Abstract

A facility for controlled environment agriculture from an energy consumption point of view was investigated at the C. G. Bhakta Institute of Biotechnology, Uka Tarsadia University (21.1667° N, 72.8333° E), Bardoli, Surat, Gujarat, India. It is a tropical wet and dry region of the state of Gujarat. The study was carried out for an even span type 2.45 m × 3.65 m greenhouse with an elevation of 34 m above the sea level under the environmental conditions. A thermal model is proposed to identify the suitable climate condition for the cultivation of different varieties of Banana (Musa) and Sugarcane (Saccharum officinarum). Banana and Sugarcanes are the main crops in the Surat district, wherein around 12,400 hector and 94,500 hector cultivation are done, respectively. The experimental study was carried out during the period of December 2017 (winter) to February 2018 (winter and summer). The proposed thermal model is helpful to indicate the hourly energy balance and average temperature distribution inside the greenhouse. The greenhouse was studied for east–west orientation. The steady state analysis was utilized to find extra thermal energy other than solar radiation needed to keep the plant temperature desirable. Experimental validation of the model was carried out in even span greenhouse. At last, some important conclusions are drawn and suggestions made for further studies based on the main characteristics and results of the study. A higher air change rate seems desirable to bring down the temperature further. It was observed that the extra heating is required during the period of December to February, whereas from March onwards a storage unit is required to absorb the energy available and utilize it whenever necessary in the given climatic condition and crop.

1. Introduction

Greenhouse technology has been utilized for around two centuries in various regions of the Earth, however, it has been promoted in Indian horticulture as of late. Over the past decade, India’s greenhouse area has increased significantly due to increased emphasis on horticulture and consequently increased financial support. In areas, where farming is not possible due to harsh agroclimatic conditions, greenhouse technology has also a unique scope. Greenhouses allow the extension of the season for growing crops in the tropical wet and dry climatic conditions of India. Considering the geographical location of Surat, high solar radiation intensity increases the air temperature inside a greenhouse to excessively high levels during summer and even during clear days of winter. Large temperature fluctuations between day and night hours, and inside temperature decreases or increases with respect to optimum levels during the day, can have a significant impact on the quantity and quality of the cultivation. To beat these sorts of issues, it is of primary importance to utilize low-cost, efficient, and dependable alternative cooling or heating technologies. During summer, the optimum inside conditions can be provided by the use of shading of cover material, natural or hybrid ventilation with side or roof openings, improved efficiency cooling systems like direct or indirect evaporative coolers, and better exploitation of alternative energy sources.

In the Surat District, the ambient temperature varies from 25° to 44 °C in summer, 22° to 34 °C in rainy season, and 10° to 26 °C in winter [1]. Banana and Sugarcane are the main crops in the Surat district. However, fluctuation of temperature in the composite season and continuous requirement of water are the prevailing conditions in the winter. Thus, there is a need to balance temperature and energy to obtain the optimum condition in order to increase the growth and yield of these crops. Moreover, solar energy allows the plants to warm up during the cold months through the greenhouse effect in greenhouse cultivation. It has been determined that in a greenhouse, the thermal energy requirement rate depends on the available solar radiation inside the greenhouse [2]. Significant studies are disbursed on various ways of heating and cooling greenhouse. These studies aimed for reduction of greenhouse energy utilization by one or several of these methods: Decrease the loss of energy to ambient environment, increase the availability of solar radiation inside the greenhouse, and increase the storage capacity of the greenhouse component [2].

Mobtaker et al. [2] investigated six most commonly used greenhouse forms for north–south and east–west orientation from the point of view of energy consumption in the climate of Tabriz, Iran. It was reported that the extra thermal energy needed to keep the plant temperature desirable for better growth of plant was minimal in a single span greenhouse which was oriented in east–west direction with a northern brick wall. The conclusion was that the northern brick wall can reduce the greenhouse heating demand by up to 31.7%. Gupta and Chandra [3] developed a mathematical model and used it to study the effects of various energy conservation measures to achieve a set of energy efficient greenhouse design features under the cold climate conditions of northern India. The combination of the design features for an energy efficient greenhouse suitable for cold weather conditions reduced the greenhouse heating requirements by 80%. Ghosal and Mishra [4] developed a quasi-steady-state thermal model to investigate the suitability of a naturally ventilated, inexpensive, and simple greenhouse with shading nets in the humid and warm climate of Bhubaneshwar, Odisha (India) during winter. It was reported that for the greenhouse with a net shading, the temperature variations were lower as compared to greenhouse without the shading net. Sethi and Sharma [5] developed an agriculture greenhouse for heating and cooling which was integrated with an aquifer coupled cavity flow heat exchanger system. They conducted the parametric study to observe the effect of various operating parameters. Singh and Tiwari [6] investigated different shapes of the greenhouse for the winter (composite climate) in New Delhi, India. The numerical model was proposed and the effect of additional energy provided to maintain the temperature was studied. It was reported that the standard peak uneven span with the use of liquefied petroleum gas gives optimum results. Further, a thermodynamic simulation model was proposed by Ben Ali et al. [7]. They used MATLAB/Simulink tool to simulate the two different conditions, i.e., transparent greenhouse and insulated greenhouse, which was installed in the Research and Technology Center of Energy in Borj Cedria, Tunisia. The results of the experiments and simulation was reported to be in agreement for the air temperature variation during nine days in March. Sengar and Kothari [8] reported that to predict the effect of different controlling parameters viz. solar radiation, temperature of air, relative humidity, ventilation, etc., a suitable thermal model can be used. Sethi and Sharma [9] and Kumar et al. [10] reported that energy balance equations considering different parameters are greatly important for predicting the air temperature in greenhouses. Hassen et al. [11] proposed a mathematical model to investigate the effect of condenser location in the standalone greenhouse in Abu Dhabi. The validation between simulation and experimental results were carried out during the month of August. A semi-solar greenhouse was designed and constructed for the experimental investigation by Mohammadi et al. [12]. Mobtakar et al. [13] developed a dynamic model to predict the internal air temperature in the single span green house in Tabriz. It was reported that the predicted and experimental data were in good agreement. Considering natural and forced convections, Chauhan et al. [14] proposed a thermal model for the bitter gourd and validated with the experimental data. Kumari et al. [15] reported the effect on thermal heating of greenhouse integrated with solar collector.

There are several models proposed during the last decade by Saberian and Sajadiye [16] (CFD simulation of greenhouse), Yu et al. [17] (Prediction of temperature in Chinese solar greenhouse using PSO), Hamdi et al. [18] (Experimental and numerical study of drying of grapes in greenhouse), Bouadila et al. [19] (improvement of climate in greenhouse using latent energy storage), Taki et al., [20] (modeling and experimentation in innovative greenhouse), Mashonjowa et al. [21] (modeling of thermal performance of naturally ventilated greenhouse in Zimbabwe), Katsoulas et al. [22] (reducing ventilation requirements in semi-closed greenhouse using increase water use efficiency), etc. However, in spite of progress and proof of various greenhouse models, it is important to understand performance criteria of greenhouse under actual climatic conditions on microclimates at the desired location and crop. Additionally, the local climatic and meteorological conditions play a vital role. Hence, a thermal model (considering steady state conditions) is proposed based on energy balance. The steady state model is easy to understand and apply by the local farmers. Therefore, the proposed model may be adopted for other crops in the wet and dry climate of the coastal regions. The proposed model is validated against the experimental findings for its suitability of growing the bananas and sugarcane for given climatic conditions. The enhancement of performance by predicting the environmental parameters is useful, particularly for the small and marginal farmers.

2. Materials and Methods

A mathematical model is proposed to investigate the thermal performance of the greenhouse. To develop the model, energy balance equations were derived to predict the environmental condition. The model development is done with certain assumptions: (1) Steady state conditions were considered, (2) one dimensional heat flow in the ground, (3) neglected the storage capacity of the greenhouse cover plant, (4) neglected the heat capacity and absorptivity, (5) thermal properties of the plant are considered to be the same in greenhouse and water, (6) neglected the radiative heat exchange between the wall and greenhouse roof. This study was conducted for even span type 2.45 m × 3.65 m greenhouse situated at Uka Tarsadia University in Surat (Gujarat), at a geographical location of (21.1667° N, 72.8333° E) with 34 m elevation above the sea level. The model’s input parameters included hourly data of ambient air temperature, vector position of the sun, and incident solar radiation on various walls/roof of the east–west oriented greenhouse. The input parameters were selected based on the climate and greenhouse conditions along with the published literature. The response parameters considered were solar radiation, plant temperature, and ambient temperature. The responses were recorded online through various instruments, and a detailed description is provided in Section 2.7.

2.1. The Available Solar Radiation on Cover of Greenhouse

On each inclined greenhouse surface, the incident solar radiation was determined using horizontal solar radiation hourly. The total radiation on greenhouse roof and each wall consisted of three elements: Diffused, beam, and reflected from the ground. Therefore, the total solar radiation available on each surface of greenhouse cover was determined utilizing (1) and (2) [5]:

At any time, the beam radiation ratio on an inclined surface to a horizontal surface (Rb) can be determined as [6]:

which the and z can be calculated as:

The view factors of inclined surface to the ground and to the sky were determined as:

2.2. Transmission of Solar Radiation through Cover of Greenhouse

Average transmittance values through cover were incorporated by frequent studies. The transmission of solar radiation through the greenhouse cover is, however, a function of the incoming refractive index, radiation, thickness, and coefficient of extinction of the cover [23]. Equation (4) was used primarily for the calculation of the hourly incidence angle of beam radiation on a greenhouse cover and in accordance with Fresnel and Bouguer’s law [23,24], the transmission of direct radiation by means of the cover of greenhouse was determined. For soil-reflected and isotropic diffuse radiation, a corresponding direct radiation angle has been defined. (i.e., 60°) [23].

2.3. Distribution of Solar Radiation inside a Greenhouse

For the development of greenhouse energy balance equations, an extremely important factor is the solar radiation distribution pattern within a greenhouse [25]. This solar radiation distribution pattern depends on the greenhouse’s size and shape. In the Northern Hemisphere, particularly in winter, most of the solar radiation for an east–west oriented greenhouse falls on the south wall and is transmitted to the inside atmosphere of the greenhouse through the greenhouse cover. A partial energy that enters the greenhouse is either decayed as short wave reflected radiation or as long wave radiation into the ambient air. Some studies have not considered this part of the solar radiation for the greenhouse thermal modeling [6,26]. To calculate the radiation loss from the north wall, Tiwari et al. [27] introduced the Fn concept.

A partial radiation transmitted from greenhouse cover falls on the inner side of other greenhouse parts. The loss of radiation from those parts were also present. In order to calculate these radiation losses, a total solar fraction (Ft) was proposed [28]. In this study, 3D shadow analysis in Auto-CAD was used to determine Fn and Ft, and radiation losses from the north wall and other parts were determined [25,29]. Using (1)–(7) and the Ft and Fn concept, total available solar radiation was calculated hourly.

2.4. Equations of Energy Balance for the Components of Greenhouse

In the greenhouse, the solar radiation incident is absorbed by various components of the greenhouse. The remainder is loss by cover outside the greenhouse. Some assumptions were reported [6,24], by considering them thermal energy balance equations for different greenhouse components, and were calculated. The equations were therefore written as follows:

2.4.1. Plants of Greenhouse

Partial transmitted solar radiation falls on the surfaces of plant that increase the temperature of the plant. The equation of energy balance for plants inside the greenhouse can be written as [24,30]:

2.4.2. Soil Layer

The greenhouse floor receives a small amount of transmitted solar radiation. For the greenhouse soil surface, the energy balance equation can be written in a steady state condition as [24]:

2.4.3. Greenhouse Air

One of the most important parameters for the plant growth is the temperature of greenhouse air. This temperature depends on energy exchange between air and all greenhouse components, i.e., the soil, plant, equipment, structure of greenhouse, and the energies infiltrated or conducted through the cover of greenhouse, door, and ventilation system. For greenhouse air, the equation of the energy balance can therefore be written as [6,24]:

From [3]:

The Equations (15)–(17) were determined using Equation (13). An equation for temperature of inside air (Tr) was determined by neglecting the heat capacity of the inside air and substituting Equation (17) in Equation (14) together with a few mathematical simplifications.

where,

2.5. Temperature of the Plant inside the Greenhouse

A differential equation of first-order for plant temperature (Tp) is determined by substituting the expression for inside air temperature Tr Equation (18) in Equation (8) [23,30]:

where:

Assuming that the heat transfer coefficients, temperature, and total solar radiation are constant for Δt time interval (Δt = 1 h), this is the general solution [4,13]:

Equation (22) shows the temperature of plants inside the greenhouse. A plant average temperature can be written by following Singh and Tiwari [6] and using mean value theorem for integrals as:

2.6. The Additional Energy Required

The parameters associated with the model development and experiments are considered based on the local climate condition and available greenhouse (Ac, Ag, Ap, Ad, Mp, T0, and τ). Some parameters are considered based on the published research by Ghosal and Mishra [4] (hpr, ha, hr, N, v, and Cp) and Mobtekar et al. [2] (αg, αp, ρc, Utc, and hd). This study was to explore the energy utilization of greenhouse for maintaining desirable plant temperature (approximately 29 °C) inside greenhouse. According to hourly available solar radiation data for greenhouse, extra thermal energy required was determined using Equation (24). Additionally, ambient air temperature, the hourly variations of solar radiation on a horizontal surface, and the details of selected greenhouses were used as inputs.

Constants used in the study are shown in Table 1.

Table 1.

Input parameters.

2.7. Experimental Details

The experiments were carried out in an even span greenhouse (8.94 m2 floor area), oriented in east–west direction. The greenhouse was covered with polyethylene plastic cover (0.2 mm thickness) (Figure 1). The hourly variation of the solar radiation, ambient and green house temperatures, and ambient and greenhouse humidity were measured and recorded online (throughout day and night).

Figure 1.

Experimental greenhouse; (a) internal view; (b) external view.

The temperatures of ambient and inside greenhouse were measured and recorded using SHT sensor (Make: M/s. Hi-Tech Marketing, Surat) (working condition range: −20 °C to 100 °C; accuracy: ±0.4 °C). These data were recorded for 1-min intervals, but for the analysis part, the hourly data were considered through averaging it out. It is because the large data storage and analysis required high end hardware. The humidity was also measured and recorded using the same SHT sensor (working condition range: 0–99% RH; accuracy: ±3% RH). The plant temperatures were measured using an infrared thermometer with a least count of 0.1 °C (Make: M/s. Hi-Tech Marketing, Surat, India). The plant temperatures were also measured and recorded for individual minutes, but analysis was done based on hourly data. There were two sensors that were used to measure and record the data of temperatures and humidity. For the analysis part, the average of two was considered. The solar radiation was measured with solar pyranometer with accuracy of ±10 w/m2 (Make: M/s. Hi-Tech Marketing, Surat).

The steady state analysis was used to analyze a greenhouse’s thermal environment. The values predicted for plant and air temperatures in the greenhouse were validated against the experimental results for typical sunny days in order to verify the proximity of the developed model.

2.8. Statistical Analysis

The proximity of experimental and predicted values has been verified with the help of different statistical indicators including the root mean square of per cent deviation (e), a coefficient of correlation (r), mean bias error (MBE), and root mean square error (RMSE) based on acquired data series. Following equations are for the statistical indicators [2,3]:

Root mean square of percent deviation

Coefficient of correlation among predicted and experimental values

Mean bias error

Root mean square error

where, Xi and Yi are the predicted and experimental values, respectively. N is the number of observations.

3. Results and Discussions

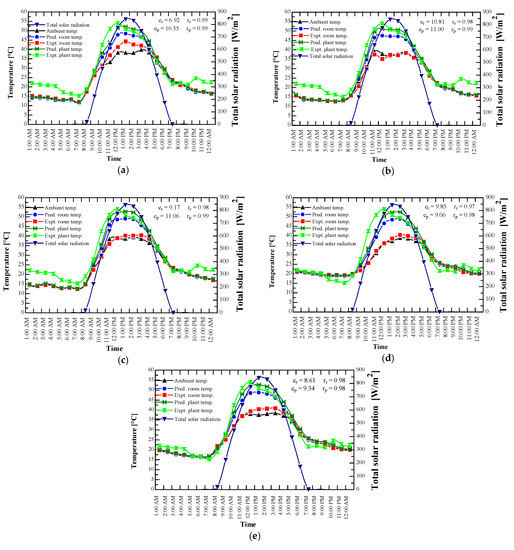

During December 2017–February 2018, the developed model has been experimentally validated for typical days. For naturally ventilated greenhouses, the experimental and predicted the values of air and plant temperatures (Tr and Tp), the ambient air temperatures (Ta) and solar radiation for typical days, i.e., on 26, 27, and 28 January 2018, have been shown in Figure 2a–c. Similarly, for the forced ventilation in greenhouses, the values of above-mentioned parameters for typical days, i.e., on 7 and 8 February 2018, have been shown in Figure 2d–e.

Figure 2.

Comparison of predicted and experimental data of ambient air temperature, greenhouse air, and plant temperatures. (a) 26 January 2018; (b) 27 January 2018; (c) 28 January 2018; (d) 7 February 2018; (e) 8 February 2018.

As can be seen from Figure 2, the predicted temperatures of greenhouse air and plants were relatively near to the experimental temperatures. Similar observations were reported by Ghosal and Mishra [4]. The statistical analysis of the root mean square percent deviation (e), a coefficient of correlation (r), mean bias error (MBE), and the root mean square error between the predicted and experimental values verified these. From the values indicated in the Figure 2, it has been shown that the root mean square percent deviation (e) among the experimental and predicted values of enclosed air and plant temperatures for both naturally and forced ventilated greenhouses varied from 6.92 to 11.06, coefficient of correlation (r) varied from 0.97 to 0.99, mean bias error (MBE) varied from 0.15 to 2.25, and root mean square error (RMSE) varied from 2.16 to 4.71. The detailed observations of the error analysis are presented in Table 2.

Table 2.

Error analysis of internal temperatures of greenhouse.

The plant temperature (Tp) and the enclosed air temperature (Tr) started to increase from 09:00 a.m. because of the incident solar radiation, and reached a value that exceeded the desirable temperature. At this stage, the excess heat energy from the greenhouse enclosure should be removed to maintain the desirable temperature of plant.

For the natural convection mode, during mid-day hours, the temperatures of air inside the greenhouse were 4–5 °C greater than the ambient air temperature, and the temperature of air inside the greenhouse was only 1–2 °C greater than the ambient air temperatures during mid-night hours. A number of air changes per minute was experimentally obtained, which has been taken into account in the model. And for forced convection mode, during mid-day hours, the temperatures of air inside the greenhouse were 2–3 °C greater than the ambient air temperatures, and the temperature of greenhouse air was only 1–2 °C greater than the temperature of an ambient air during mid-night hours.

The experimented temperatures of plant were 4–5 °C and 3–4 °C greater than the temperature of an ambient air during mid-day hours for natural and forced ventilation respectively. The temperatures of plant were fluctuated between 1–2 °C with the ambient air temperature for both natural and forced ventilation during night hours. Throughout the night, an inside temperature maintained by the greenhouse cover of 1 °C greater than the temperature of an ambient air during typical days of winter in region of South Gujarat. The temperatures of ambient air varied from 10 °C to 37 °C throughout experiment in winter. It was therefore tough to keep temperature of 29 °C inside the greenhouse for favorable plant growth.

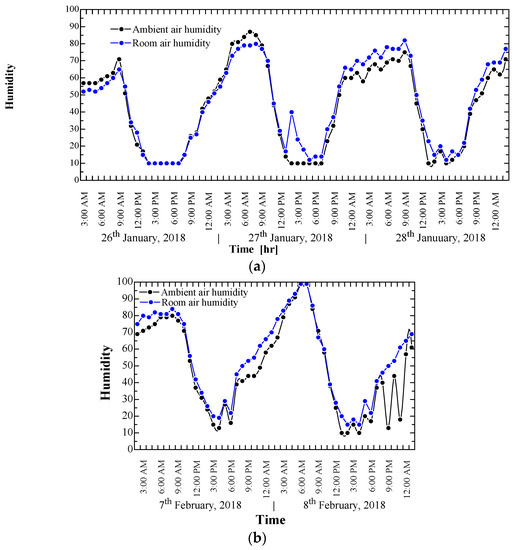

Hourly variation of ambient and greenhouse room air relative humidity for greenhouse with free ventilation during 26–28 January 2018 and with forced ventilation during 7–8 February 2018 have been shown in Figure 3. Greenhouse inside air humidity was on an average higher than the ambient air humidity.

Figure 3.

Hourly variation of humidity for ambient and greenhouse air with natural ventilation (a) during 26, 27, and 28 January 2018; (b) during 7 and 8 February 2018.

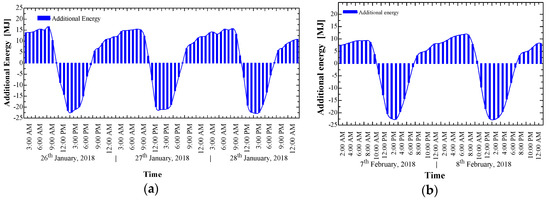

Hourly estimated values of extra thermal energy requirements for naturally ventilated greenhouses during 26–28 January 2018 and for forced ventilated greenhouses during 7–8 February 2018 have been shown in Figure 4. As can be seen from Figure 4, from 10:00 a.m. to 05:00 p.m. no amount of additional heat is required. During this duration, the heat should be absorbed from the greenhouse to maintain the desirable plant temperature. Natural ventilation is the easiest solution to enable the elimination of surplus thermal energy from the greenhouse by opening the greenhouse. In the case of greenhouses with forced ventilation, the additional energy requirements were lower in the mid-day hours.

Figure 4.

Hourly estimated values of extra thermal energy requirement for forced ventilated greenhouses (a) during 26–28 January 2018; (b) during 7 and 8 February 2018.

4. Conclusions

To predict the temperature of greenhouse air and plant, a steady state thermal model was developed. The developed model can be used for greenhouse performance studies under a variety of climatic conditions and different operating conditions.

The predicted temperatures of greenhouse air and plant for natural as well as forced convective greenhouse by the developed model were compatible with observed temperatures, which were confirmed by statistical analysis. This model can therefore be a design tool to predict the greenhouse air as well as the plant temperature for heating requirements and the hourly energy balance inside the greenhouse. Further, based the results, it is observed that the ambient temperature and greenhouse temperature are mapping together in some cases. This could be due to the assumptions made in the mathematical model. The model can be further improved by eliminating the assumptions.

The inside air temperature is highest through noon hours, and the loss of radiation was major during late evening and early morning hours. The surplus solar energy in daylight time could be prevented from being lost to the surrounding environment through ventilation, if there is any thermal energy storage system coupled with greenhouses. Thermal energy storage device is the best selection for least utilization of extra thermal energy. As per this climate, no extra heating is needed only for December to February. For March to November, only storage units can absorb the available heat and supply whenever is required.

It would be favorable to develop off-season vegetables in greenhouses if the temperature of air decreases during peak radiant hours and increases during the night time. According to the predicted plant and greenhouse air temperatures, crops can be chosen to be grown inside it. Additionally, heating or cooling requirements based on the estimated temperature of air for minimizing a fluctuation in thermal environmental conditions for a specific crop inside the greenhouse can also be known to achieve better plant development.

Author Contributions

Data collection and conceptualization, G.G., C.D., R.B., and B.S.; methodology, G.G., C.D., R.B., and B.S.; formal analysis, G.G., C.D.; investigation, G.G., C.D., R.B., and B.S.; resources, G.G., C.D., R.B., and B.S.; writing—original draft preparation, R.B. and B.S.; writing—review and editing, G.G., C.D., R.B., and B.S.; supervision, C.D., R.B., and B.S.; project administration, C.D., R.B., and B.S.; funding acquisition, R.B. and B.S. All authors have read and agreed to the published version of the manuscript.

Funding

This study received funding from King Saud University through Researchers supporting project number (RSP-2020/145).

Conflicts of Interest

The authors have no conflict of interest.

Nomenclature

| A | area (m2) |

| Ai | area of roofs and walls (m2) |

| C | specific heat (J/kg K) |

| Ev | heat transfer through ventilation (W) |

| Fn | ratio of solar fraction falling on the north wall over the total incoming radiation at the same time (-) |

| Fpr | shape factor between greenhouse room and plant (-) |

| Ft | ratio of the transmitted solar radiation falling on roof/wallsinside the greenhouse to the total transmitted solar radiations inside the greenhouse at the same time (-) |

| ha | convective heat transfer coefficient between the greenhouse floor and inside air (W/m2 K) |

| hb | bottom heat transfer coefficient between the greenhouse floor and the ground beneath (W/m2 K) |

| hd | heat transfer coefficient from the greenhouse door to the ambient air (W/m2 K) |

| hp | convective heat transfer coefficient between plant and inside air (W/m2 K) |

| hpr | convective and evaporative heat transfer coefficient from the plant to the inside air (W/m2 K) |

| hr | radiation heat transfer coefficient between plant and inside air (W/m2 K) |

| Ib | beam radiation (W/m2) |

| Id | diffuse radiation (W/m2) |

| M | total mass (kg) |

| P | partial vapor pressure at saturation (pa) |

| Qp | additional energy rate (W) |

| Rb | the ratio of beam radiation on the tilted surface to that on a horizontal surface (-) |

| Rd | view factor of tilted surface to the sky (-) |

| Rr | view factor of tilted surface to the ground (-) |

| Si(t) | total solar radiation on various walls and roofs (W/m2) |

| St | total solar radiation falling on the greenhouse cover (W) |

| T | temperature (°C) |

| t | time (s) |

| Utc | overall heat transfer coefficient of the greenhouse cover (W/m2 K) |

| Utw | overall heat transfer coefficient of the north wall (W/m2 K) |

| V | volume of greenhouse (m3) |

| v | wind velocity (m/s) |

| Greek | |

| αg | ground absorptivity of solar radiation (-) |

| αp | plant absorptivity of solar radiation (-) |

| β | slope of the surface with horizontal (degree) |

| γ | surface azimuth angle (degree) |

| γr | relative humidity (-) |

| δ | declination angle of the sun (degree) |

| ε | emissivity (-) |

| θi | incidence angle (degree) |

| θz | zenith angle (degree) |

| ρ | ground reflectivity (-) |

| ρc | north wall reflectivity (-) |

| ρw | greenhouse cover reflectivity (-) |

| σ | Stefan Boltzmann constant (W/m2 K4) |

| τ | greenhouse cover transmissivity (-) |

| ω | “hour angle (degree)” |

| φ | latitude angle of a location (degree) |

| Subscript | |

| a | ambient |

| c | greenhouse cover |

| d | greenhouse door |

| g | greenhouse ground/soil |

| p | plant |

| r | room air |

| w | north wall |

| 0 | underground |

References

- Anonymous. Handbook of Agriculture; ICAR Publication: New Delhi, India, 2010. [Google Scholar]

- Mobtaker, H.G.; Ajabshirchi, Y.; Ranjbar, S.F.; Matloobi, M. Solar energy conservation in greenhouse: Thermal analysis and experimental validation. Renew. Energy 2016, 96, 509–519. [Google Scholar] [CrossRef]

- Gupta, M.; Chandra, P. Effect of greenhouse design parameters on conservation of energy for greenhouse environmental control. Energy 2002, 27, 777–794. [Google Scholar] [CrossRef]

- Ghosal, M.K.; Mishra, J.N. Formulation and validation of a mathematical model for a naturally ventilated greenhouse with shading nets in warm and humid climate of India. Int. J. Ambient Energy 2014, 35, 94–107. [Google Scholar] [CrossRef]

- Sethi, V.P.; Sharma, S.K. Thermal modeling of a greenhouse integrated to an aquifer coupled cavity flow heat exchanger system. Sol. Energy 2007, 81, 723–741. [Google Scholar] [CrossRef]

- Singh, R.D.; Tiwari, G.N. Energy conservation in the greenhouse system: A steady state analysis. Energy 2010, 35, 2367–2373. [Google Scholar] [CrossRef]

- Ali, R.B.; Bouadila, S.; Mami, A. Experimental validation of the dynamic thermal behavior of two types of agricultural greenhouses in the Mediterranean context. Renew. Energy 2020, 147, 118–129. [Google Scholar]

- Sengar, S.H.; Kothari, S. Thermal Modeling and Performance Evaluation of Arch Shape Greenhouse for Nursery Raising. Afr. J. Math. Comput. Sci. Res. 2008, 1, 1–9. [Google Scholar]

- Sethi, V.P.; Sharma, S.K. Survey of Cooling Technologies for Worldwide Agricultural Greenhouse Applications. Sol. Energy 2007, 81, 1447–1459. [Google Scholar] [CrossRef]

- Kumar, K.S.; Tiwari, K.N.; Jha, M.K. Design and Technology for Greenhouse Cooling in Tropical and Subtropical Regions: A Review. Energy Build. 2009, 41, 1269–1275. [Google Scholar] [CrossRef]

- Hassan, G.E.; Salah, A.H.; Fath, H.; Elhelw, M.; Hassan, A.; Saqr, K.M. Optimum operational performance of a new stand-alone agricultural greenhouse with integrated-TPV solar panels. Sol. Energy 2016, 136, 303–316. [Google Scholar] [CrossRef]

- Mohammadi, B.; Ranjbar, S.F.; Ajabshirchi, Y. Application of dynamic model to predict some inside environment variables in a semi-solar greenhouse. Inf. Process. Agric. 2018, 5, 279–288. [Google Scholar] [CrossRef]

- Mobtaker, H.G.; Ajabshirchi, Y.; Ranjbar, S.F.; Matloobi, M. Simulation of thermal performance of solar greenhouse in north-west of Iran: An experimental validation. Renew. Energy 2019, 135, 88–97. [Google Scholar] [CrossRef]

- Chauhan, P.S.; Kumar, A.; Nuntadusit, C.; Banout, J. Thermal modeling and drying kinetics of bitter gourd flakes drying in modified greenhouse dryer. Renew. Energy 2018, 118, 799–813. [Google Scholar] [CrossRef]

- Kumari, N.; Tiwari, G.N.; Sodha, M.S. Performance evaluation of greenhouse having passive or active heating in different climatic zones of India. Agric. Eng. Int. CIGR E J. 2007, 9, 1–19. [Google Scholar]

- Saberian, A.; Sajadiye, S.M. The effect of dynamic solar heat load on the greenhouse microclimate using CFD simulation. Renew. Energy 2019, 138, 722–737. [Google Scholar] [CrossRef]

- Yu, H.; Chen, Y.; Hassan, S.G.; Li, D. Prediction of the temperature in a Chinese solar greenhouse based on LSSVM optimized by improved PSO. Comput. Electron. Agric. 2016, 122, 94–102. [Google Scholar] [CrossRef]

- Hamdi, I.; Kooli, S.; Elkhadraoui, A.; Azaizia, Z.; Abdelhamid, F.; Guizani, A. Experimental study and numerical modeling for drying grapes under solar greenhouse. Renew. Energy 2018, 127, 936–946. [Google Scholar] [CrossRef]

- Bouadila, S.; Kooli, S.; Skouri, S.; Lazaar, M.; Farhat, A. Improvement of the greenhouse climate using a solar air heater with latent storage energy. Energy 2014, 64, 663–672. [Google Scholar] [CrossRef]

- Taki, M.; Ajabshirchi, Y.; Ranjbar, S.F.; Rohani, A.; Matloobi, M. Modeling and experimental validation of heat transfer and energy consumption in an innovative greenhouse structure. Inf. Process. Agric. 2016, 3, 157–174. [Google Scholar] [CrossRef]

- Mashonjowa, E.; Ronsse, F.; Milford, J.R.; Pieters, J.G. Modelling the thermal performance of a naturally ventilated greenhouse in Zimbabwe using a dynamic greenhouse climate model. Sol. Energy 2013, 91, 381–393. [Google Scholar] [CrossRef]

- Katsoulas, N.; Sapounas, A.; De Zwart, F.; Dieleman, J.A.; Stanghellini, C. Reducing ventilation requirements in semi-closed greenhouses increases water use efficiency. Agric. Water Manag. 2015, 156, 90–99. [Google Scholar] [CrossRef]

- Duffie, J.A.; Beckman, W.A. Solar Engineering of Thermal Processes; John Wiley & Sons: New Jersey, NJ, USA, 2013. [Google Scholar]

- Shethi, V.P. On the selection of shape and orientation of a greenhouse: Thermal modeling and experimental validation. Sol. Energy 2009, 83, 21–38. [Google Scholar] [CrossRef]

- Gupta, R.; Tiwari, G.N.; Kumar, A.; Gupta, Y. Calculation of total solar fraction for different orientation of greenhouse using 3D-shadow analysis in Auto-CAD. Energy Build. 2012, 47, 27–34. [Google Scholar] [CrossRef]

- Chou, S.K.; Chua, K.J.; Ho, J.C.; Ooi, C.L. On the study of an energy-efficient greenhouse for heating, cooling and dehumidification applications. Appl. Energy 2004, 77, 355–373. [Google Scholar] [CrossRef]

- Tiwari, G.N.; Din, M.; Srivastava, N.S.; Jain, D.; Sodha, M.S. Evaluation of solar fraction (Fn) for the north wall of a controlled environment greenhouse: An experimental validation. Int. J. Energy Res. 2002, 26, 203–215. [Google Scholar] [CrossRef]

- Gupta, R.; Tiwari, G.N. Modeling of energy distribution inside greenhouse using concept of solar fraction with and without reflecting surface on north wall. Build. Environ. 2005, 40, 63–71. [Google Scholar] [CrossRef]

- Tiwari, G.N.; Gupta, A.; Gupta, R. Evaluation of solar fraction on north partition wall for various shapes of solarium by Auto-Cad. Energy Build. 2003, 35, 507–514. [Google Scholar] [CrossRef]

- Singh, R.D.; Tiwari, G.N. Thermal heating of controlled environment greenhouse: A transient analysis. Energy Convers. Manag. 2000, 41, 505–522. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).