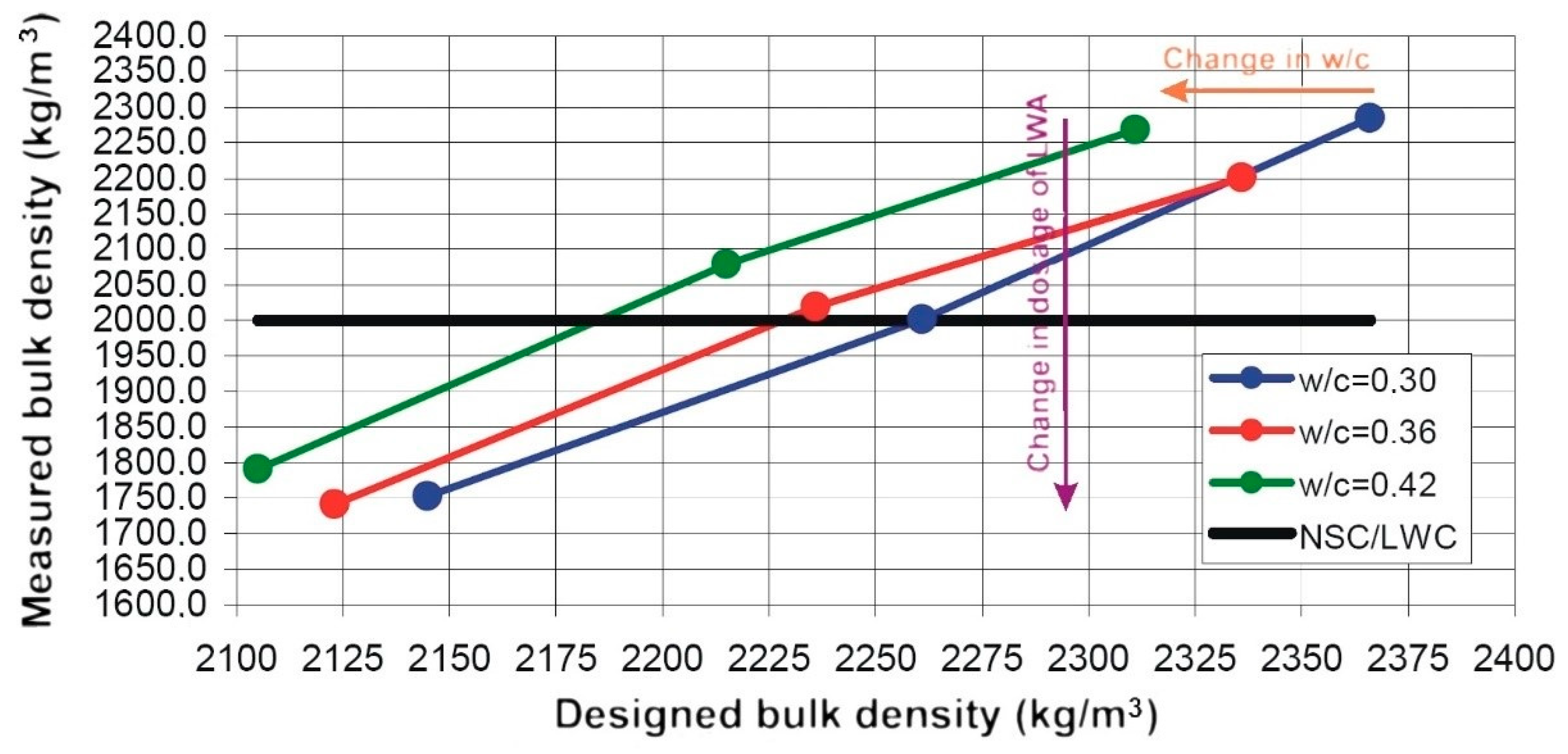

6.1. Apparent/Bulk Density

The substitution of some part of a natural aggregate by LWA necessarily leads to a change in the apparent density. This is caused, firstly, by the lower specific gravity and bulk density of the LWA in comparison with a natural aggregate (

Table 1) and, secondly, by a change in the ratio of the volume of the cement paste to the volume of the aggregate. These two aspects, on a practical basis, affect the consistency (workability) of fresh concrete (or mortar) and its related compactability. Under specific circumstances, the apparent density can be an indicator of the compactability of the fresh mixture and strength of premature and/or hardened concrete. For the purposes of this study, this was determined in order to verify the reliability and technological suitability of the recipes designed.

Some qualitative conclusions resulted from the actual measured bulk (apparent) density ρ

V (kg/m

3). LWA, at a dosage of 13.2% (by mass) and by the selected fractions 0/4 and 0/1 mixed in a mutual ratio of 75:25, in order to fully recover losses of moisture from the hydration of the sealed system, causes an approximately 15% decrease in bulk density. The significant drop in bulk density prevented us from classifying the mixture as “normal-weight” structural concrete (NSC) according to [

10], as the bulk density dropped down below 2000 kg/m

3. Similar behavior was also observed for samples with a dosage of LWA 7.0% (by mass). In proportion to the lower dosage of LWA (7.0%), a drop in bulk density was found. The relative decrease in bulk density can be expressed as 6%. The drop in bulk density was mainly caused due to the missing cement paste and improper compactability in the laboratory conditions. Tamping was used. It is recommended to compact these stiff consistencies with a vibration press, which does not exclude the use of these mixes in actual applications. The less favorable compactability of mixes containing some LWA can be attributed to the complex characteristics of LWA (e.g., its granulometry, fineness and related specific surface area, and, especially, its almost immeasurable capacity to accomplish physical binding of water on its surface), which were either partly or not at all considered in the design of the mix [

3]. A minor effect on its compactability can be attributed to the relatively low w/c. The design of the recipes was driven by low w/c (generally needed for some exposure classes), the achievement of higher strengths, and the construction of durable structures. Similarly, greater importance in the design of LWA was attributed to the homogeneity of the distribution of the LWA particles (water reservoirs) in the cement paste. In that way, the distance between the singular particles (the so-called “spacing factor”) would be minimized.

Figure 5 demonstrates the relation of the measured and expected bulk densities using three different w/c ratios and vectors with the contribution of the dosage of LWA and change in w/c.

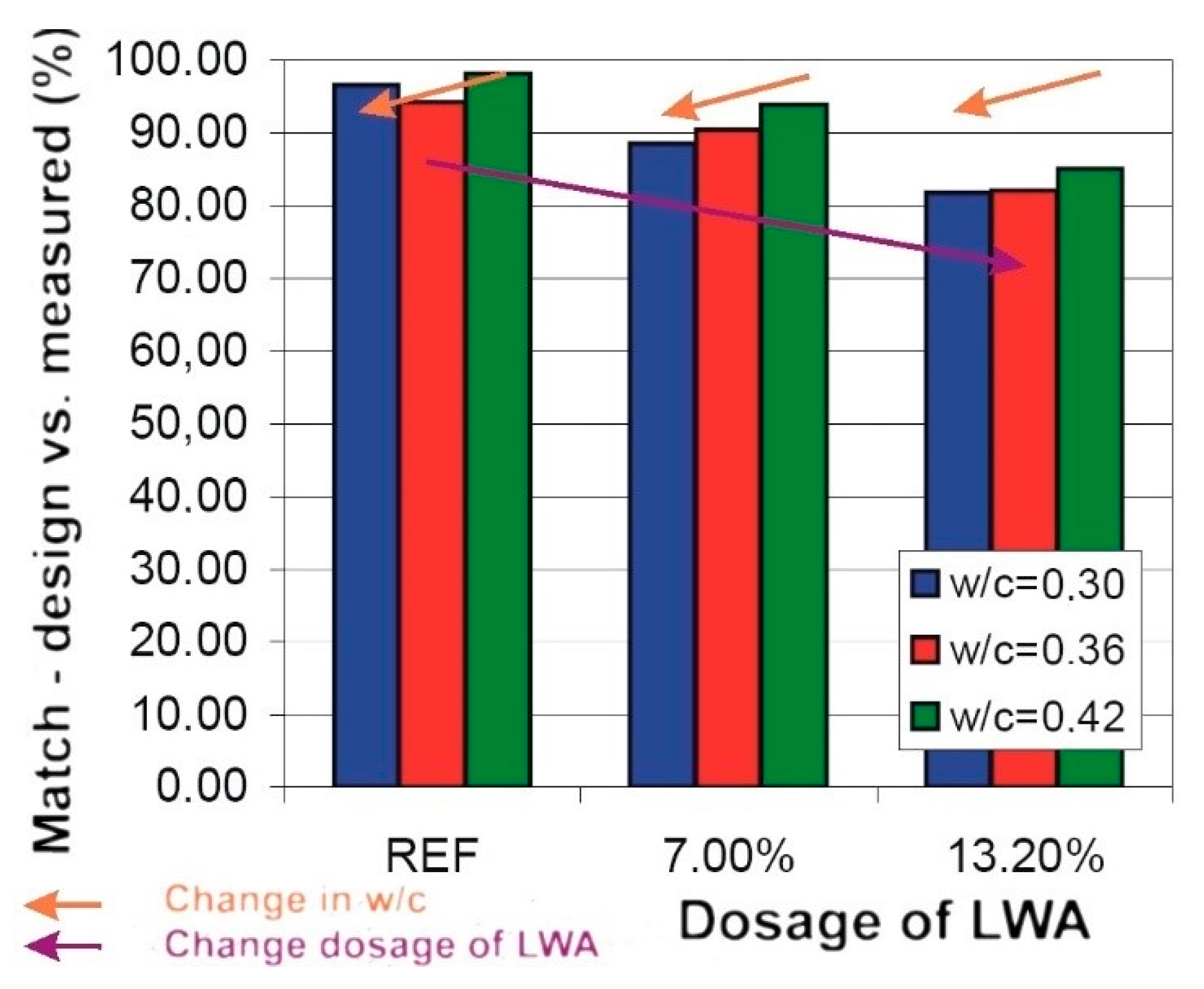

Figure 6 more clearly demonstrates the relative deviations of the measured bulk densities from the expected ones or the matching of the expectations to the actual measured data. Through a simple visual comparison, the effect of w/c, but mainly the decisive impact of the dosage of LWA, can be observed.

Figure 6 (in the reference concrete column) achieves a compliance of 94–98%, which indicates that the design method can be used as such. Moreover, the bulk density was measured after conditioning that lasted 24 h at 20 °C and RH 98%. In reality, this allows some moisture losses from the samples into the ambient environment.

Modifications or corrections can be desired for a mixture design model for IC using LWA. They can principally be done in several ways, i.e., modification of the coefficient of saturation, an increase in the expected quantity of the water physically bound to the surface of LWA, modification of the mixing ration of the LWA fractions, or the substitution of fine particles of LWA with coarser ones. It must be noted that any variability in the properties of LWA affects the overall characteristics much more than would be the case with actual concrete with greater D

max. From the point of view of bulk density, the dosage of 13.2% of LWA was excluded from further testing of the mortars [

11,

12].

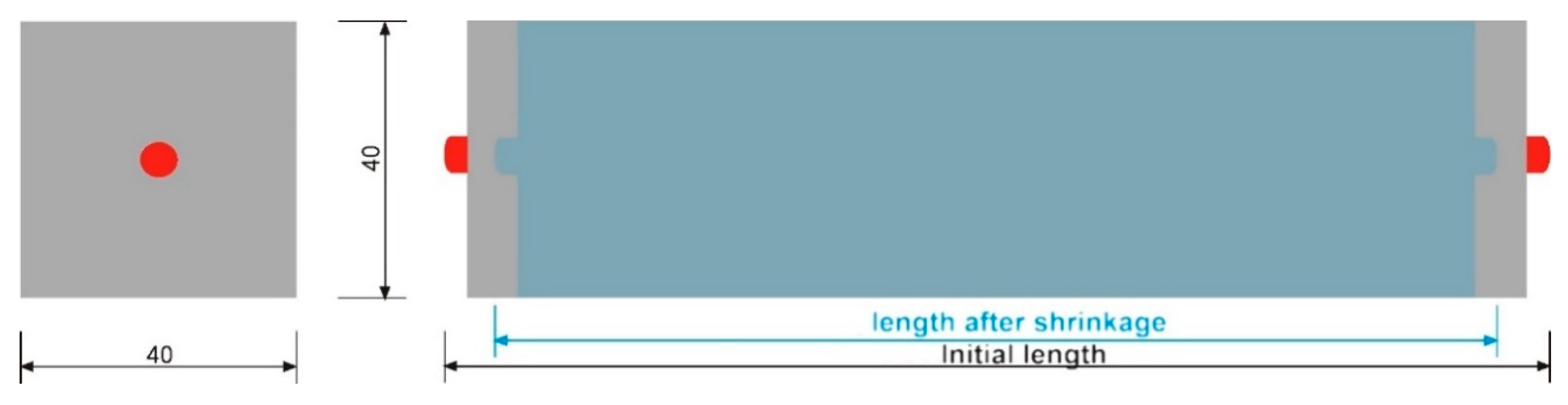

6.2. Changes in Volume

The results of the changes in volume tests (in accordance with [

9]) show changes in volume only taking place after the demolding of the testing samples (at the age of 24 h). Technically, the period characterized by the major changes in volume related to hydration is excluded from the analysis. In accordance with the findings of many authors (e.g., [

13]), it can be stated that within the first few hours after mixing, the majority of any changes in volume appear. Their nominal value can even represent four times the changes in volume measured by this conventional method on the seventh day. Therefore, the results of these tests must be interpreted as changes in volume taking place between the first and 28th days, despite the results of tests conducted by a similar approach (by [

14]) after 90 days, which have been interpreted as ultimate changes in volume (or shrinkage, if you wish). It must be noted that none of the standardized methods catch the changes in volume before the demolding of the samples. We measured the changes in volume (after demolding) upon exposure to the ambient temperature of 20 ± 2 °C and RH 95 ± 5% (an achieved level of 98%).

The development of changes in volume was carried out separately for the variants of the w/c (0.30, 0.36, and 0.42) with corresponding maximum degrees of hydration αmax (0.83, 1.00, and 1.00), respectively. For each w/c variant, we verified the impact of IC on the changes in volume. The main hypothesis behind the IC was that along with the increasing dosage of LWA (7% or 13.2%) and the quantity of the inbuilt water, the changes in volume decrease. The results demonstrated the partial correctness of this assumption. The changes in volume of an ideally sealed system (20 °C and RH 98%) can be understood as a shrinkage of an actual structure with curing ideally mitigating any water losses to the environment.

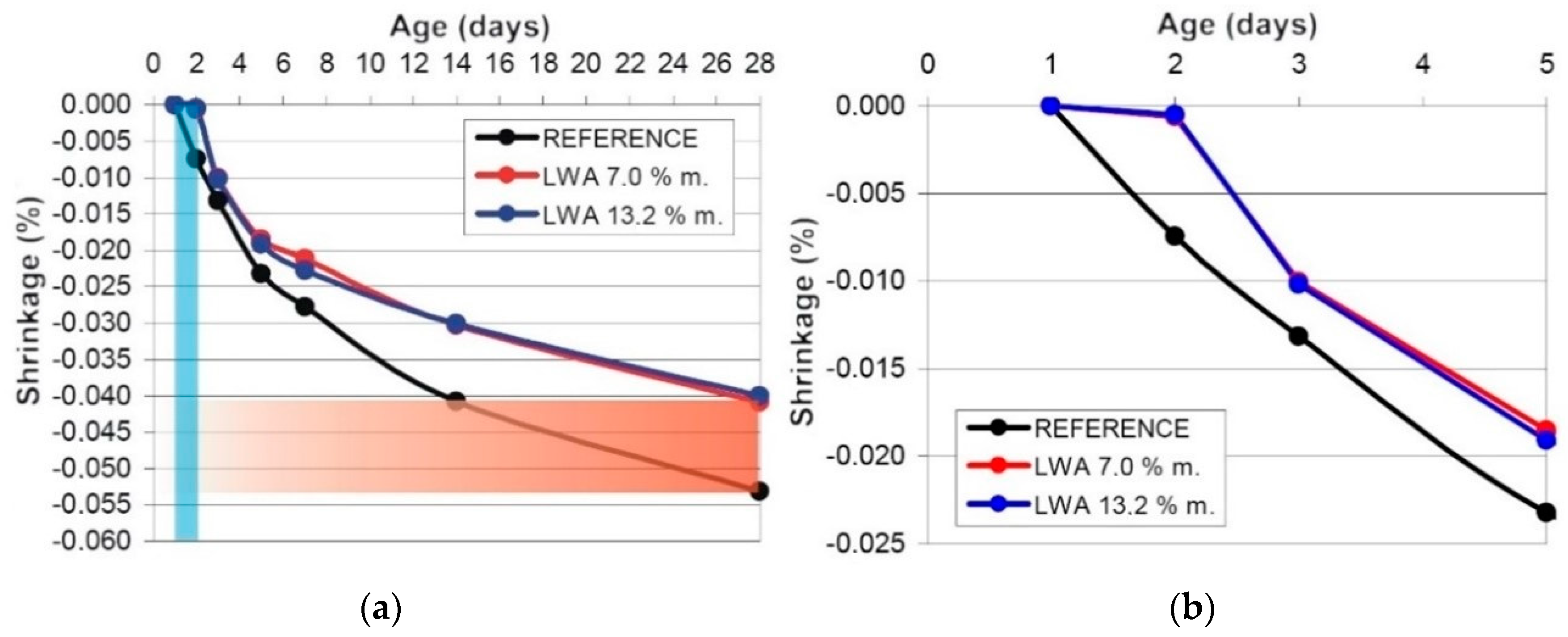

Figure 7a,b,

Figure 8a,b, and

Figure 9a,b show the measured (long term of 28 days and short term of five days) changes in volume of the samples with variable dosages of LWA (0, 7, and 13.2%) at different w/c (0.30, 0.36, and 0.42). As previously mentioned, the w/c ratio affects the maximum degree of hydration α

max (0.83, 1.00, and 1.00), which must be considered in the interpretation of the reference sample (0% LWA).

Figure 7a,b shows the evolution over time of the changes in volume of the samples with a very low w/c ratio of 0.30 (α

max = 0.83). From the maximum degree of hydration, it is obvious that the reference sample (without IC) must necessarily undergo self-desiccation and, therefore, significant changes in volume [

15]. Through our qualitative analysis of the results, we drew the partial conclusion that IC using 7% and 13.2% of LWA caused a reduction in the changes in volume (in line with previous observations [

16]). The reduction on the 28th day can be expressed as 0.015%. Under the assumption that an ideal IC is considered a state when any changes in volume are eliminated, then it can be concluded that under these conditions, the efficiency (difference in shrinkage on the 28th day) of the IC was achieved at approximately 25% (regardless of the dosage of LWA). The contribution of individual dosages of LWA was not reliably determined. The blue area (

Figure 7a) highlights the other significant finding. IC postpones the initial changes in volume (in line with [

16]), which is favorable due to the higher strengths (as unrestricted changes in volume practically do not exist). The changes in volume at an early age are captured in detail in

Figure 7b. It is clear that a change in volume (shrinkage) while IC is used appears for the first time on the second day. This means that until this time, the IC is 100% effective. As seen in

Figure 7b (later also

Figure 8b), the most likely behavior of the samples with IC during the period that was captured by the measurements should be explained. The samples with IC contained some quantities of curing water, which resulted in a slight swelling, which was also observed in [

16,

17,

18,

19]. Then, the shrinkage starts from an “elongation”, and the rate of changes in volume between the first and second day is proportional to the quantity of water released during the swelling of the concrete.

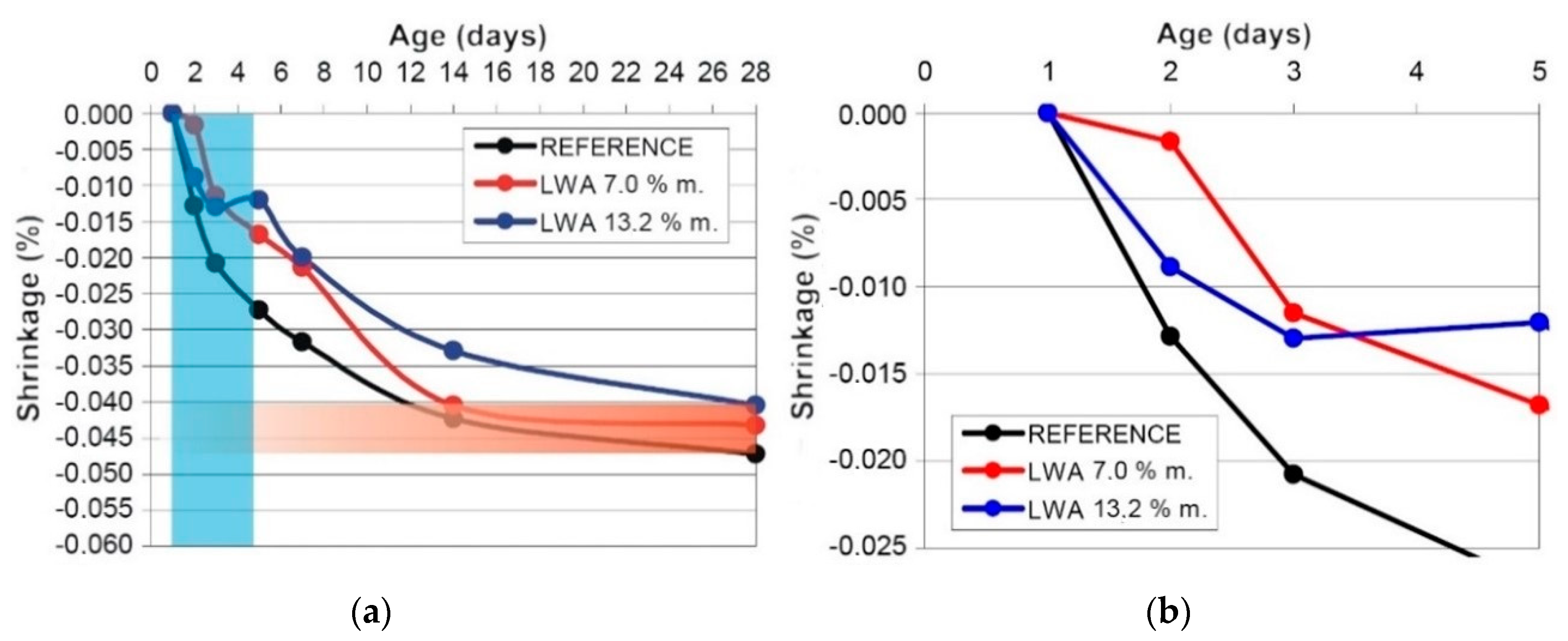

Figure 8a,b shows the evolution over time of changes in volume of the samples with a low w/c ratio of 0.36 (α

max = 1.00). The reference sample (without IC) undergoes self-desiccation, but compared to w/c 0.30 (

Figure 7a), the changes in volume are lower, which is a consequence of the higher w/c ratio. The IC using LWA at dosages of 7% and 13.2% caused a reduction of the changes in volume on the 28th day by 0.004–0.007%. The reduction on the 28th day can be expressed as 7–14% (for dosages of 7% and 13.2%, respectively). The blue area (

Figure 8a) highlights the postponing of the initial changes in volume at a dosage of 13.2%. This is observable for both dosages, but at a different value. The dosage of 7% behaves in a standard fashion on the second day; it works with an efficiency of 85% (less than in the case of w/c 0.30). The slight drop in efficiency is caused by the relative sufficiency of the water for the hydration of the cement and the related faster (not delayed) development of the changes in volume of the reference sample. From the changes in volume during the development of the sample with 13.2% LWA (

Figure 8a), we can observe a swelling on the fifth day. This non-standard behavior (not repeated in any other sample) is attributed to the heterogeneity of the distribution of large pores in LWA [

20]. The changes in volume indicate a lack of large pores (ca 50–100 nm) and an excess of small pores (10–30 nm) in the LWA, whereas on the third day, the cement paste achieves an RH limit to release the physically bound water from the tiny pores of LWA. A detailed overview of the changes in volume due to the premature age of the concrete is shown in

Figure 8b.

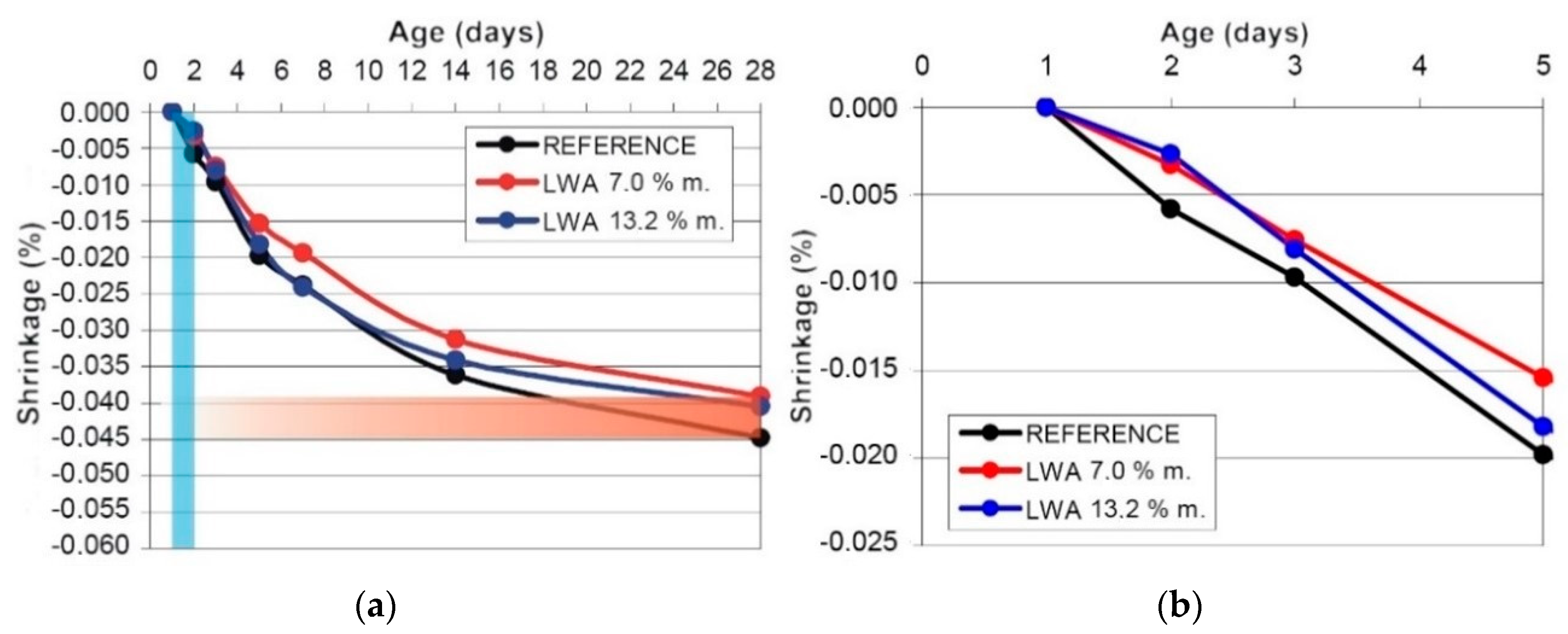

Figure 9a,b shows the evolution over time of the changes in volume of the samples (of NSC) with the quite regular w/c ratio of 0.42 (α

max = 1.00). The reference sample (without IC) did not undergo self-desiccation. The w/c ratio is sufficient for covering the need of water to achieve α

max = 1.00 without any supplementary curing water. Compared to w/c 0.30 (

Figure 7a), the changes in volume, in line with the expectations according to α

max on the age 28 day, are the same as in the case of w/c 0.36 (

Figure 8a). The IC using LWA (in dosages of 7% and 13.2%) caused an insignificant reduction in changes in volume. This reduction was determined on the 28th day with a value of 0.005%. The efficiency of IC under these conditions (on the 28th day) achieved an approximate efficiency of 10% (for both dosages of LWA). The reason for the quite low degree of efficiency can be found in the sufficient moisture for the hydration and low usage (if ever) of water from the saturated pores of LWA. From

Figure 9b, some slow changes in the development of the volume can be seen, whereas on the second day, the IC using 7% of LWA ensured an approximate efficiency of IC of 45%, while a dosage of 13.2% ensured an approximate efficiency of 53%. It is obvious that the efficiency of IC decreases with the increasing w/c (in line with [

15]). The LWA carries some potential capacity of the curing water, which can be released at a certain time; therefore, its action is limited. The time of action of the LWA tested depends on the boundary conditions of the exposure of the samples, i.e., inducing specific water losses and a drop in the RH of the cement paste. The IC of the quasi-sealed samples (RH 98%) on the second day exhibits an approximate efficiency of 92, 85, and 52% for the pastes of w/c 0.30, 0.36, and 0.42, respectively.

The reduction of the changes in volume on the seventh day, as shown by Henkensiefken and Bents [

17], cannot be achieved using LWA. The reason can be found in the pore structure of LWA, which is different. The distribution curve of the pore size was too flat and shifted to a zone of small and medium-sized pores (50 nm) [

20].

Any dramatic reduction in the absolute changes in volume by IC cannot be expected. The IC starts its action when the cement paste starts to dry out and when pores of the same size as the larger pores in LWA start to empty. This means that the largest pores in the cement paste (with the largest cumulative volume) have already formed, which is a consequence of autogenous and chemical shrinkage. The main benefit of this method is a delay in the initial changes in volume when the LWA starts to act. This time can be adjusted by a combination of curing methods.

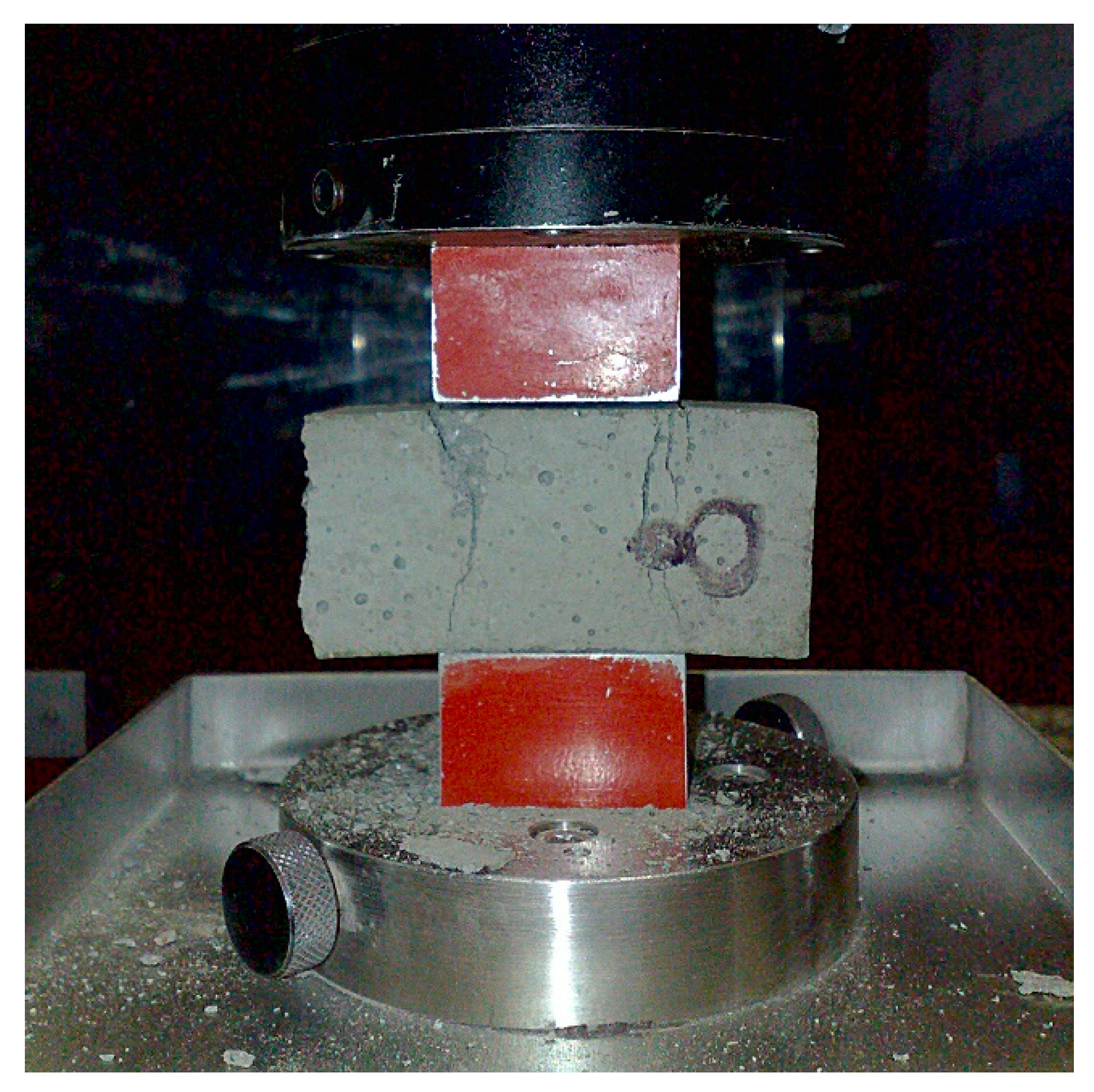

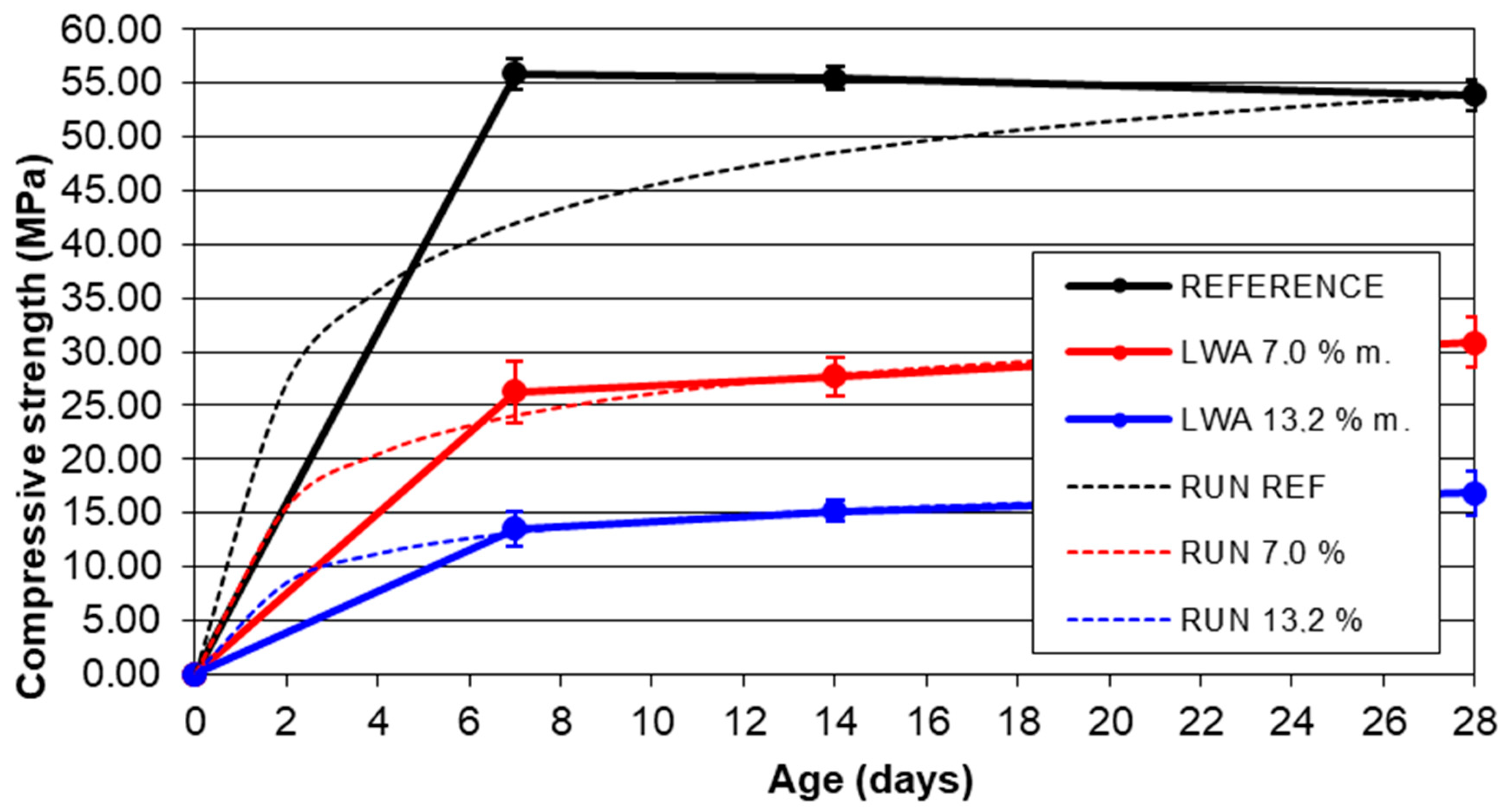

6.3. Compressive Strength

The compressive strength was determined (following [

6]) on fragments of the “mortar” prisms, which is interpreted as the mean cube strength at a certain age (7, 14, and 28 days). With these tests, we verified the effect of the LWA dosage on the mechanical performances at various w/c ratios (w/c = 0.30, 0.36, and 0.42) during exposure to the ambient temperature of 20 ± 2 °C and RH 95 ± 5% (achieved RH = 98%), see

Table 3. The mean compressive strengths f

cm(t) at age t (MPa) were supplemented by the expected evolution of the compressive strength (following the model in [

21]), where the coefficient respecting the age of the concrete and medium compressive strength on the 28th day (MPa) occurs. The formula represents the exponential character of the evolution of the compressive strength over time t (d).

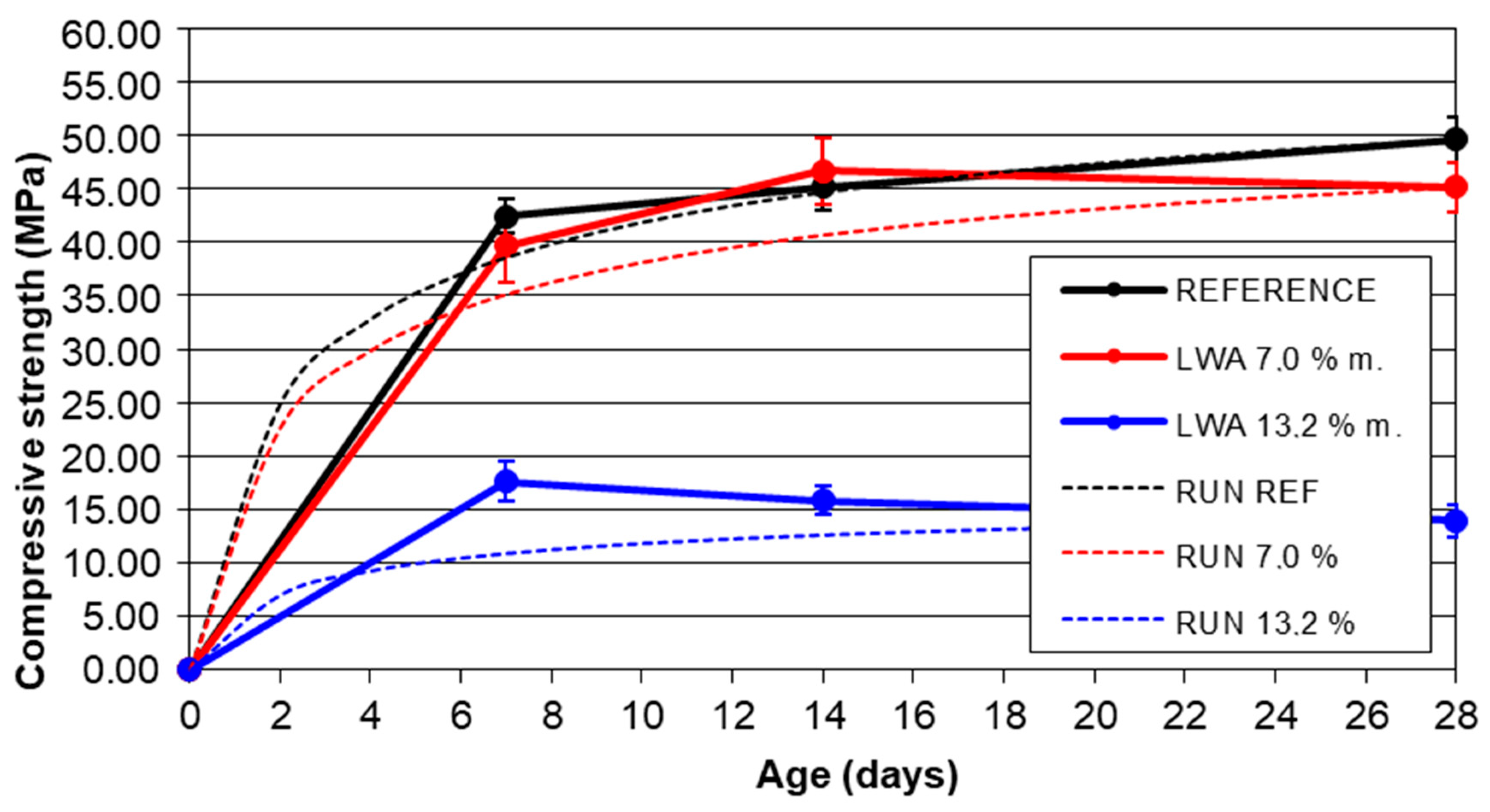

Figure 10 shows the samples (sealed system) of the low w/c ratio 0.30 (α

max = 0.83). The time-dependent evolution of the mean compressive strengths is absolutely normal. We can observe a termination of the hydration on the seventh day in the case of the reference sample, which can be attributed to the consumption of all the water by the hydration. On the other hand, the samples with a certain dosage of LWA demonstrate gradual increases in the compressive strength, which happens due to the release of the curing water from the pore structure of LWA. It can be observed that the absolute values of the final strengths of the samples with LWA are lower than the reference sample. This has a lot to do with the dosage of LWA and its impact on the significant drop in workability (see the bulk density) when replacing some portion of the natural aggregate with LWA. The altered bulk density stands behind the reduction in the final compressive strength due to the lower bulk density of LWA and the decreased workability of the mixture. A similar situation is repeated for all the w/c ratios. The difference is that with the increasing w/c ratio, the reduction in the compressive strength lowers. Assuming the use of regular concretes where we use D

max much higher than 4 mm, we do not expect any remarkable worsening of the workability.

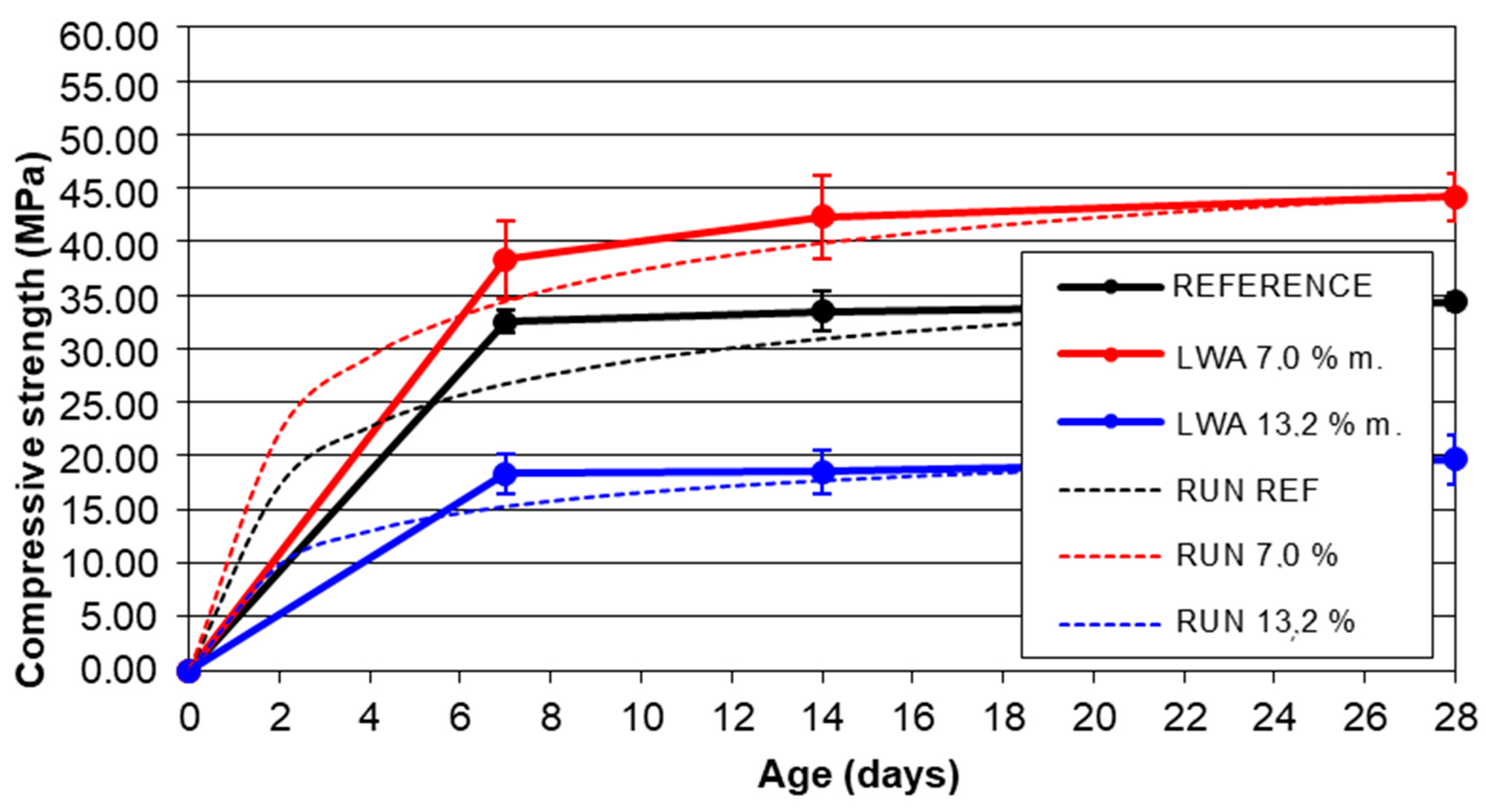

Figure 11 shows that the curing of the sealed system by a 7% dosage of LWA increased the compressive strength on the 28th day up to the values of the reference sample, despite the worsened workability and higher void content (lower bulk density). We have assumed that this relates to the relatively low w/c ratio and positive impact of IC, as already described in [

22]. The sample with a 13.2% dosage of LWA, however, has such a void content that an even higher water content that was ready to supply hydration was not enough to cover the losses of strength due to the presence of LWA and related negative phenomena. In

Figure 11 (and the others), the apparent loss of compressive strength between the seventh and 28th day can appear confusing. In reality, the compressive strength at various ages was measured on the various samples/specimens. Therefore, the apparent drop in compressive strength could also be seen as negligible, in that concerning the nature of the hydration itself, the drop is unrealistic.

Figure 12 demonstrates the evolution of the strength of the sealed system of w/c = 0.42. In this case, the compressive strength (at a dosage of LWA 7%) overcame the compressive strength of the reference sample. The samples with a dosage of LWA 13.2% still suffered from the lower strengths. However, the drop in compressive strength compared to the reference sample was eased due to the higher proportion of cement paste.