The 4.0 Industry Technologies and Their Impact in the Continuous Improvement and the Organizational Results: An Empirical Approach

Abstract

1. Introduction

2. Literature Review

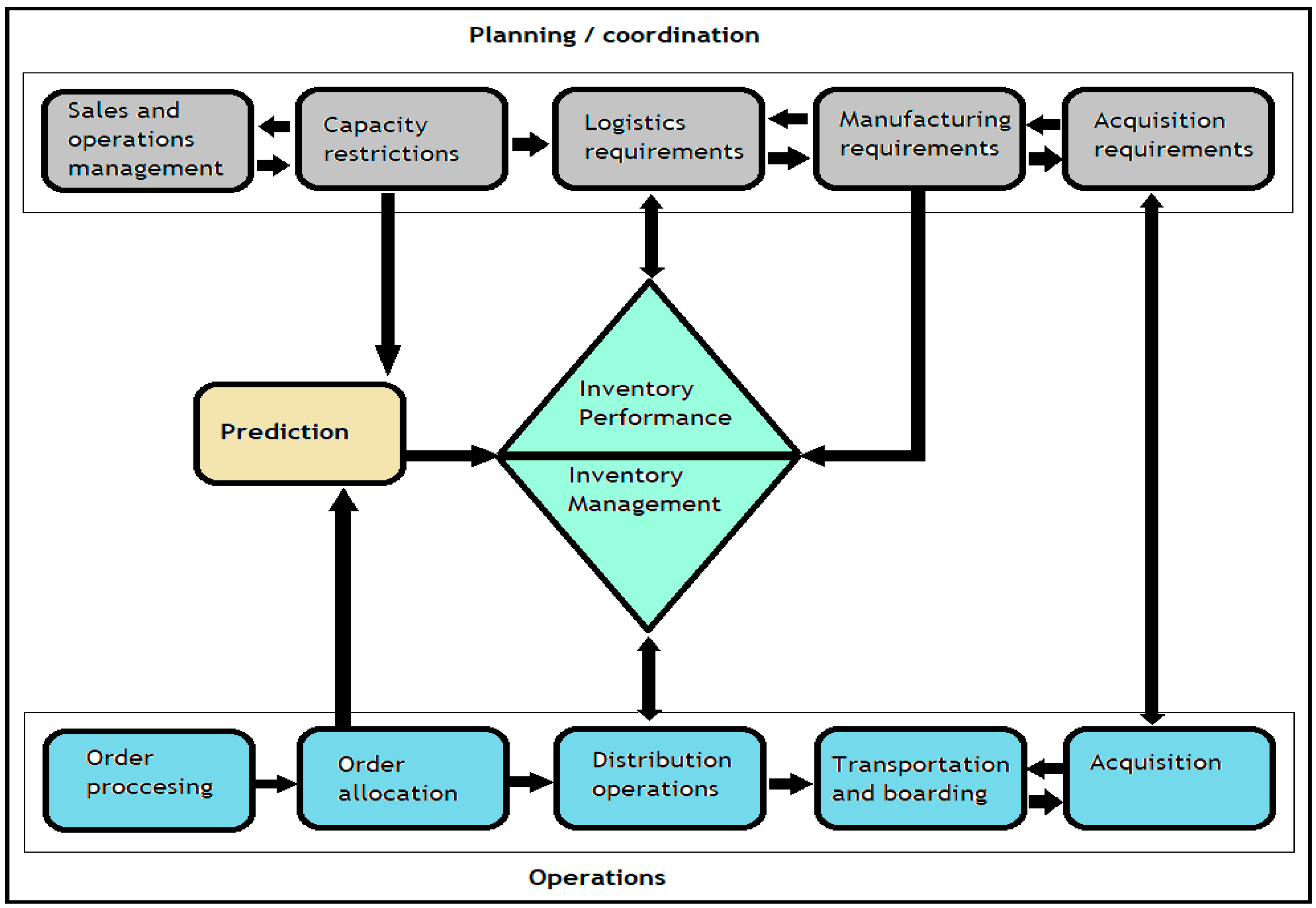

2.1. New Technologies of Industry 4.0 in Logistics Management

2.1.1. Resource Planning Systems

- Single entry of information to the system.

- Use of forces.

- It allows customization.

- It is based on a reliable structure.

- It provides functionality to interact with other modules.

- It provides the tools for complex queries.

- It provides proven implementation methodologies and theory of change.

2.1.2. Supply Chain Management (SCM)

2.1.3. Artificial Intelligence (AI)

- The importance of achieving the Sustainable Development Goals is highlighted, so that it can be used to combat extreme poverty and improve the quality of life in remote areas in many different ways, for example, by improving agricultural land and agriculture in general.

- It has the potential to create highly effective and personalized education systems that can be tailored to the needs of students.

- In healthcare, the power of computers is used to analyze and make sense of a large amount of electronic data about patients such as: ages, medical records, health status, test results, DNA images sequences, and many others, in order to improve decision-making that helps improve the quality of life of patients.

- In jobs, it reduces additional costs and salaries, increasing the effectiveness and productivity of the company. By automating activities, it enables companies to improve performance by reducing errors and improving quality and speed.

2.1.4. Cloud Computing

2.1.5. Cybersecurity

- Cybersecurity serves to shield organizations against threats and vulnerabilities caused by existing cyber-attacks in cyberspace.

- It facilitates citizens, as well as public and private companies, to benefit from the use of cyberspace through ICT, to share information between the different social actors and behaves as a database for storing information.

- It helps to protect the economic and social stability of companies from their stakeholders, since it allows the continuity of operations with greater security.

- It evaluates the threats and vulnerabilities presented by cyberattacks, in such a way that it reveals the crimes committed and the collection of evidence for their respective prosecution.

2.1.6. Autonomous Cars

- The decrease in costs related to the transport, storage, and packaging of food that currently represents 70% [28].

- The reduction of deaths and injuries on roads, due to the replacement of all human drivers by computers [29].

- The supply transportation to the population that currently does not generally use their own cars, for example, the elderly or young people who do not have a driving license [27].

- The improvement in traffic flow in cities, due to the fact that all autonomous cars would be connected in a network, working in a coordinated manner [27].

- Less pollution generated by fuels, because a higher percentage of cars would be electric [27].

2.1.7. Drones

- It provides a high temporal resolution, thanks to the ease of repetition of flights.

- It generates a lower operating cost for small projects.

- It allows the collection of high precision data and good spatial resolution since, when operating at low altitude, they generate little atmospheric interference, not being affected by clouds.

- There are no human risks for the crew, when using this type of technology. Besides, they show great ease of use for non-specialized operators.

- Ojeda Bustamante [33] also adds the following advantage of this technology: Drones are very useful for those areas that are difficult to access, referring to, for example, volcanoes, fires, areas with concentration of radioactivity, or other disaster areas, such as landslides or floods, among others.

2.1.8. Big Data, Data Analysis and Data Mining

2.1.9. Collaborative Robots

- They are systems that can be programmed in an easy and simple way.

- Personnel training is done quickly and intuitively, and without the need of prior programming knowledge.

- It provides a 100% safe environment when working with them in different phases of the manufacturing process, improving, as a consequence, product quality and prices. The various tasks can be adjusted to the process gradually, that is, there is no need to fully automatize production.

2.1.10. 3D Simulation

2.2. The Relationship between the New Technologies of Industry 4.0 and Business Results

- (1)

- For products: customization, quality, and reduction of launch times.

- (2)

- For operations: decrease in operating costs, increase of productivity, and higher visualization and control.

- (3)

- Collateral or secondary effects: sustainability and worker satisfaction.

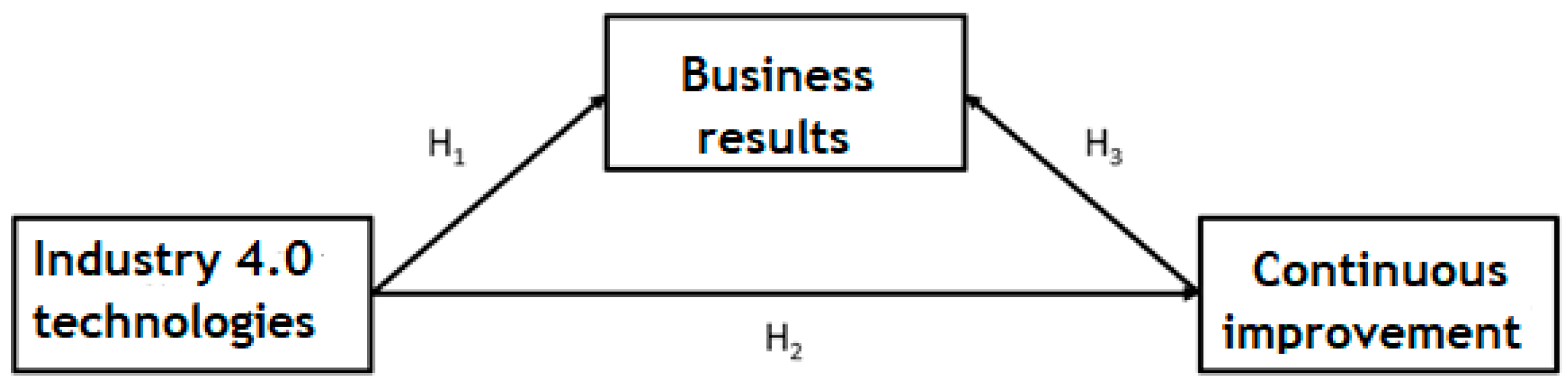

3. Hypothesis

4. Materials and Methods

4.1. Population under Study

4.2. Collection of Information

4.2.1. Data Collection Process

4.2.2. Description of the Questionnaire

- Which of the Industry 4.0 technologies do you know about? Cloud Computing Big data, Internet of things (IoT), 3D Printing, Artificial Intelligence, Augmented Reality, and Cybersecurity.

- Explain what factors you took into account for the implementation of Industry 4.0.

- Have you implemented Industry 4.0 technologies in your organization?

- Rate from 1 to 5, with 1 being the worst rating and 5 the best rating, the efficiency of logistics management with the current technologies that your company has.

- Rate from 1 to 5, with 1 being “Not at all important” and 5 “Very important”, the level of importance that your company gives to Information Technology (IT) as a facilitating tool in the development of your organization’s strategy.

- On a scale of 1 to 5, where 1 indicates “Totally disagree” and 5 “Totally agree”, check whether your company assigns improvement teams to processes.

- On a scale of 1 to 5, where 1 indicates “Totally disagree” and 5 “Totally agree”, mark if your company controls the processes through a system of indicators.

- On a scale of 1 to 5, where 1 indicates “Totally disagree” and 5 “Totally agree”, mark if your company works on continuous improvement of processes.

- On a scale of 1 to 5, where 1 indicates “Totally disagree” and 5 “Totally agree”, indicate whether your company periodically conducts opinion surveys to staff to evaluate their level of satisfaction in aspects such as: work environment, open atmosphere and communication, participation schemes, training, salary, recognition or professional perspectives.

- On a scale of 1 to 5, where 1 indicates “Totally disagree” and 5 “Totally agree”, indicate if your company makes alliances with other organizations, which help to improve logistics management, derived from external relations.

- On a scale of 1 to 5, where 1 indicates “Totally disagree” and 5 “Totally agree”, indicate whether your company at the time of organizing logistics processes takes into account the needs, expectations, requirements, and customer satisfaction.

- On a scale of 1 to 5, where 1 indicates “Totally disagree” and 5 “Totally agree”, indicate whether your company controls the degree of application of the established logistics procedures.

- On a scale of 1 to 5, where 1 indicates “Totally disagree” and 5 “Totally agree”, indicate whether your company has a method to assess the degree of effectiveness of activities.

4.3. Statistical Analysis

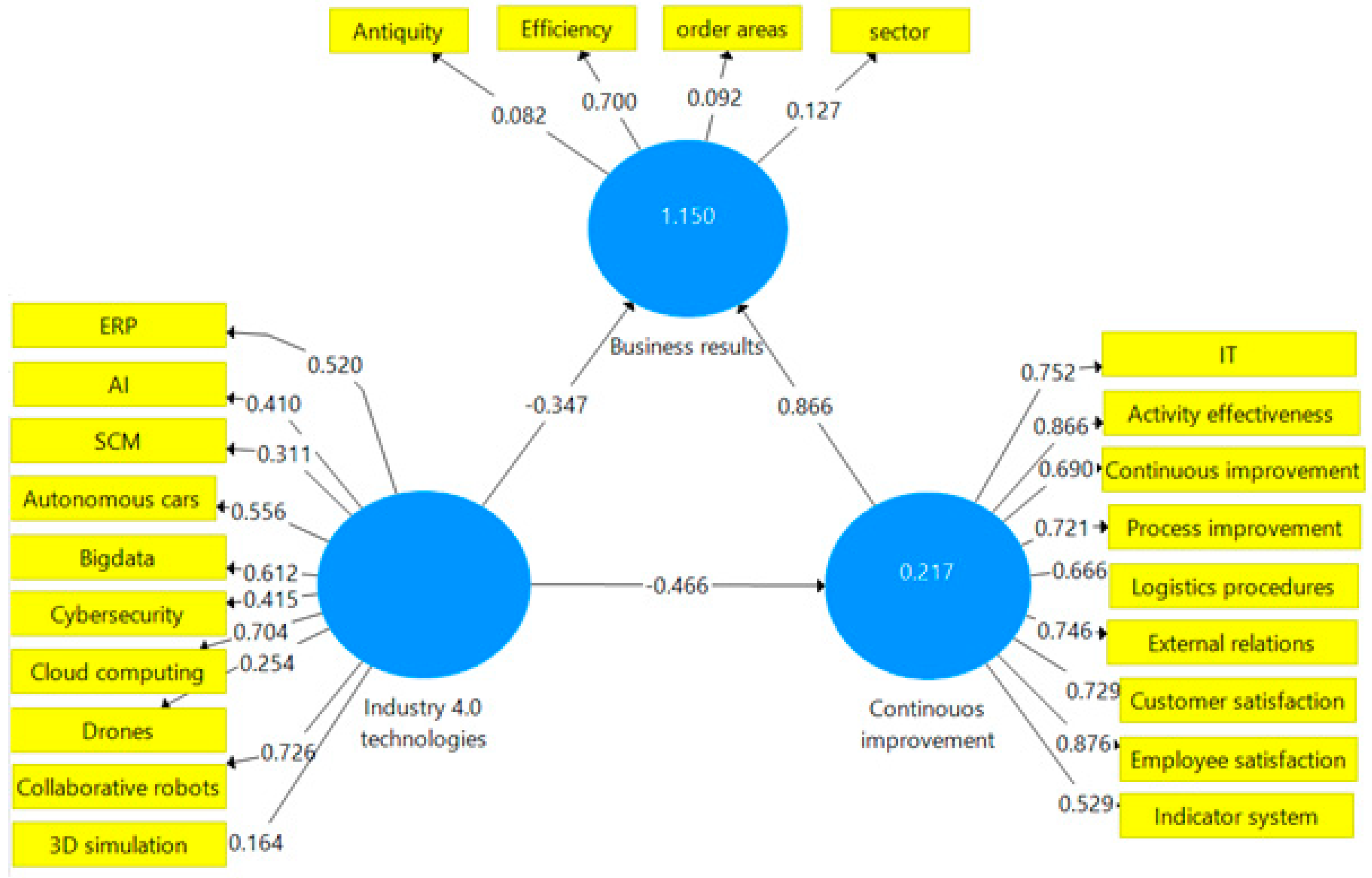

5. Results

- Answer YES or NO, regarding whether the data that your company collects, due to its logistics operation, is analyzed with an Artificial Intelligence tool.

- Regardless of the Industry 4.0 technologies your company has invested in, please state the main reason you believe the investment was made.

- While organizations seem to recognize that technological innovation is necessary to gain competitive advantage, they may not yet have begun implementing disruptive technologies. Order from 1 to 3, the three areas in which you think the investment is most evident.

- Rate from 1 to 5, with 1 being the worst rating and 5 the best rating, the efficiency of logistics management with the current technologies that your company has.

- Rate from 1 to 5, being 1 “Not important” and 5 “Very important”, the level of importance that your company gives to Information Technology (IT) as a facilitating tool in the development of your organization’s strategy.

- On a scale of 1 to 5, where 1 indicates “Strongly disagree” and 5 “Strongly agree”, check whether your company assigns improvement teams to processes.

- On a scale of 1 to 5, where 1 indicates “Totally disagree” and 5 “Totally agree”, mark if your company controls the processes through a system of indicators.

- On a scale of 1 to 5, where 1 indicates “Totally disagree” and 5 “Totally agree”, mark if your company works on continuous improvement of processes.

- On a scale of 1 to 5, where 1 indicates “Totally disagree” and 5 “Totally agree”, indicate whether your company periodically conducts opinion surveys to staff to assess their level of satisfaction in aspects such as: work environment, work environment openness and communication, participation schemes, training, salary, recognition or professional perspectives.

- On a scale of 1 to 5, where 1 indicates “Totally disagree” and 5 “Totally agree”, indicate if your company makes alliances with other organizations that help improve logistics management, derived from external relations.

- On a scale of 1 to 5, where 1 indicates “Totally disagree” and 5 “Totally agree”, indicate whether your company at the time of organizing logistics processes takes into account the needs, expectations, requirements, and customer satisfaction.

- On a scale of 1 to 5, where 1 indicates “Totally disagree” and 5 “Totally agree”, indicate whether your company controls the degree of application of the established logistics procedures.

- On a scale of 1 to 5, where 1 indicates “Totally disagree” and 5 “Totally agree”, indicate whether your company has a method to assess the degree of effectiveness of activities.

6. Discussion

7. Conclusions

- The new technologies of Industry 4.0 positively impact business results.

- The new technologies of Industry 4.0 promote continuous improvement.

- Continuous improvement leads to higher business results.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Porter, M.E. Competitive Advantage: Creating and Sustaining Superior Performance; Rei Argentina S.A: Buenos Aires, Argentina, 1991. [Google Scholar]

- del Val Román, J.L. Industry 4.0: The Digital Transformation of Industry; Conference of Directors and Deans of Computer Engineering; Faculty of Engineering of the University of Deusto: Bilbao, Spain, 2016; Available online: http://coddii.org/wp-content/uploads/2016/10/Informe-CODDII-Industria-4.0.pdf (accessed on 15 June 2021).

- González, L.G.; Díaz, C.A.C.; Gómez, N.L.G. ERP’s (Business Resource Planning) in Large and Medium-Sized Companies Allow a Competitive Advantage. 2017, pp. 1035–1054. Available online: https://www.riico.net/index.php/riico/article/view/1489/1149 (accessed on 20 July 2021).

- Quispe-Otocama, A.M.; Padilla-Martínez, M.P.; Telot-González, J.A.; Nogueira-Rivera, D. Information and communication technologies in business management of pymes commercial. Ing. Ind. 2017, 38, 81–92. [Google Scholar]

- Riascos-Erazo, S.C.; Arias-Cardona, V.H. Analysis of organizational impact on the process of implementation of ERP Information Systems-Case Study. Entramado 2016, 12, 284–302. [Google Scholar] [CrossRef]

- MBedón, I.C.; Piedrahita, L.O.C. Resource planning systems of public companies. Pro-Sci. Rev. De Prod. Cienc. E Investig. 2019, 3, 21–28. [Google Scholar]

- Silva, J.D. Supply chain management: A review from logistics and the environment. Entre Cienc. E Ing. 2017, 11, 51–59. [Google Scholar]

- Mesa, J.I.; Carreño, D.A. Methodology to apply Lean in supply chain management. Espacios 2020, 41, 30. [Google Scholar]

- Bowersox, D.J.; Closs, D.J.; Cooper, M.B. Supply Chain Logistics Management; McGraw-Hill: México, Mexico, 2002; Available online: https://books.google.com.ni/books?id=9Gu1AAAAIAAJ (accessed on 15 June 2021).

- Ohno, T. Toyota Production System: Beyond Large-Scale Production, 1st ed.; Productivity Press: Barcelona, Spain, 1991. [Google Scholar]

- Schwartz, M. Synchronizing SCM with smart inventories. Logística 360 2018, 1, 50–52. [Google Scholar]

- di Nardo, M.; Clericuzio, M.; Murino, T.; Sepe, C. An Economic Order Quantity Stochastic Dynamic Optimization Model in a Logistic 4.0 Environment. Sustainability 2020, 12, 4075. [Google Scholar] [CrossRef]

- García, L.A.M. Integral Logistics Management. Best Practices in the Supply Chain, 2nd ed.; Ecoe Ediciones: Bogotá, Colombia, 2016. [Google Scholar]

- Basco, A.I.; Beliz, G.; Coatz, D.; Garnero, P. Industry 4.0. Manufacturing the Future; Argentine Industrial Union, Inter-American Development Bank and Institute for the Integration of Latin America and the Caribbean: Buenos Aires, Argentina, 2018. [Google Scholar]

- Rouhiainen, L. Artificial Intelligence: 101 Things You Should Know about Our Future Today; Alienta Editorial: Barcelona, Spain, 2018. [Google Scholar]

- Waltersmann, L.; Kiemel, S.; Stuhlsatz, J.; Sauer, A.; Miehe, R. Artificial Intelligence Applications for Increasing Resource Efficiency in Manufacturing Companies—A Comprehensive Review. Sustainability 2021, 13, 6689. [Google Scholar] [CrossRef]

- Brossi, L.; Dodds, T.; Passeron, E. Artificial Intelligence and Youth Welfare in Latin America; LOM Ediciones: Santiago de Chile, Chile, 2019. [Google Scholar]

- Porcelli, A.M. Artificial intelligence and robotics: Its social, ethical and legal dilemmas. Derecho Glob. Estud. Sobre Derecho Justicia 2020, 6, 49–105. [Google Scholar] [CrossRef]

- Qasem, Y.A.M.; Abdullah, R.; Jusoh, Y.Y.; Atan, R.; Asadi, S. Analyzing Continuance of Cloud Computing in Higher Education Institutions: Should We Stay, or Should We Go? Sustainability 2021, 13, 4664. [Google Scholar] [CrossRef]

- Di Nardo, M. Developing a Conceptual Framework Model of Industry 4.0 for Industrial Management. Ind. Eng. Manag. Syst. 2020, 19, 551–560. [Google Scholar] [CrossRef]

- Osorio Montoya, J.A. Risk Management and Security in Cloud Computing for SMEs; Pilot University of Colombia: Bogotá, Colombia, 2018; pp. 1–11. [Google Scholar]

- Rodríguez, G.S. Cloud computing: Some technical-legal considerations. Rev. Lex 2019, 17, 147–168. [Google Scholar]

- Casado Robledo, M.J. Protecting information has been a constant throughout history. Rev. Española de Control Externo 2020, 22, 88–101. [Google Scholar]

- Caamaño Fernández, E.E.; de J. Herrera Gil, R. Cybersecurity Risk Prevention from the Forensic Audit: Combining Organizational Human Talent; NOVUM, Revista de Ciencias Sociales Aplicadas, National University of Colombia: Manizales, Colombia, 2020; Volume 1, pp. 61–80. [Google Scholar]

- Anitua Galdón, M.G. Autonomous Car Strategies of Automotive Companies and New Players; Comillas Pontifical University: Madrid, Spain, 2019; Available online: https://repositorio.comillas.edu/xmlui/bitstream/handle/11531/27730/TFG-%20Anitua%20GaldoIn%2C%20MariIa%20Gabriela.pdf?sequence=1&isAllowed=y (accessed on 30 May 2021).

- Ramírez, L.A. Autonomous Vehicles; Faculty of Sciences and Technologies, Electronics and Informatics Department, Catholic University “Nuestra Señora de la Asunción: Asunción, Paraguay, 2016; pp. 1–19. [Google Scholar]

- Li, Y.; Díaz, M.; Morantes, S.; Dorati, Y. Autonomous vehicles: Innovation in urban logistics. Rev. RIC 2018, 4, 31–39. [Google Scholar]

- Oppenheimer, A. Every Man for Himself, 1st ed.; Debate: Barcelona, Spain, 2018. [Google Scholar]

- Harari, Y.N. 21 Lessons for the 21st Century; Debate: Barcelona, Spain, 2018. [Google Scholar]

- Addati, G.A.; Pérez Lance, G. Introduction to UAVs, Drones or UAVs for Civil Use; University of CEMA: Buenos Aires, Argentina, 2014; Available online: https://www.econstor.eu/bitstream/10419/130802/1/799216895.pdf (accessed on 10 June 2021).

- Wilson, A. Dominate the Drones, Basic Guide to Start Earning Money with Drones, 1st ed.; Babelcube Inc.: Antioch, Tennessee, 2018. [Google Scholar]

- Guevara-Bonilla, M.; Meza-Leandro, A.S.; Esquivel-Segura, E.A.; Arias-Aguilar, D.; Tapia-Arenas, A.; Masís-Meléndez, F. Use of unmanned aerial vehicles (UAVs) for the monitoring and management on natural resources: A synthesis. Rev. Tecnol. En Marcha 2020, 33, 77–88. [Google Scholar]

- Ojeda Bustamante, W.; Flores Velázquez, J.; Ontiveros Capurata, R.E. Use and Handling of Drones with Applications to the Water Sector, 1st ed.; Mexican Institute of Water Technology: Ciudad de México, Mexico, 2016; Available online: https://www.imta.gob.mx/biblioteca/libros_html/riego-drenaje/uso-y-manejo-de-drones.pdf (accessed on 23 June 2021).

- Joyanes Aguilar, L. Big Data: Analysis of Large Volumes of Data in Organizations, 1st ed.; Alfaomega Grupo Editor S.A: Ciudad de México, Mexico, 2013. [Google Scholar]

- Parada Torralba, P. How Big Data has revolutionized logistics. Big Data 2020. Available online: https://www.iebschool.com/blog/big-data-en-logistica-big-data/ (accessed on 15 May 2021).

- Pape, J.P. Collaborative robots a new era in industrial automation. Pharmatech 2014, 1, 32–33. [Google Scholar]

- Gualtieri, L.; Palomba, I.; Merati, F.A.; Rauch, E.; Vidoni, R. Design of Human-Centered Collaborative Assembly Workstations for the Improvement of Operators’ Physical Ergonomics and Production Efficiency: A Case Study. Sustainability 2020, 12, 3606. [Google Scholar] [CrossRef]

- Continuous Training Course.Collaborative Robotics Application, Mexico D.F, México. 2017. Available online: https://i-ctec.org/wp-content/uploads/2017/02/Tema2_Conociendo-la-Robo%CC%81tica-Colaborativa-1.pdf (accessed on 18 May 2021).

- Del C. Casal Angulo, M. Simulation as a Methodology for Learning Non-Technical Skills in Nursing; Nursing PhD Program; University of Valencia: Valencia, Spain, 2016; Available online: https://core.ac.uk/download/pdf/71059825.pdf (accessed on 8 June 2021).

- Núñez Ricardo, F.J. Using Virtual Reality Simulators in Basic Science Teaching; Faculty of Education and Humanities, Militar University of Nueva Granada: Bogotá, Colombia, 2017; Available online: https://repository.unimilitar.edu.co/bitstream/handle/10654/17077/NuñezRicardoFedericoJavier2017.pdf?sequence=1&isAllowed=y (accessed on 18 July 2021).

- Cantú-González, J.R.; del C. Guardado García, M.; Herrera Balderas, J.L. Process simulation, a perspective in pro to the operational performance. Rev. Iberoam. De Prod. Académica y Gestión Educ. 2016, 3, 1–21. [Google Scholar]

- Torrent-Sellens, J. Industry 4.0 and business results in Spain. Oikonomics 2019, 1, 1–11. [Google Scholar]

- Blanco, R.; Fontodrona, J.; Poveda, C. Industry 4.0: The state of the art. Rev. Econ. Ind. 2017, 1, 151–164. [Google Scholar]

- Ballestero, F.; González Aranda, J.M. The use of disruptive ICTs for improving environmental sustainability and competitiveness. The opportunity represented by LifeWatch ERIC. Sostenibilidad Para La Compet. 2020, 1, 135–146. [Google Scholar]

- Lodgaard, E.; Ingvaldsen, J.A.; Aschehoug, S.; Gamme, I. Barriers to continuous improvement: Perceptions of top managers, middle managers and workers. Procedia CIRP 2016, 41, 1119–1124. [Google Scholar] [CrossRef][Green Version]

- Ghobakhloo, M. Industry 4.0, digitization, and opportunities for sustainability. J. Clean. Prod. 2020, 252, 119869. [Google Scholar] [CrossRef]

- Erol, S.; Jäger, A.; Hold, P.; Ott, K.; Sihn, W. Tangible Industry 4.0: A Scenario-Based Approach to Learning for the Future of Production. Procedia CIRP 2016, 54, 13–18. [Google Scholar] [CrossRef]

- Aznar Crespo, P. Quizzes in Google Forms [Webinar]; University of Alicante: Alicante, Spain, 2021; Available online: https://web.ua.es/es/ice/documentos/formacion/webinares/cuestionarios-en-google-forms.pdf (accessed on 7 June 2021).

- Pacheco Cárdenas, A.S. Proposal for the Implementation of Industry 4.0 in the Manufacturing Sector of Bogotá; Degree Work; Catholic University of Colombia: Bogotá, Colombia, 2020; Available online: https://repository.ucatolica.edu.co/bitstream/10983/25322/1/PROPUESTA%20DE%20IMPLEMENTACI%C3%93N%20DE%20LA%20INDUSTRIAL%204.0%20EN%20EL%20SECTOR%20MANUFACTURERO%20DE%20BOGOT%C3%81.pdf (accessed on 22 June 2021).

- National Association of Businessmen of Colombia. Digital Transformation Survey 2017; ANDI: Bogotá, Colombia, 2017; Available online: http://www.andi.com.co/Uploads/Encuesta%20Transformaci%C3%B3n%20Digital%20ANDI.pdf (accessed on 29 May 2021).

- Cano Olivos, P.; Orue Carrasco, F.; Martínez Flores, J.L.; Mayett Moreno, Y.; López Nava, G. Logistics management model for small and medium-sized companies in Mexico. Contaduría y Adm. 2015, 60, 181–203. [Google Scholar]

- Bravo Alay, K.V.; Martillo Fernández, K.E. Circular Economy and Industry 4.0 as a Strategy for International Trade in Ecuador; University of Guayaquil Faculty of Administrative Sciences: Guayaquil, Ecuador, 2019; Available online: http://repositorio.ug.edu.ec/handle/redug/45780 (accessed on 18 June 2021).

- Garson, G.D. Partial Least Squares: Regression & Structural Equation Models; School of Public & International Affairs. North Carolina State University: Asheboro, NC, USA, 2016; Available online: https://www.smartpls.com/resources/ebook_on_pls-sem.pdf (accessed on 30 June 2021).

- Otzen, T.; Manterola, C. Sampling Techniques on a Population Study. Int. J. Morphol. 2017, 35, 227–232. [Google Scholar] [CrossRef]

- University of Cordoba. Data Analysis Using Computerized Procedures. Introduction to SPSS. 1st Psychopedagogy (Academic Year 2009/2010). University of Córdoba. Faculty of Education Sciences. 2010. Available online: http://www.uco.es/dptos/educacion/invadiv/images/stories/documentos/METODOS/RECURSOS/SPSS.pdf (accessed on 9 May 2021).

- Nahuat Román, B. Influence of Intellectual Capital on Innovation: An Individual-Level Perspective. Nova Sci. 2020, 12, 1–31. [Google Scholar]

- Oviedo, H.C.; Campo-Arias, A. Approach to the use of the alpha coefficient by Cronbach. Rev. Colomb. De Psiquiatr. 2005, 24, 572–580. [Google Scholar]

- Martínez Ortega, R.M.; Tuya Pendás, L.C.; Martínez Ortega, M.; Pérez Abreu, A.; Cánovas, A.M. The correlation coefficient of the Spearman ranks characterization. Rev. Habanera De Cienc. Médicas 2009, 8. Available online: http://scielo.sld.cu/scielo.php?script=sci_arttext&pid=S1729-519X2009000200017 (accessed on 9 June 2021).

- Angelo, D.L.; Neves, A.N.; Correa, M.; Sermarine, M.; Zanetti, M.C.; Brandao, M.R.F. Psychometric Properties of the Perfectionism for Sports Performance Scale (PPS-S) for the brazilian context. Cuad. De Psicol. Del Deporte 2019, 19, 1–11. [Google Scholar] [CrossRef]

- Méndez-Giménez, A.; Fernández-Río, J.; Cecchini-Estrada, J.A. Validation of the Spanish version of the Friendship Goals Questionnaire in Physical Education. Univ. Psychol. 2014, 13, 227–238. [Google Scholar]

| Author and Year | Advantage |

|---|---|

| Lambert and Cooper (2000) | The management of all channel inventories, trying to concentrate efforts on reducing those that contribute, to a minor extent, to the total profit expected by the members of the chain. |

| Cavinato (1991), Shrank y Govindarajan (1992), and New (1997) | Reduction in total costs of the supply chain, as a consequence of the lower volume of inventories, which implies a lower cost of storage and capital investment and also higher labor productivity. |

| Cavinato (1991), Cooper and Ellram (1993), and Christopher (1998) | A long-term time horizon. |

| Cooper and Ellram (1993), Christopher (1998), and Mentzer et al. (2001) | Reduction of the product cycle timing from the raw materials of origin to the finished product that reaches the consumer, thanks to the efficient management of the supply chain elements inventories and information. |

| Christopher, Tan, Kannan, and Handfield | An improvement in customer service, thanks to the increase in product flexibility, a reduction in the necessary assets and a lower cost of supply. |

| Appearance | Advantage |

|---|---|

| Financial and economic | Financially and economically for companies, it represents savings in capital costs, cost control, and marginal benefits. |

| Disaster management | It allows business continuity and resilience, as well as the modernization of business processes. |

| Computing | With this technology, no physical space is needed to be able to store servers and databases, since they are in the ‘cloud’. |

| Cloud Access | Extended access on the network, that is, it works through standard mechanisms that promote their use by thinning client platforms (mobile phones, laptops, PDAs, 16 tablets). |

| Computing resources | Provider computing resources are grouped to serve multiple consumers, using a multi-distributed model with different physical and virtual resources dynamically allocated and reallocated, according to consumer demand. |

| Number | Advantage |

|---|---|

| 1 | By measuring logistics processes, the efficiency of the processes is improved, since a detailed and objective map of the situation and their quality is obtained. |

| 2 | Control of the company assets can be improved: vehicle fleet, stored products, pallets, etc. In this way, distribution operations are optimized, inventory levels are reduced and significant savings in costs and organization timings are obtained. |

| 3 | A segmentation of the demand occurs. If the company integrates Big Data with its CRM (Customer Management program), the needs and interests of buyers can be known. |

| 4 | It allows processes distribution optimization, allowing companies to be more agile. In addition, it offers the opportunity to discover new business models and more efficient delivery ways. |

| 5 | It allows exhaustive real-time monitoring of the status and situation of all products in order, to be able to detect possible incidents, among other things. |

| 6 | It allows to establish business parameters with which demand can be predicted and, in this way, prices adjustments of the products may be transferred to lower logistics costs. |

| 7 | Using real-time data that can be obtained from the traffic and weather situation, the best routes to deliver orders to customers can be calculated. This represents a significant saving for companies and a benefit for customers. |

| Number | Advantage |

|---|---|

| 1 | Supplementation of physical and conventional experimentation, when it is not feasible for various reasons. |

| 2 | It allows to analyze numerous effects by making various alterations. |

| 3 | It allows elements of uncertainty to be included, by admitting questions such as: what would happen if …? |

| 4 | Fast reply-times. |

| 5 | It facilitates the training of personnel and the teaching and learning of complex systems and diverse analyses. |

| 6 | It allows to experiment with new situations and anticipate results. |

| Economic Sectors | Frequency | Percentage | Valid Percentage | Accumulated Percentage |

|---|---|---|---|---|

| Agricultural | 1 | 0.9 | 0.9 | 0.9 |

| Mining | 20 | 18.3 | 18.3 | 19.3 |

| Industrial | 20 | 18.3 | 18.3 | 37.6 |

| Energy | 7 | 6.4 | 6.4 | 44.0 |

| Building | 3 | 2.8 | 2.8 | 46.8 |

| Transport | 6 | 5.5 | 5.5 | 52.3 |

| Communications | 6 | 5.5 | 5.5 | 57.8 |

| Commercial | 10 | 9.2 | 9.2 | 67.0 |

| Tourism | 4 | 3.7 | 3.7 | 70.6 |

| Education | 7 | 6.4 | 6.4 | 77.1 |

| Financial | 6 | 5.5 | 5.5 | 82.6 |

| Solidarity | 1 | 0.9 | 0.9 | 83.5 |

| Healthcare | 3 | 2.8 | 2.8 | 86.2 |

| Cultural | 1 | 0.9 | 0.9 | 87.2 |

| Other | 14 | 12.8 | 12.8 | 100 |

| Total | 109 | 100.0 | 100.0 |

| Range of Employees | Frequency | Percentage | Valid Percentage | Accumulated Percentage |

|---|---|---|---|---|

| Less than 50 | 30 | 27.5 | 27.5 | 27.5 |

| Between 50 and 250 | 56 | 51.4 | 51.4 | 78.9 |

| More than 250 | 23 | 21.1 | 21.1 | 100.0 |

| Total | 109 | 100.0 | 100.0 |

| Age | Frequency | Percentage | Valid Percentage | Accumulated Percentage |

|---|---|---|---|---|

| Less than 5 | 15 | 13.8 | 13.8 | 13.8 |

| Between 5 and 10 | 37 | 33.9 | 33.9 | 47.7 |

| More than 10 | 57 | 52.3 | 52.3 | 100.0 |

| Total | 109 | 100.0 | 100.0 |

| Question | Average | Mode | Standard Deviation | Minimum | Maximum |

|---|---|---|---|---|---|

| 1 | 1.69 | 2 | 0.465 | 1 | 2 |

| 2 | 3.63 | 5 | 1.386 | 1 | 5 |

| 3 | 3.45 | 1 | 2.794 | 1 | 10 |

| 4 | 3.92 | 5 | 1.064 | 1 | 5 |

| 5 | 4.29 | 5 | 0.797 | 1 | 5 |

| 6 | 4.17 | 5 | 0.951 | 1 | 5 |

| 7 | 4.23 | 5 | 0.939 | 1 | 5 |

| 8 | 4.23 | 5 | 0.835 | 1 | 5 |

| 9 | 3.87 | 5 | 1.255 | 1 | 5 |

| 10 | 3.94 | 5 | 1.096 | 1 | 5 |

| 11 | 4.24 | 5 | 0.952 | 1 | 5 |

| 12 | 4.09 | 4 | 0.908 | 1 | 5 |

| 13 | 4.04 | 5 | 1.036 | 1 | 5 |

| Original Sample (O) | Sample Mean (M) | Standard Deviation (STDEV) | t Statistics (l O/STDEV) | p Values | |

|---|---|---|---|---|---|

| Continuous improvement → Business results | 0.600 | 0.586 | 0.079 | 7.602 | 0.000 |

| Industry 4.0 technologies → Continuous improvement | −0.231 | −0.246 | 0.083 | 2.772 | 0.006 |

| Industry 4.0 technologies → Business results | −0.399 | −0.444 | 0.066 | 6.013 | 0.000 |

| Business Results | Continuous Improvement | Industry 4.0 Technologies | |

|---|---|---|---|

| Business results | 0.693 | ||

| Continuous improvement | 0.866 | ||

| Industry 4.0 technologies | −0.347 | −0.466 |

| Cronbach’s Alpha | rho_A | Composite Reliability | Average Variance Extracted (AVE) | |

|---|---|---|---|---|

| Business results | 0.277 | 0.492 | 0.224 | 0.130 |

| Continuous improvement | 0.916 | 0.921 | 0.913 | 0.543 |

| Industry 4.0 technologies | 0.788 | 0.797 | 0.744 | 0.250 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arredondo-Méndez, V.H.; Para-González, L.; Mascaraque-Ramírez, C.; Domínguez, M. The 4.0 Industry Technologies and Their Impact in the Continuous Improvement and the Organizational Results: An Empirical Approach. Sustainability 2021, 13, 9965. https://doi.org/10.3390/su13179965

Arredondo-Méndez VH, Para-González L, Mascaraque-Ramírez C, Domínguez M. The 4.0 Industry Technologies and Their Impact in the Continuous Improvement and the Organizational Results: An Empirical Approach. Sustainability. 2021; 13(17):9965. https://doi.org/10.3390/su13179965

Chicago/Turabian StyleArredondo-Méndez, Víctor Hugo, Lorena Para-González, Carlos Mascaraque-Ramírez, and Manuel Domínguez. 2021. "The 4.0 Industry Technologies and Their Impact in the Continuous Improvement and the Organizational Results: An Empirical Approach" Sustainability 13, no. 17: 9965. https://doi.org/10.3390/su13179965

APA StyleArredondo-Méndez, V. H., Para-González, L., Mascaraque-Ramírez, C., & Domínguez, M. (2021). The 4.0 Industry Technologies and Their Impact in the Continuous Improvement and the Organizational Results: An Empirical Approach. Sustainability, 13(17), 9965. https://doi.org/10.3390/su13179965