Postural Risk in Manual Planting Operations of Poplar: Two Options Compared

Abstract

1. Introduction

2. Materials and Methods

2.1. Study Location and Planting Material

2.2. Selection of Subjects and Organization of Work

2.3. Data Collection

2.4. Data Processing and Statistical Analysis

3. Results

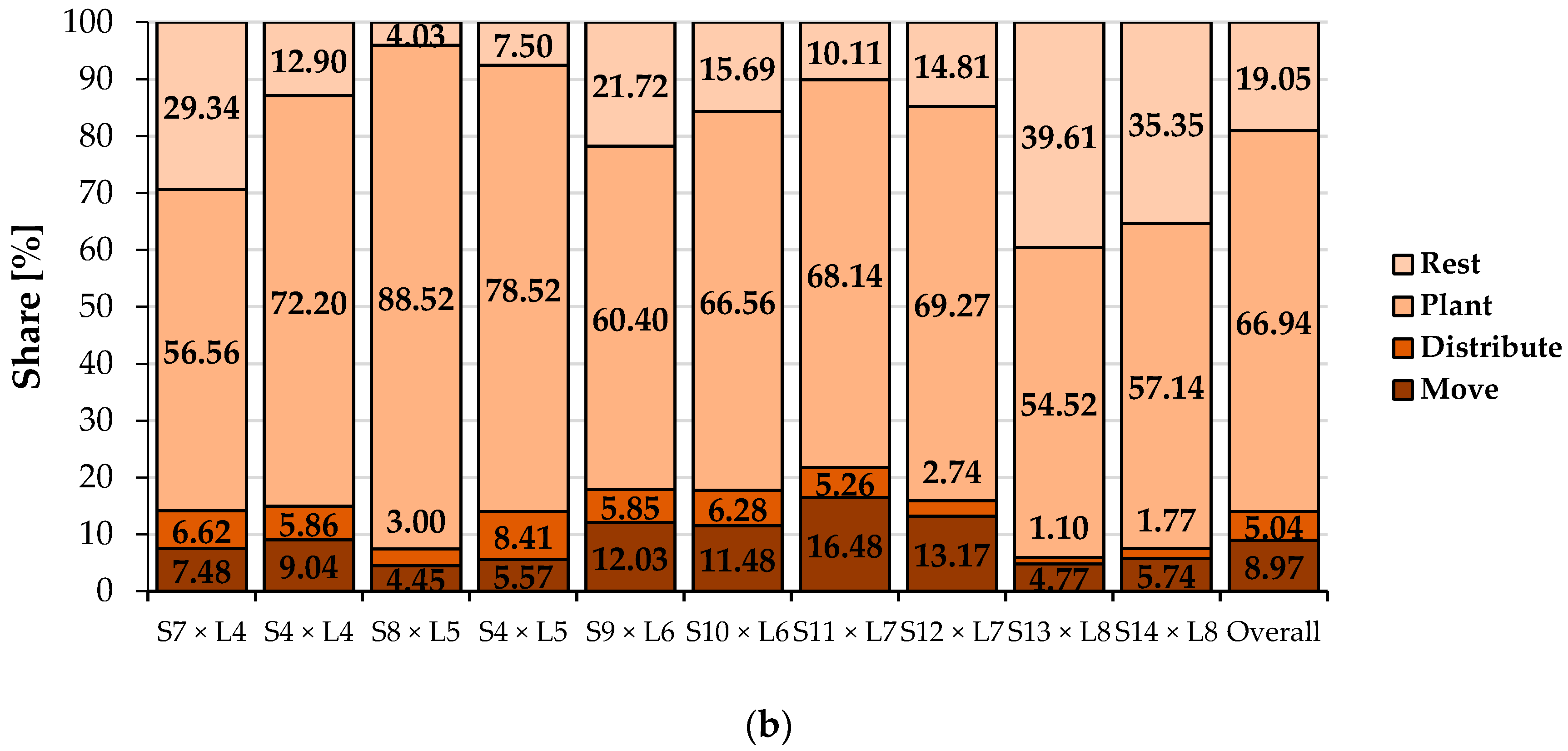

3.1. Task Share per Subjects and Types of Operations

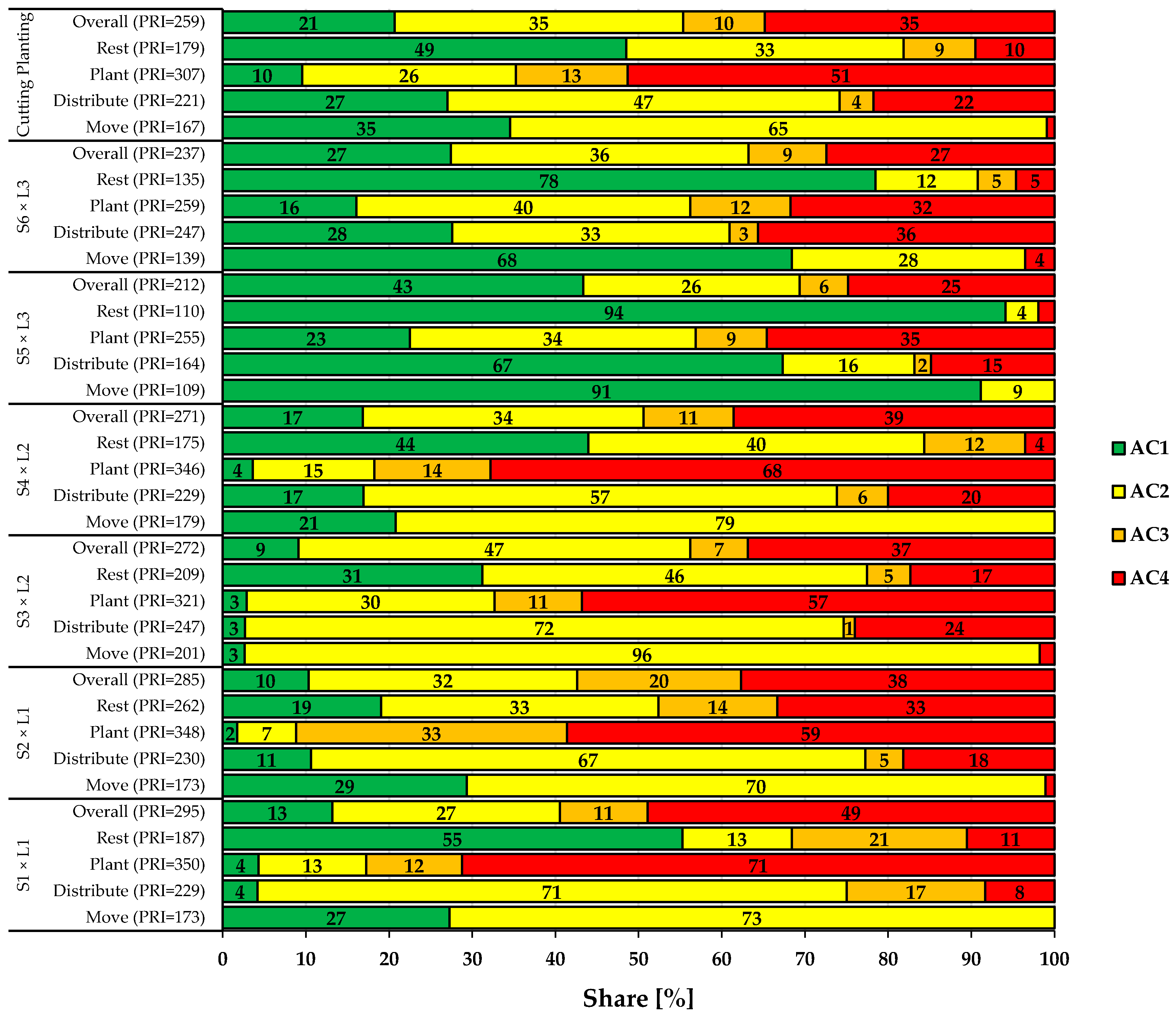

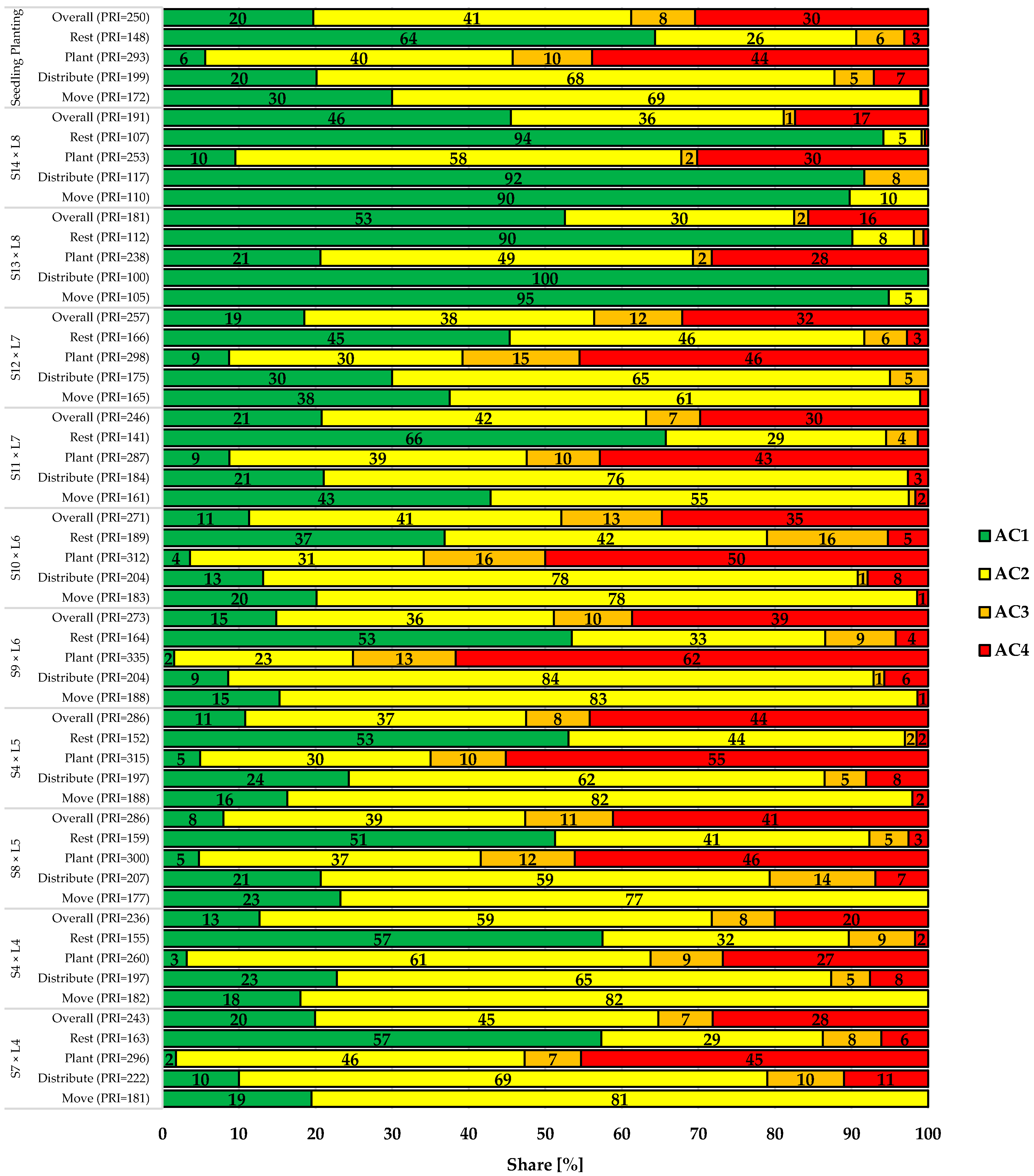

3.2. Postural Assessment

3.2.1. Cutting Planting

3.2.2. Seedling Planting

3.3. Comparison between Operations

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Dickmann, D.I.; Kuzovkina, J. Poplars and willows of the world, with emphasis on silviculturally important species. In Trees for Society and the Environment; Isebrands, J.G., Richardson, J., Eds.; The Food and Agriculture Organization of the United Nations and CABI: Rome, Italy, 2014; Volume 2, pp. 8–12. [Google Scholar]

- FAO. Improving Lives with Poplar and Willows. Synthesis of Country Progress Reports—Activities Related to Poplar and Willow Cultivation and Utilization—2008 Through 2011. In 24th Session of the International Poplar Commission, Dehradun, India, 29 October–2 November 2012; Working Paper Ipc/12; 93p; Forest Assessment, Management and Conservation Division, FAO: Rome, Italy, 2012; 104p, Available online: http://www.fao.org/forestry/ipc2012/en/ (accessed on 24 February 2019).

- Drew, A.P.; Zsuffa, L.; Mitchell, C.P. Terminology relating to woody plant biomass and its production. Biomass 1987, 12, 79–82. [Google Scholar] [CrossRef]

- Florescu, I.; Nicolescu, N.V. Silviculture; Lux Libris Publishing House: Brasov, Romania, 1996. [Google Scholar]

- Abrudan, I.V. Împăduriri; Editura Universității Transilvania din Brașov: Brasov, Romania, 2006. [Google Scholar]

- Niuwenhuis, M.; Egan, D. An evaluation and comparison of mechanised and manual tree planting on afforestation and reforestation sites in Ireland. Int. J. For. Eng. 2002, 3, 11–23. [Google Scholar] [CrossRef]

- Laine, T.; Saksa, T. Mechanized tree planting in Sweden and Finland: Current state and key factors for future growth. Forests 2018, 9, 370. [Google Scholar]

- Boja, N.; Boja, F.; Teușdea, A.; Vidrean, D.; Marcu, M.V.; Iordache, E.; Duţă, C.I.; Borz, S.A. Resource allocation, pit quality, and early survival of seedlings following two motor-manual pit-drilling options. Forests 2018, 9, 665. [Google Scholar] [CrossRef]

- Marogel-Popa, T.; Marcu, M.V.; Cheța, M.; Nuţă, I.S.; Borz, S.A. Dificultatea muncii în operații de plantare a puieților și a sadelor de plop: Analiza ritmului cardiac. Rev. Pădur. 2020, 135, 43–62. (In Romanian) [Google Scholar]

- Moskalik, T.; Borz, S.A.; Dvořák, J.; Ferencik, M.; Glushkov, S.; Muiste, P.; Lazdiņš, A.; Styranivsky, O. Timber harvesting methods in Eastern European countries: A review. Croat. J. For. Eng. 2017, 38, 231–241. [Google Scholar]

- Åstrand, P.O.; Rodahl, K. Textbook of Work Physiology—Physiological Bases of Exercise, 3rd ed.; Human Kinetics: Champaign, IL, USA, 1986. [Google Scholar]

- Marchi, E.; Chung, W.; Visser, R.; Abbas, D.; Nordfjell, T.; Mederski, P.S.; McEwan, A.; Brink, M.; Laschi, A. Sustainable forest operations (SFO): A new paradigm in a changing world and climate. Sci. Total Environ. 2018, 634, 1385–1397. [Google Scholar] [CrossRef]

- Heinimann, H.R. Forest operations engineering and management—The ways behind and ahead of a scientific discipline. Croat. J. For. Eng. 2007, 28, 107–121. [Google Scholar]

- Potočnik, I.; Poje, A. Forestry ergonomics and occupational safety in high ranking scientific journals from 2005–2016. Croat. J. For. Eng. 2017, 38, 291–310. [Google Scholar]

- David, G.C. Ergonomic methods for assessing exposure to risk of factors for work-related musculoskeletal disorders. Occup. Med. C. 2005, 55, 190–199. [Google Scholar] [CrossRef]

- Helander, M. A Guide to Human Factors and Ergonomics, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2006; pp. 224–255. [Google Scholar]

- Lupuşoru, V.; Diaconu, M.; Diaconu, S.; Ionele, A. Norme de Timp şi Producţie Unificate Pentru Lucrări din Silvicultură; S.C. ROF S.A. Suceava: Suceava, Romania, 1997. [Google Scholar]

- Hanson, J.A.; Jones, P.P. Heart rate and small postural changes in man. Ergonomics 1970, 13, 483–487. [Google Scholar] [CrossRef] [PubMed]

- Jones, A.Y.M.; Kam, C.; Lai, K.W.; Lee, H.Y.; Chow, H.T.; Lau, S.F.; Wong, L.M.; He, J. Changes in heart rate and R-wave amplitude with posture. Chin. J. Physiol. 2003, 46, 63–69. [Google Scholar] [PubMed]

- Šipinková, I.; Hahn, G.; Meyer, M.; Tadlánek, M.; Hájek, J. Effect of respiration and posture on heart rate variability. Physiol. Res. 1997, 46, 173–179. [Google Scholar]

- Şofletea, N.; Curtu, L. Dendrologie, 2nd ed.; Pentru Viaţă Publishing House: Braşov, Romania, 2008; pp. 335–336. [Google Scholar]

- Marogel-Popa, T.; Cheța, M.; Marcu, M.V.; Dută, C.I.; Ioraș, F.; Borz, S.A. Manual cultivation operations in poplar stands: A characterization of job difficulty and risks of health impairment. Int. J. Environ. Res. Public Health 2019, 16, 1911. [Google Scholar] [CrossRef]

- Zar, J.H. Biostatistical Analysis, 5th ed.; Pearson Prentice-Hall: Upper Saddle River, NJ, USA, 2010. [Google Scholar]

- Karhu, O.; Kansi, P.; Kuorinka, I. Correcting working postures in industry: A practical method for analysis. Appl. Ergon. 1977, 8, 199–201. [Google Scholar] [CrossRef]

- Björheden, R.; Apel, K.; Shiba, M.; Thompson, M. IUFRO Forest Work Study Nomenclature; The Swedish University of Agricultural Science: Garpenberg, Sweden, 1995. [Google Scholar]

- Corella-Justavino, F.; Jimenez Ramirez, R.; Meza Perez, N.; Borz, S.A. The use of OWAS in forest operations postural assessment: Advantages and limitations. Bull. Transilv. Univ. Braşov Ser. II For. Wood Ind. Agric. Food Eng. 2015, 8, 7–16. [Google Scholar]

- Zanuttini, R.; Cielo, P.; Poncino, D. The OWAS method. Preliminary results for the evaluation of the risk of work-related musculo-skeletal disorders (WMSD) in the forestry sector in Italy. For. Riv. Selvic. Ecolog. For. 2005, 2, 242–255. [Google Scholar]

- Borz, S.A.; Talagai, N.; Cheța, M.; Chiriloiu, D.; Gavilanes Montoya, A.V.; Castillo Vizuete, D.D.; Marcu, M.V. Physical strain, exposure to noise and postural assessment in motor-manual felling of willow short rotation coppice: Results of a preliminary study. Croat. J. For. Eng. 2019, 40, 377–388. [Google Scholar] [CrossRef]

- Cheţa, M.; Marcu, M.V.; Borz, S.A. Workload, exposure to noise, and risk of musculoskeletal disorders: A case study of motor-manual tree felling and processing in poplar clear cuts. Forests 2018, 9, 300. [Google Scholar] [CrossRef]

- Spinelli, R.; Aminti, G.; de Francesco, F. Postural risk assessment of firewood processing. Ergonomics 2016, 60, 1–9. [Google Scholar] [CrossRef]

- Spinelli, R.; Aminti, G.; Magagnotti, N.; De Francesco, F. Postural risk assessment of small-scale debarkers for wooden post production. Forests 2018, 9, 111. [Google Scholar] [CrossRef]

- Calvo, A. Musculoskeletal disorders (MSD) risks in forestry: A case study to propose an analysis method. Agric. Eng. Int. 2009, 11, 1–9. [Google Scholar]

- Comper, M.L.C.; Dennerlein, J.T.; dos Santos Evangelista, G.; da Silva, P.R.; Padula, R.S. Effectiveness of job rotation for preventing work-related musculoskeletal diseases: A cluster randomized controlled trial. Occup. Environ. Med. 2017, 74, 543–544. [Google Scholar] [CrossRef] [PubMed]

- Aragón-Vásquez, A.Y.; Silva-Lugo, E.D.; Nájera-Luna, J.A.; Méndez-González, J.; Hernández, F.J.; de la Cruz-Carrera, R. Postural analysis of the forestry worker in sawmills of El Salto, Durango, Mexico. Madera Bosques 2019, 25, e2531904. [Google Scholar]

- Mathiassen, S.E. Diversity and variation in biomechanical exposure: What is it, and what would we like to know? Appl. Ergon. 2006, 37, 419–427. [Google Scholar] [CrossRef] [PubMed]

- Da Costa, B.R.; Vieira, E.R. Risk factors for work-related musculoskeletal disorders: A systematic review of recent longitudinal studies. Am. J. Ind. Med. 2010, 53, 285–353. [Google Scholar] [CrossRef] [PubMed]

- Borz, S.A.; Ignea, G.; Vasilescu, M.M. Small gains in wood recovery rate when disobeying the recommended motor-manual tree felling procedures: Another reason to use proper technical prescriptions. Bioresources 2014, 9, 6938–6949. [Google Scholar] [CrossRef]

| Study Location | Forest District | Geographical Coordinates | Forest Compartment and Its Area (ha) | Species Used | Planting Scheme (m) | Planting Material |

|---|---|---|---|---|---|---|

| L1 | Sadova | 43°45′05.47″ N 23°54′56.23″ E | 106A% (0.47) | PLEA | 6 × 4 | cuttings |

| L2 | Sadova | 43°45′33.59″ N 23°52′39.86″ E | 88B% (0.89) | PLEA | 6 × 4 | cuttings |

| L3 | Calafat | 43°57′58.03″ N 22°52′55.42″ E | 91B (0.96) | PLEA | 4 × 4 | cuttings |

| L4 | Poiana Mare | 43°50′51.35″ N 23°36′06.75″ E | 22C (2.91) | PLA | 3 × 2 | seedlings |

| L5 | Poiana Mare | 43°50′12.70″ N 23°11′10.63″ E | 43A (1.45) | PLA | 3 × 2 | seedlings |

| L6 | Dăbuleni | 43°45′01.60″ N 23°57′33.55″ E | 7A,2D (1.81) | PLEA | 5 × 4 | seedlings |

| L7 | Poiana Mare | 43°50′49.75″ N 23°10′19.30″ E | 31F,31N (1.61) | PLA | 3 × 2 | seedlings |

| L8 | Dăbuleni | 43°44′49.21″ N 23°59′33.56″ E | 9D,10A (4.16) | PLEA | 5 × 4 | seedlings |

| Subject | Abbreviation in This Study | Age (years) | Body Weight (kg) | Body Height (m) | Body Mass Index | Location of Field Observation |

|---|---|---|---|---|---|---|

| Subject 1 | S1 | 53 | 81 | 1.75 | 26.45 | L1 |

| Subject 2 | S2 | 38 | 78 | 1.65 | 28.65 | L1 |

| Subject 3 | S3 | 27 | 74 | 1.73 | 24.73 1 | L2 |

| Subject 4 | S4 | 50 | 95 | 1.82 | 28.68 | L2, L4, L5 |

| Subject 5 | S5 | 45 | 87 | 1.85 | 25.42 | L3 |

| Subject 6 | S6 | 20 | 69 | 1.74 | 22.79 1 | L3 |

| Subject 7 | S7 | 49 | 78 | 1.70 | 26.99 | L4 |

| Subject 8 | S8 | 48 | 80 | 1.70 | 27.68 | L5 |

| Subject 9 | S9 | 51 | 83 | 1.75 | 27.10 | L6 |

| Subject 10 | S10 | 40 | 85 | 1.69 | 29.76 | L6 |

| Subject 11 | S11 | 54 | 75 | 1.70 | 25.95 | L7 |

| Subject 12 | S12 | 52 | 55 | 1.65 | 31.93 | L7 |

| Subject 13 | S13 | 28 | 70 | 1.80 | 21.60 1 | L8 |

| Subject 14 | S14 | 51 | 83 | 1.75 | 27.10 | L8 |

| Subject and Location | Type of Planting Operation | Number of Video Files | Length of Video Files (s) | Number of Analyzed Frames | Number of Valid and Reorganized Frames | Share of Valid and Reorganized Frames in the Collected Data (%) |

|---|---|---|---|---|---|---|

| S1 × L1 | CP | 6 | 7200 | 600 | 419 (417 3) | 5.82 (5.79 4) |

| S2 × L1 | CP | 6 | 7200 | 600 | 410 (406 3) | 5.69 (5.64 4) |

| S3 × L2 | CP | 12 | 14,400 | 1200 | 787 (781 3) | 5.47 (5.42 4) |

| S4 × L2 | CP | 12 | 14,400 | 1200 | 833 (832 3) | 5.78 (5.78 4) |

| S5 × L3 | CP | 9 | 10,800 | 900 | 659 (653 3) | 6.10 (6.05 4) |

| S6 × L3 | CP | 9 | 10,800 | 900 | 707 (707 3) | 6.55 (6.55 4) |

| S7 × L4 | SP | 20 | 23,400 1 | 1772 | 1522 (1510 3) | 6.50 (6.45 4) |

| S4 × L4 | SP | 20 | 23,400 1 | 1772 | 1358 (1349 3) | 5.80 (5.76 4) |

| S8 × L5 | SP | 81 | 14,580 2 | 1215 | 864 (818 3) | 5.93 (5.61 4) |

| S4 × L5 | SP | 81 | 14,580 2 | 1215 | 820 (679 3) | 5.62 (4.66 4) |

| S9 × L6 | SP | 12 | 13,700 1 | 1140 | 732 (722 3) | 5.34 (5.27 4) |

| S10 × L6 | SP | 12 | 13,700 1 | 1140 | 738 (729 3) | 5.39 (5.32 4) |

| S11 × L7 | SP | 14 | 16,800 | 1400 | 967 (967 3) | 5.76 (5.76 4) |

| S12 × L7 | SP | 14 | 16,800 | 1400 | 898 (880 3) | 5.35 (5.24 4) |

| S13 × L8 | SP | 17 | 19,860 1 | 1650 | 1373 (1197 3) | 6.91 (6.03 4) |

| S14 × L8 | SP | 17 | 19,860 1 | 1650 | 1377 (1211 3) | 6.93 (6.10 4) |

| Task Name and Tests Results | Operation Type | Action Category [%] | Postural Risk Index | |||

|---|---|---|---|---|---|---|

| AC1 | AC2 | AC3 | AC4 | |||

| Move χ2 = 0.582, p = 0.901 | CP | 34.56 | 64.52 | 0.00 | 0.92 | 167.28 |

| SP | 30.01 | 68.99 | 0.11 | 0.89 | 171.87 | |

| Distribute χ2 = 12.260, p = 0.007 1 | CP | 27.03 | 47.13 | 4.07 | 21.77 | 220.57 |

| SP | 20.12 | 67.65 | 5.13 | 7.10 | 199.21 | |

| Plant χ2 = 5.226, p = 0.156 | CP | 9.57 | 25.66 | 13.46 | 51.31 | 306.51 |

| SP | 5.60 | 40.16 | 10.33 | 43.90 | 292.55 | |

| Rest χ2 = 6.641, p = 0.084 | CP | 48.53 | 33.33 | 8.61 | 9.52 | 179.12 |

| SP | 64.32 | 26.29 | 6.26 | 3.13 | 148.20 | |

| Overall χ2 = 1.039, p = 0.792 | CP | 20.68 | 34.69 | 9.80 | 34.83 | 258.77 |

| SP | 19.71 | 41.49 | 8.38 | 30.42 | 249.51 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marogel-Popa, T.; Marcu, M.V.; Borz, S.A. Postural Risk in Manual Planting Operations of Poplar: Two Options Compared. Sustainability 2020, 12, 5531. https://doi.org/10.3390/su12145531

Marogel-Popa T, Marcu MV, Borz SA. Postural Risk in Manual Planting Operations of Poplar: Two Options Compared. Sustainability. 2020; 12(14):5531. https://doi.org/10.3390/su12145531

Chicago/Turabian StyleMarogel-Popa, Tiberiu, Marina Viorela Marcu, and Stelian Alexandru Borz. 2020. "Postural Risk in Manual Planting Operations of Poplar: Two Options Compared" Sustainability 12, no. 14: 5531. https://doi.org/10.3390/su12145531

APA StyleMarogel-Popa, T., Marcu, M. V., & Borz, S. A. (2020). Postural Risk in Manual Planting Operations of Poplar: Two Options Compared. Sustainability, 12(14), 5531. https://doi.org/10.3390/su12145531