Aerogel-Based Plasters and Energy Efficiency of Historic Buildings. Literature Review and Guidelines for Manufacturing Specimens Destined for Thermal Tests

Abstract

1. Introduction

2. Materials and Methods

3. Aerogel-Based Plasters and Energy Improvement

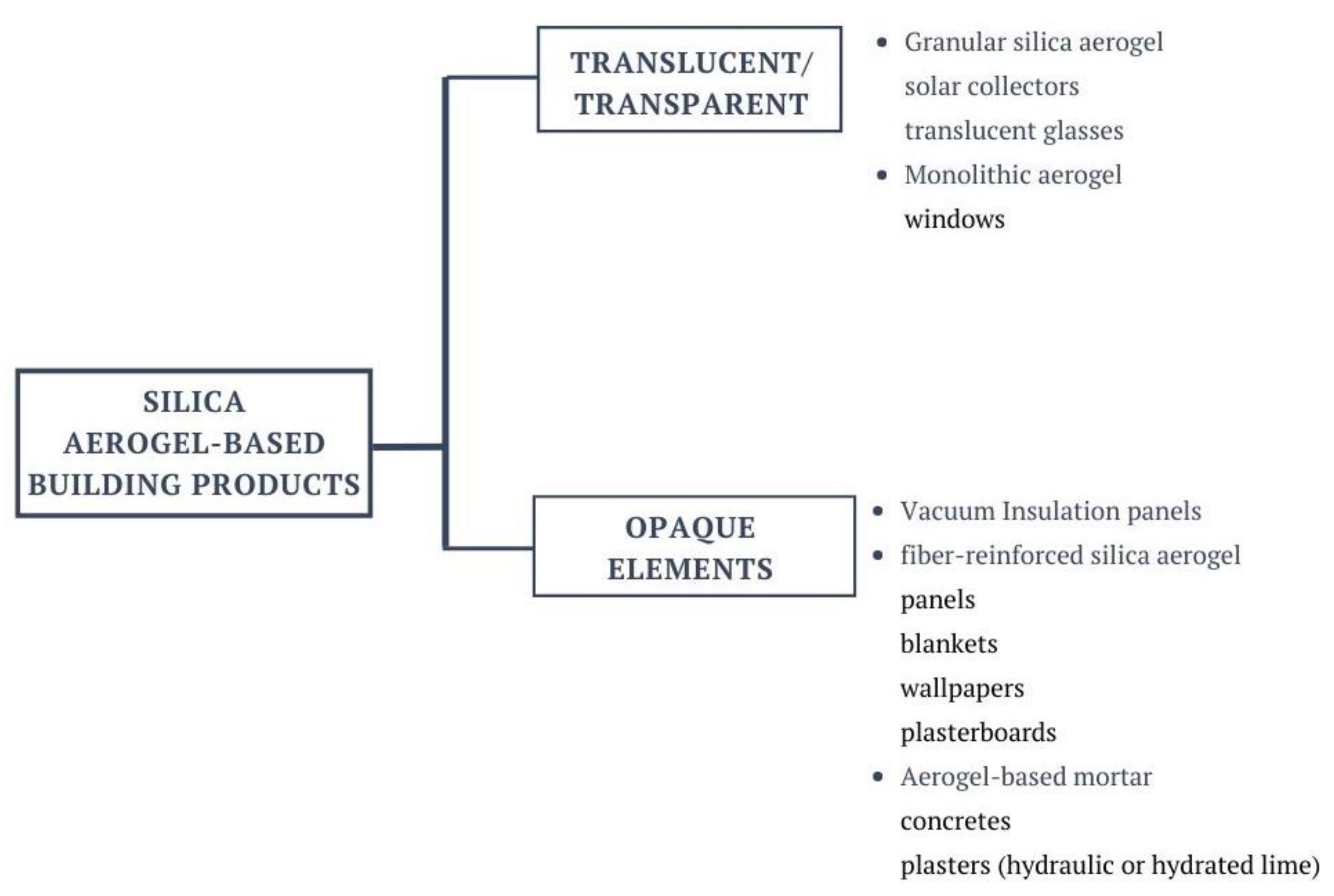

3.1. Aerogel-Based Products for Buildings: An Overview

3.2. Silica Aerogel Applied to High-Performance Plasters for Historic Building Restoration

- -

- S1: Fixit 223 embedding mortar with reinforcement mesh + Röfix 380 fine-grain lime plaster + RöfixPE 819 Sesco Öko lime color with high vapor permeability;

- -

- S2: Röfix 223 new + Röfix 380 fine-grain lime plaster + RöfixPE 819 Sesco Öko lime colour;

- -

- S3: Röfix 223 new + Röfix 775 7–10 mm grain plaster + Röfix PE 225 Reno 1 K Silikatfarbe with high vapor permeability;

- -

- S4: Röfix 223 new + Röfix 380 fine-grain lime plaster + Roöfix PE 419 Etics with high vapor permeability.

4. Thermal Characterization of Aerogel-Based Plasters

4.1. Technical Standards and Thermal Test for Building Insulation Products

- -

- Guarded Hot Plate (GHP) method (ISO 8302, UNI EN 12667);

- -

- Heat Flow Meter (HFM) method (ISO 8301, UNI EN 12667, UNI EN 12664);

- -

- Guarded Hot Box (GHB) (UNI EN ISO 8990);

- -

- Hotbox chamber with heat flow meters (UNI EN 1934);

- -

- Radial method (UNI EN ISO 8497).

4.2. Specimens Manufacturing for Thermal Laboratory Tests

5. Results: A Guideline for Assessing the Thermal Performance of Aerogel-Based Plaster

5.1. Measurements Guideline

5.2. Instructions for Making the Samples

- -

- A0: is made of three layers: a core of standard solid brick (two double UNI—Italian National Unification—bricks with a joint of natural hydraulic lime (NHL) mortar, dimensions: 250 × 250 × 50 mm), a 10 mm NHL render on both sides;

- -

- A1 = A0 + 5 mm layer of aerogel-based plaster (80%);

- -

- A2 = A0 + 10 mm layer of aerogel-based plaster (80%);

- -

- A3 = A0 + 15 mm layer of aerogel-based plaster (80%);

- -

- B = A0 + 100 mm prefinished EPS board;

- -

- C = 50 mm × 50 mm × 20 mm aerogel-based plaster (80%) only.

- -

- The solid bricks to be used for the packaging of the specimens (specimens A0, A1, A2, A3, B) must come from the same plant and the same production batch;

- -

- The natural hydraulic lime mortar used for packaging the samples must be certified and must have a technical data sheet with all the reference data for the analyses;

- -

- The laying of the plaster layer in a natural hydraulic lime mortar must take place in a single day using the same mixture for all the samples (specimens A0, A1, A2, A3, B);

- -

- First, proceed with creating the bases A0 for all the type A samples and the base for the specimen B. Once the layers of plaster have set and dried, proceed with the application of the layers of Tillica pasta in a complete cycle (specimens A0, A1, A2, A3);

- -

- The application of the plaster layer (complete cycle) must take place in a single day using the same mixture for all samples (specimens A, C);

- -

- The porous samples must be homogeneous and representative of the materials; any non-homogeneity must have dimensions less than one-tenth of the thickness of the sample;

- -

- The sample mixture must be prepared in such a way as to not alter the physical and mechanical characteristics of the individual components and in such a way as not to jeopardize the reactions during setting and drying;

- -

- The test sample must be constructed in such a way that it is representative following common practice; areas that may have different surface temperatures should be included in the measurement area in a representative way;

- -

- For transportation, all the specimens must be placed individually in suitable polystyrene or polystyrene containers to minimize the possibility of compromising their structure and characteristics;

- -

- Before the experiment, all the conditions that define the standard use of the material must be verified, such as correct setting, drying, and curing;

- -

- Samples must be stored for a sufficient period to obtain an even distribution of internal humidity. As a general rule, drying must be carried out at 105 °C until a constant mass is reached;

- -

- The sample must be placed in a ventilated desiccator under controlled and constant temperature conditions as per material specifications and subsequently stored in a polythene bag at a controlled temperature;

- -

- The thickness of the samples must be greater than that the one by which the sample, in case of imperfections, cannot vary by more than 2%;

- -

- The sample must be flat to allow the greatest possible contact between plates, parallel to them during the analyses, and with an inclination not exceeding 2%.

6. Conclusions

Funding

Acknowledgments

Conflicts of Interest

References

- Calisesi, M. Aerogel Incorporated Plasters and Mortars: The Case Study of Precast Panels; Degree Course: Building Engineering and Architecture; University of Bologna: Bologna, Italy, 2017. [Google Scholar]

- Commissione delle Comunità Europee. Libro Verde Sull’efficienza Energetica: Fare di Più Con Meno; Comunità Europee: Bruxelles, Belgium, 2005. [Google Scholar]

- Stephan, A.; Athanassi, A. Towards a more circular construction sector: Estimating and spatialising current and future non-structural material replacement flows to maintain urban building stocks. Resour. Conserv. Recycl. 2018, 119, 248–262. [Google Scholar] [CrossRef]

- Lavagna, M. Life Cycle Assessment in Edilizia; Hoepli: Milano, Italy, 2008. [Google Scholar]

- Muller, M.F.; Esmanioto, F.; Huber, N.; Loures, E.R.; Junior, O.C. A systematic literature review of interoperability in the green Building Information Modeling lifecycle. J. Clean. Prod. 2019, 223, 397–412. [Google Scholar] [CrossRef]

- Agliata, R.; Marino, A.; Mollo, L.; Pariso, P. Historic Building Energy Audit and Retrofit Simulation with Hemp-Lime Plaster. A Case Study. Sustainability 2020, 12, 4620. [Google Scholar] [CrossRef]

- Adamczyk, J.; Dylewski, R. The impact of thermal insulation investments on sustainability in the construction sector. Renew. Sustain. Energy Rev. 2017, 80, 421–429. [Google Scholar] [CrossRef]

- Cinieri, V.; Zamperini, E. Approccio lifecycle alla gestione e conservazione sostenibile del patrimonio costruito. Sci. Beni Cult. 2014, 30, 723–733. [Google Scholar]

- Monticelli, C. Life Cycle Design in Architettura; Maggioli: Santarcangelo di Romagna (RN), Italy, 2013. [Google Scholar]

- McDonough, W.; Braungart, M. Cradle to Cradle: Remaking the Way We Make Things; North Point Press: New York, NY, USA, 2003. [Google Scholar]

- Pacheco Torgal, F.; Buratti, C.; Kalaiselvam, S.; Granqvist, C.-G.; Ivanov, V. (Eds.) Nano and Biotech; Springer: Cham, Switzerland, 2016. [Google Scholar]

- Cinieri, V. Patrimonio edificato diffuso. Un Approccio Sostenibile alla Conservazione e alla Gestione. Ph.D. Thesis, University of Pavia, Pavia, Italy, 2015. [Google Scholar]

- Biscontin, G.; Driussi, G. Quale sostenibilità per il restauro? Atti del 30° Convegno di Studi Scienza e Beni Culturali. Sci. Beni Cult. 2014, 1, 964. [Google Scholar]

- CRESME. Il Mercato Delle Costruzioni 2013. Lo Scenario di Medio Periodo 2012–2016—XX Rapporto Congiunturale e Previsionale Cresme; CRESME: Rome, Italy, 2012. [Google Scholar]

- Mezzi, P. Rapporto Cresme 2019 Sulle Costruzioni: Arrestata la Caduta, si Torna (Poco) a Salire. Il Giornale Dell’architettura. Available online: https://ilgiornaledellarchitettura.com/ (accessed on 28 November 2018).

- Ambrogio, K.; Zuppiroli, M. Energia e Restauro; Franco Angeli: Milano, Italy, 2013. [Google Scholar]

- Baetens, R.; Jelle, B.P.; Gustavsend, A. Aerogel insulation for building applications: A state-of-the-art review. Energy Build. 2011, 43, 761–769. [Google Scholar] [CrossRef]

- Stahl, T.; Brunner, S.; Zimmermann, M.; Ghazi Wakili, K. Thermo-hygric properties of a newly developed aerogel based insulation rendering for both exterior and interior applications. Energy Build. 2012, 44, 114–117. [Google Scholar] [CrossRef]

- Buratti, C.; Moretti, E.; Belloni, E.; Agosti, F. Development of Innovative Aerogel Based Plasters: Preliminary Thermal and Acoustic Performance Evaluation. Sustainability 2014, 6, 5839–5852. [Google Scholar] [CrossRef]

- Ghazi Wakili, K.; Stahl, T.; Heiduk, E.; Schuss, M.; Vonbank, R.; Pont, U.; Sustr, C.; Wolosiuk, D.; Mahdavi, A. High performance aerogel containing plaster for historic buildings with structured façades. Energy Proced. 2015, 78, 949–954. [Google Scholar] [CrossRef]

- Buratti, C.; Moretti, E.; Belloni, E. Aerogel Plasters for Building Energy Efficiency. In Nano and Biotech Based Materials for Energy Building Efficiency; Pacheco Torgal, F., Buratti, C., Kalaiselvam, S., Granqvist, C.G., Ivanov, V., Eds.; Springer: Cham, Switzerland, 2016; pp. 17–40. [Google Scholar]

- Schuss, M.; Pont, U.; Mahdavi, A. Long-term experimental performance evaluation of aerogel insulation plaster. Energy Procedia 2017, 132, 508–513. [Google Scholar] [CrossRef]

- Berardi, U. Aerogel-enhanced systems for building energy retrofits: Insights from a case study. Energy Build. 2018, 159, 370–381. [Google Scholar] [CrossRef]

- Berge, A.; Johansson, P. Literature Review of High Performance Thermal Insulation; Report 2012:2; Chalmers University of Technology: Gothenburg, Sweden, 2012; pp. 1–28. [Google Scholar]

- Cuce, E.; Cuce, P.M.; Wood, C.J.; Riffat, S.B. Toward aerogel based thermal superinsulation in buildings: A comprehensive review. Renew. Sust. Energ. Rev. 2014, 34, 273–299. [Google Scholar] [CrossRef]

- Kistler, S.S. Coherent Expanded Aerogels and Jellies. Nature 1931, 127, 741. [Google Scholar] [CrossRef]

- Richter, K.; Norris, P.M.; Chang, C.-L. Aerogels: Applications, structure, and heat transfer phenomena. In Annual Review of Heat Transfer; Prasad, V., Jaluria, Y., Chen, G., Eds.; Begell House Inc.: Danbury, CT, USA, 1995; Volume 6, pp. 61–114. [Google Scholar]

- Schreiber, E.; Boy, E.; Bertsch, K. Aerogel as a Transparent Thermal Insulation Material for Buildings. In Aerogels; Fricke, J., Ed.; Springer: Berlin, Germany, 1986; pp. 133–139. [Google Scholar]

- Ramakrishnan, K.; Krishnan, A.; Shankar, V.; Srivastava, I.; Singh, A.; Radha, R. Modern Aerogels. 2006. Available online: Tue.iitm.ac.in/teaching-and-presentations/teaching/undergraduate%20courses/vy305-molecular-architecture-and-evolution-of-functions/presentations/presentations-2007/seminar-2/P4.pdf (accessed on 30 June 2020).

- Materiali superisolanti a base aerogel. In Rinnovabili.it. Il Quotidiano Sulla Sostenibilità Ambientale; Spagnolo, M., Ed. Available online: https://www.rinnovabili.it (accessed on 30 June 2020).

- Kaushika, I.N.D.; Sumathy, K. Solar transparent insulation materials: A review. Renew. Sust. Energ. Rev. 2003, 7, 317–351. [Google Scholar] [CrossRef]

- Wong, P.I.L.; Eames, P.C.; Perera, R.S. A review of transparent systems and the evaluation of payback period for building applications. J. Sol. Energy 2007, 81, 1058–1071. [Google Scholar] [CrossRef]

- Schultz, J.M.; Jensen, K.I. Evacuated aerogel glazing. Vacuum 2008, 82, 723–729. [Google Scholar] [CrossRef]

- Svendsen, S. Solar collector with monolithic silica aerogel. J. Non-Cryst. Solids 1992, 145, 240–243. [Google Scholar] [CrossRef]

- Jensen, K.I.; Schultz, J.M.; Kristiansen, F.H. Development of windows based on highly insulating aerogel glazings. J. Non-Cryst. Solids 2004, 350, 351–357. [Google Scholar] [CrossRef]

- Gangassaeter, H.F.; Jelle, B.P.; Sohrab, A.L.; Mofid, A.; Gap, T. Air-filled nanopore based high-performance thermal insulation materials. Energy Procedia 2017, 132, 231–236. [Google Scholar] [CrossRef]

- Jelle, B.P.; Gustavsen, A.; Baetens, R. Beyond vacuum insulation panels—How may it be achieved? In Proceedings of the 9th International Vacuum Insulation Symposium (IVIS 2009), London, UK, 17–18 September 2009; pp. 1–10. [Google Scholar]

- Berardi, U. The benefits of using aerogel-enhanced systems in building retrofits. Energy Procedia 2017, 134, 626–635. [Google Scholar] [CrossRef]

- Lucchi, E. Gli edifici storici nel futuro. Innovazione dei materiali per l’efficienza energetica dell’edilizia storica. Modulo 2015, 394, 172–179. [Google Scholar]

- Historic Scotland, Historic Scotland Refurbishment Case Study 2, and Refurbishment Case Study 3. 2012. Available online: https://www.engineshed.scot/publications/publication/?publicationId=4d0179ad-3306-42a0-87d8-a59300faac09 (accessed on 28 October 2020).

- Historic Scotland, Historic Scotland Refurbishment Case Study 3, and Refurbishment Case Study 3. 2012. Available online: https://www.historicenvironment.scot/archives-and-research/publications/publication/?publicationid=345e856a-5ef2-46e5-8315-a59300fc3995 (accessed on 28 October 2020).

- EURAC. Aerogel Insulation: From Mars to Historic Buildings. 2016. Available online: www.academia.bz.it/articles/aerogel-insulation-from-mars-to-historic-buildings (accessed on 30 June 2020).

- Lucchi, E.; Becherini, F.; Di Tuccio, M.C.; Troi, A.; Frick, J.; Roberti, F.; Hermann, C.; Fairnington, I.; Mezzasalma, G.; Pockelé, L.; et al. Thermal performance evaluation and comfort assessment of advanced aerogel as blown-in insulation for historic buildings. Build. Environ. 2017, 122, 258–268. [Google Scholar] [CrossRef]

- Illera, D.; Mesa, J.; Gomez, H.; Maury, H. Cellulose Aerogels for Thermal Insulation in Buildings: Trends and Challenges. Coatings 2018, 8, 345. [Google Scholar] [CrossRef]

- Masera, G.; Ghazi Wakili, K.; Stahl, T.; Brunner, S.; Galliano, R.; Monticelli, C.; Aliprandia, S.; Zanelli, A.; Elesawye, A. Development of a super-insulating, aerogel-based textile wallpaper for the indoor energy retrofit of existing residential buildings. Procedia Eng. 2017, 180, 1139–1149. [Google Scholar] [CrossRef][Green Version]

- Galliano, R.; Ghazi Wakili, K.; Stahl, T.; Binder, B.; Daniotti, B. Performance evaluation of aerogel-based and perlite-based prototyped insulations for internal thermal retrofitting: HMT model validation by monitoring at demo scale. Energy Build. 2016, 126, 275–286. [Google Scholar] [CrossRef]

- Ratke, L. Herstellung und Eigenschaften eines neuen Leichtbetons: Aerogelbeton. Beton Stahlbetonbau 2008, 103, 236–243. [Google Scholar] [CrossRef]

- Kim, S.; Seo, J.; Cha, J.; Kim, S. Chemical retreating for gel-typed aerogel and insulation performance of cement containing aerogel. Constr. Build. Mater. 2013, 40, 501–505. [Google Scholar] [CrossRef]

- Gao, T.; Jelle, B.P.; Gustavsen, A.; Jacobsen, S. Aerogel-incorporated concrete: An experimental study. Constr. Build. Mater. 2014, 52, 130–136. [Google Scholar] [CrossRef]

- Fickler, S.; Milow, B.; Ratke, L.; Schnellenbach-Held, M.; Welsch, T. Development of high performance aerogel concrete. Energy Procedia 2015, 78, 406–411. [Google Scholar] [CrossRef]

- Serina, N.g.; Jelle, B.P.; Sandberg, L.I.C.; Gao, T.; Wallevik, O.H. Experimental investigations of aerogel-incorporated ultra-high-performance concrete. Constr. Build. Mater. 2015, 77, 307–316. [Google Scholar]

- Koebel, M.; Rigacci, A.; Achard, P. Aerogel-based thermal superinsulation: An overview. J. Sol-Gel. Sci. Technol. 2012, 63, 315–339. [Google Scholar] [CrossRef]

- Ibrahim, M.; Wurtz, E.; Achard, P.; Biwole, P.H. Fostering Energy Efficiency in Buildings through Aerogel-Based Renders; ICAE: Donostia San Sebastián, Spain, May 2015; pp. 369–378. [Google Scholar]

- Dezzi Bardeschi, M. Che cos’è il Restauro? Nove Studiosi a Confronto; Torsello, B.P., Ed.; Marsilio Editori: Venezia, Italy, 2005; pp. 37–40. [Google Scholar]

- Della Torre, S. A coevolutionary approach as the theoretical foundation of planned conservation of built cultural heritage. In Preventive Conservation—From Climate and Damage Monitoring to a Systemic and Integrated Approach; Vandesande, A., Verstrynge, E., Van Balen, K., Eds.; CRC Press/Balkema: Lemmer, The Netherlands, 2020; pp. 11–18. [Google Scholar]

- Bianco, L.; Serra, V.; Fantucci, S.; Dutto, M.; Massolino, M. Thermal insulating plaster as a solution for refurbishing historic building envelopes: First experimental results. Energy Build. 2015, 95, 86–91. [Google Scholar] [CrossRef]

- Gasparoli, P. Attività di progetto sul costruito. In Manutenzione e Recupero. Criteri, Metodi e Strategie per L’intervento sul Costruito; Gasparoli, P., Talamo, C., Eds.; Alinea: Firenze, Italy, 2006; pp. 153–181. [Google Scholar]

- Gulotta, D.; Goidanich, S.; Tedeschi, C.; Toniolo, L. Commercial NHL-containing mortars for the preservation of historical architecture. Part 2: Durability to salt decay. Constr. Build. Mater. 2015, 96, 198–208. [Google Scholar] [CrossRef]

- Arte e Mestieri Snc. Available online: http://www.naturalcalk.com/tillica/ (accessed on 30 June 2020).

- Nosrati, R.; Berardi, U. Long-term performance of aerogel-enhanced materials. Energy Procedia 2017, 132, 303–308. [Google Scholar] [CrossRef]

- Berardi, U.; Nosrati, R.H. Long-term thermal conductivity of aerogel-enhanced insulating materials under different laboratory aging conditions. Energy 2018, 147, 1188–1202. [Google Scholar] [CrossRef]

- Camuffo, D. Acid rain and deterioration of monuments: How old is the phenomenon? Atmos. Environ. 1992, 26, 241–247. [Google Scholar] [CrossRef]

- García-Vera, V.E.; Lanzón, M. Physical-chemical study, characterisation and use of image analysis to assess the durability of earthen plasters exposed to rain water and acid rain. Constr. Build. Mater. 2018, 187, 708–717. [Google Scholar] [CrossRef]

- Barbero, S.; Marco, D.; Ferrua, C.; Pereno, A. Analysis on existent thermal insulating plasters towards innovative applications: Evaluation methodology for a real cost-performance comparison. Energy Build. 2014, 77, 40–47. [Google Scholar] [CrossRef]

- Deconinck, A.H. Comparative assessment of in-situ thermal characterisation techniques. In Proceedings of the 10th Nordic Symposium on Building Physics, NSB, Lund, Sweden, 15–19 June 2014; pp. 525–532. [Google Scholar]

- Fantucci, S. Tecniche di misura della trasmittanza. Master’s Thesis, Polytechnic of Torino, Torino, Italy, March 2018. [Google Scholar]

- Panzeri, A.; Erba, V.; Esposti, R.; Galbusera, G. La corretta valutazione dell’isolamento termico per il risparmio energetico in edilizia. Neo-Eubios 2015, 52, 55–62. [Google Scholar]

- Tamanti, F. Materiali isolanti per l’edilizia. Come si misura in laboratorio la loro idoneità ai requisiti di risparmio energetico. Ingenio 26 April 2014. Available online: https://www.ingenio-web.it (accessed on 30 June 2020).

- Salmon, D. Thermal conductivity of insulations using guarded hot plates, including recent developments and sources of reference materials. Meas. Sci. Technol. 2001, 12, R89–R98. [Google Scholar] [CrossRef]

| Product | Category | Main Components | Aerogel % (vol.) | ρ Kg/m3 | Th. mm | µ | λ W/mK | Source |

|---|---|---|---|---|---|---|---|---|

| AeroRock ID-VP by Rockwool | fiber-reinforced board |

| - * | - | 30; 50 | - | 0.019 | Data sheet |

| Ama Aerogel® by Aspen | fiber-reinforced board |

| - | 200 ± 10% | 3; 6; 10 | 0.05 | 0.016 | Data sheet |

| Aeropan® by Aspen | fiber-reinforced board |

| - | 230 ± 0% | 10; 20; 30; 40; 50; 60 | 0.07 | 0.015 | Data sheet |

| Spaceloft® by Aspen | fiber-reinforced blanket |

| - | 150 ± 10% | 5; 10 | 5.0 | 0.015 | Data sheet |

| Spacefill by Proctor Group (EFFESUS project) | blown-in insulation |

| Eurac | |||||

| Aerogel-based textile wallpaper (EASEE research project) | wallpaper |

| - | ρ dry 135.8 ρ 50% 136.3 | 7 | μ dry = 4–6μ wet = 2–6 | Λdry = 0.025 λ 80% = 0.026 | Masera et al., 2016 |

| Aerogel render (Stahl 2012) | plaster |

| 60–90 | ~200 | 12–13 | 4 | 0.025 | Stahl 2012 |

| Fixit 222® by RÖFIX | plaster |

| >50 | ρ dry 220 | min 30 | 4–5 | 0.028 | Data sheet Berardi 2018 |

| Hydraulic mortar + 25% aerogel | plaster |

| 25 | 735.6 | - | - | 0.1151 | Berardi 2018 |

| Hydraulic mortar by Chiraema + 50% aerogel | plaster |

| 50 | 501.0 | - | - | 0.0687 | Berardi 2018 |

| Hydraulic mortar by Chiraema + 70% aerogel | plaster |

| 70 | 260.7 | - | - | 0.0311 | Berardi 2018 |

| Saint Astier Trans Mineral Inc. + 25% aerogel | plaster |

| 25 | 735.56 | - | - | 0.1231 | Berardi 2018 |

| Saint Astier Trans Mineral Inc. + 50% aerogel | plaster |

| 50 | 515.30 | - | - | 0.0694 | Berardi 2018 |

| Aerogel-based plaster (Buratti et al. 2014) | plaster |

| 80–90 | 300–275 | 24.544.5 | - | 0.050–0.045 | Buratti et al. 2014 |

| Aerogel-based plaster (Buratti et al. 2014) | plaster |

| 91–95 | 136–126 | 24.544.5 | - | 0.021–0.019 | Buratti et al., 2014 |

| Aerogel-based plaster (Buratti et al., 2014) | plaster |

| 96–99 | 125–115 | 24.544.5 | - | 0.016–0.014 | Buratti et al., 2014 |

| Tillica pasta® | plaster |

| ρ wet 700 ρ dry 170 | 15 | ≤5.8 | 0.00175 | Data sheet |

| Description | Granular Aerogel (vol.%) | Thermal Conductivity (W/mK) |

|---|---|---|

| Natural lime plaster | - | 0.50 |

| Hydrated lime plaster + aerogel | 80–90 | 0.050–0.045 |

| Hydrated lime plaster + aerogel | 91–95 | 0.021–0.019 |

| Hydrated lime plaster + aerogel | 96–99 | 0.016–0.014 |

| Render | Thermal Conductivity (W/mK) | Price (€/sqm Rx for s = 10 mm) | Thickness Rx (mm/sqm) | Price (€/ sqm Rx) |

|---|---|---|---|---|

| Lime plaster -1 | 0.2 | 11.5 | 200 | 230.00 |

| Lime plaster -2 | 0.075 | 8.55 | 75 | 64.13 |

| Lime plaster -3 | 0.060 | 4.8 | 60 | 28.80 |

| Lime plaster -4 | 0.091 | 5.84 | 91 | 53.14 |

| Lime plaster -5 | 0.066 | 11.080 | 66 | 73.13 |

| Lime plaster -5 | 0.088 | 5.36 | 88 | 47.17 |

| Aerogel-based plaster | 0.028 | 80.00 | 28 | 224.00 |

| Method | Standards | Margin of Error | |

|---|---|---|---|

| Guarded Hot Plate (GHP) | λ | EN 12664 EN 12667 ISO 8302 | ±2% |

| Heat Flow Meter method (HFM) | λ | EN 12664 EN 12667 ISO 8301 | ±3% |

| Guarded Hot Box (GHB) | U | EN ISO 8990 | ±5% |

| Hotbox chamber with heat flowmeters | U | EN 1934 | ±5% |

| Radial method | Rt | EN ISO 8497 | ±3% |

| Overall Size | Metering Section | Guard Width | Max. Thickness (Edge Limit) for Specimen Conductivity of | Flatness Tolerance (0.025%) | Min. Thickness (Flatness Tolerance) | Max. Gap | Min. Thickness (Gap Limit) | ||

|---|---|---|---|---|---|---|---|---|---|

| ≤0.4 | 0.8 | ≥1.6 | |||||||

| 200 | 100 | 50 | 30 | 35 | 40 | 0.05 | 10.0 | 1.25 | 12.5 |

| 300 | 200 | 50 | 35 | 40 | 45 | 0.08 | 15.0 | 2.50 | 25.0 |

| 300 | 150 | 75 | 45 | 55 | 65 | 0.08 | 15.0 | 1.88 | 18.8 |

| 400 | 200 | 100 | 60 | 70 | 85 | 0.10 | 20.0 | 2.50 | 25.0 |

| 400 | 100 | 150 | 80 | 95 | 110 | 0.10 | 20.0 | 1.25 | 12.5 |

| 500 | 300 | 100 | 65 | 80 | 90 | 0.13 | 25.0 | 3.75 | 37.5 |

| 500 | 250 | 125 | 75 | 90 | 100 | 0.13 | 25.0 | 3.13 | 31.5 |

| 500 | 200 | 150 | 85 | 100 | 120 | 0.13 | 25.0 | 2.50 | 25.0 |

| 600 | 300 | 150 | 90 | 110 | 130 | 0.15 | 30.0 | 3.75 | 37.5 |

| 800 | 500 | 150 | 100 | 120 | 150 | 0.20 | 40.0 | 6.25 | 62.5 |

| 800 | 400 | 200 | 120 | 140 | 170 | 0.20 | 40.0 | 5.00 | 50.0 |

| 1000 | 500 | 250 | 150 | 180 | 210 | 0.25 | 50.0 | 6.25 | 62.5 |

| Specimen Thermal Resistance m2K/W | Maximum Allowed Contact Thermal Resistance m2K/W | Maximum Equivalent Air Layer Thickness (Apparatus + Specimen) mm |

|---|---|---|

| 0.3 | 0.001 5 | 0.037 |

| 0.4 | 0.002 0 | 0.050 |

| 0.5 | 0.002 5 | 0.063 |

| 0.6 | 0.003 0 | 0.075 |

| 0.8 | 0.004 0 | 0.100 |

| 1.0 | 0.005 0 | 0.125 |

| 1.5 | 0.007 5 | 0.188 |

| Authors | Research Topic | Test | Sample | Instrumentation | Standards |

|---|---|---|---|---|---|

| Stahl et al. 2012/Masera, Ghazi, Stahl et al. 2016 | Thermo-hygric properties of an aerogel-based insulation rendering; development of an aerogel-based textile wallpaper | Thermal conductivity | 65 × 65 × 12 mm | GHP with a single-specimen asymmetrical configuration | EN 12667 EN 12664 |

| Buratti et al. 2014 | Development of innovative aerogel-based plasters | Thermal conductivity | 300 × 300 × 10 mm | heat flow meter apparatus FOX 314 HFM with GHP | ASTMC518-C510 ISO8301 EN ISO2667 |

| Nosrati, Berardi 2017; Calisesi 2017 | Long-term performance of aerogel-enhanced materials; aerogel incorporated precast panels | Thermal conductivity | 150 × 150 × 20 mm with an EPS frame | Heat flow meter -HFM 436 λ | ASTM C518, C109/C109M–16 |

| Lucchi et al. 2017 | Thermal performance evaluation and comfort assessment of advanced aerogel as blown-in insulation for historic buildings | Thermal conductivity (C), thermal resistance (R), U-value | 500 × 500 × 100 mm covered with a thin foil, surrounded by an EPS frame | C: two-plate apparatus with GHP; R: GHB INTENT (Integrated Envelope Testing facility), HFM, sensor. | EN 12667, EN 1934 |

| Cod. | Layer | Dimensions | Model |

|---|---|---|---|

| A0 | NHL mortar (10 mm) + Full brick (50 mm) + NHL mortar (10 mm) | 250 × 250 × 70 mm |  |

| A1 | A0 + 80% aerogel plaster (5 mm) | 250 × 250 × 75 mm |  |

| A2 | A0 + 80% aerogel plaster (10 mm) | 250 × 250 × 80 mm |  |

| A3 | A0 + 80% aerogel plaster (15 mm) | 250 × 250 × 85 mm |  |

| B | A0 + EPS board (100 mm) | 250 × 250 × 170 mm |  |

| C | 80% aerogel plaster (20 mm) | 50 × 50 × 20 mm |  |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Del Curto, D.; Cinieri, V. Aerogel-Based Plasters and Energy Efficiency of Historic Buildings. Literature Review and Guidelines for Manufacturing Specimens Destined for Thermal Tests. Sustainability 2020, 12, 9457. https://doi.org/10.3390/su12229457

Del Curto D, Cinieri V. Aerogel-Based Plasters and Energy Efficiency of Historic Buildings. Literature Review and Guidelines for Manufacturing Specimens Destined for Thermal Tests. Sustainability. 2020; 12(22):9457. https://doi.org/10.3390/su12229457

Chicago/Turabian StyleDel Curto, Davide, and Valentina Cinieri. 2020. "Aerogel-Based Plasters and Energy Efficiency of Historic Buildings. Literature Review and Guidelines for Manufacturing Specimens Destined for Thermal Tests" Sustainability 12, no. 22: 9457. https://doi.org/10.3390/su12229457

APA StyleDel Curto, D., & Cinieri, V. (2020). Aerogel-Based Plasters and Energy Efficiency of Historic Buildings. Literature Review and Guidelines for Manufacturing Specimens Destined for Thermal Tests. Sustainability, 12(22), 9457. https://doi.org/10.3390/su12229457