Abstract

The mechanical harvesting of hemp is a key step toward a profitable use of the product. Various fractions (fiber, seeds, residual biomass) may be recovered, and their correct management is fundamental for complying with the requirements of processors/end users. In the light of the renewed interest for its industrial use (panels and insulators), this work proposes the use of modified commercial machines to implement a field separation of the fibrous fraction of stand-retted hemp, a practice that would be profitable if realized with the systems adopted for textile use. The present work was conducted to test the efficiency of harvesting partially macerated plants by using a modified self-propelled forage harvester (SPFH). In Northern Italy, a hemp crop was stand-retted for four months. Then, an SPFH—with rotor knives reduced in number from 24 to 12—was used. Stand-retting made it possible to separate cortical fibers from the inner stem cylinder during harvesting; 53.3% of the material (fibers and shives) was separated automatically by the SPFH together with the chopped bast fiber, while the remaining 46.7% was separated on exiting the launch tube. More than 50% of the fibers were shorter than 5 cm in length, while almost 15% were longer than 10 cm. The SPFH had an effective operating speed of 3.48 km h−1, and no clogging occurred during the test. Therefore, the combination of stand-retting with harvesting using a modified SPFH could be helpful in obtaining an early separation of fibers from shives, thus facilitating the product treatment during its subsequent processing, e.g., by enhancing the defibration.

1. Introduction

The hemp plant (Cannabis sativa, L.), which is mainly used to produce textile fibers, played a very important role in the Italian agriculture in the last century, covering a cultivated area of 75,000 hectares by the end of the 1940s [1]. After World War II, there was a progressive decline due to various factors: high labor costs, the competition of synthetic fibers, the association of this plant with illegal narcotics, and a large-scale production of cotton [2]. This decline occurred until the 1970s, when the hemp cultivation area was reduced to 1000 hectares [3]. In 2010, Italy’s National Institute for Statistics (ISTAT, https://www.istat.it/) registered 41 hectares of hemp cultivation with a production of 252 tons. In recent years, the renewed interest in hemp as a multipurpose crop has promoted a new expansion [4]. In 2018, the hemp cultivation area in Italy totaled 670 hectares, with a production of 4631 tons (http://dati.istat.it/).

In traditional retting, hemp stems steeped in stagnant or current water [5] were exposed to the degradative enzymatic action of naturally occurring microbial populations, such as sporulated aerobic bacteria (Bacillus subtilis, Bacillus polymixa), facultative anaerobes (Bacillus macerans), or anaerobes [6]. The same principle of microbiological degradation is used in the modern forms of industrial retting, where temperature, treatment duration, and microbial populations are accurately monitored [1].

A different kind of maceration is the so-called “dew-retting”, or “in-field-retting”. In this case, the cut stems of the plants are left lying on the ground where they are attacked by microorganisms, mainly filamentous fungi, whose pectolytic enzymes degrade the pectins and polysaccharides in the cell walls and middle lamellae, and release the fibers [7,8]. As stated by Réquilé et al. [9], stem retting impacts stem cohesion, and this may lead to a 75% reduction of fracture energy. This way, the subsequent defibration is facilitated, and the quality of the final product improves. Other important aspects to be considered are agronomic techniques (i.e., sowing density and harvesting time), plant portion, genotype, and, potentially, the retting or other post-harvest management of stems that affects fiber width, an important quality trait in bast fibers [10]. As already verified with other crops [11], cultivation for industrial fibers could be plausible for areas not suitable for food and feed purposes (e.g., fields polluted by heavy metals), opening further scenarios of interest only if suitable cultivation and harvesting techniques are implemented. The system is low-cost [12] but has some disadvantages. It is influenced by weather conditions and, therefore, is limited to regions where the climate makes the proliferation of these microorganisms possible [13]. In Italy, dew-retting is rarely used because of high temperatures, but it is more widespread in Northern Europe, where microbial activities thrive thanks to more moderate temperatures [6]. Furthermore, the fiber produced is more uneven, with a consequent lower quality. The maceration process is less controllable, and the soil is occupied for a longer period, causing problems or a risk of delays in soil preparation and the sowing of the next crop [8,13].

One of the main factors slowing down the development of a profitable hemp supply chain is the mechanization of the harvest [14], since the range of specifically developed machines suitable for the morphological characteristics of the hemp plant requires a high level of operator specialization, thus leading to high harvesting costs [15,16]. In their work, Gusovius et al. [15] point out that the crop characteristics require some modifications or device couplings. One of the main problems concerns machine clogging due to either the length of the stem or the wrapping of fibers in shafts and bearings. The present study aimed to develop an alternative method by facilitating and improving the stem collection for the production of industrial fiber. This study analyzed a fiber collection line for industrial use based on a stand-retting system, with a standing maceration of the plants. This system is not unknown, but it is innovative for the Italian area and was associated with a mechanical harvesting system using a self-propelled forage harvester (SPFH). The use of conventional machines modified to be suitable for harvesting crops not easily mechanized is not uncommon. In this specific case, the possibility of adopting a known practice, such as the collection of stand-retted hemp, has been evaluated in light of the new tendencies for hemp production and the renewed interest for its industrial destination. One of the main bottlenecks for hemp is the harvesting costs because the specific machines developed in national and European areas are frequently not available for ordinary farmers who want to approach hemp cultivation [14,15,16]. For this purpose, since a perfect alignment of the stems is not required, SPFH use may also be suitable for the collection of other herbaceous biomass crops as well [17]. The purposes of the work were: (i) to evaluate the efficiency of the stand-retting system and (ii) to verify the possibility of combining the use of a corn SPFH with stand-retting for a preliminary separation of fibers and shives. The ultimate goal was to obtain a high-grade product for industrial use by minimizing field operations and the need for manual labor.

2. Materials and Methods

2.1. The Machine

In the present study, a Claas Jaguar 890 SPFH machine was used (Table 1). The engine had a maximum power of 530 hp at 1800 rpm and a maximum torque of 762 Nm at 1500 rpm. The feeding system consisted of four horizontal rollers (double pair) and a shredding drum of classic design with 24 knives (12 per side). The head (Orbis 600) had a cutting width of 6.0 m with 4 horizontal rotors and a basal cutting system with two vertical feed rollers. The cut product was conveyed toward the central area of the machine, where a double pair of horizontal feed rollers compressed the product and sent it to a chopping drum with horizontal axis (length 750 mm, diameter 630 mm).

Table 1.

Characteristics of the self-propelled forage harvester (SPFH) machine used in the study.

The machine was equipped for corn silage. With its basic settings, the shredded product would have been smaller in size than required for hemp. Considering the different consistency and fibrousness of the hemp stem, it was deemed appropriate to halve the number of knives (from 12 to 6) in both sectors to increase the size of the cut biomass without reducing the speed of the chopping drum. The variation of the number of knives was deemed to be the least invasive modification, which had already produced good results with other crops (e.g., forage crops for the drying process). By removing six knives per side, the total number of knives decreased from 24 to 12. Incidentally, this repositioning did not cause the drum to unbalance. The positioning of the blades must involve the coupling of the corresponding knives, and any variation made to the cutting elements must leave untouched the 12 original supports per side. As expected, the supports without blades did not lead to any problems with the performance of the SPFH. Furthermore, it is impossible to adjust the speed of the drum because it cannot be modified. The standard number of knives (12 per side) was not used because the tests carried out with forage crops showed a theoretical minimum cutting length of less than 1.8 cm. The expected maximum (theoretical) cutting length with 6 knives per side was 3.6 cm, which, in the case of hemp, is the lowest acceptable limit. Other SPFH producers have designed drums with 16 knives (eight on each side), but these machines were not available for testing.

The original arrangement of the fixed counter-blade remained the same, while the settings of the feeding system (four horizontal rollers and the vertical loading system) were modified. Specifically, in the feeding system, the roller distance was left unchanged, while the compression load of roller feeders was increased.

2.2. Planting and Retting

The trial took place in Northern Italy at the “M. Marani” Experimental Agricultural Company located near Ravenna (RA), in the Emilia-Romagna region (44°27′47.86″ N–12°12′09.89″ E).

The variety used in the present study was “Carmagnola Selezionata”, obtained from an intense breeding activity carried out by the CREA - Agriculture and Environment of Bologna [2,18,19,20] starting from an old hemp landrace. The crop was sown on 28 March 2009, with a precision seeder, in rows spaced 20 cm apart and with a 5 cm seed-to-seed distance in each row.

In mid-August, 136 days after sowing, more than 50% of the plants were fully ripe. At this point the in-field retting process started, lasting 121 days and ending in December. For the purposes of the study, the overall area involved four plots 10 m wide and 128 m long, for a total area of slightly more than 0.5 hectares. Before the collection of the retted fibers, 3 plots of 1 m2 each were chosen at random to determine the plant density, height, and basal diameter of the stems.

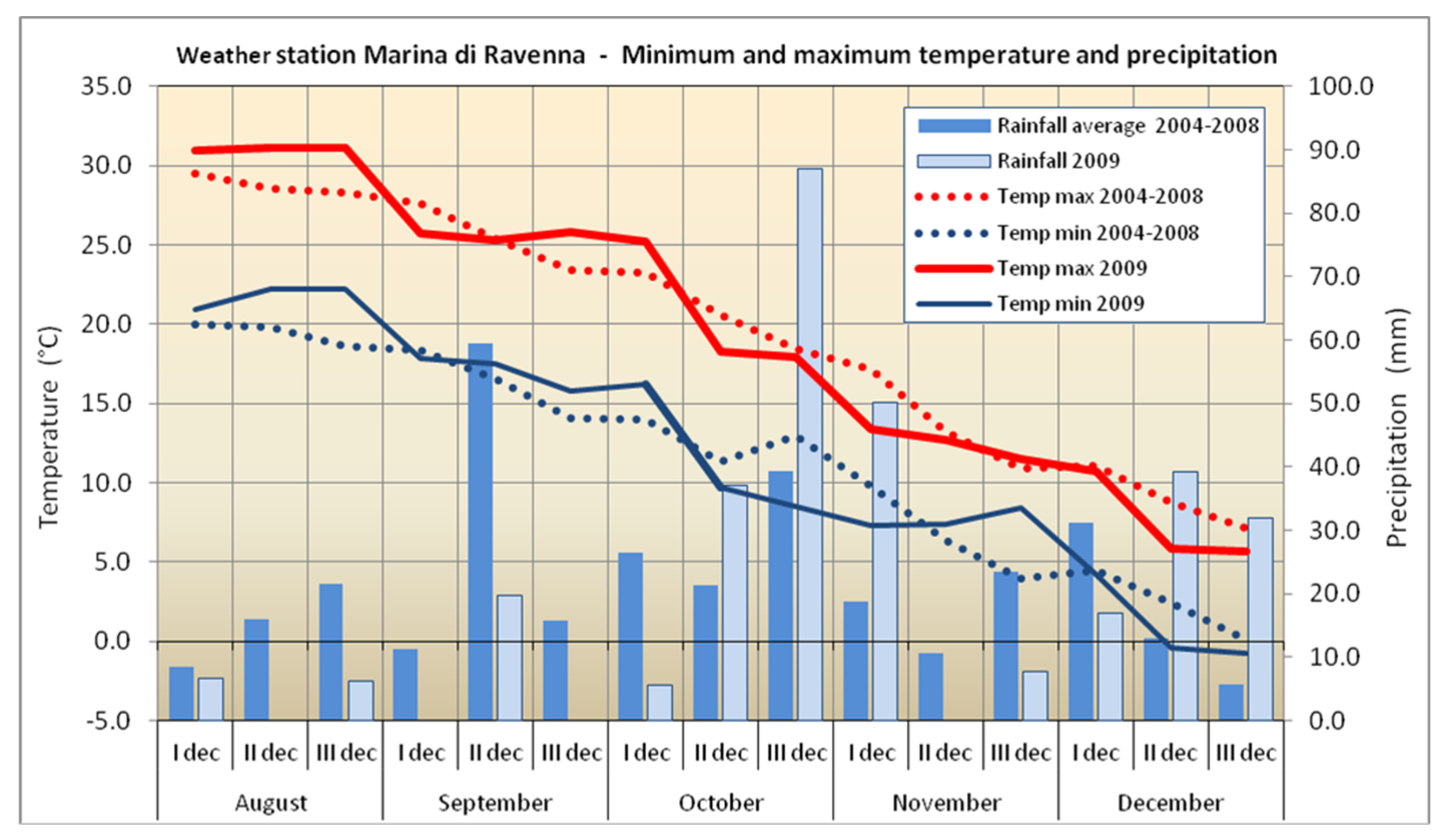

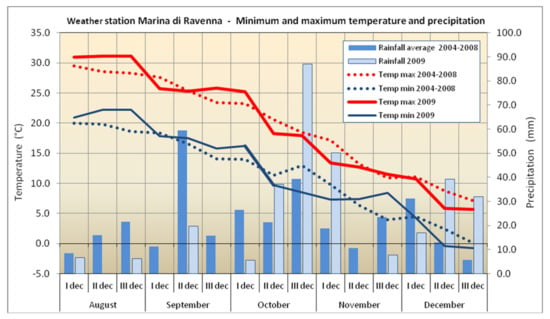

Meteorological data were obtained by the weather station of the Regional Agency for Prevention, Environment and Energy of Emilia-Romagna, located at Marina di Ravenna (44°28′49.86″ N–12°16′38.80″ E), about 6 km away from the experimental fields. To evaluate the meteorological trend during the stand-retting, the daily minimum and maximum temperature and precipitation data were compared to those for 2004–2008 (Figure 1).

Figure 1.

Hemp collection after three months of stand-retting.

2.3. Harvesting

To avoid problems with the basal woody portion of the stem while collecting as much biomass as possible, the SPFH was set up to cut at a height of 28 cm from the ground. At the end of the collection, the actual cutting height was measured in the other 3 plots (1 m2 each).

The SPFH performance was assessed using ASABE standards [21,22] and the procedures indicated by the Commission Internationale pour l’organization scientifique du travail en agriculture (CIOSTA) and the Italian Agricultural Engineering Association (AIIA) 3A R1 [23].

The shredded hemp was discharged onto a trailer (Carraro, mod. 50 trilateral tilting, loading volume up to 11.73 m3) moving parallel to the SPFH (Figure 1). Three plots measuring 5 × 6 m (the working width of the SPFH) were cut (30 m2 per plot). The biomass of each plot was collected separately. The collected material consisted of hemp fibers, shives (inner portions), and other tissues of the cortical layer (epidermis/cortex). The product discharged by the launch tube of the SPFH consisted of two parts; due to the different densities, shives formed the bottom layer in the trailer, while a mixture of fibers and shives was stratified above. Thus, two well-defined piles were formed on the trailer bed and weighed both together (fibers plus shives) and separately (shives only). Three samples (about 500 g each) were taken from the fibers-plus-shives layer and separated by hand (Figure 2). The shives separated by the machines and those separated by hand constituted the total yield on which the percentage of shives was calculated.

Figure 2.

Fibers plus shives discharged in the trailer and hand-separation of the shives.

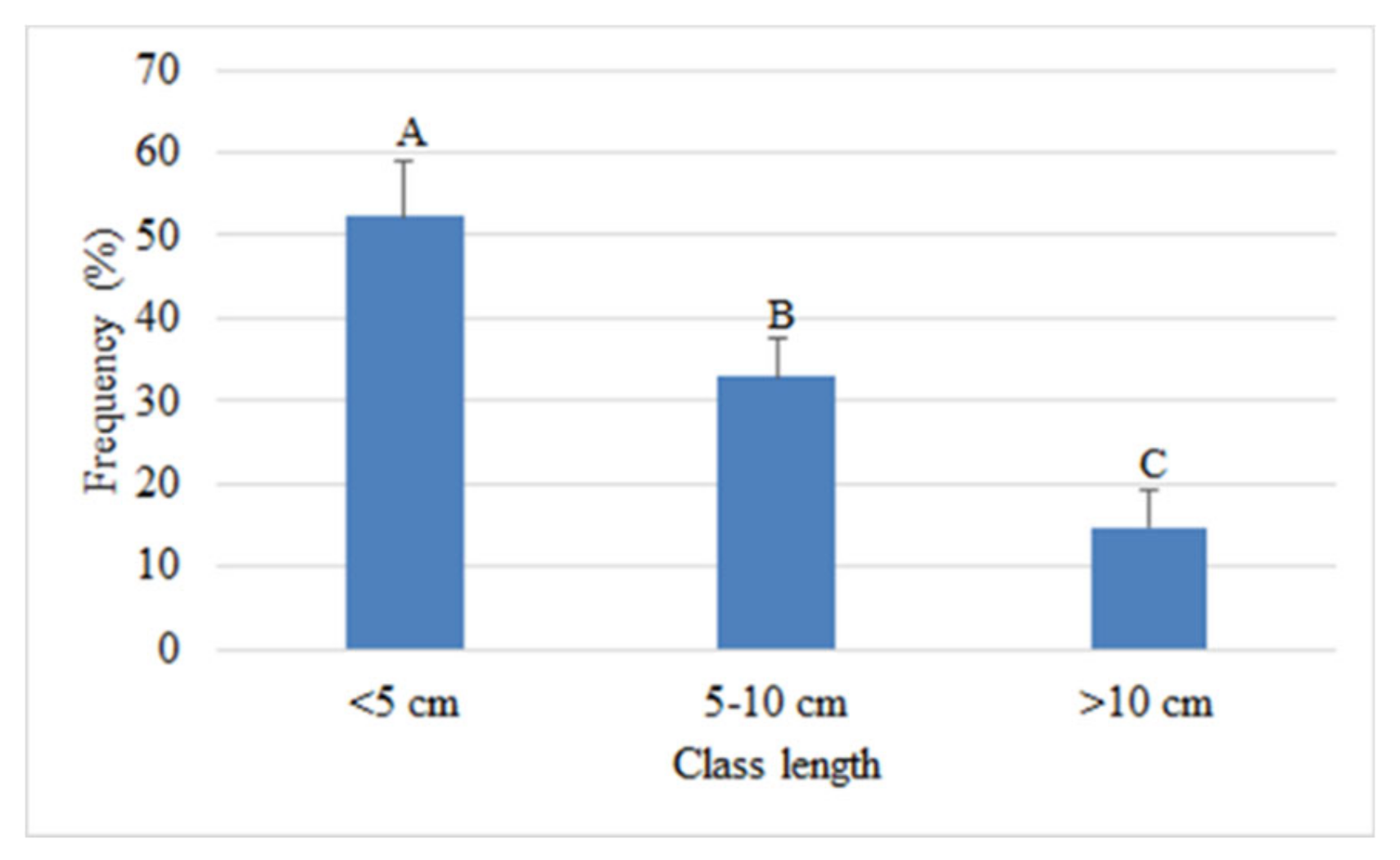

The collected material was classified according to its size. Three samples (about 500 g each) of the fibers-plus-shives piles were divided into 5 size classes: <1 cm, 1–2 cm, 2–3 cm, 3–4 cm, and >4 cm. Three further samples of the same weight (around 500 g) were used to study the fiber distribution. Once the cortical fibers were separated, both fractions were weighed separately using a scale. The shives fraction was classified by size classes applying the ranges described above. As for the fibrous fraction, 3 length classes were used: <5 cm, 5–10 cm, and >10 cm.

The total biomass harvested in the four plots amounted to 6060 kg.

2.4. Evaluation and Data Analysis

The data were submitted for variance analysis using PAST software (version 2.12, Øyvind Hammer, Natural History Museum, University of Oslo). The separation of the means was performed using Tukey’s HSD post-hoc method.

3. Results and Discussion

3.1. Meteorological Data

Field-retting relies on the colonization of stem tissue by microorganisms that gradually degrade the intercellular substances to separate bast fibers from non-fiber fractions [24,25,26]. Prolonged field-retting, up to 5 weeks and more [25], has a positive influence on fiber separation, though it is strongly affected by weather conditions because rainy weather may cause the production of over-retted fibers [27]. Environmental conditions play a key role in the length of the degradation process, modifying its effectiveness and the speed of the microorganism action, while the rainfall rate, temperature, and air humidity may affect the extent of retting [3,28].

During the study, temperatures were higher than the five-year average values in August, between the end of September and the beginning of October, and the last days of November. Negative thermal anomalies occurred from mid-October up to the first 10 days of November and throughout December (Figure 3). In five months, the maximum temperature ranged from around 31 °C in August to around 6 °C in December, while the minimum temperature ranged from around 22 °C in August to slightly negative values during the first 10 days of December.

Figure 3.

Trend in 10-day average of minimum and maximum temperature and rainfall in the August–December 2009 period compared to values for the 2004–2008 reference period.

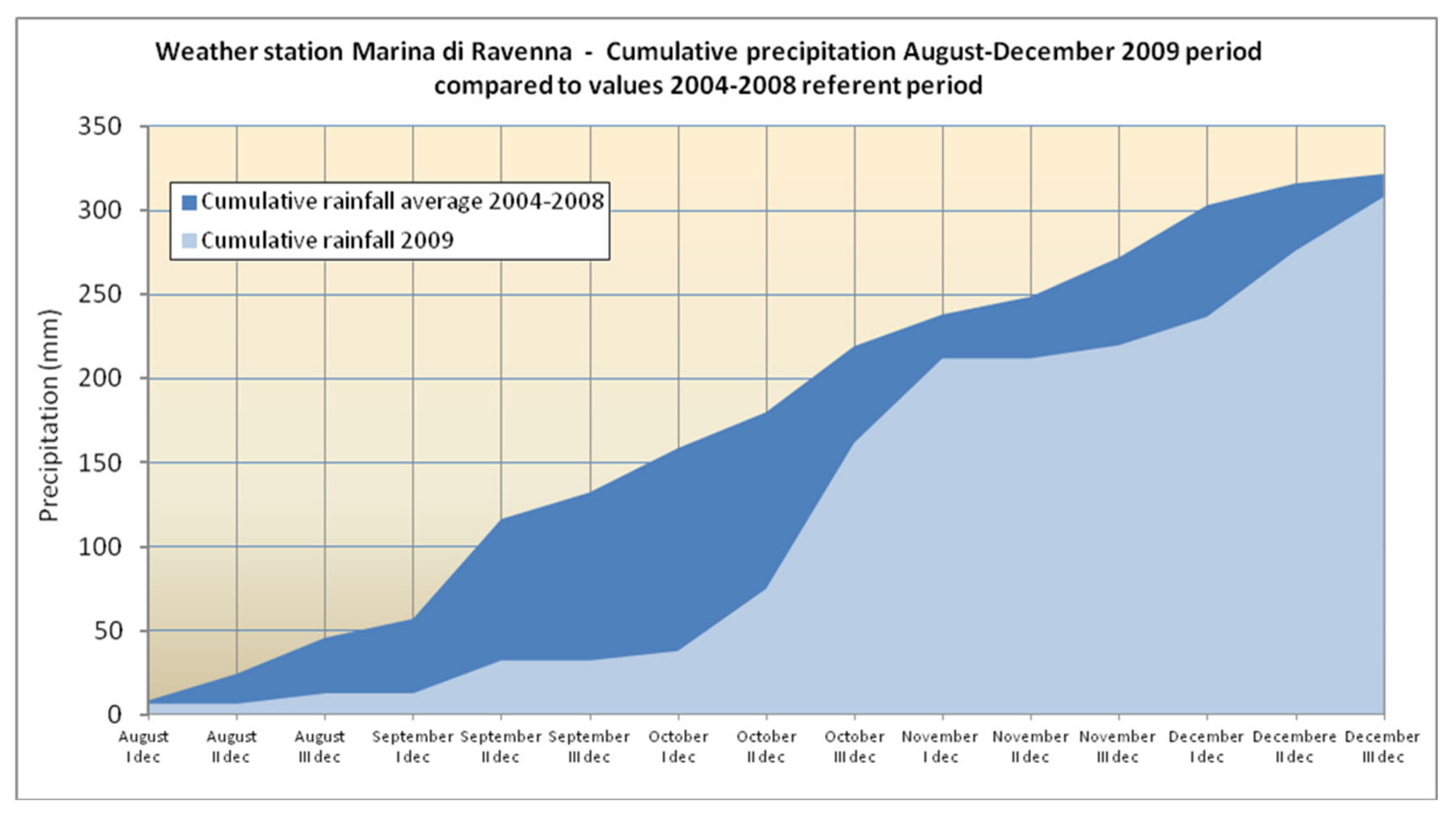

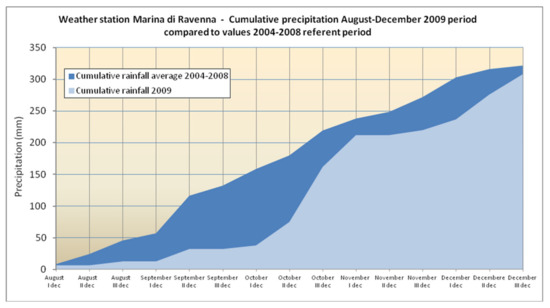

Cumulative rainfall during the experimental period amounted to 308.2 mm, corresponding to 96% of the average reference value (321.8 mm in the 2004–2008 five-year period; Figure 4). There were 33 rainy days, and these were concentrated mainly from mid-October to early November, and in December. Until mid-October the rainfall was lower than 50% of the long-term average amounts.

Figure 4.

Cumulative rainfall (mm) of August–December 2009 period compared to average values for the 2004–2008 reference period.

Rainfall concentration during this period is very important in achieving a positive effect of stand-retting on hemp. In a two-year-long experiment of dew-retting (around 20 days), Müssig and Martens [28] observed a steady degree of speed and uniformity in retting with dry and windy weather soon after cutting. The following year, the retting degree increased later in the year with the beginning of the rainfalls in October. In controlled environmental retting conditions, Bleuze et al. [7] simulated a 59-day dew-retting on hemp stems, with a mean temperature of 12 °C, and a 33-day retting with a mean temperature of 17 °C. The progressive drying of the stems observed also in the presence of weekly rains was attributed to the need to reach an equilibrium moisture content between the plants and the atmosphere. Such a process drove and helped the progressive degradation of cell walls. The observation according to which the initiation of retting in the field depends on humidity and dry conditions was confirmed by Amaducci [3]. Describing the cultivation of “baby-hemp”, he stated that the extent of field-retting was lesser with dry weather than the in presence of rainy years.

3.2. The Crop

The stand-retting process lasted 4 months; the stand-retted hemp was collected on December 11th. On this date, the plant density was on average 76 plants m−2, with a basal diameter of 9 mm and a height of 2.32 m (Figure 5).

Figure 5.

Stand-retted hemp on collection day.

Despite the late season and high relative humidity on the collection day, the condition of the crop was excellent, probably due to a constant ventilation in the early hours of the day. The plants were characterized by uniform, erect growth, with little collapse of stems. As a result, there was no problem during collection, the product was conveyed correctly, and no flooding occurred.

Four months after stand-retting, the leaves and the (uncollected) seeds had fallen to the ground. During the 4-month in-field stand-retting, no activities were carried out, and the natural process of degradation was performed by ubiquitous microorganisms. The microorganisms, in the presence of suitable climatic conditions, triggered and continued the natural degradation of tissues.

Stand-retting made it easier to separate cortical fibers from the inner stem cylinder. A visual check performed on the harvesting day revealed that the cortex and underlying phloem layer were particularly cracked and cut longitudinally, showing a partial detachment from the underlying tissues.

3.3. The Machine

One of the purposes of the present study was to verify the usefulness of a corn SPFH for the harvesting of hemp for industrial fibers. The limited availability of specially designed machines makes the use of machines designed for widespread crops a solution economically viable for the hemp chain. Therefore, due to their versatility, the SPFHs used for the collection of silage crops and herbaceous biomass crops [29,30,31] can be considered a good solution for the collection of technical fibers too.

One of the main problems in harvesting hemp is the risk of clogging. The hemp stalk is particularly tenacious and tends to roll itself around the rotating parts of the machine without breaking up, leading to a blockage of the machine. In-field maceration weakens the stems. Two factors were dealt with to reduce the risk of clogging. First, decreasing the number of knives increased the cut size of the product, reducing the effort required for the engine. Second, the ventilation and transport systems of the machine were improved so that the product was immediately removed from the shredding system as soon as it passed through it.

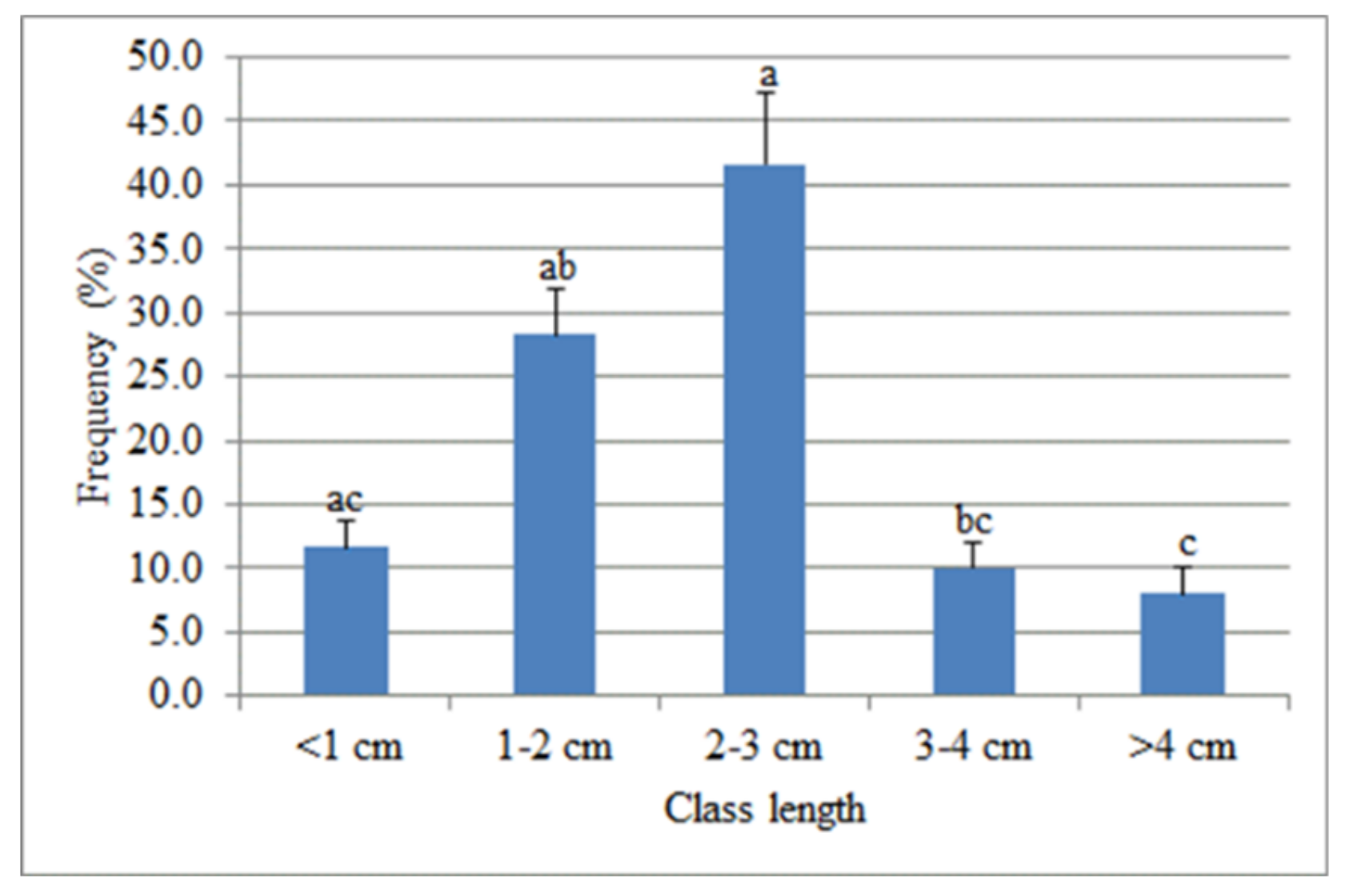

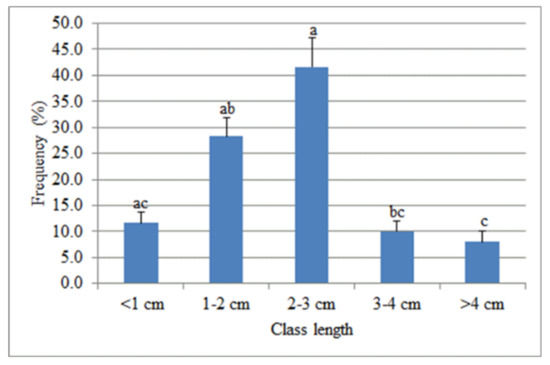

In its original setting with 24 blades, the theoretical achievable length would have been below or equal to 1.8 cm. The cutting unit was set with 12 blades to obtain longer portions and increase the length of the shredded material to 3.4 cm. The analysis of the material collected by the trailer showed that with the chosen setting the desired size was obtained for 40–50% of the chopped hemp (Figure 6). The reader must be aware that the machine was set to produce fibers that are not excessively long and that the tests aimed to obtain the maximum theoretical length with minimum intervention on the machine adjustment (the removing of knives) to avoid the replacement of the main drum. At the same time, the length of the fibers should not be too short to produce a product that can be suitable for industrial purposes (insulation material, panels, paper, “poor” short fiber fabrics).

Figure 6.

Percentage distribution of chopped hemp per length classes. The bars indicate the standard deviations. Different letters represent significant differences between the treatments (p < 0.05).

However, by setting the longest cutting length, the shredding was frequently excessive, with peaks of power absorption caused by an irregular supply flow between the head and the shredding system. In our opinion, a further increase in the length of the shredded product could create additional problems, such as a further reduction in the number of blades of the drums, and the balancing and the supplying of the engine could be adversely affected, with overloads caused by the larger time gap between the peaks of energy absorption required by each stem cutting. In synthesis, a further reduction in the number of knives would require designing another rotor with different knife positioning.

Compared to the speed usually employed for corn harvesting, the forward speed during the harvesting was reduced to avoid an overload of the engine. It was therefore possible to work without idling or the need for accessory times. On average, the SPFH traveled at 4.0 km h−1, corresponding to a working capacity of 2.08 ha h−1. The calculated field efficiency was 87%, while the additional time corresponded to 13% of the total work. As a result, the effective operating speed was 3.48 km h−1.

3.4. The Product

Among the harvesting systems developed for dual purposes (collection of seeds and stems), Gusovius et al. [15] cited a harvesting system based on a combine with straw walkers used in combination with a mowing and two-knife chopping module. Although some problems can occur during the conveyance of the whole harvested biomass through the threshing and straw cleaning units, a partial decortication of the hemp stems was observed. In the presence of dew-retting, such an involuntary treatment can have a positive effect on the separation of outer fibers and the internal woody core.

The modifications of the machine setting described in the present study were specifically planned to improve the separation between the cortical tissue and shives, and coupled with the stand-retting approach, thus anticipating and facilitating the separation work performed by a specific device [32]. The separation of hemp fibers usually takes place in processing plants. The available experiences in open fields are rather limited to experimental tests and, mainly, with green plants at the end of the cycle (without maceration). In the studies of the Universities of Bologna and Udine [33,34] with different types of prototypes consisting of semi-mounted mowers and machines with special single-blade rotors, the crop was chopped down to a variable length shorter than 100 mm. The main problem observed in adapted commercial machines is that of the green fibers twisting around the rotating surfaces after a few hours of work, resulting in frequent clogging. The use of the SPFH on green plantations also did not give positive results; CREA has had other experiences in the mechanical management of different types of machines and green tissues with a different level of aggressiveness [35,36,37], which cannot yet be applied to hemp. In the present work, the stand-retting allowed the passage through the cutting system of the machine without clogging problems. The final product showed a good separation between the two portions, which were deposited separately on the trailer platform. Since the machine performed a purely mechanical action, the resistance of the stem and fibers was of some importance. Several studies suggest that the fiber resistance to mechanical treatment is affected by the biochemical composition and structure of the cell wall [38]. Importantly, the varying degree of this resistance has been demonstrated to be influenced by dew-retting, the frequency of wet/dry cycles, and the temperature affecting the peptide bonds [39]. As observed by Marrot et al. [38], hemp performances are positively affected by retting because some pectins and lignins present in the middle lamellae are eliminated, thus making the decortication easier.

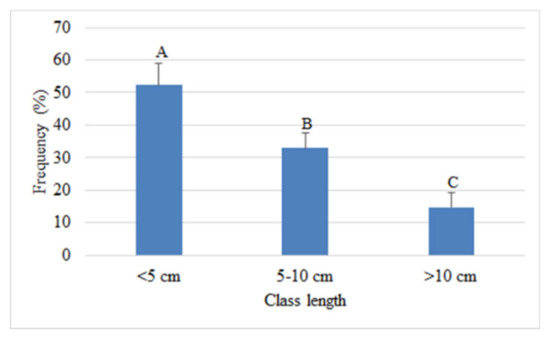

In our study, the separation efficiency was quite good directly in-field, with 53.3% (±0.66 SD) of the material separated automatically by the SPFH mixed with the chopped bast fiber, while the remaining 46.7% was separated at the outlet of the unloading SPFH tube. These percentages were the result of the system that was applied to the crop at a specific stage of growth. The result had to be considered very positive, because it made it possible to have more than half the fiber already cleaned. The fiber separation occurred at the level of the collector launch tube, and some mechanical adjustments at this level might increase the percentage of separation. The rotor of the machine with a reduced number of knives acted on stems by cutting fibers and chopping the inner part of the stem, thus producing tufts of fiber and pieces of shives. The chopping and grinding actions facilitated the separation of the cortical layer from the inner cylinder, and in the presence of larger portions, a better separation of the two products in the trailer was achieved. These parts with different shapes and specific weight behave differently; once expelled by the discharge system of SPFH, the lighter and voluminous fiber separates from the shreds of shives by creating different strips inside the trailer. The shive-free fibers were classified into three different size classes (Figure 7). More than 50% were shorter than 5 cm, while almost 15% were longer than 10 cm. The 5 cm length straddles the borderline between industrial and textile destinations, and therefore the proposed system appeared suitable for producing short fibers for industrial use. The presence of considerable percentages above 5 cm might broaden the potential uses. Basically, a two-step collection could be proposed.

Figure 7.

Percentage distribution of length classes of the separated fibers. The bars indicate the standard deviations. Different letters represent significant differences between the treatments (p < 0.01).

At the time of the physiological ripening, the seeds and other threshing byproducts [40] could be collected first as per previous experiences [41] to increase the profit possibilities for farmers. After the 4-month stand-retting, the SPFH could complete the harvest by collecting and separating the fiber for industry.

4. Conclusions

The evaluation of the technical and economic aspects of mechanical hemp harvesting for the purpose of obtaining products for specific uses is a major challenge in the pursuit of a full and valuable exploitation of crops. In this work, the modification of the number of knives in a SPFH used for corn silage combined with the in-field stand-retting process proved to be an interesting solution for the collection of hemp stems for industrial fiber only. The possible exploitation of the overall biomass (seeds, stems, and leaves) requires some reflection. With plants no taller than 2.5 m, the harvesting of seeds using a combine for sunflowers or equipped with stripper heads could be hypothesized. In this case, however, it should be kept in mind that losses caused by trampling can reach up to 25–30% of the area. When the hemp fibers are intended to produce insulating material for building uses (as might be the present case), the relevant requirements are less pressing. The key factor, instead, is the reduced production cost and hence the development of a simple and economical harvesting method.

Such an approach appeared potentially effective for obtaining an appreciable qualitative product at a relatively low cost, while using largely available machines without substantial modifications. The prolonged standing maceration for a period much longer than usual (4 months), played a decisive role, leading to a separation rate between fibers and shives higher than 46%. Overall, the technical–mechanical solutions proved to be efficient, without an evident risk of either engine overload or clogging of the rotors, making it possible to collect and separate hemp technical fibers directly in the field in a single step.

The possibility to separate the fiber directly in the field could represent a big step forward toward enhancing the efficiency of mechanization, leading to a clear advantage for subsequent industrial operations. Innovative solutions may lead to further improvements. An example could be this operation sequence: harvesting of seeds, maceration in the field for the necessary time, and fiber management in a single second step.

Author Contributions

Conceptualization, A.A.; data curation, A.A., S.E., A.C., E.S.; formal analysis, A.A., S.E., E.S.; funding acquisition, A.A.; methodology, A.A., L.D.R.; software, S.E., E.S.; validation, A.A., S.E., E.S.; writing first version A.A., A.C., S.E., E.S.; review and editing, A.A., E.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Acknowledgments

The Authors are grateful to Agrienergy Ltd., a bioenergy company of the private Bagioni Groups of Casemurate (RA), Italy, for the machines made available, and for the support of the Italian Ministry of Agriculture (MiPAAFT) under the AGROENER project (D.D. no. 26329 of 1 April 2016)—http://agroener.crea.gov.it/.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Bacci, L.L.; Baronti, S.; Angelini, L. Manuale Di Coltivazione E Prima Lavorazione Della Canapa Da Fibra; Istituto di Biometeorologia del CNR: Toscana, Italy, 2007. [Google Scholar]

- Amaducci, S. Hemp production in Italy. J. Ind. Hemp. 2008, 10, 109–115. [Google Scholar] [CrossRef]

- Ranalli, P.; Venturi, G. Hemp as a raw material for industrial applications. Euphytica 2004, 140, 1–6. [Google Scholar] [CrossRef]

- Baldini, M.; Ferfuia, C.; Zuliani, F.; Danuso, F. Suitability assessment of different hemp (Cannabis sativa L.) varieties to the cultivation environment. Ind. Crops Prod. 2020, 143. [Google Scholar] [CrossRef]

- Tahir, P.M.; Ahmed, A.B.; SaifulAzry, S.O.A.; Ahmed, Z. Retting process of some bast plant fibres and its effect on fibre quality: A review. BioResources 2011, 6, 5260–5281. [Google Scholar]

- Ranalli, P.; Casarini, B. Canapa: Il Ritorno di una Coltura Prestigiosa; Avenue Media Publishers: Bologna, Italy, 1998. [Google Scholar]

- Bleuze, L.; Lashermes, G.; Alavoine, G.; Recous, S.; Chabbert, B. Tracking the dynamics of hemp dew retting under controlled environmental conditions. Ind. Crops Prod. 2018, 123, 55–63. [Google Scholar] [CrossRef]

- Henriksson, G.; Akin, D.E.; Hanlin, R.T.; Rodriguez, C.; Archibald, D.D.; Rigsby, L.L.; Eriksson, K.E.L. Identification and retting efficiencies of fungi isolated from dew-retted flax in the United States and Europe. Appl. Environ. Microbiol. 1997, 63, 3950–3956. [Google Scholar] [CrossRef]

- Réquilé, S.; Le Duigou, A.; Bourmaud, A.; Baley, C. Peeling experiments for hemp retting characterization targeting biocomposites. Ind. Crops Prod. 2018, 123, 573–580. [Google Scholar] [CrossRef]

- Müssig, J.; Amaducci, S. Scanner based image analysis to characterise the influence of agronomic factors on hemp (Cannabis sativa L.) fibre width. Ind. Crops Prod. 2018, 113. [Google Scholar] [CrossRef]

- Jeannin, T.; Yung, L.; Evon, P.; Labonne, L.; Ouagne, P.; Lecourt, M.; Cazaux, D.; Chalot, M.; Placet, V. Native stinging nettle (Urtica dioica L.) growing spontaneously under short rotation coppice for phytomanagement of trace element contaminated soils: Fibre yield, processability and quality. Ind. Crops Prod. 2019, 145, 111997. [Google Scholar] [CrossRef]

- Bacci, L.; Di Lonardo, S.; Albanese, L.; Mastromei, G.; Perito, B. Effect of different extraction methods on fiber quality of nettle (Urtica dioica L.). Text. Res. J. 2011, 81, 827–837. [Google Scholar] [CrossRef]

- Liu, M.; Fernando, D.; Daniel, G.; Madsen, B.; Meyer, A.S.; Ale, M.T.; Thygesen, A. Effect of harvest time and field retting duration on the chemical composition, morphology and mechanical properties of hemp fibers. Ind. Crops Prod. 2015, 69, 29–39. [Google Scholar] [CrossRef]

- Pari, L.; Alfano, V.; Scarfone, A. La raccolta della canapa in Romania. Sherwood 2016, 219, 37–41. [Google Scholar]

- Gusovius, H.J.; Hoffmann, T.; Budde, J.; Lühr, C. Still special? Harvesting procedures for industrial hemp. Landtechnik 2016, 71, 14–24. [Google Scholar] [CrossRef]

- Pari, L.; Baraniecki, P.; Kaniewski, R.; Scarfone, A. Harvesting strategies of bast fiber crops in Europe and in China. Ind. Crops Prod. 2014, 68, 90–96. [Google Scholar] [CrossRef]

- Huisman, W. Optimising Harvesting and Storage Systems for Energy Crops in The Netherlands. In Proceedings of the International Conference on Crop Harvesting and Processing, Louisville, KY, USA, 9–11 February 2003; American Society of Agricultural and Biological Engineers: Louisville, KY, USA, 2003; pp. 1–19. [Google Scholar] [CrossRef]

- Grassi, G. Canapa tessile redditizia con la macerazione a terra. L’Informatore Agrar. 2009, 30, 47–49. [Google Scholar]

- Grassi, G. La canapa monoica a confronto con varieta dioiche. Inf. Agrar. 2004, 60, 57–62. [Google Scholar]

- Struik, P.C.; Amaducci, S.; Bullard, M.J.; Stutterheim, N.C.; Venturi, G.; Cromack, H.T.H. Agronomy of fibre hemp (Cannahis sativa L.) in Europe. Ind. Crops Prod. 2000, 11, 107–118. [Google Scholar] [CrossRef]

- ASABE. ASAE EP496: Agricultural Machinery Management, in: ASABE Standard; ASABE: St. Joseph, MO, USA, 2006. [Google Scholar]

- ASAE. ASAE S495, in: ASABE Standards; ASAE: St. Joseph, MO, USA, 2000; pp. 341–343. [Google Scholar]

- Bodria, L.; Pellizzi, G.; Piccarolo, P. Meccanica Agraria Vol. II: La Meccanizzazione; Il Sole24Ore: Bologna, Italy, 2006. [Google Scholar]

- Fernando, D.; Thygesen, A.; Meyer, A.; Daniel, G. Elucidating Field Retting Mechanisms of Hemp Fibres for Biocomposites: Effects of Microbial Actions and Interactions on the Cellular Micro-morphology and Ultrastructure of Hemp Stems and Bast Fibres. BioResources 2019, 14, 4047–4084. [Google Scholar]

- Mazian, B.; Bergeret, A.; Benezet, J.C.; Malhautier, L. Influence of field retting duration on the biochemical, microstructural, thermal and mechanical properties of hemp fibres harvested at the beginning of flowering. Ind. Crops Prod. 2018, 116, 170–181. [Google Scholar] [CrossRef]

- Müssig, J. Industrial Applications of Natural Fibres; John Wiley & Sons, Ltd.: West Sussex, UK, 2010. [Google Scholar] [CrossRef]

- Placet, V.; Day, A.; Beaugrand, J. The influence of unintended field retting on the physicochemical and mechanical properties of industrial hemp bast fibres. J. Mater. Sci. 2017, 52, 5759–5777. [Google Scholar] [CrossRef]

- Müssig, J.; Martens, R. Quality aspects in hemp fibre production—Influence of cultivation, harvesting and retting. J. Ind. Hemp. 2003, 8, 11–32. [Google Scholar] [CrossRef]

- Bentini, M.; Martelli, R. Prototype for the harvesting of cultivated herbaceous energy crops, an economic and technical evaluation. Biomass Bioenerg. 2013, 57, 229–237. [Google Scholar] [CrossRef]

- Pari, L.; Assirelli, A.; Acampora, A.; Giudice, A.; Del Santangelo, E. A new prototype for increasing the particle size of chopped Arundo donax (L.). Biomass Bioenerg. 2015, 74, 288–295. [Google Scholar] [CrossRef]

- Pari, L.; Assirelli, A.; Suardi, A. Raccolta del Sorgo da Fibra Affienato. Cantieri a Confronto; Sherwood: Arezzo, Italy, 2010; Volume 168, pp. 55–58. [Google Scholar]

- Grégoire, M.; Barthod-Malat, B.; Labonne, L.; Evon, P.; De Luycker, E.; Ouagne, P. Investigation of the potential of hemp fibre straws harvested using a combine machine for the production of technical load-bearing textiles. Ind. Crops Prod. 2019, 145, 111988. [Google Scholar] [CrossRef]

- Assirelli, A.; Bentini, M.; Pasini, P. La raccolta della canapa da fibra. L’Informatore Agric. 1999, 42, 93–96. [Google Scholar]

- Giovanardi, R. Canapa: Meccanizzare la raccolta. Mach. World MMW 2007, 4, 50–57. [Google Scholar]

- Assirelli, A.; Croce, S.; Acampora, A.; Civitarese, V.; Suardi, A.; Santangelo, E.; Pari, L. An innovative system for conditioning biomass sorghum [Sorghum bicolor (L.) Moench]. Trans. ASABE 2013, 56, 829–837. [Google Scholar]

- Pari, L.; Assirelli, A.; Acampora, A.; Suardi, A.; Santangelo, E. A mower conditioner to improve fiber sorghum plant drying. Appl. Eng. Agric. 2015, 5, 733–740. [Google Scholar] [CrossRef]

- Del Giudice, A.; Assirelli, A.; Gallucci, F.; Bellacima, R.; Pari, L.; Santangelo, E. Production of energy feedstock from the riparian vegetation of Arundo donax (L.): Suitability of the chopping systems. Ecol. Eng. 2017, 102, 459–467. [Google Scholar] [CrossRef]

- Marrot, L.; Lefeuvre, A.; Pontoire, B.; Bourmaud, A.; Baley, C. Analysis of the hemp fiber mechanical properties and their scattering (Fedora 17). Ind. Crops Prod. 2013, 51, 317–327. [Google Scholar] [CrossRef]

- Bennett, S.J.; Snell, R.; Wright, D. Effect of variety, seed rate and time of cutting on fibre yield of dew-retted hemp. Ind. Crops Prod. 2006, 24, 79–86. [Google Scholar] [CrossRef]

- Faugno, S.; Sannino, M.; Pacifico, S.; Cervelli, E.; Stagno, F.; Assirelli, A. New insights in hemp seed phenols and polyphenols through uhplc-esi-qtof-ms/ms analysis. Eur. Bio. Conf. Exhib. Proc. 2019, 2019, 339–343. [Google Scholar]

- Faugno, S.; Sannino, M.; Crimaldi, M.; Caracciolo, G.; Assirelli, A. Proceedings of European Biomass Conference and Exhibition—Hemp seed mechanical harvesting efficiency analysis: 26th EUBCE May. Biomass Resour. 2018, 2018, 374–377. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).