Modelling Bioeconomy Scenario Pathways for the Forest Products Markets with Emerging Lignocellulosic Products

Abstract

1. Introduction

2. Materials and Methods

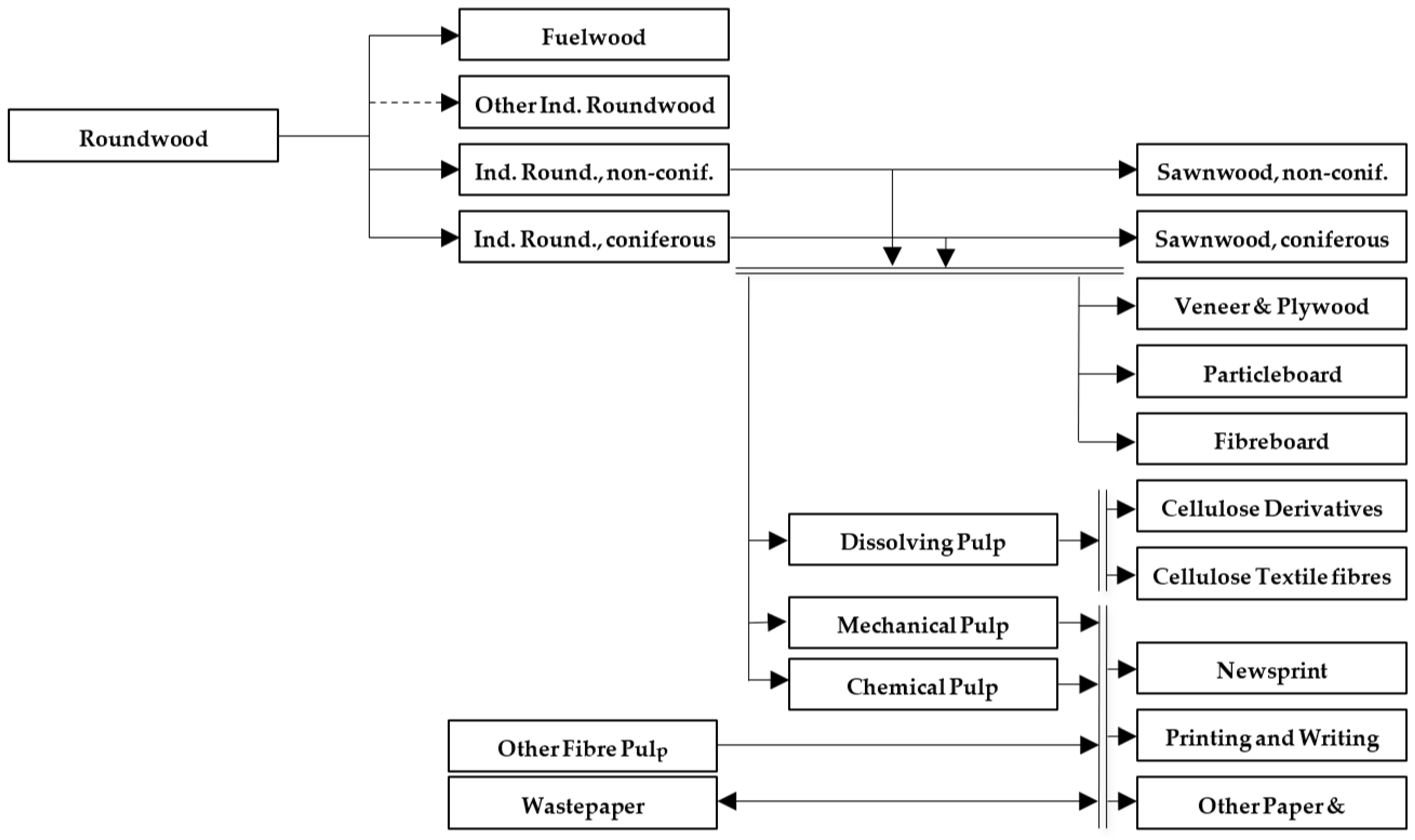

2.1. GFPM

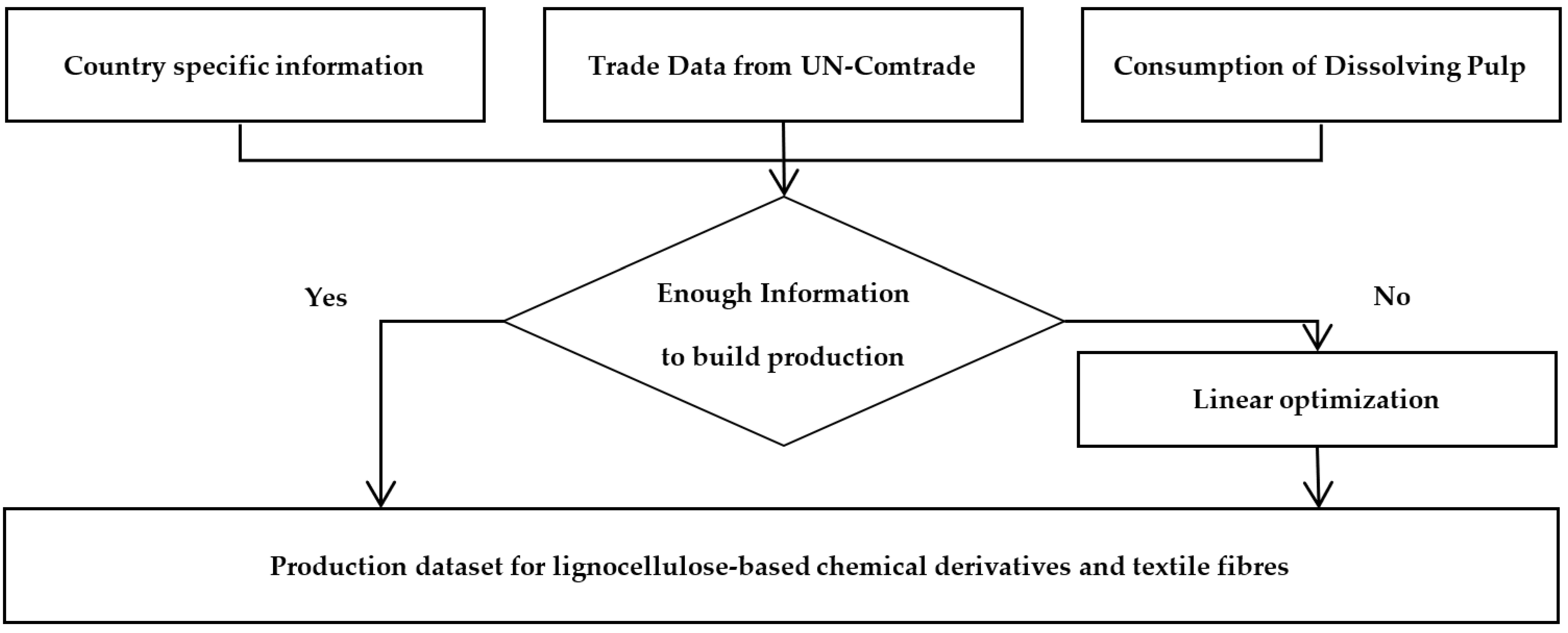

2.2. Implementation of Lignocellulose-Based Products in the GFPM Framework

2.3. Future Pathways for Bioeconomy Scenarios

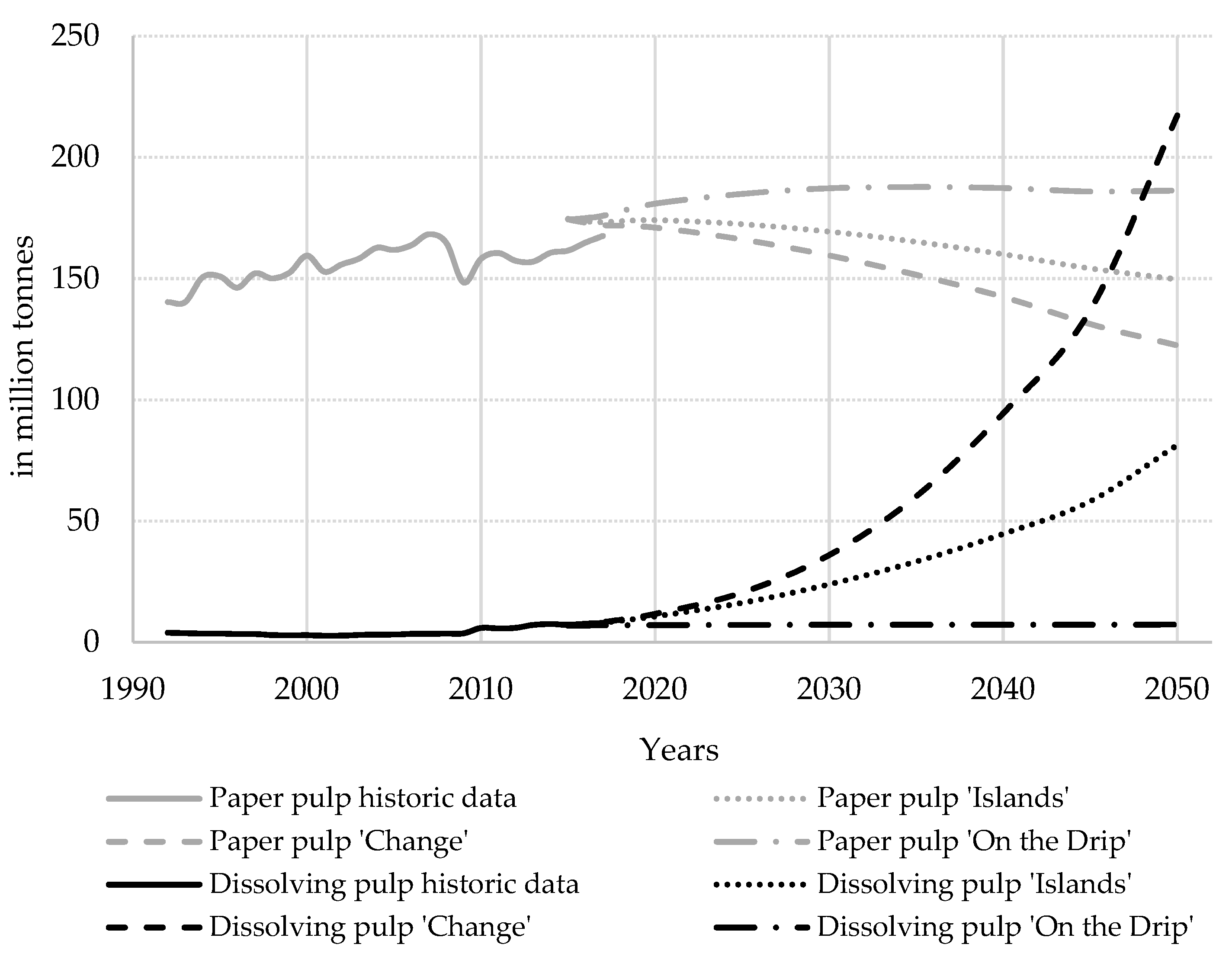

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Country | Country Specific Information about TF | Share of Global Production [25] | Dissolving Pulp (DP) Consumption in t [4] |

|---|---|---|---|

| Austria | 400 kt Capacity [24] | 9% in Europe | 355,274.00 |

| Germany | 238 kt Production in 2011 [23] | 9% in Europe | 424,000.00 |

| United Kingdom | 45 kt Capacity [24] | 9% in Europe | 48,468.00 |

| China | 66% | 4,495,676.00 | |

| India | 9% | 828,875.00 | |

| Indonesia | Viscose Production 320 kt [24] | 9% | 360,286.00 |

| Thailand | 3% | 141,129.00 | |

| USA | 1% in North America | 411,000.00 | |

| Canada | 1% in North America | 101,512.00 | |

| Japan | 1% | 167,629.00 | |

| World | 5.6 mt Production in 2016 [39] | 100% | 8,251,431.00 |

| Country | DP Input for TF in t | in % of Global |

|---|---|---|

| Austria | 319,747 | 5.1% |

| Germany | 251,651 | 4.0% |

| United Kingdom | 45,075 | 0.7% |

| China | 4,046,108 | 64.3% |

| India | 580,213 | 9.2% |

| Indonesia | 360,286 | 5.7% |

| Thailand | 141,129 | 2.2% |

| USA | 41,100 | 0.7% |

| Canada | 10,151 | 0.2% |

| Japan | 83,815 | 1.3% |

| World | 6,294,984 | 100% |

| Sceanrio | ISO Code | Country | GDPpC growth 1 | TechChange 2 | Forest Growth 3 |

|---|---|---|---|---|---|

| Bioeconomy Change | BRA | Brazil | 3.14% | 0.28% | 0.21% |

| Bioeconomy Change | CAN | Canada | 1.07% | 0.91% | 0.31% |

| Bioeconomy Change | CHN | China | 4.99% | 0.23% | 1.79% |

| Bioeconomy Change | DEU | Germany | 1.35% | 0.91% | 1.66% |

| Bioeconomy Change | FIN | Finland | 1.41% | 0.91% | 1.65% |

| Bioeconomy Change | IDN | Indonesia | 5.56% | 0.31% | 0.57% |

| Bioeconomy Change | IND | India | 5.35% | 0.28% | 1.65% |

| Bioeconomy Change | RUS | Russian Federation | 3.13% | 0.66% | 0.17% |

| Bioeconomy Change | SWE | Sweden | 1.42% | 0.73% | 1.36% |

| Bioeconomy Change | USA | United States of America | 1.44% | 0.76% | 1.10% |

| Bioeconomy Islands | BRA | Brazil | 2.25% | 0.15% | 0.22% |

| Bioeconomy Islands | CAN | Canada | 1.33% | 0.25% | 0.32% |

| Bioeconomy Islands | CHN | China | 4.18% | 0.14% | 1.88% |

| Bioeconomy Islands | DEU | Germany | 1.48% | 0.23% | 1.64% |

| Bioeconomy Islands | FIN | Finland | 1.60% | 0.26% | 1.60% |

| Bioeconomy Islands | IDN | Indonesia | 4.45% | 0.10% | 0.57% |

| Bioeconomy Islands | IND | India | 3.95% | 0.13% | 1.70% |

| Bioeconomy Islands | RUS | Russian Federation | 2.86% | 0.25% | 0.20% |

| Bioeconomy Islands | SWE | Sweden | 1.59% | 0.24% | 1.35% |

| Bioeconomy Islands | USA | United States of America | 1.53% | 0.25% | 1.11% |

| Bioeconomy on the Drip | BRA | Brazil | 2.18% | 0.13% | 0.22% |

| Bioeconomy on the Drip | CAN | Canada | 1.11% | 0.14% | 0.32% |

| Bioeconomy on the Drip | CHN | China | 4.01% | 0.14% | 1.88% |

| Bioeconomy on the Drip | DEU | Germany | 1.22% | 0.14% | 1.64% |

| Bioeconomy on the Drip | FIN | Finland | 1.30% | 0.14% | 1.60% |

| Bioeconomy on the Drip | IDN | Indonesia | 4.31% | 0.12% | 0.54% |

| Bioeconomy on the Drip | IND | India | 4.14% | 0.13% | 1.69% |

| Bioeconomy on the Drip | RUS | Russian Federation | 2.54% | 0.13% | 0.20% |

| Bioeconomy on the Drip | SWE | Sweden | 1.32% | 0.13% | 1.35% |

| Bioeconomy on the Drip | USA | United States of America | 1.13% | 0.14% | 1.11% |

References

- Moohan, J.; Stewart, S.A.; Espinosa, E.; Rosal, A.; Rodríguez, A.; Larrañeta, E.; Donnelly, R.F.; Domínguez-Robles, J. Cellulose nanofibers and other biopolymers for biomedical applications. A review. Appl. Sci. 2019, 10, 65. [Google Scholar] [CrossRef]

- Anderson, A.E.; Kalio, M.; Risto, S. System analysis for the forest sector. In System Analysis in Forestry and Forest Industries; Kalio, M., Andersson, A.E., Seppälä, R., Morgan, A., Eds.; North Holland Publishing Co.: Amsterdam, The Netherlands, 1986. [Google Scholar]

- Morland, C.; Schier, F.; Janzen, N.; Weimar, H. Supply and demand functions for global wood markets: Specification and plausibility testing of econometric models within the global forest sector. For. Policy Econ. 2018, 92, 92–105. [Google Scholar] [CrossRef]

- FAO. Forest Produtction and Trade. 2020. Available online: http://www.fao.org/faostat/en/#data/FO (accessed on 24 April 2020).

- Mohanty, A.K.; Vivekanandhan, S.; Pin, J.M.; Misra, M. Composites from renewable and sustainable resources: Challenges and innovations. Science 2018, 362, 536–542. [Google Scholar] [CrossRef]

- Purkus, A.; Lüdtke, J. A systemic evaluation framework for a multi-actor, forest-based bioeconomy governance process: The german charter for wood 2.0 as a case study. For. Policy Econ. 2020, 113, 102113. [Google Scholar] [CrossRef]

- Hansen, E.N. The role of innovation in the forest products industry. J. For. 2010, 108, 348–353. [Google Scholar] [CrossRef]

- Bajpai, P. Production of dissolving-grade pulp. BioResources 2018, 291–311. [Google Scholar] [CrossRef]

- Morrison, B.; Golden, J.S. An empirical analysis of the industrial bioeconomy: Implications for renewable resources and the environment. BioResources 2015, 10. [Google Scholar] [CrossRef]

- Kumar, H.; Christopher, L.P. Recent trends and developments in dissolving pulp production and application. Cellulose 2017, 24, 2347–2365. [Google Scholar] [CrossRef]

- Chen, C.; Duan, C.; Li, J.; Liu, Y.; Ma, X.; Zheng, L.; Stavik, J.; Ni, Y. Cellulose (dissolving pulp) manufacturing processes and properties: A mini-review. BioResources 2016, 11, 12. [Google Scholar] [CrossRef]

- Buongiorno, J.; Zhu, S.S.; Zhang, D.; Turner, J.; Tomberlin, D. The Global Forest Products Model: Structure, Estimation, and Applications; Elsevier: Amsterdam, The Netherlands, 2003. [Google Scholar]

- Riahi, K.; van Vuuren, D.P.; Kriegler, E.; Edmonds, J.; O’Neill, B.C.; Fujimori, S.; Bauer, N.; Calvin, K.; Dellink, R.; Fricko, O.; et al. The shared socioeconomic pathways and their energy, land use, and greenhouse gas emissions implications: An overview. Glob. Environ. Chang. 2017, 42, 153–168. [Google Scholar] [CrossRef]

- Buongiorno, J.; Rougieux, P.; Barkaoui, A.; Zhu, S.; Harou, P. Potential impact of a transatlantic trade and investment partnership on the global forest sector. J. For. Econ. 2014, 20, 252–266. [Google Scholar] [CrossRef]

- Johnston, C.M.T.; Buongiorno, J. Impact of brexit on the forest products industry of the UK and the rest of the world. Forestry 2017, 90, 47–57. [Google Scholar] [CrossRef][Green Version]

- Van Kooten, G.C.; Johnston, C. Global impacts of russian log export restrictions and the canada–u.S. Lumber dispute: Modeling trade in logs and lumber. For. Policy Econ. 2014, 39, 54–66. [Google Scholar] [CrossRef]

- Buongiorno, J. Global modelling to predict timber production and prices: The gfpm approach. Forestry 2014, 88, 291–303. [Google Scholar] [CrossRef]

- Turner, J.; Buongiorno, J.; Zhu, S.; Prestemon, J.; Li, R.; Bulman, L. Modelling the impact of the exotic forest pest nectria on the new zealand forest sector and its major trading partners. N. Z. J. For. Sci. 2007, 37, 383–411. [Google Scholar]

- Schier, F.; Morland, C.; Janzen, N.; Weimar, H. Impacts of changing coniferous and non-coniferous wood supply on forest product markets: A german scenario case study. Eur. J. For. Res. 2018, 137, 279–300. [Google Scholar] [CrossRef]

- FAO. Global Forest Resources Assessments. 2015. Available online: http://www.fao.org/forest-resources-assessment/past-assessments/fra-2015/en/ (accessed on 19 August 2019).

- WorldBank. World Development Indicators. 2020. Available online: http://datatopics.WorldBank.org/world-development-indicators/ (accessed on 16 August 2019).

- UnitedNations. Un Comtrade. 2019. Available online: http://comtrade.un.org/ (accessed on 12 September 2019).

- Fachagentur Nachwachsende Rohstoffe. Marktanalyse Nachwachsende Rohstoffe. Fachagentur Nachwachsende Rohstoffe e. V.: 2014; Volume 34. Available online: https://fnr.de/marktanalyse/marktanalyse.pdf (accessed on 25 August 2020).

- Lenzing. Available online: www.lenzing.com/investors/facts-and-figures/factsheet/ (accessed on 25 August 2020).

- Water Footprint Network. Viscose Fibres Production: An Assessment of Sustainable Issues. Available online: https://waterfootprint.org/media/downloads/Viscose_fibres_Sustainability.pdf (accessed on 25 August 2020).

- Schier, F.; Morland, C.; Dieter, M.; Weimar, H. Estimating supply and demand elasticities of dissolving pulp, lignocellulose-based chemical derivatives and textile fibres in an emerging forest-based bioeconomy. For. Policy Econ. 2020. under review. [Google Scholar]

- Banse, M.; Zander, K.; Babayan, T.; Bringezu, S.; Dammer, L.; Egenolf, V.; Göpel, J.; Haufe, H.; Hempel, C.; Hüfner, R.; et al. Eine Biobasierte Zukunft in Deutschland—Szenarien und Gesellschaftliche Herausforderungen; Johann Heinrich von Thünen-Institut: Braunschweig, Germany, 2020. [Google Scholar]

- Dellink, R.; Chateau, J.; Lanzi, E.; Magné, B. Long-term economic growth projections in the shared socioeconomic pathways. Glob. Environ. Chang. 2017, 42, 200–214. [Google Scholar] [CrossRef]

- Kc, S.; Lutz, W. The human core of the shared socioeconomic pathways: Population scenarios by age, sex and level of education for all countries to 2100. Glob. Environ. Chang. Hum. Policy Dimens. 2017, 42, 181–192. [Google Scholar] [CrossRef]

- Fricko, O.; Havlik, P.; Rogelj, J.; Klimont, Z.; Gusti, M.; Johnson, N.; Kolp, P.; Strubegger, M.; Valin, H.; Amann, M.; et al. The marker quantification of the shared socioeconomic pathway 2: A middle-of-the-road scenario for the 21st century. Glob. Environ. Chang. 2017, 42, 251–267. [Google Scholar] [CrossRef]

- Calvin, K.; Bond-Lamberty, B.; Clarke, L.; Edmonds, J.; Eom, J.; Hartin, C.; Kim, S.; Kyle, P.; Link, R.; Moss, R.; et al. The ssp4: A world of deepening inequality. Glob. Environ. Chang. 2017, 42, 284–296. [Google Scholar] [CrossRef]

- van Vuuren, D.P.; Stehfest, E.; Gernaat, D.E.H.J.; Doelman, J.C.; van den Berg, M.; Harmsen, M.; de Boer, H.S.; Bouwman, L.F.; Daioglou, V.; Edelenbosch, O.Y.; et al. Energy, land-use and greenhouse gas emissions trajectories under a green growth paradigm. Glob. Environ. Chang. 2017, 42, 237–250. [Google Scholar] [CrossRef]

- Buongiorno, J.; Zhu, S.; Raunikar, R.; Prestemon, J.P. Outlook to 2060 for World Forests and Forest Industries: A Technical Document Supporting the Forest Service 2010 RPA Assessment; U.S. Department of Agriculture Forest Service: Washington, DC, USA, 2012.

- Kozlowski, R.M.; Muzyczek, M.; Mackiewicz-Talarczyk, M.; Barriga-Bedoya, J. Quo vadis natural fibres in 21st century? Mol. Cryst. Liq. Cryst. 2016, 627, 198–209. [Google Scholar] [CrossRef]

- Ruiz, L. Global Textile Fibre Demand: Trends and Forecast. Available online: https://www.icac.org/Content/EventDocuments/PdfFiles4407c817_a379_45b7_b3ac_c33809c9ae4d/4OS-Global%20Textile%20Fibres%20Demand-%20Trends%20and%20Forecast.pdf (accessed on 25 August 2020).

- Textile World. Man-Made Fibers Continue to Grow. Available online: https://www.textileworld.com/textile-world/fiber-world/2015/02/man-made-fibers-continue-to-grow/ (accessed on 25 August 2020).

- Textile World. Forecast World Fibre Production. Available online: https://textile-network.com/en/Technical-Textiles/Fasern-Garne/Forecast-world-fibre-production/(gallery)/1 (accessed on 25 August 2020).

- Hempel, C.; Will, S.; Zander, K. Societal Perspectives on a Bio-Economy in Germany: An Explorative Study Using q Methodology. J. Food Syst. Dyn. 2019, 10. [Google Scholar] [CrossRef]

- CIRFS. World Production by Fibre. Available online: https://www.cirfs.org/statistics/key-statistics/world-production-fibre (accessed on 25 August 2020).

| Country Related (GDP per Capita 1) | Forest Products Related (Technological Change 2) | Global Growth of Forest Stock from 2015 to 2050 | ||||

|---|---|---|---|---|---|---|

| High sustainability scenario | SSP1 | 3.655% | Bioeconomy Change | 1.586% | Bioeconomy Change | 27.707% |

| Mid sustainability scenario | SSP4 | 2.887% | Bioeconomy Islands | 0.378% | Bioeconomy Islands | 28.462% |

| Low sustainability scenario | SSP2 | 3.018% | Bioeconomy on the Drip | 0.042% | Bioeconomy on the Drip | 27.945% |

| Commodity | Unit | Global Consumption in 2015 | Global Consumption in 2050 and Growth from 2015 to 2050 in Percentage | |||||

|---|---|---|---|---|---|---|---|---|

| Drip Scenario | Islands Scenario | Change Scenario | ||||||

| Roundwood | mil m3 | 3833.40 | 4332.87 | 13.0% | 4812.13 | 25.5% | 5479.08 | 42.9% |

| Fuelwood | mil m3 | 1847.42 | 2400.32 | 29.9% | 2394.08 | 29.6% | 1265.06 | −31.5% |

| Industrial Roundwood | mil m3 | 1832.62 | 1734.66 | −5.3% | 2219.77 | 21.1% | 4019.40 | 119.3% |

| Industrial Roundwood C | mil m3 | 1066.82 | 996.38 | −6.6% | 1199.33 | 12.4% | 2252.11 | 111.1% |

| Industrial Roundwood NC | mil m3 | 765.82 | 801.21 | 4.6% | 1163.41 | 51.8% | 1767.30 | 130.8% |

| Sawnwood | mil m3 | 464.84 | 456.61 | −1.8% | 527.54 | 13.5% | 545.06 | 17.3% |

| Sawnwood C | mil m3 | 328.95 | 318.24 | −3.3% | 369.99 | 12.5% | 365.44 | 11.1% |

| Sawnwood NC | mil m3 | 135.88 | 138.36 | 1.8% | 157.55 | 15.9% | 179.62 | 32.2% |

| Wood-based panels | mil m3 | 420.71 | 433.86 | 3.1% | 676.10 | 60.7% | 1243.24 | 195.5% |

| Fiberboard | mil m3 | 128.35 | 132.29 | 3.1% | 226.84 | 76.7% | 508.40 | 296.1% |

| Particle Board | mil m3 | 113.15 | 112.53 | −0.6% | 144.76 | 28.0% | 214.52 | 89.6% |

| Veneer Sheets and Plywood | mil m3 | 179.20 | 189.04 | 5.5% | 304.50 | 69.9% | 520.32 | 190.4% |

| Paper pulp | mil t | 174.36 | 186.32 | 6.9% | 149.67 | −14.2% | 122.45 | −29.8% |

| Newsprint | mil t | 26.70 | 27.82 | 4.2% | 22.85 | −14.5% | 14.60 | −45.3% |

| Other Paper and Board | mil t | 282.56 | 322.51 | 14.1% | 304.47 | 7.6% | 212.66 | −24.7% |

| Printing and Writing Paper | mil t | 103.44 | 115.95 | 12.1% | 85.93 | −17.1% | 60.26 | −41.8% |

| Dissolving Pulp | mil t | 6.79 | 7.26 | 6.9% | 81.33 | 1097.5% | 217.27 | 3099.1% |

| Cellulose derivatives | mil t | 2.00 | 2.28 | 14.0% | 11.56 | 477.4% | 10.38 | 418.3% |

| Cellulose regeneratives | mil t | 4.94 | 5.47 | 10.7% | 73.58 | 1388.4% | 207.06 | 4088.9% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Morland, C.; Schier, F. Modelling Bioeconomy Scenario Pathways for the Forest Products Markets with Emerging Lignocellulosic Products. Sustainability 2020, 12, 10540. https://doi.org/10.3390/su122410540

Morland C, Schier F. Modelling Bioeconomy Scenario Pathways for the Forest Products Markets with Emerging Lignocellulosic Products. Sustainability. 2020; 12(24):10540. https://doi.org/10.3390/su122410540

Chicago/Turabian StyleMorland, Christian, and Franziska Schier. 2020. "Modelling Bioeconomy Scenario Pathways for the Forest Products Markets with Emerging Lignocellulosic Products" Sustainability 12, no. 24: 10540. https://doi.org/10.3390/su122410540

APA StyleMorland, C., & Schier, F. (2020). Modelling Bioeconomy Scenario Pathways for the Forest Products Markets with Emerging Lignocellulosic Products. Sustainability, 12(24), 10540. https://doi.org/10.3390/su122410540