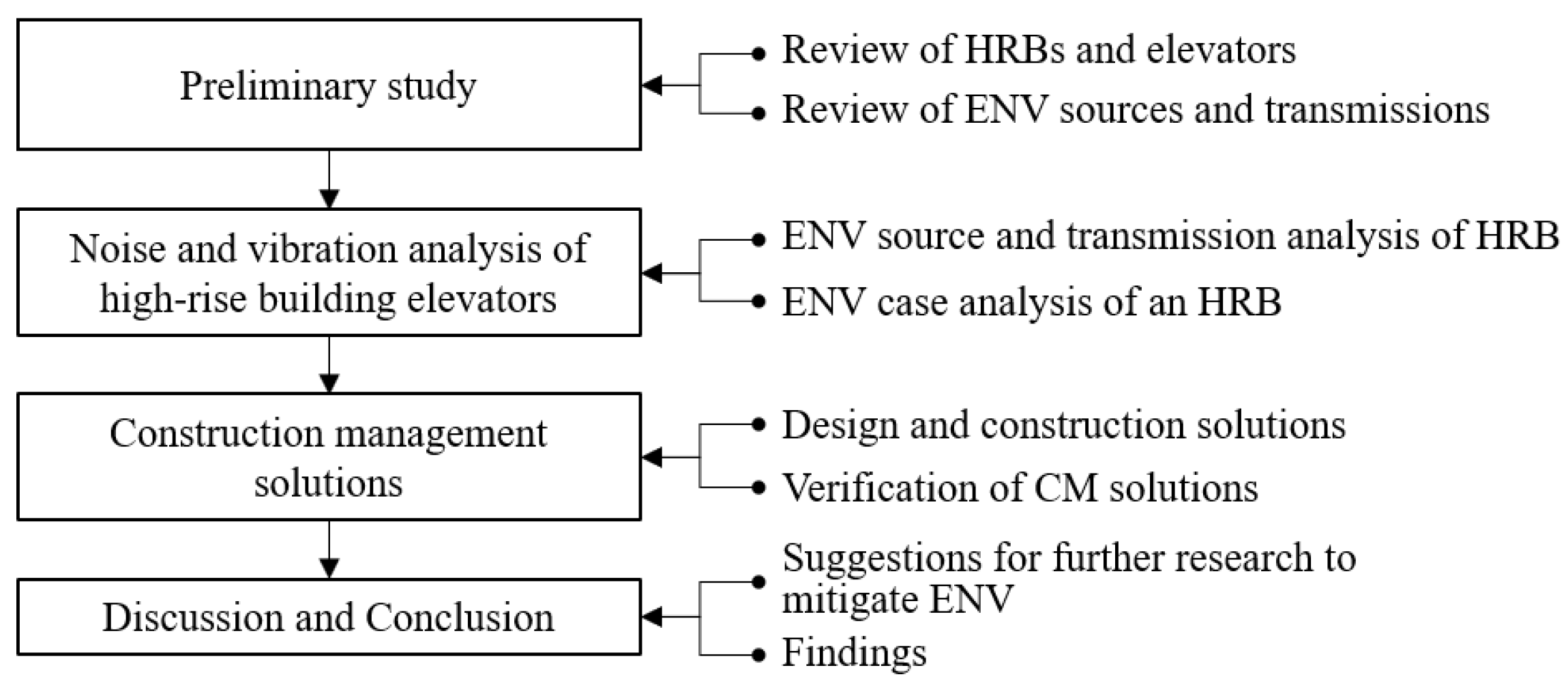

Construction Management Solutions to Mitigate Elevator Noise and Vibration of High-Rise Residential Buildings

Abstract

1. Introduction

2. ENV of HRBs

2.1. Review of HRBs and Elevators

2.2. Review of ENV Sources

3. Noise and Vibration Analysis of HRBs

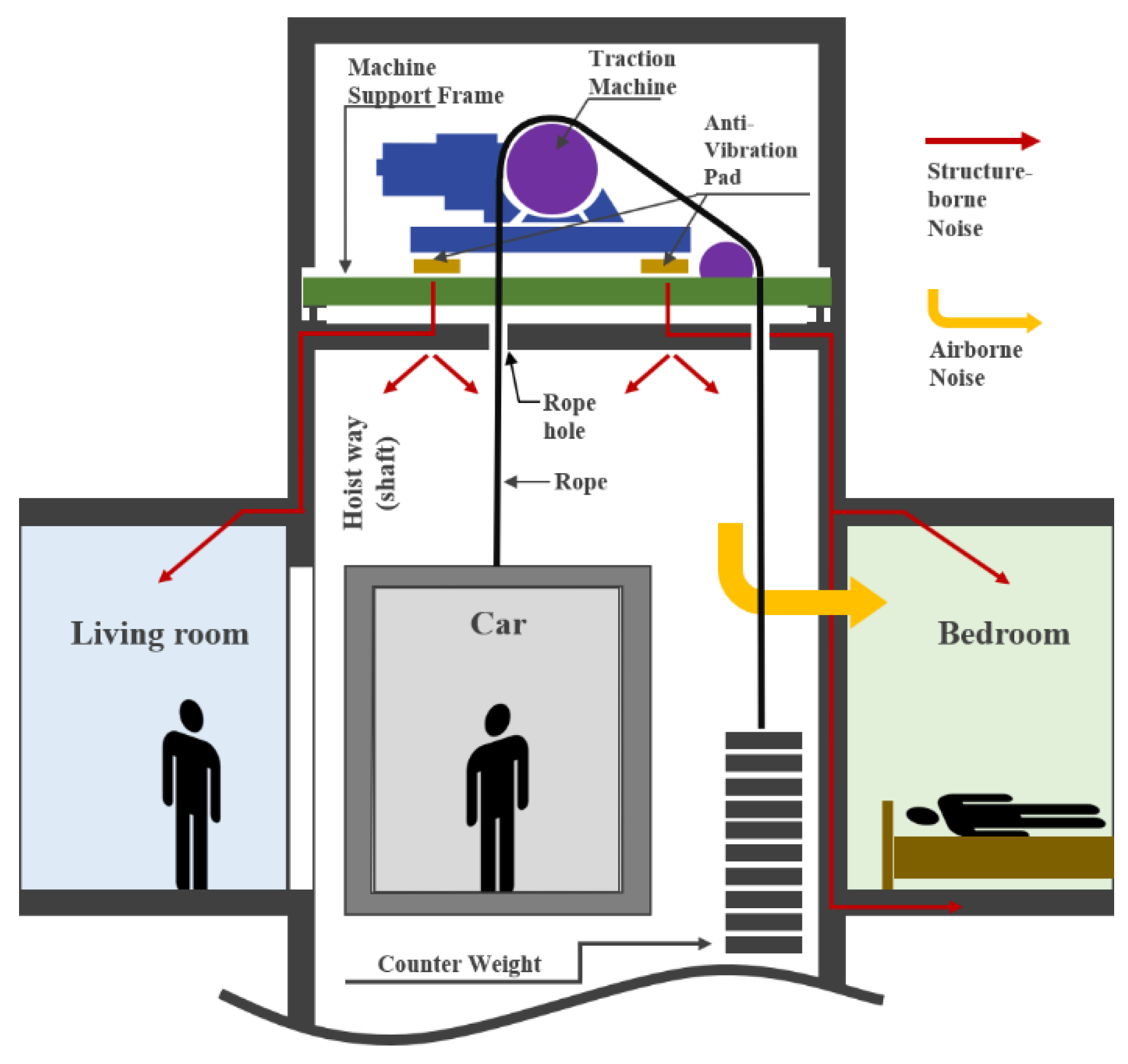

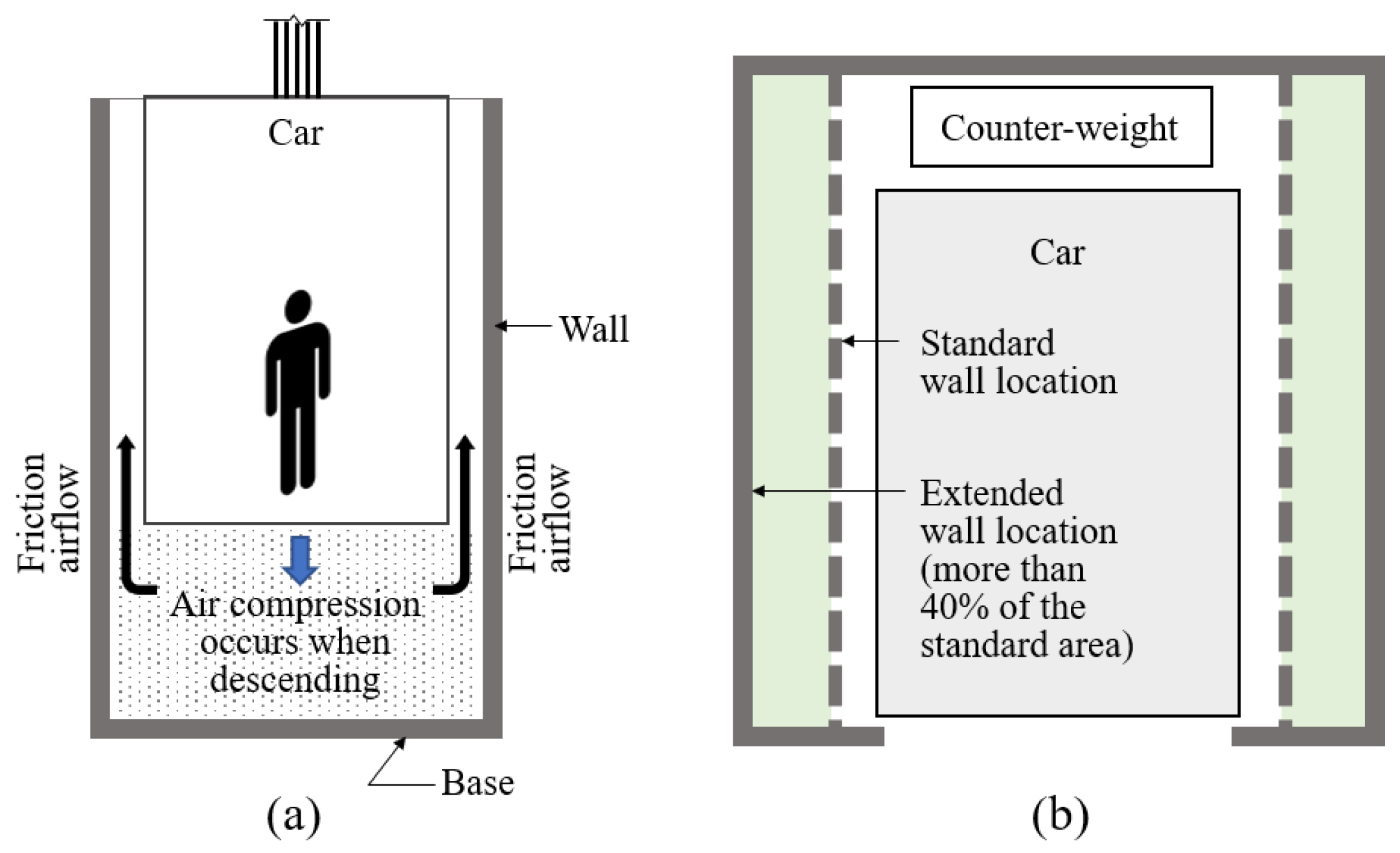

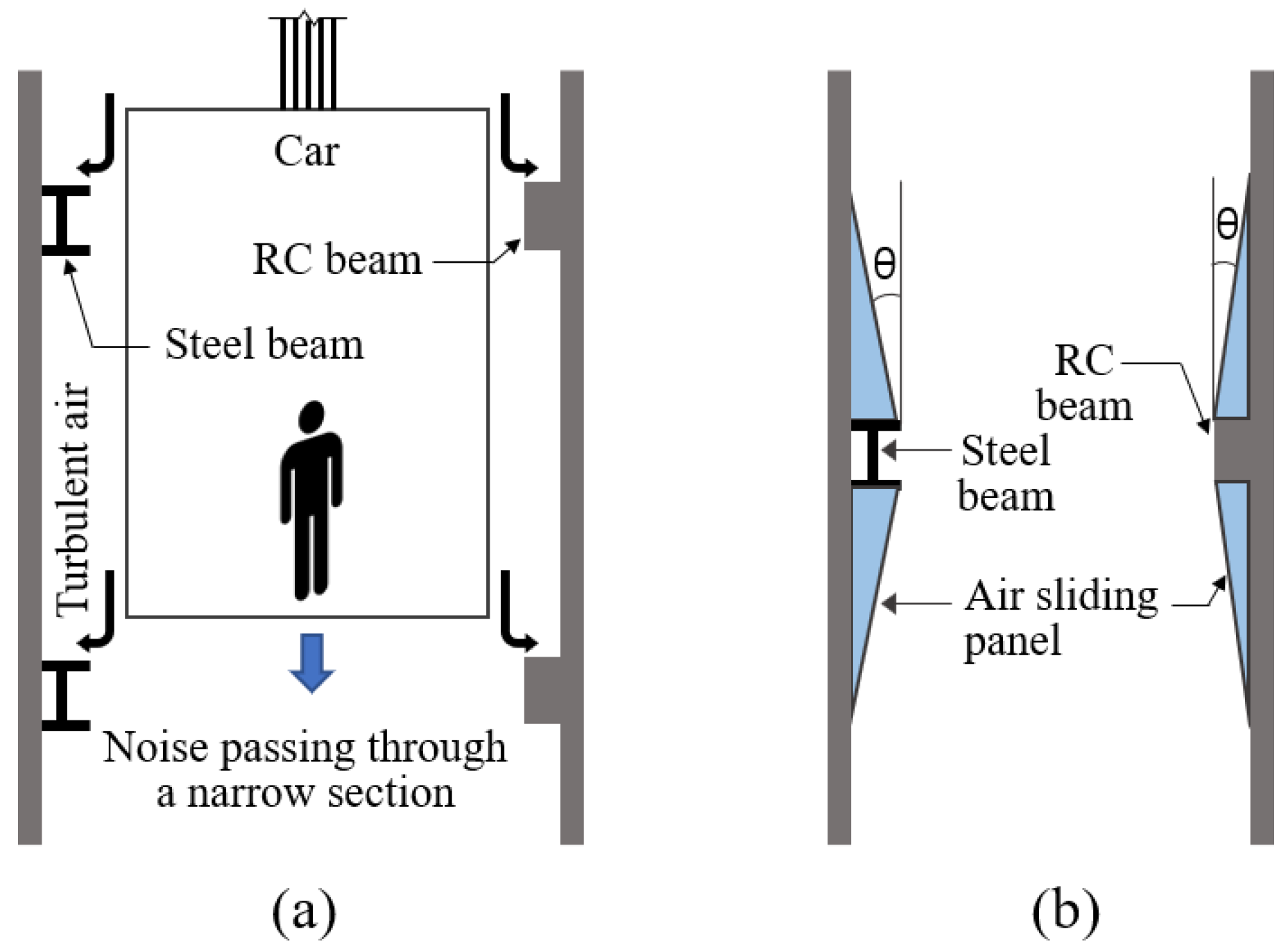

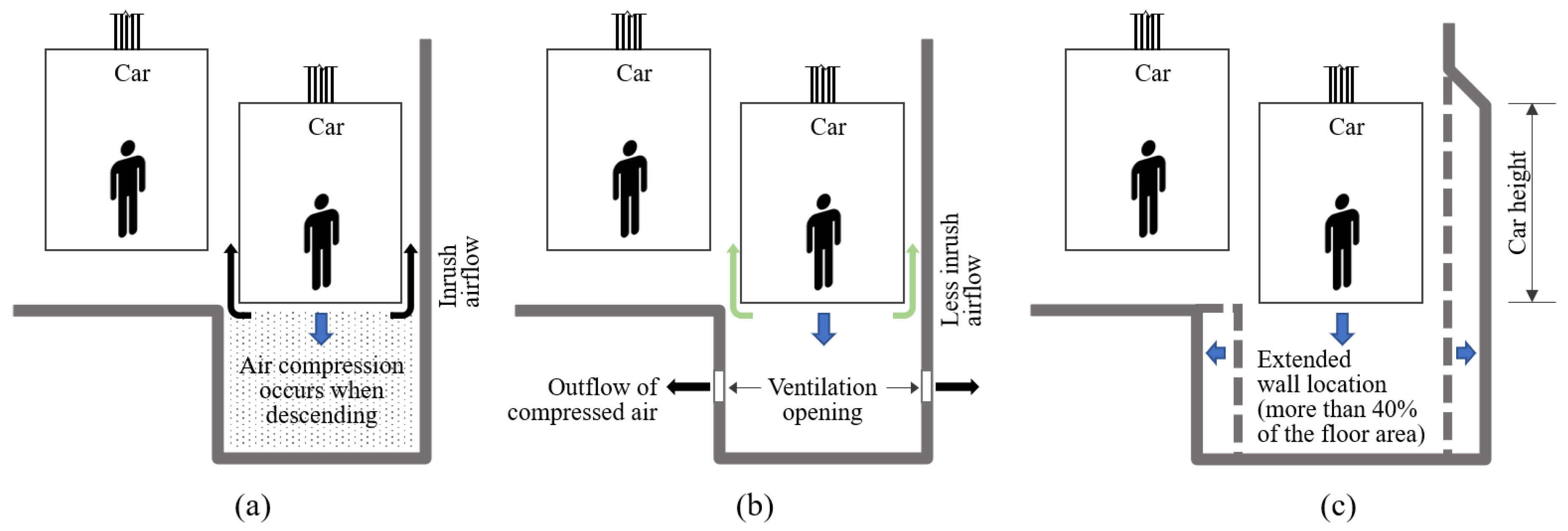

3.1. ENV Source and Transmission Analysis of HRBs

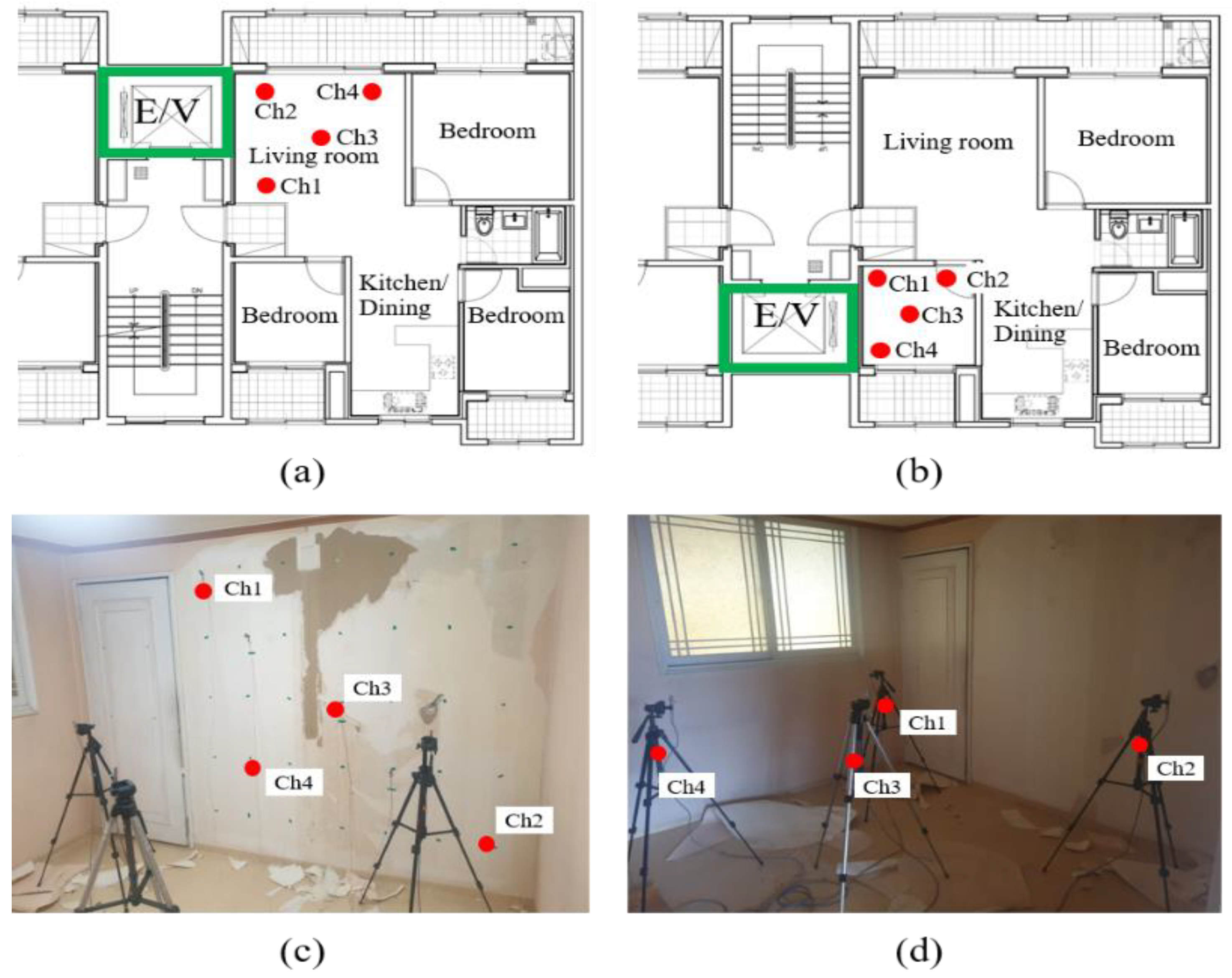

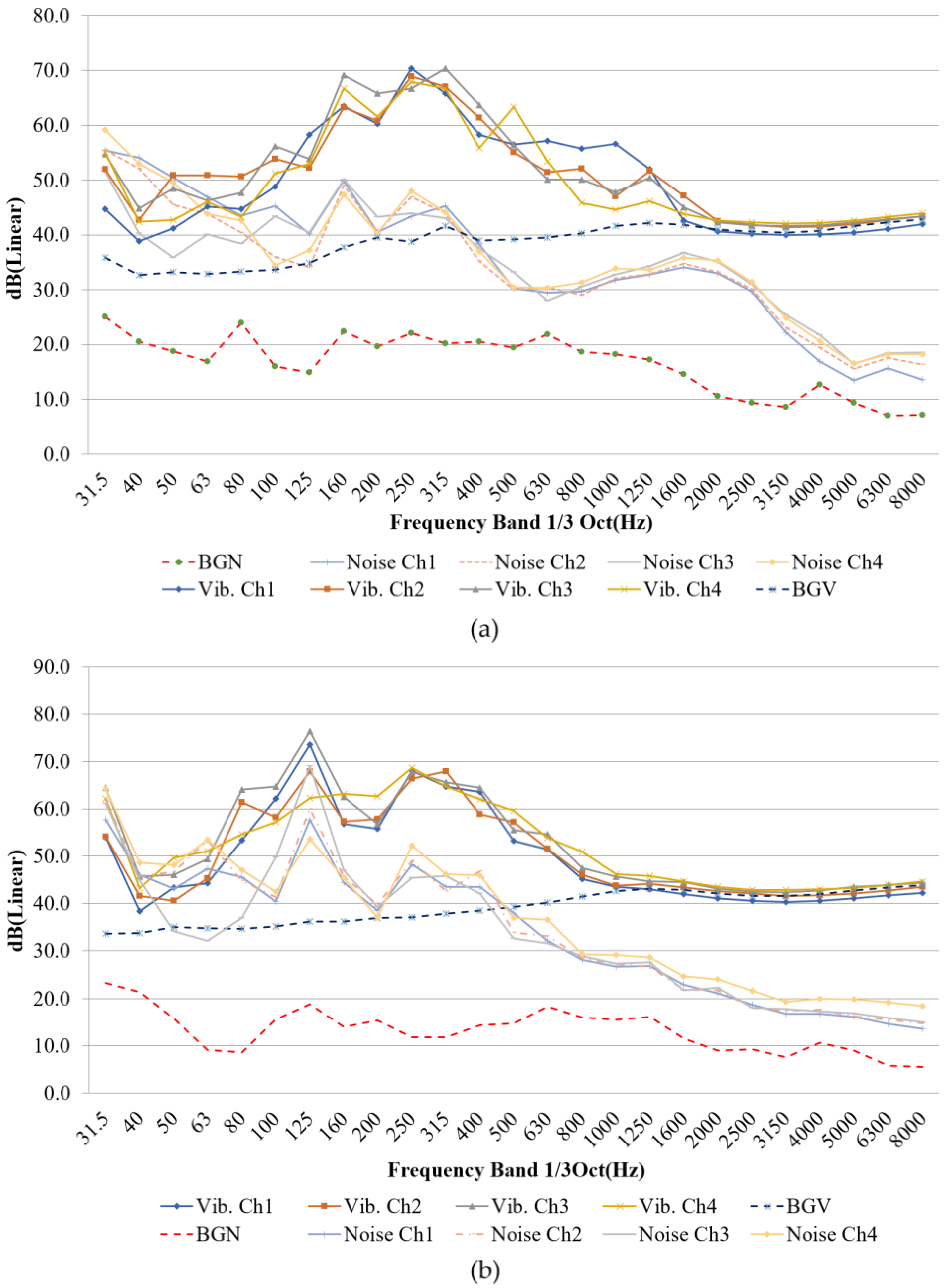

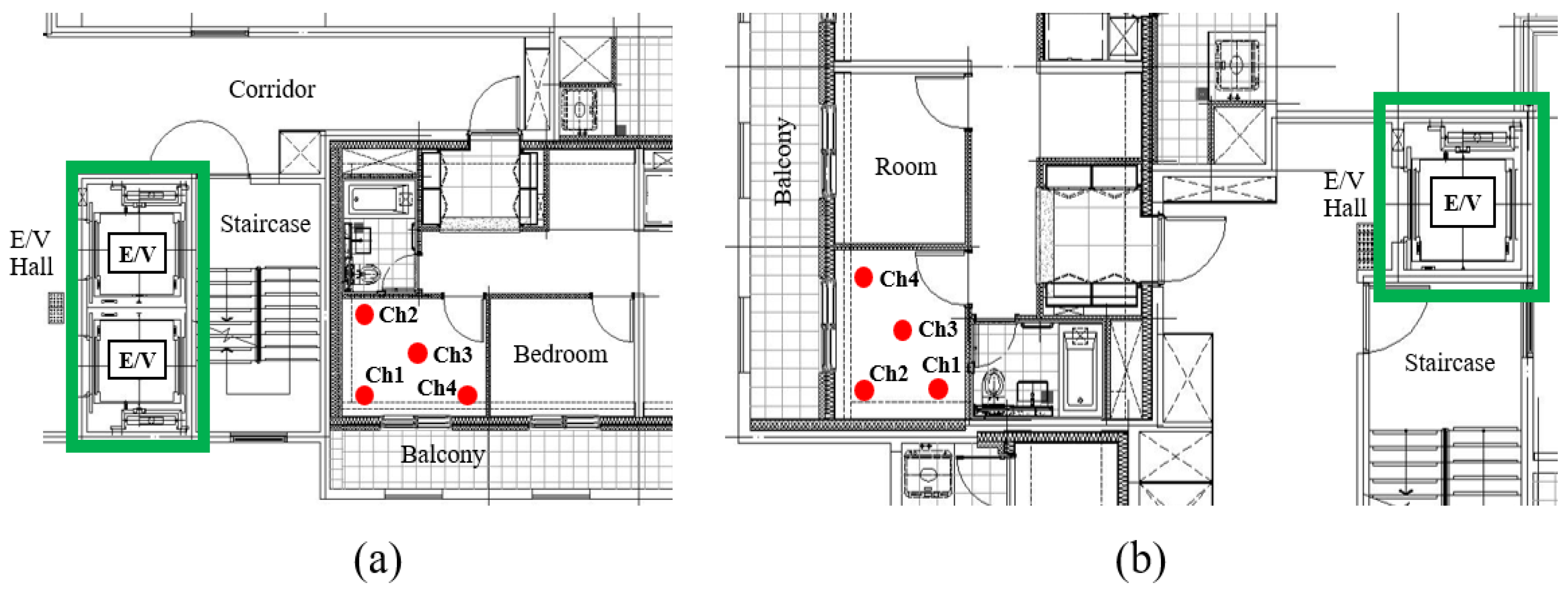

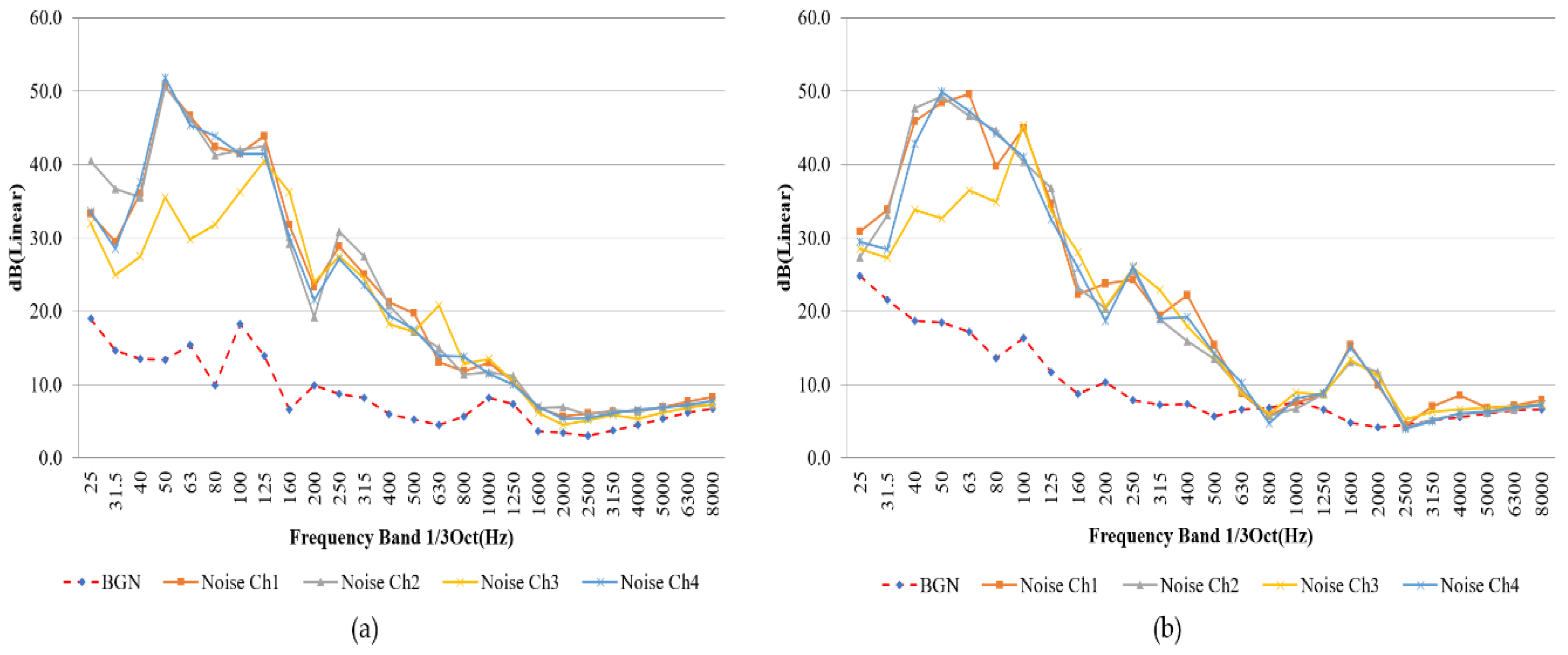

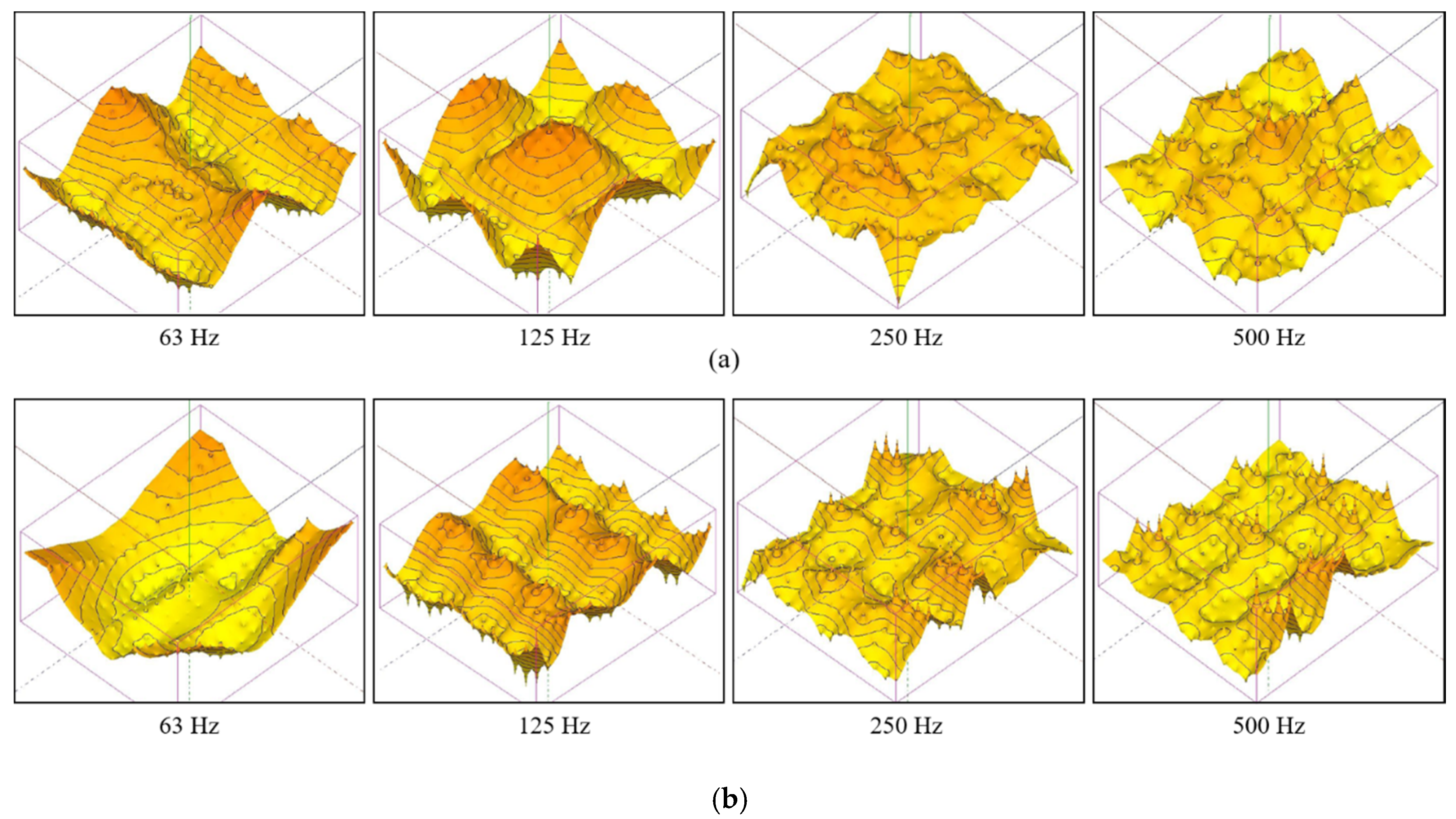

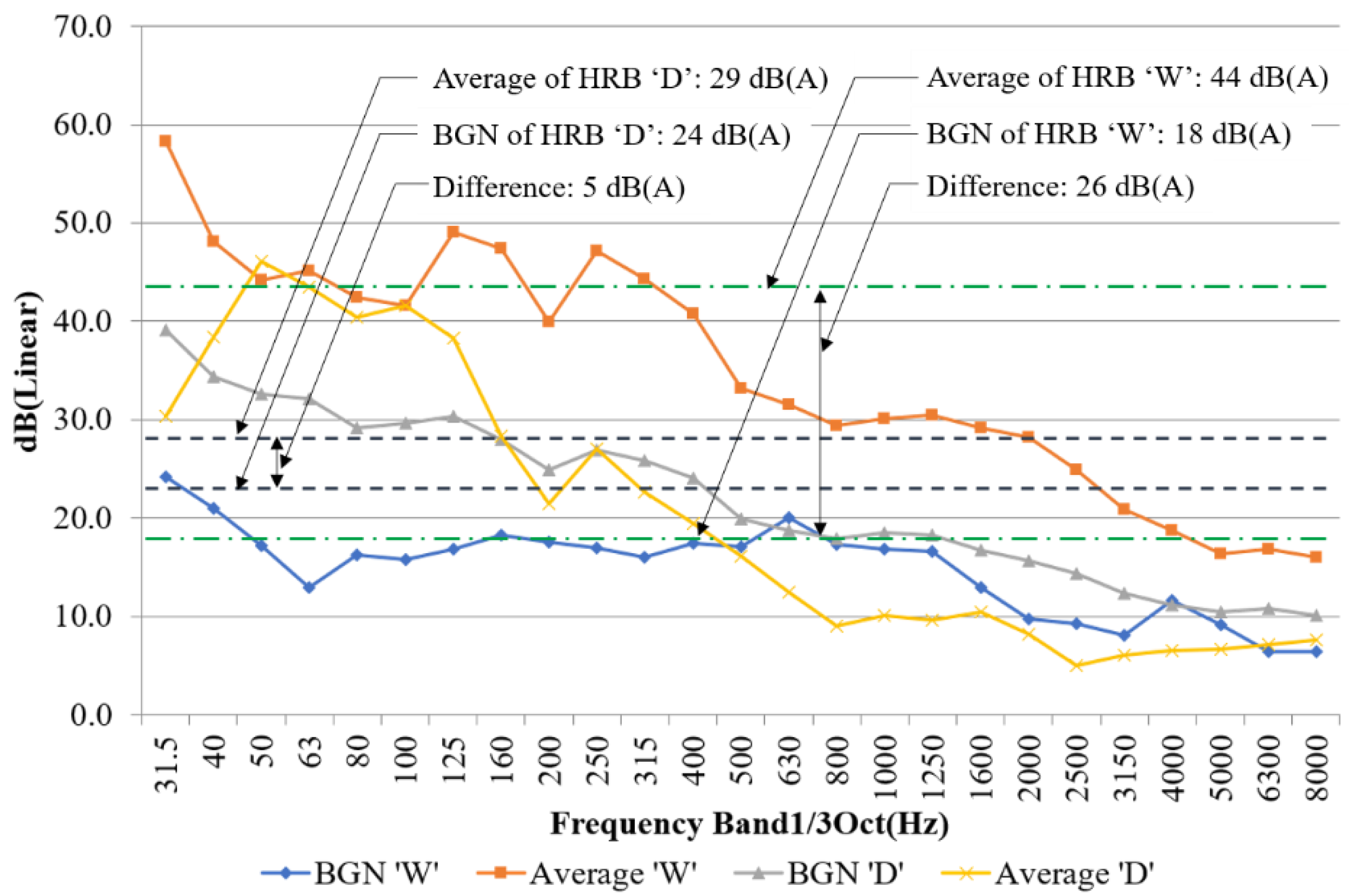

3.2. ENV Case Analysis of an HRB

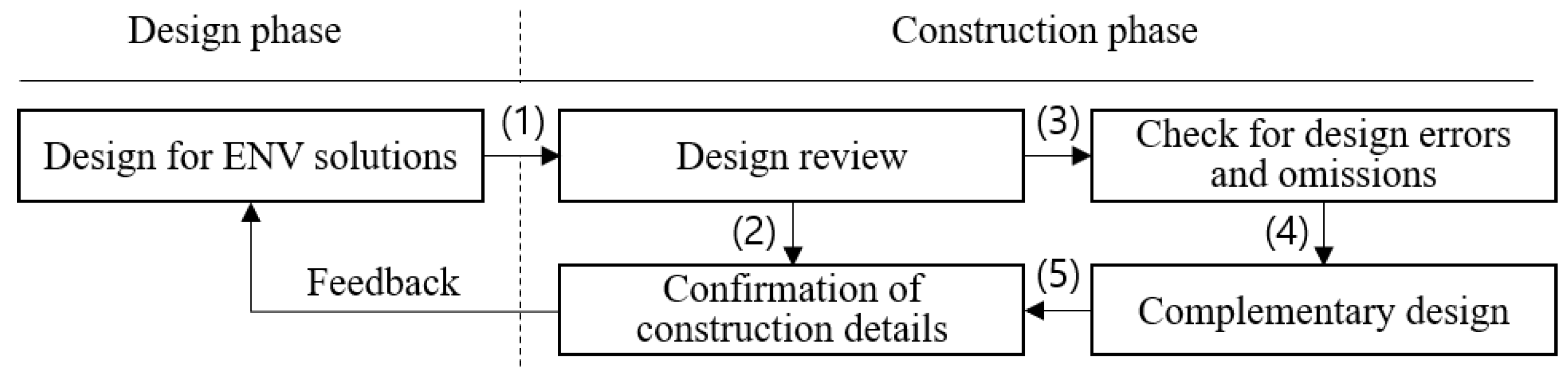

4. CM Solutions

4.1. Design Solutions

4.1.1. Separation of Residences and Elevators

4.1.2. Buffer Space Design

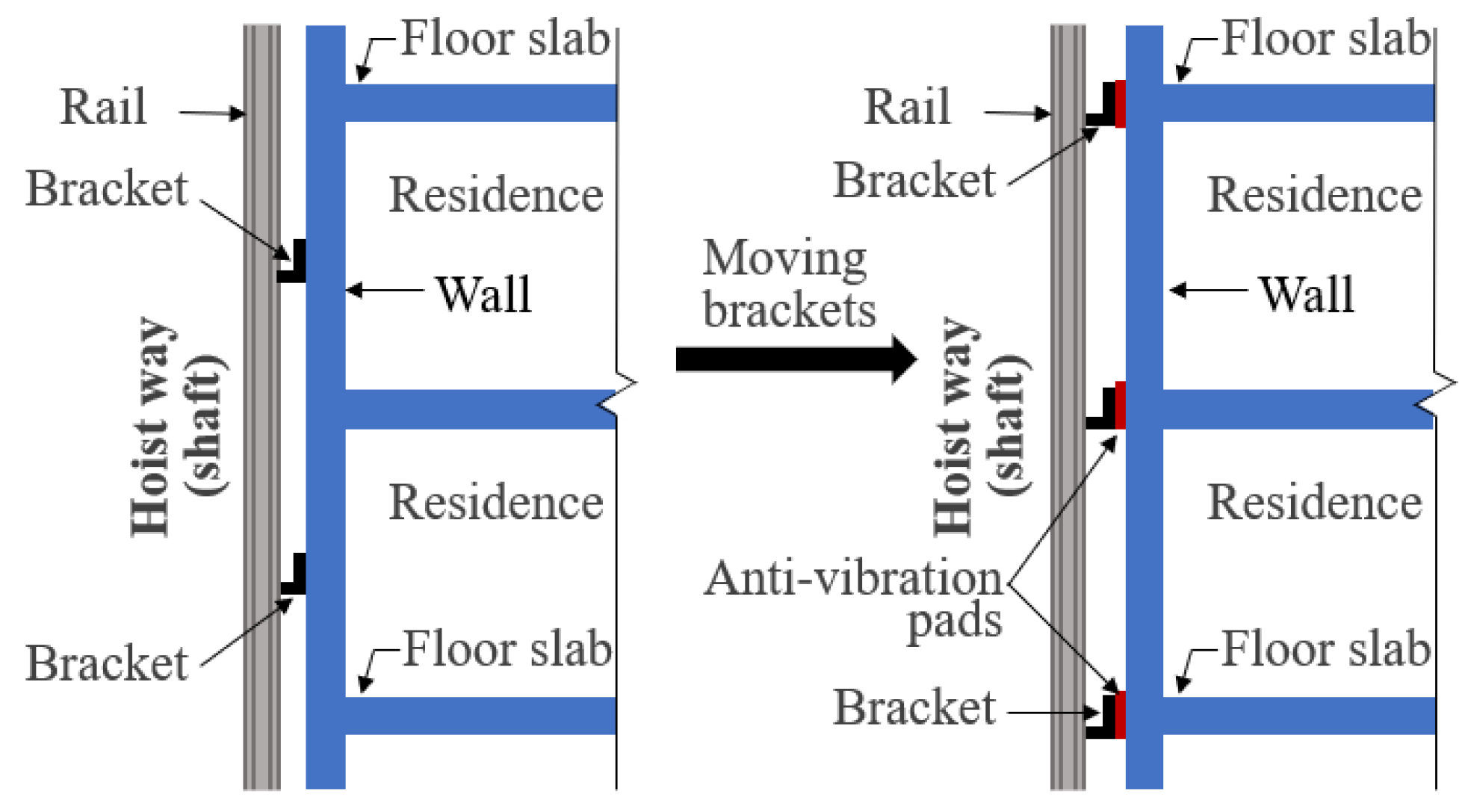

4.1.3. Change of Hoist Way Details

4.1.4. Other Design Solutions

- As shown in Figure 3, a machine support frame should be suspended from a machine room floor slab.

- The thickness of the machine room floor is designed to be possibly >350 mm, including a 200-mm-thick RC slab and 150-mm-sized light-weight concrete.

- The thickness of the wall in the machine room is designed to be >150 mm, whereas the sound absorption layer is placed within the wall.

- The thickness of the hoist way wall is designed to be >200 mm.

- If the hoist way space is sufficiently big, separated beams are supplemented. Moreover, the installation of rail brackets reduces noise a lot while an elevator is running.

- The counter-weight of the elevator is planned to be installed on the staircase or external wall rather than adjacent residences.

4.2. Construction Solutions

4.3. Verification of CM Solutions

5. Discussion

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Rashidah, S.; Che-Ani, A.I.; Sairi, A.; Tawil, N.M.; Razak, M. Classification of High-Rise Residential Building Facilities: A Descriptive Survey on 170 Housing Scheme in Klang Valley, MATEC Web of Conferences 66; Guéhot, S., Ed.; EDP Sciences: Les Ulis, France, 2016; Volume 00103, pp. 1–4. [Google Scholar] [CrossRef]

- Al-Kodmany, K. Tall buildings and elevators: A review of recent technological advances. Buildings 2015, 5, 1070–1104. [Google Scholar] [CrossRef]

- Wood, A.; Henry, S.; Safarik, D. 2014 Best Tall Buildings. In Proceedings of the CTBUH Award Ceremony, 2 November 2014; Illinois Institute of Technology (IIT): Chicago, IL, USA, 2014. [Google Scholar]

- Liu, J.; Zhang, R.; He, Q.; Zhang, Q. Study on horizontal vibration characteristics of high-speed elevator with airflow pressure disturbance and guiding system excitation. Mech. Ind. 2019, 20, 305. [Google Scholar] [CrossRef]

- Qiu, L.; Wang, Z.; Zhang, S.; Zhang, L.; Chen, J. A Vibration-Related Design Parameter Optimization Method for High-Speed Elevator Horizontal Vibration Reduction. Shock Vib. 2020. [Google Scholar] [CrossRef]

- Kawasaki, R.; Hironaka, Y.; Nishimura, M. Noise and Vibration Analysis of Elevator Traction Machine. In Proceedings of the Inter-noise 2010, Noise and Sustainability, Lisbon, Portugal, 13–16 June 2010; pp. 1–9. [Google Scholar]

- Noda, S.; Mizuno, S.; Kamijo, Y.; Matsushita, M. Prediction of Room Noise Caused by Vibration of High Power Elevator Traction Machine. In Proceedings of the 2013 International Conference on Energy, Environment, Ecosystems and Development, Lemesos, Cyprus, 21–23 March 2013; pp. 130–134. Available online: http://www.inase.org/library/2013/rhodes/bypaper/EEED/EEED-16.pdf (accessed on 25 June 2020).

- Klote, J.H. Elevator pressurization in tall buildings. Int. J. High-Rise Build. 2013, 2, 341–344. [Google Scholar] [CrossRef]

- Klote, J.H. An analysis of the influence of piston effect on elevator smoke control. In NIST Interagency/Internal Report (NISTIR)—88-3751; NIST Pubs: Gaithersburg, MD, USA, 1988. [Google Scholar] [CrossRef]

- Mutoh, N.; Kagomiya, K.; Kurosawa, T.; Konya, M.; Andoh, T. Horizontal vibration suppression method suitable for super-high-speed elevators. Electr. Eng. Japan 1999, 129, 59–73. [Google Scholar] [CrossRef]

- Szydlo, K.; Wolszczak, P.; Longwic, R.; Litak, G.; Dziubinski, M.; Drozd, A. assessment of lift passenger comfort by the Hilbert–Huang transform. J. Vib. Eng. Technol. 2020, 8, 373–380. [Google Scholar] [CrossRef]

- Szydlo, K.; Maciag, P.; Longwic, R.; Lotko, M. Analysis of vibroacoustic signals recorded in the passenger lift cabin. Adv. Sci. Technol. Res. J. 2016, 10, 193–201. [Google Scholar] [CrossRef][Green Version]

- Zhang, Y.; Sun, X.; Zhao, Z.; Su, W. Elevator ride comfort monitoring and evaluation using smartphones. Mech. Syst. Signal Process. 2018, 105, 377–390. [Google Scholar] [CrossRef]

- Fullerton, J.L. Review of elevator noise and vibration criteria, sources and control for multifamily residential buildings. In Proceedings of the Inter-Noise and Noise-Con Congress and Conference Proceedings, Honolulu, HI, USA, 3–6 December 2006; Volume 6, pp. 1230–1237. [Google Scholar]

- Kalkman Ir, C.; Buijsing, J.H.N. Noise levels in apartment block caused by lift; what can be done in order to reduce complaints. In Proceedings of the 2001 International Congress and Exhibition on Noise Control Engineering, Hague, The Netherlands, 27–30 August 2001; Available online: https://www.peutz.nl/sites/peutz.nl/files/publicaties/Peutz_Publicatie_KK_Internoise_08-2001.pdf (accessed on 25 June 2020).

- Jeong, A.Y.; Kim, K.W.; Shin, H.K.; Yang, K.S. Criteria and Characteristics of Elevator Noise in Apartments. Appl. Mech. Mater. 2017, 873, 231–236. [Google Scholar] [CrossRef]

- Lee, K.W. A Study on the Measures to Reduce Elevator Noises. Master’s Thesis, Catholic Kwandong University, Gangneung, Korea, 2013; pp. 9–35. (In Korean). [Google Scholar]

- Kim, H.S.; Kim, H.G.; Kim, M.J.; Oh, Y.I. Reduction Methods of the Elevator-Operating Noise in Apartment Housings. In Proceedings of the International Conference, Korean Society for Noise and Vibration Engineering (KSNVE), Seoul, Korea, 9–12 February 1994; pp. 619–626. Available online: http://www.dbpia.co.kr/journal/articleDetail?nodeId=NODE02420216 (accessed on 23 July 2020).

- Evans, J.B. Elevator equipment noise mitigation for high-rise residential condominium. J. Acoust. Soc. Am. 2012, 131, 3262. [Google Scholar] [CrossRef]

- Kim, M.J.; Kim, H.G.; Kim, H.S. Research on the Elevator-operating Noise and Vibration in Apartment Buildings. In Proceedings of the Korean Society for Noise and Vibration Engineering (KSNVE), Pyeongchang, Korea, 14–16 November 2001; pp. 488–493. Available online: http://www.dbpia.co.kr/journal/articleDetail?nodeId=NODE02451458 (accessed on 23 July 2020). (In Korean).

- Kim, H.G.; Kim, M.J. Reduction Method of Elevator-operating Noise and Vibration in Apartment Housings; Land and Housing Institute, Korea Land and Housing Corporation: Seongnam, Korea, 2000; pp. 1–128. Available online: https://dl.nanet.go.kr/SearchDetailView.do?cn=MONO1200102249 (accessed on 22 October 2020). (In Korean)

- Lee, S.; Kim, J.; Kim, D. A Study on the Cause of Noise and Vibration of Elevators. In Proceedings of the Korean Society for Noise and Vibration Engineering (KSNVE), Seoul, Korea, 18–21 May 1994; pp. 94–99. Available online: http://www.auric.or.kr/User/Rdoc/DocRdoc.aspx?returnVal=RD_R&dn=114296#.X03YAcgzZnI (accessed on 27 July 2020). (In Korean).

- Ingold, D. Mitigating Elevator Noise in Multifamily Residential Buildings. Available online: http://buildipedia.com/aec-pros/construction-materials-and-methods/mitigating-elevator-noise-in-multifamily-residential-buildings?print=1&tmpl=component (accessed on 2 September 2020).

- Zhou, Y.Q. In-car noise reduction for a newly developed home elevator. J. Acoust. Soc. Am. 1997, 101, 3018. [Google Scholar] [CrossRef]

- Jeon, E.S.; Cho, B.H. The countermeasure which reduces the noise and vibration of the building elevator. J. Korean Digit. Archit. Inter. Assoc. 2005, 5, 35–42. (In Korean) [Google Scholar]

- Watanabe, S.; Yumura, T.; Kariya, Y.; Hoshinoo, T. The Brake Noise Reduction Method for the Elevator Traction Machine. In Proceedings of the Transportation and Logistics Conference, Kawasaki, Japan, 8 December 2003; pp. 133–134. [Google Scholar] [CrossRef]

- Torres, J.; Haugen, K. Noise Produced by Lift In Multi-Story Apartment Building, Case Study. In Proceedings of the Inter-noise 2019, Noise Control for a Better Environment, Madrid, Spain, 16–19 June 2019. [Google Scholar]

- Kawasaki, R.; Hironaka, Y.; Tanaka, T.; Daikoku, A. Noise and vibration analysis of elevator traction machine. In Nippon Kikai Gakkai Ronbunshu, C Hen/Transactions of the Japan Society of Mechanical Engineers, Part C; Japan Society of Mechanical Engineers: Tokyo, Japan, 2010; Volume 76, pp. 2032–2038. [Google Scholar] [CrossRef][Green Version]

- Arrasate, X.; McCloskey, A.; Hernández, X.; Telleria, A. Optimum Design of Traction Electrical Machines in Lift Installations. In Proceedings of the Symposium on Lift & Escalator Technologies, Northampton, UK, 23–24 September 2015; Volume 5. Available online: https://www.researchgate.net/publication/282607214 (accessed on 28 July 2020).

- Wang, X.W.; Yu, Y.J.; Zhang, R.J.; Wang, S.C.; Tian, Y. The summary research on the noise of high-speed traction elevators. Appl. Mech. Mater. 2014, 541–542, 716–721. [Google Scholar] [CrossRef]

- Landaluze, J.; Portilla, I.; Cabezón, N.; Martínez, A.; Reyero, R. Application of active noise control to an elevator cabin. Control Eng. Pract. 2003, 11, 1423–1431. [Google Scholar] [CrossRef]

- Yu, S.; Pan, P.; Wang, H.; Chen, L.; Tang, R. Investigation on noise and vibration origin in permanent magnet electrical machine for elevator. In Proceedings of the ICEMS 2005 Proceedings of the Eighth International Conference on Electrical Machines and Systems, Nanjing, China, 27–29 September 2005; Volume 1, pp. 330–333. [Google Scholar] [CrossRef]

- Shi, L.Q.; Liu, Y.Z.; Jin, S.Y.; Cao, Z.M. Numerical simulation of unsteady turbulent flow induced by two-dimensional elevator car and counter weight system. J. Hydrodyn. 2007, 19, 720–725. [Google Scholar] [CrossRef]

- Salmon, J.K.; Yoo, Y.S. Reduction of noise and vibration in an elevator car by selectively reducing air turbulence. J. Acoust. Soc. Am. 1991, 90, 3387–3388. [Google Scholar] [CrossRef]

- Yang, I.H.; Jeong, J.E.; Jeong, U.C.; Kim, J.S.; Oh, J.E. Improvement of noise reduction performance for a high-speed elevator using modified active noise control. Appl. Acoust. 2014, 79, 58–68. [Google Scholar] [CrossRef]

- Tray Edmonds, P.E.; Fullerton, J.L. Noise and vibration control of an offset traction elevator system. In Proceedings of the INTER-NOISE 2015—44th International Congress and Exposition on Noise Control Engineering, San Francisco, CA, USA, 9–12 August 2015; Available online: https://scholar.google.com/scholar?hl=ko&as_sdt=0%2C5&q=Noise+and+vibration+control+of+an+offset+traction+elevator+system&btnG= (accessed on 25 August 2020).

- Park, C. Elevator Noises and Vibrations. Research on Construction Technology; Ssangyong Construction Co. Ltd.: Seoul, Korea, 2005; Volume 34, pp. 50–57. Available online: http://www.auric.or.kr/User/Rdoc/DocRdoc.aspx?returnVal=RD_R&dn=172387#.X02lu8gzZnI (accessed on 5 August 2020). (In Korean)

- Song, K.H. Solutions to mitigate elevator noise and vibration. J. ACRS Korean Assoc. Air Cond. Refrig. Sanit. Eng. 1999, 16, 65–76. (In Korean) [Google Scholar]

- Nam, K. Solutions to Mitigate High-Speed Elevator Noise and Vibration, Construction Management and Technology; Samsung Construction Co. Ltd.: Seoul, Korea, 1997; Volume 44, pp. 32–41. (In Korean) [Google Scholar]

- Emporis. Emporis Standards: High-Rise Building (ESN 18727). Available online: https://www.emporis.com/building/standard/3/high-rise-building (accessed on 5 August 2020).

- Korea Land and Housing Corporation, Design Guidelines (Architecture), No. 1988. 2018, p. 3. Available online: https://blog.naver.com/pvc1120/221835099946 (accessed on 28 July 2020).

- Korea Land and Housing Corporation, Design Guidelines (Electrical and Telecommunication Facilities), No. 1990. 2018, p. 138. Available online: https://blog.naver.com/PostView.nhn?blogId=pvc1120&logNo=221824014189&redirect=Dlog&widgetTypeCall=true&directAccess=false (accessed on 28 July 2020).

- ASHRAE. 2019 ASHRAE Handbook—HVAC Applications: Chapter 49 Noise and Vibration Control (TC 2.6, Sound and Vibration Control); American Society of Heating, Refrigerating and Air-Conditioning Engineers: Atlanta, GA, USA, 2019. [Google Scholar]

- National Elevator Industry, Inc. Building Transportation Standards and Guidelines NEII-1, NEII. Available online: https://nationalelevatorindustry.org/wp-content/uploads/2019/09/neii-1.pdf (accessed on 19 August 2020).

- BSI. BS 8233:2014 Guidance on Sound Insulation and Noise Reduction for Buildings; The British Standards Institution: London, UK, 2014. [Google Scholar]

- Hansen, C.H.; Goelzer, B. Engineering Noise Control. J. Acoust. Soc. Am. 1996, 100, 1279. [Google Scholar]

- Bies, D.A.; Hansen, C.H.; Howard, C.Q. Engineering Noise Control, 5th ed.; CRC Press; Taylor & Francis Group: Boca Raton, FL, USA, 2018; pp. 3–7. [Google Scholar]

- National Elevator Industry, Inc. The Benefits of Machine Room Less Elevators, The Insider; NEII: New York, NY, USA, November 2015; Available online: http://www.neii.org/insider/editions/20151112.pdf (accessed on 3 August 2020).

- Elevatorpedia. Machine Room Less Elevator. Available online: https://elevation.fandom.com/wiki/Machine_room_less_elevator (accessed on 20 August 2020).

- Crocker, M.J. General Introduction to Noise and Vibration Transducers, Measuring Equipment, Measurements, Signal Acquisition, and Processing, Handbook of Noise and Vibration Control; Crocker, M.J., Ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2007; Chapter 35; pp. 417–434. ISBN 978-0-471-39599-7. [Google Scholar]

- Ojanen, T. Aero-vibro Acoustic Simulation of an Ultrahigh-Speed Elevator. Master’s Thesis, Tampere University of Technology, Tampere, Finland, 2016. Available online: https://trepo.tuni.fi/handle/123456789/23851 (accessed on 20 August 2020).

- Foulkes, T.J. Dynamic absorbers to control elevator noise in buildings—A case study. J. Acoust. Soc. Am. 1992, 91, 2350. [Google Scholar] [CrossRef]

- Research Team, Noise Control in Architecture, Science Teaching Kit for Senior Secondary Curriculum, Hong Kong Institute of Architects. 2012, p. 11. Available online: https://minisite.proj.hkedcity.net/hkiakit/getResources.html?id=4049 (accessed on 27 August 2020).

- The Engineering ToolBox, NC-Noise Criterion. Available online: https://www.engineeringtoolbox.com/nc-noise-criterion-25.html#:~:text=%20Sound%20pressure%20levels%20are%20measured%20for%20different,8%208000%20Hz%20%3A%2045%20dB%20More%20 (accessed on 27 August 2020).

- The Engineering ToolBox, NR—Noise Rating Curve, An introduction to the Noise Rating—NR—Curve developed by the International Organization for Standardization (ISO). Available online: https://www.engineeringtoolbox.com/nr-noise-rating-d_60.html (accessed on 27 August 2020).

- Patent. WO2012176297A1—Elevator Landing Door Device—Google Patents. Available online: https://patents.google.com/patent/WO2012176297A1/en (accessed on 21 August 2020).

- Miller, R.S. Elevator shaft pressurization for smoke control in tall buildings. Build. Environ. 2011, 46, 2247–2254. [Google Scholar] [CrossRef]

- Tamura, T.; Itoh, Y. Unstable aerodynamic phenomena of a rectangular cylinder with critical section. J. Wind Eng. Ind. Aerodyn. 1999, 83, 121–133. [Google Scholar] [CrossRef]

- Oh, Y.; Joo, M.K.J.; Park, J.Y.; Kim, H.G.; Yang, K.S. Deviation of Heavy-Weight Floor Impact Sound Levels According to Measurement Positions. J. Acoust. Soc. Korea 2006, 25, 49–55. Available online: https://www.koreascience.or.kr/article/JAKO200614222983617.page (accessed on 28 August 2020). (In Korean).

| No. of Floors | Elevator Speed | Remarks |

|---|---|---|

| Under 10th floor | 60 m/min | Applied to elevators installed after June 2011 |

| 10 to 14th floor | 90 m/min | |

| 15 to 25th floor | 105 m/min | |

| 26 to 30th floor | 120 m/min | |

| 31 to 40th floor | 150 m/min | |

| Over 40th floor | 180 m/min |

| Sources | Causes | Types of Noises | |

|---|---|---|---|

| Machine Room | Motor |

|

|

| Gear and brake |

|

| |

| Control panel |

|

| |

| Hoist Way | Door |

|

|

| Rails and elevator car guide |

|

| |

| Car |

|

| |

| Description | Sources | Transmission Paths |

|---|---|---|

| Structure–borne noises | Machine room | Machinery → Anti-vibration pad → Machine support frame → Machine room slab → Hoist way wall → Residences |

| Hoist way | Elevator car guide → Rails → Rail brackets → Hoist way wall → Residences | |

| Airborne noises | Machine room | Rope hole → Hoist way wall → Residences Outside ventilation openings → Neighboring residence windows → Residences |

| Hoist way | Hoist way → Hoist way wall → Residence |

| Description | Model | Manufacturer | Details | |

|---|---|---|---|---|

| Noise | Analyzer | Apollo | SINUS | Bandwidth: DC~80 kHz/Dynamic range: 120 dB |

| Microphone | CLASS 0 (LEMO) | G.R.A.S | Bandwidth: 3.15~20 kHz/Dynamic range: 135 dB | |

| Vibration | Analyzer | SA-01 | RION | Bandwidth: 0.5~20 kHz/Dynamic range: 140 dB |

| Accelerometer | Single Axis Accelerometer (SW) | B.S.W.A | Bandwidth: 0.5~14 kHz/Maximum Acceleration: 0.0002 g rms | |

| Description | Sources | Solutions |

|---|---|---|

| Structure-Borne Noises | Machine room | Measures for vibration sources

|

| Hoist way | Measures for vibration sources

| |

| Airborne Noises | Machine room | Measures for noise sources

|

| Hoist way |

|

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oh, Y.; Kang, M.; Lee, K.; Kim, S. Construction Management Solutions to Mitigate Elevator Noise and Vibration of High-Rise Residential Buildings. Sustainability 2020, 12, 8924. https://doi.org/10.3390/su12218924

Oh Y, Kang M, Lee K, Kim S. Construction Management Solutions to Mitigate Elevator Noise and Vibration of High-Rise Residential Buildings. Sustainability. 2020; 12(21):8924. https://doi.org/10.3390/su12218924

Chicago/Turabian StyleOh, Yangki, Minwoo Kang, Kwangchae Lee, and Sunkuk Kim. 2020. "Construction Management Solutions to Mitigate Elevator Noise and Vibration of High-Rise Residential Buildings" Sustainability 12, no. 21: 8924. https://doi.org/10.3390/su12218924

APA StyleOh, Y., Kang, M., Lee, K., & Kim, S. (2020). Construction Management Solutions to Mitigate Elevator Noise and Vibration of High-Rise Residential Buildings. Sustainability, 12(21), 8924. https://doi.org/10.3390/su12218924