollut. 2013, 178, 463–473. [Google Scholar] [CrossRef]

- Ngo, N.S.; Pataki, D.E. The Energy and Mass Balance of Los Angeles County. Urban Ecosyst. 2008, 11, 121–139. [Google Scholar] [CrossRef]

- Liang, S.; Zhang, T. Comparing Urban Solid Waste Recycling from the Viewpoint of Urban Metabolism Based on Physical Input-Output Model: A Case of Suzhou in China. Waste Manag. 2012, 32, 220–225. [Google Scholar] [CrossRef]

- Khalil, H.A.E.E.; Al-Ahwal, A. Reunderstanding Cairo through Urban Metabolism: Formal versus Informal Districts Resource Flow Performance in Fast Urbanizing Cities. J. Ind. Ecol. 2021, 25, 176–192. [Google Scholar] [CrossRef]

- European Commission Extended Producer Responsabiity (ERP) in European Union. Available online: https://ec.europa.eu/environment/archives/waste/eu_guidance/introduction.html (accessed on 3 November 2021).

- Ministerio Para La Transición Ecológica y el Reto Demográfico Extended Producer Responsability (EPR) Policies in Spain. Available online: https://www.miteco.gob.es/en/calidad-y-evaluacion-ambiental/temas/prevencion-y-gestion-residuos/flujos/responsabilidad-ampliada/ (accessed on 3 November 2021).

- Lander Svendsen, N.; Kaarsberg, S.; Watson, D.; Aditi Bhasin, P.; Klugman, S.; Solstad, M.; Larssen, S. How Can Municipalities Support the Development of Industrial Symbiosis? Interreg Baltic Sea Region 2021. Available online: https://symbiosecenter.dk/wp-content/uploads/2021/01/Guide-how-can-municipalities-support-the-development-of-industrial-symbiosis-final-version.pdf (accessed on 2 November 2021).

- Vizcaíno-López, A. Contenedor Amarillo S.A., 1st ed.; Fuera de Ruta: Valencia, Spain, 2020. [Google Scholar]

- Gobierno de Aragón: Dirección General de Sostenibilidad. Plan GIRA 2018–2022; Gobierno de Aragón, Departamento de Desarrollo Rural y Sostenibilidad: Zaragoza, Spain, 2018.

- Ministerio para la Transición Ecológica y Reto Demográfico. Memoria Anual de Generación y Gestión de Residuos de Competencia Municipal, 2018; Ministerio para la Transición Ecológica y Reto Demográfico: Madrid, Spain, 2020.

- Ministerio de Agricultura Alimentación y Medio Ambiente. Plan Estatal Marco de Gestión de Residuos (PEMAR) 2016–2022; Ministerio de Agricultura Alimentación y Medio Ambiente: Madrid, Spain, 2016.

- Rigamonti, L.; Grosso, M.; Giugliano, M. Life Cycle Assessment for Optimising the Level of Separated Collection in Integrated MSW Management Systems. Waste Manag. 2009, 29, 934–944. [Google Scholar] [CrossRef] [PubMed]

- U.S. Environmental Protection Agency. Documentation for Greenhouse Gas Emission and Energy Factors Used in the Waste Reduction Model (WARM)—Containers, Packaging, and Non-Durable Goods Materials Chapters; U.S. Environmental Protection Agency: Washington, DC, USA, 2016.

- Tetra Pak Brik Comoposition. Available online: https://www.tetrapak.com/en-in/sustainability/planet/good-for-you-good-for-the-earth/tetra-pak-cartons-recyclable (accessed on 3 November 2021).

- Greenrationbook.org the Green Ration Book Resources: The Cost of Everyday Living. Available online: http://www.greenrationbook.org.uk/resources/ (accessed on 2 November 2021).

- Martínez-Gasol, C.; Farreny-Gaya, R. Modelo de Cálculo de Emisiones de Gases de Efecto Invernadero Asociadas a Determinados Escenarios de Generación de Residuos Municipales En España; Fundació Fórum Ambiental: Barcelona, Spain, 2011. [Google Scholar]

- Pérez, J.; Lumbreras, J.; Rodríguez, E.; Vedrenne, M. A Methodology for Estimating the Carbon Footprint of Waste Collection Vehicles under Different Scenarios: Application to Madrid. Transp. Res. Part D Transp. Environ. 2017, 52, 156–171. [Google Scholar] [CrossRef]

- Ministerio Para La Transición Ecológica y el Reto Demográfico España. Informe Inventarios GEI 1990–2018 (Edición2020). Anexo 7. Factores de Emisión de CO2 y PCI de Los Combustibles. Available online: https://www.miteco.gob.es/es/cambio-climatico/temas/comercio-de-derechos-de-emision/es_2020_anexovii_unfccc_nir_tcm30-379357.pdf (accessed on 2 November 2021).

- Slorach, P.C.; Jeswani, H.K.; Cuéllar-Franca, R.; Azapagic, A. Energy Demand and Carbon Footprint of Treating Household Food Waste Compared to Its Prevention. In Proceedings of the Energy Procedia; Elsevier Ltd.: Amsterdam, The Netherlands, 2019; Volume 161, pp. 17–23. [Google Scholar]

- Amigos de la Tierra El Compostaje Doméstico: Receta Para Reducir Las Emisiones de CO2. Available online: https://www.tierra.org/wp-content/uploads/2016/01/compostaje_reducir_huella_carbono_estatal.pdf (accessed on 2 November 2021).

- Wilcox, J.; Mackenzie, J. What We Waste: Tracking 20 Years of Growth in International Drinks Container Wastage, and How Refillables and Deposit Return Systems Can Reverse This Trend; Reloop Platform: Brussels, Belgium, 2021. [Google Scholar]

- Sostenibilidadresiduos.es Uso de Bolsas Personalizadas Para La Recogida Comercial En Lleida (Cataluña). Available online: https://sostenibilidadresiduos.es/media/files/Actuaciones/Codigo_01/Codi_01_2.pdf (accessed on 2 November 2021).

- Sostenibilidadresiduos.es Uso de Cubos Aireados y Bolsa Compostables Para La Recogida de La Fracción Orgánica En La Mancomunidad de Servicios de Txingudi (País Vasco). Available online: https://sostenibilidadresiduos.es/media/files/Actuaciones/Codigo_50/Codigo_50_2.pdf (accessed on 2 November 2021).

- Ecoembes Estadísticas Sobre El Reciclaje de Envases Domésticos En España. Available online: https://www.ecoembes.com/es/ciudadanos/envases-y-proceso-reciclaje/datos-de-reciclaje-en-espana (accessed on 2 November 2021).

- SendeCO2 Precio Emisiones de CO2. Available online: https://www.sendeco2.com/es/ (accessed on 2 November 2021).

- Delemare, A.; Harding-Rolls, G.; Urbancic, N.; Benegas, X. Hablan Basura: El Manual Corporativo de Soluciones Falsas a La Crisis Del Plástico; Changing Markets Foundation: Utrecht, The Netherlands, 2020. [Google Scholar]

- Ecoembes Packaging Law Information. Available online: https://www.ecoembes.com/es/ciudadanos/preguntas-frecuentes-eco#t96n17360 (accessed on 2 November 2021).

- Zaragozarecicla.org CTRUZ Information. Available online: https://www.zaragozarecicla.org/el-ctruz/que-es-el-ctruz/ (accessed on 2 November 2021).

- Zaragozarecicla.org SAICA Information. Available online: https://www.zaragozarecicla.org/3909/se-puede-reciclar-un-tetrabrick/ (accessed on 2 November 2021).

- Verallia_Group Verallia Information. Available online: https://www.verallia.com/en/our-group/about/ (accessed on 2 November 2021).

- FundacionCema.org Cemex Information. Available online: https://www.fundacioncema.org/morata-morata-de-jalon/ (accessed on 2 November 2021).

- Recycling Technologic Park López Soriano Information. Available online: https://es.wikipedia.org/wiki/PTR_L%C3%B3pez_Soriano (accessed on 2 November 2021).

- MercaZaragoza Information. Available online: https://mercazaragoza.es/ (accessed on 2 November 2021).

- Urbaser 3R2020 Project: From Waste to Resource through Recycling. Available online: https://www.urbaser.com/2020/10/urbaser-y-clh-investigan-con-exito-la-obtencion-de-combustible-a-partir-de-residuos-plasticos/ (accessed on 2 November 2021).

- Bosquedeloszaragozanos.es Bosque de Los Zaragozanos Project. Available online: https://bosquedeloszaragozanos.es/ (accessed on 2 November 2021).

- CircularBiocarbon.eu Circular Biocarbon Biorefinery Project. Available online: https://circularbiocarbon.eu/ (accessed on 2 November 2021).

| Sorting | Recycling | ||

|---|---|---|---|

| Type | Effiency | Effiency | Downcycling |

| REF | [35] | [35] | [12] |

| P&C | 86% | 100% | 80% |

| Glass | 94% | 100% | 100% |

| Plastics | 80% | 74% | 75% |

| Steel | 80% | 84% | 100% |

| Aluminium | 95% | 93% | 100% |

| Briks | 80% | 70% | 80% |

| Initial CO2 Footprint | Sorting Plant | Recycling Plant | Transport | MBT | Landfill | Landfill | |

|---|---|---|---|---|---|---|---|

| Type | Initial CO2 Footprint | Operation | Operation | Operation | Operation | Operation | Organic Decomposition |

| Unit | kgCO2eq/Tn | kgCO2eq/Tn | kgCO2eq/Tn | kgCO2eq/Tn | kgCO2eq/Tn | kgCO2eq/Tn | kgCO2eq/Tn |

| REF | [38] | [39] | [35] | [40] | [39] | [39] | [36] |

| P&C | 3310 | 4.4 | 3.6 | 29.7 | 33.4 | 8.1 | 1425 |

| Glass | 8390 | 1.2 | 427 | 29.7 | 33.4 | 8.1 | - |

| Plastics | 6800 | 30.2 | 281 | 29.7 | 33.4 | 8.1 | - |

| Steel | 5140 | 30.2 | 235 | 29.7 | 33.4 | 8.1 | - |

| Aluminium | 19,670 | 30.2 | 301 | 29.7 | 33.4 | 8.1 | - |

| Briks * | 5001 | 30.2 | 3.6 | 29.7 | 33.4 | 8.1 | - |

| Resource | Electricity | Natural Gas | Diesel | Fuel-Oil |

|---|---|---|---|---|

| Units | kgCO2eq/kWh | kgCO2eq/GJ | kgCO2eq/GJ | kgCO2eq/GJ |

| Emission factor | 0.35 | 56 | 74 | 77 |

| Initial CO2 Footprint | Transport | MBT | Landfill | Landfill | |

|---|---|---|---|---|---|

| Type | Initial CO2 Footprint | Operation | Operation | Operation | Organic Decomposition |

| Unit | kgCO2eq/Tn | kgCO2eq/Tn | kgCO2eq/Tn | kgCO2eq/Tn | kgCO2eq/Tn |

| REF | [42] | [40] | [39] | [39] | [43] |

| Organic | 3570 | 29.7 | 33.4 | 8.1 | 1825 |

| Composting | Biomethanisation | |||||

|---|---|---|---|---|---|---|

| Type | Operation | Organic Decomposition | Avoided | Operation | Organic Decomposition | Avoided |

| Units | kgCO2/Tn | kgCO2/Tn | kgCO2/Tn | kgCO2/Tn | kgCO2/Tn | kgCO2/kWh |

| REF | [39] | [39] | [11] | [39] | [39] | [39] |

| Organic | 11.9 | 172 | −26 | 18.0 | 30 | −0.35 |

| Years | 2016 | 2017 | 2018 | 2019 | ||

|---|---|---|---|---|---|---|

| Population | 661,108 | 664,938 | 666,880 | 674,997 | ||

| Total Waste (kg/cap/yr) | 356.1 | 356.2 | 366.6 | 370.4 | ||

| Mixed Waste (kg/cap/yr) | Mixed Waste | 100% | 313.0 | 312.5 | 318.0 | 321.8 |

| Organic | 40.0% | 125.2 | 125.0 | 127.2 | 128.7 | |

| Light packaging | 18.3% | 57.3 | 57.2 | 58.2 | 58.9 | |

| Paper & Cardboard | 12.2% | 38.2 | 38.1 | 38.8 | 39.3 | |

| Glass | 4.2% | 13.1 | 13.1 | 13.4 | 13.5 | |

| Textile | 5.5% | 17.2 | 17.2 | 17.5 | 17.7 | |

| Others | 19.8% | 62.0 | 61.9 | 63.0 | 63.7 | |

| Separate Collection (kg/cap/yr) | Light packaging | 11.2 | 11.7 | 12.1 | 12.9 | |

| Paper & Cardboard | 19.1 | 18.8 | 22.3 | 20.4 | ||

| Glass | 12.8 | 13.2 | 14.2 | 15.3 | ||

| Maximum Footprint (MF.) | Current Footprint (CF.) | Minimum Footprint (m.F.) | Current Avoided Emissions | Potential Avoided Emissions | Total Mass | Relative M.F. | Relative CF. | Relative m.F. | |

|---|---|---|---|---|---|---|---|---|---|

| A | B | C | A-B | B-C | D | A/D | B/D | C/D | |

| Units | t CO2 | t CO2 | t CO2 | t CO2 | t CO2 | T | t CO2/T | t CO2/T | t CO2/T |

| OF | 588,585 | 437,987 | 391,984 | 150,599 | 46,003 | 101,994 | 5.8 | 4.3 | 3.8 |

| Maximum Footprint (A) | Current Footprint (B) | Minimum Footprint (C) | Current avoided Emissions (A-B) | Potential Avoided Emissions (B-C) | Current Avoided Emissions (A-B) | Potential Avoided Emissions (B-C) | |

|---|---|---|---|---|---|---|---|

| Units | T CO2 eq | T CO2 eq | T CO2 eq | T CO2 eq | T CO2 eq | € | € |

| P&C | 208,494 | 154,607 | 87,174 | 53,887 | 67,433 | 2,694,000 € | 3,372,000 € |

| Glass | 163,549 | 91,502 | 18,084 | 72,047 | 73,418 | 3,602,000 € | 3,671,000 € |

| Plastics | 210,726 | 180,371 | 126,237 | 30,355 | 54,134 | 1,518,000 € | 2,707,000 € |

| Steel | 28,325 | 21,984 | 10,674 | 6341 | 11,310 | 317,000 € | 566,000 € |

| Aluminum | 47,360 | 32,649 | 6400 | 14,711 | 26,249 | 736,000 € | 1,312,000 € |

| Briks | 14,411 | 12,146 | 8107 | 2265 | 4039 | 113,000 € | 202,000 € |

| OF | 588,585 | 437,987 | 391,984 | 150,599 | 46,003 | 7,530,000 € | 2,300,000 € |

| Total | 1,261,450 | 931,246 | 648,660 | 330,205 | 282,586 | 16,510,000 € | 14,129,000 € |

| Measure | Waste Fraction | Results | CO2 Footprint Avoided (t CO2 eq.) | Cost Avoided € |

|---|---|---|---|---|

| DRS implementation | Aluminum cans | Recycling rate: 89% | 22,709 | 1,135,000€ |

| DRS implementation | Steel cans | Recycling rate: 89% | 9784 | 489,000€ |

| DRS implementation | Glass bottles | Recycling rate: 87% | 60,589 | 3,029,000€ |

| Collection with identification code | All separate collection | +4.8 pp | 16,278 | 814,000€ |

| Electronic card-opening locks | Organic fraction | +10.8 pp | 7763 | 388,000€ |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Valero, A.; Torrubia, J.; Anía, M.Á.; Torres, A. Assessing Urban Metabolism through MSW Carbon Footprint and Conceptualizing Municipal-Industrial Symbiosis—The Case of Zaragoza City, Spain. Sustainability 2021, 13, 12724. https://doi.org/10.3390/su132212724

Valero A, Torrubia J, Anía MÁ, Torres A. Assessing Urban Metabolism through MSW Carbon Footprint and Conceptualizing Municipal-Industrial Symbiosis—The Case of Zaragoza City, Spain. Sustainability. 2021; 13(22):12724. https://doi.org/10.3390/su132212724

Chicago/Turabian StyleValero, Antonio, Jorge Torrubia, Miguel Ángel Anía, and Alicia Torres. 2021. "Assessing Urban Metabolism through MSW Carbon Footprint and Conceptualizing Municipal-Industrial Symbiosis—The Case of Zaragoza City, Spain" Sustainability 13, no. 22: 12724. https://doi.org/10.3390/su132212724

APA StyleValero, A., Torrubia, J., Anía, M. Á., & Torres, A. (2021). Assessing Urban Metabolism through MSW Carbon Footprint and Conceptualizing Municipal-Industrial Symbiosis—The Case of Zaragoza City, Spain. Sustainability, 13(22), 12724. https://doi.org/10.3390/su132212724