Attributional & Consequential Life Cycle Assessment: Definitions, Conceptual Characteristics and Modelling Restrictions

Abstract

:1. Introduction

- Overall, literature is covered throughout the article, and this article considerably covers existing studies and findings, but also goes beyond them. Specifically, the novelty of this work is twofold: Systematic selection of definitions of ALCA and CLCA concepts from existing ones in an elaborate manner and a further explicit and structured specification of different aspects (e.g., which type of mathematical relationships are allowed or can it cover past or future impacts). For each of these aspects, as already mentioned above, we will specify conceptual characteristics and rules that delimit ALCA & CLCA modelling frameworks.

- We envision to present a broader overview than existing studies, as these have selected a definition from certain reference(s) without argumentation, or deal about only some aspects (e.g., only land-use baseline [6]) or mainly only one approach (e.g., only CLCA [7]). The intent is to cover all relevant aspects that were highlighted in literature or were relevant, this in a highly structured way. This completeness is an envisioned novelty. For each studied aspect, the objective is to compare literature considerations, evaluate them and advance reflections beyond literature, thus looking beyond what is currently handled, providing new insight.

2. Specification of Attributional and Consequential LCA Concepts

2.1. Selecting the Most Appropriate Definitions

- (a)

- Logic criterion: the underlying concept should be logic, in the sense that it does not contain contradictions (e.g., a concept that describes that A is bigger than B but also the opposite, is not logic). This does not mean that the concept cannot be abstract.

- (b)

- Name criterion: the concept should be as much as possible in line with the name (e.g., a bad choice in name would be “red bikes” for a concept on blue painted bikes)

- (c)

- Consensus criterion: the definition and concept is supported by a broad community for communication based on consensus (e.g., we call an animal of the species Canis lupus familiaris a “dog” because of convention).

- (d)

- Application criterion: the concept should be in line with the application of the concept (e.g., if a pencil is mainly used to write and not to scratch your back, then the main concept behind a pencil’s utility concerns a tool to write).

2.2. Basic Definition Explanation

2.2.1. Difference between Product System and Product Life Cycle Definitions

3. Different Conceptual Characteristics and Rules for Various Aspects

3.1. Relationships and Boundaries of the Product System

3.1.1. Types of Flows

3.1.2. System Boundaries of Product System

3.1.3. Considered Systematic Cut-Offs in Literature

3.2. Considering Time

3.3. Specify the Product System and Impact Separately or Compare Scenarios

3.4. Additivity-Restricted (ALCA) versus Free Mathematical (CLCA) Modelling Specifications

3.5. How Multifunctionality Is Dealt With

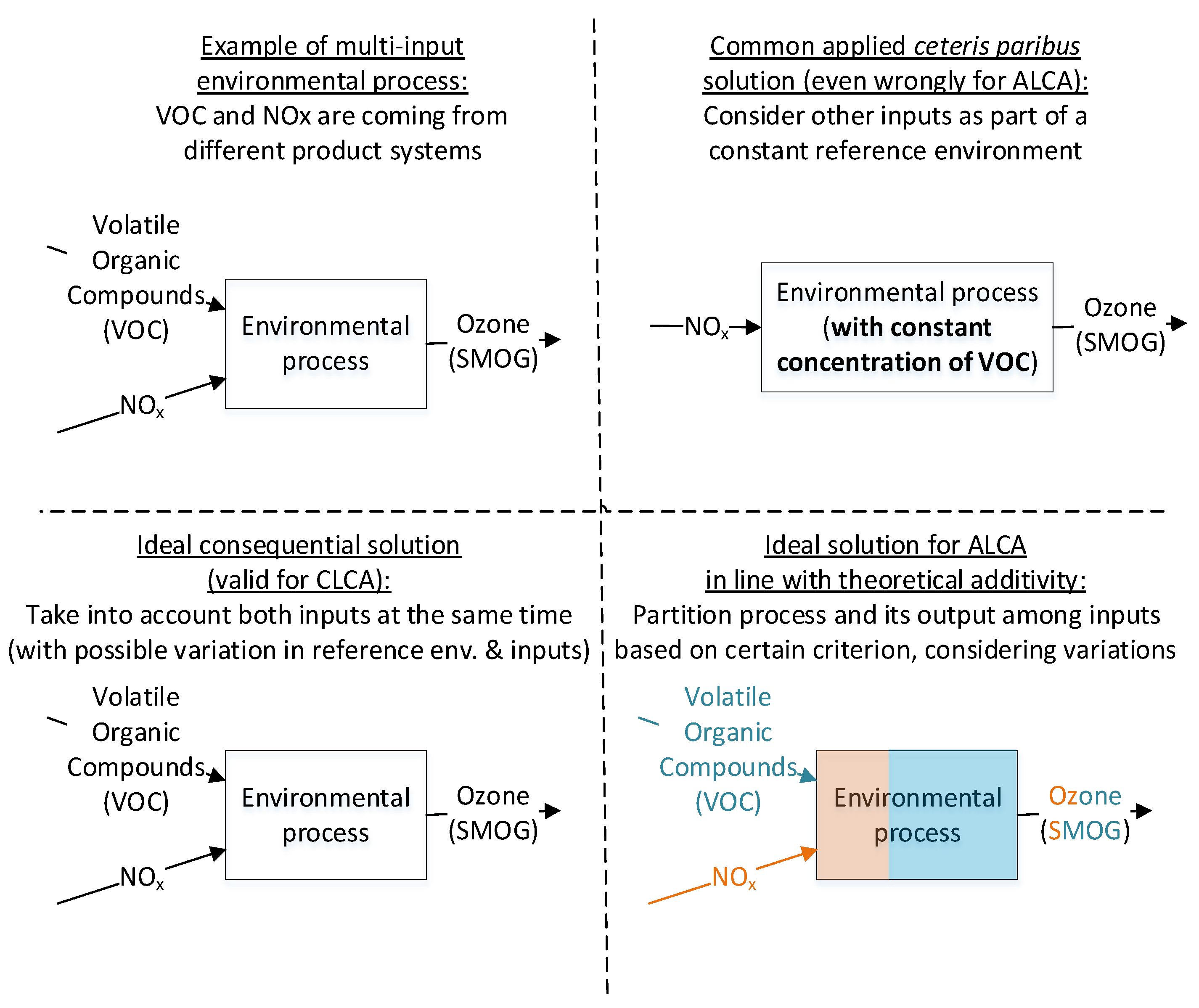

3.5.1. Environmental Multi-Input Processes and How to Deal with This

3.6. Marginal versus Average Considerations

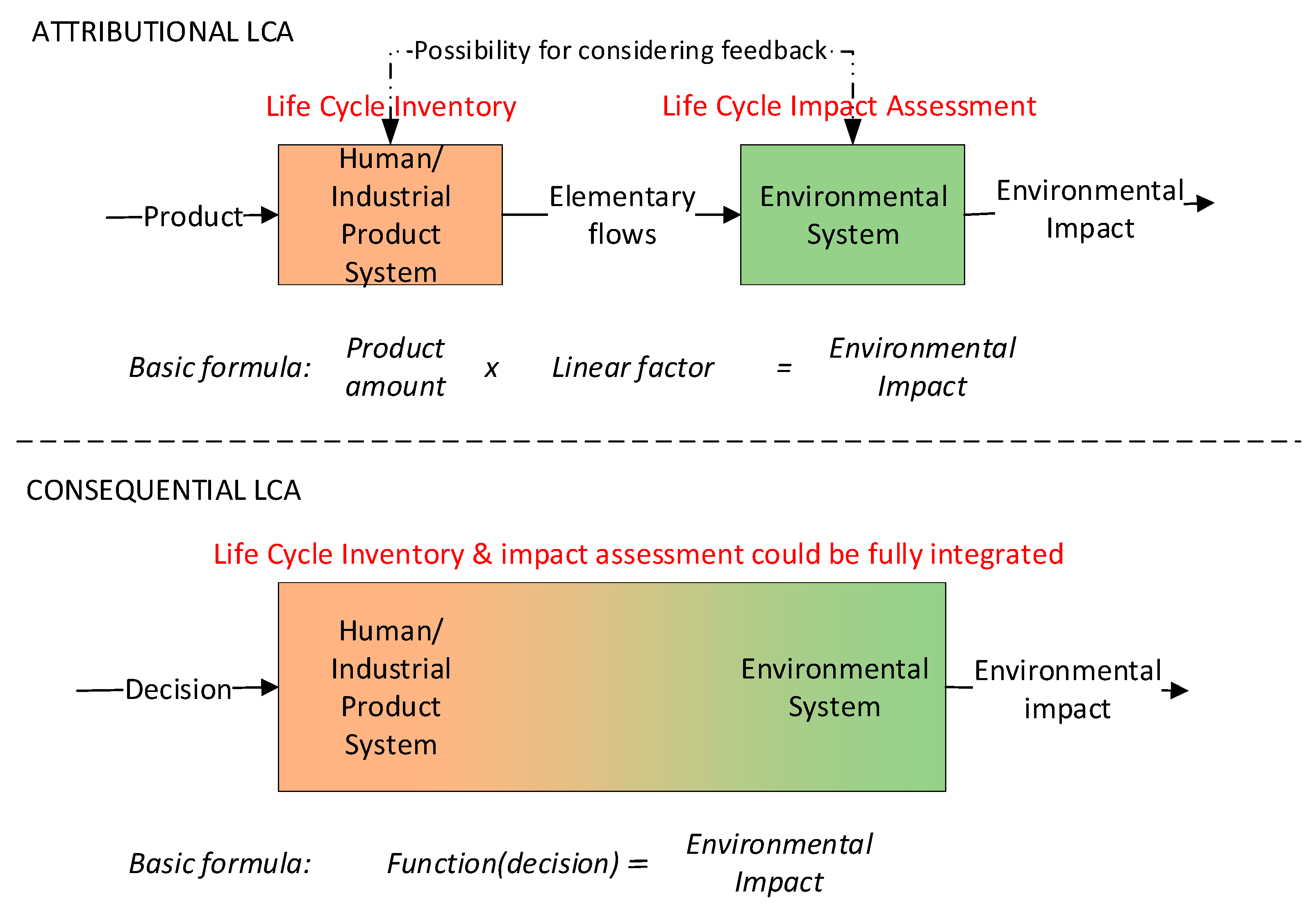

3.7. Complete Framing of Environmental Impact Assessment Coupled with the Product System

- (1).

- restricted modelling, e.g., linear, based on the additivity requirement (see Section 3.4).

- (2).

- should not exceed total, based on the additivity requirement (see Section 3.4).

- (3).

- For environmental multi-input processes, partitioning should be applied with multiple inputs originating from human/industrial system, based on the additivity requirement (see Section 3.5.1).

3.8. Overview of Aspects

3.9. Compliance of ALCA and CLCA with ISO 14040-14044

- (1).

- Decouple the definition of product system and product life cycle, and have an LCA be a study of a product system with exclusion of mentioning of product life cycle. Only for ALCA, a product system would equal a product life cycle. For CLCA, a product system would be possibly different from a product life cycle, and that’s why their definitions need to be independent and that of product system generalized. See also Section 2.2.1 on this matter.

- (2).

- Concerning multifunctionality, the prioritization and limitation of solutions for multifunctionality should be dropped. The first option of subdivision can be kept, although it is in fact rather a prevention of the problem than a solution for it. It should be specified that the solution for multifunctionality is dependent on the goal, which negates this absolute prioritization for any LCA. If desired to further specify solutions, a distinction should best be made between attributional and consequential LCA. Moretti et al. [88], and indirectly Schrijvers et al. [57], also advise to distinguish between these and link multifunctionality solutions to them. Furthermore, it should be mentioned that system expansion is possible for both ALCA and CLCA, and that for CLCA, alternatives are possible, including avoided burden. See also Section 3.5 on this matter. (The recent 2020 amendment of ISO 14044 defines “System expansion avoids allocation by integrating a functionally equivalent product system, that is assumed to be substituted by the co-product (product B), within the system boundary”. However, then system expansion would only be equal to avoided burden or substitution, losing the conceptual idea of expanding the functional unit and the system. There are moreover also other ways to address the effect of co-products in consequential LCA such as product benefit characterization [80].)

3.10. Can an Attributional Model Be Used for a Consequential Concept/Question, or Vice Versa?

- Basic concept related with relation to global burden (Section 2.2): It is imperative to realize that the scope of the modelling is different. An attributional model will propagate the environmental impact of a product life cycle (e.g., that of a car), with it being a share of a global impact. A consequential model will propagate the environmental impact of a decision (e.g., the decision to demand an extra km driven with a car), i.e., the difference in global impact between two plausible worlds: a world with and without that decision (e.g., with and without that extra km driven). The studied systems will differ. An attributional model could be used for a consequential question if the share of the global burden of the ALCA model equals the change induced by a decision as done by the CLCA model. Yet, there is nothing that theoretically guarantees their equality, failing to ensure, from a theoretical perspective, the use of attributional models for a consequential question or vice versa. A comparison of two ALCA model outcomes could be considered, with and without the decision, but the rules (as defined in the ALCA definition; see also Appendix A.3) that specify the shares of the global burden are different from that which define the difference in global impacts between a world with and without the decision.

- Relationships and boundaries of product systems (Section 3.1): An attributional model would fail to cover other types of consequential flows and effects, besides physical and service ones, most notably: information flows. To the contrary, a consequential model would cover too much types of interactions to be for sure in line with the attributional concept.

- The aspect of time (Section 3.2): When considering a product at a certain point in time, an attributional model would also consider the relative past processes that have created that product, whereas this is irrelevant for a consequential LCA concerning a decision to buy that product. The other way around, a consequential model will not cover this relative past. However, an extra demand of a product may induce production of a similar product in the future, as elaborated by Schaubroeck et al. [36], and the past processes could be seen as an approximation for future ones. Yet, for other types of decisions, this is less the case, e.g., a decision to handle waste will less likely induce the new generation of waste. This time consideration remains a considerable difference between both models and may hamper approximation of a consequential question with an attributional model.

- Specify product system separately or in scenarios (Section 3.3): When considered independent from other aspects, whether an attributional model is presented in scenarios or just the product system will not make a difference in the extent to which it can answer a consequential question, or vice versa.

- Constraints in mathematical modelling (Section 3.4): Since there is no limitation for CLCA, an attributional model, which is strictly additive (e.g., linear), is not limited in this regard to answer a consequential question, but it will do so in a more flawed manner than an adequate non-linear model. However, a non-additive consequential model (e.g., certain non-linear ones) may not be used to answer an attributional question, as the ALCA concept restricts models through the additivity requirement.

- Concerning solutions for multifunctionality (Section 3.5): The necessary use of partitioning to address multifunctionality issues in an attributional model causes considerable incompliance with a consequential model. A partitioned or partially finalized process will never be plausible, e.g., as a consequence of a decision, directly or indirectly. For a finalized process, partial inventories cannot be considered realistic. For example, consider the cogeneration process (electricity & heat), with x kg CO2 emitted per production of 1 MJ heat and 0.5 MJ of electricity. When demanding 1 MJ heat, there will always be an emission of x kg CO2 (with a cogeneration of 0.5 MJ of electricity), and not just of x × 1/1.5 MJ CO2, which is an artificial amount. The solutions of a consequential model, e.g., avoided burden, may violate the additivity requirement of ALCA, which makes it also ill advised to use a consequential model to answer an attributional question.

- Marginal versus average considerations (Section 3.6): First of all, average and marginal does not relate to the suppliers of attributional and consequential LCA, respectively. The type of “suppliers” differs, as attributional models will cover interlinked actual suppliers, whereas consequential the ones affected (indirectly) by the decision. It might be that the affected suppliers are the actual interlinked ones, which might seem more plausible for low amounts, but this is not a guaranteed matter. Coming back on the marginal versus average matter, the only limitation for attributional models is that either average or marginal derivations for LCIA should be consistently considered, but this does not hinder its usage to answer a consequential question.

- Framing of the product system and impact assessment (Section 3.7): The LCIA of an attributional model, will also have partitioned processes, creating an issue in its use to answer a consequential question. However, on other matters (e.g., type of relationships or additivity-restricted), there is no issue to answer a consequential question, but there will be a lower adequacy to address all non-linear relationships.

4. Conclusion and Further Outlook

4.1. Relevance of This Work in Hindsight

- (1).

- There are misconceptions of what the concepts entail. For example, CLCA is still recently wrongly considered as a method that is theoretically typical for large-scale decisions [30,102] and/or only additionally considers market mechanisms, such as price changes [25,34,103]. These restrictions would be incorrect from a theoretical perspective, following the definition we argue here (see Table 1).

- (2).

- The main key standard text on LCA, ISO 14040-14044, remains vague and contradictory regarding these methods. The main body of ISO 14040-14044 has a definition of product system that relates with product life cycle (ALCA) but then in annex A of ISO 14040, a definition linked with CLCA is given. Theoretically, it cannot be both. Furthermore, concepts are also brought forward in that annex A that are very close to ALCA and CLCA, but they are not called like that, adding more to the confusion (see Section 3.9).

- (3).

- There seems to be also a tendency of ignoring ALCA and CLCA in literature, which could also be linked with a lack in clarity. Most notably, for the multifunctionality issue, ALCA and CLCA theoretically necessitate different types of solutions, and this has been overlooked or ignored in literature. This has been discussed by Schaubroeck et al. [80] (see also Section 3.5).

4.2. Reflections on Fixing of Definitions

4.3. Overall Discrepancy between ALCA and CLCA

4.4. Other Sustainability Pillars and Aspects

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

Appendix A.1. Overview of Definitions of Key Terms as Used in This Article

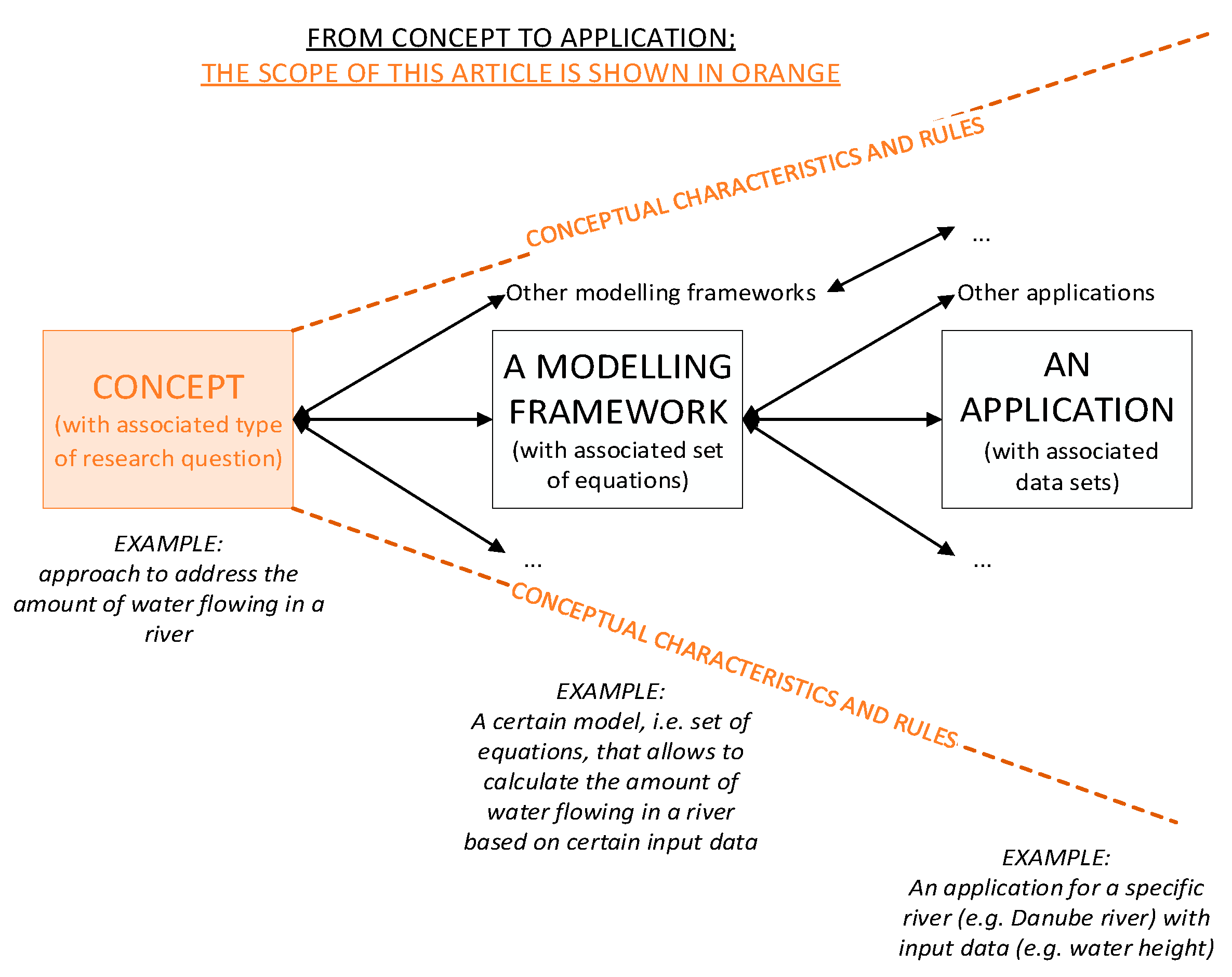

| Term | Definition in dictionary (Cambridge online dictionary 29.01.21) | Specification in this context, based on the definition in the dictionary | Example of Figure 1 | Example in the context of ALCA & CLCA |

|---|---|---|---|---|

| Method/approach | Method: “ a particular way of doing something” Approach: “ a way of considering or doing something” | In this context, we focus on a scientific method that addresses how something will be done in a scientific way. | The Water flow method | e.g., LCA, ALCA, CLCA |

| Concept | Concept: “a principle or idea” “an idea, theory, etc. about a particular subject” | The concept of a method, the point of focus here, implies the theoretical dimension of it. It will specify what that “something” is. It may thus relate with a certain (type of) goal or research question type. | Approach to address the amount of water flowing in a river. | e.g., for CLCA: “The consequential approach attempts to provide information on the environmental burdens that occur, directly or indirectly, as a consequence of a decision (usually represented by changes in demand for a product).” |

| (Conceptual) characteristics | Characteristic: “a typical or noticeable quality of someone or something.” “a typical or noticeable feature of someone or something” | A certain conceptual characteristic of a method, will entail a certain quality or feature of it. | A conceptual characteristic is that it deals with flowing water | e.g., a characteristic of ALCA is that of additivity, as described in Table 1: “In theory, if one were to conduct attributional LCAs of all final products, one would end up with the total observed environmental burdens worldwide” |

| Modelling framework | In the context of mathematics and computing, modelling: “ the activity of using mathematical models (=simple descriptions of a system or process) to make calculations or predict what might happen” Framework: “a system of rules, ideas, or beliefs that is used to plan or decide something” | The modelling framework of a method, the point of focus here, covers the practical manifestation of it. It will entail an operational model based on a set of rules, such as mathematical models. Comment: Because of practical limitations, it can be that a modelling framework does not entirely live up to the theoretical or conceptual requirement of the method. (in fact, it hardly is the case). Moreover, a modelling framework developed for method A, could be considered for method B, but then there might be conflict in certain conceptual aspects not being fulfilled. | A certain model, i.e., set of equations, that allows to calculate the amount of water flowing in a river based on certain input data | The modelling framework for CLCA as presented by Weidema et al. (2013) and operational in Simapro. |

| Application | Application: “ the act of using something for a particular purpose” | In our context, it implies the use of a modelling framework with a certain specific input (e.g., certain input values), providing a specific output (e.g., certain output values). | An application for a specific river (e.g., Danube river) with input data (e.g., water height) | e.g., the application of CLCA to a case on car replacement, as done in the work of Schaubroeck et al. [36] |

| Modelling restrictions | Restriction: “ something that limits someone’s actions or movement, or limits the amount, size, etc., of something” | A restriction imposed on the model (e.g., it can be only additive). In our context, it relates to the restrictions set out by the concept and its characteristics. If a modelling framework does not meet these restrictions, in theory, it does not answer the associated type of research question. | A modelling restriction example is the focus on using physics equations that apply to fluids | e.g., a modelling restriction imposed by the additivity requirement of ALCA, is that a modelling framework should follow that rule (e.g., guaranteed by linearity) |

Appendix A.2. Mathematical Elaboration

Appendix A.2.1. The General Function That Couples Products to Impacts

Appendix A.2.2. Derivation of ALCA Model type, Focusing on a Linear Model

Appendix A.2.3. Derivation of CLCA Model Type, with Optional Linearity

Appendix A.2.4. Contrasting ALCA and CLCA

Appendix A.2.5. In Terms of Conventional Matrix-Based LCA Calculations

Appendix A.3. Rules in CLCA and ALCA

| CLCA | ALCA | |

|---|---|---|

| Basic concept/rule | The direct and indirect environmental burdens of consequences of a decision are assessed—This follows pure consequential thinking. | Defines a portion of the global burden that can be linked with a product life cycle, which is also the product system. What a “portion” and “product life cycle” entail, needs to be explained via additional rules |

| Additional conceptual restrictions/rules | (there are no additional rules. What the product system and impact entail, are based on consequential relationships and follow the basic concept to the letter) | The specification of what a product life cycle encompasses: As presented in Table 1, the product life cycle is defined through the product system as the processes that interlink through physical, energy and service flows with the main process that provides the functional unit (rule 1 & rule 2). The “portion” is defined through: Theoretical additivity: the sum of all ALCA of all final products should represent total global burden (see Table 1). Moreover, this rule indirectly implies following modelling restrictions (see Section 3.4):

|

Appendix A.4. Overview of Specific and Prominent Novelties of This Work in the Context of ALCA and CLCA

| No. | Section | Novelty |

| 1 | Section 1 and further | The distinction between concepts, modelling frameworks and applications of methods allowing to better define and grasp ALCA and CLCA. In literature these things have been mistaken for one another in the context of ALCA and CLCA. For example, there is the wrong notion that the CLCA concept only covers additional market mechanisms since a lot of applications or modelling frameworks focus on these. |

| 2 | Section 2.1 | An elaborate evaluation of definitions using criteria, striving for objectivity, going beyond a mere biased selection of definitions. In literature, a thoroughly argued selection based on various criteria is lacking to the best of our knowledge. |

| 3 | Section 2.2.1 | Pointing out that the definition of product system according to CLCA and that of ALCA as product life cycle, are not the same, and that the ISO 14040 is contradictory in presenting in its main body the ALCA definition of product system but a definition aligned with CLCA in its annex A. |

| 4 | Section 3.1 | Whereas it is clear that CLCA covers consequential effects, we have now also specified that in ALCA this is not exclusively as preceding causes are also covered in the product system. This negates recent thinking in literature that ALCA would be consequential [17]. |

| 5 | Section 3.1.2 | While in literature [42] it has been considered that impacts would be finite, we have innovatively argued that these can be infinite. Hence, we have also pointed out that it might be needed to have a certain cut-off. |

| 6 | Section 3.2 | In literature [23], it has already been made apparent that ALCA and CLCA can cover processes and products in the past, present and future. Yet, in our work, we additionally point out that for CLCA this is the relative future after the decision, whereas for ALCA this covers past and future processes relative to the product delivery. |

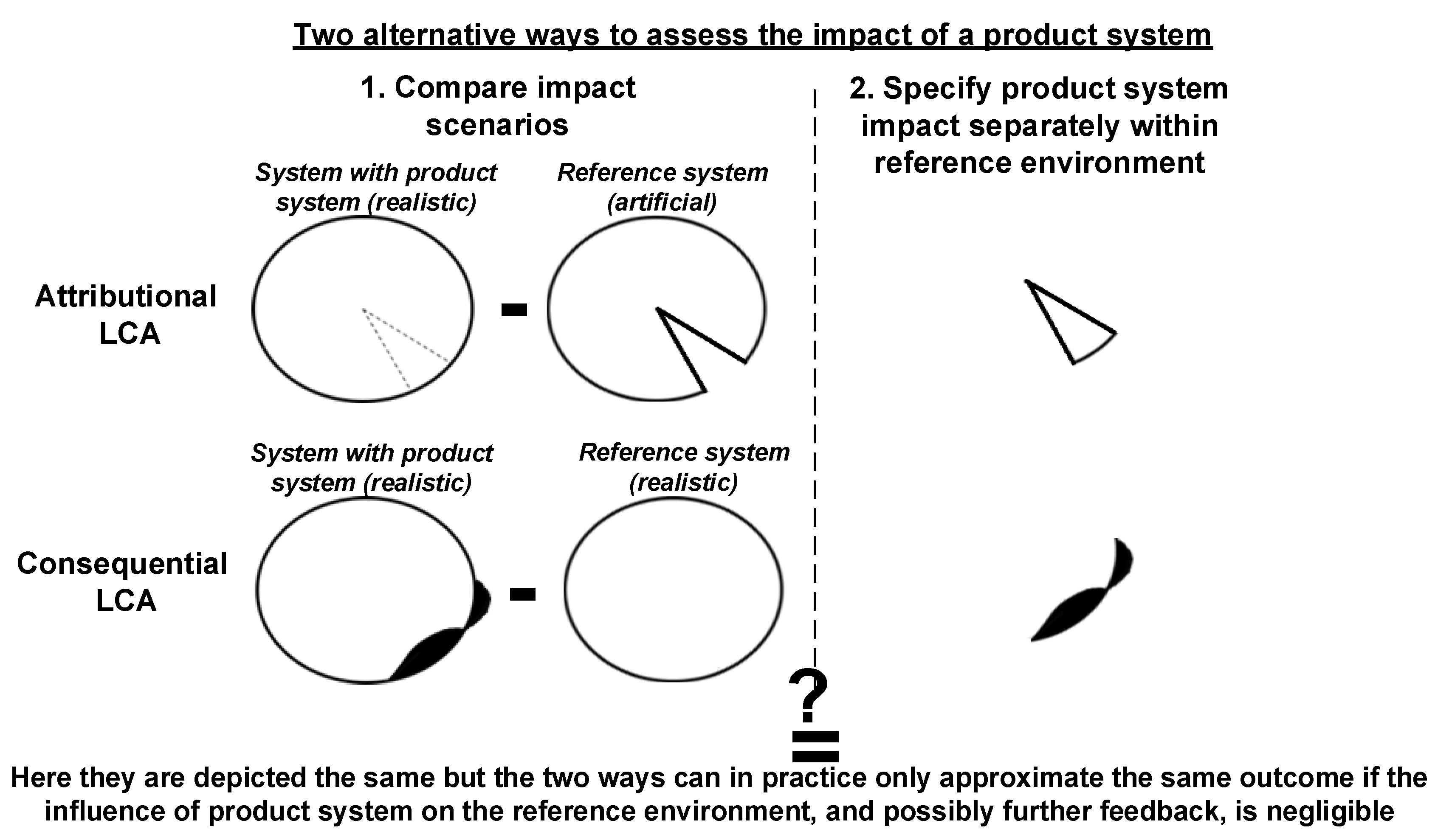

| 7 | Section 3.3 | For a single LCA, we have brought forward that this can be considered both for ALCA and CLCA by (a) the product system and its impact separately, and (b) a difference between scenarios: one with and one without the product system. In case of CLCA these scenarios are both realistic, while for ALCA the one without the product system is artificial. Literature [7] had mainly only focused on scenarios for CLCA. |

| 8 | Section 3.4 | While in literature, CLCA has been brought forward as being restricted to linear modelling [78], we have now clearly specified that it is not the case. We have also pointed out that additivity may be reached by linearity in ALCA, but that other solutions to meet the additivity requirement might exist. Furthermore, we have highlighted the need for a double counting check in ALCA. |

| 9 | Section 3.5 | We have brought forward the overlooked issue of multi-input environmental processes that should also be partitioned in case of ALCA. |

| 10 | Section 3.6 | In literature [43], average is commonly associated with ALCA and marginal with CLCA. We have unraveled that this is not the case and that average and marginal should be considered dependent on the case for ALCA and CLCA. |

| 11 | Section 3.6 | For LCIA, we have pointed out that amount-specific characterization is the ideal solution, and that average and marginal considerations are just approximations. |

| 12 | Section 3.7 | Whereas in literature a distinction between attributional and consequential LCIA is commonly not made, we have brought forward that additional restrictions for attributional LCIA are needed due to additivity restrictions (e.g., partitioning of multi-input environmental processes). |

References

- EU Commission Better Regulation Toolbox. Available online: https://ec.europa.eu/info/law/law-making-process/planning-and-proposing-law/better-regulation-why-and-how/better-regulation-guidelines-and-toolbox/better-regulation-toolbox_en (accessed on 5 February 2020).

- Hellweg, S.; Canals, L.M.I. Emerging Approaches, Challenges and Opportunities in Life Cycle Assessment. Science 2014, 344, 1109–1113. [Google Scholar] [CrossRef]

- Guinée, J.B.; Cucurachi, S.; Henriksson, P.J.G.; Heijungs, R. Digesting the Alphabet Soup of LCA. Int. J. Life Cycle Assess. 2018, 23, 1507–1511. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Porcelli, R.; Marazza, D.; Contin, A.; Righi, S. Subjectivity in the consequential approach to LCA: A review about the interpretation of the concept in literature. In Proceedings of the XIII Convegno della Rete Italiana LCA, Rome, Italy, 13–14 June 2019; pp. 447–452. [Google Scholar]

- Palazzo, J.; Geyer, R.; Suh, S. A Review of Methods for Characterizing the Environmental Consequences of Actions in Life Cycle Assessment. J. Ind. Ecol. 2020, 24, 815–829. [Google Scholar] [CrossRef]

- Soimakallio, S.; Cowie, A.; Brandão, M.; Finnveden, G.; Ekvall, T.; Erlandsson, M.; Koponen, K.; Karlsson, P.-E. Attributional Life Cycle Assessment: Is a Land-Use Baseline Necessary? Int. J. Life Cycle Assess. 2015, 20, 1364–1375. [Google Scholar] [CrossRef]

- Zamagni, A.; Guinée, J.; Heijungs, R.; Masoni, P.; Raggi, A. Lights and Shadows in Consequential LCA. Int. J. Life Cycle Assess. 2012, 17, 904–918. [Google Scholar] [CrossRef]

- Environmental Management—Life Cycle Assessment—Principles and Framework; ISO 14040; ISO: Geneva, Switzerland, 2006.

- Environmental Management—Life Cycle Assessment—Requirements and Guidelines; ISO 14044; ISO: Geneva, Switzerland, 2006.

- de Haes, H.A.U.; Jolliet, O.; Finnveden, G.; Hauschild, M.; Krewitt, W.; Müller-Wenk, R. Best Available Practice Regarding Impact Categories and Category Indicators in Life Cycle Impact Assessment. Int. J. Life Cycle Assess. 1999, 4, 66–74. [Google Scholar] [CrossRef]

- Schaubroeck, T. Towards a General Sustainability Assessment of Human/Industrial and Nature-Based Solutions. Sustain. Sci. 2018, 13, 1185–1191. [Google Scholar] [CrossRef]

- Weidema, B.P.; Schmidt, J.; Fantke, P.; Pauliuk, S. On the Boundary between Economy and Environment in Life Cycle Assessment. Int. J. Life Cycle Assess. 2018, 23, 1839–1846. [Google Scholar] [CrossRef]

- Guinée, J.B.; Heijungs, R.; Huppes, G.; Zamagni, A.; Masoni, P.; Buonamici, R.; Ekvall, T.; Rydberg, T. Life Cycle Assessment: Past, Present, and Future. Environ. Sci. Technol. 2011, 45, 90–96. [Google Scholar] [CrossRef]

- Heijungs, R. Economic Drama and the Environmental Stage: Formal Derivation of Algorithmic Tools for Environmental Analysis and Decision-Support from a Unified Epistemological Principle; Leiden University: Leiden, The Netherlands, 1997. [Google Scholar]

- Schaubroeck, T.; Alvarenga, R.A.F.; Verheyen, K.; Muys, B.; Dewulf, J. Quantifying the Environmental Impact of an Integrated Human/Industrial-Natural System Using Life Cycle Assessment; A Case Study on a Forest and Wood Processing Chain. Environ. Sci. Technol. 2013, 47, 13578–13586. [Google Scholar] [CrossRef] [PubMed]

- Baitz, M.; Albrecht, S.; Brauner, E.; Broadbent, C.; Castellan, G.; Conrath, P.; Fava, J.; Finkbeiner, M.; Fischer, M.; Fullana Palmer, P.I.; et al. LCA’s Theory and Practice: Like Ebony and Ivory Living in Perfect Harmony? Int. J. Life Cycle Assess. 2013, 18, 5–13. [Google Scholar] [CrossRef] [Green Version]

- Yang, Y. A Unified Framework of Life Cycle Assessment. Int. J. Life Cycle Assess. 2019, 24, 620–626. [Google Scholar] [CrossRef]

- Suh, S.; Yang, Y. On the Uncanny Capabilities of Consequential LCA. Int. J. Life Cycle Assess. 2014, 19, 1179–1184. [Google Scholar] [CrossRef] [Green Version]

- Ekvall, T. Moral Philosophy, Economics, and Life Cycle Inventory Analysis; SAE International: Warrendale, PA, USA, 2000. [Google Scholar]

- Tillman, A.-M. Significance of Decision-Making for LCA Methodology. Environ. Impact Assess. Rev. 2000, 20, 113–123. [Google Scholar] [CrossRef] [Green Version]

- Weidema, B.P. Market Information in Life Cycle Assessment; Enviromental Project No. 863; Danish Enviromental Protection Agency: Copenhagen, Denmark, 2003. [Google Scholar]

- Weidema, B.P. Market Aspects in Product Life Cycle Inventory Methodology. J. Clean. Prod. 1993, 1, 161–166. [Google Scholar] [CrossRef]

- Brandão, M.; Martin, M.; Cowie, A.; Hamelin, L.; Zamagni, A. Consequential life cycle assessment: What, how, and why? In Encyclopedia of Sustainable Technologies; Elsevier: Amsterdam, The Netherlands, 2017; pp. 277–284. ISBN 978-0-12-804792-7. [Google Scholar]

- Brander, M. Conceptualising Attributional LCA Is Necessary for Resolving Methodological Issues Such as the Appropriate Form of Land Use Baseline. Int. J. Life Cycle Assess. 2016, 21, 1816–1821. [Google Scholar] [CrossRef] [Green Version]

- Earles, J.M.; Halog, A. Consequential Life Cycle Assessment: A Review. Int. J. Life Cycle Assess. 2011, 16, 445–453. [Google Scholar] [CrossRef]

- Ekvall, T.; Azapagic, A.; Finnveden, G.; Rydberg, T.; Weidema, B.P.; Zamagni, A. Attributional and Consequential LCA in the ILCD Handbook. Int. J. Life Cycle Assess. 2016, 21, 293–296. [Google Scholar] [CrossRef]

- Finnveden, G.; Hauschild, M.Z.; Ekvall, T.; Guinée, J.; Heijungs, R.; Hellweg, S.; Koehler, A.; Pennington, D.; Suh, S. Recent Developments in Life Cycle Assessment. J. Environ. Manag. 2009, 91, 1–21. [Google Scholar] [CrossRef]

- JRC-IES. ILCD Handbook: General Guide for Life Cycle Assessment—Detailed Guidance; Publications Office of the European Union: Luxembourg, 2010. [Google Scholar]

- Plevin, R.J.; Delucchi, M.A.; Creutzig, F. Using Attributional Life Cycle Assessment to Estimate Climate-Change Mitigation Benefits Misleads Policy Makers. J. Ind. Ecol. 2014, 18, 73–83. [Google Scholar] [CrossRef]

- Schuller, O.; Baitz, M.; Saint-Antonin, V.; Collet, P.; Sabathier, J. Attributional vs. Consequential LCA Methodology Overview, Review and Recommendations with Focus on Well-to-Tank and Well-to-Wheel Assessments; EUCar: Etterbeek, Belgium, 2020. [Google Scholar]

- UNEP-SETAC. Global guidance principles for life cycle assessment databases—A basis for greener processes and products. In Shonan Guidance Principles; UNEP-SETAC: Paris, France, 2011. [Google Scholar]

- Attribution—Definition of Attribution in English by Oxford Dictionaries. Available online: https://en.oxforddictionaries.com/definition/attribution (accessed on 21 March 2019).

- Plevin, R.J.; Delucchi, M.A.; Creutzig, F. Response to “On the Uncanny Capabilities of Consequential LCA” by Sangwon Suh and Yi Yang (Int. J. Life Cycle Assess., doi:10.1007/S11367-014-0739-9). Int. J. Life Cycle Assess. 2014, 19, 1559–1560. [Google Scholar] [CrossRef]

- Rajagopal, D. A Step Towards a General Framework for Consequential Life Cycle Assessment. J. Ind. Ecol. 2017, 21, 261–271. [Google Scholar] [CrossRef]

- Sonnemann, G.; Vigon, B.; Baitz, M.; Frischknecht, R.; Krinke, S.; Suppen, N.; Weidema, B.; Wolf, M.-A. The context for global guidance principles for life cycle inventories. In Global Guidance Principles for Life Cycle Assessment Databases—A Basis for Greener Processes and Products—“Shonan Guidance Principles”; UNEP-SETAC: Paris, France, 2011. [Google Scholar]

- Schaubroeck, S.; Schaubroeck, T.; Baustert, P.; Gibon, T.; Benetto, E. When to Replace a Product to Decrease Environmental Impact? A Consequential LCA Framework and Case Study on Car Replacement. Int. J. Life Cycle Assess. 2020, 25, 1500–1521. [Google Scholar] [CrossRef]

- Brander, M.; Burritt, R.L.; Christ, K.L. Coupling Attributional and Consequential Life Cycle Assessment: A Matter of Social Responsibility. J. Clean. Prod. 2019, 215, 514–521. [Google Scholar] [CrossRef] [Green Version]

- Cambridge English Dictionary PHYSICAL—Meaning in the Cambridge English Dictionary. Available online: https://dictionary.cambridge.org/dictionary/english/physical (accessed on 2 March 2020).

- Hertwich, E. Understanding the Climate Mitigation Benefits of Product Systems: Comment on “Using Attributional Life Cycle Assessment to Estimate Climate-Change Mitigation…. ” J. Ind. Ecol. 2014, 18, 464–465. [Google Scholar] [CrossRef]

- Mill, J.S. A System of Logic; Harper: Manhattan, NY, USA, 1843. [Google Scholar]

- Holland, P.W. Statistics and Causal Inference. J. Am. Stat. Assoc. 1986, 81, 945–960. [Google Scholar] [CrossRef]

- Weidema, B.; Grbeš, A.; Miguel, B. The implicit boundary conditions of attributional and consequential LCA. In Proceedings of the ISIE Conference 2015: Taking Stock of Industrial Ecology, Guildford, UK, 7–10 July 2015. [Google Scholar]

- Ekvall, T.; Weidema, B.P. System Boundaries and Input Data in Consequential Life Cycle Inventory Analysis. Int. J. Life Cycle Assess. 2004, 9, 161–171. [Google Scholar] [CrossRef]

- Baustert, P.; Schaubroeck, T.; Navarrete Gutiérrez, T.; Gibon, T.; Benetto, E. System boundaries in CLCA and the link with uncertainty—A case study on mobility policies in Luxembourg. In Proceedings of the 23nd SETAC Europe LCA Case Study Symposium, Barcelona, Spain, 27–28 November 2017. [Google Scholar]

- Schaubroeck, T.; Baustert, P.; Igos, E.; Benetto, E. Is a Sustainability Assessment a Shot in the Dark? How to Deal with Its Nonquantified Uncertainty? Environ. Sci. Technol. 2020, 54, 2051–2053. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Brandão, M.; Clift, R.; Cowie, A.; Greenhalgh, S. The Use of Life Cycle Assessment in the Support of Robust (Climate) Policy Making: Comment on “Using Attributional Life Cycle Assessment to Estimate Climate-Change Mitigation …”. J. Ind. Ecol. 2014, 18, 461–463. [Google Scholar] [CrossRef]

- Hellweg, S.; Hofstetter, T.B.; Hungerbuhler, K. Discounting and the Environment Should Current Impacts Be Weighted Differently than Impacts Harming Future Generations? Int. J. Life Cycle Assess. 2003, 8, 8. [Google Scholar] [CrossRef]

- Levasseur, A.; Brandão, M.; Lesage, P.; Margni, M.; Pennington, D.; Clift, R.; Samson, R. Valuing Temporary Carbon Storage. Nat. Clim. Chang. 2011, 2, 6–8. [Google Scholar] [CrossRef]

- Levasseur, A.; Lesage, P.; Margni, M.; Deschênes, L.; Samson, R. Considering Time in LCA: Dynamic LCA and Its Application to Global Warming Impact Assessments. Environ. Sci. Technol. 2010, 44, 3169–3174. [Google Scholar] [CrossRef]

- Schaubroeck, T.; Rugani, B. A Revision of What Life Cycle Sustainability Assessment Should Entail: Towards Modeling the Net Impact on Human Well-Being. J. Ind. Ecol. 2017, 21, 1464–1477. [Google Scholar] [CrossRef] [Green Version]

- Schrijvers, D.L.; Loubet, P.; Sonnemann, G. Developing a Systematic Framework for Consistent Allocation in LCA. Int. J. Life Cycle Assess. 2016, 1–18. [Google Scholar] [CrossRef]

- Schrijvers, D.L.; Loubet, P.; Sonnemann, G. Critical Review of Guidelines against a Systematic Framework with Regard to Consistency on Allocation Procedures for Recycling in LCA. Int. J. Life Cycle Assess. 2016, 21, 994–1008. [Google Scholar] [CrossRef]

- Weidema, B.P. In Search of a Consistent Solution to Allocation of Joint Production. J. Ind. Ecol. 2018, 22, 252–262. [Google Scholar] [CrossRef]

- Weidema, B.P.; Bauer, C.; Hischier, R.; Mutel, C.; Nemecek, T.; Reinhard, J.; Vadenbo, C.; Wernet, G. Overview and Methodology: Data Quality Guidelines for the Ecoinvent Database Version 3; Ecoinvent Report 1 (v3); The Ecoinvent Centre: Zurich, Switzerland, 2013. [Google Scholar]

- Wernet, G.; Bauer, C.; Steubing, B.; Reinhard, J.; Moreno-Ruiz, E.; Weidema, B. The Ecoinvent Database Version 3 (Part I): Overview and Methodology. Int. J. Life Cycle Assess. 2016, 21, 1218–1230. [Google Scholar] [CrossRef]

- Schrijvers, D. Evaluation Environnementale Des Options de Recyclage Selon La Méthodologie D’analyse de Cycle de Vie: Établissement D’une Approche Cohérente Appliquée Aux Études de Cas de l’industrie Chimique. Ph.D. Thesis, Université de Bordeaux, Bordeaux, France, 2017. [Google Scholar]

- Schrijvers, D.; Loubet, P.; Sonnemann, G. Archetypes of Goal and Scope Definitions for Consistent Allocation in LCA. Sustainability 2020, 12, 5587. [Google Scholar] [CrossRef]

- Cardellini, G.; Mutel, C.L.; Vial, E.; Muys, B. Temporalis, a Generic Method and Tool for Dynamic Life Cycle Assessment. Sci. Total Environ. 2018, 645, 585–595. [Google Scholar] [CrossRef] [PubMed]

- Collinge, W.O.; Landis, A.E.; Jones, A.K.; Schaefer, L.A.; Bilec, M.M. Dynamic Life Cycle Assessment: Framework and Application to an Institutional Building. Int. J. Life Cycle Assess. 2013, 18, 538–552. [Google Scholar] [CrossRef]

- Pigné, Y.; Gutiérrez, T.N.; Gibon, T.; Schaubroeck, T.; Popovici, E.; Shimako, A.H.; Benetto, E.; Tiruta-Barna, L. A Tool to Operationalize Dynamic LCA, Including Time Differentiation on the Complete Background Database. Int. J. Life Cycle Assess. 2020, 25, 267–279. [Google Scholar] [CrossRef] [Green Version]

- Tiruta-Barna, L.; Pigné, Y.; Navarrete Gutiérrez, T.; Benetto, E. Framework and Computational Tool for the Consideration of Time Dependency in Life Cycle Inventory: Proof of Concept. J. Clean. Prod. 2016, 116, 198–206. [Google Scholar] [CrossRef]

- Soimakallio, S.; Brandão, M.; Ekvall, T.; Cowie, A.; Finnveden, G.; Erlandsson, M.; Koponen, K.; Karlsson, P.-E. On the Validity of Natural Regeneration in Determination of Land-Use Baseline. Int. J. Life Cycle Assess. 2016, 21, 448–450. [Google Scholar] [CrossRef]

- Koellner, T.; de Baan, L.; Beck, T.; Brandão, M.; Civit, B.; Margni, M.; Canals, L.M.I.; Saad, R.; de Souza, D.M.; Müller-Wenk, R. UNEP-SETAC Guideline on Global Land Use Impact Assessment on Biodiversity and Ecosystem Services in LCA. Int. J. Life Cycle Assess. 2013, 18, 1188–1202. [Google Scholar] [CrossRef] [Green Version]

- Heijungs, R. Is Mainstream LCA Linear? Int. J. Life Cycle Assess. 2020, 25, 1872–1882. [Google Scholar] [CrossRef]

- Suh, S.; Huppes, G. Methods for Life Cycle Inventory of a Product. J. Clean. Prod. 2005, 13, 687–697. [Google Scholar] [CrossRef]

- Merciai, S. An Input-Output Model in a Balanced Multi-Layer Framework. Resour. Conserv. Recycl. 2019, 150, 104403. [Google Scholar] [CrossRef]

- Merciai, S.; Schmidt, J. Methodology for the Construction of Global Multi-Regional Hybrid Supply and Use Tables for the EXIOBASE v3 Database. J. Ind. Ecol. 2018, 22, 516–531. [Google Scholar] [CrossRef] [Green Version]

- Suh, S.; Weidema, B.; Schmidt, J.H.; Heijungs, R. Generalized Make and Use Framework for Allocation in Life Cycle Assessment. J. Ind. Ecol. 2010, 14, 335–353. [Google Scholar] [CrossRef]

- Heijungs, R. Towards eco-efficiency with LCA’s prevention principle: An epistemological foundation of LCA using axioms. In Product Innovation and Eco-Efficiency; Springer: Berlin/Heidelberg, Germany, 1998; pp. 175–185. [Google Scholar]

- Müller, H.-G.; Wu, Y.; Yao, F. Continuously Additive Models for Nonlinear Functional Regression. Biometrika 2013, 100, 607–622. [Google Scholar] [CrossRef] [Green Version]

- Ma, H.; Zhu, Z. Continuously Dynamic Additive Models for Functional Data. J. Multivar. Anal. 2016, 150, 1–13. [Google Scholar] [CrossRef]

- Beck, N.; Jackman, S. Beyond Linearity by Default: Generalized Additive Models. Am. J. Polit. Sci. 1998, 42, 596–627. [Google Scholar] [CrossRef]

- Biedermann, S.; Dette, H.; Woods, D.C. Optimal Design for Additive Partially Nonlinear Models. Biometrika 2011, 98, 449–458. [Google Scholar] [CrossRef] [Green Version]

- Weidema, B.P.; Pizzol, M.; Schmidt, J.H.; Thoma, G. Social Responsibility Is Always Consequential-Rebuttal to Brander, Burritt and Christ (2019): Coupling Attributional and Consequential Life Cycle Assessment: A Matter of Social Responsibility. J. Clean. Prod. 2019. [Google Scholar] [CrossRef]

- Arvesen, A.; Luderer, G.; Pehl, M.; Bodirsky, B.L.; Hertwich, E.G. Deriving Life Cycle Assessment Coefficients for Application in Integrated Assessment Modelling. Environ. Model. Softw. 2018, 99, 111–125. [Google Scholar] [CrossRef]

- Marvuglia, A.; Benetto, E.; Rege, S.; Jury, C. Modelling Approaches for Consequential Life-Cycle Assessment (C-LCA) of Bioenergy: Critical Review and Proposed Framework for Biogas Production. Renew. Sustain. Energy Rev. 2013, 25, 768–781. [Google Scholar] [CrossRef]

- Yang, Y.; Heijungs, R. On the Use of Different Models for Consequential Life Cycle Assessment. Int. J. Life Cycle Assess. 2017, 23, 751–758. [Google Scholar] [CrossRef]

- Weidema, B.; Ekvall, T.; Heijungs, R. Guidelines for Applications of Deepened and Broadened LCA; Deliverable; LCA: Hendersonville, TN, USA, 2009.

- Heimersson, S.; Svanström, M.; Ekvall, T. Opportunities of Consequential and Attributional Modelling in Life Cycle Assessment of Wastewater and Sludge Management. J. Clean. Prod. 2019, 222, 242–251. [Google Scholar] [CrossRef]

- Schaubroeck, T.; Gibon, T.; Igos, E.; Benetto, E. Sustainability Assessment of Circular Economy over Time: Modelling of Finite and Variable Loops & Impact Distribution among Related Products. Resour. Conserv. Recycl. 2021, 168, 105319. [Google Scholar] [CrossRef]

- Majeau-Bettez, G.; Dandres, T.; Pauliuk, S.; Wood, R.; Hertwich, E.; Samson, R.; Strømman, A.H. Choice of Allocations and Constructs for Attributional or Consequential Life Cycle Assessment and Input-Output Analysis. J. Ind. Ecol. 2018, 22, 656–670. [Google Scholar] [CrossRef]

- Weidema, B.P.; Schmidt, J.H. Avoiding Allocation in Life Cycle Assessment Revisited. J. Ind. Ecol. 2010, 14, 192–195. [Google Scholar] [CrossRef]

- Majeau-Bettez, G.; Wood, R.; Strømman, A.H. Unified Theory of Allocations and Constructs in Life Cycle Assessment and Input-Output Analysis. J. Ind. Ecol. 2014, 18, 747–770. [Google Scholar] [CrossRef]

- Schaubroeck, T.; Benetto, E. A need for a better characterisation of product benefit in life cycle sustainability assessment. In Proceedings of the SETAC Europe 28th Annual Meeting, Rome, Italy, 13 May 2018. [Google Scholar]

- Cherubini, F.; Strømman, A.H.; Ulgiati, S. Influence of Allocation Methods on the Environmental Performance of Biorefinery Products—A Case Study. Resour. Conserv. Recycl. 2011, 55, 1070–1077. [Google Scholar] [CrossRef]

- Wardenaar, T.; van Ruijven, T.; Beltran, A.M.; Vad, K.; Guinée, J.; Heijungs, R. Differences between LCA for Analysis and LCA for Policy: A Case Study on the Consequences of Allocation Choices in Bio-Energy Policies. Int. J. Life Cycle Assess. 2012, 17, 1059–1067. [Google Scholar] [CrossRef] [Green Version]

- Weidema, B.P. Estimation of the Size of Error Introduced into Consequential Models by Using Attributional Background Datasets. Int. J. Life Cycle Assess. 2017, 22, 1241–1246. [Google Scholar] [CrossRef]

- Moretti, C.; Corona, B.; Edwards, R.; Junginger, M.; Moro, A.; Rocco, M.; Shen, L. Reviewing ISO Compliant Multifunctionality Practices in Environmental Life Cycle Modeling. Energies 2020, 13, 3579. [Google Scholar] [CrossRef]

- Atkinson, R. Atmospheric Chemistry of VOCs and NOX. Atmos. Environ. 2000, 34, 2063–2101. [Google Scholar] [CrossRef]

- Heijungs, R.; Guinée, J.B.; Huppes, G.; Lankreijer, R.M.; Udo de Haes, H.A.; Wegener Sleeswijk, A.; Ansems, A.M.M.; Eggels, P.G.; van Duin, R.; de Goede, H.P.; et al. Environmental Life Cycle Assessment of Products: Guide and Backgrounds (Part 1); CML: Leiden, The Netherlands, 1992. [Google Scholar]

- Cambridge English Dictionary Marginal. Available online: https://dictionary.cambridge.org/dictionary/english/marginal (accessed on 8 June 2021).

- Wikipedia. Marginal Concepts; Wikipedia: San Francisco, CA, USA, 2020. [Google Scholar]

- Marginal—Definition of Marginal by Oxford Dictionary on Lexico.Com Also Meaning of Marginal. Available online: https://www.lexico.com/definition/marginal (accessed on 14 June 2021).

- Pizzol, M.; Scotti, M. Identifying Marginal Supplying Countries of Wood Products via Trade Network Analysis. Int. J. Life Cycle Assess. 2016, 22, 1146–1158. [Google Scholar] [CrossRef]

- Sacchi, R. A Trade-Based Method for Modelling Supply Markets in Consequential LCA Exemplified with Portland Cement and Bananas. Int. J. Life Cycle Assess. 2018, 23, 1966–1980. [Google Scholar] [CrossRef]

- Boulay, A.-M.; Benini, L.; Sala, S. Marginal and Non-Marginal Approaches in Characterization: How Context and Scale Affect the Selection of an Adequate Characterization Model. The AWARE Model Example. Int. J. Life Cycle Assess. 2019. [Google Scholar] [CrossRef]

- Forin, S.; Berger, M.; Finkbeiner, M. Comment to “Marginal and Non-Marginal Approaches in Characterization: How Context and Scale Affect the Selection of an Adequate Characterization Factor: The AWARE Model Example”. Int. J. Life Cycle Assess. 2020. [Google Scholar] [CrossRef]

- Heijungs, R. The Average versus Marginal Debate in LCIA: Paradigm Regained. Int. J. Life Cycle Assess. 2021, 26, 22–25. [Google Scholar] [CrossRef]

- De Meester, S.; Van der Vorst, G.; Van Langenhove, H.; Dewulf, J. Sustainability assessment methods and tools. In Management Principles of Sustainable Industrial Chemistry; Reniers, G.L.L., Sörensen, K., Vrancken, K., Eds.; Wiley-VCH Verlag GmbH & Co. KGaA: Hoboken, NJ, USA, 2013; pp. 55–88. ISBN 978-3-527-64948-8. [Google Scholar]

- Hauschild, M.Z.; Goedkoop, M.; Guinée, J.; Heijungs, R.; Huijbregts, M.; Jolliet, O.; Margni, M.; Schryver, A.D.; Humbert, S.; Laurent, A.; et al. Identifying Best Existing Practice for Characterization Modeling in Life Cycle Impact Assessment. Int. J. Life Cycle Assess. 2013, 18, 683–697. [Google Scholar] [CrossRef]

- Swart, P.; Alvarenga, R.A.F.; Dewulf, J. Abiotic resource use. In Life Cycle Impact Assessment; Hauschild, M.Z., Huijbregts, M.A.J., Eds.; LCA Compendium—The Complete World of Life Cycle Assessment; Springer Netherlands: Dordrecht, The Netherlands, 2015; pp. 247–269. ISBN 978-94-017-9743-6. [Google Scholar]

- JRC-IES. ILCD Handbook: Framework and Requirements for Life Cycle Impact Assessment Models and Indicators; Publications Office of the European Union: Luxembourg, 2010. [Google Scholar]

- Niero, M.; Jensen, C.L.; Fratini, C.F.; Dorland, J.; Jørgensen, M.S.; Georg, S. Is Life Cycle Assessment Enough to Address Unintended Side Effects from Circular Economy Initiatives? J. Ind. Ecol. 2021, in press. [Google Scholar] [CrossRef]

- Zimek, M.; Schober, A.; Mair, C.; Baumgartner, R.J.; Stern, T.; Füllsack, M. The Third Wave of LCA as the “Decade of Consolidation”. Sustainability 2019, 11, 3283. [Google Scholar] [CrossRef] [Green Version]

- Weidema, B.P.; Pizzol, M.; Schmidt, J.; Thoma, G. Attributional or Consequential Life Cycle Assessment: A Matter of Social Responsibility. J. Clean. Prod. 2018, 174, 305–314. [Google Scholar] [CrossRef]

- Schaubroeck, T. The Concept of Cultural Ecosystem Services Should Not Be Abandoned. BioScience 2019. [Google Scholar] [CrossRef]

- Guinée, J. Life cycle sustainability assessment: What is it and what are its challenges? In Taking Stock of Industrial Ecology; Clift, R., Druckman, A., Eds.; Springer International Publishing: Berlin/Heidelberg, Germany, 2016; pp. 45–68. ISBN 978-3-319-20570-0. [Google Scholar]

- Klöpffer, W. Life Cycle Sustainability Assessment of Products. Int. J. Life Cycle Assess. 2008, 13, 89–95. [Google Scholar] [CrossRef]

- Rödger, J.-M.; Kjær, L.L.; Pagoropoulos, A. Life cycle costing: An introduction. In Life Cycle Assessment: Theory and Practice; Hauschild, M.Z., Rosenbaum, R.K., Olsen, S.I., Eds.; Springer International Publishing: Cham, Switzerland, 2018; pp. 373–399. ISBN 978-3-319-56475-3. [Google Scholar]

- Farinha, T. The contribution of terology for a sustainable future. In Proceedings of the 3rd WSEAS International Conference on Energy Planning, Energy Saving, Environmental Education, WSEAS, Canary Islands, Spain, 1–3 July 2009. [Google Scholar]

- Heijungs, R.; Guinée, J. Some fundamentals on ALCA and CLCA. In EcoSD Annual Workshop: Consequential LCA; Presses des Mines: Paris, France, 2015; pp. 41–48. ISBN 978-2-35671-149-6. [Google Scholar]

| Definitions | ||

|---|---|---|

| Which Objective or Question Does It Address? | Specification of Product System | |

| Attributional LCA | “The attributional approach attempts to provide information on what portion of global burdens can be associated with a product c (and its life cycle)” [31] | “The system analysed ideally contains processes that are actually directly linked by (physical a, energy, and service b) flows to the unit process that supplies the functional unit or reference flow” [31] “In theory, if one were to conduct attributional LCAs of all final products, one would end up with the total observed environmental burdens worldwide” [31] |

| Consequential LCA | “The consequential approach attempts to provide information on the environmental burdens that occur, directly or indirectly, as a consequence of a decision (usually represented by changes in demand for a product).” [31] | “In theory, the systems analysed in these LCAs are made up only of processes that are actually affected by the decision, that is, that change their output due to a signal they receive from a cause-and-effect chain whose origin is a particular decision” [31] |

| Example in Which Final and Non-Final Products Are Intended to Be Both Considered and Thus Their ALCA Results Added | |||

|---|---|---|---|

| Global Amount (Fixed) | Example 1 | Example 2 | |

| Amount of Washing product (non-final product) | 25 (used for clothing at 0.005 L per clothing usage, i.e., 200 clothing per L) | 1 L of washing product: implies 200 clothing usage | 10 L of washing product: implies 2000 clothing usages |

| Amount of clothing usage (final product) | 5000 usages of clothing | 4500 usages of clothing | 3500 usages of clothing |

| Recalculated final product of clothing usage amount | 200 + 4500 = 4700 (<5000) | 2000 + 3500 = 5500 (>5000) | |

| Evaluation | Ok for ALCA; no double-counting | not ok for ALCA: double-counting, unless an extrapolated world is considered (with 5500 clothing usages as final products) | |

| Type of Definition | Definition |

|---|---|

| Marginal (small) | “very small in amount or effect” [91] |

| Marginal (change) | “In [economics], marginal concepts are associated with a specific change in the quantity used of a good or service” [92] |

| Marginal (small change) | “relating to or resulting from small or unit changes” [93] |

| ALCA | CLCA | |

|---|---|---|

| LCIA Dataset (e.g., the amount of additional global warming induced) | ideally amount-specific, but in practice marginal or average CF are both possible. This needs to be specified (but should be consistently one of the two) | ideally amount-specific, but in practice marginal or average CF are both possible. This needs to be specified |

| Supplier—special case of effect, focusing on suppliers of products/services | Interlinked suppliers are considered that have provided the product or service during the product life cycle (e.g., electricity mix over period of consumption) | The consequential suppliers that is/are induced by the decision at the global level should be considered, which are not necessarily the interlinked ones (e.g., new supplier that will meet the extra amount of electricity demanded) |

| Decision or Product life cycle (e.g., impact of one specific marginal apple amount or average of the global market) | It can be marginal or average amounts. This needs to be specified | It can be marginal or average amounts. This needs to be specified |

| ALCA | CLCA | |

|---|---|---|

| Basic concept/Relation with global burden (Section 2.2) | Share of the global impact linked with a product life cycle. | Change in global impact induced by a decision and its consequences. |

| Relationships and boundaries of the product system, of which the impact is assessed (Section 3.1) | All processes have interlinked relationships based on physical, energy and service flows, constituting the product life cycle, which is also the product system. The product system can be infinite, and propagated amount as well. | The induced processes (solely consequential) by the decision, constituting the product system. The product system can be infinite, and propagated amount as well. |

| The aspect of time (Section 3.2) | Absolutely: processes can be considered in past, present or future. Relatively: considers processes also before product finalization, i.e., relative past consideration. | Absolutely: Decision and processes can be considered in past, present or future. Relatively: Only considers processes after decision, i.e., no relative past consideration. |

| Specify product system and its impact separately or in scenarios (Section 3.3) | Can be both: Separately: share of human/industrial system and its global impact. Scenario: difference between world and a hypothetical world without product system and its impact. | Can be both: Separately: the additional processes induced by the decision. Scenario: difference between the impact of different realistic scenarios that represent decision choices. |

| Constraints in mathematical modelling due to theoretical concept (Section 3.4) | restricted by additivity (e.g., guaranteed by linearity), necessitating a validity check or consideration of extrapolated world. | Not restricted. |

| How multifunctionality is dealt with (Section 3.5) | Needs to be done through partitioning processes, both for LCI and, in case of environmental multi-input processes, for LCIA. An alternative is system expansion. | The complete processes are considered with additional co-function effects. The latter are dependent on the market, an example of a co-function effect is substitution. An alternative is system expansion. |

| Marginal versus average considerations in the assessment (Section 3.6) | Interlinked suppliers need to be considered. Amount-specific effects is advised but in practice average or marginal impact effects are possible and should be consistently considered. Average or marginal product consideration is possible. | Consequential suppliers need to be considered. Amount-specific effects is advised but in practice average or marginal impact effects are possible. Average or marginal product consideration is possible. |

| Complete framing of environmental impact assessment, coupled with product system (Section 3.7) | Environmental impact assessment is purely consequential (with exception of inventory indicators), but limited by additivity, e.g., necessitating partitioning. This all, necessitates a separate consideration from the product system, due to these other rules. | Environmental impact assessment is completely consequential and unbound, leading to a possibility for full integration with the product system. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schaubroeck, T.; Schaubroeck, S.; Heijungs, R.; Zamagni, A.; Brandão, M.; Benetto, E. Attributional & Consequential Life Cycle Assessment: Definitions, Conceptual Characteristics and Modelling Restrictions. Sustainability 2021, 13, 7386. https://doi.org/10.3390/su13137386

Schaubroeck T, Schaubroeck S, Heijungs R, Zamagni A, Brandão M, Benetto E. Attributional & Consequential Life Cycle Assessment: Definitions, Conceptual Characteristics and Modelling Restrictions. Sustainability. 2021; 13(13):7386. https://doi.org/10.3390/su13137386

Chicago/Turabian StyleSchaubroeck, Thomas, Simon Schaubroeck, Reinout Heijungs, Alessandra Zamagni, Miguel Brandão, and Enrico Benetto. 2021. "Attributional & Consequential Life Cycle Assessment: Definitions, Conceptual Characteristics and Modelling Restrictions" Sustainability 13, no. 13: 7386. https://doi.org/10.3390/su13137386

APA StyleSchaubroeck, T., Schaubroeck, S., Heijungs, R., Zamagni, A., Brandão, M., & Benetto, E. (2021). Attributional & Consequential Life Cycle Assessment: Definitions, Conceptual Characteristics and Modelling Restrictions. Sustainability, 13(13), 7386. https://doi.org/10.3390/su13137386