An Experimental Investigation on Tribological Behaviour of Tire-Derived Pyrolysis Oil Blended with Biodiesel Fuel

Abstract

1. Introduction

2. Materials and Methods

2.1. Tire Pyrolysis Oil Production and Purification

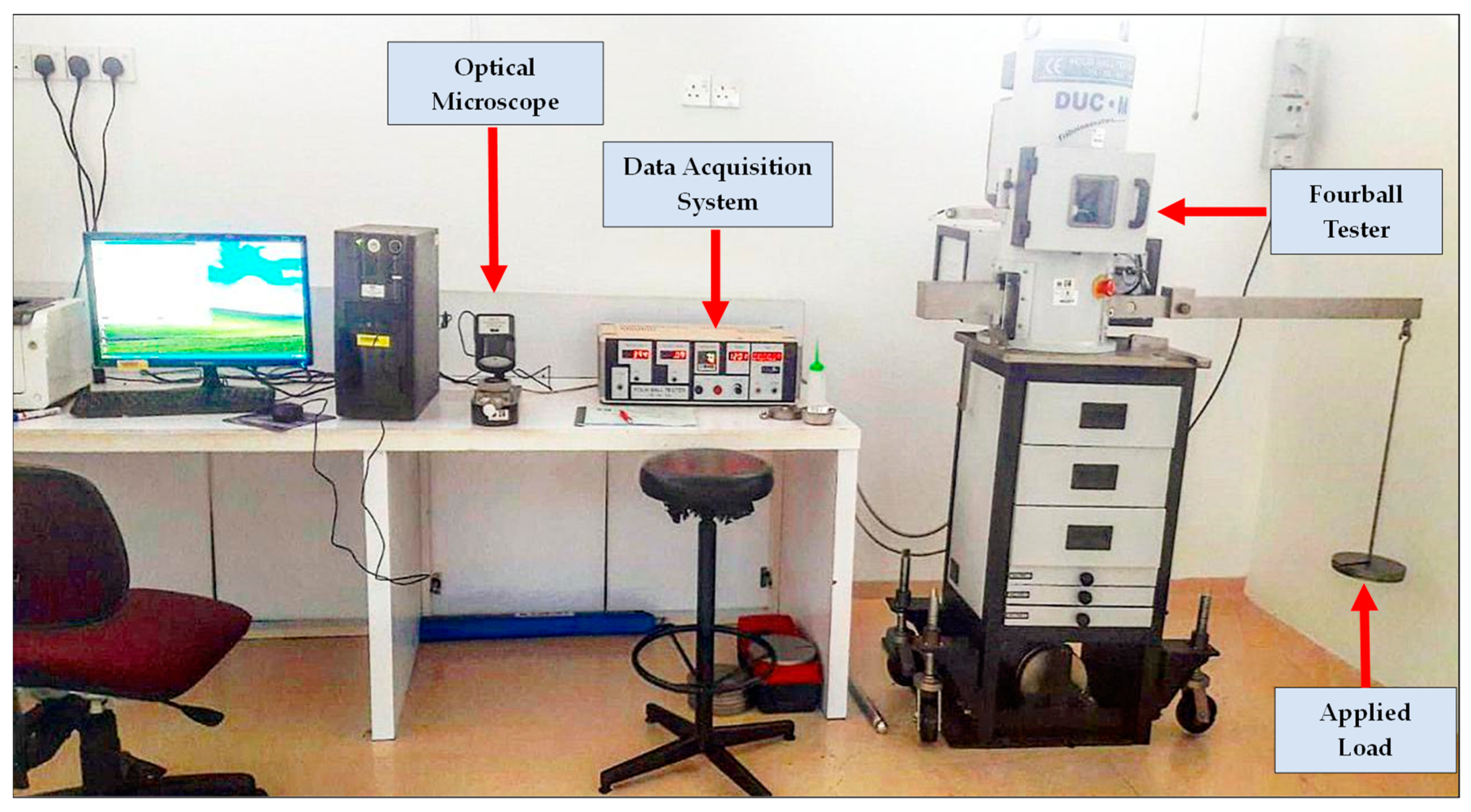

2.2. Test Setup

2.3. Test Procedure

2.3.1. Friction Evaluation

2.3.2. Flash Temperature Parameter

2.3.3. Wear Evaluation

3. Results and Discussion

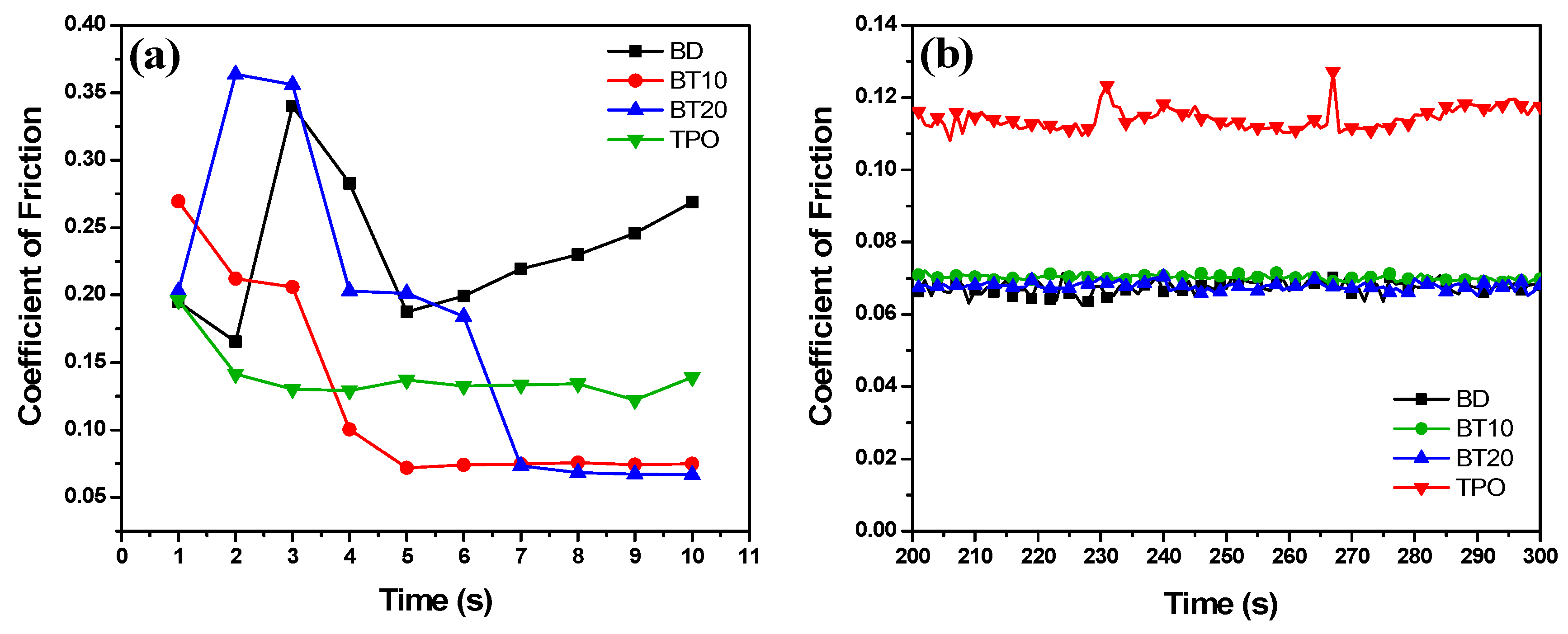

3.1. Friction Behaviour

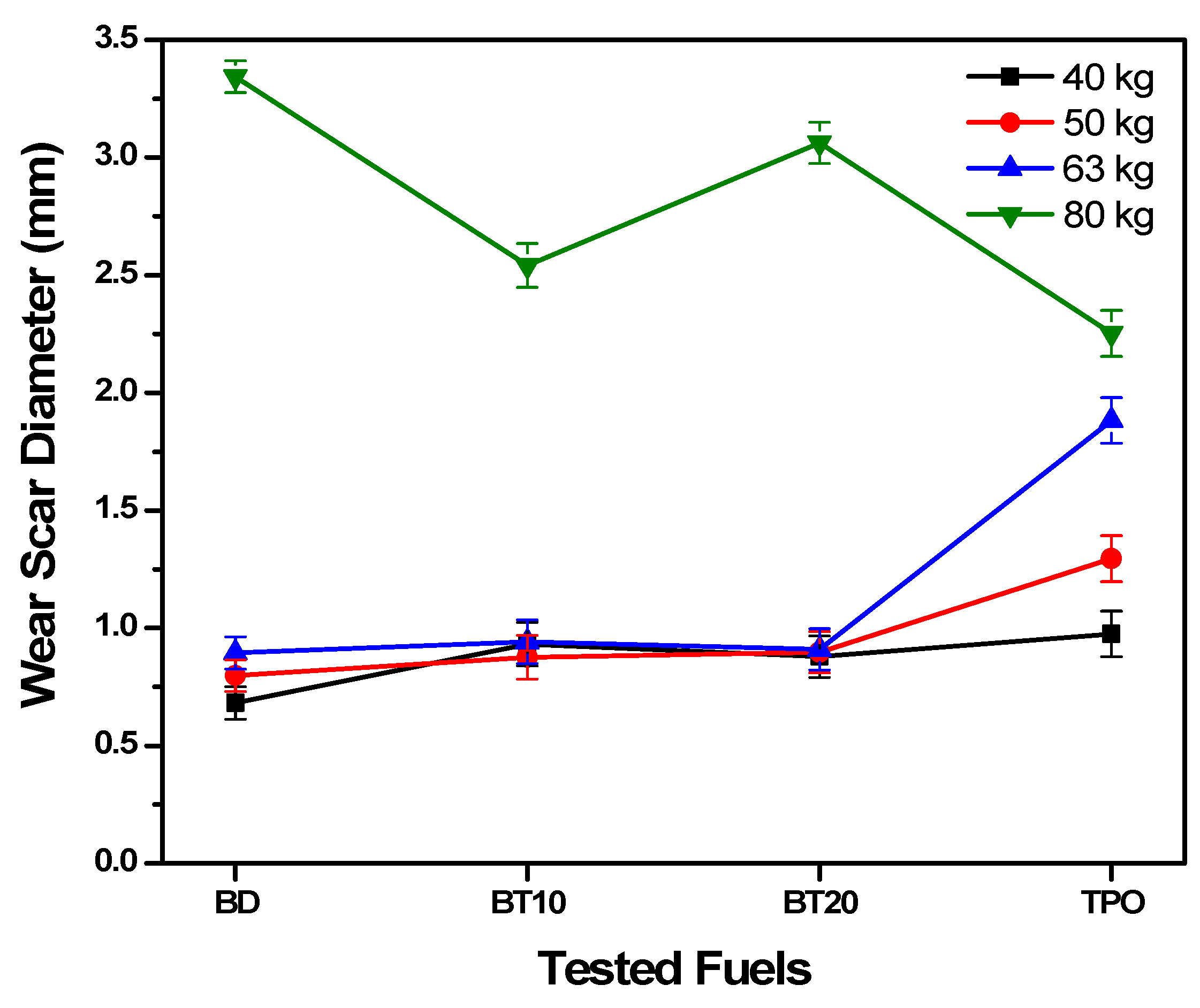

3.2. Wear Behaviour

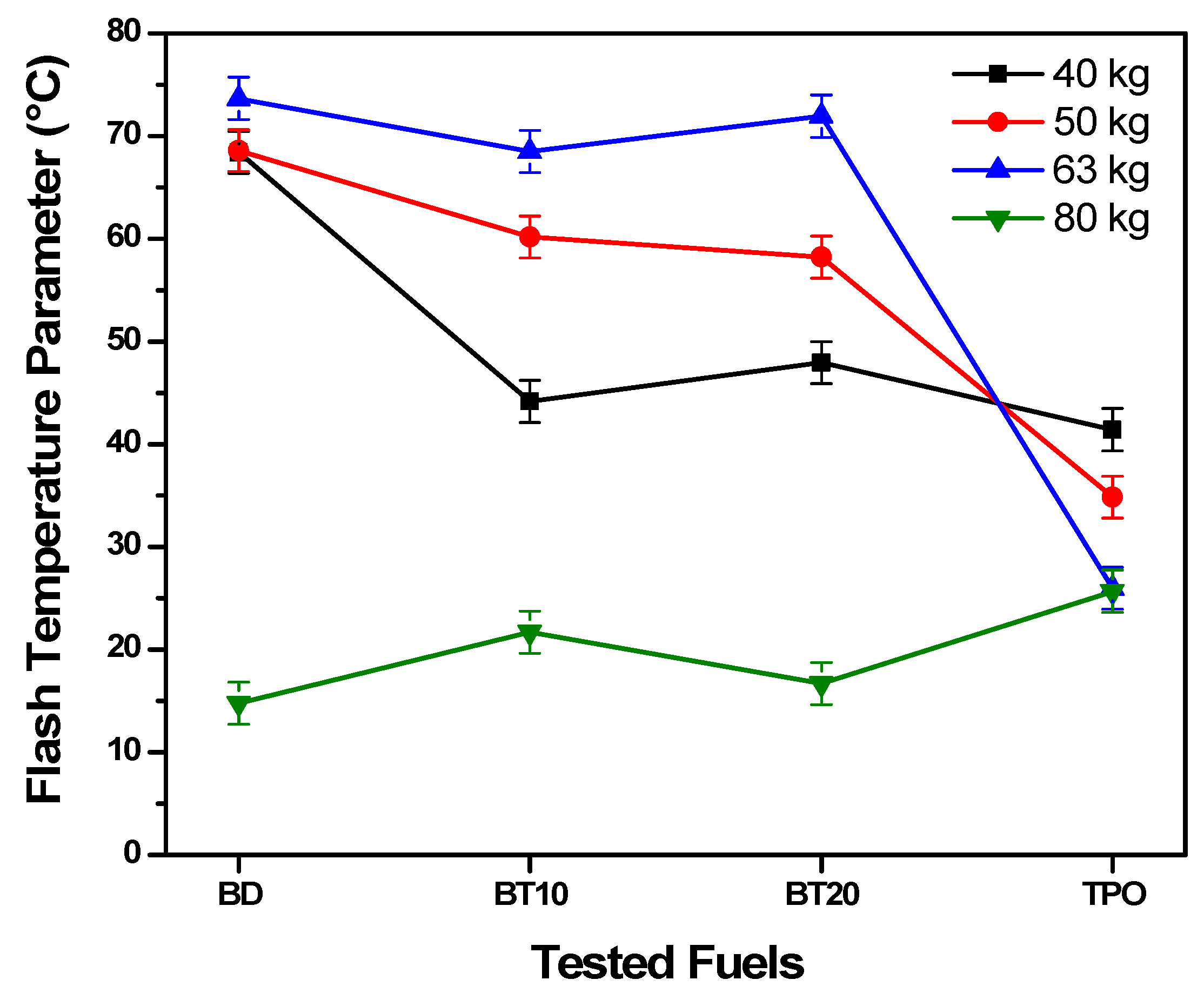

3.3. Flash Temperature Parameter

3.4. Morphological Analysis

4. Conclusions

- BT10, BT20, and TPO have 49.66%, 28.63%, and 41% lower unsteady coefficient of friction, respectively, than biodiesel. In contrast to the variable performance of biodiesel fuel, the BT10 and TPO showed a smooth behaviour of the unsteady friction coefficient.

- In comparison to biodiesel fuel, at low and high loads, TPO and BT10 exhibit better wear patterns. The WSD of TPO, BT10, and BT20 were as 32.62%, 23.99% and 8.37%, respectively, lower than the biodiesel fuel at 80 kg load. The higher sulphur content in the TPO shows better anti-wear behaviour.

- TPO demonstrates a higher load-carrying capacity that reflects its ability to be used in higher loads and extreme situations of pressure.

- The wear behaviour of fuel blends tested suggests that for a particular application, moderate friction behaviour, as well as higher load-carrying capacity, can be achieved.

- Compared to other fuels, TPO has a maximum FTP of 25.67 °C at 80 kg load. The FTP results shown by BT10 and BT20 are similar to biodiesel fuel at low loads but a better performance of BT10 and BT20 at high loads. However, biodiesel fuel (14.77 °C) was rated with the lowest FTP value.

- The SEM micrographs revealed that BT10 and BT20 showed lower metal extrusion compared to biodiesel fuel. Morphology showed that biodiesel fuel particles are broad and are shortened with the rise in the percentage of TPO.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Murugesan, A.; Umarani, C.; Subramanian, R.; Nedunchezhian, N. Bio-diesel as an alternative fuel for diesel engines—A review. Renew. Sustain. Energy Rev. 2009, 13, 653–662. [Google Scholar] [CrossRef]

- Dhar, A.; Agarwal, A.K. Performance, emissions and combustion characteristics of Karanja biodiesel in a transportation engine. Fuel 2014, 119, 70–80. [Google Scholar] [CrossRef]

- Lam, M.K.; Tan, K.T.; Lee, K.T.; Mohamed, A.R. Malaysian palm oil: Surviving the food versus fuel dispute for a sustainable future. Renew. Sustain. Energy Rev. 2009, 13, 1456–1464. [Google Scholar] [CrossRef]

- Han, X.; Zeng, H.; Bartocci, P.; Fantozzi, F.; Yan, Y. Phytohormones and effects on growth and metabolites of microalgae: A review. Fermentation 2018, 4, 25. [Google Scholar] [CrossRef]

- Duan, P.; Jin, B.; Xu, Y.; Wang, F. Co-pyrolysis of microalgae and waste rubber tire in supercritical ethanol. Chem. Eng. J. 2015, 269, 262–271. [Google Scholar] [CrossRef]

- Mokhtar, N.M.; Omar, R.; Idris, A. Microwave Pyrolysis for Conversion of Materials to Energy: A Brief Review. Energy Sources Part A Recovery Util. Environ. Eff. 2012, 34, 2104–2122. [Google Scholar] [CrossRef]

- Verma, P.; Zare, A.; Jafari, M.; Bodisco, T.A.; Rainey, T.; Ristovski, Z.D.; Brown, R.J. Diesel engine performance and emissions with fuels derived from waste tyres. Sci. Rep. 2018, 8, 2457. [Google Scholar] [CrossRef]

- ACEA. ACEA Pocket Guide; European Automobile Manufacturers’ Association: Brussel, Belgium, 2016. [Google Scholar]

- Voelcker, J. 1.2 Billion Vehicles On World’s Roads Now, 2 Billion By 2035: Report. Available online: https://www.greencarreports.com/news/1093560_1-2-billion-vehicles-on-worlds-roads-now-2-billion-by-2035-report (accessed on 18 October 2018).

- Liu, L.; Cai, G.; Zhang, J.; Liu, X.; Liu, K. Evaluation of engineering properties and environmental effect of recycled waste tire-sand/soil in geotechnical engineering: A compressive review. Renew. Sustain. Energy Rev. 2020, 126, 109831. [Google Scholar] [CrossRef]

- Islam, M.N.; Nahian, M.R. Improvement of Waste Tire Pyrolysis Oil and Performance Test with Diesel in CI Engine. J. Renew. Energy 2016, 2016, 1–8. [Google Scholar] [CrossRef]

- Li, W.; Huang, C.; Li, D.; Huo, P.; Wang, M.; Han, L.; Chen, G.; Li, H.; Li, X.; Wang, Y.; et al. Derived oil production by catalytic pyrolysis of scrap tires. Chin. J. Catal. 2016, 37, 526–532. [Google Scholar] [CrossRef]

- Khan, M.Z.H.; Ikram Hossain, M.D.; Pobitra Kumar Halder, M.D.; Rafiul Hasan, M.R.A.-M. Fuel Properties of Pyrolytic Tyre Oil and Its Blends with Diesel Fuel—Towards Waste Management. Int. J. Environ. Waste Manag. 2016, 18, 335–348. [Google Scholar] [CrossRef]

- Pinto, G.M.; De Souza, T.A.Z.; Coronado, C.J.R.; Flôres, L.F.V.; Chumpitaz, G.R.A.; Silva, M.H. Experimental Investigation of the Performance and Emissions of a Diesel Engine Fuelled by Blends Containing Diesel S10, Pyrolysis Oil from Used Tires and Biodiesel from Waste Cooking Oil. Environ. Prog. Sustain. Energy 2019, 38, 13199. [Google Scholar] [CrossRef]

- Karagoz, M.; Uysal, C.; Agbulut, U.; Saridemir, S. Energy, exergy, economic and sustainability assessments of a compression ignition diesel engine fueled with tire pyrolytic oil–diesel blends. J. Clean. Prod. 2020, 264, 121724. [Google Scholar] [CrossRef]

- Pote, R.N.; Patil, R.K. Combustion and emission characteristics analysis of waste tyre pyrolysis oil. SN Appl. Sci. 2019, 294. [Google Scholar] [CrossRef]

- Solmaz, H.; Yilmaz, E.; Yes, D. Production of waste tyre oil and experimental investigation on combustion, engine performance and exhaust emissions. J. Energy Inst. 2019, 92, 1406–1418. [Google Scholar] [CrossRef]

- Sharma, A.; Murugan, S. Potential for using a tyre pyrolysis oil-biodiesel blend in a diesel engine at different compression ratios. Energy Convers. Manag. 2015, 93, 289–297. [Google Scholar] [CrossRef]

- García-Contreras, R.; Martínez, J.D.; Armas, O.; Murillo, R.; García, T. Study of a residential boiler under start-transient conditions using a tire pyrolysis liquid (TPL)/diesel fuel blend. Fuel 2015, 158, 744–752. [Google Scholar] [CrossRef]

- Singh, D.; Soni, S.L.; Sharma, D.; Kumari, D. Waste Tyre Oil as Alternative Fuel in CI Engine: A Review. Int. J. Adv. Res. Innov. Ideas Educ. 2017, 3, 577–585. [Google Scholar]

- Silva e Mello, V.; Do Vale Souza, E.R.; De Araújo Oliveira, M.V.; Alves, S.M. Effect of desulfurization of diesel and its blends with biodiesel on metallic contact. Mater. Res. 2014, 17, 82–88. [Google Scholar] [CrossRef][Green Version]

- Quek, A.; Balasubramanian, R. Liquefaction of waste tires by pyrolysis for oil and chemicals—A review. J. Anal. Appl. Pyrolysis 2013, 101, 1–16. [Google Scholar] [CrossRef]

- Ushakov, S.; Valland, H.; Æsøy, V. Combustion and emissions characteristics of fish oil fuel in a heavy-duty diesel engine. Energy Convers. Manag. 2013, 65, 228–238. [Google Scholar] [CrossRef]

- Demirbas, A. Progress and recent trends in biodiesel fuels. Energy Convers. Manag. 2009, 50, 14–34. [Google Scholar] [CrossRef]

- Fazal, M.A.; Haseeb, A.S.M.A.; Masjuki, H.H. Biodiesel feasibility study: An evaluation of material compatibility; Performance; emission and engine durability. Renew. Sustain. Energy Rev. 2011, 15, 1314–1324. [Google Scholar] [CrossRef]

- Kannan, D.; Pachamuthu, S.; Nurun Nabi, M.; Hustad, J.E.; Løvås, T. Theoretical and experimental investigation of diesel engine performance, combustion and emissions analysis fuelled with the blends of ethanol, diesel and jatropha methyl ester. Energy Convers. Manag. 2012, 53, 322–331. [Google Scholar] [CrossRef]

- Ozsezen, A.N.; Canakci, M. Determination of performance and combustion characteristics of a diesel engine fueled with canola and waste palm oil methyl esters. Energy Convers. Manag. 2011, 52, 108–116. [Google Scholar] [CrossRef]

- Haseeb, A.S.M.A.; Sia, S.Y.; Fazal, M.A.; Masjuki, H.H. Effect of temperature on tribological properties of palm biodiesel. Energy 2010, 35, 1460–1464. [Google Scholar] [CrossRef]

- Celik, I.; Aydin, O. Effects of B100 Biodiesel on Injector and Pump Piston. Tribol. Trans. 2011, 54, 424–431. [Google Scholar] [CrossRef]

- Mujtaba, M.A.; Masjuki, H.H.; Kalam, M.A.; Noor, F.; Farooq, M.; Ong, H.C.; Gul, M.; Soudagar, M.E.M.; Bashir, S.; Rizwanul Fattah, I.M.; et al. Effect of Additivized Biodiesel Blends on Diesel Engine Performance, Emission, Tribological Characteristics, and Lubricant Tribology. Energies 2020, 13, 3375. [Google Scholar] [CrossRef]

- Mujtaba, M.A.; Masjuki, H.H.; Kalam, M.A.; Ong, H.C.; Gul, M.; Farooq, M.; Soudagar, M.E.M.; Ahmed, W.; Harith, M.H.; Yusoff, M.N.A.M. Ultrasound-assisted process optimization and tribological characteristics of biodiesel from palm-sesame oil via response surface methodology and extreme learning machine—Cuckoo search. Renew. Energy 2020, 158, 202–214. [Google Scholar] [CrossRef]

- Chauhan, B.S.; Kumar, N.; Cho, H.M. A study on the performance and emission of a diesel engine fueled with Jatropha biodiesel oil and its blends. Energy 2012, 37, 616–622. [Google Scholar] [CrossRef]

- Serrano, L.M.V.; Câmara, R.M.O.; Carreira, V.J.R.; Gameiro da Silva, M.C. Performance study about biodiesel impact on buses engines using dynamometer tests and fleet consumption data. Energy Convers. Manag. 2012, 60, 2–9. [Google Scholar] [CrossRef]

- Thangavelu, S.K.; Arthanarisamy, M. Experimental investigation on engine performance, emission, and combustion characteristics of a DI CI engine using tyre pyrolysis oil and diesel blends doped with nanoparticles. Environ. Prog. Sustain. Energy 2020, 39, e13321. [Google Scholar] [CrossRef]

- Vihar, R.; Seljak, T.; Rodman Oprešnik, S.; Katrašnik, T. Combustion characteristics of tire pyrolysis oil in turbo charged compression ignition engine. Fuel 2015, 150, 226–235. [Google Scholar] [CrossRef]

- Hamzah, M.H.; Alias, A.; Mamat, R.; Abdullah, A.A. Performance analysis of diesel engine running with tyre-derived fuel. In Proceedings of the 1st International Postgraduate Conference on Mechanical Engineering, Pahang, Malaysia, 17 January 2019; pp. 1–10. [Google Scholar]

- Hurdogan, E.; Ozalp, C.; Kara, O.; Ozcanli, M. Experimental investigation on performance and emission characteristics of waste tire pyrolysis oil diesel blends in a diesel engine. Int. J. Hydrogen Energy 2017, 42, 23373–23378. [Google Scholar] [CrossRef]

- Habibullah, M.; Masjuki, H.H.; Kalam, M.A.; Zulkifli, N.W.M.; Masum, B.M.; Arslan, A.; Gulzar, M. Friction and wear characteristics of Calophyllum inophyllum biodiesel. Ind. Crop. Prod. 2015, 76, 188–197. [Google Scholar] [CrossRef]

- Mosarof, M.H.; Kalam, M.A.; Masjuki, H.H.; Alabdulkarem, A.; Habibullah, M.; Arslan, A.; Monirul, I.M. Assessment of friction and wear characteristics of Calophyllum inophyllum and palm biodiesel. Ind. Crop. Prod. 2016, 83, 470–483. [Google Scholar] [CrossRef]

- Barsari, M.A.N.; Shirneshan, A. An Experimental Study of Friction and Wear Characteristics of Sunflower and Soybean Oil Methyl Ester under the Steady-State Conditions by the Four-Ball Wear Testing Machine. J. Tribol. 2018, 141, 24. [Google Scholar] [CrossRef]

- Singh, Y.; Singla, A.; Singh, A.K. Tribological characteristics of Mongongo-oil–based biodiesel blended lubricant. Energy Sources Part A Recovery Util. Environ. Eff. 2017, 39, 332–338. [Google Scholar] [CrossRef]

- Alves, S.M.; De Farias, A.C.M.; Mello, V.S.; Oliveira, J.J. Effect of soybean biodiesel addition on tribological performance of ultra-low sulfur diesel. J. Tribol. 2018, 141. [Google Scholar] [CrossRef]

- Hulwan, D.B.; Joshi, S.V. Performance, emission and combustion characteristic of a multicylinder DI diesel engine running on Diesel–Ethanol–Biodiesel blends of high ethanol content. Appl. Energy 2011, 88, 5042–5055. [Google Scholar] [CrossRef]

- Wain, K.S.; Perez, J.M.; Chapman, E.; Boehman, A.L. Alternative and low sulfur fuel options: Boundary lubrication performance and potential problems. Tribol. Int. 2005, 38, 313–319. [Google Scholar] [CrossRef]

- Zulkifli, N.W.M.; Azman, S.S.N.; Kalam, M.A.; Masjuki, H.H.; Yunus, R.; Gulzar, M. Lubricity of bio-based lubricant derived from different chemically modified fatty acid methyl ester. Tribol. Int. 2016, 93, 555–562. [Google Scholar] [CrossRef]

- Nikanjam, M.; Henderson, P.T. Lubricity of low sulfur diesel fuels. SAE Tech. Pap. 1993, 1–9. [Google Scholar] [CrossRef]

- Habibullah, M.; Masjuki, H.H.; Kalam, M.A.; Gulzar, M.; Arslan, A.; Zahid, R. Tribological Characteristics of Calophyllum inophyllum–Based TMP (Trimethylolpropane) Ester as Energy-Saving and Biodegradable Lubricant. Tribol. Trans. 2015, 58, 1002–1011. [Google Scholar] [CrossRef]

- Masjuki, H.H.; Maleque, M.A. Investigation of the anti-wear characteristics of palm oil methyl ester using a four-ball tribometer test. Wear 1997, 206, 179–186. [Google Scholar] [CrossRef]

- Shahabuddin, M.; Masjuki, H.H.; Kalam, M.A.; Bhuiya, M.M.K.; Mehat, H. Comparative tribological investigation of bio-lubricant formulated from a non-edible oil source (Jatropha oil). Ind. Crop. Prod. 2013, 47, 323–330. [Google Scholar] [CrossRef]

- Sperring, T.P.; Nowell, T.J. SYCLOPS—A qualitative debris classification system developed for RAF early failure detection centres. Tribol. Int. 2005, 38, 898–903. [Google Scholar] [CrossRef]

| Tested Samples | Apparatus | Ball Material | Working Conditions | Tribological Characteristics Comparison with Diesel | References |

|---|---|---|---|---|---|

| CIB10, CIB20, CIB30, CIB50, CIB100, DF (Calophyllum inophyllum (CI)) | FBT | Carbon–chromium steel | 27 °C, the normal load of 40, 50, 63, and 80 kg for 300 s at 1800 rpm speed | Friction and wear ▼ with the ▲ of concentration of biodiesel and friction and wear ▼ with ▲ of load. | [38] |

| PB10, PB20, PB100, CIB10, CIB20, CIB100, DF (Palm oil biodiesel (PB), Calophyllum inophyllum (CI)), | FBT | Carbon–chromium steel | 27 °C, 45 °C, 60 °C, and 75 °C, normal load of 40 and 80 kg for 300 s at 1800 rpm speed | Friction and wear ▼ with the ▲ of concentration of biodiesel and friction and wear ▼ with ▲ load and temperature. | [39] |

| B0, B10, B20, B50, B100 (Sunflower, Soybean) | FBT | Carbon–chromium steel | 75 °C, load 40 kg for 300 s and 3600 s at 600, 900, 1200, and 1800 rpm | Friction and wear ▼ with the ▲ of concentration of biodiesel and friction and wear ▲ with ▲ of speed. | [40] |

| MO5, MO8, MO12 Mongongo-oil biodiesel MO5 (5% Mongongo oil-95% SAE 20W-40) | pin-on-disc tribometer | aluminium-silicon alloy | 27 °C, the normal load of 40, 80, and 120 N, for 300 s and 3600 s at 600, 900, 1200, and 1800 rpm varying speed | Friction ▼ with the ▲ load and wear ▲ with ▲ of load. | [41] |

| B0, B5, B20, B100 (Soybean) | High-frequency reciprocating rig | AISI 52100 steel | 60 °C, 1.96 N for 75 min at 50 Hz frequency | Friction ▲ with the ▲ of concentration of biodiesel. | [42] |

| Parameters | ASTM Standard | Raw TPO |

|---|---|---|

| Calorific value (MJ/Kg) | ASTM D240 | 43.09 |

| Kinematic viscosity @ 40 °C (cSt) | ASTM D7042 | 4.74 |

| Density @ 15 °C (kg/m3) | ASTM D4052 | 927 |

| Flashpoint (°C) | ASTM D93 | <40 |

| Pour point (°C) | ASTM D97 | <40 |

| Sulphur (mass, %) | ASTM D4294 | 0.77 |

| Ash (mass, %) | ASTM D462 | 0.009 |

| Carbon residue (m/m, %) | ASTM D4530 | 1.07 |

| Acid number (mg KOH/g) | ASTM D664 | 1.03 |

| Water by distillation (V/V, %) | ASTM D95 | 0.10 |

| Sediment by extraction (m/m, %) | ASTM D473 | 0.097 |

| Fuel | Density | Kinematic Viscosity | Calorific Value |

|---|---|---|---|

| (kg/m3) | (cSt) | (MJ/kg) | |

| 15 °C | 40 °C | ||

| Biodiesel | 875.5 | 4.45 | 38.89 |

| BT10 | 886 | 4.21 | 39.26 |

| BT20 | 896 | 4.13 | 39.37 |

| TPO | 946 | 2.23 | 41.81 |

| Standard | Apparatus | Made | Model | Accuracy | |

|---|---|---|---|---|---|

| Calorific value | ASTM D240 | Bomb calorimeter | IKA, UK | C2000 | ±0.1% MJ/kg |

| Kinematic viscosity | ASTM D7042 | Stabinger viscometer | Anton Paar, UK | SVM 3000 | ±0.35% |

| Density | ASTM D4052 | Stabinger viscometer | Anton Paar, UK | SVM 3000 | ±0.1 kg/m3 |

| Friction and wear | ASTM D2266 | Four ball testers | DUCOM, India | TR-30L-IAS | - |

| Wear scar diameter | ASTM D4172 | Optical microscope | IKA, UK | C2000 | ±0.01 mm |

| Scanning electron microscope (SEM) | X30/X2000 | SEM | Hitachi | S3400N | 3.0 nm at 30 kV |

| Specification | Units | Detail | Accuracy |

|---|---|---|---|

| Model | - | Make: DUCOM TR-30L-IAS | |

| Speed | RPM | 300–3000 | 1 |

| Oil Temperature | °C | Ambient temperature to 100 | 0.5 |

| Maximum axial load | N | 10,000 | 0.5 |

| Range of scar | μm | 100–4000 | 0.5 |

| Diameter of ball | mm | 12.7 | |

| Image measuring system | Optical microscope | ||

| Make: Radical instrument, 220 V, 50 Hz | |||

| Image acquisition system | Web camera, 12 megapixels | ||

| Software | Winducom 2010 |

| Parameter | Values |

|---|---|

| Standard | ASTM D2266 |

| Speed (rpm) | 1800 |

| Load (kg) | 40, 50, 63 and 80 |

| Temperature of Fuel (°C) | 27 |

| Time (s) | 300 |

| Material of Ball | Carbon–chromium steel (SKF) |

| Composition | 85.06% Fe ;10.2% C; 0.07% S; 0.45% Si; 0.42% Mn; 0.06% Ni; 1.46% Cr; 0.12% P; 2.15% Zn |

| Ball Diameter (mm) | 12.7 |

| Ball Hardness (HRc) | 62 |

| Ball Surface roughness (μm) | 0.1 C.L.A |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yaqoob, H.; Teoh, Y.H.; Jamil, M.A.; Rasheed, T.; Sher, F. An Experimental Investigation on Tribological Behaviour of Tire-Derived Pyrolysis Oil Blended with Biodiesel Fuel. Sustainability 2020, 12, 9975. https://doi.org/10.3390/su12239975

Yaqoob H, Teoh YH, Jamil MA, Rasheed T, Sher F. An Experimental Investigation on Tribological Behaviour of Tire-Derived Pyrolysis Oil Blended with Biodiesel Fuel. Sustainability. 2020; 12(23):9975. https://doi.org/10.3390/su12239975

Chicago/Turabian StyleYaqoob, Haseeb, Yew Heng Teoh, Muhammad Ahmad Jamil, Tahir Rasheed, and Farooq Sher. 2020. "An Experimental Investigation on Tribological Behaviour of Tire-Derived Pyrolysis Oil Blended with Biodiesel Fuel" Sustainability 12, no. 23: 9975. https://doi.org/10.3390/su12239975

APA StyleYaqoob, H., Teoh, Y. H., Jamil, M. A., Rasheed, T., & Sher, F. (2020). An Experimental Investigation on Tribological Behaviour of Tire-Derived Pyrolysis Oil Blended with Biodiesel Fuel. Sustainability, 12(23), 9975. https://doi.org/10.3390/su12239975