1. Introduction

The large consumption of fossil fuels has contributed to a steady increase in air pollutant emissions and greenhouse gas emissions, leading to severe air pollution and global climate change. China surpassed the United States to become the world’s largest energy consumer, and its energy consumption accounted for 21.92% of the world in 2012 [

1,

2]. It is worth noting that the proportion of coal in China’s primary energy consumption was approximately 70% in 2012 [

3]. This coal-based energy consumption structure determined the thermal-based power generation structure, which will not change significantly in the next decade. During the “Twelfth Five-Year Plan” period (2011–2015), China’s annual coal utilization for thermal power generation accounted for roughly 63% of its total coal consumption, and about 90% of the country’s electricity is consumed in urban areas [

4]. Therefore, the electricity power industry is a key sector that supports and promotes the rapid development of Chinese cities. According to 2014 statistics, the installed capacity of thermal power plants in China increased from 768.34 GW to 1525.27 GW (65.93% of the total installed power capacity) during 2011–2015, and the thermal power generation increased from 3900.3 billion kWh to 4230.7 billion kWh (73.68% of total power generation) [

4,

5]. The coal-fired power plants of China’s power industry are the main source of conventional air pollutant emissions and greenhouse gas emissions. From 2011 to 2015, the annual average emissions of sulfur dioxide (SO

2), nitrogen oxides (NO

x), and Total Suspended Particulates (TSP) from coal-fired power plants accounted for about 30%, 36.4%, and 11.8%, respectively [

6]. Meanwhile, carbon dioxide (CO

2) emissions from coal-fired power plants contributed 45% of the total CO

2 emissions from fossil fuel combustion in the country. These large quantities of greenhouse gases and air pollutants have aggravated urban air pollution. This means that air pollutants and greenhouse gases must be effectively controlled in the power industry to maximize the co-benefits of reducing carbon and air pollutant emissions [

7].

The literature shows that the focus of current studies is mainly on the co-benefits at the global, regional, and national levels [

1,

8,

9,

10,

11,

12,

13,

14]. Few of them have explored the co-benefits at a local level (i.e., at the city and province level) [

6,

15]. It is necessary to detect the impact of local policies (i.e., local air pollution control policies) on the co-benefits, especially in developing countries such as China, which have the biggest and most rapid development of urbanization and industry in the world. Without this comprehensive assessment, it is impossible to understand the synergy and correlation between energy-related climate change and air pollution [

1].

Our study addressed the knowledge gap and we utilized the study to account for the level of synergy of climate change and air pollution, quantify the size of co-benefits achieved, and assess the co-reduction efficiency of CO2 and air pollutants emissions in China’s electric power industry at the local level. It focuses on the CO2 emissions reduction from air pollution control devices (APCDs) and measures in China’s power industry by using case studies. These include the co-benefits of structural and technical emission reduction measures of the power industry on controlling air pollutants (SO2, NOx, and TSP) and greenhouse gases (CO2). Furthermore, we made a comparison analysis for better understanding co-benefits produced at local places. It can be more intuitive to compare the synergistic effect and impact of co-benefits of reduction measures between local provinces and cities with different levels of development, which is still blank in the previous studies on co-benefits in China’s power industry.

2. Methodology

In this study, coal-fired power plants in three provinces and cities in the more developed regions of eastern China including the Shanghai, Jiangsu, and Zhejiang provinces in the Yangtze River Delta region, and Yunnan Province in the less developed western region of China, were selected as case studies. Then, the synergistic emission reduction factors and effects of structural emission reduction measures, which refer to utilizing renewables such as hydropower, wind power, and solar power for generating electricity in power plants, and technical emission reduction measures, which refer to APCDs of power plants (including desulfurization, denitrification, and dust removal measures) were assessed, and these co-control results were compared in all four of the above case regions. The study included thermal power (including independent power and captive power) and clean energy generation (including hydropower, wind power, and solar power) in the power industry. Among them, independent thermal power plants were selected as the main research objects, occupying 60% of the total number of thermal power plants in the case regions. In addition, the air pollution emissions from the independent thermal power plants accounted for approximately 80% of air pollutants discharged from all thermal power plants in China [

4,

5]. Another reason behind the selection of the study objects is that the research data of case studies are more accessible and available than other provinces and cities in China.

In order to identify the size and the ability of reduction of CO

2 and air pollutants, this study first quantified the emissions and emission factors of air pollutants (SO

2, NO

x, and TSP) and CO

2 from independent thermal power plants (representing the entire thermal power industry as the main study object) in Yunnan, Shanghai, Jiangsu, and Zhejiang. Secondly, in order to further determine whether the various emission reduction measures have co-benefits, the synergistic reduction effects of these reduction measures were comprehensively evaluated by the combined analysis of co-control factors and the equivalent emission index of air pollutants. The data adopted in the study include energy use, economic parameters, technical and structural measures, mainly derived from statistical yearbooks and reports including the China Statistical Yearbook (2010–2016) [

4], the China Energy Statistics Yearbook (2010–2016) [

16], the China Electricity Yearbook (2010–2016) [

17], the China Environmental Statistics Yearbook (2010–2016) [

18], and the China Environmental Statistics Annual Report (2010–2016) [

5].

The research method is described as follows:

2.1. Waste Gases Emissions Calculation

The air pollutant (SO

2, NO

x, and TSP) emissions data for each case region in this study were obtained from the air pollutant discharge data of independent thermal power plants in the respective regions. The data all came from the China Electricity Yearbook (2016) and the China Environmental Statistical Annual Report (2015) [

5,

17].

For each case region, the analysis of greenhouse gas carbon dioxide emissions was based on the Intergovernmental Panel on Climate Change (IPCC) carbon emission factor calculation method. The formula is as follows:

where

is annual CO

2 emissions (tons/year),

is the annual energy consumption in independent thermal power plants (tons/year), and

is the emission factor of CO

2 in independent thermal power plants, which is based on the relevant values in the 2006 IPCC Guidelines for National Greenhouse Gas Inventories [

19] and the China Energy Data Analysis Manual 2016 [

20].

In order to evaluate the effect and benefits of reducing air pollution and CO

2 emissions uniformly, the study constructs the equivalent emission index of air pollutants (also known as APeq) by using the method of Mao et al. [

21,

22]. It can summarize the total emission reduction effects to reflect the linear cumulative effect of the synergistic reduction of air pollutants and greenhouse gases. The normalized formula is as follows:

where α, β, γ, δ, ϵ, θ are the weight factors of corresponding air pollutants. This study focuses on SO

2, NOx, TSP, and CO

2 emissions and emission reductions, so the above formula is adjusted to:

where S, N, T, and C are emission reductions of SO

2, NOx, TSP, and CO

2, respectively, and

are the weight factors of corresponding air pollutants, which are based on the price evaluation value of the externalization effect of the abovementioned air pollutants. In this paper, the weight factor values were obtained by the “pollution discharge fees” in the case regions [

5,

23,

24,

25]. The concentration limits and APeq equivalent factors of various air pollutants and greenhouse gases are shown in

Table 1.

Thus, the calculation formula of APeq in this study can be written as follows:

where APeq is the equivalent emission index of air pollutants. S, N, T, and C are emission reductions of SO

2, NO

x, TSP, and CO

2, respectively.

2.2. Emission Factors

Calculating the emission factors of the thermal power industry in different regions helps to initially compare the emission intensity of the power industry among the case regions, and to provide basic data for subsequent calculation and analytical steps. Emission factors are divided into direct and indirect emission factors. The direct emission factor refers to the pollutants emitted per unit of thermal power fuel in tons per ton of standard coal equivalent (t/tce), while the indirect emission factor refers to the amount of pollutants emitted per unit of thermal power product consumption (e.g., electricity) in grams per kilowatt hour (g/kWh). Selecting 2015 as the base year, this study first calculated the emission factors of CO2, SO2, NOx, and TSP in the independent thermal power plants in each region, and then estimated the emission reduction effects of direct and indirect energy saving, respectively. These effects’ calculations served as the basic parameters for subsequent analysis. The emission factor calculation formula is as follows:

where j is air pollutant j (CO

2, SO

2, NO

x, TSP, and APeq),

is the direct emission factor of air pollutant j (tons/tce),

is the annual emissions of air pollutant j (tons/year), and

is the annual fuel consumption of independent power plants (tce/year).

where j is air pollutant j (CO

2, SO

2, NO

x, TSP, and APeq),

is the indirect emission factor of air pollutant j (tons/kWh),

is the annual emissions of air pollutant j (tons/year), and

is the annual electricity production (kWh/year).

2.3. Emission Reduction Effects

According to the emission factors above and energy saving data of the identified measures, the emission reductions of air pollutants and CO2 by energy conservation and emission reduction measures were calculated. This research categorized two energy conservation and emission reduction measures. One is structural emission reduction measures, namely, clean energy power generation measures such as hydropower, wind power, and solar power. The other is technical emission reduction measures, i.e., the end Air Pollution Control Devices (APCDs) of thermal power plants. With respect to APCDs, this paper discusses the three most prevalent devices including desulfurization, denitrification, and dust removal devices.

The waste gas emission reductions of clean power were analyzed based on the clean power production and the direct emission factors mentioned above. The formula is as follows:

where

is the annual emissions reduction of measure i (clean power) of air pollutant j (tons),

is the direct emission factor of air pollutant j (tons/tce), and

represents the annual energy saving by measure i, i.e., the coal reserved by replacing thermal power production (tce).

is calculated by the following formula:

where

is the annual electricity production of measure i (kWh) and

is the coal consumption per electricity production in each region (tce/kWh).

In 2015, the synergistic factor of APCDs on air pollutants and carbon dioxide in China’s newly built thermal power units were calculated with the quality conservation method that was made by Zhao et al. [

26]. Based on this research, the specific synergistic emission reduction factors are listed in

Table 2.

Emission reduction factor is used to represent the ability of reduction measures on reducing pollution emissions. In this paper, these factors were calculated by this formula as follows:

where

is the emission reduction factor of measure i (APCDs and clean power) on air pollutants j,

is the annual emissions reduction of measure i on air pollutant j (tons/year), and

is the indirect emission factor of air pollutant j (g/kWh).

2.4. Synergy Factors

In order to further analyze the synergies and co-benefits of emission reduction measures, this study involved the calculation of the synergy factors of these measures, which can determine whether the various emission reduction measures have co-benefits, i.e., positive synergies on different air pollutants, CO

2, and energy consumption, and confirm their degree of synergy. F was defined as the synergy factor, and its calculation formula is as follows:

where

is the synergy factor; which is the ratio of the amount of change in the synergistic factor a and the amount of change in the target factor b under the action of the abatement measure i;

is the indirect impact of abatement measure i on synergistic factor a; i.e., its emission reductions for air pollutants (SO

2; NOx; and TSP) and CO

2; and energy savings if it increases energy consumption and emissions;

is negative;

is the direct effect of the measure i on the target factor b, and the rest is the same as

.

If F < 0, the abatement measure i has a negative synergy. If F = 0, the measure i has no synergy. If F > 0, the measure i has a positive synergy (e.g., co-benefits). If 0 < F < 1, the measure i has a positive synergy, and the degree of influence on b is higher than a. If F = 1, the measure i has a positive synergy, and the degree of effect on a and b is the same. If F > 1, the measure i has a positive synergy and the degree of influence on a is higher than b.

3. Results and Discussion

3.1. Electricity Production Structure

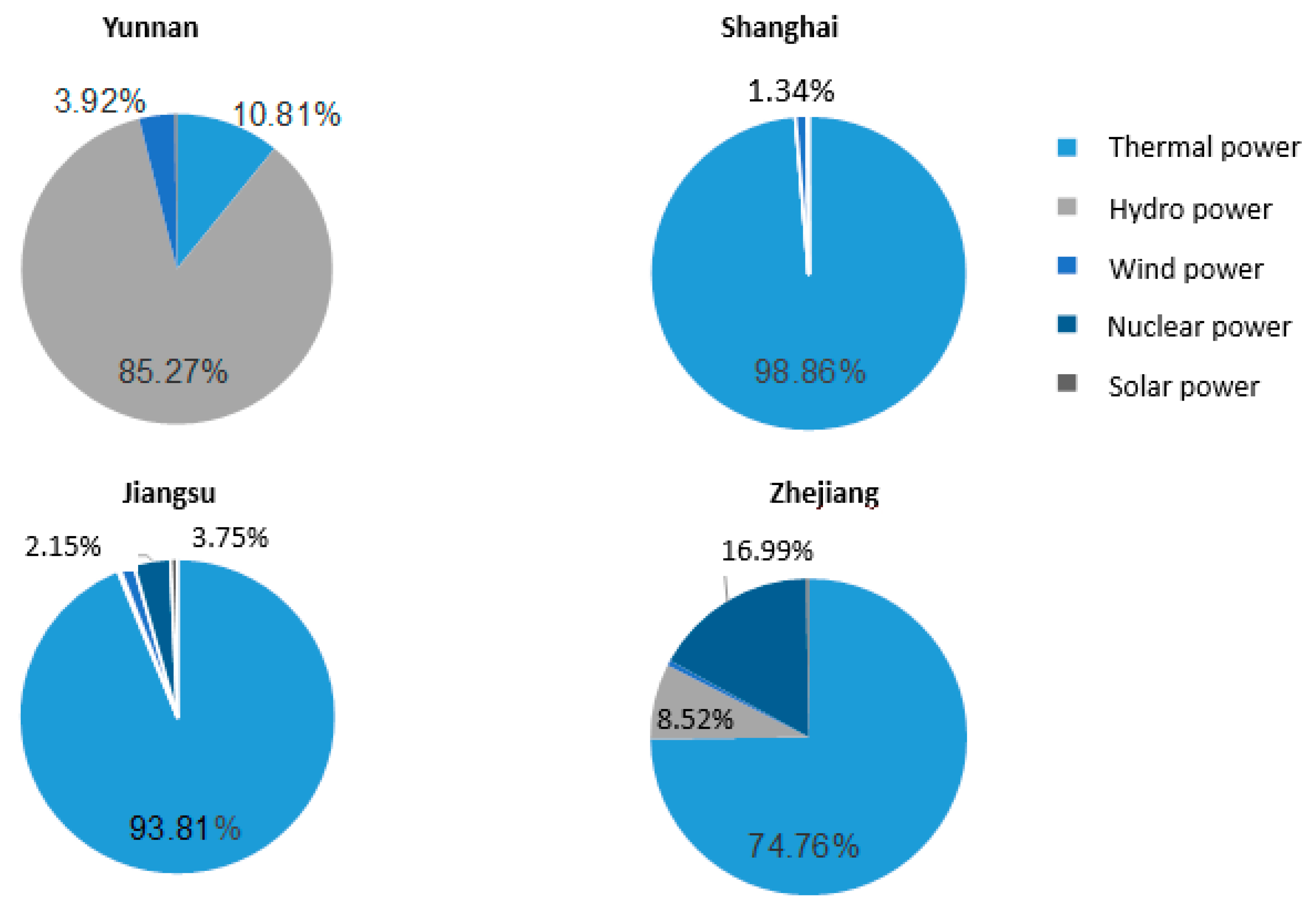

The composition of power generation in Yunnan Province, Jiangsu Province, Zhejiang Province, and Shanghai City for 2015 is shown in

Figure 1. The proportion of hydropower generation in Yunnan Province (85.27%) was approximately eight times that of thermal power generation (10.81%), and wind power and solar power generation accounted for a small proportion (3.92% in total). There was no hydropower generation in Shanghai and the proportion of thermal power generation was extremely high (98.66%), while the sum of wind power and solar wind power generation only accounted for 1.34% of the city’s total power generation. Jiangsu’s thermal power generation (93.81%) was about 16 times that of the sum of nuclear power, hydropower, wind power, and solar power generation. Among all of the four clean power options, nuclear power was the largest clean energy generation method in Jiangsu. The proportion of thermal power generation in Zhejiang Province (74.76%) was lower than that in Shanghai and Jiangsu Provinces, and nuclear power was the largest (16.69%) clean energy generation method, which was the same as in Jiangsu. The proportion of hydropower, wind power, and solar power generation (8.52%) was also higher, compared with Shanghai and Jiangsu. In summary, in the power generation structure of 2015, Yunnan Province mainly relied on hydropower generation, and the power industry of “Jiangsu Province, Zhejiang Province, and Shanghai City” were dominated by thermal power. The proportion of thermal power in Shanghai, Jiangsu, and Zhejiang provinces decreased in this order, and nuclear power was the largest clean energy generation method both in Jiangsu and Zhejiang.

3.2. Waste Gas Emissions

3.2.1. Air Pollutant Emissions

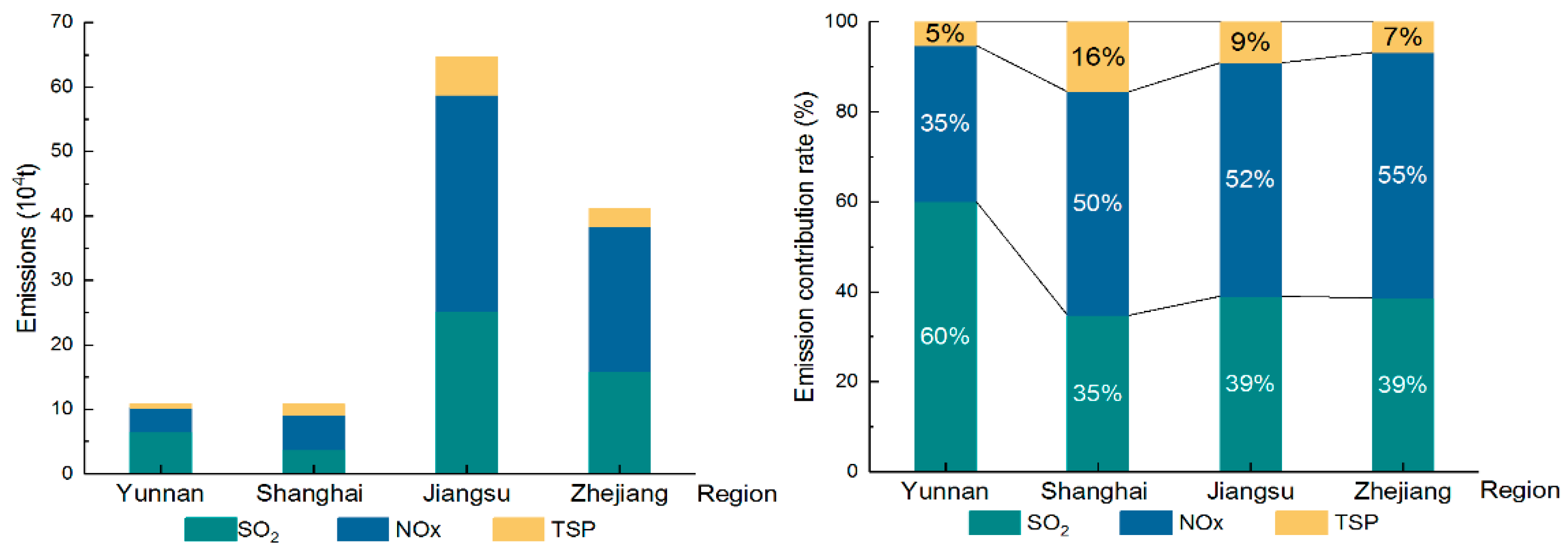

As shown in

Figure 2, the air pollutant emissions in thermal power plants of the economically developed provinces of Jiangsu and Zhejiang in 2015 were much larger than those in the economically developing Yunnan area, while in the same economically developed city of Shanghai, air pollutant emissions were almost the same as those in Yunnan Province. This was mainly because Shanghai’s electricity consumption is mostly supplied by Jiangsu and Zhejiang provinces and there are fewer local thermal power plants. Furthermore, the air pollutant emissions structures in Jiangsu, Zhejiang, and Shanghai were similar, and NO

x contributed the most, and TSP the least, to overall emissions. In Yunnan Province, SO

2 emissions accounted for the largest proportion and were greater than the NO

x emissions proportions in the other three case regions, and the TSP ratio was the smallest and less than the TSP emissions percentage of the other regions.

3.2.2. CO2 Emission

Using Formula (1) described in

Section 2, in 2015, the energy consumption and CO

2 emissions of the independent thermal power plants in the four regions, excluding the self-supplied power plants in other industries such as steel and construction, were determined and are shown in

Table 3. It is concluded that the annual energy consumption and annual CO

2 emissions of independent thermal power plants in Jiangsu Province in 2015 were the highest among four case regions, followed by Zhejiang Province. Both energy consumption and CO

2 emissions were the smallest in Yunnan Province.

3.2.3. Emission Factors

The direct and indirect emission factors for the independent thermal power plants in each region’s power sector were calculated by using Equations (6) and (7) and shown in

Table 4. Among the four regions, Yunnan’s independent thermal power plant had the highest direct emission factors for SO

2 and NO

x, followed by Zhejiang, while the two factor values were lower and close to each other. The TSP direct emission factor in Shanghai’s independent thermal power plant was the highest, followed by Yunnan’s plants, and the lowest was in Jiangsu and Zhejiang. Due to the nonavailability and nonaccessibility of emissions data from field research, the direct CO

2 emission factors in this study were calculated using the IPCC carbon emission factor, which was the same in the four regions. Among the four types of waste gases, the direct emission factor of CO

2 was the highest, followed by NO

x and SO

2, while that of TSP was the lowest.

Among these four regions, Yunnan’s independent thermal power plants had the highest indirect emission factors for SO2, NOx, and CO2, followed by Zhejiang Province, Jiangsu Province, and Shanghai City. Shanghai’s independent thermal power plants had the highest TSP indirect emission factor, which was close to Yunnan’s. Various similar rules were identified in the values of the direct and indirect emission factors of the four types of waste gases: the CO2 emission factor had the highest value, followed by order of NOx, SO2, and TSP. Combining the above emissions and emission factors, due to differences in economic development structure, fuel composition, combustion mode, and exhaust gas treatment, the emission intensity of air pollutants and carbon dioxide in the Yunnan thermal power industry (independent thermal power plants) was much higher than the other three case regions in 2015. The emission intensity was the weakest in Shanghai as compared to the other regions.

3.3. Emission Reductions in the Electricity Industry

3.3.1. Emission Reductions by Structural Emission Reduction Measures

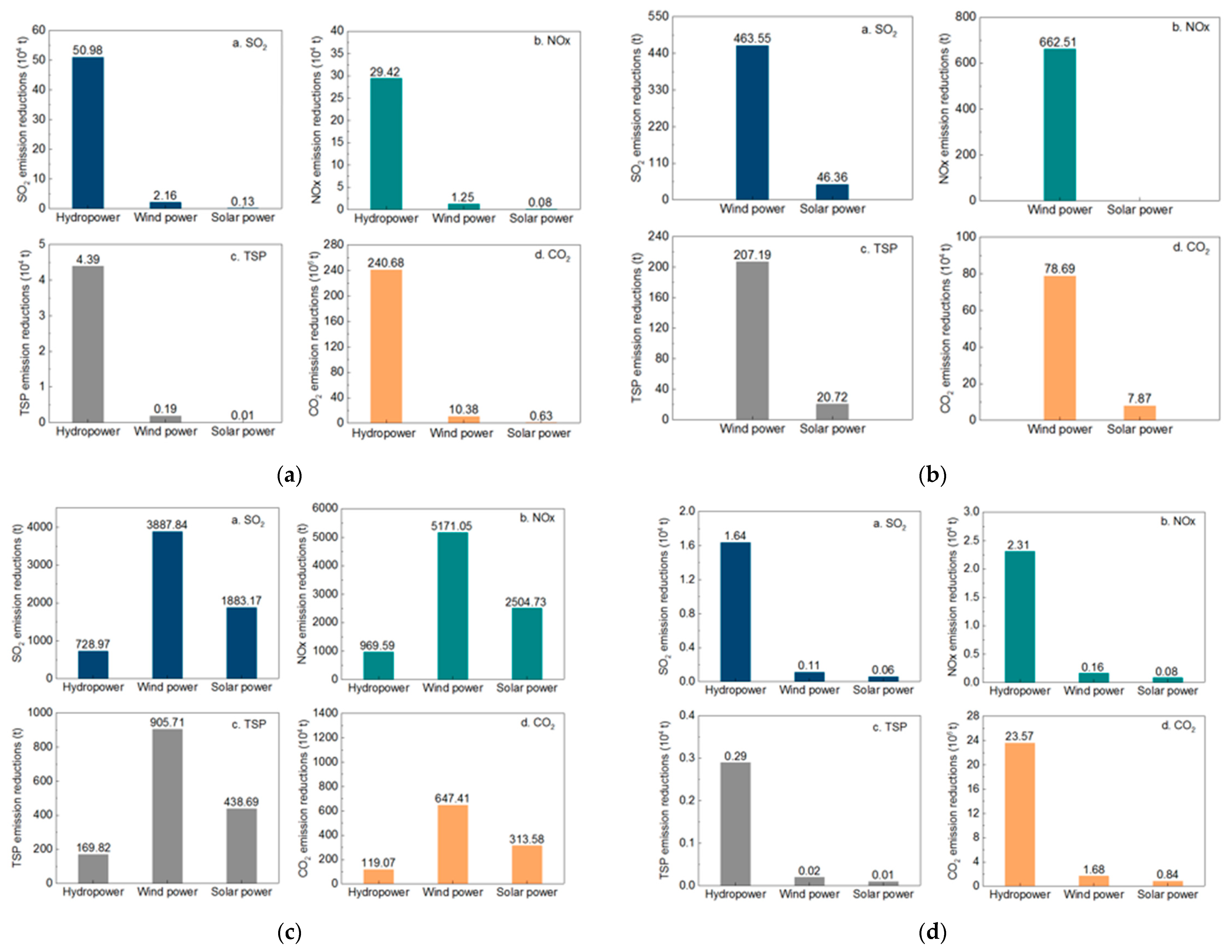

The analysis results of emission reductions by clean energy generation measured in various regions for 2015 are shown in

Figure 3. Due to the structure of clean energy power generation measures, hydropower in the Yunnan and Zhejiang Provinces displayed the best removal effect on four types of exhaust gases, and the exhaust gas removal effect of wind power and solar power generation were weaker. The waste gas removal effect of Shanghai’s wind power was much stronger than its solar power generation. In Jiangsu, the waste gas removal effect of wind power was the best, closely followed by solar power generation, while hydropower exhibited the worst removal effect.

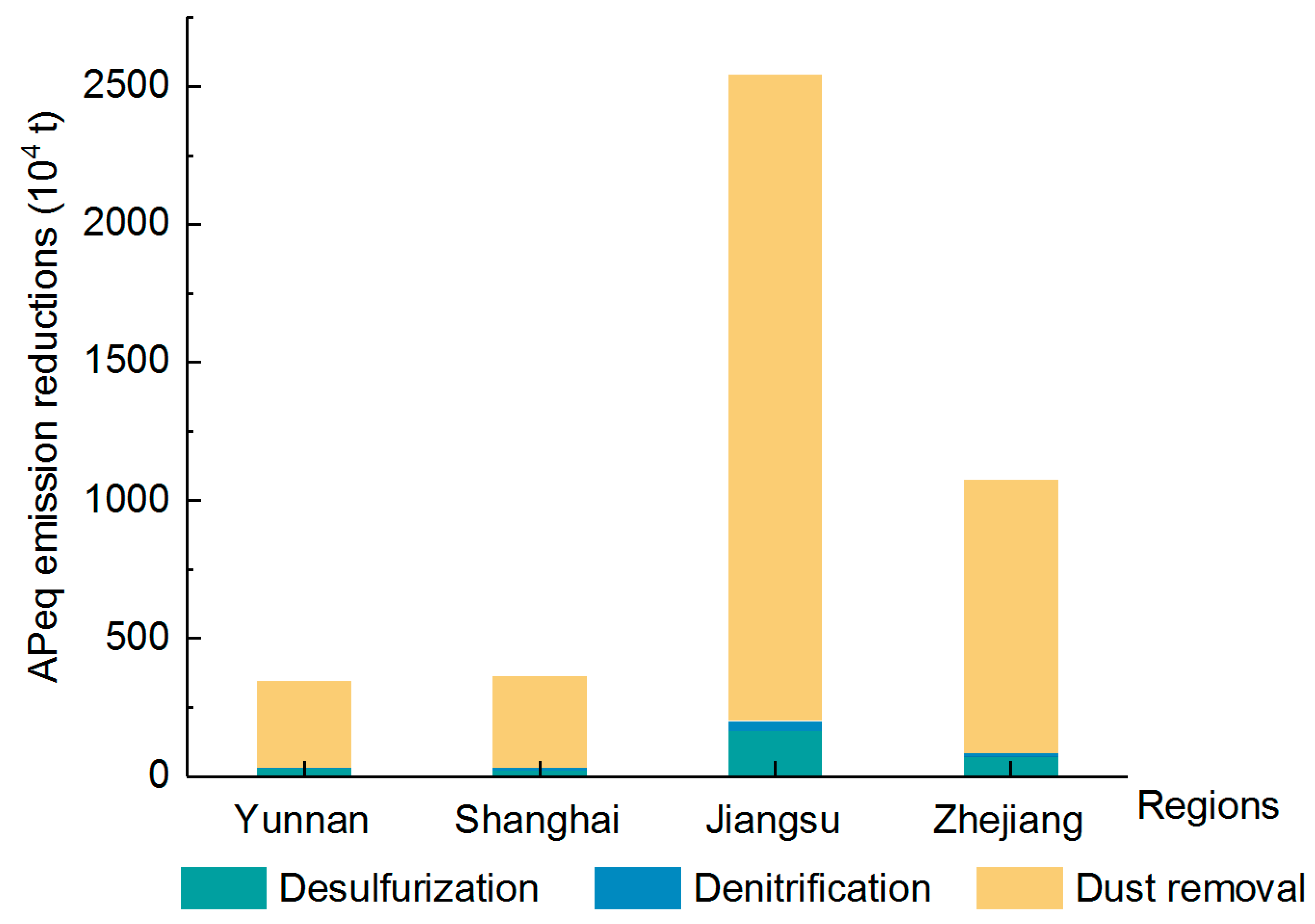

3.3.2. Emission Reductions by Technical Emission Reduction Measures

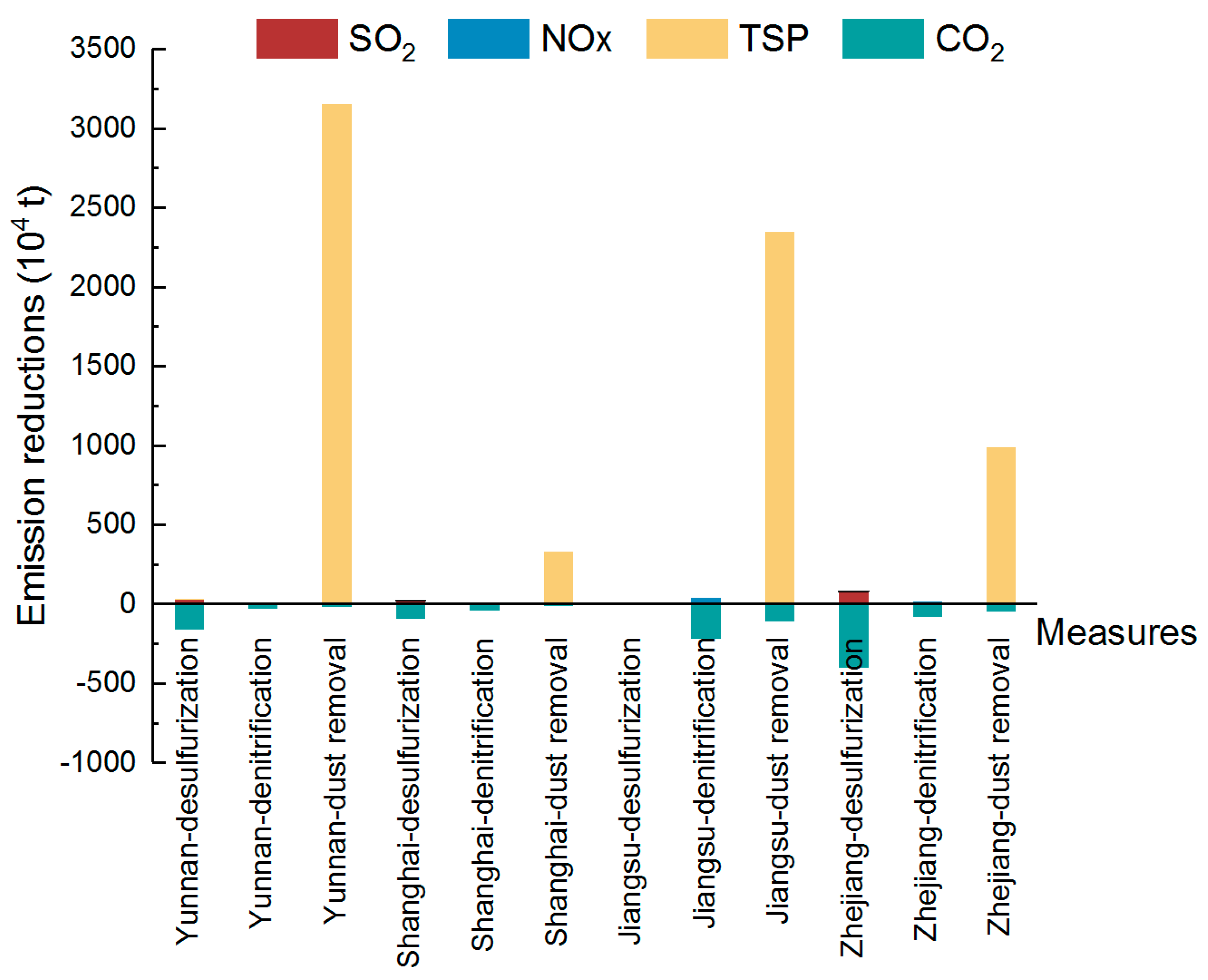

According to the statistical yearbook data, the 2015 emission reductions of the APCDs in independent power plants in the four case regions are shown in

Figure 4. Similar characteristics and patterns for waste gas emission reductions by different APCDs were found in Yunnan, Shanghai, Jiangsu, and Zhejiang: (1) The amount of TSP removal by dust removal equipment was extremely high and much greater than SO

2 removal by desulfurization equipment and NO

x removal by denitrification equipment. (2) The three types of equipment had a certain increase in CO

2 emissions due to the electricity consumption of the equipment, and the increase in emissions decreased from desulfurization, denitrification to dust removal. (3) The emission reductions of coal-fired power plants in Jiangsu Province was higher than that of the other regions due to the area’s energy consumption associated with rapid economic development.

In order to achieve a normalized comparison of emission reduction effects, the impacts of different APCDs on the air pollutant equivalent, APeq, are illustrated in

Figure 4 and

Figure 5. The results showed that the removal of APeq by APCDs in each region decreased in the order of dust removal, desulfurization, and denitrification, and the effect of removing pollutants with de-dusting equipment was the best. Similarly, the emission reductions of the three types of APCDs in the thermal power plants in Jiangsu Province were higher than those in other regions.

3.3.3. Emission Reduction Factors Analysis

Based on the analysis results of the above two sections, the emission reduction factors and emission reductions of different energy conservation and emission reduction measures in each case area in 2015 are summarized in

Table 5. There were certain patterns and characteristics in emission reduction factors of the four regions including: (1) All of the emission reduction factors for clean energy power generation measures were positive. (2) The CO

2 emission reduction factor was much higher than other air pollutants. (3) The emission reduction factors of APCDs on target pollutants were greater than the emission reduction factors of the corresponding clean energy power generation measures for the same type of pollutant. However, the emission reduction factors of each type of APCD for nontarget pollutants (i.e., NO

x and TSP) were negative, i.e., there was an increase in emissions. (4) The emission reduction factors of APCDs on APeq declined from dust removal, desulfurization to denitrification, and the emission reduction factor of dust removal on APCDs was higher than the APeq emission reduction factors of clean energy power generation measures.

3.4. Co-Benefits

The results presented in

Table 6 were derived from the synergistic effects research method described above. It can be seen that the synergy factors of structural emission reduction measures in the four regions of Yunnan, Shanghai, Jiangsu, and Zhejiang were positive, implying that all of these measures have co-benefits, and the degree of co-control of CO

2 by these measures was far above its level of synergistic control over various air pollutants. Technical emission reduction measures (desulfurization, denitrification, and dust removal) consumed electrical energy, so the results showed that they had negative synergies on CO

2 emissions reduction whilst reducing the emissions of the target pollutants (SO

2, NO

x, and TSP); however, the negative synergistic degree was not very high. In addition, these technical measures had few co-benefits (0 < F < 1) or large negative synergies on reducing nontarget pollutants and CO

2.

With respect to the co-control ability of CO

2 emissions, structural reduction measures in the four regions of Yunnan, Shanghai, Jiangsu, and Zhejiang were superior to thermal power plant technology emission reduction measures, mainly because APCDs required additional power consumption and caused CO

2 emissions to increase. Meanwhile, based on the absolute values of the synergy factors in

Table 6, it can be confirmed that the technical emission reduction measures increased the other two nontarget pollutants while reducing the target pollutants, and had no co-control effect on CO

2. This finding confirmed and strengthened the theory that technical emission reduction measures had no co-benefits or only weak co-benefits, while the structural emission reduction measures had obvious co-benefits on controlling the three types of air pollutants and CO

2. Specifically, the co-benefits of wind power and solar power generation were higher than those of hydropower.

3.5. Discussion

Through the analysis of synergies and co-benefits of energy conservation and emission reduction measures in the electric industry in Yunnan, Shanghai, Jiangsu, and Zhejiang, the main findings of this study include the following:

In all case regions, the CO2 emission factor was the highest, followed by NOx, SO2, and then TSP.

The emission intensity was the strongest in Yunnan Province. A comprehensive comparison of emissions and emission factors, due to differences in economic development structure, fuel composition, combustion mode, and exhaust gas treatment, determined that in 2015, the emission intensity of air pollutants and CO2 in the Yunnan thermal power industry (independent thermal power plants) was much higher than the other three case regions. The emission intensity was the weakest in Shanghai as compared to the other regions.

With respect to directly removing target pollutants, technical emission reduction measures were superior to structural ones. Due to the structure of clean energy power generation measures in 2015, hydropower in the Yunnan and Zhejiang Provinces showed the best removal effect on four types of exhaust gas, whereas the exhaust gas removal effect of wind power and solar power generation were weaker. The waste gas removal effect of Shanghai’s wind power was much stronger than its solar power generation. In Jiangsu, the waste gas removal effect of wind power was the best, closely followed by solar power generation. The worst removal effect was demonstrated by hydropower. Similar characteristics and patterns for emission reductions of waste gases by different APCDs were found in Yunnan, Shanghai, Jiangsu, and Zhejiang: the three types of equipment had a certain increase in CO2 emissions because of the electricity consumption of the equipment, and the increase in emissions decreased from desulfurization, denitrification to dust removal. The removal of APeq by APCDs in each region decreased in the order of dust removal, desulfurization, and denitrification, and the effect of removing pollutants by de-dusting equipment was the best. Among the case regions, because of the energy consumption associated with rapid economic development in Jiangsu Province, its absolute emission reduction values of coal-fired power plants were higher than those of other regions.

Similar to emission reductions, there were certain patterns and characteristics in the emission reduction factors of the four regions: (a) All of the emission reduction factors of clean energy power generation measures were positive. (b) The CO2 emission reduction factor was much higher than other air pollutants. (c) The emission reduction factors of APCDs on target pollutants were greater than the emission reduction factors of the corresponding clean energy power generation measures for the same type of pollutant. However, the emission reduction factors of each type of APCD for nontarget pollutants were negative, i.e., there was an increase in emissions. (d) The emission reduction factors of APCDs on APeq declined from dust removal, desulfurization to denitrification, and the emission reduction factor of dust removal on APCDs was higher than the APeq emission reduction factors of clean energy power generation measures.

The co-benefits of structural emission reduction measures were better than that of technical measures. In terms of the synergistic control ability of CO2 emissions, the structural reduction measures in the four regions were superior to thermal power plant technology emission reduction measures, mainly because APCDs required additional power consumption and caused CO2 emissions to increase. Meanwhile, based on the absolute value of the synergy factors of these two types of measures, it can be confirmed that the technical emission reduction measures increased the other two nontarget pollutants emissions while reducing the target pollutants, and had no co-benefits on CO2. This finding revealed and strengthened the theory that technical emission reduction measures had no or few co-benefits, while the structural emission reduction measures had evident co-benefits on controlling the three types of air pollutants and CO2. Specifically, the positive synergies of wind power and solar power generation were higher than those of hydropower.

4. Conclusions

Climate change and environmental degradation are big challenges in the 21st century for China, which has prioritized economic development but with serious carbon and pollution emissions for decades. Considering that the coal-fired power plants of China’s power industry are the main source of air pollutant emissions and CO2 emissions, understanding synergies and identifying the co-benefits of reducing CO2 and air pollutants in the process of implementing synergistic measures is curial for sustainable development in the power industry. Furthermore, the co-benefits of reducing CO2 and air pollutants achieved at the local level plays an import role in promoting the low carbon sustainable development in China’s power industry.

The study puts the focus on assessing synergies and co-benefits of energy conservation and emission reduction measures in the power industry in Yunnan, Jiangsu, and Zhejiang provinces and Shanghai City through evaluating emissions, emission factors, APeq, and synergy factors of air pollutants and CO2. Selected case studies were three local provinces and one city with different levels of development. A comprehensive comparison of emissions and emission factors was made, due to differences in economic development structure, fuel composition, combustion mode, and exhaust gas treatment technologies, and determined that in 2015, the emission intensity of air pollutants and CO2 in the Yunnan thermal power industry was much higher than the other three case regions. It means that more priorities should be given to promote the low carbon development in the less-developed western region such as Yunnan province.

The outcomes of analysis also show that co-benefits of structural emission reduction measures were better than that of technical measures. In terms of the synergistic control ability of CO2 emissions, the structural emission reduction measures in the four case studies were superior to technology emission reduction measures, mainly because APCDs required additional power consumption and caused CO2 emissions to increase. Meanwhile, based on the absolute value of the synergy factors of these two types of measures, it can be confirmed that the technical emission reduction measures increased the other two nontarget pollutants emissions while reducing the target pollutants, and had no co-benefits on CO2. These results mean that promoting renewable energy (i.e., promoting the structural emission reduction measures) will lead to overall co-benefits of reducing CO2 and air pollutants. Specifically, the co-benefits of wind power and solar power generation were higher than hydropower. Also considering a certain increase in CO2 emissions produced because of the electricity consumption in the operation process of APCDs, there is still room for reducing CO2 emissions in the power industry in the four case regions. In order to achieve overall low carbon sustainability, the carbon reduction should be addressed in adopting APCDs in the power industry.

The quantitative method of study can be applied to similar researches and outcomes of study also can be used as a reference for promoting the power industry’s sustainable development in other developing countries. It is worth noting the uncertainty existing in the study due to errors in the process of collecting data and the method utilized. For example, unified IPCC emission factors are adopted in the study, which is deviated from the actual value in the four case regions. And the data of carbon emissions are not opened and published so far in statistical yearbooks at all levels in China, and the results of carbon emissions are different in varies studies because of different methods used. Therefore, errors could inevitably occur in the process of calculation by using the data and method in this study. In order to overcome the existing shortcomings of study, future research should pay more attention to the data collection and research methodology. More data sources can be considered and the research method can be improved through learning from the latest similar researches in the next step of study. Otherwise, the cost-effective analysis to the co-benefits achieved by implementing synergistic control measures is an important topic for future research as well.

Author Contributions

P.J. proposed this research, designed the paper, and made the part of the manuscript. A.A. made the data collection and analysis of carbon and air pollution emissions. H.D. made the data collection and analysis of co-benefits of carbon and air pollution reduction, and made the part of results and discussion. X.Y. supported the design of this paper and reviewed this paper. All authors have read and agreed to the published version of the manuscript.

Funding

The research was funded by the National Natural Science Foundation of China (Grant No.: 71774033) and Fudan Tyndall Centre of Fudan University (Grant No.: IDH6286315).

Acknowledgments

We would like to thank the supports from the founders and also thank the editor and reviewers for their valuable comments to improve this work.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Jiang, P.; Chen, Y.; Geng, Y.; Dong, W.; Xue, B.; Xu, B. Analysis of the co-benefits of climate change mitigation and air pollution reduction in China. J. Clean. Prod. 2013, 58, 130–137. [Google Scholar] [CrossRef]

- Xue, B.; Ma, Z.; Geng, Y.; Heck, P.; Ren, W.; Tobias, M.; Maas, A.; Jiang, P.; Oliveira, J.A.P.D.; Fujita, T. A life cycle co-benefits assessment of wind power in China. Renew. Sustain. Energy Rev. 2015, 41, 338–346. [Google Scholar] [CrossRef]

- Yang, Y.; Yang, Z.; Xu, G.; Wang, N. Situation and Prospect of Energy Consumption for China’s Thermal Power Generation. Proc. CSEE 2013, 33, 1–11. (In Chinese) [Google Scholar]

- National Bureau of Statistics of China. China Statistical Yearbook 2016; China Statistics Press: Beijing, China, 2016. (In Chinese)

- Ministry of Environmental Protection of the People’s Republic of China. China Environmental Statistics Annual Report 2015; China Environmental Press: Beijing, China, 2015. (In Chinese)

- Zheng, J.; Sun, X.; Zhang, M.Y.; Zhu, Y.; Gao, S.; Jiang, P. The co-benefits of GHGs mitigation and air pollution control: A literature review. Ecol. Econ. 2015, 31, 133–137. (In Chinese) [Google Scholar]

- Gu, A.; Teng, F.; Feng, X. Analysis and evaluation of coordination effect of greenhouse gases in pollutant control policies of major sectors. China Popul. Resour. Environ. 2016, 26, 10–17. [Google Scholar]

- Bollen, J.; Zwaan, B.V.D.; Eerens, H.C.; Brink, C.; Bollen, J. Local air pollution and global climate change. Resour. Energy Econ. 2009, 31, 161–181. [Google Scholar] [CrossRef]

- Bollen, J.; Brink, C. Air pollution policy in Europe: Quantifying the interaction with greenhouse gases and climate change policies. Energy Econ. 2014, 46, 202–215. [Google Scholar] [CrossRef]

- Bollen, J. Co-Benefits of Climate Policy. 2009. Available online: http://internationalenergyworkshop.org/iew2009/speakersdocs/Bollen-et-al_Co-benefitsOfClimatePolicy.pdf. (accessed on 29 November 2019).

- Amann, M.; Bertok, I.; Borken-Kleefeld, J.; Cofala, J.; Heyes, C.; Hglund-Isaksson, L.; Klimont, Z.; Nguyen, B.; Posch, M.; Rafaj, P.; et al. Cost-effective control of air quality and greenhouse gases in Europe: Modeling and policy applications. Environ. Model. Softw. 2011, 26, 1489–1501. [Google Scholar] [CrossRef]

- Vuuren, D.; Cofala, J.; Eerens, H.; Oostenrijk, R.; Heyes, C.; Klimont, Z.; Elzen, M.G.J.D.; Amann, M. Exploring the ancillary benefits of the Kyoto Protocol for air pollution in Europe. Energy Policy 2006, 34, 444–460. [Google Scholar] [CrossRef]

- Rive, N. Climate policy in Western Europe and avoided costs of air pollution control. Ecol. Model. 2010, 27, 103–115. [Google Scholar] [CrossRef]

- Puppim de Oliveira, J.; Antonio, P. Green Economy and Good Governance for Sustainable Development: Opportunities, Promises and Concerns (Chapter 14); United Nations University Press: Tokyo, Japan, 2012. [Google Scholar]

- Cai, J.; Gao, S.; Sun, X.; Jiang, P.; Zheng, J.; Zhang, M. A review of research on synergistic benefits of environment, economy and social development. China Popul. Resour. Environ. 2016, 26, 44–47. [Google Scholar]

- National Bureau of Statistics. China Energy Statistics Yearbook; China Statistics Press: Beijing, China, 2016. (In Chinese)

- Yu, C. China Electric Power Yearbook (2010–2016); China Electric Power Press: Beijing, China, 2016. (In Chinese) [Google Scholar]

- National Bureau of Statistics. China Environmental Statistics Yearbook; China Statistics Press: Beijing, China, 2016. (In Chinese)

- Intergovernmental Panel on Climate Change. 2006 IPCC Guidelines for National Greenhouse Gas. Inventories. 2006. Available online: https://www.researchgate.net/publication/40104270_2006_IPCC_Guidelines_for_National_Greenhouse_Gas_Inventories (accessed on 29 November 2019).

- Power Planning and Design Institute. China Energy Data Analysis Manual 2016. 2017. Available online: http://www.cnrec.org.cn/cbw/zh/2016-09-20-513.html (accessed on 29 November 2019). (In Chinese).

- Mao, X.; Zeng, A.; Liu, S.; Hu, T.; Xing, Y. Assessment of SO2, NOx and CO2 co-control effects by technological reduction measures in iron&steel industry. Acta Sci. Circumstantiae 2012, 32, 1253–1260. (In Chinese) [Google Scholar]

- Mao, X.; Zeng, A.; Hu, T.; Xing, Y.; Liu, S. Study of Coordinate Control Effect Assessment of Technological Measures for Emissions Reduction. China Popul. Resour. Environ. 2011, 21, 1–7. (In Chinese) [Google Scholar]

- Lu, H.; Zheng, W.; Li, W.; Wang, L.; Wu, N.; Bao, Z.; Zhang, X. Benefit-cost analysis of desulfurization technology and ultra-low emission transformation in coal-fired power plants. Environ. Eng. 2018, 36, 97–102. (In Chinese) [Google Scholar]

- Liang, Y.; Zhu, Y.; Wang, X. Optimal configuration of micro-grid power supply based on levelized cost of electricity analysis. South. Power Syst. Technol. 2016, 10, 56–61. (In Chinese) [Google Scholar]

- Liu, X.; Bai, K.; Deng, C.; Song, P.; Yang, W. Research on levelized cost of energy model of large-scale wind power project. Renew. Energy Resour. 2016, 34, 1853–1858. (In Chinese) [Google Scholar]

- Zhao, H.; Ma, W.; Dong, H.; Jiang, P. Analysis of co-effects on air pollutants and CO2 emissions generated by end-of-pipe measures of pollution control in China’s coal-fired Power Plants. Sustainability 2017, 9, 499. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).