The Limitations of an Air-Oxidation Breakaway Model to Predict a Zirconium Fire in a Spent Nuclear Fuel Pool Accident

Abstract

:1. Introduction

2. Review of the Air-Oxidation Breakaway Model in the MELCOR Code

- ∙

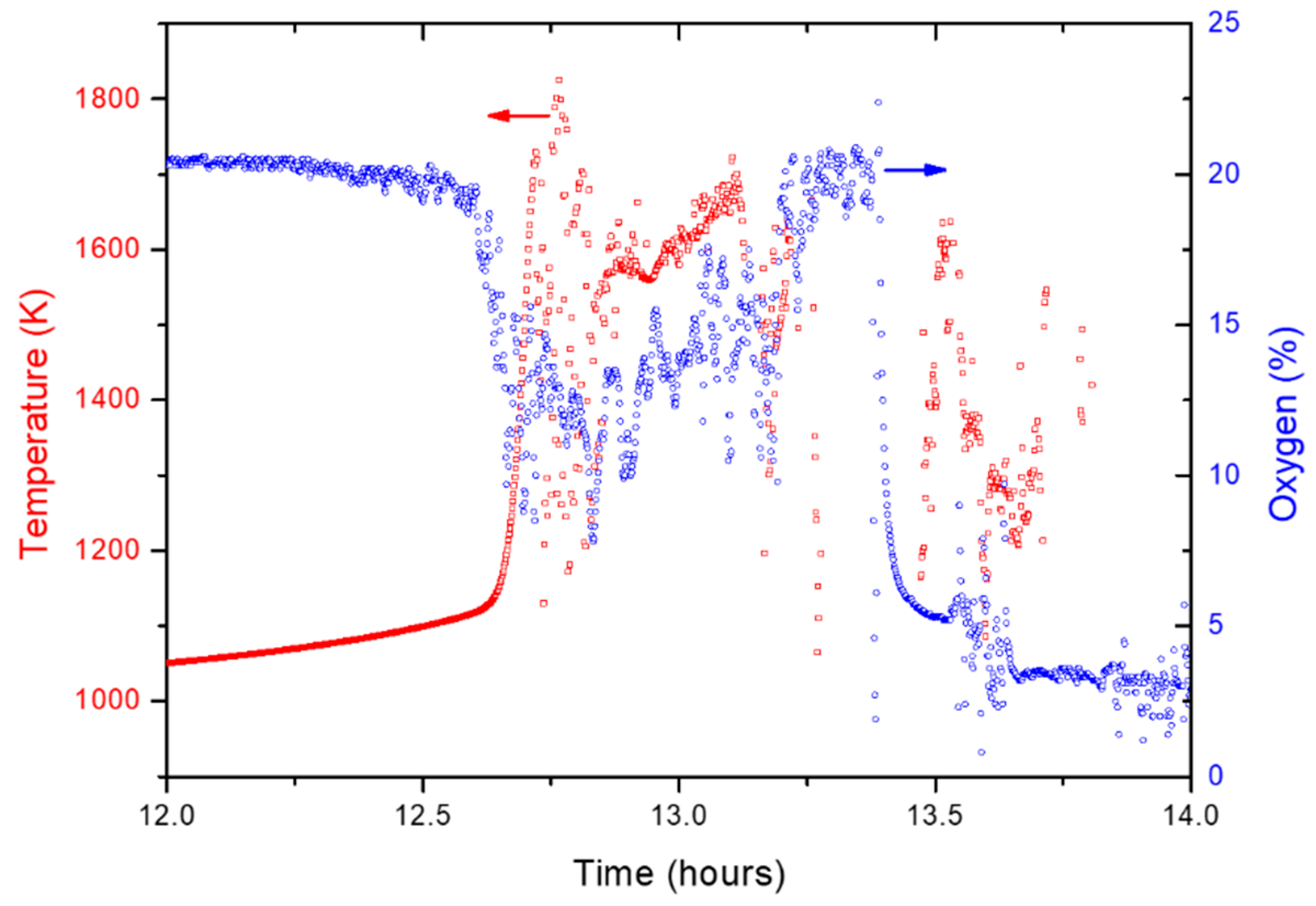

- ANL air-oxidation test data showed no “zirconium fire phenomenon” during air-oxidation tests at 773–1173 K [15]. In other words, air-oxidation breakaway did not trigger a zirconium fire. It seems a strong assumption that the air-oxidation breakaway is the direct cause of the zirconium fire. However, only separate-effect tests with very small Zry-4 samples were performed in the ANL air-oxidation tests. For this reason, it seems that an abrupt high heat release in the fuel assembly scale might induce the zirconium ignition in the integral effect tests like the SFP project experiments [1,2,14].

- ∙

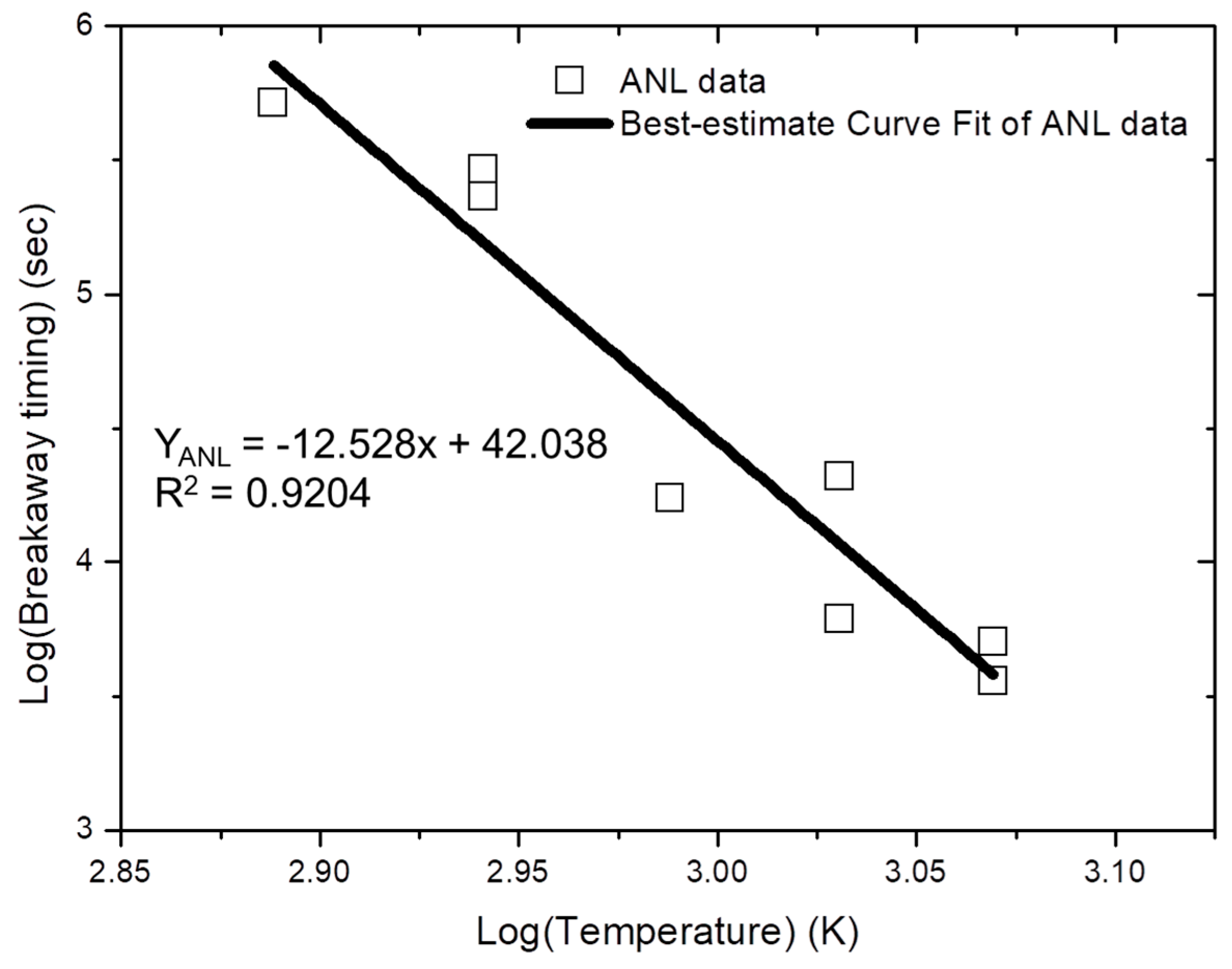

- The relationship between air-oxidation breakaway time and temperature was considered as linearly correlated on a log–log scale. However, no sound physical meaning was supported by this model fitting. Only 8 data points were fitted, and also each data point was scattered to some extent.

- ∙

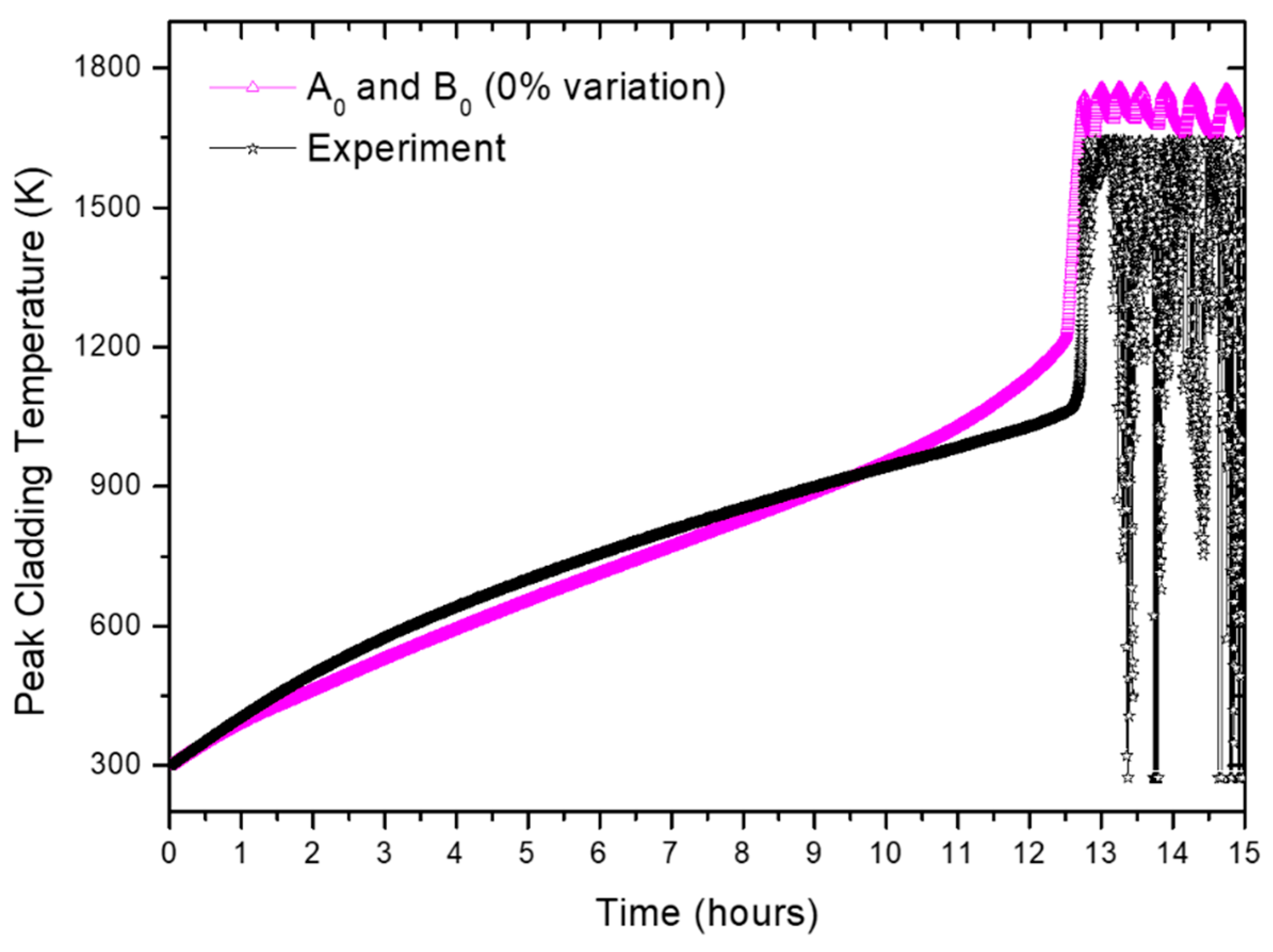

- The fitted breakaway time is given as a function of temperature with the exponent coefficient as follows: Time to breakaway (T) = T−12.528∙1042.038. If the model parameters are slightly altered, the calculated breakaway timing will be significantly shifted. Let one model parameter (−12.528) be called A0 and the other (42.038) be called B0. For example, at a fixed temperature of 1100 K with these A0 and B0, the time to breakaway is 8619 sec. If the value of A0 is altered from −1% to 1% with the fixed B0 at the fixed temperature of 1100 K, the time to breakaway changes from 3591 to 20,683 s. The variation in the breakaway time is −58% to 140% when the value of model parameter A0 varies from −1% to 1%. The model parameter A0 was from the fitting of the experimental data, and this fitted value includes its own error from the curve fitting. In this respect, the model concept (i.e., curve-fitting model in log–log scale) introduces a high uncertainty to the prediction of the target value. Another example is the variation of the other parameter B0 from −1 to 1% with the fixed A0 at the fixed temperature of 1100 K. In this case, the variation of the breakaway time is 3277 to 22,669 s and its percentage is −62% to 163%. From these simple calculations at a fixed cladding temperature with a very small variation of model parameters, the predictions of air-oxidation breakaway were varied. However, the actual cladding temperature in a postulated SFP complete LOCA is not fixed but varied according to the accident progression.

3. Sensitivity Analysis on the Occurrence of Zirconium Fire in the SFP Complete LOCA

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Durbin, S.G.; Lindgren, E.R.; Goldmann, A.S.; Zavisca, M.; Yuan, Z.; Karimi, R.; Krall, A.; Khatib-Rahbar, M.; Zigh, A.; Velazquez-Lozada, A.; et al. Spent Fuel Pool Project Phase I: Pre-Ignition and Ignition Testing of a Single Commercial 17×17 Pressurized Water Reactor Spent Fuel Assembly under Complete Loss of Coolant Accident Conditions, US NRC, NUREG/CR-7215; US NRC: Rockville, MD, USA, 2016. [Google Scholar]

- Durbin, S.G.; Lindgren, E.R.; Humphries, L.; Yuan, Z.; Zavisca, M.; Khatib-Rahbar, M.; Beaton, R.; Zigh, A.; Gonzalez, S. Spent Fuel Pool Project Phase II: Pre-Ignition and Ignition Testing of a 1×4 Commercial 17×17 Pressurized Water Reactor Spent Fuel Assembly under Complete Loss of Coolant Accident Conditions, US NRC, NUREG/CR-7216; US NRC: Rockville, MD, USA, 2016. [Google Scholar]

- Lyman, E.; Schoeppner, M.; von Hippel, F.N. Nuclear safety regulation in the post-Fukushima era. Science 2017, 356, 808–809. [Google Scholar] [CrossRef] [PubMed]

- von Hippel, F.N.; Schoeppner, M. Economic losses from a fire in a dense-packed U.S. spent fuel pool. Sci. Glob. Secur. 2017, 25, 80–92. [Google Scholar] [CrossRef]

- von Hippel, F.N.; Schoeppner, M. Reducing the danger from fires in spent fuel pools. Sci. Glob. Secur. 2016, 24, 141–173. [Google Scholar] [CrossRef]

- Wu, X.; Li, W.; Zhang, Y.; Tian, W.; Su, G.; Qiu, S. Analysis of the loss of pool cooling accident in a PWR spent fuel pool with MAAP5. Ann. Nucl. Energy 2014, 72, 198–213. [Google Scholar] [CrossRef]

- Kaliatka, A.; Ognerubov, V.; Vileiniskis, V. Analysis of the processes in spent fuel pools of Ignalina NPP in case of loss of heat removal. Nucl. Eng. Des. 2010, 240, 1073–1082. [Google Scholar] [CrossRef]

- Fleurot, J.; Lindholm, I.; Kononen, N.; Ederli, S.; Jaeckel, B.; Kaliatka, A.; Duspiva, J.; Steinbrueck, M.; Hollands, T. Synthesis of spent fuel pool accident assessments using severe accident codes. Ann. Nucl. Energy 2014, 74, 58–71. [Google Scholar] [CrossRef]

- Mochizuki, H. Evaluation of spent fuel pool temperature and water level during SBO. Ann. Nucl. Energy 2017, 109, 548–556. [Google Scholar] [CrossRef]

- Zhang, Z.W.; Du, Y.; Liang, K.S. Advanced modeling techniques of a spent fuel pool with both RELAP5 and MELCOR and associated accident analysis. Ann. Nucl. Energy 2017, 110, 160–170. [Google Scholar] [CrossRef]

- Ahn, K.-I.; Shin, J.-U.; Kim, W.-T. Severe accident analysis of plant-specific spent fuel pool to support a SFP risk and accident management. Ann. Nucl. Energy 2016, 89, 70–83. [Google Scholar] [CrossRef]

- Coindreau, O.; Jäckel, B.; Rocchi, F.; Alcaro, F.; Angelova, D.; Bandini, G.; Barnak, M.; Behler, M.; Da Cruz, D.F.; Dagan, R.; et al. Severe accident code-to-code comparison for two accident scenarios in a spent fuel pool. Ann. Nucl. Energy 2018, 120, 880–887. [Google Scholar] [CrossRef]

- Adorni, M.; Herranz, L.E.; Hollands, T.; Ahn, K.-I.; Bals, C.; D’Auria, F.; Horvath, G.L.; Jaeckel, B.S.; Kim, H.-C.; Lee, J.-J.; et al. OECD/NEA Sandia Fuel Project phase I: Benchmark of the ignition testing. Nucl. Eng. Des. 2016, 307, 418–430. [Google Scholar] [CrossRef]

- Lindgren, E.R.; Durbin, S.G. Characterization of Thermal-Hydraulic and Ignition Phenomena in Prototypic, Full-Length Boiling Water Reactor Spent Fuel Pool Assemblies after a Postulated Complete Loss-of-Coolant Accident, US NRC, NUREG/CR-7143; US NRC: Rockville, MD, USA, 2013. [Google Scholar]

- Natesan, K.; Soppet, W.K. Air Oxidation Kinetics for Zr-Based Alloys, US NRC, NUREG/CR-6846; US NRC: Rockville, MD, USA, 2014. [Google Scholar]

| A0 | −3% | −2% | −1% | 0% | 1% | 2% | 3% | |

|---|---|---|---|---|---|---|---|---|

| B0 | ||||||||

| −3% | S1 | S2 | S3 | S4 | S5 | S6 | S7 | |

| −2% | S8 | S9 | S10 | S11 | S12 | S13 | S14 | |

| −1% | S15 | S16 | S17 | S18 | S19 | S20 | S21 | |

| 0% | S22 | S23 | S24 | S25 | S26 | S27 | S28 | |

| 1% | S29 | S30 | S31 | S32 | S33 | S34 | S35 | |

| 2% | S36 | S37 | S38 | S39 | S40 | S41 | S42 | |

| 3% | S43 | S44 | S45 | S46 | S47 | S48 | S49 | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, S.; Park, M.B. The Limitations of an Air-Oxidation Breakaway Model to Predict a Zirconium Fire in a Spent Nuclear Fuel Pool Accident. Sustainability 2019, 11, 6364. https://doi.org/10.3390/su11226364

Park S, Park MB. The Limitations of an Air-Oxidation Breakaway Model to Predict a Zirconium Fire in a Spent Nuclear Fuel Pool Accident. Sustainability. 2019; 11(22):6364. https://doi.org/10.3390/su11226364

Chicago/Turabian StylePark, Sanggil, and Min Bum Park. 2019. "The Limitations of an Air-Oxidation Breakaway Model to Predict a Zirconium Fire in a Spent Nuclear Fuel Pool Accident" Sustainability 11, no. 22: 6364. https://doi.org/10.3390/su11226364

APA StylePark, S., & Park, M. B. (2019). The Limitations of an Air-Oxidation Breakaway Model to Predict a Zirconium Fire in a Spent Nuclear Fuel Pool Accident. Sustainability, 11(22), 6364. https://doi.org/10.3390/su11226364