The main result of this research is the proposal of an ANN-based procedure to be used in the early design stages of structural materials and elements. In order to guarantee that the designed ANNs are reliable tools, a validation of the network is also required. In the following subsection, the ANN input and the design, selection, and validation procedure are described and explained in detail.

3.1. The FEM Model as ANN Input

As indicated previously, some of the parameter combinations are used in the ANN learning process. If all the combinations were used, the network does not learn; in fact, it only would provide the given data. In ANN design, the learning stage is carried out with a representative sample, and the validation is performed by using data that have not been applied in the learning stage. Once the validation is done, the network will be ready to use.

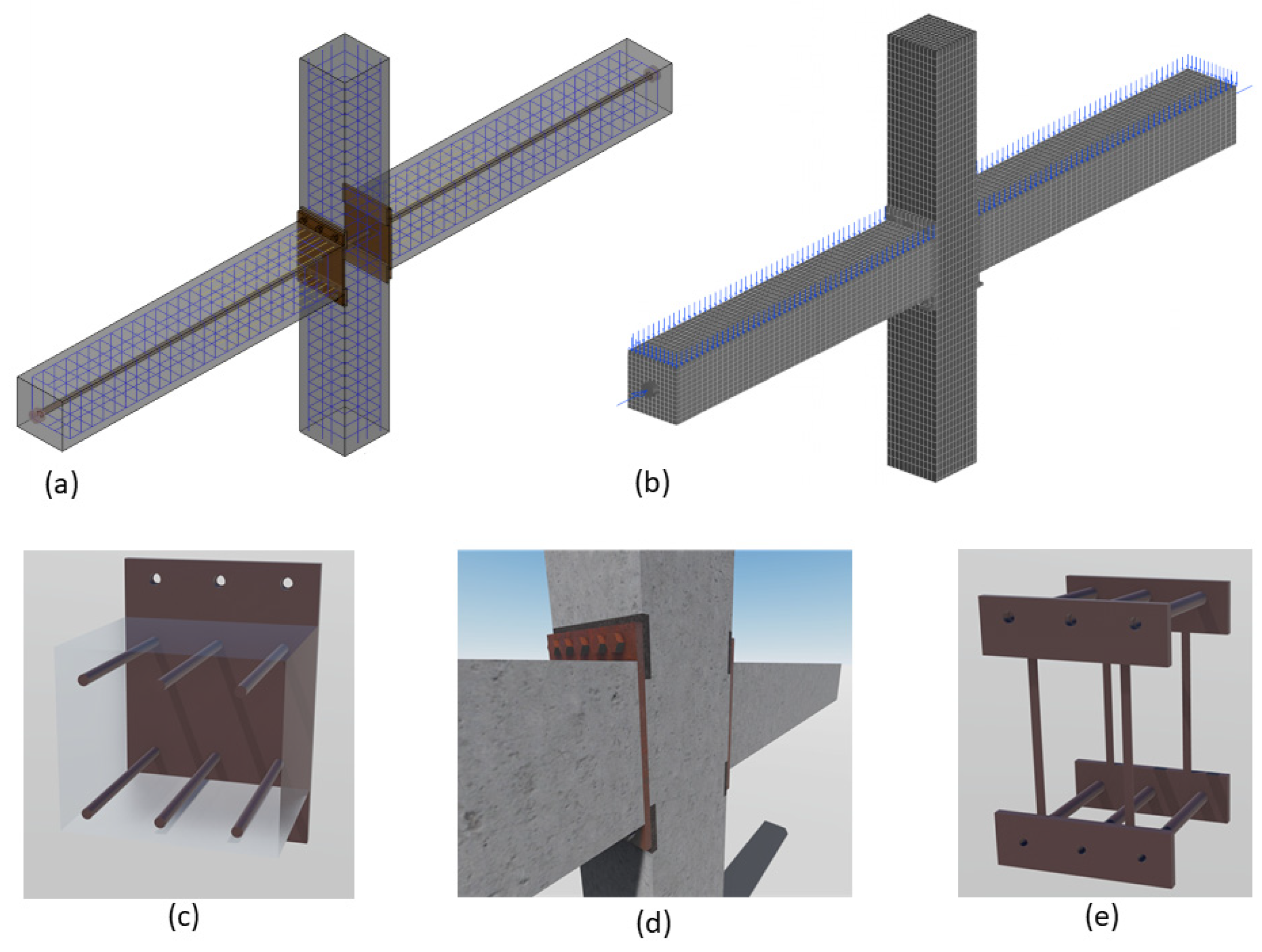

For the input learning process, the FEM model, as described in

Section 2 (description of the case study), has been implemented. The parametric calculations have been carried out by using different values of the variables (

Section 2).

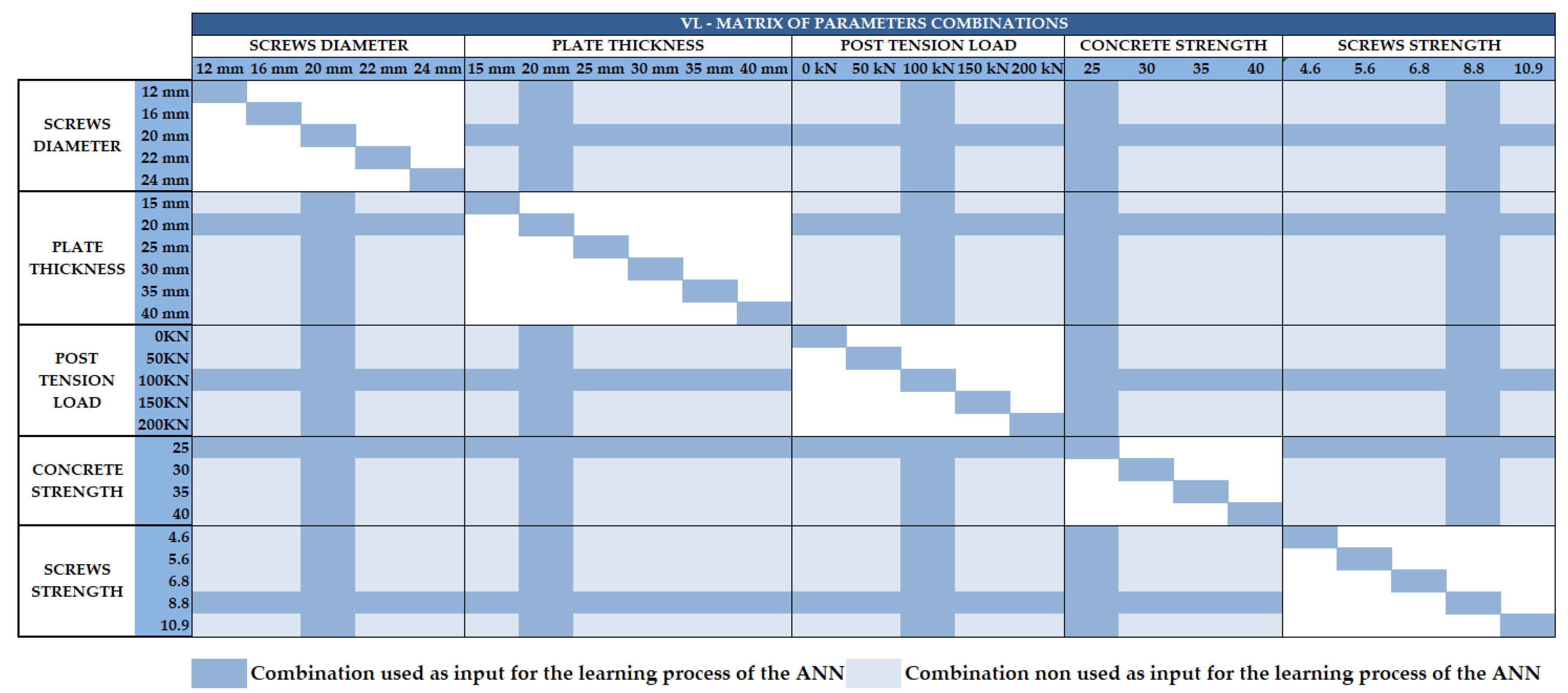

Figure 3 summarizes the parameter combinations and those used in the learning process.

A main concern is to perform a proper selection of the learning process data. For this reason, in this research, the selected sample is representative of all the possible variables, but it is taken into account that most of the parameters (plate thickness, screw diameter and strength, and concrete strength) are not continuous, as they are normalized and standardized discrete industrial values; for instance, screw diameters are 12, 16, 20 mm, etc., but no decimal values are used. The only continuous value could be the post-tensioning load. However, following the actual practice in construction works, common discrete values are also selected for the PT-Load. The number of variables includes the design variables defined in

Section 2.2 and provided in

Figure 3: (i) six for the plate thickness (15, 20, 25, 30, 35, and 40 mm), (ii) five for the screw diameter (12, 16, 20, 22, and 24 mm), (iii) five for the PT-Load (0, 50, 100, 150, and 200 kN), (iv) four for the concrete strength (25, 30, 35, and 40 MPa), and (v) five for the screw resistance (4.6, 5.6, 6.8, 8.8, and 10.9). Once a variable set has been chosen and fixed, one of them within the set is varied along its range. For instance, keeping the rest of variables fixed (screw diameter, PT-Load, concrete strength, and screw resistance with a fixed value), results will be obtained by varying the sheet metal thickness from 12, 16, 20, 22, and 24 mm, using the results as input for the learning step. That process is repeated with the other variables. For each variable value variation, an FEM model has been built and the numerical data are obtained step by step. This procedure provides a reliable input (2 million units of data), as the ANNs can learn the relationship between stresses in different elements when a parameter is modified, but also the relationships when other parameters are selected.

For each FEM model, an increasing value of the load has been applied over the beam surface. The vertical deformation and nodal stress values have been recorded step by step for each node. All the steps (including the intermediate ones) from the initial and the final stage have been analyzed and saved to be used as input for the learning process. The recorded data have relevant implicit information, as the relationships between stresses and deformations in adjacent nodes are considered in the FEM analysis.

In the combinations that have been used as input, the parameters are recorded in each sub-step of the FEM numerical model, as shown in

Table 2. In each combination, the followed structure is the same for all the files in order to allow for an adequate reading and operation for the ANNs. The columns include the step and node number for an easy identification in the numerical model, as well as the material stresses, where

and

are the concrete stress in the X and Y directions, V

xy and V

xz are the concrete shear stress along the XY and XZ planes, respectively, and

is the Von Misses stress in the steel elements.

3.2. Implementation of the ANNs: Design and Selection of the ANN Models

In this research, four different ANNs have been designed, one per each element: beams, plates, post-tensioning tendon (PT), and screws. The same ANN that has been modelled for the beam could be used to predict column stresses. It is worth mentioning that the column nodes have not been studied because the stresses in the column nodes are lower than those of beams, and no relevant results would be provided.

In the ANN design, a key factor is to obtain a network that is as simple as possible and that does not include non-relevant data. It is worth highlighting that all the information that is provided in FEM model calculations would be high enough to make the network unfeasible.

In this work, as the FEM model implicitly takes into account the strain–stress relation, it is possible to eliminate or neglect the node position, as well as the relation among nodes. The main goal is to predict when a network element is going to collapse. Thus, the network can be dimensioned. Once each element is analyzed for both materials (concrete and steel), the main interest is locating the most loaded node step by step, and comparing it with its limit value. In this way, the network learns the stress increase that is produced by the elements, and that depends on the applied load. Thus, a network for each different element allows for predicting the stress field. Additionally, the designed network learns how a parameter variation influences the stress path (e.g., changing the concrete or screw strengths). Therefore, the network can be applied to any parametric change (e.g., an increase in the structural element dimensions). Moreover, it does not depend on the number of nodes of the numerical model. In the case of not having made the simplification, the number and name of each node should be kept. In this way, a main concern is to be clear on the required data and how to locate them.

The initial stage of the ANN design consists of defining the network architecture. The most common neural networks include an input layer, a hidden layer, and an output layer, as this is enough to solve most problems [

17]. In this research, all the ANNs have the same basic structure: a multilayer perceptron developed in C# by using Visual Studio community 2019 [

34]. A simple backpropagation algorithm is implemented [

3]. The input layer has six neurons that are the input variables: steps, screw diameter, concrete strength, screw strength, PT-Load, and plate thickness (

Figure 3). Regarding the hidden layers, it is worth noting that, in general, one hidden layer is sufficient. However, when the number of neurons in a single layer increases, the predictive efficiency does not increase, and for complex problems, two hidden layers could be required [

10,

17]. After a trial-and-error stage with one hidden layer and with a neuron number increase, the networks do not converge. For that reason, two hidden layers are required to obtain a faster and better convergence. The number of neurons in the hidden layer depends on the complexity of the ANN, including the number of inputs and outputs or input variable continuity [

35]. A minimum number of neurons is required to minimize the output error and to reduce the learning process, but the stability of the network must be guaranteed. The two hidden layers have different neurons depending on the complexity of the calculation and on the dispersion of the input data. The output layer has only one neuron, which is the maximum prediction stress in any element node.

Figure 4 depicts the ANN configuration scheme.

In the definition of the ANN topology, a trial-and-error process is required at different stages ([

13,

17,

35,

36,

37,

38]): (i) in the definition of neurons in the hidden layers, (ii) in the testing and learning process, and (iii) in the selection of the random weights. Those trial-and-error procedures make it possible to establish a suitable and stable network. Trial and error may be extended to building several networks, stopping and testing them at different stages of learning, and initializing the network with different random weights. Each network must be tested and analyzed, and the most appropriate network must be chosen in each project. In this research, the followed process required trial-and-error iterations on each network to obtain both good convergence and stability. The numbers of neurons in the hidden layers were gradually increased to reach convergence, and the structure of each ANN is the minimum required to reach that objective. The final configuration and parameters of the designed ANNs are summarized in

Table 3.

Due to the field variability of the nodal stress in plates and beams (tensions and compressions are located simultaneously in the element, as well as the sign variation along steps), the ANNs require extra hidden layers to guarantee good convergence.

For a better understanding of the ANN configuration, a flowchart of the ANN algorithm is provided in

Figure 5.

One of the main advantages of implementing the use of ANNs within the structural material design stage is the significant decrease in the required computing time if compared to conventional FEM analyses (e.g., those exclusively performed via FEM). Indeed, once the ANN has learned, the estimation is immediately provided for any new configuration. In this study, the time consumed in the learning process was 16 hours for each ANN, using approximately 1.8 million iterations.

The proposed ANN predicts the stiffness matrix solved in the FEM model, providing the maximum expected nodal stress for each element: plates, screws, beams, or tendons. It is worth noting that solving that matrix is one of the most time-consuming steps in FEM analyses. Moreover, the computing time increases exponentially in nonlinear analyses. The data prediction is immediately provided according to the applied input and for any surface loading value applied on the upper face of the beam. In addition, the ANN can solve the nonlinear behavior (in terms of both material and geometry) of the designed connection.

Each step from the FEM model has a direct relationship with the load applied, so an implicit relation between the applied load and the element stresses could be easily obtained (step = load).

3.3. ANN Validation

In the ANN validation, 1.8 million entries have been used. Those entries are distributed in 40 files by randomly varying the parameters. Ten additional numerical calculations have been performed, comparing the elements of the FEM results to the ANN prediction step by step. The parameters that have been applied in the validation are summarized in

Table 4. In the selection procedure, a random variation of the parameters has been applied. After that procedure, the FEM model is updated, and the results are compared with those predicted by the ANN.

The maximum and average errors in the learning process are assessed by comparing the actual stress value with the curve of adjustment that the ANN provides.

Table 5 summarizes the average nodal stress error in all the steps and sub-steps. The maximum difference, in percentage, between the actual and the predicted stresses is also provided in every node for all the steps and sub-steps. The average error value would be monotonically reduced with the same input in case more iterations were done in the learning process. However, there is a point where its reduction after many iterations is negligible, that is, it becomes asymptotic. If more entries were used, a new learning process would be necessary, and the final error is expected to be lower than the one obtained.

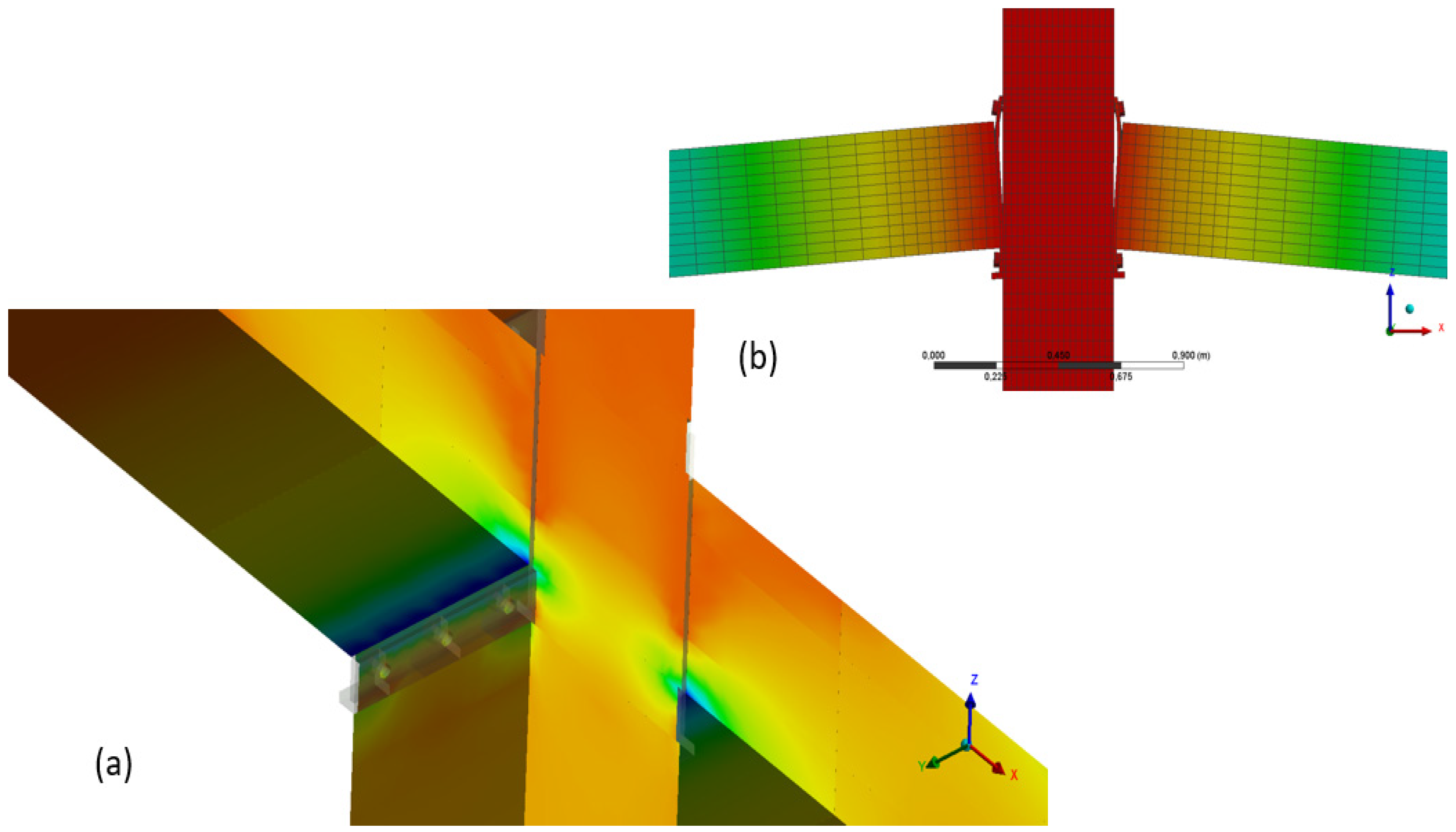

As observed, a maximum error of 7.36% is detected in plates, while the average error is 2.19%. That indicates deviations in some nodes that are located in areas of concentrated stresses (

Figure 6), or in steps that are close to the material strength limit. Similar results are detected in screws, beams, and posttensioned tendons.

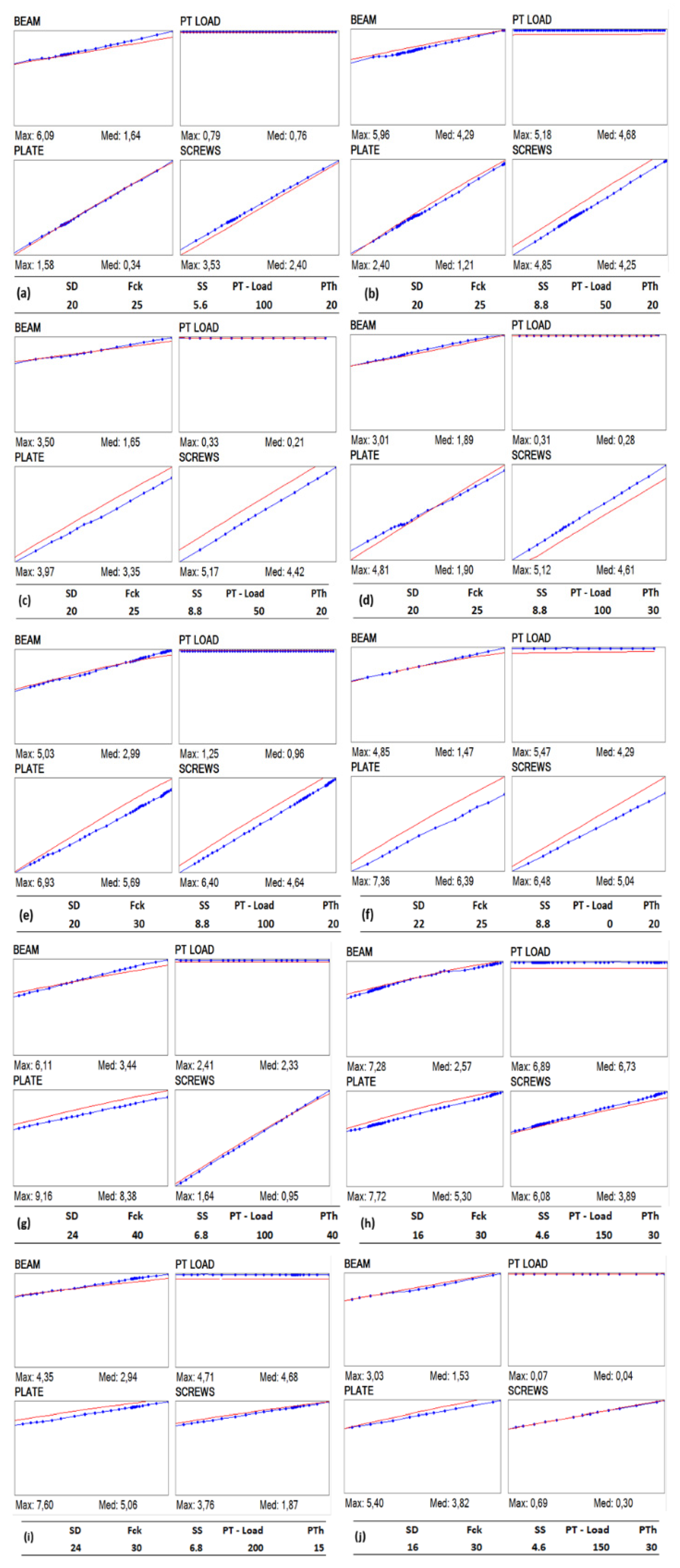

Four different ANNs have been developed to predict the element results: beam, plate, tendons, and screws. For each FEM model, four comparisons have been made (

Figure 7), one for each ANN. In the comparisons, maximum nodal stresses in each element (beam, plate, PT, or screws) per step are provided and compared (in red) with the maximum nodal stress of each step from the FEM numerical analysis (in blue). For concrete, the maximum stress is compared to the maximum principal stress (

). In the steel elements, the Von Misses stress criterion is used. The load values range from 0 to the maximum obtained in the corresponding FEM analysis. The maximum and average errors are provided.

Regarding FEM values, in

Table 6 and

Table 7, step-by-step comparisons for each element are depicted. Only the final steps are included.

When the applied loads are increased and the concrete is close to the strength limit, maximum deviations between the predicted stresses and the FEM solutions are obtained. Under 0.08 MPa, the difference is lower than 3%. The maximum stress in concrete when 0.08 MPa is applied is 19.69 MPa. Due to the applications of partial safety factors, as required by Codes [

31,

39], the maximum concrete stress that is expected in real structures is close to 50% of the strength limit. Thus, the provided stress field is satisfactory enough, accomplishing the Code requirements, and corroborating that the ANN is an efficient design tool.

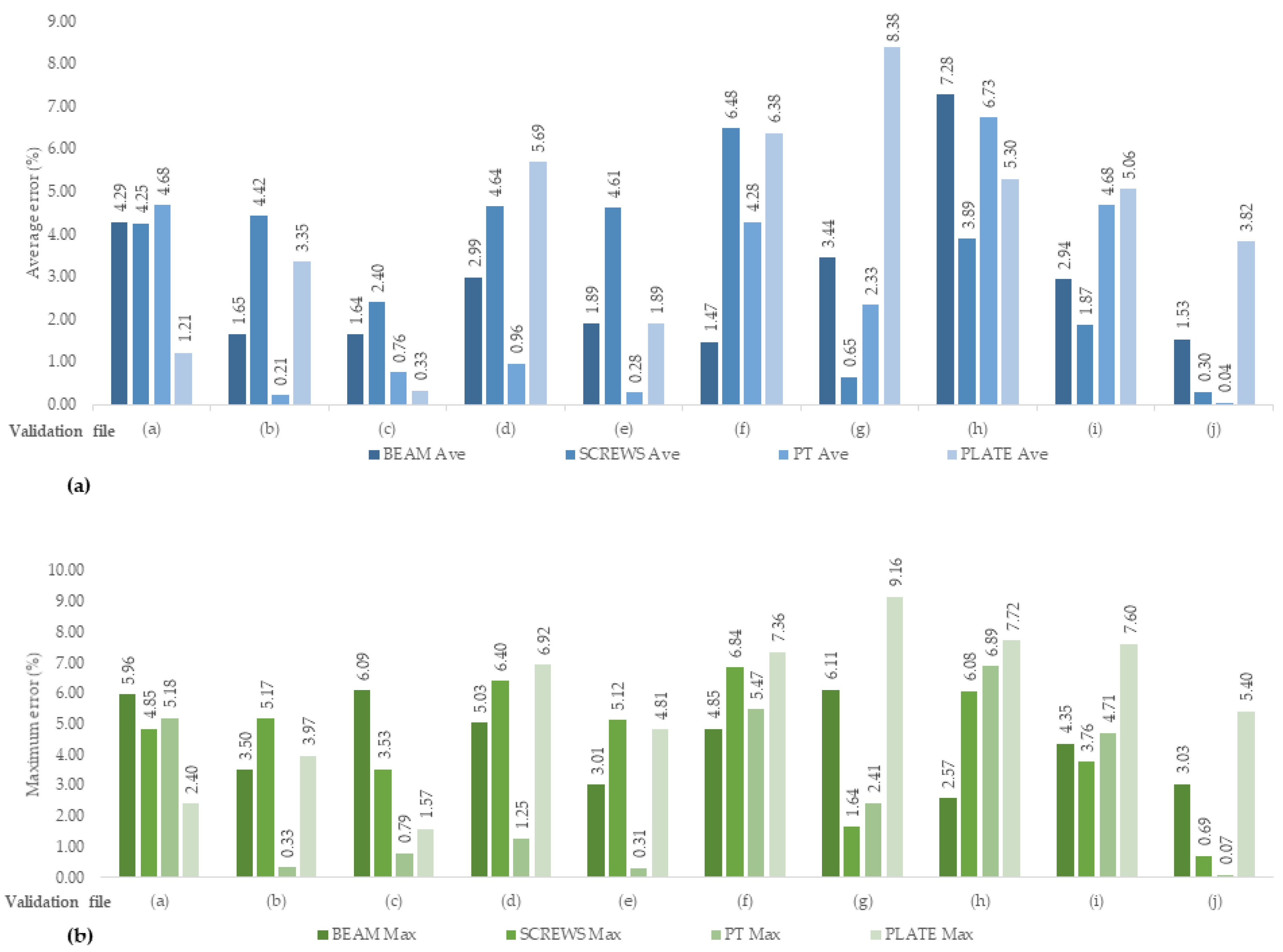

In the validation process, six different parameter combinations from the FEM analysis have been used. The obtained average and maximum errors in each element are summarized in

Figure 8.

As observed, a maximum error of 9.16% is obtained in the worst scenario. The maximum errors are obtained in the final steps of each calculation due to the stress concentrations or to the first cracking in concrete. As this situation is an anomaly in the increasing stress curve, the ANN has difficulties in learning and predicting those values. Taking into account that in the most common structural design methods, safety factors are applied, the obtained stress field is around 50% of the strength limit. As observed in

Table 6 and

Table 7 and

Figure 7, the maximum errors appear at the end of the comparison, when concrete is close to the strength limit. It should be noted that for the PT, the maximum error is low, 0.79%. As the average error is lower than 8.38% in all the validation cases, it can be stated that the designed networks are reliable tools for stress prediction and design. The differences between the predicted and the FEM model values in the tensioned parts (i.e., screws or PT tendon) remain stable. More differences are detected in beams (1.47%–6.11%) and plates (0.33%–8.38%), although stresses remain within acceptable ranges.

It is worth noting that the designed ANNs share some features with other research works. Thus, the procedure developed by Ashour et al. [

14] is similar to that used in this work, where different ANNs were implemented by varying some parameters and using a back-propagation algorithm with a trial-an-d-error process to determine the number of hidden layers and neurons. In the work by Ashour et al. [

14], the network used fewer neurons in one hidden layer. In this research, due to both the variability of the nodal stress field and the number of input data, an extra hidden layer was required. In addition, the number of neurons needs to be increased to reach convergence. In the same research line, Lorenzi et al. [

40], after using a back-propagating ANN, highlighted the feasibility of using ANNs to predict concrete compressive strength based on a pull-out test on concrete. Those authors applied different ANNs with three hidden layers and a variable number of neurons in each layer, with a maximum of 80 neurons. In this work, two hidden layers were required, with a maximum of 25 neurons in the beam. That is due to the great number of nodes and to the stress variability in both value and sign when the load increases. Almeida Junior [

15] also obtained satisfactory predictive results on the load capacity of adhesive anchors, proposing an ANN with two hidden layers with three and two neurons, and the training process time was 12 seconds. In this research, due to the number of inputs, the number of neurons in the hidden layers, and the number of hidden layers, approximately 16 hours were needed to train the worst scenario. The similar conclusions on time reduction that the ANN provides when compared to common numerical analyses are remarkable.

Taking into account the obtained dispersion in the values and the final step location (which are close to the concrete limit strength), as well as the strength limit of actual structures, it can be stated that the proposed ANN is adequate for designing structural materials. It can be concluded that the designed ANN is a powerful and useful tool to be used in the design stage of structural materials and components.