The Synergy in the Economic Production System: An Empirical Study with Chinese Industry

Abstract

1. Introduction

2. Methodology

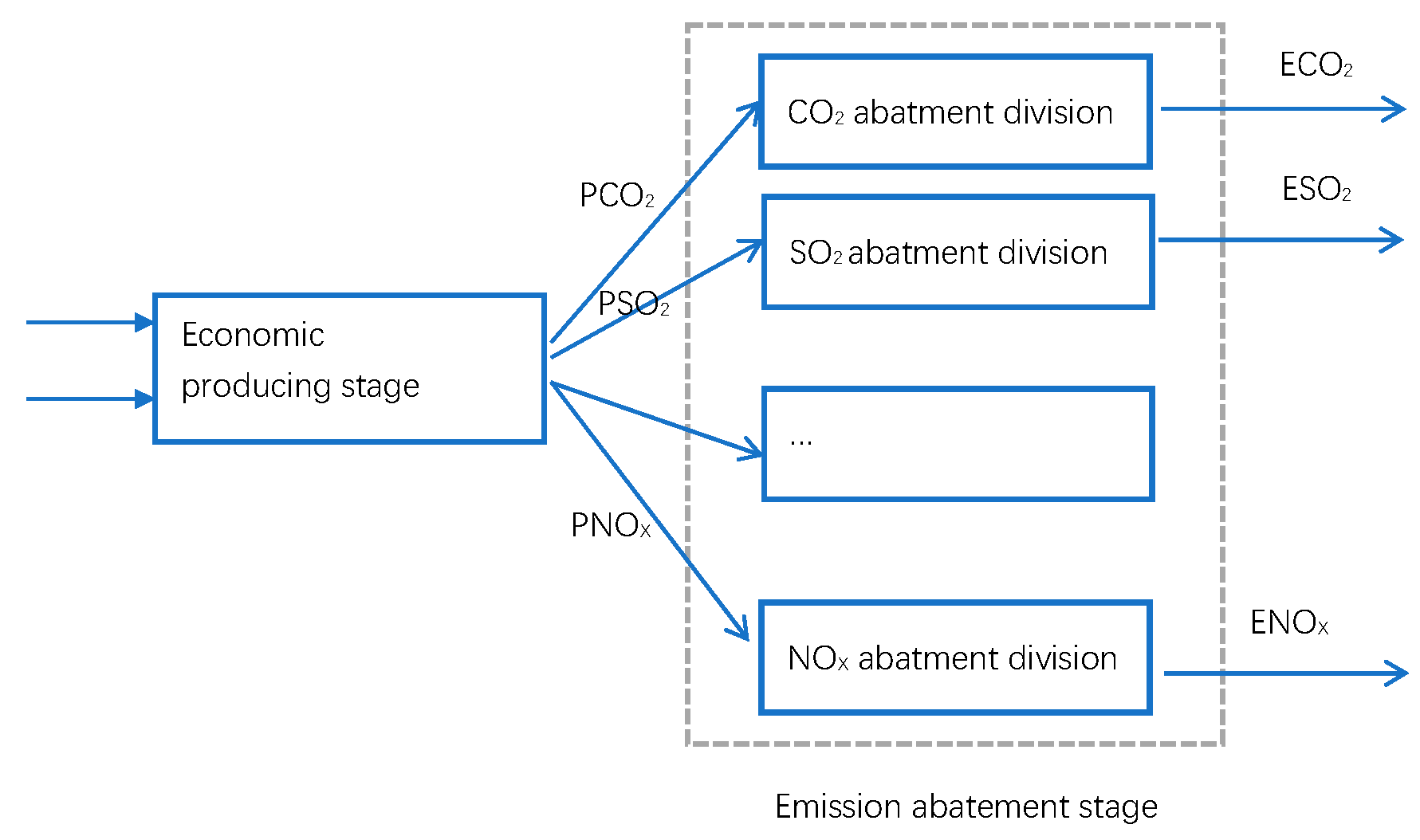

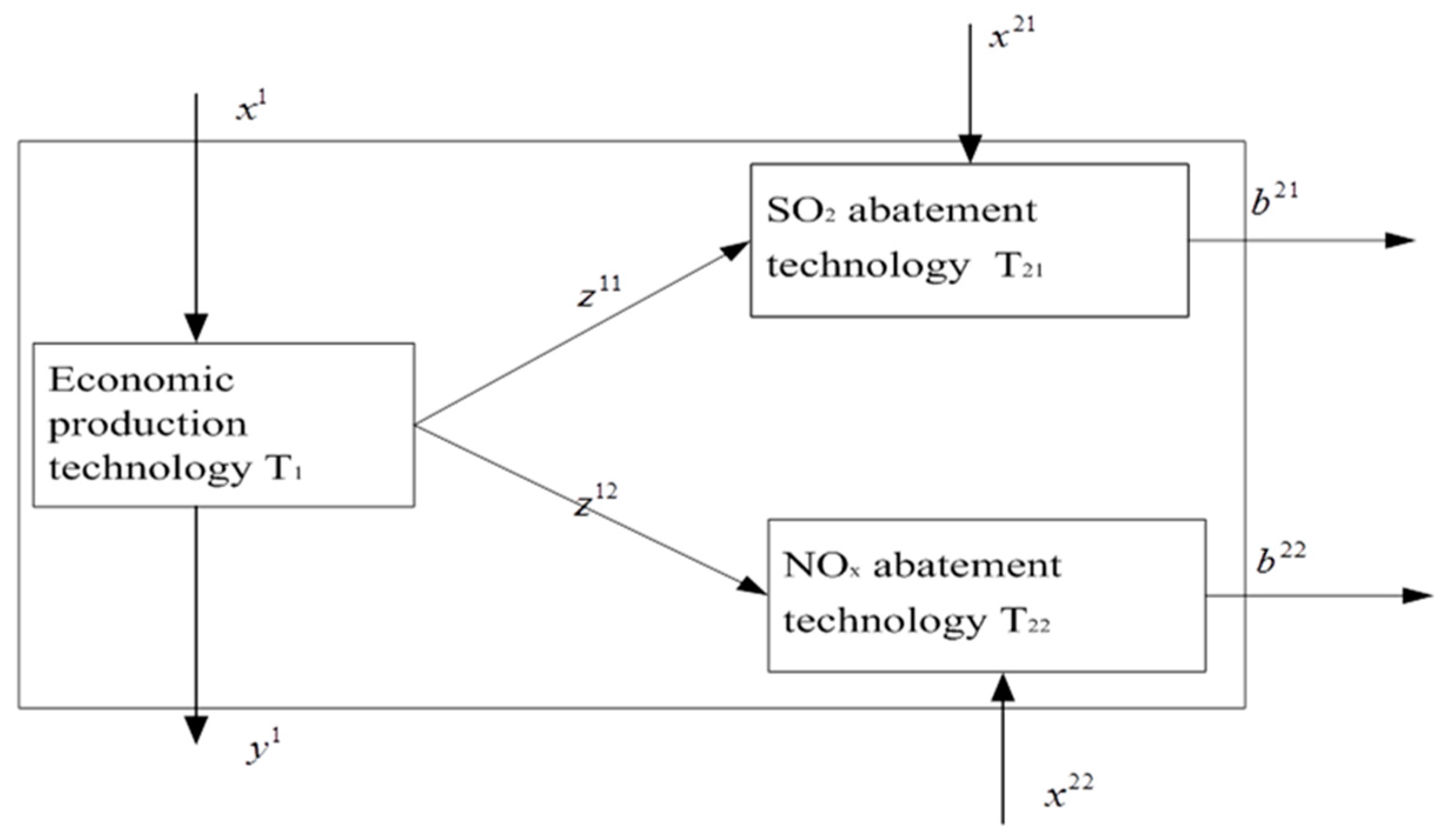

2.1. The Production System

2.2. The Network DEA Model

3. An Empirical Study of China’s Industrial Inefficiency

3.1. Data Description

3.2. Results of the Analysis

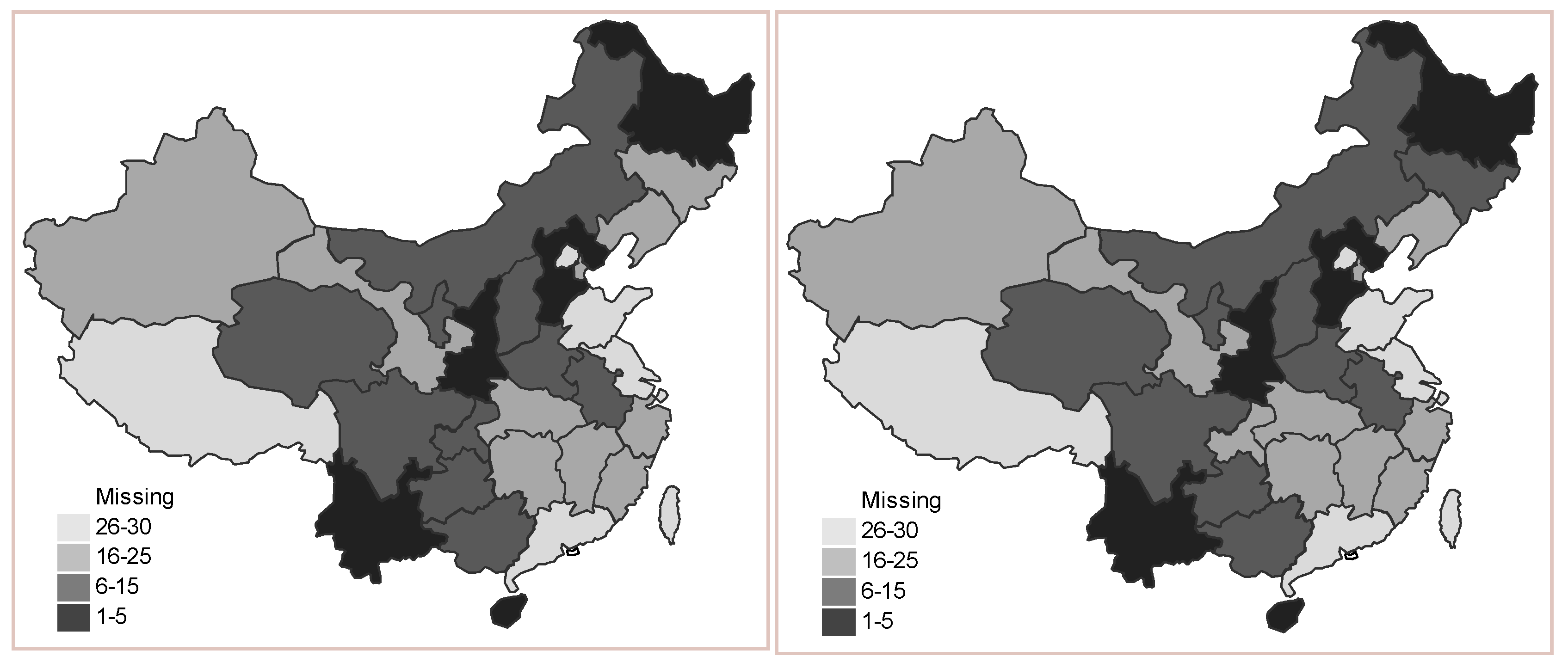

3.2.1. The Analysis of the Inefficiency of Three Areas in China

3.2.2. Statistical Analysis of the Inefficiency Score

3.2.3. Regional Distribution of the Inefficiency Score

4. Discussion and Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Sanz-Díaz, M.T.; Velasco-Morente, F.; Yñiguez, R.; Díaz-Calleja, E. An analysis of Spain’s global and environmental efficiency from a European Union perspective. Energy Policy 2017, 104, 183–193. [Google Scholar] [CrossRef]

- Lacko, R.; Hajduová, Z. Determinants of environmental efficiency of the EU countries using two-step DEA approach. Sustainability 2018, 10, 3525. [Google Scholar] [CrossRef]

- Song, M.; Zhang, J.; Wang, S. Review of the network environmental efficiencies of listed petroleum enterprises in China. Renew. Sustain. Energy Rev. 2015, 43, 65–71. [Google Scholar] [CrossRef]

- Chen, Y.; Cook, W.D.; Kao, C.; Zhu, J. Network DEA pitfalls: Divisional efficiency and frontier projection under general network structures. Eur. J. Oper. Res. 2013, 226, 507–515. [Google Scholar] [CrossRef]

- Guo, C.; Shureshjani, R.A.; Foroughi, A.A.; Zhu, J. Decomposition weights and overall efficiency in two-stage additive network DEA. Eur. J. Oper. Res. 2016, 257, 896–906. [Google Scholar] [CrossRef]

- Hampf, B. Separating environmental efficiency into production and abatement efficiency: A nonparametric model with application to US power plants. J. Product. Anal. 2014, 41, 457–473. [Google Scholar] [CrossRef][Green Version]

- Bian, Y.; Liang, N.; Xu, H. Efficiency evaluation of Chinese regional industrial systems with undesirable factors using a two-stage slacks-based measure approach. J. Clean. Prod. 2015, 87, 348–356. [Google Scholar] [CrossRef]

- Lozano, S. Technical and environmental efficiency of a two-stage production and abatement system. Ann. Oper. Res. 2015, 255, 199–219. [Google Scholar] [CrossRef]

- Wu, J.; Zhu, Q.; Ji, X.; Chu, J.; Liang, L. Two-stage network processes with shared resources and resources recovered from undesirable outputs. Eur. J. Oper. Res. 2016, 251, 182–197. [Google Scholar] [CrossRef]

- Wilson, R. Architecture of power markets. Econometrica 2002, 70, 1299–1340. [Google Scholar] [CrossRef]

- Sueyoshi, T.; Goto, M. Operational synergy in the US electric utility industry under an influence of deregulation policy: A linkage to financial performance and corporate value. Energy Policy 2011, 39, 699–713. [Google Scholar] [CrossRef]

- Buonocore, J.J.; Lambert, K.F.; Burtraw, D.; Sekar, S.; Driscoll, C.T. An analysis of costs and health co-benefits for a U.S. power plant carbon standard. PLoS ONE 2016, 11, e0156308. [Google Scholar] [CrossRef] [PubMed]

- Klausbruckner, C.; Annegarn, H.; Henneman, L.R.F.; Rafaj, P. A policy review of synergies and trade-offs in South African climate change mitigation and air pollution control strategies. Environ. Sci. Policy 2016, 57, 70–78. [Google Scholar] [CrossRef]

- Zotter, K.A. “End-of-pipe” versus “process-integrated” water conservation solutions: A comparison of planning, implementation and operating phases. J. Clean. Prod. 2004, 12, 685–695. [Google Scholar] [CrossRef]

- De, V.K.; Weustenraad, J.; Nolf, C.; Wolfs, V.; De, M.B.; Shannon, K.; Willems, P. Green-blue water in the city: Quantification of impact of source control versus end-of-pipe solutions on sewer and river floods. Water Sci. Technol. 2014, 70, 1825–1837. [Google Scholar]

- Vezzaro, L.; Sharma, A.K.; Ledin, A.; Mikkelsen, P.S. Evaluation of stormwater micropollutant source control and end-of-pipe control strategies using an uncertainty-calibrated integrated dynamic simulation model. J. Environ. Manag. 2015, 151, 56–64. [Google Scholar] [CrossRef]

- Chen, L.; Wang, Y.-M.; Lai, F. Semi-disposability of undesirable outputs in data envelopment analysis for environmental assessments. Eur. J. Oper. Res. 2017, 260, 655–664. [Google Scholar] [CrossRef]

- Färe, R.; Grosskopf, S. Nonparametric productivity analysis with undesirable outputs: Comment. Am. J. Agric. Econ. 2003, 85, 1070–1074. [Google Scholar] [CrossRef]

- Chang, Y.T.; Park, H.S.; Jeong, J.B.; Lee, J.W. Evaluating economic and environmental efficiency of global airlines: A SBM-DEA approach. Trans. Res. Part D Transp. Environ. 2014, 27, 46–50. [Google Scholar] [CrossRef]

- Liu, W.; Zhou, Z.; Ma, C.; Liu, D.; Shen, W. Two-stage DEA models with undesirable input-intermediate-outputs. Omega 2015, 56, 74–87. [Google Scholar] [CrossRef]

- Sueyoshi, T.; Goto, M. Environmental assessment on coal-fired power plants in US north-east region by DEA non-radial measurement. Energy Econ. 2015, 50, 125–139. [Google Scholar] [CrossRef]

- Fukuyama, H.; Weber, W.L. A slacks-based inefficiency measure for a two-stage system with bad outputs. Omega 2010, 38, 398–409. [Google Scholar] [CrossRef]

- Lozano, S. Slacks-based inefficiency approach for general networks with bad outputs: An application to the banking sector. Omega 2016, 60, 73–84. [Google Scholar] [CrossRef]

- Bian, Y.; Yan, S.; Xu, H. Efficiency evaluation for regional urban water use and wastewater decontamination systems in China: A DEA approach. Resour. Conserv. Recycl. 2014, 83, 15–23. [Google Scholar] [CrossRef]

- Wu, H.-Q.; Shi, Y.; Xia, Q.; Zhu, W.-D. Effectiveness of the policy of circular economy in China: A DEA-based analysis for the period of 11th five-year-plan. Resour. Conserv. Recycl. 2014, 83, 163–175. [Google Scholar] [CrossRef]

- Sueyoshi, T.; Yuan, Y. China’s regional sustainability and diversified resource allocation: DEA environmental assessment on economic development and air pollution. Energy Econ. 2015, 49, 239–256. [Google Scholar] [CrossRef]

| Type | Name | Unit |

|---|---|---|

| Economic production stage | ||

| Inputs | Industrial fixed assets | Billion RMB |

| Energy consumption | Million tons of standard coal | |

| Desirable output | Industrial output value | Billion RMB |

| Intermediate variables | Yield of industrial SO2 | Thousand tons |

| Yield of industrial NOX | Thousand tons | |

| Pollutant abatement stage | ||

| SO2 abatement division | ||

| Inputs | Operational cost of desulphurization facilities | Million RMB |

| Number of desulphurization facilities | Set | |

| Undesirable output | Emission of SO2 | Thousand tons |

| NOX abatement division | ||

| Inputs | Operational cost of denitrification facilities | Million RMB |

| Number of denitrification facilities | Set | |

| Undesirable output | Emission of NOX | Thousand tons |

| Mean | S.D. | Min | Max | |

|---|---|---|---|---|

| Industrial fixed assets | 945.69 | 674.31 | 72.02 | 2774.01 |

| Energy consumption | 72.48 | 48.16 | 8.49 | 199.09 |

| Industrial output value | 3032.36 | 3034.44 | 179.91 | 11870.55 |

| Yield of SO2 | 1977.59 | 1231.49 | 114.84 | 5004.97 |

| Yield of NOX | 597.63 | 372.45 | 85.67 | 1338.19 |

| Operational cost of desulfuration facilities | 1801.45 | 1471.56 | 146.64 | 5613.81 |

| Number desulphurization facilities | 698.93 | 806.47 | 16.00 | 3392.00 |

| Emission of SO2 | 637.19 | 378.39 | 33.04 | 1543.77 |

| Operational cost of denitrification facilities | 220.10 | 274.52 | 0.39 | 1111.55 |

| Number of denitrification facilities | 27.83 | 28.16 | 2.00 | 126.00 |

| Emission of NOX | 552.55 | 341.48 | 71.85 | 1238.17 |

| E10 | E11 | E12 | E1 | E21 | E22 | E2 | Es | |

|---|---|---|---|---|---|---|---|---|

| East | 0.36% | 38.31% | 26.47% | 65.14% | 67.56% | 33.24% | 100.80% | 165.94% |

| Central | 19.27% | 75.13% | 57.95% | 152.35% | 88.40% | 63.77% | 152.17% | 304.52% |

| West | 108.64% | 81.65% | 64.12% | 254.41% | 90.82% | 67.43% | 158.26% | 412.66% |

| All | 45.11% | 64.02% | 48.67% | 157.80% | 81.65% | 53.92% | 135.57% | 293.36% |

| Chi-Squared | p-Value | Hypothesis Test | |

|---|---|---|---|

| E10 | 12.029 | 0.0024 *** | Rejected |

| E11 | 12.164 | 0.0023 *** | Rejected |

| E12 | 8.869 | 0.0119 ** | Rejected |

| E1 | 17.759 | 0.0001 *** | Rejected |

| E21 | 12.005 | 0.0025 *** | Rejected |

| E22 | 8.521 | 0.0141 ** | Rejected |

| E2 | 8.802 | 0.0123 ** | Rejected |

| Es | 17.759 | 0.0001 *** | Rejected |

| Null Hypothesis | Z-Statistics | Significance | Result |

|---|---|---|---|

| −3.437 | 0.00 *** | Rejected | |

| −0.939 | 0.3478 | No rejected |

| Null Hypothesis | Z-Statistics | Significance | Result |

|---|---|---|---|

| E11 = E12 | 2.809 | 0.005 *** | Rejected |

| E21 = E22 | 4.938 | 0.000 *** | Rejected |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shao, Y.; Han, S. The Synergy in the Economic Production System: An Empirical Study with Chinese Industry. Sustainability 2019, 11, 980. https://doi.org/10.3390/su11040980

Shao Y, Han S. The Synergy in the Economic Production System: An Empirical Study with Chinese Industry. Sustainability. 2019; 11(4):980. https://doi.org/10.3390/su11040980

Chicago/Turabian StyleShao, Yanmin, and Song Han. 2019. "The Synergy in the Economic Production System: An Empirical Study with Chinese Industry" Sustainability 11, no. 4: 980. https://doi.org/10.3390/su11040980

APA StyleShao, Y., & Han, S. (2019). The Synergy in the Economic Production System: An Empirical Study with Chinese Industry. Sustainability, 11(4), 980. https://doi.org/10.3390/su11040980