New Business Models for Sustainable Spare Parts Logistics: A Case Study

Abstract

1. Introduction and Literature Review

2. Materials and Methods: The FIL3D Project

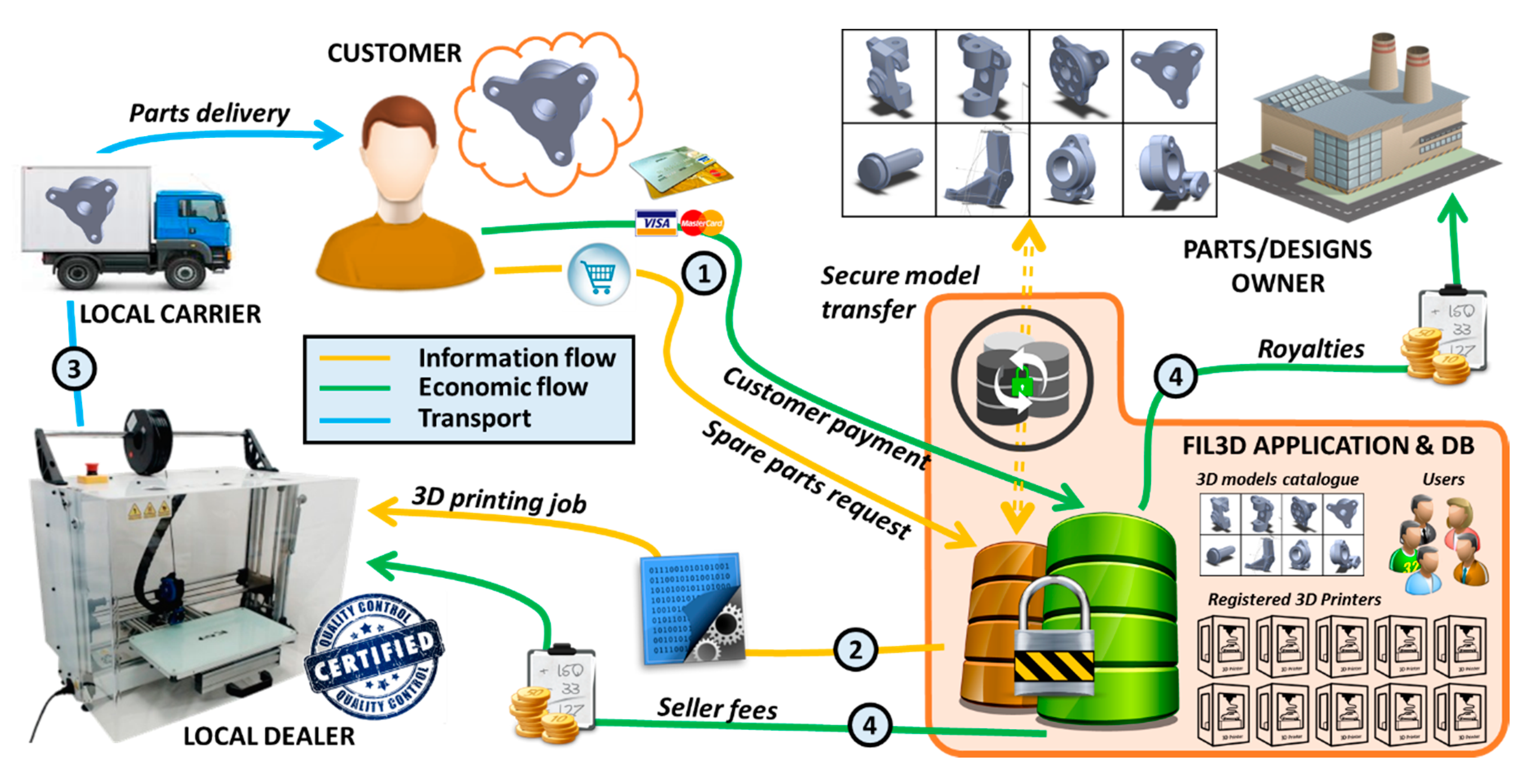

2.1. Proposed Service

- Sets of 3D parts/models/designs of different owners/manufacturers, with their associated information about intellectual property rights (IPR), royalties, materials, tolerances, colors, and printing specifications, etc.

- 3D printing hubs: registered local 3D-printing producers (dealers/resellers), including their location, printing capabilities (materials, sizes, etc.), certifications (whether they are certified by certain manufacturers or not), costs, response/delivery times, and reviews, etc.

- Registered customers with personal profile, delivery address, billing information, and order history, etc.

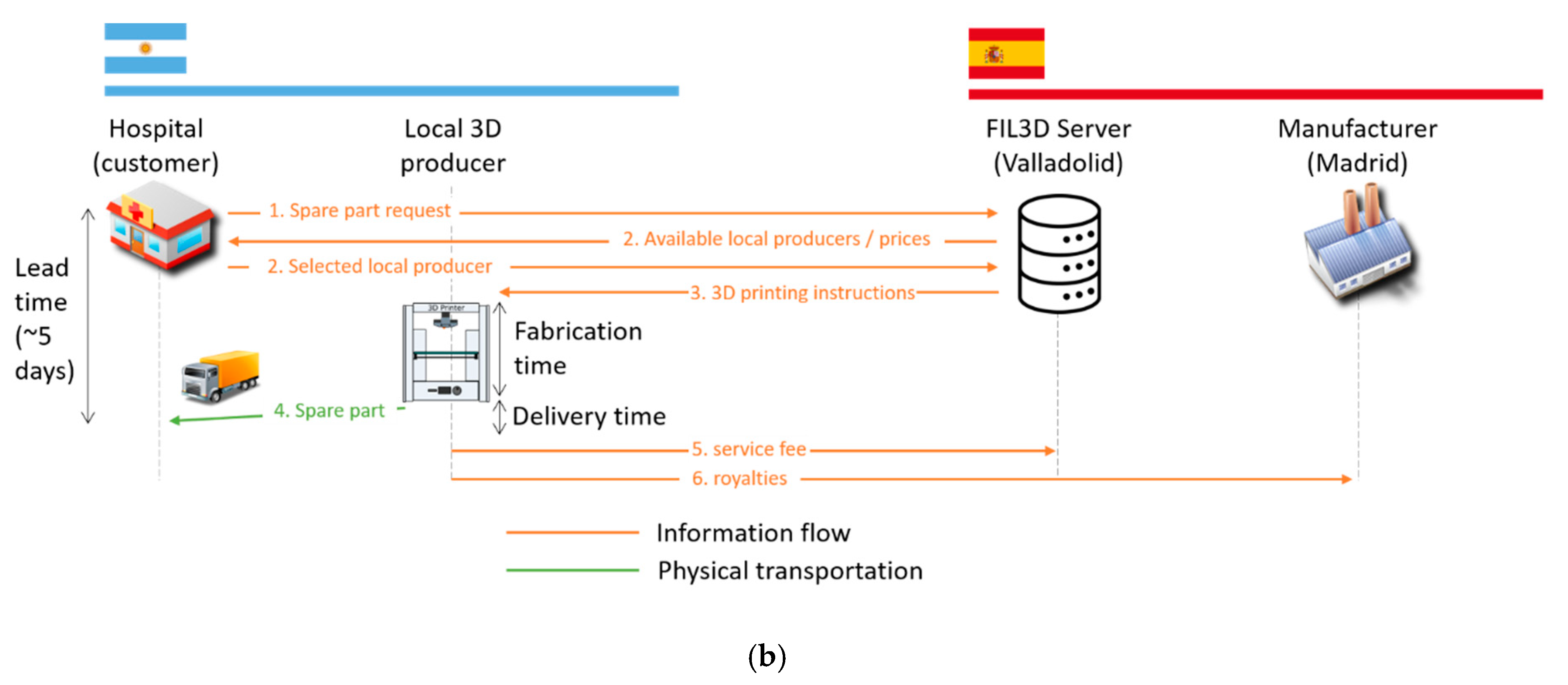

- Customers log into the system to request a spare part. The system will offer a list of registered 3D printers and their associated information (3D technology, speed, delivery time, and price, etc.). Customers may use this information to purchase the replacement part that they need by selecting their preferred local dealer. The system also processes customers’ payments.

- The system searches and processes the required 3D model in the database, where the instructions to print the spare part are stored. This information is sent through the digital supply chain to the selected local dealer. Note that IPR have been considered in this project. If printing a spare part requires obtaining permission from an owner, it is requested prior to sending the instructions to the local dealer. Then the system processes 3D models by remotely queuing the job in the dealer’s hub.

- Once the spare part has been printed, it is delivered to the customer directly from the local dealer.

- The local dealer receives its fee from the FIL3D application and the design’s owner receives their royalties.

2.2. FIWARE

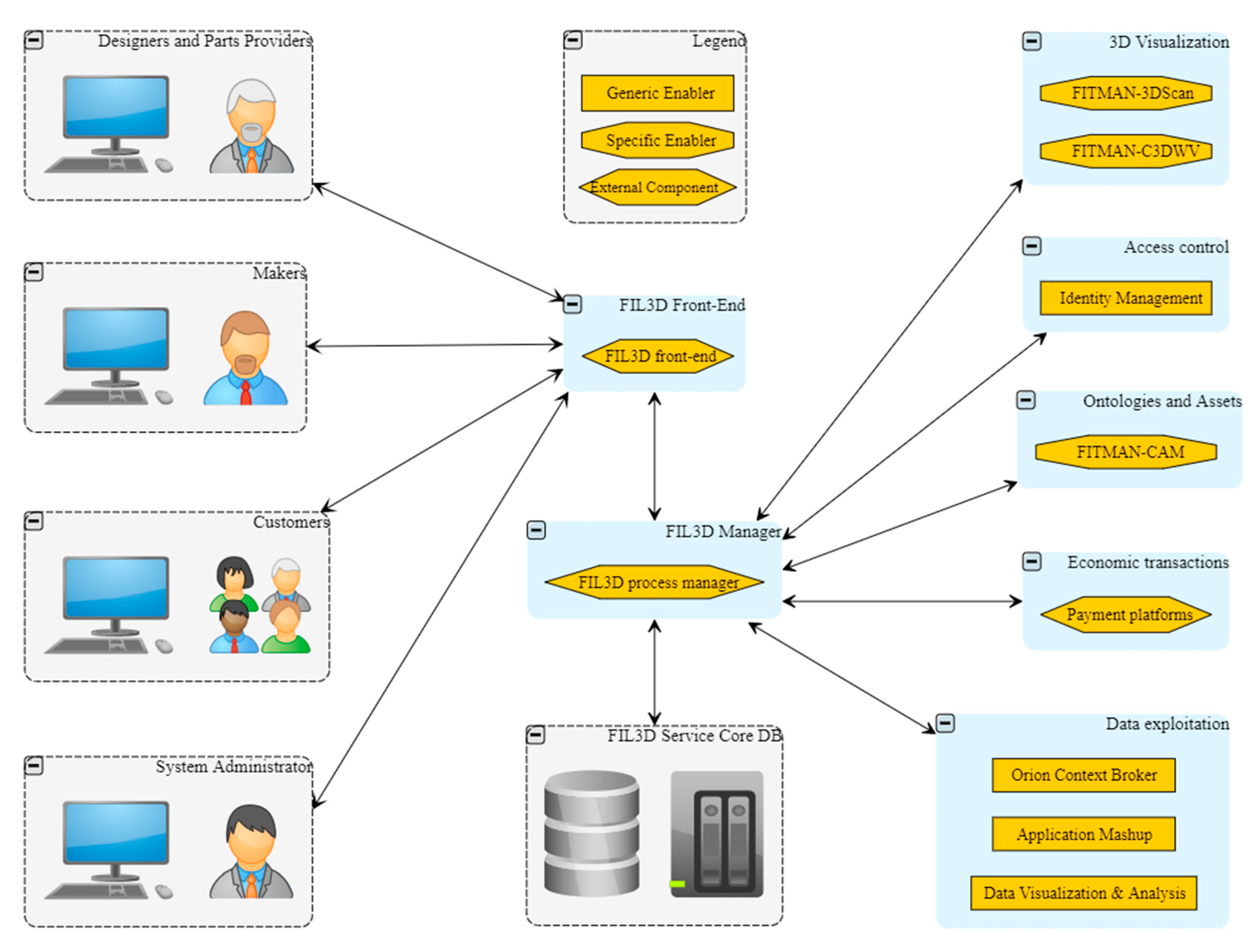

2.3. Implementation

- A secure payment platform which guarantees that each party pays/receives the corresponding fee. It also handles cancelations and service claims.

- An IPR-consistent data management system which guarantees that the IPR issues associated with data exchanges are fulfilled.

- A Business Core Module that implements all business processes (represented to the lower right part of Figure 1), including:

- ○

- Registration of actors of the service platform (customers, parts owners, and local producers);

- ○

- Uploading 3D models by owners into the database (with their associated information);

- ○

- Ordering, selecting models from the repository database, and the preferred local dealer;

- ○

- Order Processing, to generate, place and track the orders assigned to dealers;

- ○

- Acceptance and confirmation of service, when it has been accepted and performed by the dealer, and that parts have been delivered to the customer;

- ○

- Cancelations, by either customers or dealers, and service claims (late deliveries, or low quality, etc.);

- ○

- Secure economic exchanges platform: i) customers will be able to pay using several secure methods; ii) if the dealer accepts the job, the corresponding royalties are paid to the owner; iii) when the job is printed and delivered, the dealer receives its commission;

- ○

- Requests of new models to owners for their inclusion in the catalog.

- User Interface for each actor and business process integrated into the service, including 3D edition and visualization, task information, management dashboard, and user profiles, etc.:

- ○

- A Secure Data Management System, as most designs will be protected by IPR;

- ○

- A 3D Model Processing Module, to generate and queue a secure printing job;

- ○

- A Secure Payment Platform for customer payments, warranty coverages, royalties, and retributions, etc.

2.4. The FABulous Project

2.5. The Company: Dima3D

3. Experimentation and Results

3.1. Description of the Business Trial

- The company that played the “Local maker” role had to refine the parameterization of 3D printers because it determined the way that designs had to be analyzed so they could provide accurate quotations for each model and 3D printing technology. The company DIMA3D played this role.

- The companies that played the “Designer/manufacturer” role had to create a categorized catalog based on 3D designs and how they had to be specified, so that the system could calculate quotations for customers according to the makers’ specifications.

- These companies defined the printers’ certifications process and the specifications for the printed spare parts. The royalties, fees, and tariffs were also determined at this point.

- Finally, a fictitiously created customer simulated orders, which were attended to by the FIL3D platform.

- Test the consistency of all the platform features.

- Make a realistic approach to 3D printers’ specification for different technologies.

- Analyze user experience and refine interfaces and administration indicators.

- Test the business process, information and payment flows.

- Refine the service platform according to the test results and partners’ feedback.

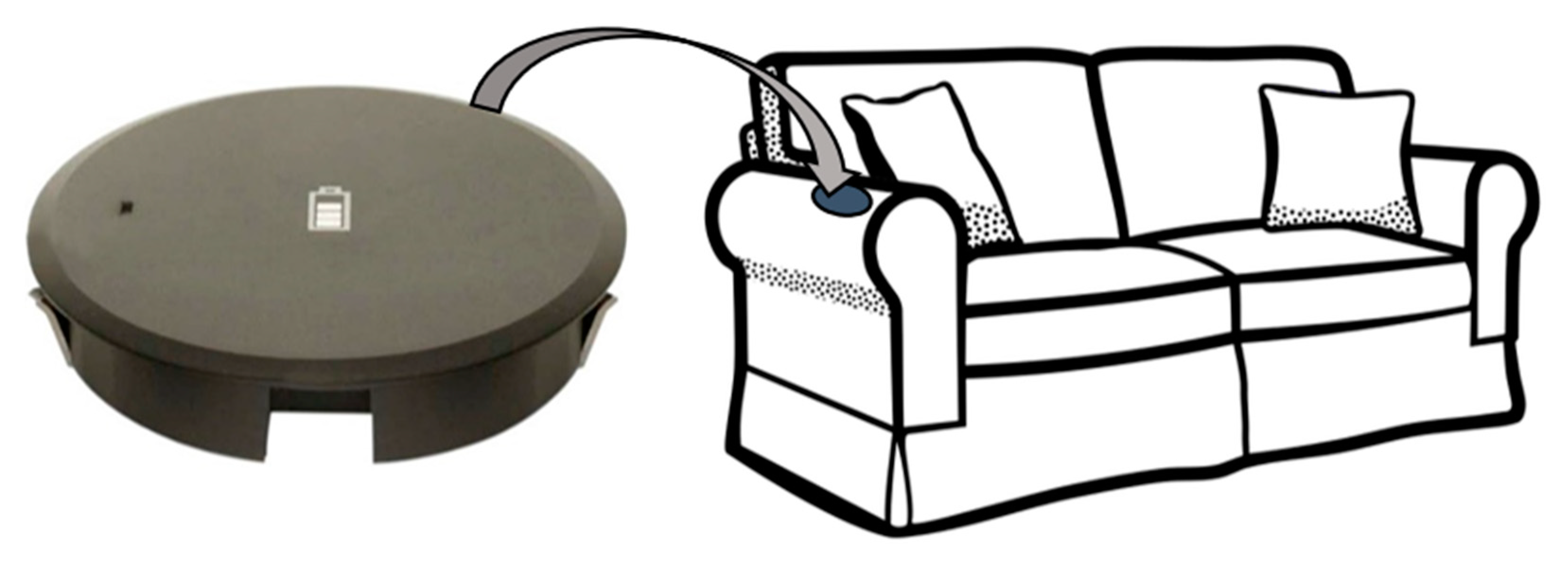

3.2. Experiment 1: The Furniture Manufacturer

- They could avoid the investment to manage new inventories, while reducing costs due to the compulsory warranty period.

- The after-sales service will be a new source of value for the company, which will allow it to exploit its innovations with zero marginal costs.

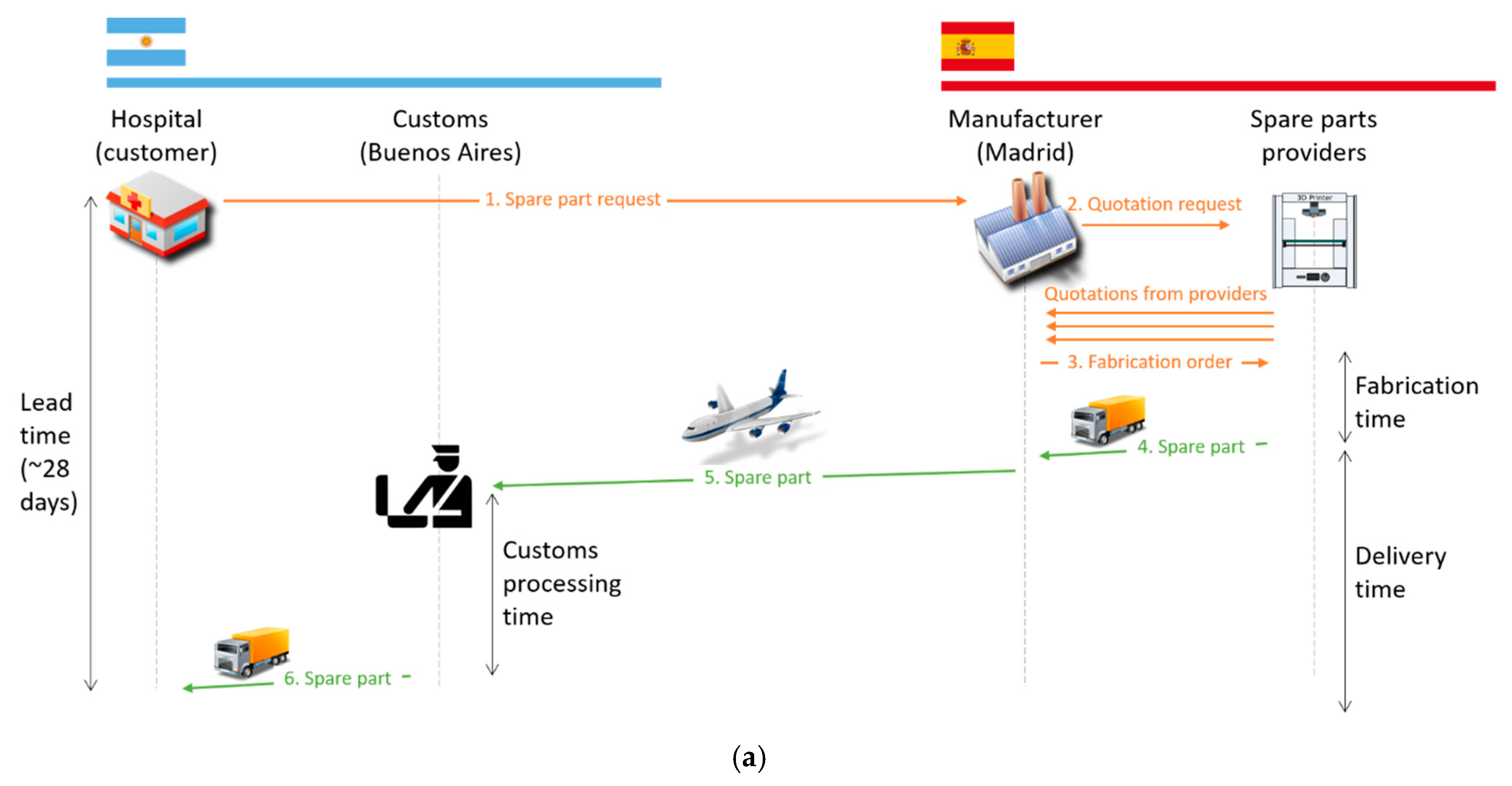

3.3. Experiment 2: The Manufacturer of Electronic Components in the Healthcare Sector

- The customer orders replacements for one or more boxes from the manufacturer.

- The manufacturer requests a quotation (and delivery time) from several of the 3D printing manufacturers that it works with. It sends the STereoLithography (STL) files for a quotation.

- The manufacturer places the order with one of the providers.

- The manufacturer receives the order and proceeds with its packaging. An exportation invoice is attached. Some procedures with take place the logistics operator.

- The shipment goes through customs in the destination country. The administrative process is followed.

- The customer pays the import taxes and a logistic operator delivers the shipment.

- The customer orders the spare part directly from the FIL3D application.

- The customer either selects a local supplier or FIL3D automatically assigns the order to the certified supplier that provides the best conditions in time and cost terms.

- The spare part is sent to the customer.

- Quality Service: reducing the time to deliver spare parts, while ensuring their quality with a certified local maker.

- Cost reduction: the administrative process and logistics required to deliver spare parts to end customers were fully minimized. This is also relevant during the warranty period as the company can proceed with orders to ensure that components are in place on time, while zero stocks are required.

- After-sales service: it can be a source of extra income instead of a cost driver. The company will receive the set royalties, if it decides to, or simply provides the way to acquire spare parts at a low cost from a local provider.

4. Discussion and Conclusions

- Small and medium manufacturers (the “Designer/manufacturer” who owns the IPR) that wish to guarantee the supply of spare parts without having to increase their logistics costs.

- Local 3D printer owners and businesses located closely to end customers (“Local makers”).

4.1. What Benefits does FIL3D Offer to the Participants in This Project?

4.2. Limitations and Aspects to Develop

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Mellor, S.; Hao, L.; Zhang, D.Z. Additive manufacturing: A framework for implementation. Int. J. Prod. Econ. 2014, 149, 194–201. [Google Scholar] [CrossRef]

- Verboeket, V.; Krikke, H. The disruptive impact of additive manufacturing on supply chains: A literature study, conceptual framework and research agenda. Comput. Ind. 2019, 111, 91–107. [Google Scholar] [CrossRef]

- Büyüközkan, G.; Göçer, F. Digital Supply Chain: Literature review and a proposed framework for future research. Comput. Ind. 2018, 97, 157–177. [Google Scholar] [CrossRef]

- Mohr, S.; Khan, O. 3D Printing and Its Disruptive Impacts on Supply Chains of the Future. Technol. Innov. Manag. Rev. 2015, 5, 20–25. [Google Scholar] [CrossRef]

- Daduna, J.R. Disruptive effects on logistics processes by additive manufacturing. IFAC-PapersOnLine 2019, 52, 2770–2775. [Google Scholar] [CrossRef]

- Preindl, R.; Nikolopoulos, K.; Litsiou, K. Transformation strategies for the supply chain: The impact of industry 4.0 and digital transformation. Supply Chain Forum: Int. J. 2020, 21, 26–34. [Google Scholar] [CrossRef]

- Baumers, M.; Dickens, P.; Tuck, C.; Hague, R. The cost of additive manufacturing: Machine productivity, economies of scale and technology-push. Technol. Forecast. Soc. Chang. 2016, 102, 193–201. [Google Scholar] [CrossRef]

- Holmström, J.; Holweg, M.; Khajavi, S.H.; Partanen, J. The direct digital manufacturing (r)evolution: Definition of a research agenda. Oper. Manag. Res. 2016, 9, 1–10. [Google Scholar] [CrossRef]

- Knofius, N.; Van Der Heijden, M.; Zijm, H. Moving to additive manufacturing for spare parts supply. Comput. Ind. 2019, 113, 103134. [Google Scholar] [CrossRef]

- Heinen, J.J.; Hoberg, K. Assessing the potential of additive manufacturing for the provision of spare parts. J. Oper. Manag. 2019, 65, 810–826. [Google Scholar] [CrossRef]

- Dekker, R.; Pinçe, Ç.; Zuidwijk, R.; Jalil, M. On the use of installed base information for spare parts logistics: A review of ideas and industry practice. Int. J. Prod. Econ. 2013, 143, 536–545. [Google Scholar] [CrossRef]

- Pérès, F.; Noyes, D. Envisioning e-logistics developments: Making spare parts in situ and on demand. Comput. Ind. 2006, 57, 490–503. [Google Scholar] [CrossRef]

- Wyman, O. 3D printing is already starting to threaten the traditional spare parts supply chain. Forbes 2017. [Google Scholar]

- Li, Y.; Cheng, Y.; Hu, Q.; Zhou, S.; Ma, L.; Lim, M.K. The influence of additive manufacturing on the configuration of make-to-order spare parts supply chain under heterogeneous demand. Int. J. Prod. Res. 2018, 57, 3622–3641. [Google Scholar] [CrossRef]

- Chekurov, S.; Metsä-Kortelainen, S.; Salmi, M.; Roda, I.; Jussila, A. The perceived value of additively manufactured digital spare parts in industry: An empirical investigation. Int. J. Prod. Econ. 2018, 205, 87–97. [Google Scholar] [CrossRef]

- Frandsen, C.S.; Nielsen, M.M.; Chaudhuri, A.; Jayaram, J.; Govindan, K. In search for classification and selection of spare parts suitable for additive manufacturing: A literature review. Int. J. Prod. Res. 2019, 58, 970–996. [Google Scholar] [CrossRef]

- Kostidi, E.; Nikitakos, N. Additive Manufacturing of Spare Parts in the Maritime Industry in the Digital Era; Full Paper; IAME: Athens, Greece, 2019. [Google Scholar]

- Savastano, M.; Amendola, C.; D’Ascenzo, F.; Massaroni, E. 3-D Printing in the Spare Parts Supply Chain: An Explorative Study in the Automotive Industry. In Digitally Supported Innovation; Springer: Cham, Germany, 2016; Volume 18, pp. 153–170. [Google Scholar]

- Mami, F.; Fallaha, S.; Margni, M.; Revéret, J.-P. Evaluating Eco-Efficiency of 3D Printing in the Aeronautic Industry. J. Ind. Ecol. 2017, 21, S37–S48. [Google Scholar] [CrossRef]

- Kleer, R.; Piller, F.T. Local manufacturing and structural shifts in competition: Market dynamics of additive manufacturing. Int. J. Prod. Econ. 2019, 216, 23–34. [Google Scholar] [CrossRef]

- Beltagui, A.; Kunz, N.; Gold, S. The role of 3D printing and open design on adoption of socially sustainable supply chain innovation. Int. J. Prod. Econ. 2020, 221, 107462. [Google Scholar] [CrossRef]

- Despeisse, M.; Baumers, M.; Brown, P.; Charnley, F.; Ford, S.; Garmulewicz, A.; Knowles, S.; Minshall, T.; Mortara, L.; Reed-Tsochas, F.; et al. Unlocking value for a circular economy through 3D printing: A research agenda. Technol. Forecast. Soc. Chang. 2017, 115, 75–84. [Google Scholar] [CrossRef]

- Kellens, K.; Baumers, M.; Gutowski, T.G.; Flanagan, W.; Lifset, R.; Duflou, J. Environmental Dimensions of Additive Manufacturing: Mapping Application Domains and Their Environmental Implications. J. Ind. Ecol. 2017, 21, S49–S68. [Google Scholar] [CrossRef]

- Mehrpouya, M.; Dehghanghadikolaei, A.; Fotovvati, B.; Vosooghnia, A.; Emamian, S.S.; Gisario, A. The Potential of Additive Manufacturing in the Smart Factory Industrial 4.0: A Review. Appl. Sci. 2019, 9, 3865. [Google Scholar] [CrossRef]

- Peng, T.; Kellens, K.; Tang, R.; Chen, C.; Chen, G. Sustainability of additive manufacturing: An overview on its energy demand and environmental impact. Addit. Manuf. 2018, 21, 694–704. [Google Scholar] [CrossRef]

- European-Commission. What is an SME? Available online: https://ec.europa.eu/growth/smes/business-friendly-environment/sme-definition_en (accessed on 29 February 2020).

- Mittal, S.; Khan, M.A.; Romero, D.; Wuest, T. A critical review of smart manufacturing & Industry 4.0 maturity models: Implications for small and medium-sized enterprises (SMEs). J. Manuf. Syst. 2018, 49, 194–214. [Google Scholar]

- Martinsuo, M.; Luomaranta, T. Adopting additive manufacturing in SMEs: Exploring the challenges and solutions. J. Manuf. Technol. Manag. 2018, 29, 937–957. [Google Scholar] [CrossRef]

- Kaartinen, H.; Pieska, S.; Vahasoyrinki, J. Digital manufacturing toolbox for supporting the manufacturing SMEs. In Proceedings of the 2016 7th IEEE International Conference on Cognitive Infocommunications (CogInfoCom), Wrocław, Poland, 16–18 October 2016; p. 000076. [Google Scholar]

- Mittal, S.; Romero, D.; Wuest, T. Towards a Smart Manufacturing Toolkit for SMEs. In Product Lifecycle Management to Support Industry 4.0. PLM 2018. IFIP Advances in Information and Communication Technology, vol 540; Springer: Cham, Germany, 2018; pp. 476–487. [Google Scholar]

- Shah, S.; Mattiuzza, S.; Ganji, E.N.; Coutroubis, A.D. Contribution of Additive Manufacturing Systems to Supply Chain. In Proceedings of the 2017 International Conference on Industrial Engineering, Management Science and Application (ICIMSA), Seoul, Korea, 16–18 December 2017; pp. 1–5. [Google Scholar]

- Savolainen, J.; Collan, M. How Additive Manufacturing Technology Changes Business Models?—Review of Literature. Addit. Manuf. 2020, 32, 101070. [Google Scholar] [CrossRef]

- Müller, J.M.; Buliga, O.; Voigt, K.-I. Fortune favors the prepared: How SMEs approach business model innovations in Industry 4.0. Technol. Forecast. Soc. Chang. 2018, 132, 2–17. [Google Scholar] [CrossRef]

- Niaki, M.K.; Nonino, F. Impact of additive manufacturing on business competitiveness: A multiple case study. J. Manuf. Technol. Manag. 2017, 28, 56–74. [Google Scholar] [CrossRef]

- Shah, S.; Mattiuzza, S. Adoption of Additive Manufacturing Approaches: The Case of Manufacturing SMEs. In Proceedings of the 2018 IEEE International Conference on Engineering, Technology and Innovation (ICE/ITMC), Stuttgart, Germany, 17–20 June 2018; pp. 1–8. [Google Scholar]

- Yin, R.K. Designing Case Studies. In Case Study Research and Applications: Design and Methods, 6th ed.; SAGE Publications, Inc.: Los Angeles, CA, USA, 2017. [Google Scholar]

- Niaki, M.K.; Nonino, F. Additive manufacturing management: A review and future research agenda. Int. J. Prod. Res. 2016, 55, 1–21. [Google Scholar]

- Fabulous. FABulous: The 3D Printing European Accelerator. Available online: http://fabulous-fi.eu (accessed on 28 February 2020).

- Fiware. FIWARE: The Open Source Platform for Our Smart Digital Future. Available online: https://www.fiware.org/ (accessed on 28 February 2020).

- Zaharov, A.A.; Nissenbaum, O.V.; Ponomarov, K.Y.; Shirokih, A.V. Use of Open-Source Internet of Things Platform in Education Projects. In Proceedings of the 2018 Global Smart Industry Conference (GloSIC), Chelyabinsk, Russia, 13–15 November 2018; pp. 1–6. [Google Scholar]

- Westerweel, B.; Song, J.-S.J.; Basten, R.J. 3D Printing of Spare Parts Via IP License Contracts. SSRN Electron. J. 2019, 2019, 1–33. [Google Scholar] [CrossRef]

- Sureshchandar, G.; Rajendran, C.; Anantharaman, R. The relationship between service quality and customer satisfaction—A factor specific approach. J. Serv. Mark. 2002, 16, 363–379. [Google Scholar] [CrossRef]

- Ford, S.; Despeisse, M. Additive manufacturing and sustainability: An exploratory study of the advantages and challenges. J. Clean. Prod. 2016, 137, 1573–1587. [Google Scholar] [CrossRef]

- Nascimento, D.L.M.; Alencastro, V.; Quelhas, O.L.G.; Caiado, R.G.G.; Garza-Reyes, J.A.; Lona, L.R.; Tortorella, G.L. Exploring Industry 4.0 technologies to enable circular economy practices in a manufacturing context. J. Manuf. Technol. Manag. 2019, 30, 607–627. [Google Scholar] [CrossRef]

- Minetola, P.; Calignano, F.; Galati, M. Comparing geometric tolerance capabilities of additive manufacturing systems for polymers. Addit. Manuf. 2020, 32, 101103. [Google Scholar] [CrossRef]

- Davis, C.S.; Hillgartner, K.E.; Han, S.H.; Seppala, J.E. Mechanical strength of welding zones produced by polymer extrusion additive manufacturing. Addit. Manuf. 2017, 16, 162–166. [Google Scholar] [CrossRef]

- Suresh, A.; Udendhran, R.; Yamini, G. Internet of Things and Additive Manufacturing: Toward Intelligent Production Systems in Industry 4.0. In Internet of Things for Industry 4.0. EAI/Springer Innovations in Communication and Computing; Springer: Cham, Germany, 2019; Volume 2020, pp. 73–89. [Google Scholar]

| Challenge | FIWARE Specific Platform | Applications |

|---|---|---|

| Crowd-sourced and cloud-based design and services for 3D Printing | FITMAN DyVisual | Standard 3D model visualization. |

| FITMAN 3DScan | Handle 3D model acquisition and storage: input files, database exchanges, and 3D scanning, etc. | |

| FITMAN 3D Web Viewer | Visualization and collaborative edition or customization of 3D models by users/designers. | |

| Manufacturing and Logistics Tools and Services | FITMAN DyCEP | Real-time control and decision-making in the manufacturing process. |

| FITMAN SEM | Arrange transfers between authorized peers for Intellectual Property Rights (IPR) management. Action triggering on production events. | |

| FITMAN-BPM | Implementation of the business logic, including task management. | |

| FITMAN-CAM | Specify and store users’ information assets and attributes. | |

| FITMAN-Anlzer | Analyze customer satisfaction and evaluate the social impact of the service and its marketing actions. | |

| GE Orion Context Broker | Handle and publish application context information. | |

| GE Application Mashup | Create a dashboard with key management indicators for users. | |

| GE Data Visualization and Analysis | Statistical analysis of application data and report generation. | |

| GE Identity Management | Provide a secure access system for the application so that each user is identified and Intellectual Property Rights (IPR) issues can be considered. |

| Company (Role) | Reasons | Expectations from the Participation of the Partner |

|---|---|---|

| Designer/manufacturer (a company that needs to guarantee the supply of spare parts at a distant location from the manufacturing site) | Besides their own designs, these companies may be in contact with many other designers and manufacturers. They may have several patents for innovative furniture parts. They have already prototyped some of their designs by 3D printing. | They are expected to provide some designs to be included in the service catalog. They can provide a realistic approach to the spare parts market for their sector (prices, design fees, certifications, etc.). |

| Local maker (a 3D printing company whose equipment is located near the end customer) | They have experience in 3D printers of several manufacturers and technologies. They have experience in prototyping for different customers: private, companies, etc. Large printing capability based on several 3D printing machines. They have experience in testing other online printing platforms. | Feedback from using the functionalities for makers. Refinement of 3D printers’ parameterization to specify both technical and economic aspects so that makers can provide more accurate budgets for designs. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

González-Varona, J.M.; Poza, D.; Acebes, F.; Villafáñez, F.; Pajares, J.; López-Paredes, A. New Business Models for Sustainable Spare Parts Logistics: A Case Study. Sustainability 2020, 12, 3071. https://doi.org/10.3390/su12083071

González-Varona JM, Poza D, Acebes F, Villafáñez F, Pajares J, López-Paredes A. New Business Models for Sustainable Spare Parts Logistics: A Case Study. Sustainability. 2020; 12(8):3071. https://doi.org/10.3390/su12083071

Chicago/Turabian StyleGonzález-Varona, José M., David Poza, Fernando Acebes, Félix Villafáñez, Javier Pajares, and Adolfo López-Paredes. 2020. "New Business Models for Sustainable Spare Parts Logistics: A Case Study" Sustainability 12, no. 8: 3071. https://doi.org/10.3390/su12083071

APA StyleGonzález-Varona, J. M., Poza, D., Acebes, F., Villafáñez, F., Pajares, J., & López-Paredes, A. (2020). New Business Models for Sustainable Spare Parts Logistics: A Case Study. Sustainability, 12(8), 3071. https://doi.org/10.3390/su12083071