Effects of Receiver Parameters on Solar Flux Distribution for Triangle Cavity Receiver in the Fixed Linear-Focus Fresnel Lens Solar Concentrator

Abstract

1. Introduction

2. Physical Model and Numerical Method

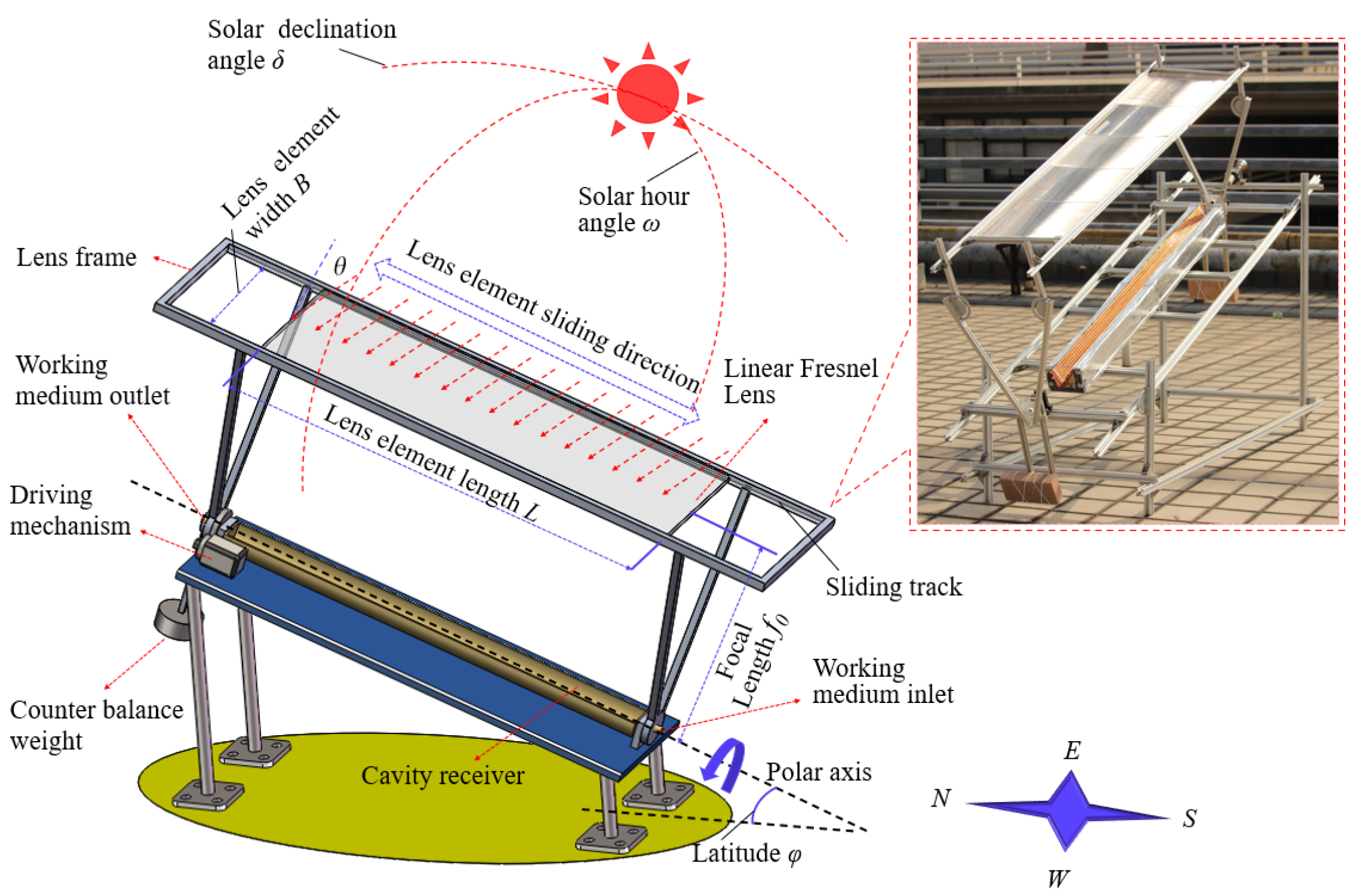

2.1. Physical Model

2.2. Numerical Simulation Model

2.3. Optical Work Validation

2.4. Uniformity Factor (UF)

2.5. Simulation Method

3. Results and Discussion

3.1. Effect of Receiver Position f

3.2. Effect of Receiver Internal Surface Absorptivity αab

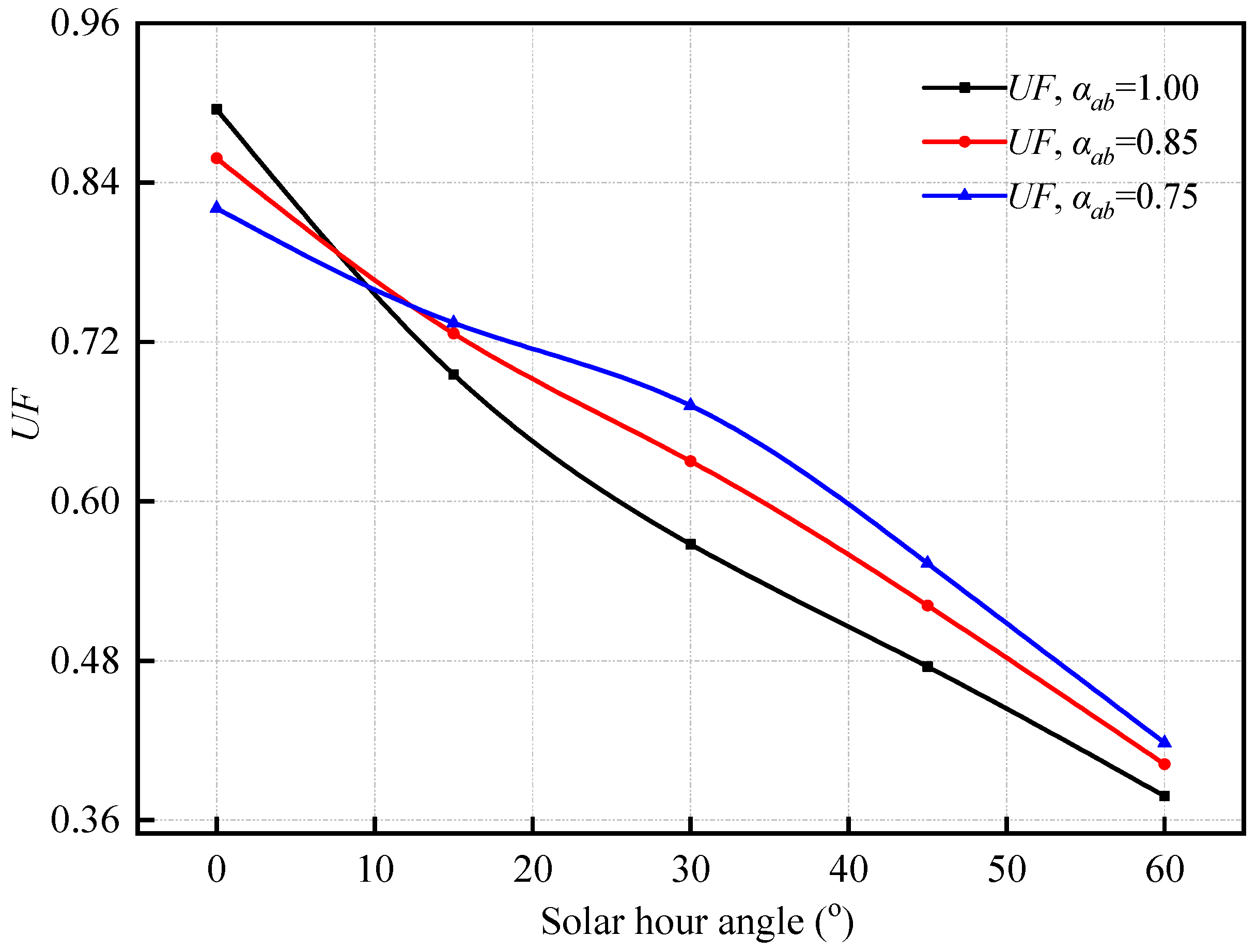

3.3. Effect of End Reflection Plane Reflectivity ρr

3.4. Analysis of Variance

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclatures

| αab | Receiver internal surface absorptivity |

| αtr | Apex angle of triangle cavity receiver (degree) |

| β | Deflection angle of CCD camera |

| δ | Sun declination angle (degree) |

| θ | Incidence angle of direct solar radiation (degree) |

| ρr | End reflection plane reflectivity |

| φ | Local latitude angle (degree) |

| ω | Solar hour angle (degree) |

| B | Lens element width of fixed linear linear-focus Fresnel lens solar concentrator (mm) |

| Btr | Opening width of triangle cavity receiver (mm) |

| f | Receiver position (mm) |

| f0 | Focal length of linear Fresnel lens (mm) |

| Id | Direct radiation value (W/m2) |

| L | Lens element length of fixed linear linear-focus Fresnel lens solar concentrator (mm) |

| Llens | Length of linear Fresnel lens |

| Ltarget | Length of Lambert target |

| Ltr | Opening length of triangle cavity receiver(mm) |

| S0 | Horizontal angle of polar axis (degree) |

| Wlens | Width of linear Fresnel lens |

| Wtarget | Width of Lambert target |

Abbreviations

| FLFLSC | Fixed linear-focus Fresnel lens solar concentrator |

| MCRT | Monte Carlo ray tracing |

| PMMA | Polymethyl methacrylate |

| UF | Uniformity factor |

References

- Bhusal, Y.; Hassanzadeh, A.; Jiang, L.; Winston, R. Technical and economic analysis of a novel low-cost concentrated medium-temperature solar collector. Renew. Energy 2020, 146, 968–985. [Google Scholar] [CrossRef]

- Sarwar, J.; Shad, M.R.; Hasnain, A.; Ali, F.; Kakosimos, K.E.; Ghosh, A. performance analysis and comparison of a concentrated photovoltaic system with different phase change materials. Energies 2021, 14, 2911. [Google Scholar] [CrossRef]

- Pasupathi, M.K.; Alagar, K.; P, M.J.S.; M.M, M.; Aritra, G. Characterization of hybrid-nano/paraffin organic phase change material for thermal energy storage applications in solar thermal systems. Energies 2020, 13, 5079. [Google Scholar] [CrossRef]

- Diao, R.; Sun, L.; Yang, F.; Lin, B. Performance of building energy supply systems using renewable energy. Int. J. Energy Res. 2020, 44, 9960–9973. [Google Scholar] [CrossRef]

- Liu, B.; Zhang, X.; Ji, J. Review on solar collector systems integrated with phase-change material thermal storage technology and their residential applications. Int. J. Energy Res. 2021, 45, 8347–8369. [Google Scholar] [CrossRef]

- Mukhtar, M.; Ameyaw, B.; Yimen, N.; Quixin, Z.; Bamisile, O.; Adun, H.; Dagbasi, M. Building retrofit and energy conservation/efficiency review: A techno-environ-economic assessment of heat pump system retrofit in housing stock. Sustainability 2021, 13, 983. [Google Scholar] [CrossRef]

- Gulaliyev, M.G.; Mustafayev, E.R.; Mehdiyeva, G.Y. Assessment of solar energy potential and its ecological-economic efficiency: Azerbaijan case. Sustainability 2020, 12, 1116. [Google Scholar] [CrossRef]

- Fuqiang, W.; Ziming, C.; Jianyu, T.; Yuan, Y.; Yong, S.; Linhua, L. Progress in concentrated solar power technology with parabolic trough collector system: A comprehensive review. Renew. Sustain. Energy Rev. 2017, 79, 1314–1328. [Google Scholar] [CrossRef]

- Sing, C.K.L.; Lim, J.S.; Walmsley, T.G.; Liew, P.Y.; Goto, M.; Salim, S.A.Z.B.S. Time-dependent integration of solar thermal technology in industrial processes. Sustainability 2020, 12, 2322. [Google Scholar] [CrossRef]

- Zhai, H.; Dai, Y.; Wu, J.; Wang, R.; Zhang, L. Experimental investigation and analysis on a concentrating solar collector using linear Fresnel lens. Energy Convers. Manag. 2010, 51, 48–55. [Google Scholar] [CrossRef]

- Qiu, Y.; Li, M.; Wang, K.; Liu, Z.; Xue, X. Aiming strategy optimization for uniform flux distribution in the receiver of a linear Fresnel solar reflector using a multi-objective genetic algorithm. Appl. Energy 2017, 205, 1394–1407. [Google Scholar] [CrossRef]

- Prasad, G.C.; Reddy, K.S.; Sundararajan, T. Optimization of solar linear Fresnel reflector system with secondary concentrator for uniform flux distribution over absorber tube. Sol. Energy 2017, 150, 1–12. [Google Scholar] [CrossRef]

- Wang, G.; Chen, Z.; Hu, P.; Cheng, X. Design and optical analysis of the band-focus Fresnel lens solar concentrator. Appl. Therm. Eng. 2016, 102, 695–700. [Google Scholar] [CrossRef]

- Pham, T.T.; Vu, N.H.; Shin, S. Novel design of primary optical elements based on a linear Fresnel lens for concentrator photovoltaic technology. Energies 2019, 12, 1209. [Google Scholar] [CrossRef]

- Lin, M.; Sumathy, K.; Dai, Y.; Zhao, X. Performance investigation on a linear Fresnel lens solar collector using cavity receiver. Sol. Energy 2014, 107, 50–62. [Google Scholar] [CrossRef]

- Zhao, D.; Xu, E.; Wang, Z.; Yu, Q.; Xu, L.; Zhu, L. Influences of installation and tracking errors on the optical performance of a solar parabolic trough collector. Renew. Energy 2016, 94, 197–212. [Google Scholar] [CrossRef]

- FuQiang, W.; Jianyu, T.; Lanxin, M.; Chengchao, W. Effects of glass cover on heat flux distribution for tube receiver with parabolic trough collector system. Energy Convers. Manag. 2015, 90, 47–52. [Google Scholar] [CrossRef]

- Jamil, B.; Bellos, E. Development of empirical models for estimation of global solar radiation exergy in India. J. Clean. Prod. 2019, 207, 1–16. [Google Scholar] [CrossRef]

- Yao, Y.; Hu, Y.; Gao, S.; Yang, G.; Du, J. A multipurpose dual-axis solar tracker with two tracking strategies. Renew. Energy 2014, 72, 88–98. [Google Scholar] [CrossRef]

- Herrera-Romero, J.V.; Colorado-Garrido, D.; Soberanis, M.E.; Flota-Bañuelos, M. Estimation of the optimum tilt angle of solar collectors in Coatzacoalcos, Veracruz. Renew. Energy 2020, 153, 615–623. [Google Scholar] [CrossRef]

- Al-Taani, H.; Arabasi, S. Solar irradiance measurements using smart devices: A cost-effective technique for estimation of solar irradiance for sustainable energy systems. Sustainability 2018, 10, 508. [Google Scholar] [CrossRef]

- Eldin, S.S.; Abd-Elhady, M.S.; Kandil, H.A. Feasibility of solar tracking systems for PV panels in hot and cold regions. Renew. Energy 2016, 85, 228–233. [Google Scholar] [CrossRef]

- Almutairi, K.; Mostafaeipour, A.; Jahanshahi, E.; Jooyandeh, E.; Himri, Y.; Jahangiri, M.; Issakhov, A.; Chowdhury, S.; Dehshiri, S.H.; Dehshiri, S.H.; et al. Ranking locations for hydrogen production using hybrid wind-solar: A Case Study. Sustainability 2021, 13, 4524. [Google Scholar] [CrossRef]

- Pavlovic, S.; Bellos, E.; Loni, R. Exergetic investigation of a solar dish collector with smooth and corrugated spiral absorber operating with various nanofluids. J. Clean. Prod. 2018, 174, 1147–1160. [Google Scholar] [CrossRef]

- Abed, N.; Afgan, I. An extensive review of various technologies for enhancing the thermal and optical performances of parabolic trough collectors. Int. J. Energy Res. 2020, 44, 5117–5164. [Google Scholar] [CrossRef]

- Li, S.; Xu, G.; Luo, X.; Quan, Y.; Ge, Y. Optical performance of a solar dish concentrator/receiver system: Influence of geometrical and surface properties of cavity receiver. Energy 2016, 113, 95–107. [Google Scholar] [CrossRef]

- Wang, H.; Huang, J.; Song, M.; Yan, J. Effects of receiver parameters on the optical performance of a fixed-focus Fresnel lens solar concentrator/cavity receiver system in solar cooker. Appl. Energy 2019, 237, 70–82. [Google Scholar] [CrossRef]

- Li, C.; Lyu, Y.; Li, C.; Qiu, Z. Energy performance of water flow window as solar collector and cooling terminal under adaptive control. Sustain. Cities Soc. 2020, 59, 102152. [Google Scholar] [CrossRef]

- Wang, H.; Huang, J.; Song, M.; Hu, Y.; Wang, Y.; Lu, Z. Simulation and experimental study on the optical performance of a fixed-focus Fresnel lens solar concentrator using polar-axis tracking. Energies 2018, 11, 887. [Google Scholar] [CrossRef]

- Wu, G.; Zheng, H.; Ma, X.; Kutlu, C.; Su, Y. Experimental investigation of a multi-stage humidification-dehumidification desalination system heated directly by a cylindrical Fresnel lens solar concentrator. Energy Convers. Manag. 2017, 143, 241–251. [Google Scholar] [CrossRef]

- Jiang, Y.; Yan, H.; Zhang, X. Beam-shaping method for uniform illumination by superposition of tilted Gaussian beams. Opt. Eng. 2010, 49, 044203. [Google Scholar] [CrossRef]

- Daabo, A.M.; Mahmoud, S.; Al-Dadah, R.K. The effect of receiver geometry on the optical performance of a small-scale solar cavity receiver for parabolic dish applications. Energy 2016, 114, 513–525. [Google Scholar] [CrossRef]

- Pushkar, S. Modeling the substitution of natural materials with industrial byproducts in green roofs using life cycle assessments. J. Clean. Prod. 2019, 227, 652–661. [Google Scholar] [CrossRef]

- Gao, T.; Erokhin, V. Capturing a Complexity of nutritional, environmental, and economic impacts on selected health parameters in the Russian high north. Sustainability 2020, 12, 2151. [Google Scholar] [CrossRef]

| Component | Parameter | Symbol | Value |

|---|---|---|---|

| Fixed linear linear-focus Fresnel lens solar concentrator | Lens element width | B | 400 mm |

| Lens element length | L | 1500 mm | |

| Focal length | f0 | 650 mm | |

| Triangle cavity receiver | Opening width | Btr | 80 mm |

| Opening length | Ltr | 1500 mm | |

| Apex angle | αtr | 60° | |

| Solar source | Direct solar radiation value | Id | 800 W/m2 |

| Item | Sun Declination Angle δ | Offset Distance (mm) |

|---|---|---|

| 1 | 0° | 0 |

| 2 | 8° | 87 |

| 3 | 16° | 183 |

| 4 | 23.45° | 286 |

| Level | Experiment Factor | ||||

|---|---|---|---|---|---|

| f (A) | αab (B) | ρr (C) | δ (D) | ω (E) | |

| 1 | 600 mm | 1.00 | 1.00 | 0° | 0° |

| 2 | 625 mm | 0.85 | 0.85 | 8° | 15° |

| 3 | 650 mm | 0.75 | 0.75 | 16° | 30° |

| 4 | 675 mm | / | / | 23.45° | 45° |

| 5 | 700 mm | / | / | / | 60° |

| Source | SS # | df | MS | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 19.401 a | 15 | 1.293 | 127.954 | <0.0001 |

| A | 2.788 | 4 | 0.697 | 68.957 | <0.0001 * |

| B | 0.337 | 2 | 0.169 | 16.678 | <0.0001 * |

| C | 0.006 | 2 | 0.003 | 0.278 | 0.757 |

| D | 4.744 | 3 | 1.581 | 156.445 | <0.0001 * |

| E | 11.552 | 4 | 2.888 | 285.702 | <0.0001 * |

| Error | 8.926 | 883 | 0.010 | / | / |

| Total | 210.753 | 900 | / | / | / |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Hu, Y.; Peng, J.; Song, M.; Li, H. Effects of Receiver Parameters on Solar Flux Distribution for Triangle Cavity Receiver in the Fixed Linear-Focus Fresnel Lens Solar Concentrator. Sustainability 2021, 13, 6139. https://doi.org/10.3390/su13116139

Wang H, Hu Y, Peng J, Song M, Li H. Effects of Receiver Parameters on Solar Flux Distribution for Triangle Cavity Receiver in the Fixed Linear-Focus Fresnel Lens Solar Concentrator. Sustainability. 2021; 13(11):6139. https://doi.org/10.3390/su13116139

Chicago/Turabian StyleWang, Hai, Yanxin Hu, Jinqing Peng, Mengjie Song, and Haoteng Li. 2021. "Effects of Receiver Parameters on Solar Flux Distribution for Triangle Cavity Receiver in the Fixed Linear-Focus Fresnel Lens Solar Concentrator" Sustainability 13, no. 11: 6139. https://doi.org/10.3390/su13116139

APA StyleWang, H., Hu, Y., Peng, J., Song, M., & Li, H. (2021). Effects of Receiver Parameters on Solar Flux Distribution for Triangle Cavity Receiver in the Fixed Linear-Focus Fresnel Lens Solar Concentrator. Sustainability, 13(11), 6139. https://doi.org/10.3390/su13116139