Abstract

Climate change is a fact. Global warming of the planet is a result of the emission of greenhouse gases into the atmosphere and the cause of serious sustainability issues. The objective of this article is to highlight the potential of the Six Sigma methodology to reduce energy consumption in the productive sphere, with consequential reductions in pollutant emissions. We present a systematic literature review that highlights the increasing interest from academics and practitioners in using quality management philosophies for addressing sustainability issues. From the analysis carried out, it is clear that Lean is being used in this regard but the potential of Six Sigma is not being exploited. Taking advantage of the best of both approaches (Lean Six Sigma) can contribute to reducing energy consumption in industrial processes and contribute to mitigating the impacts of those processes on climate change. Moreover, through keyword analysis, we found that the three dimensions of sustainability are currently gaining importance in the literature, when previously only the economic pillar was relevant. Finally, we raise some questions for reflection for academics but also for practitioners, as the problem is a global problem that should be faced by all the community.

1. Introduction

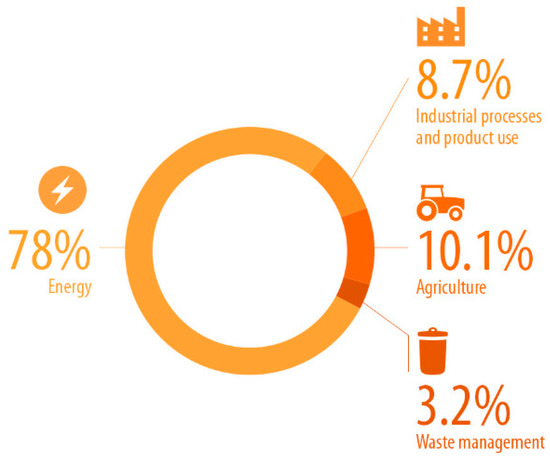

The need for energy and related services to meet the demands of human, social and economic development is increasing [1]. Securing energy supply while reducing its contribution to climate change are the two great challenges of the energy sector on the road to a sustainable future [2,3]. Global warming is not a prediction; emissions of greenhouse gases, especially carbon dioxide (CO2), are threatening the health of the planet. At the UN Conference on Climate Change in 2015, held in Paris, 195 countries agreed on a plan to reduce emissions of CO2 and other greenhouse gases (Figure 1), with the aim of limiting the increase in the global temperature of the planet to below 2 °C (relative to pre-industrial levels). The link between CO2 and global warming has created the famous “greenhouse effect” [4]. The scientific evidence for global warming is clear [5,6]. More than 11,000 scientists from around the world recently signed a manifesto alarming about this fact and encouraging the public, policymakers and the business community to effect major transformations in the ways our global society functions and interacts with natural ecosystems [6]. The consequences of this problem will only intensify if we do not face the realities of climate change; to do this, humanity must achieve some meaningful solutions to address the threat of global warming. Furthermore, a key to success is companies that can improve their industrial processes to reduce energy consumption and thereby help reduce the emission of greenhouse gases into the atmosphere. In fact, energy is one of the main areas emphasized by the manifesto.

Figure 1.

Greenhouse gas emissions in the EU by sector, 2015 [7].

There are several management philosophies for business improvement that can help to achieve better organizational performance such as Total Quality Management (TQM), Lean or Six Sigma.

We focus on Six Sigma because it is a methodology that allows companies to improve the efficiency of their production processes and reduce energy consumption by reducing defects [8]. Over the years, a wide variety of corporations worldwide have implemented Six Sigma in the efficient management of energy in their production processes and, as a result, they have reduced costs while reducing CO2 emissions. DuPont de Nemours has been using Six Sigma since 1999 to improve various aspects of their processes, including analysis and improvement of energy conversion processes, such as steam boilers, turbine generators, central cooling, compressed air, HVAC systems (Heating Ventilating and Air Conditioned systems), and manufacturing processes of heating and refining. They have sustained considerable energy savings over time, with annual savings of over $250,000 being quite frequent, surpassing $2 billion in cumulative savings in 2002, with 10,000 projects completed or in progress [8]. For its part, Dow Chemical adopted the Six Sigma methodology in 1998 to improve the quality and productivity of its processes, launching in 1999 a corporate program to incorporate it in all its businesses and functions, achieving a cumulative reduction in 2003 of $1.5 trillion in costs. This includes its energy-saving program in its Texas and Louisiana plants with savings of $935,000 per year [9]. 3M at its facilities in the UK has applied Six Sigma to a curing oven in the production process of adhesive tapes, achieving annual savings of 1,658,000 kWh gas (29% reduction in energy consumption, and oven reduction of 4.7% of the energy consumption of the whole plant) [10]. Other notable examples are: (a) Baxter International saves $300,000 in energy costs per year; (b) General Electric has reduced gas emissions by 250,000 tons, saving $70 million in energy costs since 2005; and (c) Toyota Motor Manufacturing North America has reduced gas emissions by 30% per vehicle produced since 2000 [11].

Therefore, improving processes reduces the energy required to operate the manufacturing equipment, so there are fewer CO2 emissions and less dependence on non-renewable energy. For this reason, the interest in the Six Sigma methodology in both business and academic fields has grown over time [12].

The aim of this article is threefold. First, through a bibliometric review analysis, we expect to identify publication trends, the most relevant journals where studies addressing the topic are published, and the most important authors (and countries). Second, from a network analysis of keywords, we identify different aspects involved (and their evolution) in the study of sustainability using management improvement tools. Third, with the information extracted from these two points, we discuss the need for important changes in business for achieving sustainability objectives to help mitigate climate change.

2. Production Management Philosophies

Several methodologies are available for process improvement, and each company should choose one depending on its circumstances. These include Six Sigma, Lean Management, Lean Six Sigma, Agile Management, Re-engineering, Total Quality Management, Just-In-Time, Kaizen, Hoshin Planning, and Poka-Yoka, among others [13]. However, among all of them, there are two that have been more directly related to business sustainability and sustainability in general: Lean and Six Sigma [14,15,16].

2.1. Six Sigma

In the late 1980s, engineers at Motorola developed the Six Sigma methodology in order to reduce the variability of their production processes to a level where defects had an extremely low probability of occurrence [17]. They changed the traditional quality levels that were being used at that time (measuring defects in thousands of opportunities) to move toward measuring defects per million opportunities (DPMO). In this way, by using statistical analysis to minimize variation, Six Sigma allows for improvements in data-driven processes, since operating with Six Sigma quality levels produces 99.9997% accuracy, with only 3.4 defects per million opportunities.

Statistical terms may seem arbitrary and abstract. When we look at real-world examples, the meaning of the Sigma levels becomes quite clear. What is a good level of Sigma? In a world that operates on a 3.8 Sigma level, 200,000 doctors would write incorrect drug prescriptions per year, but there will be only 68 if they operate at Six Sigma levels. These are some very dramatic differences in process performance with only a 2.2 Sigma level difference.

In the literature, there are many studies examining the impact of the use of Six Sigma in the sustainability of organizations. They are focused on three major areas: (a) costs (cost reduction, reduction of defects, waste reduction, reducing waiting times, reducing unnecessary inventories) [18], (b) quality (increased quality products and services, reducing process variability) [19], and (c) satisfaction (accelerated delivery time, process and production cycle, increased customer and employee satisfaction) [20]. Chugani et al. [15] found 70 articles that analyze the impact of Six Sigma on environmental sustainability. They concluded that defect reduction being the main objective of Six Sigma implies a reduction in the resources used, which positively impacts on the environment.

The DMAIC structure (define-measure-analyze-improve-control) facilitates the statistical definition of a problem as well as its solution [20]. In this way, and because the whole process is based on data, subjectivity and arbitrariness are eliminated when making difficult decisions. The steps are as follows:

- Define: In this first step, you will define the problem and how it is affecting the current process.

- Measure: During this step, you will measure the current data. By examining the process that is already in place and identifying what is not working, you can begin finding ways to make improvements.

- Analysis: Once all current data are measured, you can begin analyzing them to get to the root of the problem.

- Improvement: In this step, solutions should come up. Test your solutions, and make improvements as needed.

- Control: After implementing the new process, you must continue to make improvements over time. Moreover, these changes will only last if employees continue to refine and maintain the process.

2.2. Lean

The concept of Lean Thinking was developed from Toyota Production Systems and is based on the idea of eliminating waste. It includes a strong process analysis orientation, which means that every step in the work processes is evaluated. It tries to reduce or eliminate those that do not add value [13]. Compared with Six Sigma, which is focused on effectiveness, efficiency is the goal of Lean, reducing the average cycle time, excess inventory and the average response time. It focuses mainly on the following eight deadly wastes for balancing the workload and increasing speed and flow:

- Defects and scrap: Defective products that have to be reworked, repaired, or scrapped.

- Overproduction: Producing more than is necessary. This is an issue that generally slips under the radar, and is not considered to be a problem. However, overproduction is unique in the increasing of the other wastes.

- Waiting: Idle time before the next processing step.

- Non-value added processing: Performing activities that add no value to the product or service from the customer’s perspective.

- Transportation: Movement of material or data from one place to another. Transportation involves the touching, moving, and relocating of raw materials, tools, finished goods, etc., for use at different stages of a process.

- Inventory: Supply in excess. This occurs when more supplies than are needed are ordered, and the inventory is tracked poorly.

- Motion waste: Movement of employees and equipment that do not add value to a product or service, such as walking to and from the copier, excessive effort or process steps, such as an operator reaching far above their head to complete a task, and where something is reversed or undone, such as putting down components and reversing a fixture each time a process is completed.

- Unutilized employee skills: Not using people’s abilities, skills, and experience to the fullest extent.

In particular, Lean has been usually related to green practices in the literature about sustainable issues. According to Dües et al. [21], the overlap of the Lean and Green paradigms is constituted by the following common attributes: Waste and waste reduction techniques, people and organization, lead time reduction, supply chain relationship, KPI (Key Performance Indicators): Service level, and the fact that they share common tools and practices. For this reason, it is a management improvement philosophy liable to be used to address sustainability issues.

2.3. Lean Six Sigma

There are many differences between Lean and Six Sigma, but they can be complementary [22]. Lean looks at ways to increase flow, while Six Sigma focuses on achieving consistent results. On the other hand, Lean is used primarily in production, while Six Sigma can be used in production as well as non-production environments. From the union of the two approaches appears Lean Six Sigma. The term was first introduced into the literature around 2000 as an evolution of Six Sigma [20].

As leading practitioners and academics in the field have mentioned, the integration of two systems can achieve better results than what either system could achieve alone. The integrated approach (Lean Six Sigma) works better than previous approaches because it integrates the human (such as leadership, customer focus, cultural change, etc.) and process aspects (process capability, process management, statistical thinking) of process improvement [22].

It has been used in different industries [23], especially in manufacturing and healthcare [24,25,26].

2.4. Operational Excellence

There is no clear definition of what Operational Excellence (OPEX) is since there are multiple views of the concept, but a good approximation would be doing the right thing, the right way, every time, even when no one is watching [27]. The idea of “operational excellence” has been around for almost 20 years, but today it is gaining popularity again due to sustainability issues. The reason is that this term is closely linked to the mission of any company: Optimize its processes to offer truly competitive products and services and stand out in an increasingly saturated environment. In this sense, the integration of Lean with Six Sigma is a good approach towards Operational Excellence according to some authors [22]. Others, on the contrary, consider that OPEX should enlarge the perspective of efficiency (productivity), effectiveness (customer/market orientation) and optimization of production processes to see operations as setting levers by providing enablers as a central role for operational long-term success [28].

Therefore, although it seems that OPEX is going a step further in the quality management approaches mentioned above, its complexity of application leads to its underutilization.

In the following bibliometric analysis, we identify these four approaches with concepts related to sustainability to see what has been written and what remains to be said in relation to the topic.

3. Bibliometric Analysis

3.1. Data Collection

A systematic literature review aims to systematically search for and synthesize research evidence based on the principles of transparency and replicability [29]. In this paper, we used the design proposed by Tranfield et al. [30] consisting of three stages: Planning, conducting, and diffusion of results.

We used multiple databases to get a more complete view of research [31]. Specifically, we considered two of the most important databases: Web of Science (WOS) and Scopus. The combinations of keywords introduced in the search engine are shown in Table 1. They should appear in the title, abstract or keywords, in the case of Scopus, or the topic in WOS. We include the philosophies, keywords related to sustainability issues, and the word sustainability. We want to remark that we introduced another row in the search related to management for change and Corporate Social Responsibility concepts, but it did not return any results. In the discussion, we will deepen this aspect.

Table 1.

Search results.

Some documents have several of the keywords used and, therefore, they appear in more than one search. For this reason, the total of items found is not the sum of the partial matches. We decided to split the main search to highlight the unalike use of these methodologies to address the issue of sustainability in companies and therefore the remaining potential for improvement. As can be seen in Table 1, more than 95% of the documents are related to Lean.

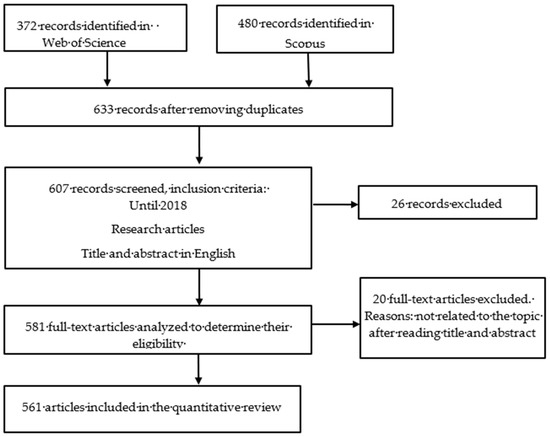

We used the common methodology for reporting systematic reviews, PRISMA (Preferred Reporting Items for Systematic Reviews and Meta-Analyses) [32]. The items found met all the criteria for inclusion in the analysis. As shown in Figure 2, we considered only scientific papers, i.e., no books, doctoral theses, etc. [33], and only written in English. Moreover, the time limit of the study ends in 2019 (the last search was conducted on 20th November).

Figure 2.

PRISMA (Preferred Reporting Items for Systematic Reviews and Meta-Analyses) Flowchart.

The 561 articles that make up the final sample are the result of eliminating duplicate items, those with incomplete information, or those not related to the topic after an analysis of the abstract. According to the Scopus categories classification, they are mainly indexed in journals in the areas of engineering (50%), business/management (28%), environmental (18%), and energy (13%).

The extracted information (authors, year of publication, journal, document title, number of citations, keywords, etc.) was exported to Excel to be analyzed in depth. Before starting the data analysis, a homogenization step to improve the consistency of results was carried out.

3.2. Review Results

3.2.1. Evolution of the Number of Publications

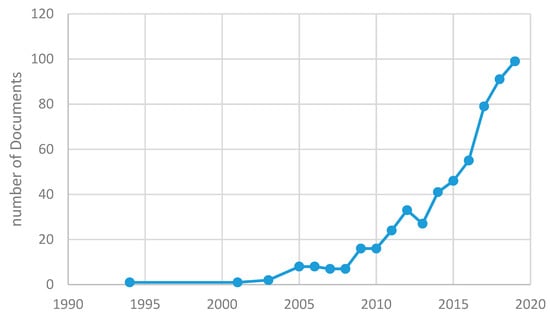

The first article addressing the topic of study, i.e., increasing efficiency to mitigate climate change by applying management improvement philosophies, was in 1994 under the title “How green production might sustain the world” [34] (Table 2). The table also shows that 50% of the documents are found after 2015. This fact highlights the novelty of this field of research. Figure 3 graphically represents the exponential growth of this literature. Sustainability issues are gaining importance in the industrial and business areas, which are usually worried about productivity without being concerned about its consequences.

Table 2.

Evolution of publications.

Figure 3.

Trend of publications.

3.2.2. Authors and Countries

We found 1427 authors that had published a document regarding the topic analyzed. They are academics but also practitioners, as Lean and Six Sigma are process improvement strategies from industry. In Table 3, authors are listed who have five papers or more in our dataset. As can be seen, J.A. Garza-Reyes is the reference author addressing sustainability issues in industry by using Lean and Six Sigma.

Table 3.

Main authors.

On the other hand, analyzing the countries where research has been conducted, considering the country of affiliation of each author and not the nationality, 65 countries are found. The United States is the leading country with 98 publications (1453 citations), i.e., 17.4% of the papers of our sample. It is remarkable that being the country with the most papers and the second in the number of citations, none of this country’s authors feature among the most productive authors included in the previous table. This denotes a great dispersion of works.

The United Kingdom is the next country in terms of production of papers, with 64 documents, but it is the most cited with 1846 citations. Then, India, Italy, and Brazil appear with 36, 29 and 25 papers, respectively, with less than 500 citations.

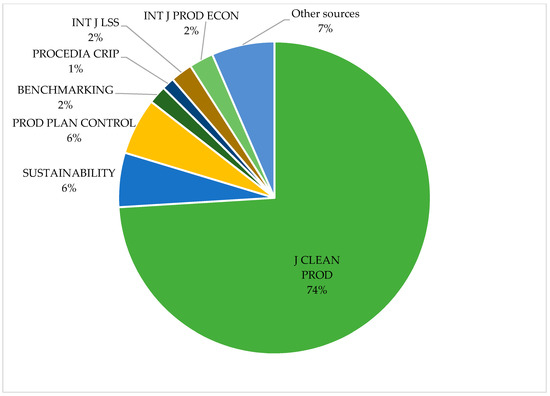

3.2.3. Journals

The number of sources that have published any document related to this topic, including journals and conference proceedings, according to our database is 326. It is a high number considering our sample of 561. Table 4 shows the ones that have published more than five documents, and Figure 4 shows the distribution of the citations among them. As previous reviews did, we also found that the Journal of Cleaner Production is the most important outlet of publications related to the topic and agglutinates a large number of citations [14]. It is followed by Sustainability, and Production Planning and Control.

Table 4.

Journals.

Figure 4.

Distribution of citations (main sources).

3.2.4. Keywords

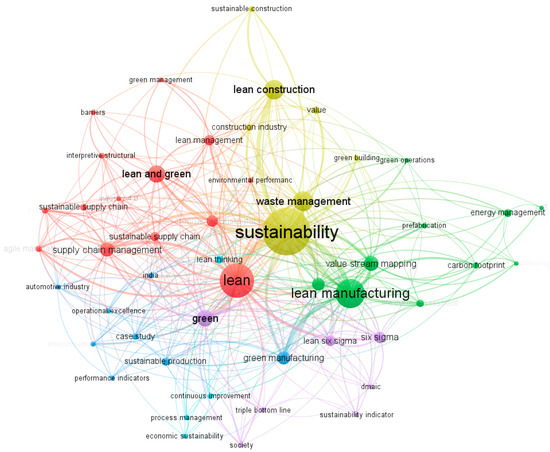

Authors use keywords for characterizing their works. Therefore, from the analysis of keywords, we can observe what they are talking about. In Table 5, the top 10 keywords used are listed. Moreover, we used a software tool designed for visualizing scientific landscapes: VOSviewer [35].

Table 5.

Main keywords.

In VOSviewer, the size of the nodes and the keyword name represent their weight, i.e., occurrences (number of times repeated). The distance between two nodes reflects the strength of the relationship between them; a shorter distance means a stronger relation. On the other hand, the line between two keywords indicates their co-occurrence, the times that appear together, and its thickness represents the degree of this frequency. Finally, according to their association strength, the software splits these keywords into different clusters (with different colors). It should be noted that each keyword can only be included in one cluster [36].

We found 785 keywords in the database. Using the default minimum of co-occurrence, we plot the 50 most repeated in Figure 5.

Figure 5.

Keyword network visualization.

The biggest nodes are the keywords in Table 5, as they appear more times in the dataset. It is not surprising that “sustainability” is in the middle of the figure, as the appearance of this word was expressed in the database search. Moreover, “Lean” was found in almost all the papers.

On the other hand, the cluster analysis (Table 6) reveals six topics included in this field. Cluster #1 accounts for 14 items related to lean management and environmental sustainability, but also resilience and barriers to managing it. Cluster #2 highlights one of the areas included in the manifesto where world scientists are warning of a climate emergency: Energy. The importance of energy management to reduce carbon footprint and CO2 emissions is a powerful reason for using improvement methodologies of management.

Table 6.

Cluster analysis.

Clusters #3 and #4 have a sectoral bias. They include keywords related to the production and construction industries. Especially in construction, Lean has had a great impact as can be seen in keywords such as “green building” or “lean construction”.

“Six Sigma” and related keywords such as “DMAIC" are included in Cluster #5. It should be noticed that in this group important words for the future of sustainability appear, such as “society” and “Triple Bottom Line” (TBL). This means that papers addressing this issue by applying Six Sigma evaluate their performance in a broader perspective to create greater business value as TBL is an accounting framework with three parts: Social (human), environmental (or ecological) and financial (or economic).

Finally, Cluster #6 accounts for four items related to process management in general.

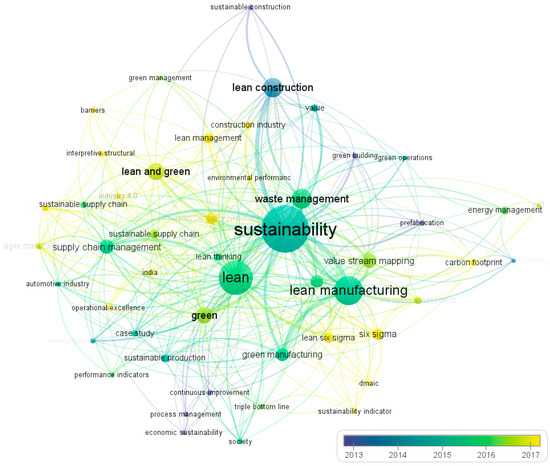

Another interesting analysis is the evolution of these keywords over time. Figure 6 uses a color scale to show the average number of publications per year in relation to each keyword. From this figure, we can draw some conclusions. First, the chronological axis (which shows the average of publications per year of each keyword as mentioned) makes us see that it is a fairly new field, i.e., most of the publications are very new.

Figure 6.

Keyword trend visualization.

The trend reveals that the keywords in yellow such as “carbon footprint”, “CO2”, “barriers”, “resilience”, and “industry 4.0” are recently used in papers addressing sustainability issues. On the other hand, as a management philosophy, Six Sigma analysis is newly applied regarding this topic according to the keywords’ trend (“Lean Six Sigma”, “Six Sigma”, and “DMAIC”, all in yellow). On the contrary, “Lean” is in the middle of the axis, which means that it was used in the past and also nowadays.

According to sustainability issues, this term is in the center of the figure as the most important keyword, but economic sustainability or sustainable production (purple and dark green) are outpaced terms and environmental sustainability is now focusing debates (yellow).

To be sustainable, the three fundamental pillars or TBL should be considered: The economic, social and environmental. If one of these three pillars is weak, a process (or company) may be viable, equitable, and bearable due to the interaction between these pillars; nevertheless, as a whole, it is unsustainable [37].

3.2.5. Main Themes

From this review analysis, we could also identify the main aspects addressed by the research within the field of sustainability through management methodologies (Lean, Six Sigma, Lean Six Sigma, and Operational Excellence). In this regard, the interest of authors is focused on four main themes. They are included in Table 7. On the one hand, they are related to the design of ecological products, including sustainable management of the supply chain and the reduction of waste. On the other hand, especially for the ones that are addressed by Six Sigma, they are concerned with the reduction of emissions and energy saving.

Table 7.

Main thematic interests.

4. Discussion and Future Research

The management methodologies analyzed in this article have served and still serve fundamentally to improve the efficiency of production processes, either reducing waste and gas emissions or consuming less energy. With this propose, they collaborate to mitigate the harmful effects that production processes have for sustainability and their effects on climate change.

From the results of the analysis of the keywords (Table 7) and the themes identified in the literature (Table 7), several important gaps that could focus the research in the coming years are derived. Then, we list the ten proposals that would be interesting to investigate to shed light on such a crucial issue as sustainability.

4.1. Research Gap 1—Employee Involvement

What is the involvement of employees in the application and proper functioning of the Lean and Six Sigma methodologies? The implementation of any improvement system requires a clear and determined commitment of employees who must apply it. Without this commitment, these systems are bound to fail. In fact, in many cases, companies have great difficulties in maintaining these systems over time, especially when workers resist changes or are not satisfied with their implementation. Therefore, employees’ resilience could be a research line within the topic.

4.2. Research Gap 2—Organizational Culture

What role does organizational culture play? Is it a facilitating element of the application of the Lean and Six Sigma methodologies in order to achieve environmental objectives? Rigid corporate cultures, based on the past inertia and strict supervision, will hardly contribute to the company adopting new practices, new ways of doing things that allow not only improvements in efficiency but, above all, generate positive results in the preservation of the planet and in the fight against climate change. In this sense, to achieve economic, social and environmental sustainability, companies must encourage the active and team participation of their employees in the definition and application of improvements. Properly trained personnel can detect opportunities for improvement and provide solutions in the efficient and sustainable use of resources. On the contrary, barriers and resilience can emerge in the organization.

4.3. Research Gap 3—Knowledge Management

Why is the influence of knowledge management and organizational learning on the implementation of Lean and Six Sigma not mentioned in the articles analyzed? It is obvious that the implementation of these systems to make production processes more sustainable requires a wide and gradual learning process of both employees and the organization as a whole to learn the techniques and methods to take advantage of their use. Besides, this implies knowledge management, either from generating new knowledge within the company and/or from capturing external knowledge, especially from the technical knowledge necessary to adopt new technologies and practices that reduce the effects of the company activity on the environment and global warming.

4.4. Research Gap 4—TMTs

What role do the top management teams (TMTs) play? Why is the application of Lean or Six Sigma addressing sustainability issues not related to the management of change? No articles were found in this regard when we introduced these words into our search engine to build our sample. It seems clear that the use of the Lean and Six Sigma systems means changing the way of carrying out productive activities within the company, especially in those companies that adopt them for the first time. Therefore, leadership is a cornerstone of change, and the commitment of the management team and the board of directors is ineludible. Future research should address this issue.

4.5. Research Gap 5—CSR

What about Corporate Social Responsibility (CSR)? When we did the article search, we introduced a line with these concepts, and the databases only returned one article [52]. It is also surprising that articles linking Lean and Six Sigma solving environmental aspects of production processes are not focusing on the different aspects of corporate social responsibility and their stakeholders. Sustainability is a key aspect of company CSR; so, authors addressing environmental issues in companies could incorporate this vision into their research.

Given the growing awareness in society about different environmental problems (climate change, thawing, desertification, air and sea pollution), consumers are increasingly demanding companies that use green practices and ecological products and services. “Society” appears in cluster #5 as one of the most repeated keywords in our sample. For this reason, companies that really become “green” (i.e., that seriously change their practices, not just marketing campaigns empty of content) can gain competitive advantages in response to socially responsible stakeholders. Consequently, the application of measures and actions to mitigate climate change and other environmental problems is now a strategic issue.

4.6. Research Gap 6—Six Sigma Implementation

As can be seen in Table 1, 95% of the documents found refer to Lean Manufacturing, i.e., the majority of the research that is a reflection of what is happening in the industry is focused on this management philosophy. Second is Six Sigma, followed by Lean Six Sigma and, to a lesser extent, Operational Excellence, all of them far away from Lean. Therefore, the first question is: Why is Lean applied more? Or, why has Six Sigma not got the same interest addressing the problem of climate change? It may be due to several factors. In the first place, Lean Manufacturing allows for adjusting the production processes without using sophisticated statistical techniques, and therefore it is easier, faster and cheaper than Six Sigma. Therefore, companies prefer to use Lean before Six Sigma, which in turn leads to greater academic interest in Lean. The problem is that Lean does not focus on the root problem, which makes Six Sigma more efficient and more sustainable over time.

Second, the characteristics of Lean make it susceptible to be applied for addressing sustainability issues. According to the papers analyzed, it has important effects on the conservation of the environment by reducing waste (i.e., eliminating resources or practices that do not add value) and contributing to the reduction of consumption energy, reducing waste generation, etc. On the other hand, it is more difficult to see the relationship between Six Sigma and environment sustainability. However, the combination of both methodologies presents the greatest potential to achieve a stronger contribution to the preservation of the environment. Therefore, more research implementing Six Sigma or both approaches should be carried out.

4.7. Research Gap 7—Indicators

The well-known Lean and Green relation suggests that companies that use Lean Manufacturing obtain better environmental results compared to companies that do not use this approach. According to the documents analyzed, which use quantitative data, we observe that this is not always true. Lean Manufacturing’s objectives focus on improving production, which can have positive environmental effects with the reduction in resource consumption, but they can also cause negative effects (e.g., more energy consumption for improving product quality).

On the other hand, not all companies use the same indicators to capture environmental effects, which are usually linked to productive activity. Then, the different studies are not comparable either between sectors or within the same sector, and their results are difficult to assess. Consequently, academics and practitioners should agree on methods for measuring Lean and Six Sigma performance and also the environmental indicators valid for any economic activity.

4.8. Research Gap 8—Circular Economy

Even using this word on the search engine, the documents analyzed do not refer to the Circular Economy (only four of them incorporated this concept among their keywords). Why is there so little academic interest in applying Lean and Six Sigma to a circular economic model? Nowadays, it seems crucial for sustainability that companies be more oriented towards the preservation of the environment, not insisting on the application of Linear Economy. However, in fact, throughout recent decades, and especially until the end of the 20th century, while the Lean and Six Sigma tools were being developed, the emphasis was on promoting the Linear Economy, disdainfully disregarding the first serious warnings about climate change. For a long period of time, in the Linear Economy, sustainability was associated with economic growth, applying for this the creation of large production infrastructures put at the service of a growing population of potential clients (around 200,000 people are born every day), convinced that it was the best way to avoid a Malthusian crisis (one that occurs when food resources are clearly insufficient to maintain the population, generating hunger, diseases, and wars that decimate humanity) [53]. In this sense, a high price is currently being paid for the continued use and abuse of natural resources at the service of an economic system incompatible with the conservation and maintenance of the planet and its ecosystems. It is too late to avoid the damage that climate change is causing. However, in the face of a real climatic emergency, actions must be taken to mitigate its effects as much as possible. Civil society must be duly informed of the actual emergency situation, and administrations and politicians must join their best efforts toward the following:

- The global application of Lean Manufacturing techniques, extending to all manufacturing operations. This is a key action to improve the sustainability of the social structure, while substantially reducing greenhouse gas emissions.

- The application of the Six Sigma and Lean Six Sigma methodologies to increasingly complex problems [20] that require deepening the interactions of dependent and independent variables in processes whose variation may cause resource overconsumption, especially important in the case of different energy sources.

- Changing the current paradigm of production of goods and services, encouraging and extending the application of the concept of the Circular Economy, so that it is inexorably and progressively replacing the Linear Economy. The current linear socio-economic system is characterized by discarding products at the end of their useful life, filling the world’s dumps and decomposing nature’s life cycle, which prevents a truly sustainable economic development, focused on the long term. In nature, there are no landfills: All the elements fulfill a function continuously and are reused for use in different stages [54]. The application of Six Sigma and Lean Six Sigma in a Linear Economy leads to the unsustainability of the system since the efficiency improvements achieved in the production processes only serve to encourage massive and runaway consumption, based also on planned obsolescence, exhaustion of natural resources, and filling landfills and seas with waste and plastics. On the contrary, their application to a Circular Economy would produce positive effects on the environment. Companies would be more sustainable since reusing materials reduces obsolescence and allows products to be linked to the real needs and concerns of consumers.

4.9. Research Gap 9—Operational Excellence

As mentioned above, the concept of Operational Excellence (OPEX) appears in very few documents in the sample. This is quite surprising since both Lean Manufacturing and Six Sigma aim precisely to reach the highest levels of excellence in production processes, yet only a few documents are related to OPEX. Then, why is the literature not explicitly related to OPEX? Operational Excellence implies using the company’s total capacity (processes, technology, and human talent) to implement optimization strategies that guarantee the effectiveness of operations and business success. In essence, it consists of doing the right things correctly. As a result, it expects the best technical and financial results, aspects where the Lean Six Sigma approach especially contributes. Moreover, if OPEX is also applied to achieve the best environmental results in the company’s activities, it is surprising that it scarcely appears in the literature that addresses these issues. Surely, the reason is that seeking efficiency in the current Linear Economy does not allow for obtaining environmental excellence.

Consequently, the Operational Excellence model should be aligned towards a Circular Economy. The OPEX model should include the following elements:

- Asset Productivity: Companies must manage their assets, tangible and intangible, to obtain maximum performance and productivity, i.e., they must be used in those tasks where they provide maximum and sustainable use. To achieve this, Lean should be combined with Six Sigma tools.

- Capital Effectiveness: Managers must apply capital resources on investments guaranteeing the obtainment of reductions in the generation of waste, in energy consumption, and in the emission of greenhouse gases. This can only be achieved using Six Sigma.

- Operations Risk Management: Environmental risks must also be included in business management risk. Managers should conduct policies and actions that reduce these risks as much as possible.

- Organizational Development: It is about promoting policies and actions for the development of people working in the organization: Training in environmental issues, improvement of the work environment, and the establishment of teams to address process improvements and to develop solutions to environmental problems caused by the activity of the company, among others.

- Social Corporate Responsibility: Collaboration for climate change mitigation is necessary for a company committed to being socially responsible, and it responds to the demands of stakeholders to protect the interests of the community.

- Industrial Symbiosis: It is about collaborating with other companies (suppliers, distributors, even other sectors and other economic and social agents) to share resources, develop new technologies, coordinate their activities, and thus jointly reduce energy demand and reduce waste generation. Here, the key is to apply the Lean and Six Sigma tools to supply chain management to make it sustainable.

- Extend the Lifetime of Products and Services: We must fight against planned obsolescence since it is the cause of a large part of the waste generated. For this, innovation in products with a longer life cycle, and whose value for the consumer is maintained for long periods, must be encouraged.

- Additive Manufacturing: Reduces the complexity of production processes, simplifying the business value chain. This helps to generate greater productivity of resources and to reduce costs, but also to generate less waste.

- Improved Maintainability and Reparability: In the line proposed by the Circular Economy, consumers should be able to repair damaged or damaged products, to extend their useful life, which would allow for the reduction of current consumerism and the reduction of waste.

- Collaborative Economy: Economic relations based on collaboration between agents located closer to each other should reduce freight transport distances, with energy and emissions savings involved.

4.10. Research Gap 10—Social Impact

From the literature review carried out, it can be seen that the authors focused primarily on analyzing the application of Lean and Six Sigma on improving the efficiency of production processes (economic impact), and how this can also affect the environment in a positive way (environmental impact). These are mostly articles that address technical aspects of production, without considering the organizational and strategic aspects of their application or their use in another context outside the company. Thus, important gaps are observed in the research, e.g., considering the social impact of the application of green actions in production areas. In the analysis of the keywords, the triple bottom line, which includes social, economic and environmental concerns, is related to the Six Sigma cluster. This fact denotes the necessity of further implementing this approach in companies as a tool that can take into account the three pillars of sustainability.

5. Conclusions

This paper highlights the need to use certain tools to help companies and society in general to reduce the amount of energy consumed. Six Sigma can be a solution for improving efficiency and contributing to mitigating the effects of climate change.

The bibliometric analysis carried out shows an increasing academic interest in research regarding improving energy efficiency in industrial processes through the application of Lean and Six Sigma approaches. This demonstrates that process improvement based on error reduction (Six Sigma) and waste reduction (Lean) is being taken into consideration by both academics and practitioners to solve this global problem.

The use of these methodologies, especially Six Sigma, can be seen as an opportunity to contribute to the fight against climate change, which should be part of company corporate social responsibility. However, the commitment of the management is required with a strategic vision and the promotion of an organizational culture with environmental values.

We cannot stop climate change because it is already here. Nor can we mitigate or reverse all harmful effects because it is too late. However, we can slow down the worsening process and thus gain time for our species to adapt to the new circumstances more gradually and effectively. In any case, in the very near future, we will face difficult crossroads, and the only way to get out of them is to use our rational capacity augmented by the power of tools such as Six Sigma.

Natural resources are scarce and, consequently, raw materials are finite, and the volume of waste cannot continue to grow due to serious environmental problems. If we want to leave a habitable planet in inheritance, we must urgently move towards a Circular Economy. It is necessary to encourage governments, companies, and citizens to rethink processes and apply the seven Rs of the Circular Economy: Reduce, reuse, repair, regift, recover, recycle, and redesign.

Despite the contributions of this study, it also has some limitations. The literature review is based on a limited number of databases. We included two important ones, but others such as Google Scholar would increase coverage. On the other hand, by the use of English as a filter, we underestimate researchers who use other languages. VOSviewer establishes by default the number of 5 as a threshold. This fact is a limitation as some information is not taken into consideration, but it allows us to visualize the dataset more clearly. We could modify this number but a large number of keywords would make the figure unreadable. These limitations can be opportunities for further research on this topic.

Author Contributions

All the authors designed the research. The data was collected and analyzed by A.N. and A.V.-S., R.F.-R. contributed to the literature review and supervision. The paper is written by A.N., A.V.-S., and R.F.-R., A.N. reviewed and edit the manuscript. All authors have read and agreed to the published version of the manuscript.

Funding

The study has not received external funding.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Edenhofer, O.; Madruga, R.P.; Sokona, Y.; Seyboth, K.; Matschoss, P.; Kadner, S.; Zwickel, T.; Eickemeier, P.; Hansen, G.; Schlömer, S.; et al. Renewable Energy Sources and Climate Change Mitigation: Special Report of the Intergovernmental Panel on Climate Change; Intergovernmental Panel on Climate Change: Geneva, Swissland, 2011; ISBN 9781139151153. [Google Scholar]

- Abbasi, T.; Abbasi, S. Renewable Energy Sources: Their Impact on Global Warming and Pollution; PHI Learning: New Delhi, India, 2010; ISBN 978-81-203-3994-1. [Google Scholar]

- Kaygusuz, K. Energy for sustainable development: A case of developing countries. Renew. Sustain. Energy Rev. 2012, 16, 1116–1126. [Google Scholar] [CrossRef]

- Anderson, T.R.; Hawkins, E.; Jones, P.D. CO2, the greenhouse effect and global warming: From the pioneering work of Arrhenius and Callendar to today’s Earth System Models. Endeavour 2016, 40, 178–187. [Google Scholar] [CrossRef] [PubMed]

- Dai, A. Increasing drought under global warming in observations and models. Nat. Clim. Chang. 2013, 3, 52–58. [Google Scholar] [CrossRef]

- Ripple, W.J.; Wolf, C.; Newsome, T.M.; Barnard, P.; Moomaw, W.R. World Scientists’ Warning of a Climate Emergency. BioScience 2019, 70, 8–12. [Google Scholar] [CrossRef]

- European Parliament Greenhouse Gas Emissions by Country and Sector (Infographic). Available online: http://www.europarl.europa.eu/news/en/headlines/society/20180301STO98928/greenhouse-gas-emissions-by-country-and-sector-infographic (accessed on 7 October 2019).

- George, M. The Lean Six Sigma Guide to Doing More with Less: Cut Cost, Reduce Waste, and Lower Your Overhead; Wiley & Sons: Hoboken, NJ, USA, 2010; ISBN 978-0-470-53957-6. [Google Scholar]

- Tannenbaun, K. Applying Six Sigma Methodology to Energy-Saving Projects. Available online: https://texasiof.ceer.utexas.edu/texasshowcase/pdfs/casestudies/cs_dow_sixsigma.pdf (accessed on 20 October 2019).

- Pask, F.; Sadhukhan, J.; Lake, P.; McKenna, S.; Perez, E.B.; Yang, A. Systematic approach to industrial oven optimisation for energy saving. Appl. Therm. Eng. 2014, 71, 72–77. [Google Scholar] [CrossRef]

- EPA. The Lean and Energy Toolkit: Achieving Process Excellence Using Less Energy; EPA: Washington, DC, USA, 2007. [Google Scholar]

- Niñerola, A.; Sánchez-Rebull, M.-V.; Hernández-Lara, A.-B. Six Sigma literature: A bibliometric analysis. Total Qual. Manag. Bus. Excell. 2019, 1–22. [Google Scholar] [CrossRef]

- Gershon, M. Choosing which process improvement methodology to implement. J. Appl. Bus. Econ. 2010, 10, 61–69. [Google Scholar]

- Cherrafi, A.; Elfezazi, S.; Chiarini, A.; Mokhlis, A.; Benhida, K. The integration of lean manufacturing, Six Sigma and sustainability: A literature review and future research directions for developing a specific model. J. Clean. Prod. 2016, 139, 828–846. [Google Scholar] [CrossRef]

- Chugani, N.; Kumar, V.; Garza-Reyes, J.A.; Rocha-Lona, L.; Upadhyay, A. Investigating the green impact of Lean, Six Sigma and Lean Six Sigma. Int. J. Lean Six Sigma 2017, 8, 7–32. [Google Scholar] [CrossRef]

- Nadeem, S.P.; Garza-Reyes, J.A.; Anosike, A.I.; Kumar, V. Coalescing the lean and circular economy. Proc. Int. Conf. Ind. Eng. Oper. Manag. 2019, 2019, 1082–1093. [Google Scholar]

- Smith, B. Six Sigma design. IEEE Spectr. 1993, 30, 42–47. [Google Scholar] [CrossRef]

- Frigerio, N.; Matta, A. Analysis of an energy oriented switching control of production lines. Procedia CIRP 2015, 29, 34–39. [Google Scholar] [CrossRef]

- Stewart, R.A.; Spencer, C.A. Six-sigma as a strategy for process improvement on construction projects: A case study. Constr. Manag. Econ. 2006, 24, 339–348. [Google Scholar] [CrossRef]

- Antony, J.; Snee, R.; Hoerl, R. Lean Six Sigma: Yesterday, today and tomorrow. Int. J. Qual. Reliab. Manag. 2017, 34, 1073–1093. [Google Scholar] [CrossRef]

- Dües, C.M.; Tan, K.H.; Lim, M. Green as the new Lean: How to use Lean practices as a catalyst to greening your supply chain. J. Clean. Prod. 2013, 40, 93–100. [Google Scholar] [CrossRef]

- Antony, J. Six Sigma vs Lean: Some perspectives from leading academics and practitioners. Int. J. Product. Perform. Manag. 2011, 60, 185–190. [Google Scholar] [CrossRef]

- Raja Sreedharan, V.; Raju, R. A systematic literature review of Lean Six Sigma in different industries. Int. J. Lean Six Sigma 2016, 7, 430–466. [Google Scholar] [CrossRef]

- De Koning, H.; Verver, J.P.; van den Heuvel, J.; Bisgaard, S.; Does, R.J.M.M. Lean six sigma in healthcare. J. Healthc. Qual. 2006, 28, 4–11. [Google Scholar] [CrossRef]

- Ahmed, S.; Manaf, N.H.A.; Islam, R. Effects of Lean Six Sigma application in healthcare services: A literature review. Rev. Environ. Health 2013, 28, 189–194. [Google Scholar] [CrossRef]

- Mason, S.E.; Nicolay, C.R.; Darzi, A. The use of Lean and Six Sigma methodologies in surgery: A systematic review. Surgeon 2015, 13, 91–100. [Google Scholar] [CrossRef]

- Liu, H.; Jazayeri, E.; Dadi, G.B. Establishing the Influence of Owner Practices on Construction Safety in an Operational Excellence Model. J. Constr. Eng. Manag. 2017, 143. [Google Scholar] [CrossRef]

- Jaeger, A.; Matyas, K.; Sihn, W. Development of an assessment framework for operations excellence (OsE), based on the paradigm change in operational excellence (OE). Procedia CIRP 2014, 17, 487–492. [Google Scholar] [CrossRef]

- Kitchenham, B.; Charters, S. Guidelines for Performing Systematic Literature Reviews in Software Engineering Version 2.3. 2007. Available online: https://userpages.uni-koblenz.de/~laemmel/esecourse/slides/slr.pdf (accessed on 15 December 2019).

- Tranfield, D.; Denyer, D.; Smart, P. Towards a methodology for developing evidence-informed management knowledge by means of systematic review. Br. J. Manag. 2003, 14, 207–222. [Google Scholar] [CrossRef]

- Keathley-Herring, H.; Van Aken, E.; Gonzalez-Aleu, F.; Deschamps, F.; Letens, G.; Orlandini, P.C. Assessing the maturity of a research area: Bibliometric review and proposed framework. Scientometrics 2016, 109, 927–951. [Google Scholar] [CrossRef]

- Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D.G. Preferred reporting items for systematic reviews and meta-analyses: The PRISMA statement. Int. J. Surgey 2010, 8, 336–341. [Google Scholar] [CrossRef] [PubMed]

- VanRaan, A. The use of bibliometric analysis in research performance assessment and monitoring of interdisciplinary scientific developments. Technol. Assess.-Theory Pract. 2003, 1, 20–29. [Google Scholar]

- Hart, S. How green production might sustain the world. ILLAHEE-J. Northwest Environ. 1994, 10, 4–14. [Google Scholar]

- Van Eck, N.J.; Waltman, L. Software survey: VOSviewer, a computer program for bibliometric mapping. Scientometrics 2010, 84, 523–538. [Google Scholar] [CrossRef]

- Van Eck, N.J.; Waltman, L. VOSviewer Manual; Univeristeit Leiden: Leiden, The Netherland, 2017. [Google Scholar]

- Raven, P.; Berg, L.; Hassenzahl, D. Environment; John WILEY & Sons: Jefferson City, MO, USA, 2010. [Google Scholar]

- Kleindorfer, P.R.; Singhal, K.; Van Wassenhove, L.N. Sustainable operations management. Prod. Oper. Manag. 2005, 14, 482–492. [Google Scholar] [CrossRef]

- Corbett, C.J.; Klassen, R.D. Extending the horizons: Environmental excellence as key to improving operations. Manuf. Serv. Oper. Manag. 2006, 8, 5–22. [Google Scholar] [CrossRef]

- Al-dujaili, M.A.A. The Role of Companies in Accomplishing Environmental Sustainability Engineering. Chem. Eng. 2014, 39, 535–540. [Google Scholar]

- Miller, G.; Pawloski, J.; Standridge, C. A case study of lean, sustainable manufacturing. J. Ind. Eng. Manag. 2010, 3, 11–32. [Google Scholar]

- Faulkner, W.; Badurdeen, F. Sustainable Value Stream Mapping (Sus-VSM): Methodology to visualize and assess manufacturing sustainability performance. J. Clean. Prod. 2014, 85, 8–18. [Google Scholar] [CrossRef]

- Brown, A.; Amundson, J.; Badurdeen, F. Sustainable value stream mapping (Sus-VSM) in different manufacturing system configurations: Application case studies. J. Clean. Prod. 2014, 85, 164–179. [Google Scholar] [CrossRef]

- Piercy, N.; Rich, N. The Relationship Between Lean Operations and Sustainable Operations. Int. J. Oper. Prod. Manag. 2015, 35, 282–315. [Google Scholar] [CrossRef]

- Azevedo, S.G.; Carvalho, H.; Duarte, S.; Cruz-Machado, V. Influence of green and lean upstream supply chain management practices on business sustainability. IEEE Trans. Eng. Manag. 2012, 59, 753–765. [Google Scholar] [CrossRef]

- Fahimnia, B.; Sarkis, J.; Eshragh, A. A tradeoff model for green supply chain planning: A leanness-versus-greenness analysis. Omega 2015, 54, 173–190. [Google Scholar] [CrossRef]

- Ugarte, G.M.; Golden, J.S.; Dooley, K.J. Lean versus green: The impact of lean logistics on greenhouse gas emissions in consumer goods supply chains. J. Purch. Supply Manag. 2016, 22, 98–109. [Google Scholar] [CrossRef]

- Ottelin, J.; Heinonen, J.; Junnila, S. Carbon and material footprints of a welfare state: Why and how governments should enhance green investments. Environ. Sci. Policy 2018, 86, 1–10. [Google Scholar] [CrossRef]

- Cai, W.; Lai, K.-H.; Iu, C.; Wei, F.; Ma, M.; Jia, S.; Jiang, Z.; Lv, L. Promoting sustainability of manufacturing industry through the lean energy-saving and emission-reduction strategy. Sci. Total Environ. 2019, 665, 23–32. [Google Scholar] [CrossRef]

- Brindley, C.; Oxborrow, L. Aligning the sustainable supply chain to green marketing needs: A case study. Ind. Mark. Manag. 2014, 43, 45–55. [Google Scholar] [CrossRef]

- Ciccullo, F.; Pero, M.; Caridi, M.; Gosling, J.; Purvis, L. Integrating the environmental and social sustainability pillars into the lean and agile supply chain management paradigms: A literature review and future research directions. J. Clean. Prod. 2018, 172, 2336–2350. [Google Scholar] [CrossRef]

- Ross, J.; Penesis, J.; Badrick, T. Improving laboratory economic and environmental performance by the implementation of an environmental management system. Accredit. Qual. Assur. 2019, 24, 319–327. [Google Scholar] [CrossRef]

- Tellmann, U. Catastrophic populations and the fear of the future: Malthus and the genealogy of liberal economy. Theory Cult. Soc. 2013, 30, 135–155. [Google Scholar] [CrossRef]

- Michelini, G.; Moraes, R.N.; Cunha, R.N.; Costa, J.M.; Ometto, A.R. From linear to circular economy: PSS conducting the transition. Procedia CIRP 2017, 64, 2–6. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).