A Review of Practice and Implementation of the Internet of Things (IoT) for Smallholder Agriculture

Abstract

1. Introduction

2. Approach

3. Results and Discussion

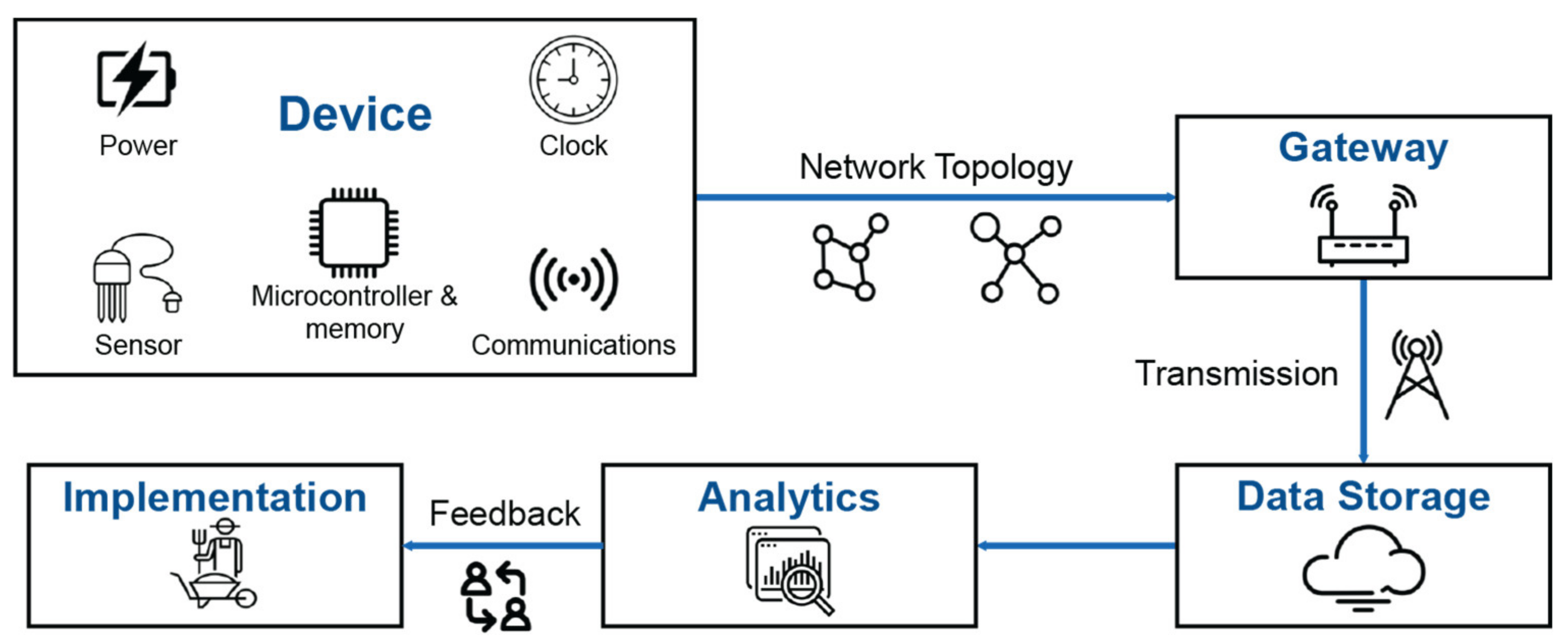

3.1. Current State of IoT for Agriculture

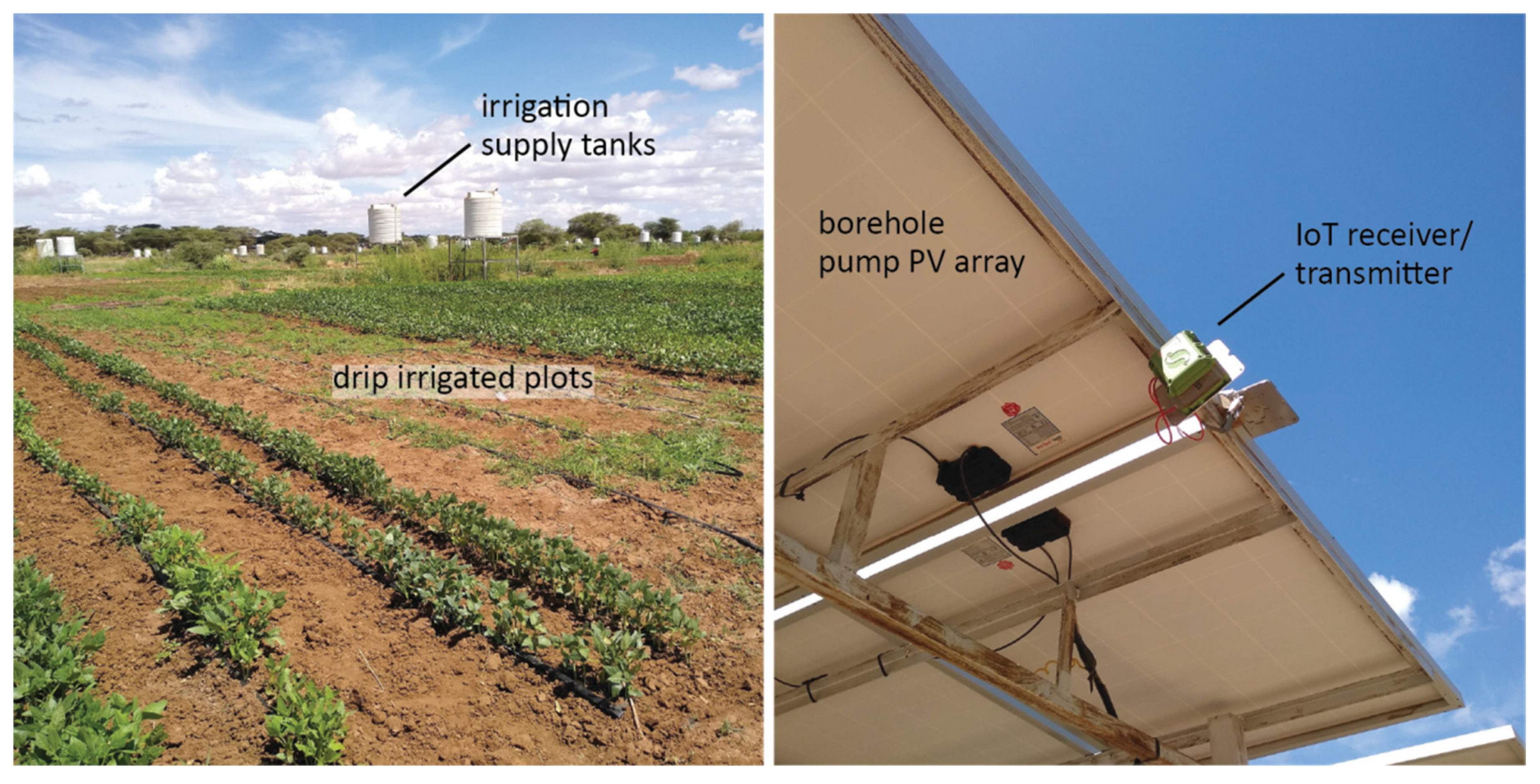

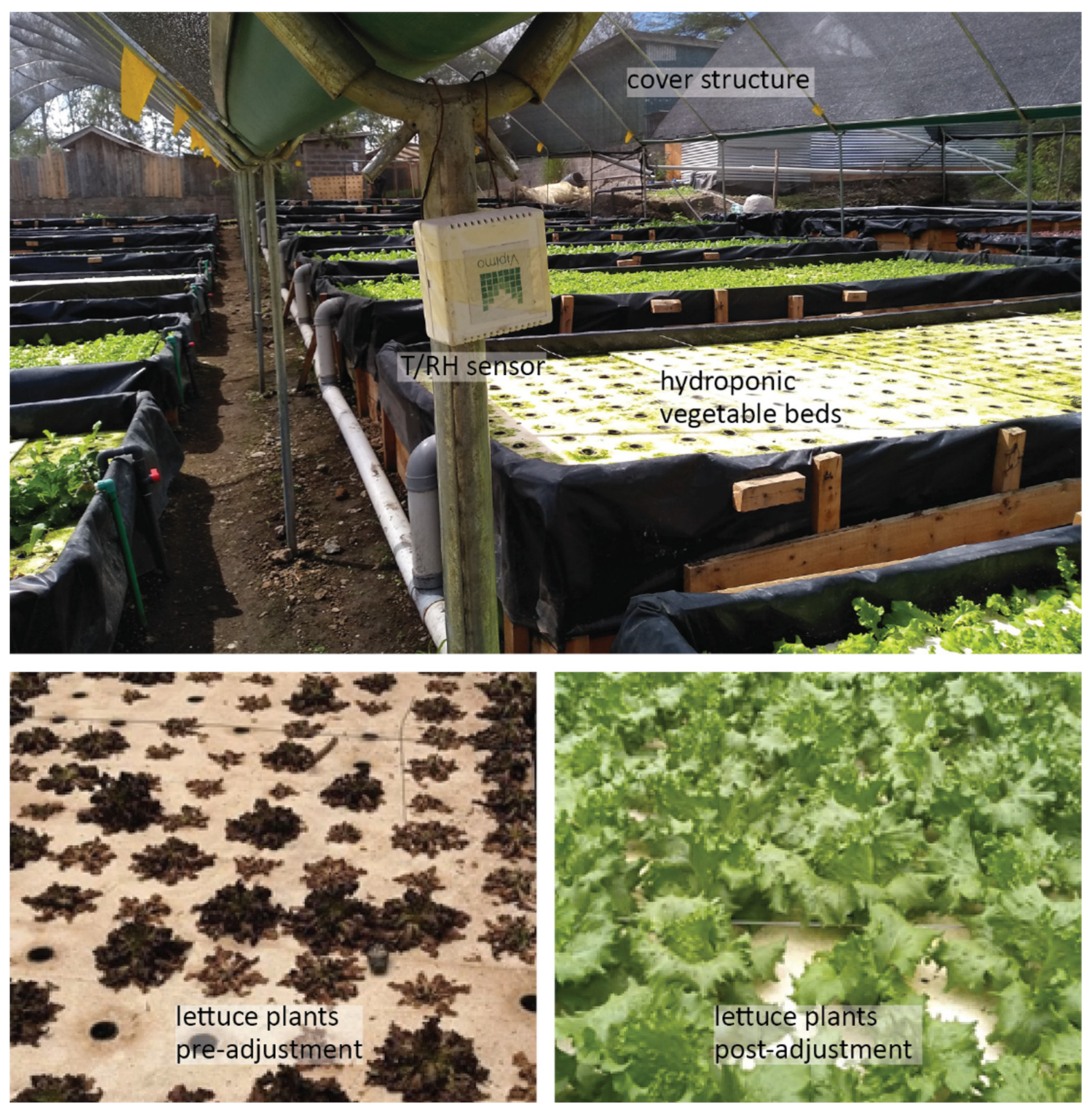

3.2. Implementation Cases

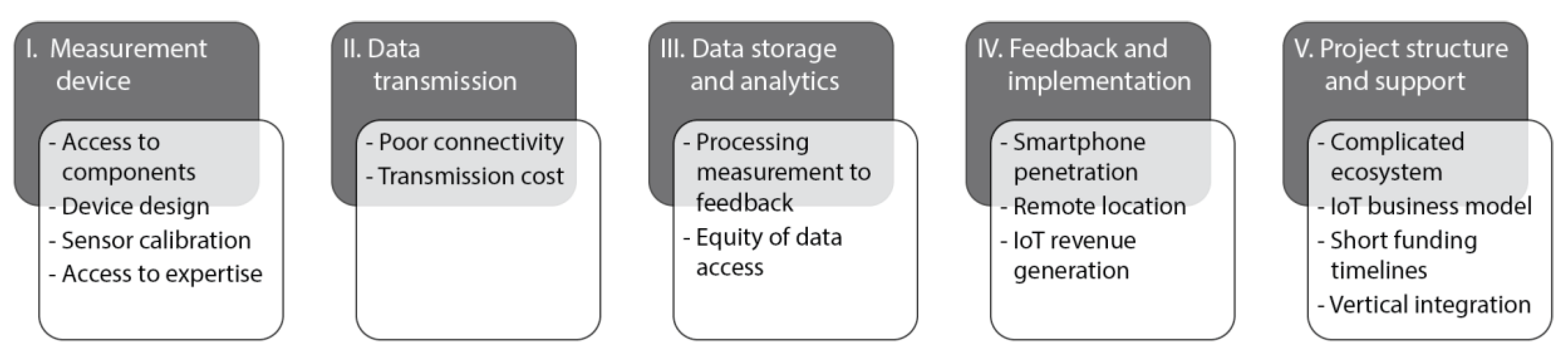

3.3. Discussion of Challenges and Recommendations

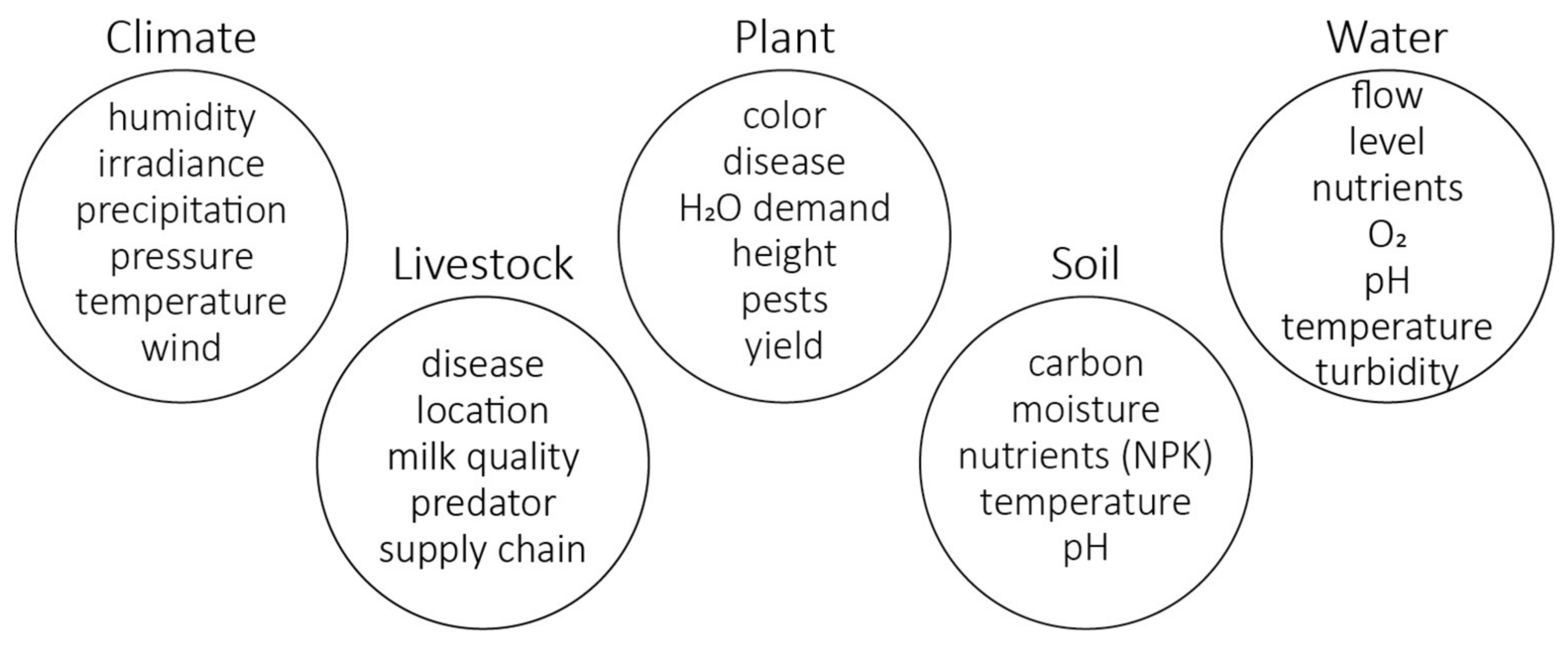

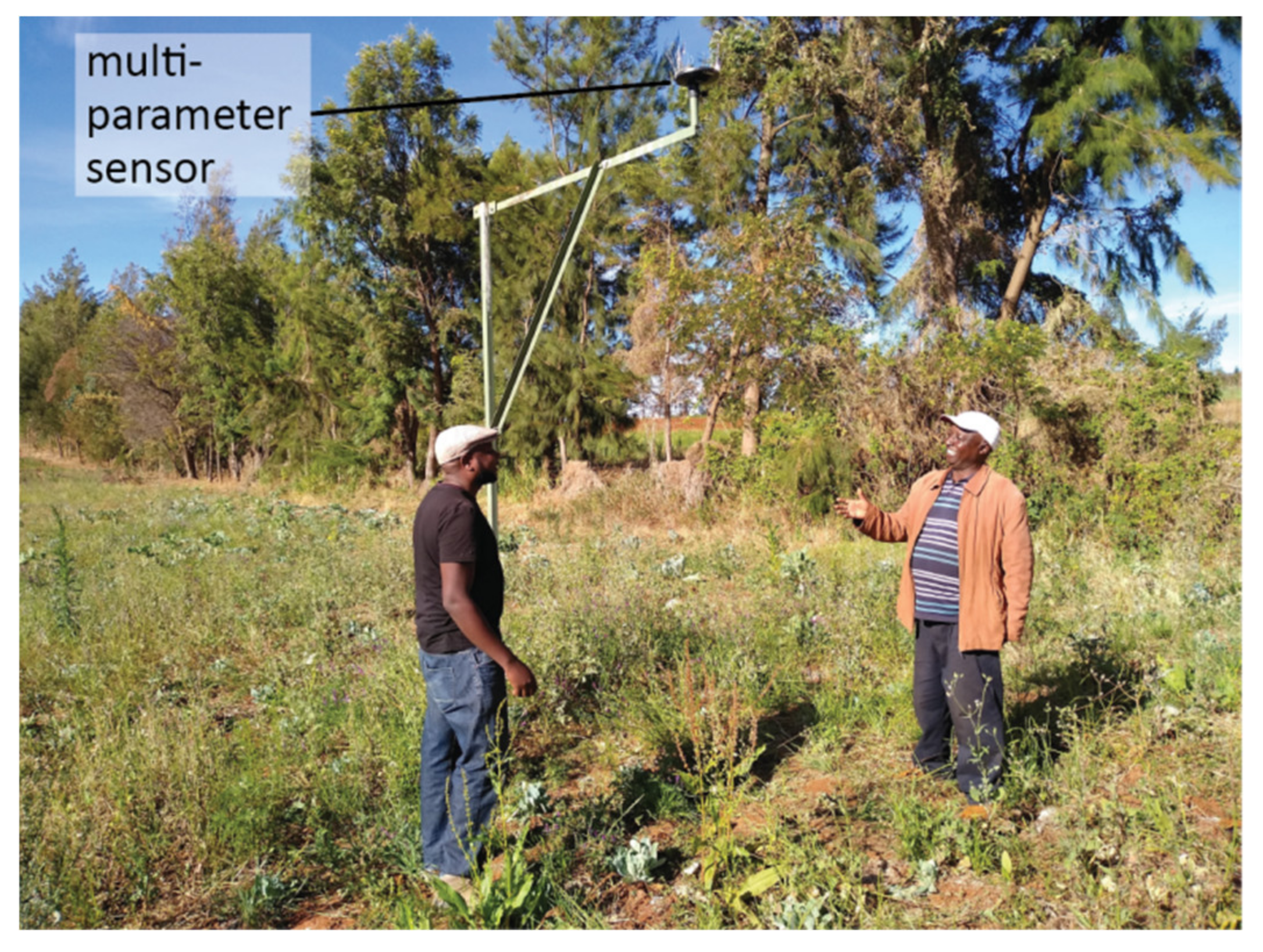

3.3.1. Measurement Device Challenges

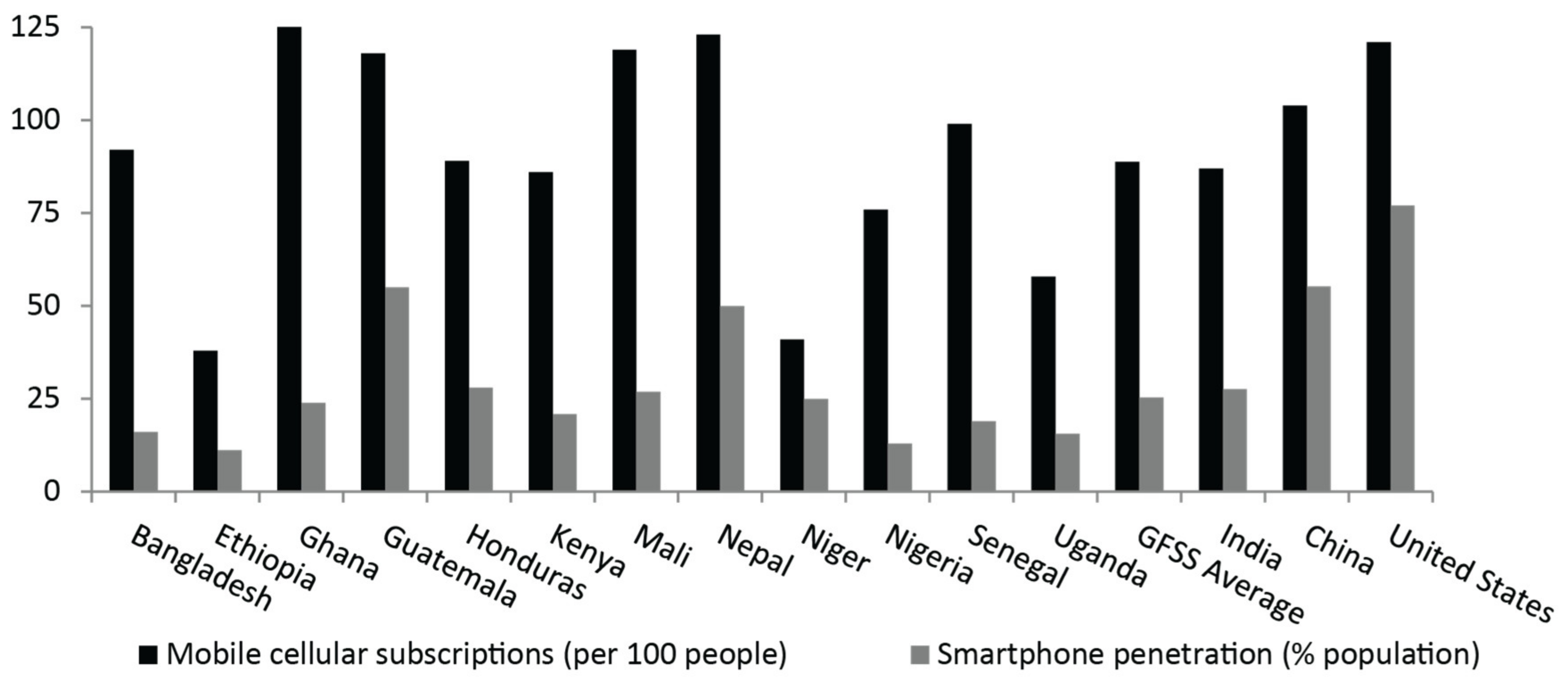

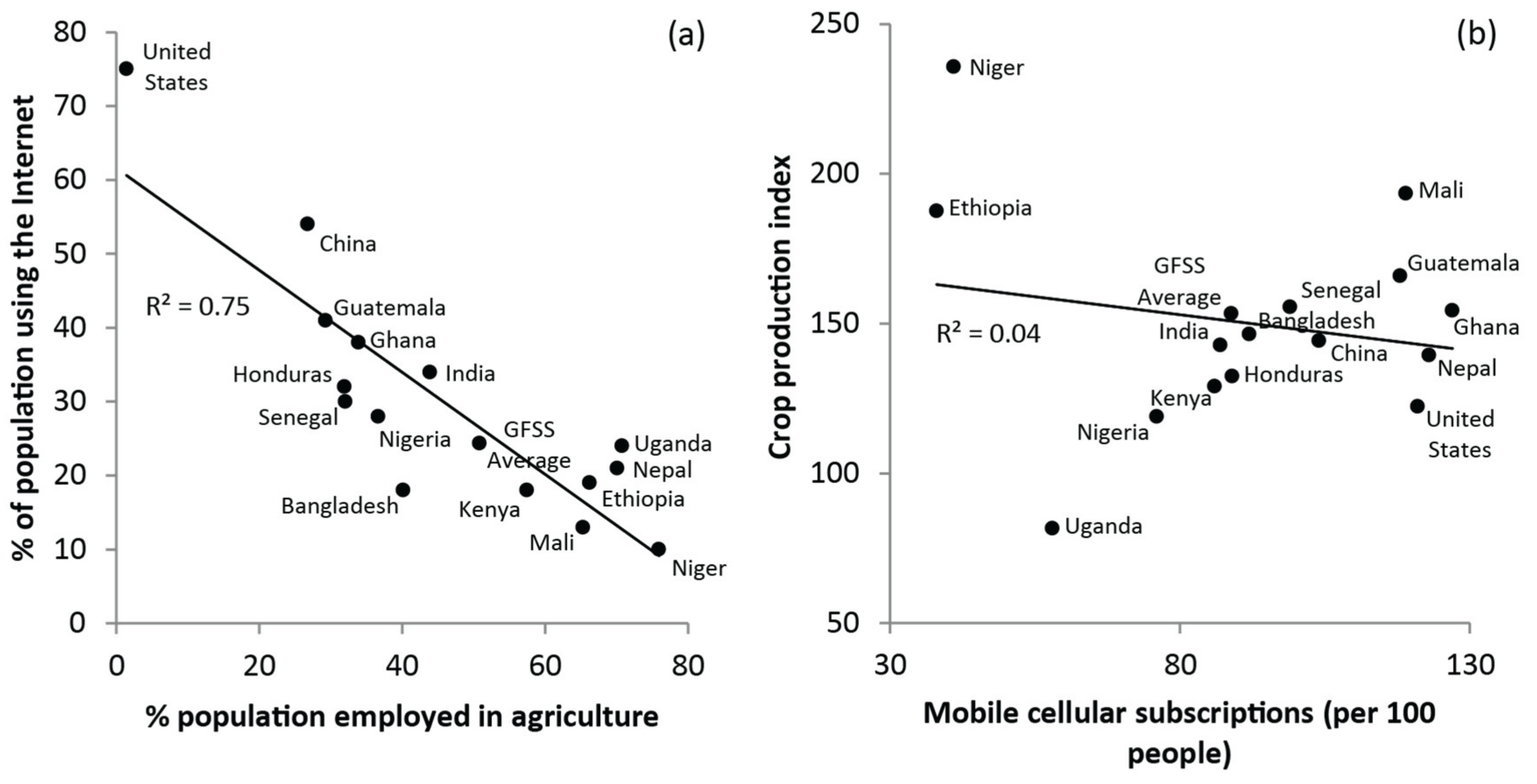

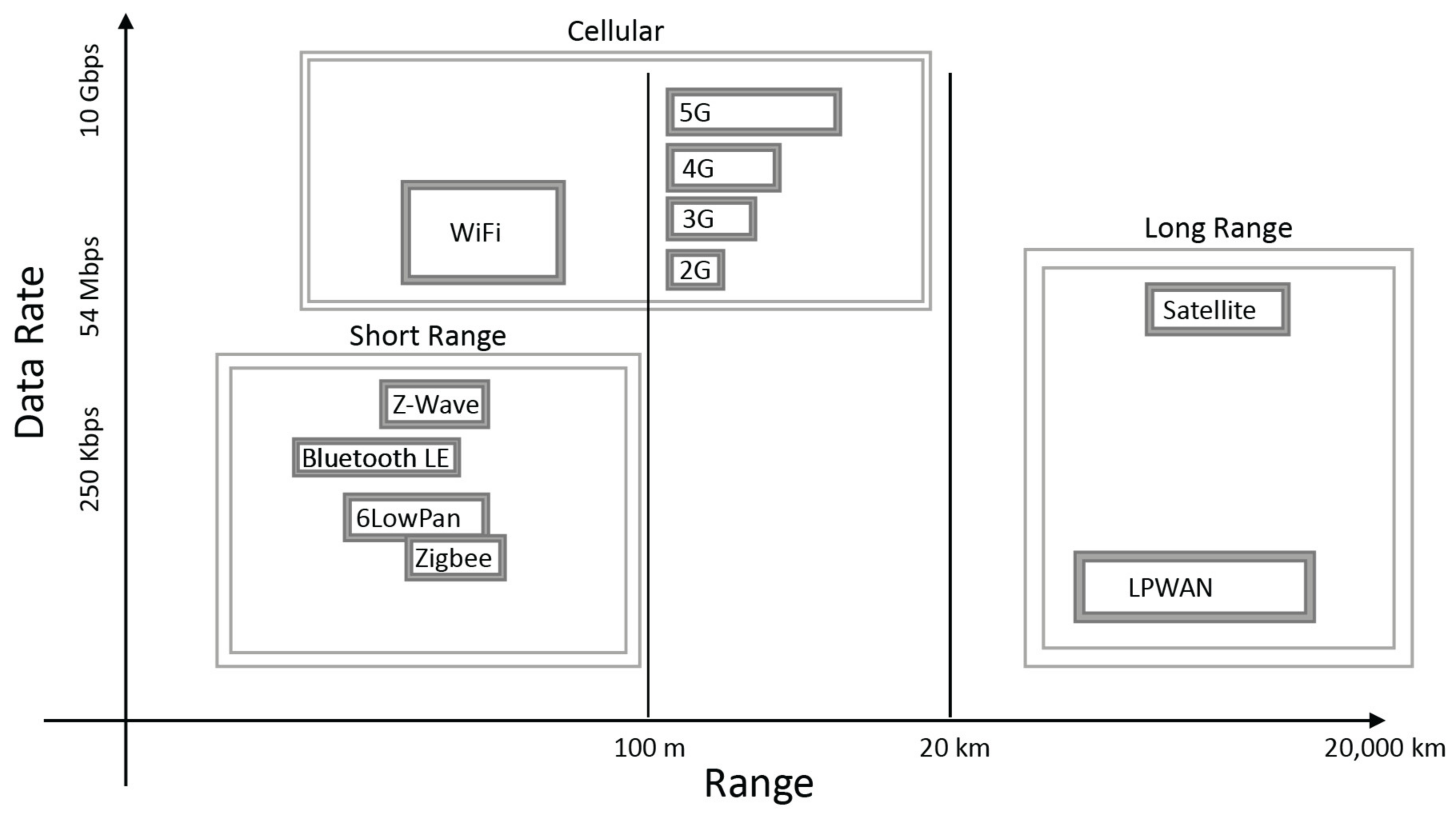

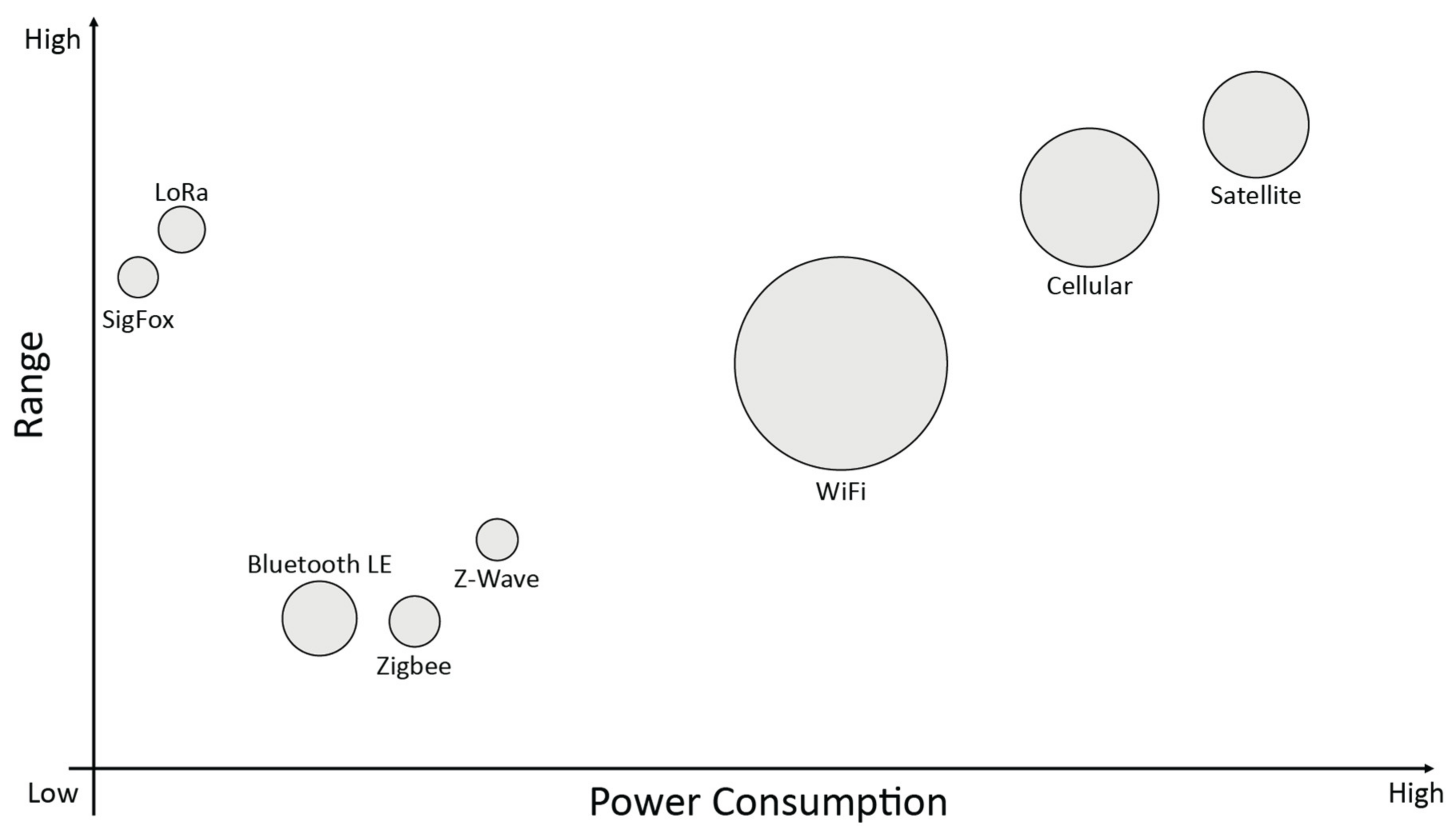

3.3.2. Data Transmission Challenges:

3.3.3. Data Storage and Analytics

3.3.4. Feedback and Implementation

3.3.5. Project Structure and Support

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- BBC. The High-Tech Farming Revolution; BBC World News: London, UK, 2019. [Google Scholar]

- FAO. How to Feed the World in 2050; FAO: Rome, Italy, 2009. [Google Scholar]

- Gray, B.; Babcock, L.; Tobias, L.; McCord, M.; Herrera, A.; Cadavid, R. Digital Farmer Profiles: Reimagining Smallholder Agriculture; Grameen Foundation: Washington, DC, USA, 2018. [Google Scholar]

- Ayaz, M.; Ammad-Uddin, M.; Sharif, Z.; Mansour, A.; Aggoune, E.-H.M. Internet-of-Things (IoT)-Based Smart Agriculture: Toward Making the Fields Talk. IEEE Access 2019, 7, 129551–129583. [Google Scholar] [CrossRef]

- Liu, Y.; Langemeier, M.R.; Small, I.M.; Joseph, L.; Fry, W.E. Risk Management Strategies using Precision Agriculture Technology to Manage Potato Late Blight. Agron. J. 2017, 109, 562–575. [Google Scholar] [CrossRef]

- Small, I.M.; Joseph, L.; Fry, W. Evaluation of the BlightPro Decision Support System for Management of Potato Late Blight Using Computer Simulation and Field Validation. Phytopathology 2015, 105, 1545–1554. [Google Scholar] [CrossRef] [PubMed]

- Van Evert, F.K.; Gaitán-Cremaschi, D.; Gaitán-Cremaschi, D.; Kempenaar, C. Can Precision Agriculture Increase the Profitability and Sustainability of the Production of Potatoes and Olives? Sustainability 2017, 9, 1863. [Google Scholar] [CrossRef]

- Saab, M.T.A.; Jomaa, I.; Skaf, S.; Fahed, S.; Todorović, M. Assessment of a Smartphone Application for Real-Time Irrigation Scheduling in Mediterranean Environments. Water 2019, 11, 252. [Google Scholar] [CrossRef]

- Bragagnolo, J.; Amado, T.J.C.; Nicoloso, R.S.; Santi, A.L.; Fiorin, J.E.; Tabaldi, F. Optical crop sensor for variable-rate nitrogen fertilization in corn: II—Indices of fertilizer efficiency and corn yield. Rev. Bras. Ciênc. Solo 2013, 37, 1299–1309. [Google Scholar] [CrossRef]

- Scharf, P.C. Crop Sensors for Managing Nitrogen; Foundation for Arable Research: Christchurch, New Zealand, 2009. [Google Scholar]

- Fanzo, J. From big to small: The significance of smallholder farms in the global food system. Lancet Planet. Health 2017, 1, e15–e16. [Google Scholar] [CrossRef]

- Maumbe, B.M.; Okello, J. Uses of Information and Communication Technology (ICT) in Agriculture and Rural Development in Sub-Saharan Africa. In Technology, Sustainability, and Rural Development in Africa; IGI Global: Hershey, PA, USA, 2013; pp. 113–134. [Google Scholar]

- Garrity, J. Harnessing the Internet of Things for Global Development. SSRN Electron. J. 2015. [Google Scholar] [CrossRef]

- Masinde, M. IoT applications that work for the African continent: Innovation or adoption? In Proceedings of the 2014 12th IEEE International Conference on Industrial Informatics (INDIN), Porto Alegre, Brazil, 27–30 July 2014; pp. 633–638. [Google Scholar]

- Dlodlo, N.; Kalezhi, J.; Nomusa, D. The internet of things in agriculture for sustainable rural development. In Proceedings of the 2015 International Conference on Emerging Trends in Networks and Computer Communications (ETNCC), Windhoek, Namibia, 17–20 May 2015; pp. 13–18. [Google Scholar] [CrossRef]

- Kshetri, N. The economics of the Internet of Things in the Global South. Third World Q. 2016, 38, 1–29. [Google Scholar] [CrossRef]

- Munyua, H.; Adera, E.; Jensen, M. Emerging ICTs and their potential in revitalizing small scale agriculture in Africa. Agric. Inf. Worldw. 2009, 2, 3–9. [Google Scholar]

- McEwen, A.; Cassimally, H. Designing the Internet of Things; Wiley: Hoboken, NJ, USA, 2013; ISBN 9781118430651. [Google Scholar]

- Borgia, E. The Internet of Things vision: Key features, applications and open issues. Comput. Commun. 2014, 54, 1–31. [Google Scholar] [CrossRef]

- U.S. Government. U.S. Government Global Food Security Strategy FY 2017–2021; U.S. Government: Washington, DC, USA, 2016.

- Akuku, B.; Makini, F.; Wasilwa, L.; Kamau, G.; Makelo, M. Application of innovative ICT tools for linking Agricultural research knowledge and extension services to farmers in Kenya. In Proceedings of the 7th UbuntuNet Alliance Annual Conference, Lusaka, Zambia, 13–14 November 2014; pp. 13–20. [Google Scholar]

- Krell, N.T.; Giroux, S.A.; Guido, Z.; Hannah, C.; Lopus, S.E.; Caylor, K.K.; Evans, T.P. Smallholder farmers’ use of mobile phone services in central Kenya. Clim. Dev. 2020, 12, 1–13. [Google Scholar] [CrossRef]

- World Bank. World Bank Open Data. Available online: https://data.worldbank.org/indicator (accessed on 29 March 2019).

- Newzoo. Global Mobile Market Report; Newzoo: San Francisco, CA, USA, 2019. [Google Scholar]

- Antony, A.P.; Lu, J.; Sweeney, D.J. Seeds of Silicon: Internet of Things for Smallholder Agriculture; Massachusetts Institute of Technology: Cambridge, MA, USA, 2019; Available online: https://d-lab.mit.edu/resources/publications/seeds-silicon-internet-things-smallholder-agriculture (accessed on 4 May 2020).

- Bogue, R. Sensors key to advances in precision agriculture. Sens. Rev. 2017, 37, 1–6. [Google Scholar] [CrossRef]

- Hsieh, H.-F.; Shannon, S.E. Three Approaches to Qualitative Content Analysis. Qual. Health Res. 2005, 15, 1277–1288. [Google Scholar] [CrossRef]

- Jain, M.; Singh, B.; Srivastava, A.A.K.; Malik, R.K.; McDonald, A.J.; Lobell, D.B. Using satellite data to identify the causes of and potential solutions for yield gaps in India’s Wheat Belt. Environ. Res. Lett. 2017, 12, 094011. [Google Scholar] [CrossRef]

- Cecil, M.; Estes, L.D.; Evans, T.P.; Wolf, A. Using in situ Sensor Networks and Remotely Sensed Imagery to Improve Site-Specific Understanding of Maize Yield Variance. In AGU Fall Meeting; American Geophysical Union: San Francisco, CA, USA, 2019. [Google Scholar]

- Dean, T.J.; Bell, J.P.; Baty, A.J.B. Soil moisture measurement by an improved capacitance technique, Part I. Sensor design and performance. J. Hydrol. 1987, 93, 67–78. [Google Scholar] [CrossRef]

- IDEO.org. The Magic Stick. Available online: https://www.ideo.org/perspective/the-magic-stick (accessed on 17 August 2018).

- Gardner, C.; Dean, T.; Cooper, J. Soil Water Content Measurement with a High-Frequency Capacitance Sensor. J. Agric. Eng. Res. 1998, 71, 395–403. [Google Scholar] [CrossRef]

- Eller, H.; Denoth, A. A capacitive soil moisture sensor. J. Hydrol. 1996, 185, 137–146. [Google Scholar] [CrossRef]

- Makario, J.; Ngetich, K.; Maina, C. Long Range Low Power Sensor Networks for Agricultural Monitoring—A Case Study in Kenya. In Proceedings of the 2019 IST-Africa Week Conference (IST-Africa), Nairobi, Kenya, 8–10 May 2019; pp. 1–8. [Google Scholar]

- Payero, J.O.; Qiao, X.; Khalilian, A.; Mirzakhani-Nafchi, A.; Davis, R. Evaluating the Effect of Soil Texture on the Response of Three Types of Sensors Used to Monitor Soil Water Status. J. Water Resour. Prot. 2017, 9, 566–577. [Google Scholar] [CrossRef]

- Yamazoe, N.; Shimizu, Y. Humidity sensors: Principles and applications. Sens. Actuators 1986, 10, 379–398. [Google Scholar] [CrossRef]

- Bi, H.; Yin, K.; Xie, X.; Ji, J.; Wan, S.; Sun, L.-T.; Terrones, M.; Dresselhaus, M.S. Ultrahigh humidity sensitivity of graphene oxide. Sci. Rep. 2013, 3, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Larson, G.F. Electrical Sensor for Measuring Moisture in Landscape and Agricultural Soils. U.S. Patent 4531087, 23 June 1985. [Google Scholar]

- Mulenga, R.; Kalezhi, J.; Musonda, S.K.; Silavwe, S. Applying Internet of Things in Monitoring and Control of an Irrigation System for Sustainable Agriculture for Small-Scale Farmers in Rural Communities. In Proceedings of the 2018 IEEE PES/IAS PowerAfrica, Cape Town, South Africa, 28–29 June 2018; pp. 1–9. [Google Scholar]

- Meyer, T.C.; Hancke, G.P. Design of a smart sprinkler system. In Proceedings of the TENCON 2015—2015 IEEE Region 10 Conference, Macao, China, 1–4 November 2015; Volume 2016, pp. 1–6. [Google Scholar]

- Bogena, H.; Huisman, J.A.; Oberdörster, C.; Vereecken, H. Evaluation of a low-cost soil water content sensor for wireless network applications. J. Hydrol. 2007, 344, 32–42. [Google Scholar] [CrossRef]

- Staggenborg, S.A.; Carignano, M.; Haag, L. Predicting Soil pH and Buffer pH In Situ with a Real-Time Sensor. Agron. J. 2007, 99, 854–861. [Google Scholar] [CrossRef]

- IDEO.org. Spoilage Sensor. Available online: https://www.ideo.org/perspective/spoilage-sensor (accessed on 17 August 2018).

- Wild, K.; Auernhammer, H. A weighing system for local yield monitoring of forage crops in round balers. Comput. Electron. Agric. 1999, 23, 119–132. [Google Scholar] [CrossRef]

- Potapovs, A.; Avotins, A.; Apse-Apsitis, P.; Gorobetz, M.; Ceirs, P. Continuous Crop Weight Measurement Sensor Calibration Algorithm for Industrial Greenhouse. In Proceedings of the 2018 IEEE 59th International Scientific Conference on Power and Electrical Engineering of Riga Technical University (RTUCON), Riga, Latvia, 12–13 November 2018; pp. 1–6. [Google Scholar]

- Jagtap, S.; Bhatt, C.; Thik, J.; Rahimifard, S. Thik Monitoring Potato Waste in Food Manufacturing Using Image Processing and Internet of Things Approach. Sustainability 2019, 11, 3173. [Google Scholar] [CrossRef]

- Janssen, S.; Schmitt, K.; Blanke, M.; Bauersfeld, M.L.; Wöllenstein, J.; Lang, W. Ethylene detection in fruit supply chains. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2014, 372, 20130311. [Google Scholar] [CrossRef]

- Chaudhary, D.; Nayse, S.; Waghmare, L. Application of Wireless Sensor Networks for Greenhouse Parameter Control in Precision Agriculture. Int. J. Wirel. Mob. Networks 2011, 3, 140–149. [Google Scholar] [CrossRef]

- Ahonen, T.; Virrankoski, R.; Elmusrati, M. Greenhouse Monitoring with Wireless Sensor Network. In Proceedings of the 2008 IEEE/ASME International Conference on Mechtronic and Embedded Systems and Applications, Beijing, China, 12–15 October 2008; pp. 403–408. [Google Scholar]

- Murphy, F.E.; Popovici, E.; Whelan, P.; Magno, M. Development of an heterogeneous wireless sensor network for instrumentation and analysis of beehives. In Proceedings of the 2015 IEEE International Instrumentation and Measurement Technology Conference (I2MTC) Proceedings, Pisa, Italy, 11–14 May 2015; Volume 2015, pp. 346–351. [Google Scholar]

- Tilly, N.; Hoffmeister, D.; Cao, Q.; Huang, S.; Lenz-Wiedemann, V.; Miao, Y.; Bareth, G. Multitemporal crop surface models: Accurate plant height measurement and biomass estimation with terrestrial laser scanning in paddy rice. J. Appl. Remote. Sens. 2014, 8, 83671. [Google Scholar] [CrossRef]

- Friedli, M.; Kirchgessner, N.; Grieder, C.; Liebisch, F.; Mannale, M.; Walter, A. Terrestrial 3D laser scanning to track the increase in canopy height of both monocot and dicot crop species under field conditions. Plant Methods 2016, 12, 9. [Google Scholar] [CrossRef]

- Sun, H.; Zhu, Q.; Ren, J.; Barclay, D.; Thomson, W. Combining Image Analysis and Smart Data Mining for Precision Agriculture in Livestock Farming. In Proceedings of the 2017 IEEE International Conference on Internet of Things (iThings) and IEEE Green Computing and Communications (GreenCom) and IEEE Cyber, Physical and Social Computing (CPSCom) and IEEE Smart Data (SmartData), Exeter, UK, 21–23 June 2017; Volume 2018, pp. 1065–1069. [Google Scholar]

- Saeys, W.; Lenaerts, B.; Craessaerts, G.; De Baerdemaeker, J. Estimation of the crop density of small grains using LiDAR sensors. Biosyst. Eng. 2009, 102, 22–30. [Google Scholar] [CrossRef]

- Weiss, U.; Biber, P. Plant detection and mapping for agricultural robots using a 3D LIDAR sensor. Robot. Auton. Syst. 2011, 59, 265–273. [Google Scholar] [CrossRef]

- Filippa, G.; Cremonese, E.; Migliavacca, M.; Galvagno, M.; Sonnentag, O.; Humphreys, E.R.; Hufkens, K.; Ryu, Y.; Verfaillie, J.; Di Cella, U.M.; et al. NDVI derived from near-infrared-enabled digital cameras: Applicability across different plant functional types. Agric. For. Meteorol. 2018, 249, 275–285. [Google Scholar] [CrossRef]

- Nie, P.; Dong, T.; He, Y.; Qu, F. Detection of Soil Nitrogen Using Near Infrared Sensors Based on Soil Pretreatment and Algorithms. Sensors 2017, 17, 1102. [Google Scholar] [CrossRef] [PubMed]

- Piikki, K.; Söderström, M.; Eriksson, J.; John, J.M.; Muthee, P.I.; Wetterlind, J.; Lund, E. Performance Evaluation of Proximal Sensors for Soil Assessment in Smallholder Farms in Embu County, Kenya. Sensors 2016, 16, 1950. [Google Scholar] [CrossRef] [PubMed]

- Shepherd, K.; Walsh, M.G.; Walsh, M. Infrared Spectroscopy—Enabling an Evidence-Based Diagnostic Surveillance Approach to Agricultural and Environmental Management in Developing Countries. J. Near Infrared Spectrosc. 2007, 15, 1–19. [Google Scholar] [CrossRef]

- Colaço, A.F.; Bramley, R.G.V. Do crop sensors promote improved nitrogen management in grain crops? Field Crop Res. 2018, 218, 126–140. [Google Scholar] [CrossRef]

- Habte, A.; Sengupta, M.; Andreas, A.; Narasappa, R.; Thomas, T.; Wolf, A.; Gueymard, C.A. Characterization of a Low-Cost Multi-Parameter Sensor for Solar Resource Applications. In Proceedings of the 2018 IEEE 7th World Conference on Photovoltaic Energy Conversion (WCPEC) (A Joint Conference of 45th IEEE PVSC, 28th PVSEC & 34th EU PVSEC), Waikoloa Village, HI, USA, 10–15 June 2018; pp. 2309–2312. [Google Scholar]

- Mwebaze, E.; Owomugisha, G. Machine Learning for Plant Disease Incidence and Severity Measurements from Leaf Images. In Proceedings of the 2016 15th IEEE International Conference on Machine Learning and Applications (ICMLA), Anaheim, CA, USA, 18–20 December 2016; pp. 158–163. [Google Scholar]

- Bbosa, D.; Brumm, T.J.; Bern, C.J.; Rosentrater, K.A.; Raman, D.R. Evaluation of Hermetic Maize Storage in 208 Liter (55 Gal) Steel Barrels for Smallholder Farmers. Trans. ASABE 2017, 60, 981–987. [Google Scholar] [CrossRef]

- Park, D.H.; Kang, B.-J.; Cho, K.-R.; Shin, C.; Cho, S.-E.; Park, J.W.; Yang, W.-M. A Study on Greenhouse Automatic Control System Based on Wireless Sensor Network. Wirel. Pers. Commun. 2009, 56, 117–130. [Google Scholar] [CrossRef]

- Ham, J.M.; Senock, R.S. On the Measurement of Soil Surface Temperature. Soil Sci. Soc. Am. J. 1992, 56, 370–377. [Google Scholar] [CrossRef]

- Weddi, J.D. SciDev.Net. September 2019. Available online: https://www.scidev.net/sub-saharan-africa/fisheries/feature/using-internet-technology-to-improve-cage-fish-farming.html# (accessed on 18 April 2019).

- Michalski, A. Flow measurements in open irrigation channels. IEEE Instrum. Meas. Mag. 2000, 3, 12–16. [Google Scholar] [CrossRef]

- Nagel, C.; Beach, J.; Iribagiza, C.; Thomas, E.A. Evaluating Cellular Instrumentation on Rural Handpumps to Improve Service Delivery—A Longitudinal Study in Rural Rwanda. Environ. Sci. Technol. 2015, 49, 14292–14300. [Google Scholar] [CrossRef] [PubMed]

- Blumstein, D.T.; Mennill, D.J.; Clemins, P.; Girod, L.; Yao, K.; Patricelli, G.; Deppe, J.L.; Krakauer, A.; Clark, C.; Cortopassi, K.A.; et al. Acoustic monitoring in terrestrial environments using microphone arrays: Applications, technological considerations and prospectus. J. Appl. Ecol. 2011, 48, 758–767. [Google Scholar] [CrossRef]

- Maina, C.; Muchiri, D.; Njoroge, P. Cost Effective Acoustic Monitoring of Biodiversity and Bird Populations in Kenya; bioRxiv: Cold Spring Harbor, NY, USA, 2016. [Google Scholar]

- Amusa, K.A.; Opeodu, F.A.; Adewusi, A.; Adewunmi, T.O. A SONAR-Based Water Level Monitoring System: An Experimental Design. FUOYE J. Eng. Technol. 2018, 3, 21–24. [Google Scholar]

- Maina, C. IoT at the grassroots—Exploring the use of sensors for livestock monitoring. In Proceedings of the 2017 IST-Africa Week Conference (IST-Africa), Windhoek, Namibia, 30 May–2 June 2017; pp. 1–8. [Google Scholar]

- Halachmi, I.; Guarino, M.; Bewley, J.; Pastell, M. Smart Animal Agriculture: Application of Real-Time Sensors to Improve Animal Well-Being and Production. Annu. Rev. Anim. Biosci. 2019, 7, 403–425. [Google Scholar] [CrossRef] [PubMed]

- Workman, R. Measuring Road Condi/on of the First Mile. Atdf J. 2019, 9, 18–27. [Google Scholar]

- Thomas, E.A.; Needoba, J.; Kaberia, D.; Butterworth, J.; Adams, E.C.; Oduor, P.; Macharia, D.; Mitheu, F.; Mugo, R.; Nagel, C. Quantifying increased groundwater demand from prolonged drought in the East African Rift Valley. Sci. Total. Environ. 2019, 666, 1265–1272. [Google Scholar] [CrossRef]

- Métras, S.R.; Magalhaes, R.J.S.; Dinh, Q.H.; Fournié, G.; Gilbert, J.; Huu, D.; Roland-Holst, D.; Otte, J.; Pfeiffer, D.U. An assessment of the feasibility of a poultry tracing scheme for smallholders in Vietnam. Rev. Sci. Tech. de l’OIE 2011, 30, 703–714. [Google Scholar] [CrossRef]

- Kubasu, L.N.; Wachira, H. Tackling cattle rustling menace using RFID/GPS livestock traceability applications in North Rift Kenya: Assessment of the options and way forward. In Proceedings of the IST Africa, Durban, South Africa, 19–21 May 2010; pp. 1–8. [Google Scholar]

- Mutembesa, D.; Mwebaze, E.; Nsumba, S.; Omongo, C.; Mutaasa, H. Mobile Community Sensing with Smallholder Farmers in a Developing Nation; a Scaled Pilot for Crop Health Monitoring. arXiv 2019, arXiv:1908.07047. Available online: https://arxiv.org/abs/1908.07047 (accessed on 10 April 2019).

- Zheleva, M.; Bogdanov, P.; Zois, D.-S.; Xiong, W.; Chandra, R.; Kimball, M. Smallholder Agriculture in the Information Age. In Proceedings of the 2017 Workshop on Recognizing Families In the Wild—RFIW ’17; Association for Computing Machinery (ACM), Santa Barbara, CA, USA, 27 october 2017; pp. 59–70. [Google Scholar]

- Neményi, M.; Mesterházi, P.; Pecze, Z.; Stépán, Z. The role of GIS and GPS in precision farming. Comput. Electron. Agric. 2003, 40, 45–55. [Google Scholar] [CrossRef]

- Ferrández-Pastor, F.-J.; García-Chamizo, J.M.; Nieto-Hidalgo, M.; Mora-Martínez, J. Precision Agriculture Design Method Using a Distributed Computing Architecture on Internet of Things Context. Sensors 2018, 18, 1731. [Google Scholar] [CrossRef]

- Mekki, K.; Bajic, E.; Chaxel, F.; Meyer, F. A comparative study of LPWAN technologies for large-scale IoT deployment. ICT Express 2019, 5, 1–7. [Google Scholar] [CrossRef]

- Raymond, J. The Internet of Things: A Study in Hype, Reality, Disruption and Growth; US Research: Bethesda, MD, USA, 2014. [Google Scholar]

- Daum, T.; Villalba, R.; Anidi, O.; Mayienga, S.M.; Gupta, S.; Birner, R. Uber for Tractors? Opportunities and Challenges of Digital Tools for Tractor Hire in India and Nigeria. SSRN Electron. J. 2020. [Google Scholar] [CrossRef]

- Pandey, B.; Foster, R.; Holthaus, J.; Shrestha, B.; Ngetich, B.; Kunen, E.; Romero, M.; Seo, T.; Renné, D. Solar Water Pumping: Kenya and Nepal Market Acceleration. In Proceedings of the ISES Solar World Congress 2015, Daegu, Korea, 8–12 November 2015; pp. 1–12. [Google Scholar] [CrossRef]

- Dorigo, W.; Wagner, W.; Hohensinn, R.; Hahn, S.; Paulik, C.; Xaver, A.; Gruber, A.; Drusch, M.; Mecklenburg, S.; Van Oevelen, P.; et al. The International Soil Moisture Network: A data hosting facility for global in situ soil moisture measurements. Hydrol. Earth Syst. Sci. 2011, 15, 1675–1698. [Google Scholar] [CrossRef]

- Turman-Bryant, N.; Nagel, C.L.; Stover, L.; Muragijimana, C.; Thomas, E.A. Improved Drought Resilience Through Continuous Water Service Monitoring and Specialized Institutions—A Longitudinal Analysis of Water Service Delivery Across Motorized Boreholes in Northern Kenya. Sustainability 2019, 11, 3046. [Google Scholar] [CrossRef]

- Wilson, D.; Coyle, J.R.; Thomas, E.A. Ensemble machine learning and forecasting can achieve 99% uptime for rural handpumps. PLoS ONE 2017, 12, e0188808. [Google Scholar] [CrossRef] [PubMed]

- Maina, C.; Smith, M.; Mwebaze, E.; Mubangizi, M.; Quinn, J.A.; Neil, D. Data Science Africa—An Initiative to Bridge the Data Science Skills Gap in Africa. In Proceedings of the SciDataCon, Denver, CO, USA, 12–13 September 2016; pp. 1–4. [Google Scholar]

- Pongnumkul, S.; Chaovalit, P.; Surasvadi, N. Applications of Smartphone-Based Sensors in Agriculture: A Systematic Review of Research. J. Sens. 2015, 2015, 1–18. [Google Scholar] [CrossRef]

| Sensor Type | Agricultural Parameter |

|---|---|

| Electrical capacitance | Soil moisture [30,31,32,33,34,35], ambient humidity [36,37] |

| Electrical conductivity | Soil moisture [34,38,39,40], soil and water pH [41], ambient humidity [34,42] |

| Load cell | Weight of harvested crops [43,44], crop waste [45] |

| Electrochemical | Ethylene concentration in crop storage [46], greenhouse CO2 concentration [47,48], beehive monitoring [49] |

| Optical | Crop height measurement [50,51], livestock and predator monitoring [52], volume of harvested grain [53], plant mapping [54], NDVI [55], soil composition [56,57,58], N content [9,10,59], solar irradiance [60], plant disease detection [61], crop waste [45] |

| Thermocouple, thermistor | Seed and crop storage [62], greenhouse monitoring [34,48,63], soil temperature [34,64], water temperature [65] |

| Pressure and flow rate | Irrigation water flow [66], handpump usage [67] |

| Acoustic | Animal detection [68,69], water level [70], grain silo level [3] |

| Accelerometer | Livestock monitoring [71,72], crop transport [73], handpump usage [67] |

| Magnetic flux | Electrical current and power consumption [74] |

| RFID | Livestock and poultry tracking [75,76], supply chain tracking, asset tracking |

| GPS | e-Extension [77], equipment navigation, livestock tracking [76,78], wireless fencing, asset tracking [79] |

| Protocol | Description | Advantages | Disadvantages |

|---|---|---|---|

| Zigbee | IEEE 802.15.4-based specification using mesh network topology and suitable for short- to medium-range | Long battery life (node sleep mode) > 65,000 nodes in a mesh network License-free frequency band | Short range (10–100 m) Incompatibility with other protocols Signal interference in 2.4 GHz band |

| Z-Wave | Mesh network protocol that uses low-energy radio waves and proprietary radio system | Devices are interoperable Suitable for low-power devices | Max 232 nodes in a mesh network Not suitable for high-power devices |

| LoRa (Long Range) | Long-range, low-power, and low-bitrate protocol that uses star topology and unlicensed ISM frequency bands | Long range (10 km) Low power consumption | Actual line-of-sight range of ~2 km Large bandwidth for data transmission |

| WiFi | IEEE 802.11 standards used for the wireless communications of short-distance local area networks | Broad device support Easy setup Inexpensive | Short range (~20 m) |

| Bluetooth Low Energy (BLE) | Wireless personal area network with low power consumption and cost | Broad device support License-free 2.4 GHz band Frequency-hopping reduces signal interference | Low bandwidth Short range (<100 m) |

| SigFox low-power wide area network (LPWAN) | Proprietary service tailored to IoT networks in a star topology operating on unlicensed ISM frequency band | Low power consumption Low-cost because the network and computing complexity is managed in the cloud | Not supported in all countries Susceptible to signal interference in some countries |

| Cellular | Network distributed in “cells” served by a fixed location transceiver. Most use star topology | Broad device support Available globally with large and growing infrastructure | Bandwidth can be limited due to network traffic High power |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Antony, A.P.; Leith, K.; Jolley, C.; Lu, J.; Sweeney, D.J. A Review of Practice and Implementation of the Internet of Things (IoT) for Smallholder Agriculture. Sustainability 2020, 12, 3750. https://doi.org/10.3390/su12093750

Antony AP, Leith K, Jolley C, Lu J, Sweeney DJ. A Review of Practice and Implementation of the Internet of Things (IoT) for Smallholder Agriculture. Sustainability. 2020; 12(9):3750. https://doi.org/10.3390/su12093750

Chicago/Turabian StyleAntony, Anish Paul, Kendra Leith, Craig Jolley, Jennifer Lu, and Daniel J. Sweeney. 2020. "A Review of Practice and Implementation of the Internet of Things (IoT) for Smallholder Agriculture" Sustainability 12, no. 9: 3750. https://doi.org/10.3390/su12093750

APA StyleAntony, A. P., Leith, K., Jolley, C., Lu, J., & Sweeney, D. J. (2020). A Review of Practice and Implementation of the Internet of Things (IoT) for Smallholder Agriculture. Sustainability, 12(9), 3750. https://doi.org/10.3390/su12093750