Environmental Assessment of Two Use Cycles of Recycled Aggregate Concrete

Abstract

1. Introduction

1.1. Literature Review of the Environmental Assessment of Recycled Aggregate Concrete

1.2. Literature Review of Mechanical Properties and Durability of Recycled Aggregate Concrete

2. Materials and Methods

2.1. Materials

- NAC: Natural aggregate concrete made entirely with NA and OPC;

- RAC C100: Recycled aggregate concrete with natural sand and coarse RCA (100% replacement ratio) and OPC;

- RAC C100 F30: Recycled aggregate concrete with coarse RCA (100% replacement ratio), fine RCA (30% replacement ratio), and OPC;

- RAC C100 F30 P5: Recycled aggregate concrete with recycled coarse aggregate (100% replacement ratio), recycled fine aggregate (30% replacement ratio), and with partial replacement of OPC with RCP (5% replacement ratio).

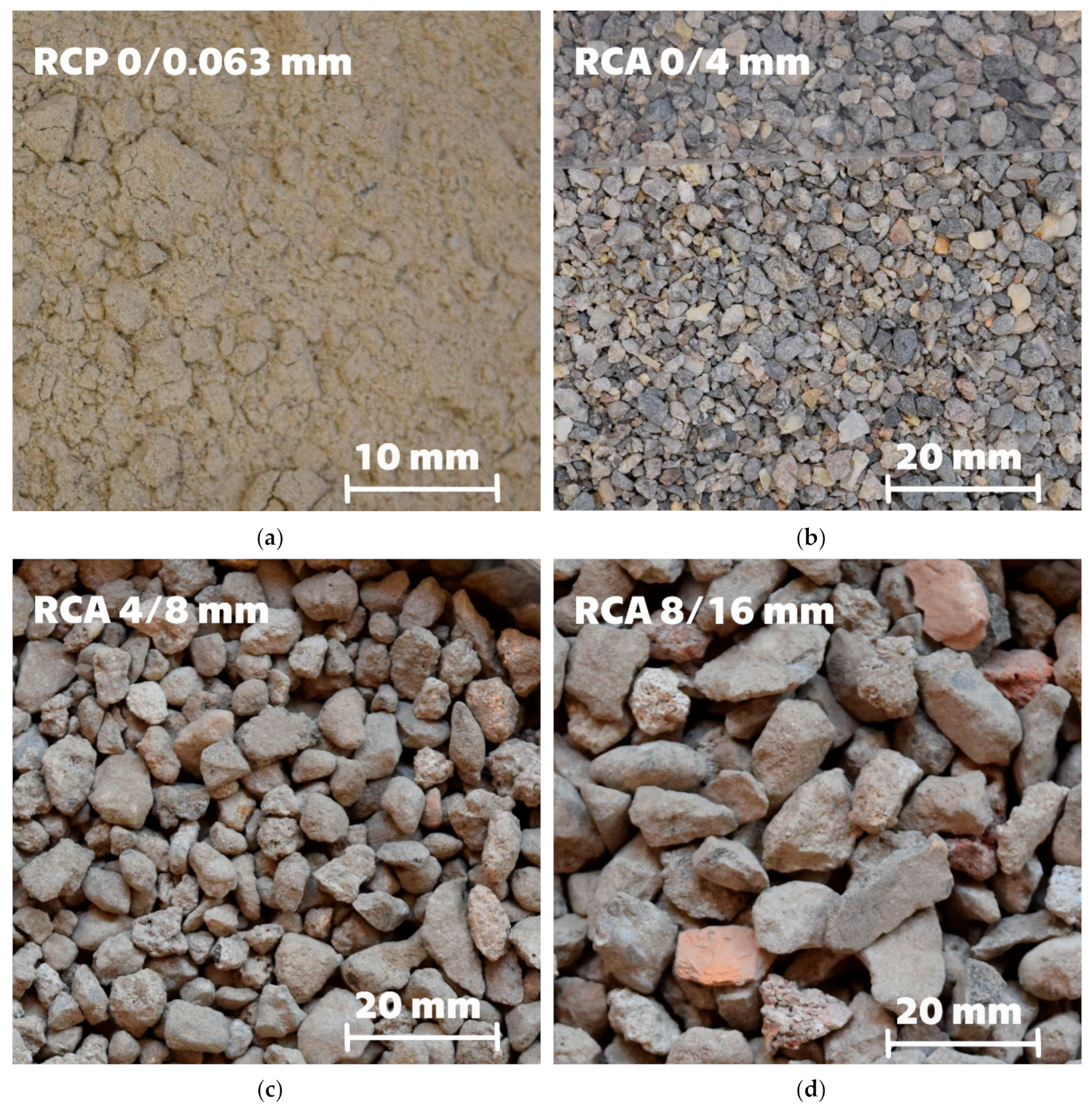

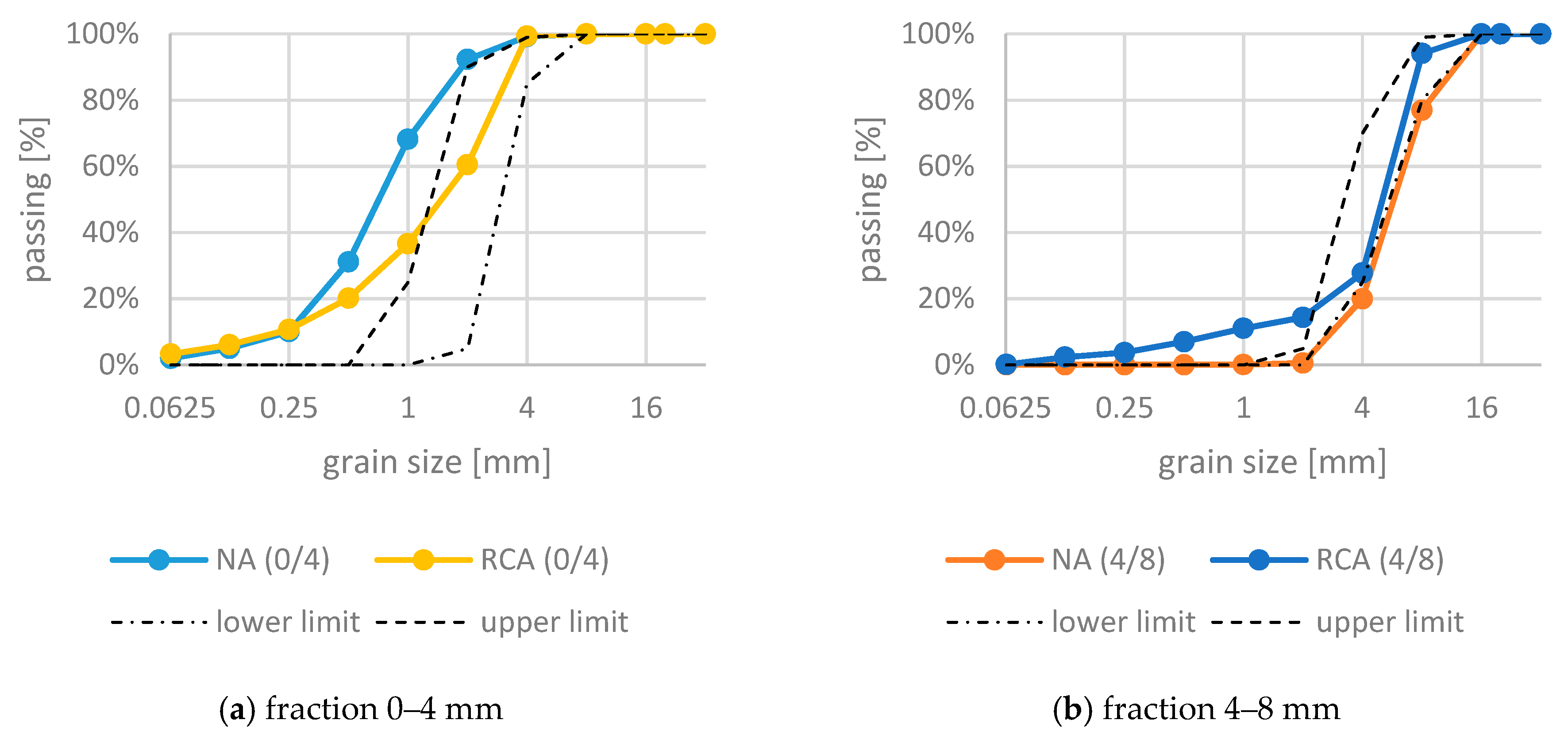

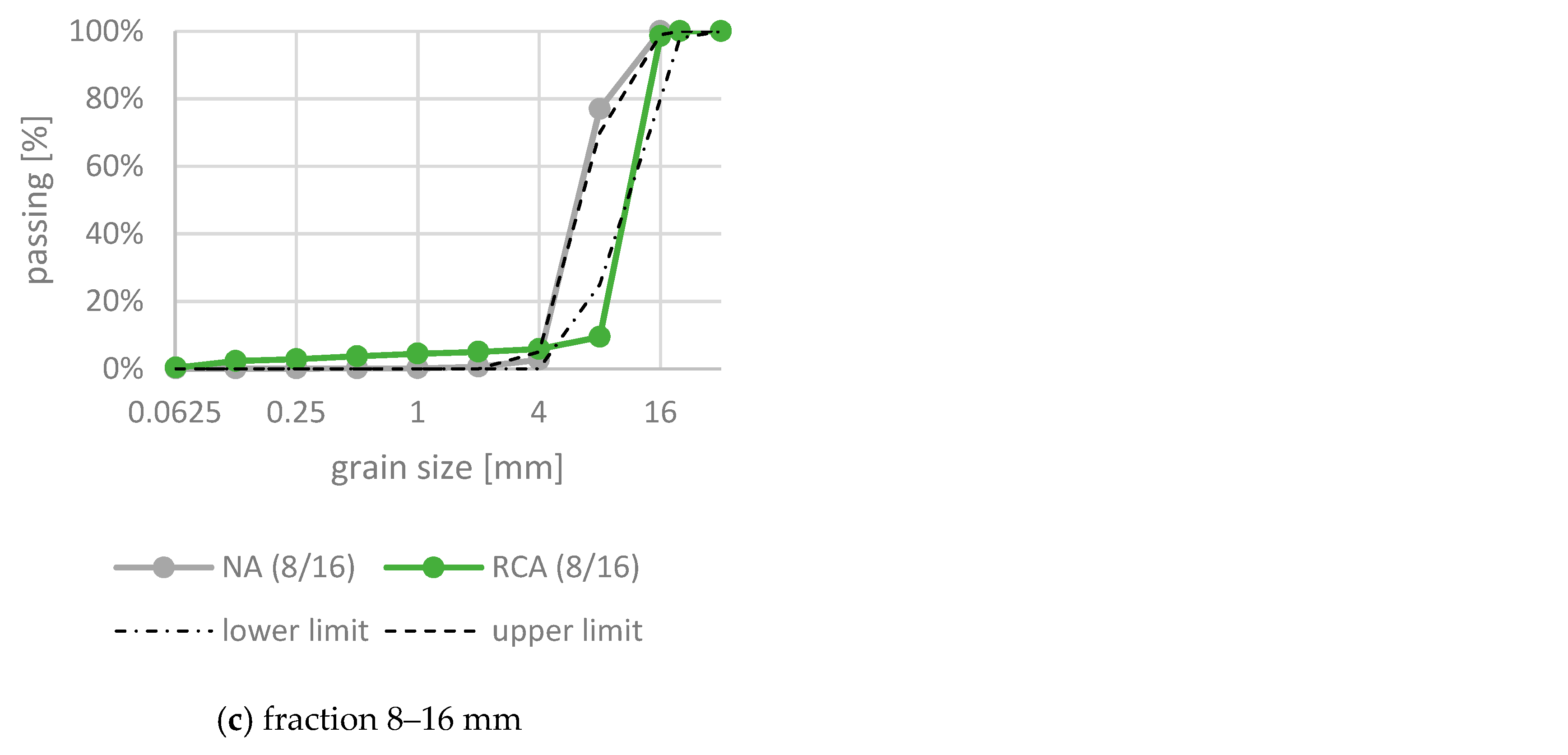

2.1.1. Recycled Concrete Aggregate Properties

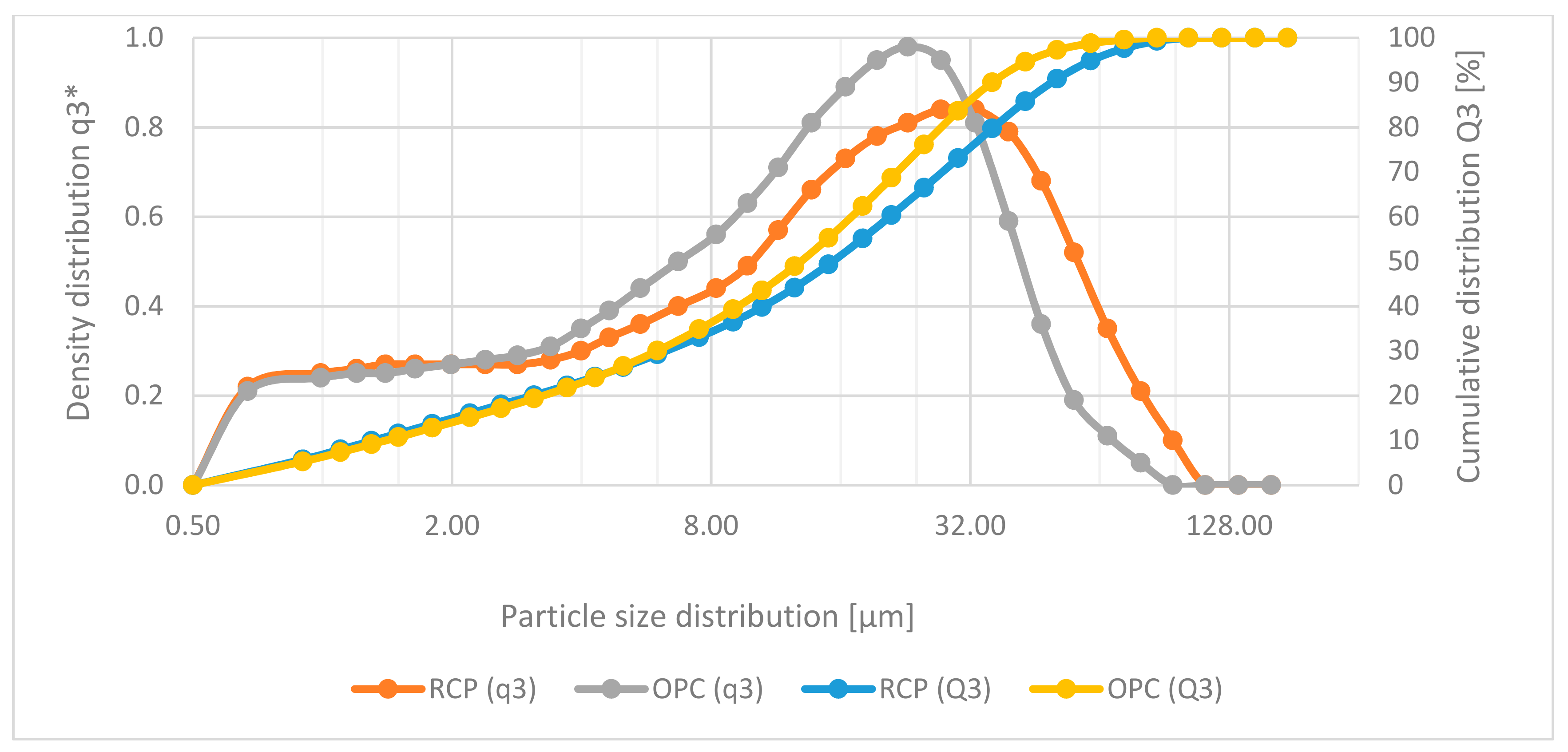

2.1.2. Recycled Concrete Powder

2.1.3. Concrete Mixes

2.1.4. Tests of Concrete Properties

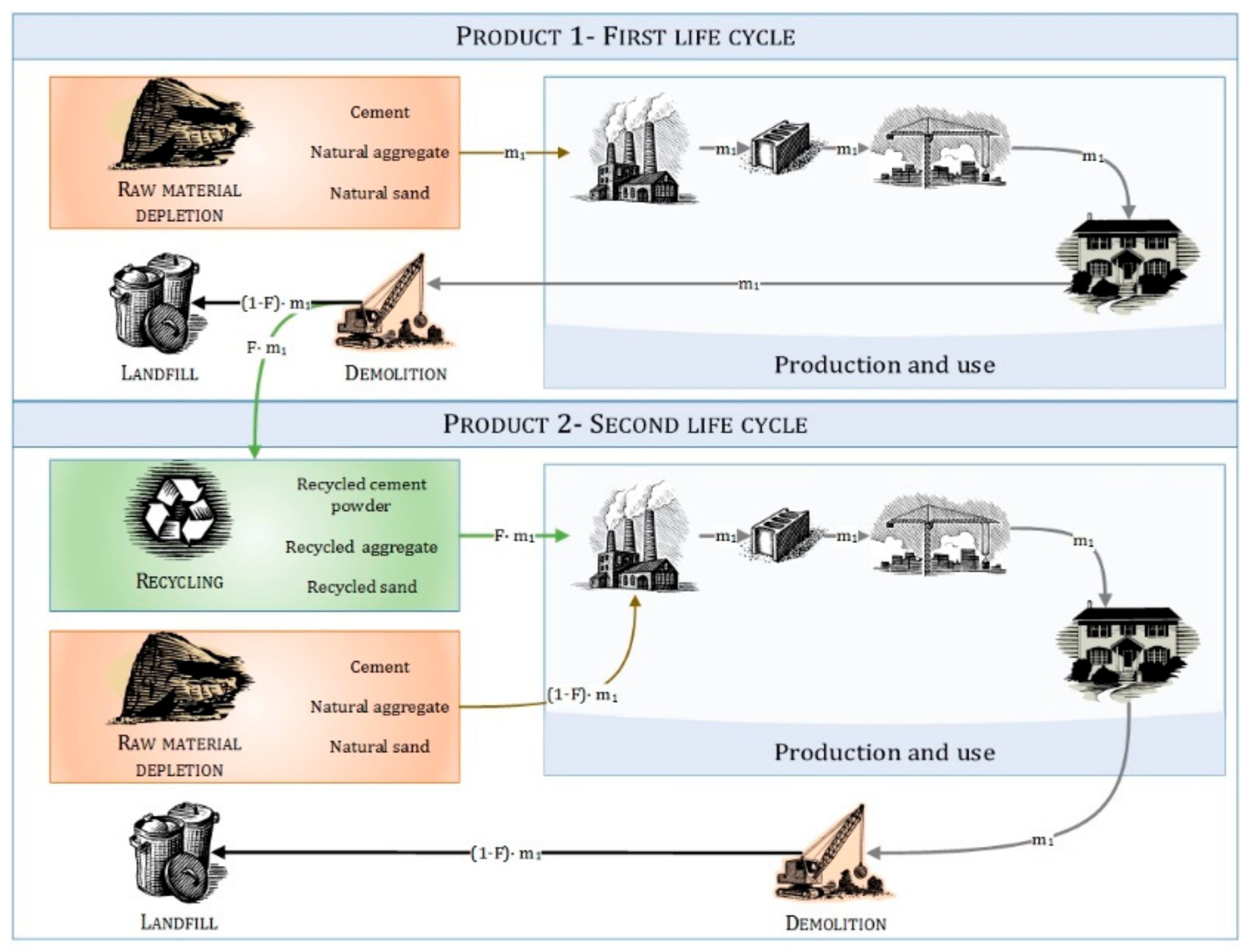

2.2. Environmental Assessment Methodology

2.2.1. Goal, Scope, and Functional Unit

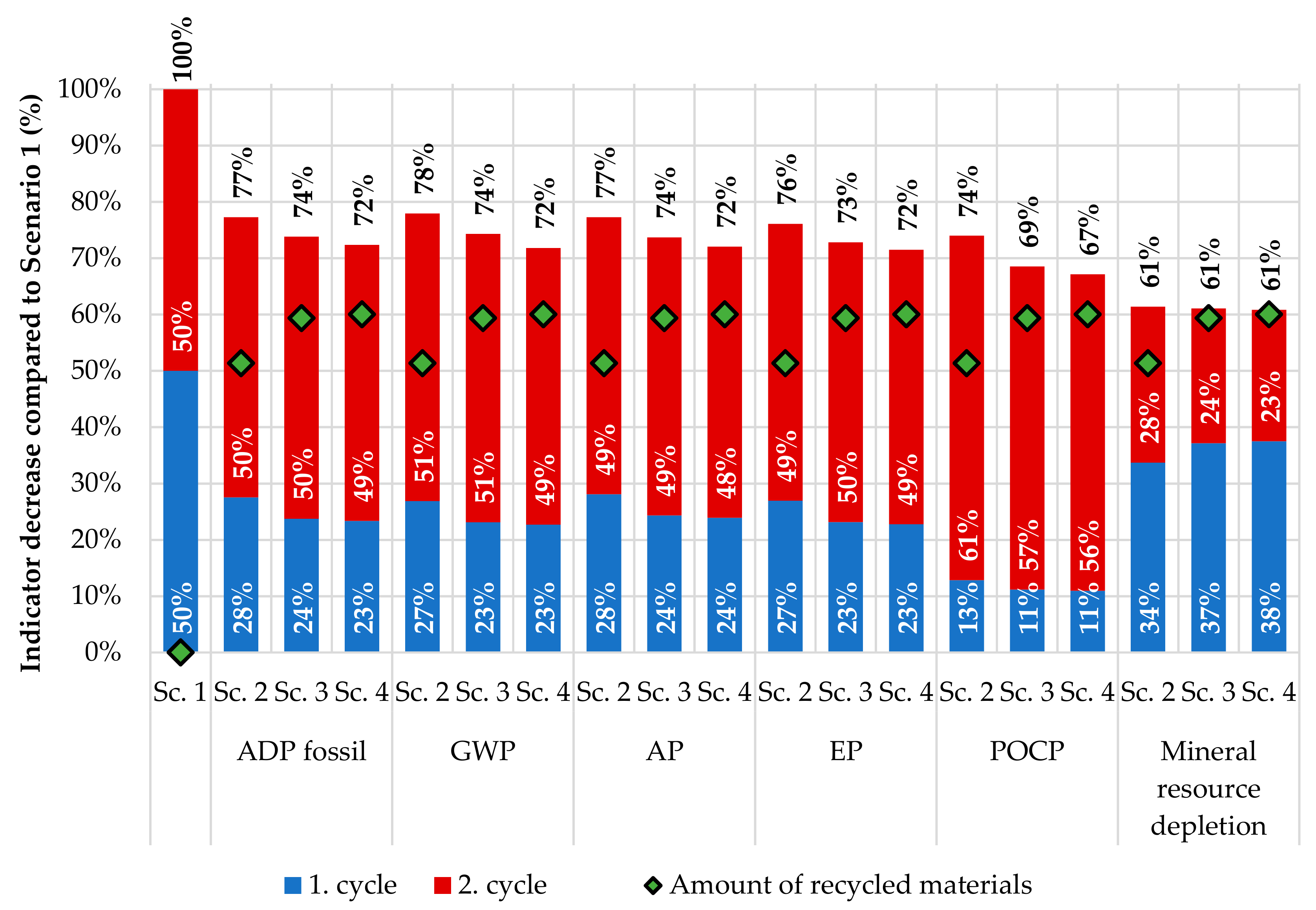

- SCENARIO 1: Two natural aggregate concrete (NAC) elements which ended in a landfill; the cycle included natural aggregate production, cement production, concrete production, use in structure, and landfill for 100% of concrete; this cycle was counted twice.

- SCENARIO 2: One natural aggregate concrete element and one recycled aggregate concrete element in which 0.49 m3 of the NAC element was used as partial replacement of primary sources; the cycle included natural aggregate production (sand), cement production, use in structure, landfill for part of concrete waste which was not recycled, recycled aggregate production, concrete production, use in structure, and landfill.

- SCENARIO 3: One natural aggregate concrete element and one recycled aggregate concrete element in which 0.56 m3 of the NAC element was used as partial replacement of primary sources; the cycle included the same processes as SCENARIO 2.

- SCENARIO 4: One natural aggregate concrete element and one recycled aggregate concrete element in which 0.57 m3 of the NAC element was used as partial replacement of primary sources; the cycle included the same processes as Scenarios 2 and 3.

2.2.2. Life Cycle Inventory (LCI) Data

2.2.3. Life Cycle Impact Assessment (LCIA)

3. Results

4. Discussion

5. Conclusions

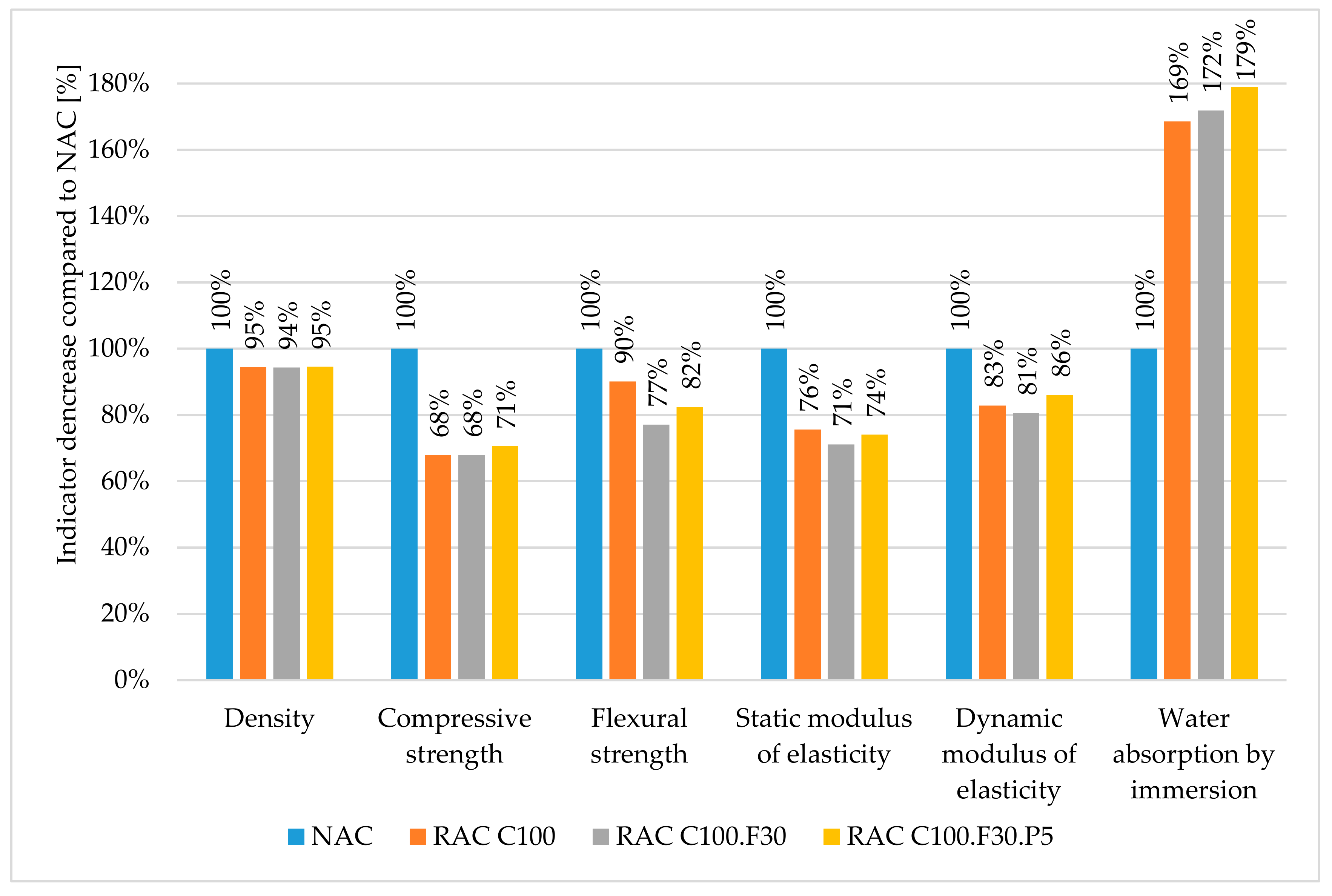

- The properties of concrete are negatively influenced by the full replacement of coarse aggregate by recycled concrete aggregate. The partial replacement of natural sand by fine recycled aggregate (up to 30%) and partial replacement of cement (up to 5%) has no further significant impact on the properties of concrete.

- If the lower strength class of concrete is used for the beam, the height of the beam has to be higher. However, the amount of added material is not significant and has no significant influence on the environmental assessment.

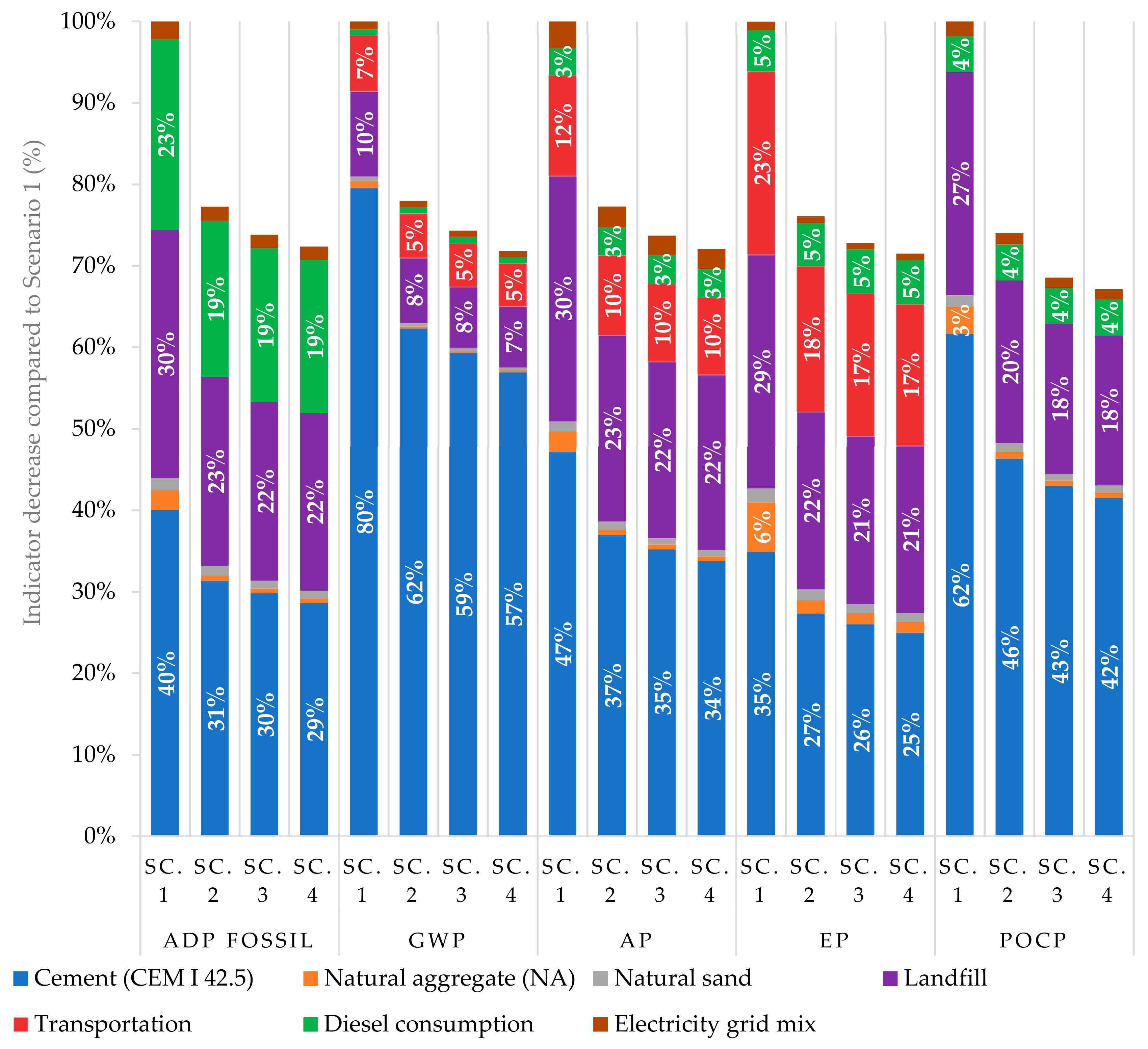

- The influence of cement production is the highest for all of the impact categories, as expected from many previous studies.

- The contribution of the aggregate production phase to the total impacts of concrete is rather small. The contribution of gravel production is below 5%, and the contribution of natural sand production is below 2%.

- The environmental impacts of RAC and NAC (with gravel aggregate) production are very similar. However, if part of the NAC from the first use cycle is used as partial replacement of primary sources in the RAC (the second use cycle), it is clear that all impact categories are improved.

- The importance of transportation and landfilling is verified. The influence of the landfill phase and the transportation showed a high impact for Scenario 1, where all the material was landfilled, indicating the benefits of recycling.

Author Contributions

Funding

Conflicts of Interest

References

- International Union of Testing and Research Laboratories for Materials and Structures; Technical Committee 37-DRC; Hansen, T.C. Recycling of Demolished Concrete and Masonry: Report of Technical Committee 37-DRC, Demolition and Reuse of Concrete; E & FN Spon: London, UK; New York, NY, USA, 1992; ISBN 978-0-203-62645-0. [Google Scholar]

- Transforming Our World: The 2030 Agenda for Sustainable Development. In A New Era in Global Health; Rosa, W., Ed.; Springer Publishing Company: New York, NY, USA, 2017; ISBN 978-0-8261-9011-6. [Google Scholar]

- Srivastava, R.K.; Vijay, S.; Torres, E. Reduction of Multi-pollutant Emissions from Industrial Sectors: The U.S. Cement Industry—A Case Study. In Global Climate Change—The Technology Challenge; Advances in Global Change Research; Springer: Dordrecht, The Netherlands, 2011; pp. 241–272. ISBN 978-90-481-3152-5. [Google Scholar]

- Marinković, S.B.; Malešev, M.; Ignjatović, I. 11—Life cycle assessment (LCA) of concrete made using recycled concrete or natural aggregates. In Eco-Efficient Construction and Building Materials; Woodhead Publishing: Philadelphia, PA, USA, 2014; pp. 239–266. ISBN 978-0-85709-767-5. [Google Scholar]

- Cement Technology Roadmap 2009: Carbon Emissions Reductions up to 2050; WBCSD Publications Library: Geneva, Switzerland, 2009.

- Marinković, S.B. Life cycle assessment (LCA) aspects of concrete. In Eco-Efficient Concrete; Elsevier: Amsterdam, The Netherlands, 2013; pp. 45–80. ISBN 978-0-85709-424-7. [Google Scholar]

- New Approach Suggests Path to Emissions-Free Cement. Available online: http://news.mit.edu/2019/carbon-dioxide-emissions-free-cement-0916 (accessed on 29 September 2019).

- Braunschweig, A.; Kytzia, S.; Bischof, S. Recycled Concrete: Environmentally Beneficial over Virgin Concrete. In Proceedings of the XVI ERMCO Congress, Berlin, Germany, 21–22 June 2012; p. 12. [Google Scholar]

- Pacheco Torgal, F.; Jalali, S. Eco-Efficient Construction and Building Materials; Springer: London, UK, 2011; ISBN 978-0-85729-891-1. [Google Scholar]

- Weil, M.; Jeske, U.; Schebek, L. Closed-loop recycling of construction and demolition waste in Germany in view of stricter environmental threshold values. Waste Manag. Res. 2006, 24, 197–206. [Google Scholar] [CrossRef] [PubMed]

- Evangelista, L.; Guedes, M.; de Brito, J.; Ferro, A.C.; Pereira, M.F. Physical, chemical and mineralogical properties of fine recycled aggregates made from concrete waste. Constr. Build. Mater. 2015, 86, 178–188. [Google Scholar] [CrossRef]

- Tošić, N.; Marinković, S.; Dašić, T.; Stanić, M. Multicriteria optimization of natural and recycled aggregate concrete for structural use. J. Clean. Prod. 2015, 87, 766–776. [Google Scholar] [CrossRef]

- Serres, N.; Braymand, S.; Feugeas, F. Environmental evaluation of concrete made from recycled concrete aggregate implementing life cycle assessment. J. Build. Eng. 2016, 5, 24–33. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Soomro, M.; Evangelista, A.C.J. A review of recycled aggregate in concrete applications (2000–2017). Constr. Build. Mater. 2018, 172, 272–292. [Google Scholar] [CrossRef]

- Hossain, M.U.; Poon, C.S.; Lo, I.M.; Cheng, J.C. Comparative environmental evaluation of aggregate production from recycled waste materials and virgin sources by LCA. Resour. Conserv. Recycl. 2016, 109, 67–77. [Google Scholar] [CrossRef]

- Marinković, S.; Radonjanin, V.; Malešev, M.; Ignjatović, I. Comparative environmental assessment of natural and recycled aggregate concrete. Waste Manag. 2010, 30, 2255–2264. [Google Scholar] [CrossRef]

- Jullien, A.; Proust, C.; Martaud, T.; Rayssac, E.; Ropert, C. Variability in the environmental impacts of aggregate production. Resour. Conserv. Recycl. 2012, 62, 1–13. [Google Scholar] [CrossRef]

- Nayana, A.Y.; Kavitha, S. Evaluation of C02 emissions for green concrete with high volume slag, recycled aggregate, recycled water to build eco environment. Int. J. Civ. Eng. Technol. 2017, 8, 703–708. [Google Scholar]

- Eco-Efficient Construction and Building Materials: Life Cycle Assessment (lca), Eco-Labelling and Case Studies; Woodhead Publishing Series in Civil and Structural Engineering; Woodhead Pub.: Philadelphia, PA, USA, 2014; ISBN 978-0-85709-767-5.

- Marinković, S.B.; Ignjatović, I.; Radonjanin, V. 23—Life-cycle assessment (LCA) of concrete with recycled aggregates (RAs). In Handbook of Recycled Concrete and Demolition Waste; Pacheco-Torgal, F., Tam, V.W.Y., Labrincha, J.A., Ding, Y., de Brito, J., Eds.; Woodhead Publishing Series in Civil and Structural Engineering; Woodhead Publishing: Philadelphia, PA, USA, 2013; pp. 569–604. ISBN 978-0-85709-682-1. [Google Scholar]

- Evangelista, L.; de Brito, J. Environmental Life Cycle Assessment of Concrete Made with Fine Recycled Concrete Aggregates. p. 6. Available online: https://www.researchgate.net/publication/235939400_Environmental_life_cycle_assessment_of_concrete_made_with_fine_recycled_concrete_aggregates (accessed on 4 November 2019).

- Marinković, S.; Dragaš, J.; Ignjatović, I.; Tošić, N. Environmental assessment of green concretes for structural use. J. Clean. Prod. 2017, 154, 633–649. [Google Scholar] [CrossRef]

- Knoeri, C.; Sanyé-Mengual, E.; Althaus, H.-J. Comparative LCA of recycled and conventional concrete for structural applications. Int. J. Life Cycle Assess. 2013, 18, 909–918. [Google Scholar] [CrossRef]

- Park, W.-J.; Kim, T.; Roh, S.; Kim, R. Analysis of Life Cycle Environmental Impact of Recycled Aggregate. Appl. Sci. 2019, 9, 1021. [Google Scholar] [CrossRef]

- Choi, H.; Lim, M.; Choi, H.; Kitagaki, R.; Noguchi, T. Using Microwave Heating to Completely Recycle Concrete. J. Environ. Prot. 2014, 5, 583–596. [Google Scholar] [CrossRef]

- Shima, H.; Tateyashiki, H.; Matsuhashi, R.; Yoshida, Y. An advanced concrete recycling technology and its applicability assessment through input-output analysis. J. Adv. Concr. Technol. 2005, 3, 53–67. [Google Scholar] [CrossRef]

- Gámez-García, D.C.; Gómez-Soberón, J.M.; Corral-Higuera, R.; Almaral-Sánchez, J.L.; Gómez-Soberón, M.C.; Gómez-Soberón, L.A. LCA as comparative tool for concrete columns and glulam columns. J. Sustain. Archit. Civ. Eng. 2015, 11, 21–31. [Google Scholar] [CrossRef][Green Version]

- Evangelista, L.; de Brito, J. Mechanical behaviour of concrete made with fine recycled concrete aggregates. Cem. Concr. Compos. 2007, 29, 397–401. [Google Scholar] [CrossRef]

- Topçu, I.B. Physical and mechanical properties of concretes produced with waste concrete. Cem. Concr. Res. 1997, 27, 1817–1823. [Google Scholar] [CrossRef]

- Topçu, İ.B.; Şengel, S. Properties of concretes produced with waste concrete aggregate. Cem. Concr. Res. 2004, 34, 1307–1312. [Google Scholar] [CrossRef]

- Tam, V.W.Y. Economic comparison of concrete recycling: A case study approach. Resour. Conserv. Recycl. 2008, 52, 821–828. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Tam, C.M. Diversifying two-stage mixing approach (TSMA) for recycled aggregate concrete: TSMAs and TSMAsc. Constr. Build. Mater. 2008, 22, 2068–2077. [Google Scholar] [CrossRef]

- Kong, D.; Lei, T.; Zheng, J.; Ma, C.; Jiang, J.; Jiang, J. Effect and mechanism of surface-coating pozzalanics materials around aggregate on properties and ITZ microstructure of recycled aggregate concrete. Constr. Build. Mater. 2010, 24, 701–708. [Google Scholar] [CrossRef]

- Kou, S.; Poon, C.; Agrela, F. Comparisons of natural and recycled aggregate concretes prepared with the addition of different mineral admixtures. Cem. Concr. Compos. 2011, 33, 788–795. [Google Scholar] [CrossRef]

- Verian, K.P.; Ashraf, W.; Cao, Y. Properties of recycled concrete aggregate and their influence in new concrete production. Resour. Conserv. Recycl. 2018, 133, 30–49. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Tam, C.M. Assessment of durability of recycled aggregate concrete produced by two-stage mixing approach. J. Mater. Sci. 2007, 42, 3592–3602. [Google Scholar] [CrossRef]

- Etxeberria, M.; Vázquez, E.; Marí, A.; Barra, M. Influence of amount of recycled coarse aggregates and production process on properties of recycled aggregate concrete. Cem. Concr. Res. 2007, 37, 735–742. [Google Scholar] [CrossRef]

- Zaharieva, R.; Buyle-Bodin, F.; Wirquin, E. Frost resistance of recycled aggregate concrete. Cem. Concr. Res. 2004, 34, 1927–1932. [Google Scholar] [CrossRef]

- Gao, D.; Zhang, L.; Nokken, M.; Zhao, J. Mixture Proportion Design Method of Steel Fiber Reinforced Recycled Coarse Aggregate Concrete. Materials 2019, 12, 375. [Google Scholar] [CrossRef]

- Poon, C.S.; Shui, Z.H.; Lam, L.; Fok, H.; Kou, S.C. Influence of moisture states of natural and recycled aggregates on the slump and compressive strength of concrete. Cem. Concr. Res. 2004, 34, 31–36. [Google Scholar] [CrossRef]

- Nili, M.; Sasanipour, H.; Aslani, F. The Effect of Fine and Coarse Recycled Aggregates on Fresh and Mechanical Properties of Self-Compacting Concrete. Materials 2019, 12, 1120. [Google Scholar] [CrossRef]

- Li, C.; Wang, F.; Deng, X.; Li, Y.; Zhao, S. Testing and Prediction of the Strength Development of Recycled-Aggregate Concrete with Large Particle Natural Aggregate. Materials 2019, 12, 1891. [Google Scholar] [CrossRef]

- Arredondo-Rea, S.P.; Corral-Higuera, R.; Gómez-Soberón, J.M.; Gámez-García, D.C.; Bernal-Camacho, J.M.; Rosas-Casarez, C.A.; Ungsson-Nieblas, M.J. Durability parameters of reinforced recycled aggregate concrete: Case study. Appl. Sci. Switz. 2019, 9, 617. [Google Scholar] [CrossRef]

- Corinaldesi, V. Mechanical and elastic behaviour of concretes made of recycled-concrete coarse aggregates. Constr. Build. Mater. 2010, 24, 1616–1620. [Google Scholar] [CrossRef]

- Dhir, R.K.; de Brito, J.; Silva, R.V.; Lye, C.Q. 9—Deformation of Concrete Containing Recycled Concrete Aggregate. In Sustainable Construction Materials; Dhir, R.K., de Brito, J., Silva, R.V., Lye, C.Q., Eds.; Woodhead Publishing Series in Civil and Structural Engineering; Woodhead Publishing: Philadelphia, PA, USA, 2019; pp. 283–363. ISBN 978-0-08-100985-7. [Google Scholar]

- Dhir, R.K.; de Brito, J.; Silva, R.V.; Lye, C.Q. 10—Recycled Aggregate Concrete: Durability Properties. In Sustainable Construction Materials; Dhir, R.K., de Brito, J., Silva, R.V., Lye, C.Q., Eds.; Woodhead Publishing Series in Civil and Structural Engineering; Woodhead Publishing: Philadelphia, PA, USA, 2019; pp. 365–418. ISBN 978-0-08-100985-7. [Google Scholar]

- Silva, R.V.; Neves, R.; de Brito, J.; Dhir, R.K. Carbonation behaviour of recycled aggregate concrete. Cem. Concr. Compos. 2015, 62, 22–32. [Google Scholar] [CrossRef]

- Silva, R.V.; de Brito, J.; Dhir, R.K. Prediction of the shrinkage behavior of recycled aggregate concrete: A review. Constr. Build. Mater. 2015, 77, 327–339. [Google Scholar] [CrossRef]

- Chinchillas-Chinchillas, M.J.; Rosas-Casarez, C.A.; Arredondo-Rea, S.P.; Gómez-Soberón, J.M.; Corral-Higuera, R. SEM Image Analysis in Permeable Recycled Concretes with Silica Fume. A Quantitative Comparison of Porosity and the ITZ. Materials 2019, 12, 2201. [Google Scholar] [CrossRef]

- CSN EN 206+A1. Concrete: Specification, Performance, Production and Conformity; Czech Standardization Agency: Prague, Czech Republic, 2018. [Google Scholar]

- Corinaldesi, V. Structural Concrete Prepared with Coarse Recycled Concrete Aggregate: From Investigation to Design. Available online: https://www.hindawi.com/journals/ace/2011/283984/ (accessed on 4 March 2018).

- Fortova, K.; Pavlu, T. The Utilization of the Finest Fraction of Recycled Aggregate from CDW for Concrete. IOP Conf. Ser. Earth Environ. Sci. 2019, 290, 012013. [Google Scholar] [CrossRef]

- Kwan, A.K.H.; Ng, P.L.; Huen, K.Y. Effects of fines content on packing density of fine aggregate in concrete. Constr. Build. Mater. 2014, 61, 270–277. [Google Scholar] [CrossRef]

- Šeps, K.; Broukalová, I. Mechanical Properties of Cement Composites with Alternative Binders. Adv. Mater. Res. 2015, 1106, 37–40. [Google Scholar] [CrossRef]

- Ženíšek, M.; Vlach, T.; Laiblová, L. Dosage of Silica Fume in High Performance Concrete. Key Eng. Mater. 2016, 677, 98–102. [Google Scholar] [CrossRef]

- Ženíšek, M.; Vlach, T.; Laiblová, L. Options for Improving the Workability of High Performance Concrete. Adv. Mater. Res. 2015, 1106, 53–56. [Google Scholar] [CrossRef]

- Holčapek, O. Resistance of refractory cement composite to cyclic temperature loading. Key Eng. Mater. 2016, 677, 23–28. [Google Scholar] [CrossRef]

- Letelier, V.; Tarela, E.; Moriconi, G. Mechanical Properties of Concretes with Recycled Aggregates and Waste Brick Powder as Cement Replacement. Procedia Eng. 2017, 171, 627–632. [Google Scholar] [CrossRef]

- Zhu, P.; Mao, X.; Qu, W.; Li, Z.; Ma, Z.J. Investigation of using recycled powder from waste of clay bricks and cement solids in reactive powder concrete. Constr. Build. Mater. 2016, 113, 246–254. [Google Scholar] [CrossRef]

- Letelier, V.; Ortega, J.M.; Tarela, E.; Muñoz, P.; Henríquez-Jara, B.I.; Moriconi, G. Mechanical Performance of Eco-Friendly Concretes with Volcanic Powder and Recycled Concrete Aggregates. Sustainability 2018, 10, 3036. [Google Scholar] [CrossRef]

- Pavlů, T.; Kočí, V.; Šefflová, M. Study Replacement of Cement with Recycled Cement Powder and the Environmental Assessment. Solid State Phenom. 2016, 249, 136–141. [Google Scholar] [CrossRef]

- Abdel-Gawwad, H.A.; Heikal, E.; El-Didamony, H.; Hashim, F.S.; Mohammed, A.H. Recycling of concrete waste to produce ready-mix alkali activated cement. Ceram. Int. 2018, 44, 7300–7304. [Google Scholar] [CrossRef]

- Kwon, E.; Ahn, J.; Cho, B.; Park, D. A study on development of recycled cement made from waste cementitious powder. Constr. Build. Mater. 2015, 83, 174–180. [Google Scholar] [CrossRef]

- Chandara, C.; Azizli, K.A.M.; Ahmad, Z.A.; Sakai, E. Use of waste gypsum to replace natural gypsum as set retarders in portland cement. Waste Manag. 2009, 29, 1675–1679. [Google Scholar] [CrossRef]

- Gartner, E.; Hirao, H. A review of alternative approaches to the reduction of CO2 emissions associated with the manufacture of the binder phase in concrete. Cem. Concr. Res. 2015, 78, 126–142. [Google Scholar] [CrossRef]

- Evangelista, L.; de Brito, J. Concrete with fine recycled aggregates: A review. Eur. J. Environ. Civ. Eng. 2014, 18, 129–172. [Google Scholar] [CrossRef]

- De Brito, J.; Saikia, N. Recycled Aggregate in Concrete; Green Energy and Technology; Springer London: London, UK, 2013; ISBN 978-1-4471-4539-4. [Google Scholar]

- Hansen, T.C. Recycling of Demolished Concrete and Masonry; CRC Press: Boca Raton, FL, USA, 2004; ISBN 978-0-203-62645-0. [Google Scholar]

- Boehme, L.; Vrijders, J.; Van Gysel, A. Valorisation of Recycled Concrete Aggregates in Concrete C20/25 & C25/30; KHBO: Brugge, Belgium, 2012. [Google Scholar]

- ISO 12491. Statistical Methods for Quality Control of Building Materials and Components; ISO: Geneva, Switzerland, 1997. [Google Scholar]

- International Organization for Standardization (ISO). ISO 14040: Environmental Management—Life Cycle Assessment—Principles and Framework; ISO: Geneva, Switzerland, 1997. [Google Scholar]

- International Organization for Standardization (ISO). ISO 14044: Environmental Management, Life Cycle Assessment, Requirements and Guidelines; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- Pacheco-Torgal, F. 1—Introduction to the recycling of construction and demolition waste (CDW). In Handbook of Recycled Concrete and Demolition Waste; Woodhead Publishing Series in Civil and Structural Engineering; Woodhead Publishing: Philadelphia, PA, USA, 2013; pp. 1–6. ISBN 978-0-85709-682-1. [Google Scholar]

- Hiete, M. 4—Waste management plants and technology for recycling construction and demolition (C&D) waste: State-of-the-art and future challenges. In Handbook of Recycled Concrete and Demolition Waste; Pacheco-Torgal, F., Tam, V.W.Y., Labrincha, J.A., Ding, Y., de Brito, J., Eds.; Woodhead Publishing Series in Civil and Structural Engineering; Woodhead Publishing: Philadelphia, PA, USA, 2013; pp. 53–75. ISBN 978-0-85709-682-1. [Google Scholar]

- Coelho, A.; de Brito, J. 7—Conventional demolition versus deconstruction techniques in managing construction and demolition waste (CDW). In Handbook of Recycled Concrete and Demolition Waste; Woodhead Publishing Series in Civil and Structural Engineering; Woodhead Publishing: Philadelphia, PA, USA, 2013; pp. 141–185. ISBN 978-0-85709-682-1. [Google Scholar]

- Coelho, A.; de Brito, J. 9—Preparation of concrete aggregates from construction and demolition waste (CDW). In Handbook of Recycled Concrete and Demolition Waste; Woodhead Publishing Series in Civil and Structural Engineering; Woodhead Publishing: Philadelphia, PA, USA, 2013; pp. 210–245. ISBN 978-0-85709-682-1. [Google Scholar]

- Ding, T.; Xiao, J.; Tam, V.W.Y. A closed-loop life cycle assessment of recycled aggregate concrete utilization in China. Waste Manag. 2016, 56, 367–375. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Luo, W.; Wang, J.; Wang, Y.; Xu, Y.; Xiao, J. A review of life cycle assessment of recycled aggregate concrete. Constr. Build. Mater. 2019, 209, 115–125. [Google Scholar] [CrossRef]

- Turk, J.; Cotič, Z.; Mladenovič, A.; Šajna, A. Environmental evaluation of green concretes versus conventional concrete by means of LCA. Waste Manag. 2015, 45, 194–205. [Google Scholar] [CrossRef] [PubMed]

- Hossain, M.U.; Poon, C.S.; Lo, I.M.C.; Cheng, J.C.P. Evaluation of environmental friendliness of concrete paving eco-blocks using LCA approach. Int. J. Life Cycle Assess. 2016, 21, 70–84. [Google Scholar] [CrossRef]

- Collins, F. Inclusion of carbonation during the life cycle of built and recycled concrete: Influence on their carbon footprint. Int. J. Life Cycle Assess. 2010, 15, 549–556. [Google Scholar] [CrossRef]

- Colangelo, F.; Forcina, A.; Farina, I.; Petrillo, A. Life Cycle Assessment (LCA) of Different Kinds of Concrete Containing Waste for Sustainable Construction. Buildings 2018, 8, 70. [Google Scholar] [CrossRef]

- García-Segura, T.; Yepes, V.; Alcalá, J. Life cycle greenhouse gas emissions of blended cement concrete including carbonation and durability. Int. J. Life Cycle Assess. 2014, 19, 3–12. [Google Scholar] [CrossRef]

- Guo, Z.; Tu, A.; Chen, C.; Lehman, D.E. Mechanical properties, durability, and life-cycle assessment of concrete building blocks incorporating recycled concrete aggregates. J. Clean. Prod. 2018, 199, 136–149. [Google Scholar] [CrossRef]

- Kleijer, A.L.; Lasvaux, S.; Citherlet, S.; Viviani, M. Product-specific Life Cycle Assessment of ready mix concrete: Comparison between a recycled and an ordinary concrete. Resour. Conserv. Recycl. 2017, 122, 210–218. [Google Scholar] [CrossRef]

- Hossain, M.U.; Xuan, D.; Poon, C.S. Sustainable management and utilisation of concrete slurry waste: A case study in Hong Kong. Waste Manag. 2017, 61, 397–404. [Google Scholar] [CrossRef]

- Handbook on Life Cycle Assessment: Operational Guide to the ISO Standards; Eco-Efficiency in Industry and Science; Guinée, J., Ed.; Springer: Dordrecht, The Netherlands, 2002; ISBN 978-1-4020-0228-1. [Google Scholar]

- Estanqueiro, B.A.M. Life Cycle Assessment of the Use of Recycled Aggregates in the Production of Concrete; UTL: Lisboa, Portugal, 2011; p. 10. [Google Scholar]

| Oven-Dry Density (kg/m3) | Water Absorption (%) | |

|---|---|---|

| NA (0/4 mm) | 2600 | 2.9 |

| NA (4/8 mm) | 2650 | 1.1 |

| NA (8/16 mm) | 2650 | 0.8 |

| RCA (0/4 mm) | 2300 | 8.3 |

| RCA (4/8 mm) | 2350 | 6.0 |

| RCA (8/16 mm) | 2500 | 4.2 |

| SiO2 | Al2O3 | CaO | Fe2O3 | MgO | Na2O | SO3 | LOI | |

|---|---|---|---|---|---|---|---|---|

| OPC | 20.2 | 4.7 | 61.9 | 3.0 | 2.6 | 0.2 | 3.9 | 3.5 |

| RCP | 34.6 | 10.5 | 28.8 | 5.0 | 5.8 | 1.7 | 1.8 | 11.8 |

| Density (g/cm3) | Specific Surface Area (cm2/g) | |

|---|---|---|

| OPC | 3.044 | 3.630 |

| RCP | 2.585 | 3.635 |

| NAC | RAC | |||

|---|---|---|---|---|

| Type of Concrete | RAC C100 | RAC C100.F30 | RAC C100.F30.P5 | |

| NA 0/4 mm (kg) | 767 | 784 | 603 | 603 |

| NA 4/8 mm (kg) | 458 | 0 | 0 | 0 |

| NA 8/16 mm (kg) | 726 | 0 | 0 | 0 |

| RCA 0/4 mm (kg) | 0 | 0 | 216 | 216 |

| RCA 4/8 mm (kg) | 0 | 364 | 310 | 310 |

| RCA 8/16 mm (kg) | 0 | 710 | 714 | 714 |

| OPC CEM I 42.5 R (kg) | 320 | 320 | 320 | 304 |

| RCP (kg) | 0 | 0 | 0 | 16 |

| Effective w/c ratio (-) | 0.50 | 0.50 | 0.50 | 0.50 |

| Density | Compressive Strength | Flexural Strength | Static Modulus of Elasticity | Dynamic Modulus of Elasticity | Target Strength Class | |

|---|---|---|---|---|---|---|

| Type of Concrete | (kg/m3) | (MPa) | (MPa) | (GPa) | (GPa) | (-) |

| NAC | 2340 | 49.5 | 5.0 | 34.0 | 48.0 | C30/37 |

| RAC C100 | 2210 | 33.6 | 4.5 | 25.7 | 40.0 | C20/25 |

| RAC C100 F30 | 2210 | 33.6 | 3.8 | 24.2 | 39.0 | C20/25 |

| RAC C100 F30 P5 | 2210 | 35.0 | 4.1 | 25.2 | 41.6 | C20/25 |

| Natural Aggregate | Recycled Aggregate | |

|---|---|---|

| ADP fossil (MJ) | 0.0314 | 0.0160 |

| GWP (kg CO2-Eq.) | 0.0024 | 0.0012 |

| AP (kg SO2-Eq.) | 1.53E-05 | 8.91E-06 |

| EP (kg Phosphate-Eq.) | 5.32E-06 | 2.04E-06 |

| POCP (kg Ethene-Eq.) | 2.82E-10 | 5.56E-15 |

| Cement (CEM I 42.5) | Natural Aggregate (NA) | Natural Sand | Landfill | Transportation | Diesel Consumption | Electricity Grid Mix | |

|---|---|---|---|---|---|---|---|

| SCENARIO 1 | |||||||

| ADP fossil (MJ) | 1260 | 77 | 47 | 960 | 0 | 736 | 70 |

| GWP (kg CO2-eq) | 561.5 | 5.9 | 3.9 | 73.6 | 48.6 | 4.8 | 7.0 |

| AP (kg SO2-eq) | 0.700 | 0.038 | 0.018 | 0.446 | 0.183 | 0.049 | 0.049 |

| EP (kg phosphate-eq) | 0.074 | 0.013 | 0.004 | 0.061 | 0.048 | 0.011 | 0.002 |

| POCP (kg ethene-eq) | 0.094 | 0.005 | 0.002 | 0.042 | 0.000 | 0.007 | 0.003 |

| SCENARIO 2 | |||||||

| ADP fossil (MJ) | 988 | 20 | 37 | 730 | 0 | 604 | 55 |

| GWP (kg CO2-eq) | 440.0 | 1.6 | 3.1 | 55.9 | 38.5 | 5.3 | 5.4 |

| AP (kg SO2-eq) | 0.548 | 0.010 | 0.015 | 0.339 | 0.145 | 0.050 | 0.038 |

| EP (kg phosphate-eq) | 0.058 | 0.003 | 0.003 | 0.047 | 0.038 | 0.011 | 0.002 |

| POCP (kg ethene-eq) | 0.074 | 0.001 | 0.002 | 0.032 | 0.000 | 0.007 | 0.002 |

| SCENARIO 3 | |||||||

| ADP fossil (MJ) | 941 | 17 | 30 | 691 | 0 | 595 | 52 |

| GWP (kg CO2-eq) | 419.0 | 1.3 | 2.5 | 52.9 | 37.7 | 5.4 | 5.2 |

| AP (kg SO2-eq) | 0.522 | 0.008 | 0.012 | 0.321 | 0.142 | 0.051 | 0.037 |

| EP (kg phosphate-eq) | 0.056 | 0.003 | 0.002 | 0.044 | 0.037 | 0.012 | 0.002 |

| POCP (kg ethene-eq) | 0.070 | 0.001 | 0.001 | 0.030 | 0.000 | 0.007 | 0.002 |

| SCENARIO 4 | |||||||

| ADP fossil (MJ) | 903 | 17 | 30 | 686 | 0 | 592 | 52 |

| GWP (kg CO2-eq) | 402.0 | 1.3 | 2.5 | 52.6 | 37.5 | 5.4 | 5.2 |

| AP (kg SO2-eq) | 0.501 | 0.008 | 0.012 | 0.319 | 0.141 | 0.051 | 0.036 |

| EP (kg phosphate-eq) | 0.053 | 0.003 | 0.002 | 0.044 | 0.037 | 0.012 | 0.002 |

| POCP (kg ethene-eq) | 0.067 | 0.001 | 0.001 | 0.030 | 0.000 | 0.007 | 0.002 |

| SCENARIO 1 | SCENARIO 2 | SCENARIO 3 | SCENARIO 4 | |

|---|---|---|---|---|

| ADP fossil (MJ) | 3150 | 2434 | 2326 | 2280 |

| GWP (kg CO2-eq) | 705.3 | 550.0 | 524.2 | 506.6 |

| AP (kg SO2-eq) | 1.483 | 1.146 | 1.093 | 1.069 |

| EP (kg phosphate-eq) | 0.214 | 0.163 | 0.156 | 0.153 |

| POCP (kg ethene-eq) | 0.153 | 0.118 | 0.112 | 0.109 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pavlů, T.; Kočí, V.; Hájek, P. Environmental Assessment of Two Use Cycles of Recycled Aggregate Concrete. Sustainability 2019, 11, 6185. https://doi.org/10.3390/su11216185

Pavlů T, Kočí V, Hájek P. Environmental Assessment of Two Use Cycles of Recycled Aggregate Concrete. Sustainability. 2019; 11(21):6185. https://doi.org/10.3390/su11216185

Chicago/Turabian StylePavlů, Tereza, Vladimír Kočí, and Petr Hájek. 2019. "Environmental Assessment of Two Use Cycles of Recycled Aggregate Concrete" Sustainability 11, no. 21: 6185. https://doi.org/10.3390/su11216185

APA StylePavlů, T., Kočí, V., & Hájek, P. (2019). Environmental Assessment of Two Use Cycles of Recycled Aggregate Concrete. Sustainability, 11(21), 6185. https://doi.org/10.3390/su11216185