1. Introduction

Masonry structures are among the oldest buildings across the world and not only in Europe. In addition to listed buildings of special architectural or historic interest, new masonry houses are still being built. Considering the sustainability of all these buildings, providing the load-bearing capacity of masonry structures becomes a very important issue. The service life of existing structures is affected not only by the materials or common use of the building but also by the environment. Seismicity or vibrations due to coalmining activities could decrease the reliability of buildings. In this case, restorations through post-tensioning of masonry objects using steel tendons lead to higher stiffness of damaged structures [

1].

Masonry is a composite material; problems with restorations of masonry structures by post-tensioning are extensive, and they include the definition of actual masonry properties according to suitable diagnostics of the specific structure, selection of appropriate procedures and parameters for prestressing, bad weather conditions or equipment failure [

2], possible utilization of experimental measuring of the masonry to define partial masonry parameters, and numerical modeling of this composite using the values measured. This article describes, in detail, experimental masonry testing performed to define the elastic modulus and compares the measured results with nonlinear numerical models. The ultimate goal of partial steps is to verify models so that they can be used for the design of post-tensioned masonry structures.

The compressive strength of masonry can be determined by measuring cylindrical samples obtained from core drilling [

3] according to current standards [

4]. Another method suitable for the determination of masonry properties uses flat jacks [

5,

6]. This method, based on the measuring system of two flat jacks, was created to define local states of stress and compressive strength and to determine the deformation characteristics of masonry. The elasticity modulus of masonry can also be determined using the procedure in [

7] through a test of masonry compressive strength perpendicular to bed joints on a masonry sample provided by the standard. Masonry testing in order to obtain deformation characteristics was also dealt with by [

8], who measured compressive strength and elasticity modulus on masonry columns.

After diagnostics of the object in question, a suitable measure is defined to improve the material properties of the object [

9]. This article anticipates tightening of the object using tension ropes. This very efficient method for stiffening buildings is used in the Czech Republic, mainly in the Moravian-Silesian region, where significant cracks of objects occur not only due to undermining of the territory after coalmining activities but also due to nearby underground collectors in municipalities, tunnels, etc. Post-tensioning of the masonry can be achieved using steel ropes or tendons. These steel components are inserted into premilled grooves that may be at the outside or inside face of the masonry. Ends of steel components are fixed in steel angle pieces or special anchors. It is important to define correct prestressing procedures and technologies, to select a suitable prestressing system of anchors, arrangement, and embedding of prestressing cables, and to define the prestressing procedure and the extent of prestressing forces in individual cables.

According to [

10,

11], it is possible to select a safe and confirmed value of prestressing force of approximately 1/10 or 1/15 of masonry compression strength perpendicular to bed joints. Post-tensioning is usually made in the horizontal direction (i.e., parallel to bed joints). According to [

12], the masonry compression strength may raise 0.1 to 0.85 times the strength perpendicular to bed joints. According to the results in [

13], this value is closer to 0.1 to 0.25 times. This range depends on the percentage of filled head joints with mortar. For masonry with well-filled head joints, a value of 0.7 to 0.8 is considered.

It is often very difficult to obtain masonry properties in the direction parallel to bed joints. Knowing them is, however, necessary for the proposal of prestressing forces. Current researchers—e.g., [

14]—still use sources more than 30 years old as their input masonry parameters [

15]. Currently, the masonry elasticity modulus or compressive strength can be defined under Eurocode 6 [

16] or using the procedure under EN 1052-1 [

7]; these procedures are, however, designed primarily for the direction perpendicular to bed joints. Therefore, laboratory measuring is carried out, from which the compressive strength or elasticity modulus parallel to bed joints can be defined [

17].

This article is oriented toward the effective acquisition of deformation characteristics of masonry in the horizontal direction, which may help select a simpler and more precise numerical model for modeling structural complexes in practice. We may then better and more easily define prestressing forces and losses of prestress in anchorage devices of prestressing components for masonry restoration. On the basis of the definition of deformation characteristics of masonry in the bed joint direction, it would be possible to derive relations of elasticity moduli that are not included in current standards and regulations. Looking forward, our aim for future research is to focus on the definition of missing regulations, taking into account the influence of masonry stress in the direction parallel to the bed joint.

Masonry measuring also allows for comparisons with mathematical modeling and verification of results. Experimental measuring is relatively financially demanding and time-consuming. This comparison is, thus, suitable for the utilization of numerical simulations, which, if applied properly, can help in design activities and may, for the most part, substitute experimental testing.

For numerical simulations of masonry, two basic principles are used: detailed micromodels [

18] and macromodels [

19].

The micromodel represents actual masonry compounds in detail, taking into account their arrangement in the structure. The only problem is presented in contact areas between individual bricks and mortar. This model usually requires just a small mortar cutout, through which the behavior of bricks and mortar can be examined in detail. This model is rather suitable for scientific purposes.

The macromodel is more helpful for practice and project designers. Masonry is overall shown as a compact homogenized material. The macromodel is important for a complex overview of the influence of stress on the whole structure or for capturing interactions between individual parts of the structure. There are several procedures or methods for defining homogenized characteristics. The macromodel can be expressed as an isotropic or orthotropic material.

2. Course of Experimental Masonry Testing

Experimental masonry samples were processed in a prepared laboratory facility designed to test the triaxial state of stress of a prestressed masonry corner (

Figure 1), with a plane view of 900 × 900 mm; the total height of the laboratory facility was 1550 mm. The walling material was a solid burnt brick with a production size of 290 × 140 × 65 mm and lime mortar. The masonry thickness was 440 mm for individual test samples MS_1, MS_2, and MS_3. The masonry surface was not plastered. The actual height of samples after the brickwork was 850 and the length was 850 mm. The temperature at which the laboratory facility was operated ranged within 20–25 °C.

In the course of bricklaying, a prestressing bar (type HPT 26; diameter, 26 mm; elasticity modulus, 185 ± 10 GPa) was inserted into the bed joints. Bars were smooth without grooves or other surface finishing. An anchoring plate was fitted to one end of the bar and fixed with a liner and nut.

Anchoring plates of 300 × 300 mm were laid on a mortar layer to transfer pressure to the masonry from the prestressing bar. The thickness of anchoring plates for masonry MS_1 and MS_2 was 20 mm, and that for masonry MS_3 was 40 mm. Prior to applying the load, the structure was left standstill for at least 28 days, allowing the mortar to reach its full strength. To define actual masonry strengths, testing on specific brick and mortar samples was performed as described in

Section 2.1. The other end of the prestressing bar was fitted with a prestressing device (i.e., a hollow cylinder for importing pressure forces). A steel plate was installed between the masonry and cylinder to prevent masonry movement, in addition to an I-section that was part of the laboratory facility. Everything was then secured using a nut at the end of the cylinder (

Figure 2).

In the second stage, a vertical load of 0.1 MPa was applied from the top to the masonry corner structure. Values of prestressing forces were defined as a function of the overall masonry strength determined by calculation according to [

16]. Values of prestressing forces were selected safely with respect to the quality of mortar filled in joints from 10% to 50% or 70% of the overall masonry compression strength. Measured deformations were recorded using potentiometric sensors fitted to the laboratory facility.

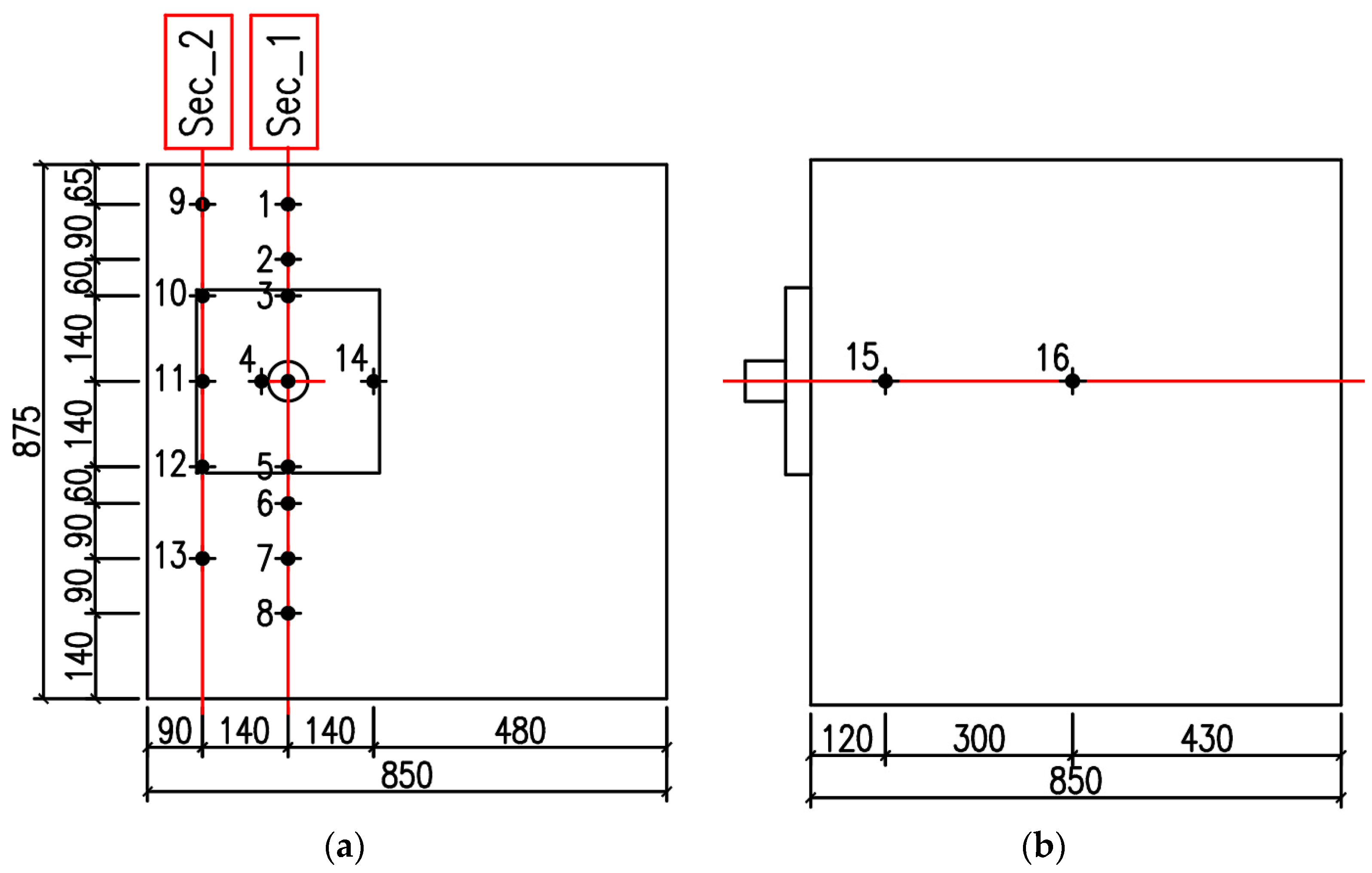

Figure 3 shows the locations of individual sensors. A total of 16 sensors for the measurement of deformations were used. In addition, cut Sec_1 is indicated in

Figure 3, passing the center of the anchoring plate (sensors 1 to 8), as well as cut Sec_2, passing the edge of the anchoring plate (sensors 9 to 13), whereas sensor 14 is on the anchoring plate. Sensors 15 and 16 were used in the direction of the prestressing force.

The interval of measured values of individual movements was 10 s. The measurements were performed according to ČSN 73 2030 [

20].

The aim of this testing was not only to measure deformations, but also to monitor masonry behavior at the point of local stress from gradually increasing prestress. The testing allowed for simulating the behavior of masonry reinforced with a prestressing tendon at the moment of tensioning; thus, the performed tests were short-term tests.

2.1. Defining Mechanical Masonry Properties

Mechanical properties are important for the design and assessment of masonry structures, as well as for use in the case of numerical masonry simulations.

Historical mortars showed a typically poor quality of lime. With increasing lime quality, its content in mortars then declined, and the hydrate of lime/sand ratio stabilized at a value 1:3 to 1:4, which is currently used. This ratio depends on the size of sand particles used. Curing of lime mortar and increases in strength are slow processes. The final compressive strength of cured lime mortars is relatively low and usually does not exceed 0.4 MPa.

Since the mortar of historical buildings is very fragile and sensitive to restoration processed involving prestressing, it is important to know the actual mechanical properties of the composite materials in the specific structure. Therefore, the aim of setting individual testing samples was to apply mortars with low strength corresponding to the strengths of historical mortars with a lime/sand ratio of 1:4.

Primarily, the strength of bricks was determined. The basic compressive strength of masonry units is the mean compressive strength

, which is determined by strength tests of complete masonry units under the European standard [

4]. According to [

7], the property of masonry units is a normalized mean compressive strength

, determined as follows:

where

is the mean compressive strength of masonry units, and

is the factor expressing the influence of width and height of masonry unit.

To obtain mean values of the mechanical properties of bricks, 18 brick samples were tested. Their density was 15.35 , their compressive strength was 9.910 MPa (standard deviation 2.33 MPa) and their tensile strength was 3.185 MPa (standard deviation 0.77 MPa).

Subsequently, the mortar strength was determined by testing six samples (for each test sample of masonry) according to [

21], with the values for individual samples presented in

Table 1.

The compressive strength of masonry components together with the strength of the mortar used is the basic characteristic used to determine the draught compressive strength, tensile strength, and shear strength of masonry. The resulting masonry compressive strength can be defined using several methods: via calculation of the determined strengths of bricks and mortar [

16], via laboratory testing to directly define the characteristic compressive strength of masonry

[

7], or via defining the strength of “historical” buildings with reference to an already expired standard [

22], whereby the masonry strength can be defined using a table, as suggested in [

23].

In ČSN ISO 13,822 [

22], the characteristic compressive strength of nonreinforced masonry was calculated from the strengths of masonry units and mortar determined according to the following formula:

where

is the compressive strength of mortar,

is a constant depending on the group of masonry units used and on the masonry bond type in the wall,

is a constant depending on the thickness of bed joints and mortar type, and

is a constant depending on mortar type. The resulting masonry compressive strength obtained using this calculation is presented in

Table 2.

Table 2 also shows the value of

, which represents the maximum force imported to the masonry through the anchoring plate 300 × 300 mm in the course of load application, whereas

[

16] is the maximum value of concentrated load applied to the anchoring plate surface 300 × 300 mm. For masonry samples MS_1 and MS_2, the maximum value of the concentrated load was not exceeded, and a total of five loading steps were carried out. The concentrated load value was exceeded for masonry sample MS_3 (by approximately 3%), where seven loading steps were carried out.

2.2. Defining Deformation Characteristics of Masonry

Masonry is an orthotropic material with various properties in different directions. The main concerns when defining the mechanical and deformation characteristics of masonry are the properties in the directions perpendicular and parallel to bed joints. According to [

16], it is possible to define a short-term secant modulus of masonry elasticity

, a secant modulus of masonry elasticity

[

7], or possibly a long-term modulus of elasticity [

16], which depends on the creep coefficient. All above moduli of elasticity are based on properties in the direction perpendicular to the bed joint.

The modulus of elasticity of individual materials can be defined through laboratory testing using Eurocodes. For each testing sample of masonry, six brick and six mortar samples were taken during the course of the walling process. The value of the modulus of elasticity of masonry units

was determined under the standard in [

4], and the modulus of elasticity of mortar

was determined under the standard in [

21]. Values of the mortar modulus of elasticity for masonry samples MS_2 and MS_3 could not be determined.

The value of the short-term secant modulus of elasticity

is defined as follows [

16]:

where

is the suggested coefficient for burnt bricks, the value of which is 1000, and

is the characteristic compressive strength of masonry. Values obtained using Equation (1) are defined for the direction perpendicular to bed joints.

The secant modulus of masonry elasticity

can be defined according to [

7]. It is a secant modulus set for load application in the direction perpendicular to bed joints. Within the experiment, the secant modulus was defined for the testing sample MS_3 according to the respective standard [

7], except for the fact that the load was applied in the direction parallel to the bed joint. The defined secant modulus described the relative deformation of the testing sample when one-third of the compressive strength was achieved. Its value was 0.485 GPa, corresponding to 40% of the short-term elasticity modulus

.

Table 3 and

Figure 4 show the course of relative deformation depending on stress recorded by four sensors: sensor 4 installed in the middle of the anchoring plate, sensor 11 on the edge of the anchoring plate, and the average value of deformation from sensors 15 and 16 installed on the lateral face of masonry. When the load reached 50 kN, the same relative deformation occurred on both the anchoring plate and the lateral face of masonry.

Another option to define the modulus of elasticity is the method outlined in [

24], using prestressing forces imported to the masonry. There are two possible methods based on properties in the direction parallel to bed joints. Both methods were derived for the masonry, in which deformations caused by prestressing force occurred on both sides of the masonry. For all experimental tests mentioned in this article, formulas defining elasticity moduli were modified for deformations caused by prestressing force on one side of the masonry only. On the other side of the masonry, deformations were prevented by the laboratory facility.

The effective modulus of elasticity

is defined below as a function of local deformation and depends on the size and rigidity of anchoring plates.

Here, is the load from the prestressing force, is the masonry length in the direction of the acting force, is the area of the anchoring plate, and is the masonry deformation in the acting force axis.

The composite modulus of comprehensive masonry elasticity

, defined below, is suitable for modeling structural complexes and is not as sensitive to the rigidity of anchoring plates as the effective modulus of elasticity.

Here, is the load from the prestressing force, is the masonry length in the direction of the acting force, is the area of the anchoring plate, is the height of anchoring plate, and is the fictitious deformation of masonry taking into account the effects of masonry compression area in the acting force axis.

Table 4 summarizes the masonry’s moduli of elasticity including the elasticity moduli of both materials used (brick and mortar). For bricks, the average value of

was 4.2 GPa (standard deviation 0.58 GPa). Results of elasticity moduli

and

were defined for a load corresponding to 50% of the load capacity of the masonry compressive strength.

2.3. Masonry Deformations Obtained from Measuring

A prestressing force up to 50% of the masonry compressive strength (in the perpendicular direction to bed joints) was applied to testing samples MS_1 and MS_2, such that the concentric load value was not exceeded. A force exceeding the value of concentric load defined in [

16] was applied to testing sample MS_3.

The measured deformations on the surface of the anchoring plate and the masonry at various distances from the compression force action are shown in

Figure 5,

Figure 6 and

Figure 7. These figures show the shape of masonry compression at the point of the anchoring plate and its immediate surroundings.

It is apparent from

Figure 6 and

Figure 7 that not only the masonry strength but also the rigidity of spread footings has a significant influence on the course of deformations.

Figure 7 shows the deformation courses for the seven load steps, where we can see that the masonry was destroyed after the fifth load step.

Upon exceeding the masonry loading capacity of testing sample MS_3, the mortar joints showed cracks and two perpendicular masonry components were torn off (see

Figure 8). The shear crack was caused by normal tensile stress in the mortar joint, which exceeded the local masonry tensile strength.

The deformation values due to stress corresponding to a maximum of 50% of the masonry compressive strength are summarized in

Table 5, including maximum values in the middle of the anchoring plate (sensor No. 4) and at the edge of the anchoring plate (sensor No. 11).

3. Numerical Analysis of Masonry

Masonry can be classified as a composite of two different materials with various properties. Numerical modeling of these composites is a relatively complicated task due to the need for obtaining the material characteristics of individual masonry compounds. Three-dimensional (3D) computer-generated models take the nonlinear behavior of the structure into account. For numerical modeling, it is possible to use two general approaches. The first approach is based on the actual arrangement of individual masonry compounds (i.e., micromodel). The geometry of masonry components and mortar joints may show certain deviations from dimensional parameters of the actual test sample. These geometric deviations may be caused by an unrealistic inspection of the exact location of individual components in the whole test sample. The other approach anticipates that the structure is considered a homogenized material with brick and mortar properties (i.e., macromodel). The numerical analysis outcomes herein focused only on the model with homogenized properties (i.e., macromodel).

Numerical analysis was carried out using ANSYS software [

25]. The calculation of numerical finite element models using ANSYS software began with entering the input data. The material characteristics, geometry of the structure, correct boundary conditions, and load applied to the structure were defined. After entering the input data as accurately as possible, component analysis was performed, including the generation of a finite element network, creation of element stiffness matrices, and creation of element loading vectors. The values were obtained from a set of equations, and the overall analysis of the structure was, thus, achieved.

SOLID65 was used as the finite element for both mortar and brick, which allowed supporting the model behavior of the mortar element as a physically nonlinear material, while including reinforcement effects, as well as the detection of cracks incurred in the masonry. SOLID65 is a 3D finite element with eight nodes.

The values of elasticity moduli , , and were selected as input data to the model. These moduli were suitable for a concentrated load acting in the bed joint direction. is suitable in the case of loads acing perpendicularly to bed joints, whereas and are suitable for numerical models with an actual arrangement of individual masonry compounds.

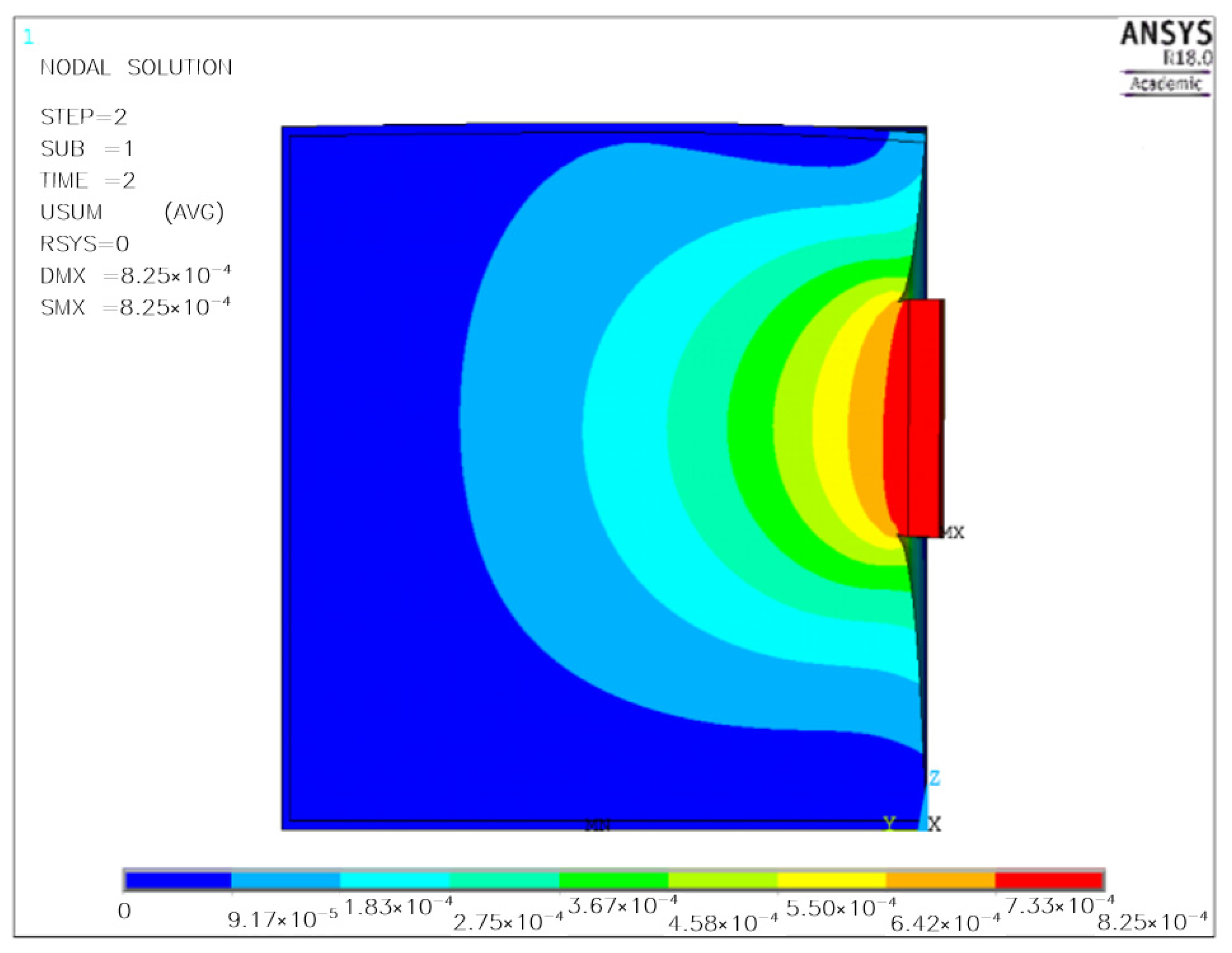

Figure 9,

Figure 10 and

Figure 11 show the outputs of the course of deformations derived from numerical modeling of sample MS_3 in terms of moduli

,

and

. Deformation courses were similar for all models; however, the values of resulting deformations differed. According to the assumption of an increase in the values of elasticity moduli, the deformations of masonry due to prestressing force declined.

Table 6 presents a comparison of the resulting deformations for individual test samples in the middle of the anchoring plate and at its edge. Values are only stated for the load corresponding to 50% of the masonry compressive strength.

The measured deformation of sample MS_3 (

Figure 12) occurred between deformations for elasticity moduli

and

derived from the numerical model. The difference between

and

was within 0.5 mm. On the other hand, for the modulus of elasticity

, it was impossible to acquire deformation values prior to execution of the experiment. In spite of that, both approaches could be considered sufficiently suitable for defining the modulus of elasticity of masonry with concentrated stress. On the other hand, the elasticity modulus

was found to be unsuitable for cases of concentrated stress (i.e., a prestressing force).

The objective of numerical analyses was a simulation of the experiments carried out, allowing a comparison of the destruction mechanism and the size of maximum deformation in the selected loading steps. With respect to the use of elasticity moduli and for numerical simulations and the total calculated deformations, the differences were acceptable.

4. Discussion

On the basis of the determination of deformation characteristics of the masonry in the direction of bed joints, the ratios between moduli of elasticity in the horizontal and vertical directions,

and

, were derived for the tested masonry samples, as presented in

Table 7.

For each sample, the resulting ratios of elasticity moduli in the horizontal and vertical directions were different. The resulting courses of deformation measured during the experiment ranged between the ratios and from 0.1 to 0.23. The mean value of the ratio between moduli of elasticity in the horizontal and vertical directions for was 0.175 (17.5%), while that for was 0.133 (13.3%).

It should be noted that a comparison of the results was only performed for three samples of masonry. Moreover, the size of the test sample was limited by the dimensions of the laboratory equipment. Vertical loads will also have a significant effect on the stiffness of the masonry in the horizontal direction. The characteristic compressive strength of the masonry will be needed as an input value for the determination of prestressing force when applied to a specific object. However, this is not an easy task in the case of many damaged buildings.