1. Introduction

With the quick growth of manufacturing enterprises, the problems associated with large energy consumption and environmental pollution become more and more serious. In “Made in China 2025”, the strategic goal of carbon dioxide emissions in the manufacturing industry is clarified, that is, carbon dioxide emissions per unit of industrial added value in 2025 will be 40% lower than in 2015. As a result, enterprise pays more attention to strengthening awareness of resources and environmental protection, to optimizing and improving the green environment, and to enhancing green innovative capabilities. By building a new green manufacturing service innovation system, manufacturing enterprises can promote green innovation performance to maintain persistent development of the enterprise [

1,

2,

3]. At the same time, when manufacturing enterprises conduct green innovation activities, their innovative performance will be restricted by the objective constraints of various realistic conditions, which include the formation of innovation teams, the level of innovation service, the status of production equipment, the economic cost of operation, the period of development and design, etc. According to the demand of improving innovation performance [

4,

5,

6], manufacturing enterprises need to integrate existing internal and external innovation resources, research and development conditions and infrastructure to carry out dynamic green innovation activities. In the green innovation activities of manufacturing enterprises, new product research and development is the core element related to the survival and development of enterprises. The best project is selected from a series of alternative innovative product programs, which are then put into production practice. The procedure is the key decision making factor in product development action. The quality of a project selection based on market demand or customer preference directly affects the innovation performance of manufacturing enterprises. Therefore, the scientific evaluation and selection of an alternative innovative product project is the basis for the scientific decision making of enterprise innovation activities, and is also an important part of the enterprise’s innovative activities, which meet customer needs and improve enterprise innovation performance.

In some previous work, researchers have tried to put forward many research methods and evaluation models, such as technique for order preference by similarity to ideal solution [

7], analytic hierarchy process [

8], the fuzzy evaluation method [

9,

10], the grey evaluation method [

11], and the comprehensive application of these methods. The existing research results only consider the technical information of the innovative project or various relevant factors of the external market environment, as well as information processing of the selection-making, the method of weight determining, and so on. However, the influence of customers’ green preferences and enterprise performance on project selection is seldom considered at same time [

12,

13]. Considering the complexity of an innovation scheme selection for customers’ green preferences, the correlation between the customers’ green preferences and innovation performance in enterprise is often difficult to accurately identify. Thus, the traditional single evaluation method is not adequate for dealing with the fuzzy information of enterprise performance and customers’ preferences in innovative project selection.

This paper focuses on studying the problem of green innovation project selection for consumer’s green preferences in manufacturing enterprises. Combined with the consumer’s green preferences, the indicators for innovation performance in enterprise are analyzed. A correlation analysis mechanism based on a fuzzy clustering analysis and the wavelet neural network (WNN) method was designed for selecting the green innovation project. Our contribution is to provide an effective method to help enterprise identify the correlation between customers’ green preferences and indicators of innovation performance, then evaluate and select the green innovation project under consumer’s green requirements management, to improve operational efficiency and reduce costs.

The rest of this paper is organized as follows.

Section 2 describes a literature review.

Section 3 proposes a performance indicator system for green innovation project selection for consumers’ green preferences.

Section 4 designs a decision method based on fuzzy clustering analysis and the WNN method for selecting the design project of green innovation.

Section 5 provides an example of manufacturing enterprise preferences for consumers’ green preferences, which shows the feasibility of the proposed decision method.

Section 6 concludes the paper.

2. Literature Review

The evaluation and selection of innovative projects is critical in enterprise innovation, and the selection result directly affects the performance of the enterprise [

14]. Combined with the current demand for green development in enterprise, there are quite a few works in the related field, including green innovation performance, selection methods of green innovation projects, and so on.

In the research of green innovation performance in the manufacturing enterprise, including low-carbon technology innovation, enterprise technology transfer, green innovation ability evaluation and so on, there are certain factors that could enhance enterprise innovation performance effectively. Hoffert et al. [

15] considered that the low-carbon technological innovation is a breakthrough innovation focusing on renewable resource technology, and the energy technology innovation derives from some enterprises raising their energy prices. Alphen et al. [

16] compared the development and application of low-carbon technology among developed countries and concluded that low-carbon technology innovation can continuously promote the growth of enterprise innovation performance. Zhang [

17] believed that low-carbon technological innovation in manufacturing enterprises could help enterprises reduce energy consumption, reduce environmental pollution, control the cost of industrial waste gas and wastewater treatment, and improve enterprise performance. Hou and Chen [

18] used an improved Slacks Based Measure -Directional Distance Function (SBM-DDF) model to estimate the green technology innovation performance of high patent density manufacturers, and their research showed that the environmental regulation of manufacturers had an inhibition effect, an enterprise scale factor, and that market competition and foreign investment promote industrial green technology performance significantly. Xu and Guan [

19] presented an environmental innovation indicator system for manufacturing enterprises based on three aspects: the environmental innovation investment capability, the environmental innovation output capability and the environmental innovation support capability.

And there is some research on enterprise innovation performance that considers customer preference. Zhao et al. [

20] constructed one simulation model based on a computational experiment method, which simulated the evolution process of consumers’ preferences and the environmental innovation process of enterprises in different scenarios, the results showed that the mutations of consumers’ environmental preferences play an important role in promoting preference changes regarding the whole of the environment.

In terms of innovative project evaluation and selection, there are several selection methods for green innovation projects in manufacturing enterprises proposed by scholars. For example, according to different innovative design indexes of mechanical products, different fuzzy numbers were used to evaluate and select design schemes, which solved the uncertainty of evaluation in the design scheme selection of mechanical products [

21]; an improved Vise Kriterijumsa Optimizacija I Kompromisno Resenje (VIKOR) evaluation model was proposed for the design project selection of agile manufacturing [

22]. Combined with rough sets, a rough grey analysis algorithm was proposed, which improved the effectiveness and objectivity of the evaluation process of conceptual design schemes [

23]. Additionally, an innovation project selection method based on an integrated analytic network process (ANP) and fuzzy set theory was proposed [

24]. Ngan [

25] presented an innovation scheme selection model for improved fuzzy binary semantics. Zhang et al. [

26] presented a green design selection method which involves many aspects, such as material selection, process planning, structure optimization, recycling, and so on. By using this fuzzy clustering method, the environmental similarity relationship between components in an optimized set is studied, which realizes the fast selection of subsets of similar parts with potential for environmental performance optimization. Zuo et al. [

27] presented an evaluation method which combined the intuitionistic fuzzy set with information axiom. The membership and non-membership of the evaluation needed to be considered synthetically and was transformed from the evaluation value and the hesitation degree given by the decision makers. To integrate the evaluation value of the decision makers was a necessary step before calculating the information divergence between the system range and design range by intuitionistic fuzzy cross entropy. The rank of all the innovation projects was obtained according to the information contents of innovation projects calculated by the proposed method.

Specially, there is some research on innovative project selection that considers customer information. Yang et al. [

28] proposed a multi-attribute decision-making evaluation method for a product innovation design scheme. The criteria weights determination method was put forward through integrating the Kano model and rough set theory based on an analysis of customers’ demand preferences, which made the evaluation process reflect the customers’ needs effectively and improve the rationality of the criteria’s weights. Li et al. [

29] proposed a novel method for rapid response to customer requirements in product optimization design via fuzzy clustering and conjoint analysis-quality function deployment (CA-QFD). Cheng et al. [

30] built a descriptive demand model of customers based on an axiomatic design, aiming at providing requirement information with the characteristics of abstractness and vagueness in the process of constructing a requirement model. The fuzzy demands could be quantified through conjoint analysis and transformed into a specific performance index and the characteristic parameters of product design. Then, a design incidence matrix could be established through analyzing the correlation between those indexes and parameters. Furthermore, the matrix was clustered by the fuzzy tree clustering algorithm. The best clustering thresholds were identified according to the clustering validity index, and optimal clustering results could be obtained. Zhao et al. [

31] proposed a classification method of low carbon products design based on multidimensional association function; by computing the similarity and frequency, the corresponding extension correlation function under variable customers’ demand is established to realize the selection of low-carbon design scheme.

Though there have been quite a few works in the related field [

14,

31], there are still some areas that can be worked upon. Such as the background given above shows, the correlation between enterprise performance and customer preference is not considered simultaneously in the selection of an innovation project. Moreover, considering the customers’ green preferences in innovation project evaluation and selection requires further study.

In response, this paper presents an identification method for correlation based on fuzzy clustering analysis and the wavelet neural network (F-WNN) model to solve the problems of green innovation project selection under uncertain and fuzzy information environments. The proposed method can not only deal with the correlation between the customers’ green preferences and enterprise innovation performance, but also avoid the diversity and uncertainty of the evaluation information given by evaluators in innovation project selection. Moreover, both quantitative and qualitative data standardized transformation in real-life applications can be considered in this proposed method.

4. The Selection Method of Innovation Design Projects Based on F-WNN

4.1. The Fuzzy Clustering Identification of Enterprise Innovation Performance

For manufacturing enterprises, the correlations between indicators for innovative performance and customers’ green preferences are uncertainty, complex, and fuzzy. According to these characteristics, a scientific analysis method is used to classify the many indicators for innovative performance in accordance with the customers’ green preferences. Fuzzy clustering analysis (FCA) is a classification method that divides the sample space into multiple subspaces according to the similarity of sample nature [

41,

42]. It can reasonably distinguish the comprehensive indicators for green innovation performance in manufacturing enterprises and identify the indicators that are strongly related to the customers’ green preferences. It has high objectivity in dealing with fuzzy and uncertain problems, and the results have obvious advantages such as a hierarchical structure, so the clustering analysis of research objects is more reasonable and objective.

Therefore, this paper selects the fuzzy clustering analysis method to study the indicators of production and service innovation performance in manufacturing enterprises with customers’ green preferences. The calculation steps are as follows:

Step 1. is defined as unidentified set of indicators for innovation performance in the enterprise. is represented by a set of scoring data vectors , to obtain the scoring matrix of indicator ;

Step 2. The data are standardized, and a fuzzy similarity matrix is constructed. In general, each indicator or index may have different magnitudes and orders of magnitude units. In order to make the data of different indicators or index variables be compared together, a certain transformation process is required. The

-th row element of the matrix

X is processed by standardized transformation as follows:

where

;

,

.

In order to make the standardized data in the closed interval of [0, 1], the extreme value standardization formula is adopted:

With and . After conversion, the maximum data in any row becomes 1, the minimum data becomes 0, and the remaining data is between 0 and 1. The standardized matrix of indicators is obtained: .

Step 3. The distance between the feature vectors of two factors is defined by the Euclidean distance:

Step 4. Using correlation coefficients, the degree of similarity in each factor is calculated, and the fuzzy similarity matrix

is constructed:

With , , .

Step 5. Using the transitive closure method, the fuzzy similarity relation matrix

R is transformed into a fuzzy equivalent matrix

. Although R satisfies reflexivity and symmetry, it is not necessarily transitive. So

should meet the transitivity: if

,

, then

. Then the transitive closure of R is constructed by square self-synthesis method. In order to further accelerate the convergence rate of fuzzy equivalent matrix, the follow processing is carried out:

Till (), and , meet the reflexivity, symmetry, and transitivity.

Step 6. The objective function of the optimal fuzzy matrix and the optimal fuzzy clustering center matrix to be solved, and validity to be tested:

is normalized characteristic value of -th sample for index, is weight of index, is relative membership of -th sample belonging to class, is the clustering center of index in the class, , .

With , , .

According to

expressions and Lagrange functions, an iterative formula is constructed:

An average fuzzy entropy function

is defined, to describe the uncertainty degree of fuzzy clustering divided into

categories:

The average fuzzy entropy value of partition is smaller, and the smaller the uncertainty degree of clustering then the better the clustering effect will be.

Step 7. The fuzzy classification relationship of which satisfies the transmission is clustered, then the cluster spectrum diagram is obtained, and a validity test is performed.

4.2. The Wavelet Network Model of Green Innovation Project Selection

There is an internal and implicit mapping relationship between the innovation performance index and the choice of enterprise innovation scheme using fuzzy clustering. The intrinsic decision and driving relationship between them are as shown as follows: there are many indicators for innovation performance, each of which may have a different impact on innovation schemes. This complex intrinsic correlation determines the complex nonlinear mapping relation between performance indicators and innovation scheme optimization. The wavelet neural network (WNN) can reflect the complex mathematical relation [

43,

44,

45]. The wavelet neural network adopts a non-linear wavelet basis function, which has a very strong nonlinear mapping function and is very effective in seeking the complex relationship between the indicators for innovation performance in enterprise and the optimization of innovation schemes [

46,

47].

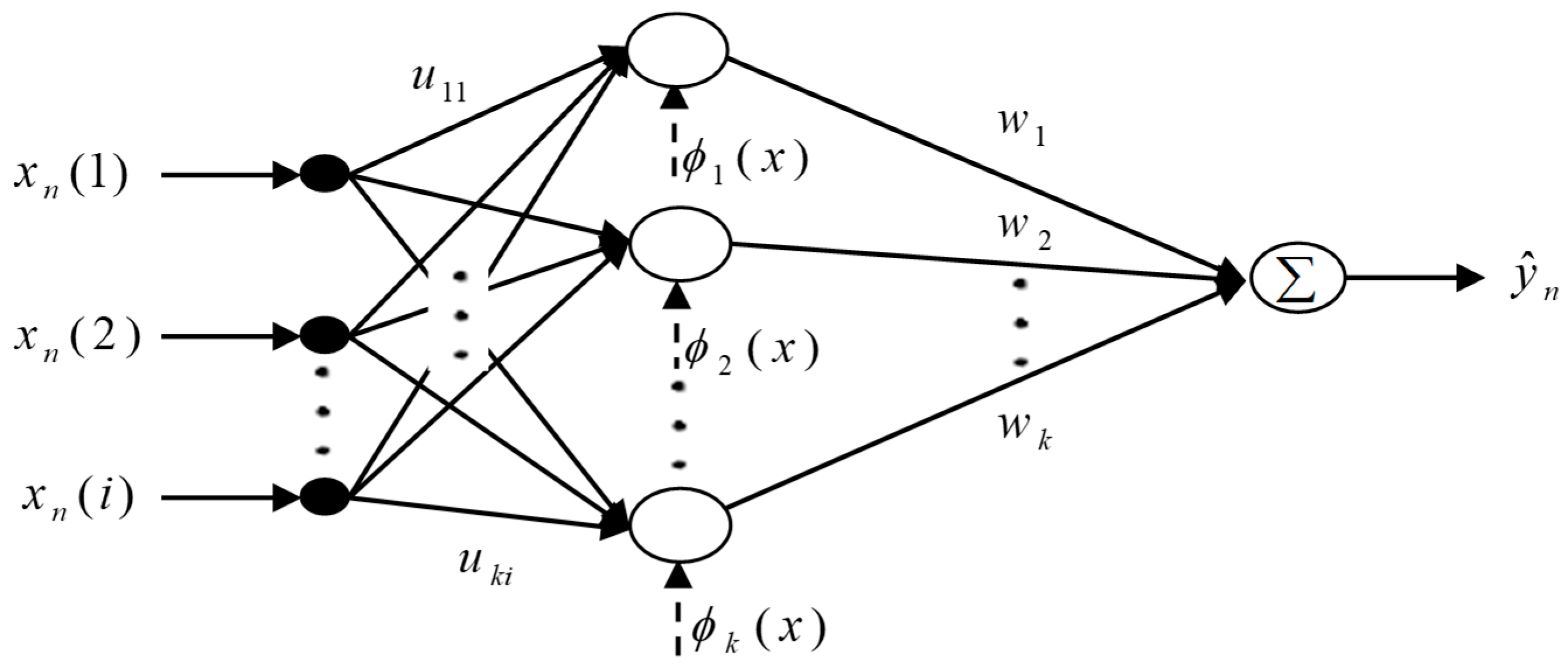

The optimal selection model of green innovation schemes for manufacturing enterprises is shown in

Figure 1, which is described as follows:

In this model, is the input data of indicators after a fuzzy cluster, and is the output selection/evaluation value of the green innovation project, respectively; is the indicators number of innovation performance in enterprise. At same time, is the wavelet function, and are network weight coefficients. In brief, the connections between input units and hidden units are called weights and the connections between hidden units and output units are called . The dilation and translation parameters, are defined as , . And, is the number of wavelet bases.

Since the proposed green project selection model based on wavelet network has the characteristics of variability, those parameters , , , , should be determined to ensure the best fit between the evaluation values and the real values.

is a parameters set that can be adjusted in learning and training, and the parameter , , , can be optimized by the energy function of the minimum mean square error (MSE). These parameters vary in the negative gradient direction of the output error formula.

The error function

E is taken as:

The value of can be determined using a stepwise test, and the fitting error of the optimal selection of green innovation schemes can be defined according to the actual empirical value. So, if we set the fitting error as D, the number of hidden layer neurons in the network as , and the number of samples as S, after calculating, can be found. If , then ; otherwise, add 1, that is . Till , is met, so the optimal value of is equal to . Thus, the optimal structure of the network is determined.

A Morlet wavelet is used as a wavelet mother function, which is a Gaussian wave of cosine modulation. It has a high resolution in time-frequency domain, expressed as follows:

The specific algorithm of Morlet wavelet network is showed as follows:

- (1)

The numbers of wavelet neurons in the input layer and output layer are and , and the number of wavelet neurons in the hidden layer is .Then, the weight coefficients of network connection are and , the translation factor and dilation factor of wavelet basis are assigned with random initial values, respectively. After that, the approximation accuracy is , and the wavelet network parameters are initialized.

- (2)

Input learning sample and corresponding expected output .

- (3)

Through the self-learning of the wavelet network, the network output is calculated by using the current network parameters.

- (4)

The instantaneous gradient of the energy function of the MSE for different parameters is calculated:

Within those functions, is learning rate and is momentum term. The larger value of causes learning instability, a smaller value will reduce the learning speed. So, a raining iteration variable rate is used. While is the momentum term that prevents falling into a local minimum.

- (5)

The descent algorithm of iterative gradient is used to change the weight in the negative gradient direction of the error function and realize the back propagation of the error function.

- (6)

When the absolute value of error function is less than the pre-set approximation accuracy, the network learning is stopped, otherwise, return to step (2).

5. Results

An example of impact identification for innovation performance and case analysis of scheme selection is given. An automobile manufacturing enterprise hoped to identify the impact of the green innovation performance of the enterprise based on the collection and sorting of the green preference data of customers, and then to carry out the innovation design of the enterprise’s products, the improvement and upgrading of production and sales and service, and to enhance the comprehensive competitiveness of the enterprise in the market of green innovation. Therefore, first of all, we used the above fuzzy clustering identification method to analyze and identify the innovation performance of the enterprise, and then used Matlab product tools for programming and simulating.

Considering customers’ green preferences for disassembly, recyclability, remanufacturing, environmental protection of materials, low-carbon manufacturing, transportation and sales environment, energy saving and the low consumption of innovative products, etc., the correlation degree between customer preferences and the green innovation performance of manufacturing enterprises were divided into five levels: very low, low, medium, high, very high, with the corresponding score values are “5, 4, 3, 2, 1”, respectively. Then 15 experts with experience in technology Research and Development (R&D) or innovation management and who were familiar with the green innovation activity processes of manufacturing enterprises, were utilized to determine the evaluation set of innovation performance indicators for manufacturing enterprises based on their practical experience, as shown in

Table 2:

Step 1. As defined above, the unidentified set of indicators for innovation performance in the enterprise was

. For each indicator, the number of experts with the same association degree were added, and the experts score value was summed as

. So, the evaluation vector of

was

, using formulas (1) and (2), an evaluation matrix was standardized and normalized to obtain the fuzzy correlation matrix of indicators, as shown in

Table 3:

Step 2. The normalized Euclidean distance matrix

U can be obtained by Formula (3):

The fuzzy similarity matrix

is calculated by Formula (4), and the fuzzy equivalent matrix

is obtained by Formula (5):

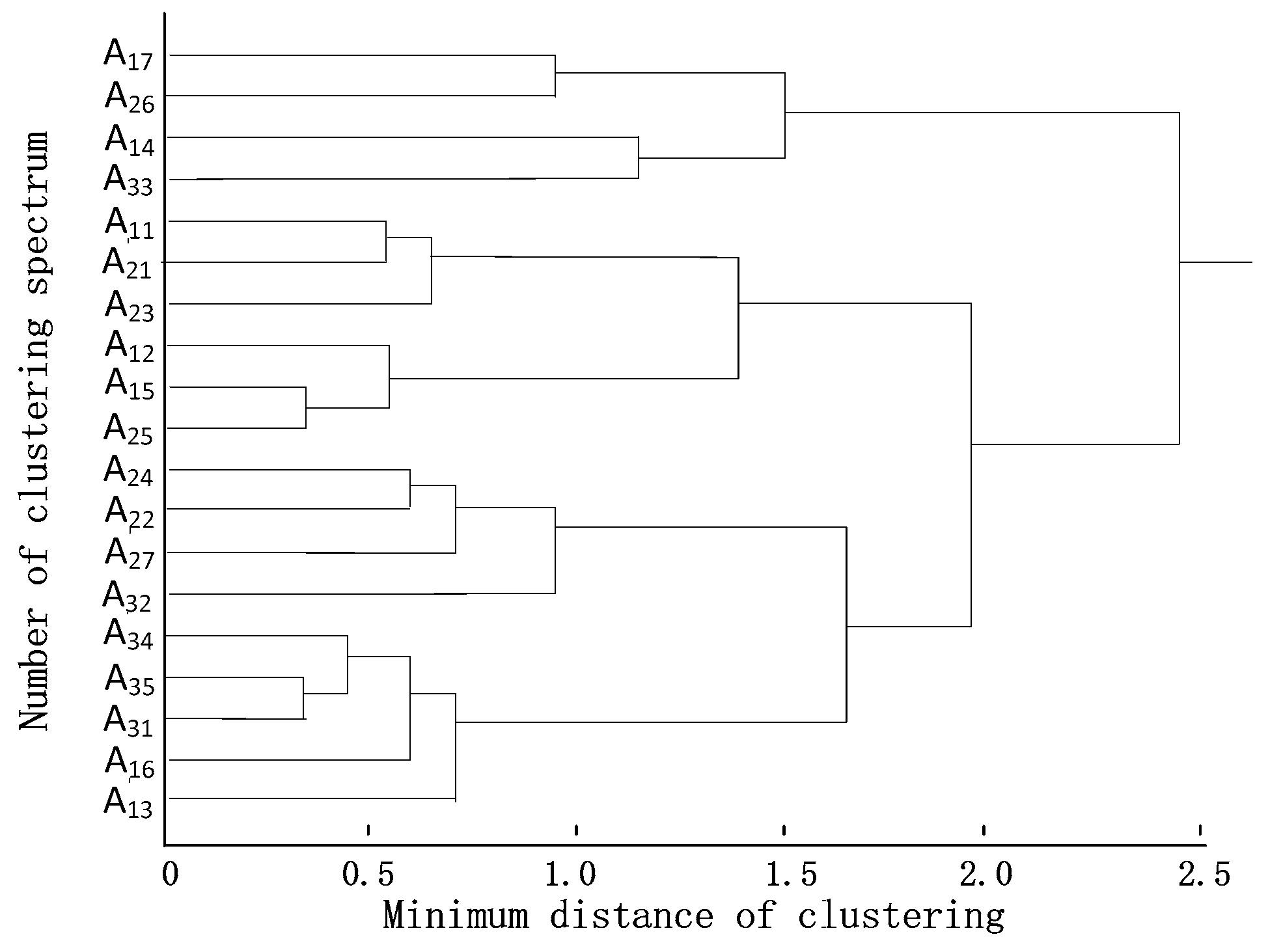

Step 3. According to

R, the shortest distance clustering graph is drawn, as shown in

Figure 2.

Step 4. Based on the shortest distance clustering graph and Formula (10) with average fuzzy entropy function , the average fuzzy entropy and partial clustering number in the model can be received. The result showed: when the cluster’s number was 2, 3, 4, 5, 6, 7, 8, 9, the average fuzzy entropy was 0.85, 0.82, 0.61, 0.59, 0.56, 0.62, 0.64, and 0.78, respectively.

Finally, using different clustering numbers and average fuzzy entropy , when the optimal clustering number was 6, we can understand that the minimum average fuzzy entropy was 0.56. According to the clustering graph, the clustering number and the average fuzzy entropy, the indicators for innovation performance in an enterprise considering customers’ green preferences can be divided into six categories, and the final clustering results were as follows: , , , , , . was highly correlated with customer preference for producing a low-carbon environment, with a preference for the disassembly of innovative products, with a preference for innovative product recycling, with a preference for innovative product remanufacturing, with a preference for energy saving and low consumption, and with a preference for the environmental protection of innovative product materials.

For example, it was by considering customers’ preference for energy conservation and low consumption of innovative products, environmental protection of materials and recyclable products that this automobile manufacturing enterprise chose its innovative projects. From the previous result of fuzzy analysis, we learned that customers’ preference for energy conservation and low consumption was highly correlated with four factors of enterprise innovation performance: the sales of innovative design products , the sales growth rate of an innovative product , the number of patents applied for innovative products , and the degree of green technology innovation of products . Additionally, the preference for material environmental protection has great relevance to five factors of enterprise innovation performance: the new product development speed , the innovative product quality , customer satisfaction with green preference , the number of green innovation services , and the quality of green innovation services . At same time, the preference for product recyclability is highly correlated with the innovation product development cycle , the product market share , and the innovation product profit margin .

So, the wavelet network can be trained by using 120 groups of history data of the car manufacturing enterprise, which has a bigger correlation degree with enterprise innovation performance and also includes indicators such as the total sale, sales increase, number of patents, degree of technological innovation, and so on. Meanwhile, all data is unitary processed. During the procedure of the wavelet network training, based on the experimental verification of real data, small random numbers were selected according to the initial weights and deviations. Then, the number of the input node was 9, the output node was 1, the effective hidden layer nodes was 10, learning rate factor = 0.5, momentum items = 0.8, and the number of samples N = 64, finally, after 244 iterations, the desired wavelet neural network model can be obtained.

The trained wavelet network model could be used to select the green innovation project of the enterprise, senior executives and technical experts who are familiar with green innovation activities can evaluate the effects of the A, B and C projects. Then, the evaluation values were put into the trained wavelet network, through the network model operation, the final results of network output were respectively: 0.61, 0.56, 0.84. Compared with the output results, project C was selected to be the best manufacturing enterprise innovation projects for customer’s green preferences. The selection results were based on fuzzy theory and the wavelet network, and the manufacturing enterprise innovation projects for customer’s green preferences are shown in

Table 4.

The methods of Analytic Hierarchy Process (AHP) [

48] and information entropy [

49] were respectively applied to select innovative projects, and the ranking results are shown in

Table 5.

As shown in

Table 5, the ranking results obtained by the three selection methods were basically the same, which proves that the F-WNN selection method is relatively reasonable.

The project with highest green performance value can be selected as the optimal enterprise green innovation scheme. Based on the results, we can achieve enterprise performance project optimization, improvement, and further application. When the personalized customers’ green preferences are satisfied, this proposed method can greatly speed up manufacturing enterprise research and development efficiency, save on development costs, and so on.

To illustrate the availability and feasibility of the proposed project selecting method, we compared our project selection method based on the fuzzy clustering pretreatment WNN model with the WNN, Back Propagation (BP), Support Vector Machine (SVM), and Grey Model (GM) model. Among those models, WNN is comprised of a three-layer structure, BP adopts a log-sigmoid function, the type of SVM is selected as RBF by using a one-to-many algorithm. Then, we can get the root mean square error (RMSE) and the average accuracy of those models. So, we can get a better average accuracy and less RMSE than the extended F-WNN model in this paper. Furthermore, the comparison data showed that the more effective the evaluation, the higher the practical value will be in the F-WNN. The comparison results are shown in

Table 6.