Global Sourcing in Fast Fashion Retailers: Sourcing Locations and Sustainability Considerations

Abstract

1. Introduction

2. Theoretical Background

2.1. Sustainability in Fashion Supply Chains

2.2. Offshore Outsourcing

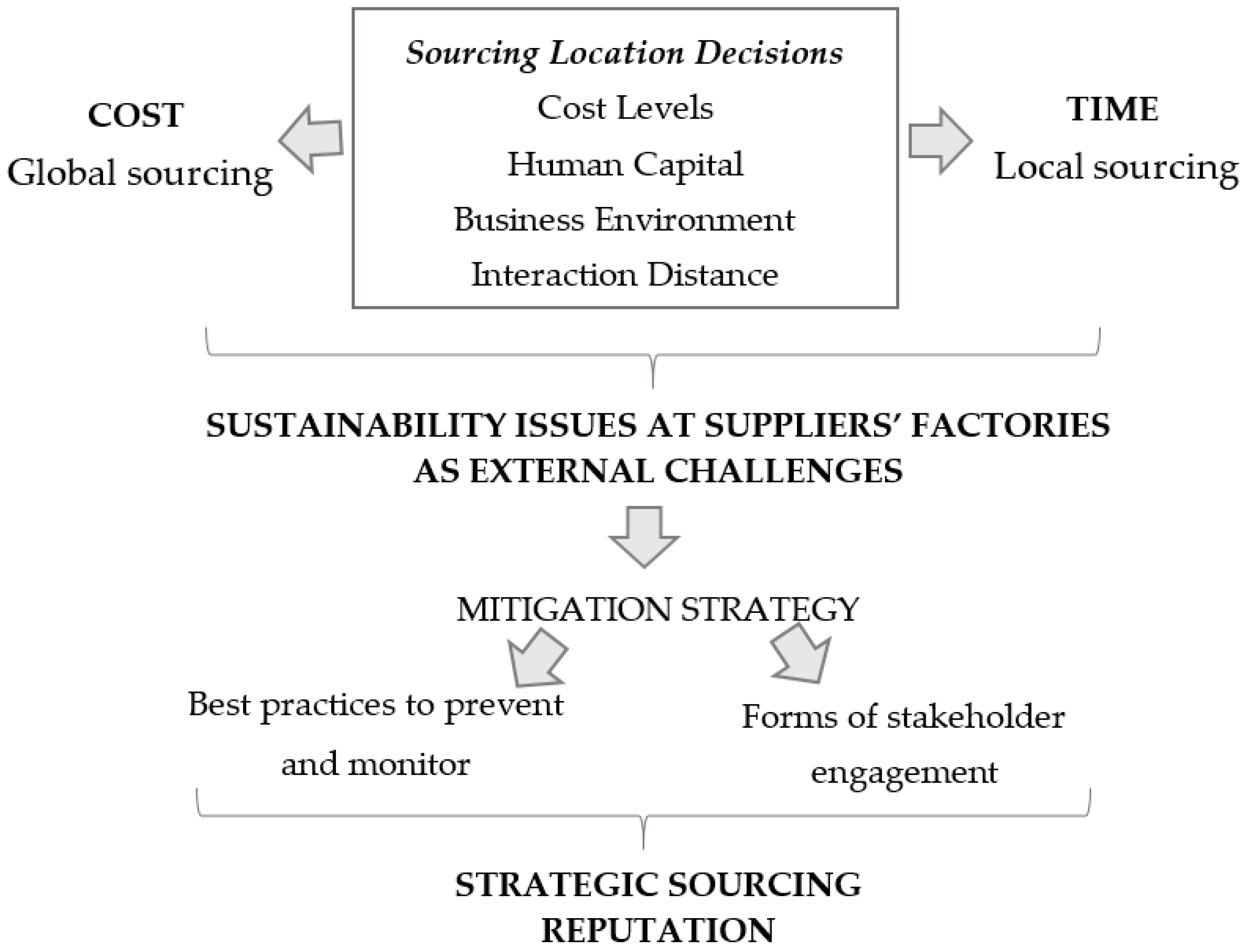

Offshoring Location Decisions

- cost levels (wages, infrastructures costs, and tax and regulations);

- human capital (education, availability);

- business environment (infrastructures, regulations, industrial context, and country risk); and

- interaction distance (geographic, linguistic, and cultural) between onshore and oftion distance (geographic, linguistic, and cultural) between onshore and offshore locations [67].

2.3. Global Sourcing in Fast Fashion Companies

3. A Proposed Theoretical Framework of Sourcing Locations in Fast Fashion Retailers

- Fast fashion retailers hold a low degree of control over the negative effects deriving from offshore suppliers’ sustainability issues in sourcing markets, which can be managed as an external cause and, consequently, the corresponding challenge can be dealt with through forms of stakeholder and local community engagement [61].

- The need to reduce manufacturing costs in order to limit the final price together with the need for fast time to market [30] represent the two main strategic objectives pursued by large fast fashion retailers.

- It can be argued that fast fashion retailers hold sufficient managerial and financial resources to face offshoring challenges.

4. Methodology

- Sample Selection

- Data Collection

5. Results

6. Discussion

7. Conclusions

Funding

Conflicts of Interest

Appendix A

| Retailers | Country | English | Sector |

|---|---|---|---|

| Retailer 1 | Japan | YES | supermarket chain |

| Retailer 2 | Iceland | YES | food |

| Retailer 3 | Usa | YES | high tech |

| Retailer 4 | Netherlands | NO | |

| Retailer 5 | Poland | NO | |

| Retailer 6 | United Arab Emirates | YES | beauty, fashion and gift |

| Retailer 7 | Spain | NO | |

| Retailer 8 | Belgium | YES | food |

| Retailer 9 | Russian Federation | YES | apparel children’s goods |

| Retailer 10 | Taiwan | YES | operation of department stores |

| Retailer 11 Retailer C | Usa | YES | apparel |

| Retailer 12 Retailer B | Sweden | YES | apparel |

| Retailer 13 | Colombia | YES | furniture |

| Retailer 14 | Sweden | YES | food |

| Retailer 15 | Chile | NO | |

| Retailer 16 Retailer A | Spain | YES | apparel |

| Retailer 17 | Japan | YES | electronics |

| Retailer 18 | New Zealand | YES | travel and adventure outdoor apparel |

| Retailer 19 | Finland | YES | food |

| Retailer 20 | United Kingdom | YES | home retailing |

| Retailer 21 | Belgium | NO | |

| Retailer 22 | USA | YES | home retailing |

| Retailer 23 | Peru | NO | |

| Retailer 24 | Greece | YES | food processing |

| Retailer 25 | UK | YES | home, furniture, food, apparel, etc. |

| Retailer 26 | Japan | YES | fashion and accessories |

| Retailer 27 | Switzerland | YES | food processing |

| Retailer 28 | Japan | YES | convenience stores |

| Retailer 29 | Australia | YES | department stores |

| Retailer 30 | Spain | NO | |

| Retailer 31 | Taiwan | NO | |

| Retailer 32 | Taiwan | NO | |

| Retailer 33 | Austria | NO | |

| Retailer 34 | austria | NO | |

| Retailer 35 | Finland | NO | |

| Retailer 36 | USA | YES | merchandise |

| Retailer 37 | Japan | YES | convenience, grocery, clothing stores |

| Retailer 38 | Chile | NO | |

| Retailer 39 | Taiwan | YES | department stores |

| Retailer 40 | Finland | YES | retail trade |

| Retailer 41 | Taiwan | NO | |

| Retailer 42 | Taiwan | NO | |

| Retailer 43 | USA | YES | department stores |

| Retailer 44 | Germany | NO | food processing |

| Retailer 45 | USA | YES | home retailing |

| Retailer 46 | USA | YES | luxury jewellery |

| Retailer 47 | USA | YES | apparel and home fashion |

| Retailer 48 | USA | YES | industrial & construction |

| Retailer 49 | USA | YES | department stores |

| Retailer 50 | MEXICO | YES | department stores |

| Retailer 51 | Australia | YES | department stores |

| Retailer 52 | South Africa | YES | department stores |

| Retailer 53 | Italy | YES | travel retailing |

References

- Javalgi, R.; Dixit, A.; Scherer, R. Outsourcing to emerging markets: Theoretical perspectives and policy implications. J. Int. Manag. 2009, 15, 156–168. [Google Scholar] [CrossRef]

- Kotabe, M.; Mol, M.; Murray, J.Y. An evolutionary stage theory of outsourcing and competence destruction: A triad comparison of the consumer electronics industry. Manag. Int. Rev. 2008, 48, 65–93. [Google Scholar] [CrossRef]

- Liu, Y.; Zhu, Q.; Seuring, S. Linking capabilities to green operations strategies: The moderating role of corporate environmental proactivity. Int. J. Prod. Econ. 2017, 187, 182–195. [Google Scholar] [CrossRef]

- Tate, W.; Ellram, L.M.; Schoenherr, T.M.; Petersen, K.J. Global competitive conditions driving the manufacturing location decision. Bus. Horiz. 2014, 57, 381–390. [Google Scholar] [CrossRef]

- Theyel, G.; Hofmann, K.; Gregory, M. Understanding Manufacturing Location Decision Making: Rationales for Retaining, Offshoring, Reshoring, and Hybrid Approaches. Econ. Dev. Q. 2018, 32, 300–312. [Google Scholar] [CrossRef]

- Emirhüseyinoğlu, G.; Ekici, A. Dynamic facility location with supplier selection under quantity discount. Comput. Ind. Eng. 2019, 134, 64–74. [Google Scholar] [CrossRef]

- Ellram, L.M. Offshoring, reshoring and the manufacturing location decision. J. Supply Chain Manag. 2013, 49, 3. [Google Scholar] [CrossRef]

- Kotabe, M.; Murray, J.Y. Global sourcing strategy and sustainable competitive advantage. Ind. Mark. Manag. 2004, 33, 7–14. [Google Scholar] [CrossRef]

- Freise, M.; Seuring, S. Social and environmental risk management in supply chains: A survey in the clothing industry. Logist. Res. 2015, 8, 2. [Google Scholar] [CrossRef]

- Auke, E.; Simaens, A. Corporate responsibility in the fast fashion industry: How media pressure affected corporate disclosure following the collapse of Rana Plaza. Int. J. Entrep. Innov. Manag. 2019, 23, 356–382. [Google Scholar] [CrossRef]

- Jacobs, B.W.; Singhal, V.R. The effect of the Rana Plaza disaster on shareholder wealth of retailers: Implications for sourcing strategies and supply chain governance. J. Oper. Manag. 2017, 49, 52–66. [Google Scholar] [CrossRef]

- Köksal, D.; Strähle, J.; Müller, M. Social sustainability in apparel supply chains—The role of the sourcing intermediary in a developing country. Sustainability 2018, 10, 1039. [Google Scholar] [CrossRef]

- Jia, P.; Govindan, K.; Choi, T.M.; Rajendran, S. Supplier selection problems in fashion business operations with sustainability considerations. Sustainability 2015, 7, 1603–1619. [Google Scholar] [CrossRef]

- Chowdhury, M.M.H.; Agarwal, R.; Quaddus, M. Dynamic capabilities for meeting stakeholders’ sustainability requirements in supply chain. J. Clean. Prod. 2019, 215, 34–45. [Google Scholar] [CrossRef]

- Sirilertsuwan, P.; Hjelmgren, D.; Ekwall, D. Exploring current enablers and barriers for sustainable proximity manufacturing. J. Fash. Mark. Manag. 2019, 23, 551–571. [Google Scholar] [CrossRef]

- Karaosman, H.; Perry, P.; Brun, A.; Morales-Alonso, G. Behind the runway: Extending sustainability in luxury fashion supply chains. J. Bus. Res. 2018. [Google Scholar] [CrossRef]

- Saeed, M.A.; Kersten, W. Drivers of sustainable supply chain management: Identification and classification. Sustainability 2019, 11, 1137. [Google Scholar] [CrossRef]

- Lee, S.Y.; Klassen, R.D. Drivers and enablers that foster environmental management capabilities in small-and medium-sized suppliers in supply chains. Prod. Oper. Manag. 2008, 17, 573–586. [Google Scholar] [CrossRef]

- Tachizawa, M.E.; Yew Wong, C. Towards a theory of multi-tier sustainable supply chains: A systematic literature review. Supply Chain Manag. Int. J. 2014, 19, 643–663. [Google Scholar] [CrossRef]

- Barnes, L.; Lea-Greenwood, G. Fast fashion in the retail store environment. Int. J. Retail Distrib. Manag. 2010, 38, 760–772. [Google Scholar] [CrossRef]

- Barnes, L.; Lea-Greenwood, G. Fast Fashioning the supply chain: Shaping the research agenda. J. Fash. Mark. Manag. 2006, 10, 259–271. [Google Scholar] [CrossRef]

- Sheridan, M.; Moore, C.; Nobbs, K. Fast fashion requires fast marketing. J. Fash. Mark. Manag. 2006, 10, 301–315. [Google Scholar] [CrossRef]

- Cachon, G.P.; Swinney, R. The value of fast fashion: Quick response, enhanced design, and strategic consumer behavior. Manag. Sci. 2011, 57, 778–795. [Google Scholar] [CrossRef]

- Arrigo, E. Fast fashion business model: An overview. In Handbook of Research on Global Fashion Management and Merchandising; IGI Global: Hershey, PA, USA, 2016; pp. 186–209. [Google Scholar]

- Sull, D.; Turconi, S. Fast fashion lessons. Bus. Strategy Rev. 2008, 19, 4–11. [Google Scholar] [CrossRef]

- Taplin, I.M. Who is to blame? A re-examination of fast fashion after the 2013 factory disaster in Bangladesh. Crit. Perspect. Int. Bus. 2014, 10, 72–83. [Google Scholar] [CrossRef]

- Bruce, M.; Daly, L.; Towers, N. Lean or agile: A solution for supply chain management in the textiles and clothing industry? Int. J. Oper. Prod. Manag. 2004, 24, 151–170. [Google Scholar] [CrossRef]

- Christopher, M.; Peck, H.; Towill, D.R. A taxonomy for selecting global supply chain strategies. Int. J. Logist. Manag. 2006, 17, 277–287. [Google Scholar] [CrossRef]

- Tokatli, N. Global sourcing: Insights from the global clothing industry—The case of Zara, a fast fashion retailer. J. Econ. Geogr. 2008, 8, 21–38. [Google Scholar] [CrossRef]

- Bruce, M.; Daly, L. Buyer behaviour for fast fashion. J. Fash. Mark. Manag. 2006, 10, 329–344. [Google Scholar] [CrossRef]

- Tate, W.; Ellram, L.; Bals, L.; Hartmann, E. Offshore outsourcing of services: An evolutionary perspective. Int. J. Prod. Econ. 2009, 120, 512–524. [Google Scholar] [CrossRef]

- Ndubisi, N.O.; Nygaard, A. The ethics of outsourcing: When companies fail at responsibility. J. Bus. Strategy 2018, 39, 7–13. [Google Scholar] [CrossRef]

- Kano, L. Global value chain governance: A relational perspective. J. Int. Bus. Stud. 2018, 49, 684–705. [Google Scholar] [CrossRef]

- Fine, C. Intelli-Sourcing to Replace Offshoring as Supply Chain Transparency Increases. J. Supply Chain Manag. 2013, 49, 6–7. [Google Scholar] [CrossRef]

- Weber, R.P. Basic Content Analysis; Sage: Newbury Park, CA, USA, 1980. [Google Scholar]

- Krippendorff, K. Content analysis. In International Encyclopedia of Communication; Barnouw, E., Gerbner, G., Schramm, W., Worth, T.L., Gross, L., Eds.; Oxford University Press: New York, NY, USA, 1989; Volume 1, pp. 403–407. [Google Scholar]

- Krippendorff, K. Content Analysis: An Introduction to Its Methodology; Sage Publications: London, UK, 2012. [Google Scholar]

- Schreier, M. Qualitative Content Analysis in Practice; Sage Publications: London, UK, 2012. [Google Scholar]

- Finfgeld-Connett, D. Use of content analysis to conduct knowledge-building and theory-generating qualitative systematic reviews. Qual. Res. 2014, 14, 341–352. [Google Scholar] [CrossRef]

- Caro, F.; Martinez-De-Albeniz, V. Fast fashion: Business model overview and research opportunities. In Retail Supply Chain Management: Quantitative Models and Empirical Studies, 2nd ed.; Agrawal, N., Smith, S.A., Eds.; Springer: New York, NY, USA, 2014. [Google Scholar]

- Shen, B.; Li, Q.; Dong, C.; Perry, P. Sustainability issues in textile and apparel supply chains. Sustainability 2017, 9, 1592. [Google Scholar] [CrossRef]

- Karaosman, H.; Morales-Alonso, G.; Brun, A. From a systematic literature review to a classification framework: Sustainability integration in fashion operations. Sustainability 2017, 9, 30. [Google Scholar] [CrossRef]

- Caniato, F.; Caridi, M.; Crippa, L.; Moretto, A. Environmental sustainability in fashion supply chains: An exploratory case based research. Int. J. Prod. Econ. 2012, 135, 659–670. [Google Scholar] [CrossRef]

- Kim, H.; Jung Choo, H.; Yoon, N. The motivational drivers of fast fashion avoidance. J. Fash. Mark. Manag. Int. J. 2013, 17, 243–260. [Google Scholar] [CrossRef]

- Kaikobad, N.K.; Bhuiyan, M.Z.A.; Sultana, F.; Rahman, M. Fast fashion: Marketing, recycling and environmental issues. Int. J. Humanit. Soc. Sci. Invent. 2015, 4, 2319–7714. [Google Scholar]

- Pedersen, E.R.G.; Andersen, K.R. Sustainability innovators and anchor draggers: A global expert study on sustainable fashion. J. Fash. Mark. Manag. 2015, 19, 315–327. [Google Scholar] [CrossRef]

- Missimer, M.; Robèrt, K.H.; Broman, G. A strategic approach to social sustainability—Part 2: A principle-based definition. J. Clean. Prod. 2017, 140, 42–52. [Google Scholar] [CrossRef]

- Edgeman, R.; Neely, A.; Eskildsen, J.; Kozlowski, A.; Searcy, C.; Bardecki, M. Corporate sustainability reporting in the apparel industry. Int. J. Product. Perform. Manag. 2015, 64, 377–397. [Google Scholar]

- Seuring, S.; Müller, M. From a literature review to a conceptual framework for sustainable supply chain management. J. Clean. Prod. 2008, 16, 1699–1710. [Google Scholar] [CrossRef]

- Carter, C.R.; Liane Easton, P. Sustainable supply chain management: Evolution and future directions. Int. J. Phys. Distrib. Logist. Manag. 2011, 41, 46–62. [Google Scholar] [CrossRef]

- Brown, G. Bangladesh: Currently the worst, but possibly the future’s best. New Solut. J. Environ. Occup. Health Policy 2015, 24, 469–473. [Google Scholar] [CrossRef]

- Tayles, M.; Drury, C. Moving from Make/Buy to strategic sourcing: The outsource decision process. Long Range Plan. 2001, 34, 605–622. [Google Scholar] [CrossRef]

- Trent, R.J.; Monczka, R.M. Understanding integrated global sourcing. Int. J. Phys. Distrib. Logist. Manag. 2003, 33, 607–629. [Google Scholar] [CrossRef]

- Coe, N.; Dicken, P.; Hess, M. Global production networks realizing potential. J. Econ. Geogr. 2008, 8, 271–295. [Google Scholar] [CrossRef]

- Bals, L.; Jensen, P.D.Ø.; Larsen, M.M.; Pedersen, T. Exploring layers of complexity in offshoring research and practice. In The Offshoring Challenge: Strategic Design and Innovation for Tomorrow’s Organization; Pedersen, T., Bals, L., Jensen, P.D.O., Larsen, M.M., Eds.; Springer: London, UK, 2013; pp. 1–18. [Google Scholar]

- Mehrjoo, M.; Pasek, Z.J. Risk assessment for the supply chain of fast fashion apparel industry: A system dynamics framework. Int. J. Prod. Res. 2016, 54, 28–48. [Google Scholar] [CrossRef]

- Manuj, I.; Mentzer, J.T. Global supply chain risk management strategies. Int. J. Phys. Distrib. Logist. Manag. 2008, 38, 192–223. [Google Scholar] [CrossRef]

- Vidal, C.J.; Goetschalcks, M. Strategic production-distribution models: A critical review with emphasis on global supply chain models. Eur. J. Oper. Res. 1997, 98, 1–18. [Google Scholar] [CrossRef]

- Larsen, M.M.; Manning, S.; Pedersen, T. Uncovering the hidden costs of offshoring: The interplay of complexity, organizational design, and experience. Strateg. Manag. J. 2013, 34, 533–552. [Google Scholar] [CrossRef]

- Hines, T. Supply Chain Strategies, Structures and Relationships. In Fashion Marketing Contemporary Issues; Hines, T., Bruce, M., Eds.; Elsevier: Amsterdam, The Netherlands, 2007. [Google Scholar]

- Manning, S. Mitigate, tolerate or relocate? Offshoring challenges, strategic imperatives and resource constraints. J. World Bus. 2014, 49, 522–535. [Google Scholar] [CrossRef]

- Kocabasoglu, C.; Suresh, N.C. Strategic sourcing: An empirical investigation of the concept and its practices in US manufacturing firms. J. Supply Chain Manag. 2006, 42, 4–16. [Google Scholar] [CrossRef]

- Eltantawy, R.; Giunipero, L.; Handfield, R. Strategic sourcing management’s mindset: Strategic sourcing orientation and its implications. Int. J. Phys. Distrib. Logist. Manag. 2014, 44, 768–795. [Google Scholar] [CrossRef]

- Porter, M. The Competitive Advantage of Nations; Free Press: New York, NY, USA, 1990. [Google Scholar]

- Dunning, J.H.; Narula, R. The investment development path revisited: Some emerging issues. In Foreign Direct Investment and Governments: Catalysts for Economic Restructuring; Dunning, J.H., Narula, R., Eds.; Routledge: London, UK, 1996; pp. 1–41. [Google Scholar]

- Kogut, B. International management and strategy. In Handbook of Strategy and Management; Pettigrew, A.M., Thomas, H., Whittington, R., Eds.; Sage: London, UK, 2002; pp. 261–278. [Google Scholar]

- Jensen, P.D.O.; Pedersen, T. The economic geography of offshoring: The fit between activities and local context. J. Manag. Stud. 2011, 48, 352–372. [Google Scholar] [CrossRef]

- Tate, W.L. Offshoring and reshoring: U.S. insights and research challenges. J. Purch. Supply Manag. 2014, 20, 66–68. [Google Scholar] [CrossRef]

- Mihm, B. Fast fashion in a flat world: Global sourcing strategies. Int. Bus. Econ. Res. J. 2010, 9, 55–63. [Google Scholar] [CrossRef]

- Doyle, S.A.; Moore, C.M.; Morgan, L. Supplier management in fast moving fashion retailing. J. Fash. Mark. Manag. 2006, 10, 272–281. [Google Scholar] [CrossRef]

- Ellram, L.M. The supplier selection decision in strategic partnerships. J. Supply Chain Manag. 1990, 26, 8. [Google Scholar] [CrossRef]

- De Boer, L.; Labro, E.; Morlacchi, P. A review of methods supporting supplier selection. Eur. J. Purch. Supply Manag. 2001, 7, 75–89. [Google Scholar] [CrossRef]

- Ho, W.; Xu, X.; Dey, P.K. Multi-criteria decision making approaches for supplier evaluation and selection: A literature review. Eur. J. Oper. Res. 2010, 202, 16–24. [Google Scholar] [CrossRef]

- Bhutta, K.S.; Huq, F. Supplier selection problems: A comparison of the total cost of ownership and analytic hierarchy process approaches. Supply Chain Manag. Int. J. 2002, 7, 126–135. [Google Scholar] [CrossRef]

- Guercini, S.; Runfola, A. Sourcing strategies in clothing retail firms: Product complexity versus overseas supply chain. J. Cust. Behav. 2004, 3, 305–334. [Google Scholar] [CrossRef]

- Morris, R. Computerized content analysis in Management Review: A demonstration of Advantages & Limitations. J. Manag. 1994, 20, 903–931. [Google Scholar]

- Turker, D.; Altuntas, C. Sustainable supply chain management in the fast fashion industry: An analysis of corporate reports. Eur. Manag. J. 2014, 32, 837–849. [Google Scholar] [CrossRef]

- Graneheim, U.H.; Lindgren, B.M.; Lundman, B. Methodological challenges in qualitative content analysis: A discussion paper. Nurse Educ. Today 2017, 56, 29–34. [Google Scholar] [CrossRef]

- Indulska, M.; Hovorka, D.S.; Recker, J. Quantitative approaches to content analysis: Identifying conceptual drift across publication outlets. Eur. J. Inf. Syst. 2012, 21, 49–69. [Google Scholar] [CrossRef]

- Finfgeld-Connett, D.; Johnson, E.D. Literature search strategies for conducting knowledge-building and theory-generating qualitative systematic reviews. J. Adv. Nurs. 2013, 69, 194–204. [Google Scholar] [CrossRef]

- Comai, G. Quantitative Analysis of Web Content in Support of Qualitative Research. Examples from the Study of Post-Soviet De Facto States. Stud. Transit. States Soc. 2017, 9, 14–34. [Google Scholar]

- Riff, D.; Lacy, S.; Fico, F.; Watson, B. Analyzing Media Messages: Using Quantitative Content Analysis in Research; Routledge: London, UK, 2019. [Google Scholar]

- Global Reporting Initiative (GRI) Database. 2019. Available online: http://database.globalreporting.org (accessed on 10 October 2019).

- Corbin, J.; Strauss, A. Techniques and Procedures for Developing Grounded Theory. In Basics of Qualitative Research, 3rd ed.; Sage: Thousand Oaks, CA, USA, 2008. [Google Scholar]

- Berg, A.; Berlemann, B.; Hedrich, S.; Magnus, K.H.; Mathews, B.; Russo, B. Sourcing in a volatile world. In The East Africa Opportunity; McKinsey Report; McKinsey: London, UK, 2015. [Google Scholar]

- Best Global Retailers. 2019. Available online: www.deloitte.com (accessed on 15 July 2019).

- Best Global Brands Ranking. 2019. Available online: www.interbrand.com (accessed on 15 July 2019).

| % Cost-Related Content | % Time-Related Content | % Sustainability-Related Content | |

|---|---|---|---|

| Retailer A | 2.38 | 0.60 | 25.61 |

| Retailer B | 1.91 | 1.02 | 10.66 |

| Retailer C | 1.09 | 0.69 | 10.59 |

| Manufacturing | Sourcing Countries | % Local Sourcing | % Global Sourcing | Number of Suppliers and Factories | % Suppliers by Geographical Area | Sourcing Organization | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2014 | 2018 | 2014 | 2018 | 2014 | 2018 | 2014 | 2018 | 2014 | 2018 | 2014 | 2018 | ||

| Retailer A | 50% in-house, 50% outsourced | 50 countries (Europe, Africa, America, and Asia) | 43 countries (Europe, Africa, America and Asia) | 55% | 57% | 45% | 43% | 1625 suppliers and 5382 production factories | 1866 suppliers and 7235 factories | 40% Europe, 46.7% Asia, 8.3% Africa, 4.9% America | 35% Europe, 64% Asia and Africa, 1% USA | 10 supplier clusters | 12 clusters with Social Sustainability Teams |

| Retailer B | Totally outsourced | 27 countries (EMEA, South Asia, Far East) | 42 countries (EMEA, South Asia, Far East, Africa) | Less than 1% | 2% | 99% | 98% | 850 suppliers connected to 1926 factories | 840 suppliers connected to about 1800 factories | 25.3% EMEA, 30.7% South Asia, 44% Far East | 23.9% EMEA, 30.3% South Asia, 44.3% Far East, 1.5% Africa | 21 locally-based production offices in Europe, Asia, and Africa | A production office in every sourcing country |

| Retailer C | Totally outsourced | Greater China (27%), South Asia, South East Asia | 40 countries (Greater China, South Asia, South East Asia) | 2% | 0% | 98% | 100% | 300 suppliers and 1107 factories | 700 vendors connected to about 774 factories | Greater China (27%), South Asia + Southeast Asia (62%), Row (11%) | Greater China (26%), South Asia + Southeast Asia (67%), America (5%), Row (2%) | Three top sourcing regions, sourcing teams | Sourcing Teams |

| 2011 | 2012 | 2013 | 2014 | 2015 | 2016 | 2017 | 2018 | |

|---|---|---|---|---|---|---|---|---|

| Retailer A | ||||||||

| EMEA | 41% | 41% | 41% | 40% | 40% | 37% | 35% | 35% |

| Asia | 46% | 47% | 46% | 47% | 48% | 52% | 54% | 56% |

| America | 4% | 5% | 5% | 5% | 4% | 4% | 3% | 1% |

| Africa | 9% | 8% | 8% | 8% | 8% | 8% | 8% | 8% |

| Tot Suppliers | 1490 | 1434 | 1592 | 1625 | 1725 | 1805 | 1824 | 1866 |

| Retailer B | ||||||||

| EMEA | 29% | 26% | 23% | 25% | 25% | - | - | 24% |

| South Asia | 29% | 31% | 32% | 31% | 32% | - | - | 30% |

| Far East | 42% | 43% | 45% | 44% | 43% | - | - | 44% |

| Africa | 0% | 0% | 0% | 0% | 0% | - | - | 2% |

| Tot Suppliers | 747 | 785 | 872 | 850 | 820 | - | - | 842 |

| Retailer C | ||||||||

| Sourcing countries | 50 | 40 | 40 | 40 | 40 | 40 | 50 | 40 |

| China | 27% | 26% | 28% | 27% | 24% | 23% | 22% | 21% |

| Vietnam | - | - | - | - | - | 25% | 25% | 28% |

| Local sourcing | 2% | 2% | 2% | 2% | 1% | 0 | 0 | 0 |

| Tot Suppliers | 1020 | 1000 | 1000 | 1000 | 1000 | 800 | 800 | 700 |

| Supplier Categorization and Rating | Supplier Selection and Management | Best Practices | Forms of Stakeholder Engagement | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Retailer A | 2014 | 2015 | 2016 | 2017 | 2018 | Compliance to Code of Conduct for Manufacturers and Suppliers, initial assessment and others over time through audits | Audit teams to verify compliance to Code of Conduct; classroom training for suppliers; management systems for the supply chain traceability; Implementation of the Strategic Plan for Stable and Sustainable Supply Chain 2014-2018 Workers at the centre Programmes Work In Supplier Clusters. | Global Framework Agreement with IndustriALL Global Union and alliances with the International Labour Organization (ILO), the UN Global Compact and Better Than Cash Alliance. Participation in ACT (Action, Collaboration, Transformation), the Ethical Trading Initiative and the Bangladesh Accord | |

| Five categories. Strategic suppliers (A+B) are responsible for 93% of total production in 2014 and 96% in 2018 | A | 42% | 42% | 38% | 36% | 35% | |||

| B | 43% | 46% | 51% | 53% | 56% | ||||

| C | 8% | 7% | 5% | 5% | 4% | ||||

| CAP | 3% | 2% | 3% | 4% | 3% | ||||

| Rejected | 4% | 3% | 3% | 2% | 2% | ||||

| Retailer B | 2014 | 2015 | 2016 | 2017 | 2018 | Compliance to Code of Conduct, initial assessment and others over time through audits, Individual meetings, 130 sustainability experts. | Full Audit Programme (FAP), Index Code of Conduct (ICoC), anonymous supplier surveys, close relations and constant dialogue with business partners, monitoring, assessment, training, reporting. | Several Partnerships with (among others): Better Cotton Initiative (BCI), Sustainable Apparel Coalition (SAC), Fair Labor Association (FLA), Fair Wage Network (FWN), Better Work, International Labour Organisation (ILO), UNI Global Union, WWF, Ethical Trading Initiative (ETI), Fair wage network (FWN). | |

| Four categories. Strategic suppliers (platinum+gold) responsible of 60% of total production in 2014 and 2018 | Platinum | - | - | - | 1.28% | ||||

| Gold | - | - | - | - | 16.27% | ||||

| Silver | - | - | - | - | 52.26% | ||||

| Other | - | - | - | - | 30.19% | ||||

| Retailer C | 2014 | 2015 | 2016 | 2017 | 2018 | Compliance to Code of Vendor Conduct (COVC). Assessments and development of a country-specific approach to assessing risk and improving work in factories | Sourcing teams & sustainability teams; assessing & approving factories; training; compliance with Code of Vendor Conduct; Better Program for monitoring factories; visits; interviews; factory rating. | Partnerships with: Verité, Alliance for Bangladesh Worker Safety, Better Work’s Workplace Cooperation Program, Project on Sustainable Labor Practices in Global Supply Chains, International Labor Organization (ILO) Cornell Project on Sustainable Labor Practices, Life and Building Safety Initiative (LABS). | |

| Three categories. Strategic suppliers (green + yellow) represent 84% of suppliers in 2014 and 98% in 2018 | Green | 12.2% | 42.3% | 35% | 36.9% | 38.6% | |||

| Yellow | 36.2% | 39.2% | 48.9% | 58.1% | 59.4% | ||||

| Red | 18.7% | 18.5% | 16% | 5% | 1.8% | ||||

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arrigo, E. Global Sourcing in Fast Fashion Retailers: Sourcing Locations and Sustainability Considerations. Sustainability 2020, 12, 508. https://doi.org/10.3390/su12020508

Arrigo E. Global Sourcing in Fast Fashion Retailers: Sourcing Locations and Sustainability Considerations. Sustainability. 2020; 12(2):508. https://doi.org/10.3390/su12020508

Chicago/Turabian StyleArrigo, Elisa. 2020. "Global Sourcing in Fast Fashion Retailers: Sourcing Locations and Sustainability Considerations" Sustainability 12, no. 2: 508. https://doi.org/10.3390/su12020508

APA StyleArrigo, E. (2020). Global Sourcing in Fast Fashion Retailers: Sourcing Locations and Sustainability Considerations. Sustainability, 12(2), 508. https://doi.org/10.3390/su12020508