Multi-Objective Sustainable Truck Scheduling in a Rail–Road Physical Internet Cross-Docking Hub Considering Energy Consumption

Abstract

:1. Introduction

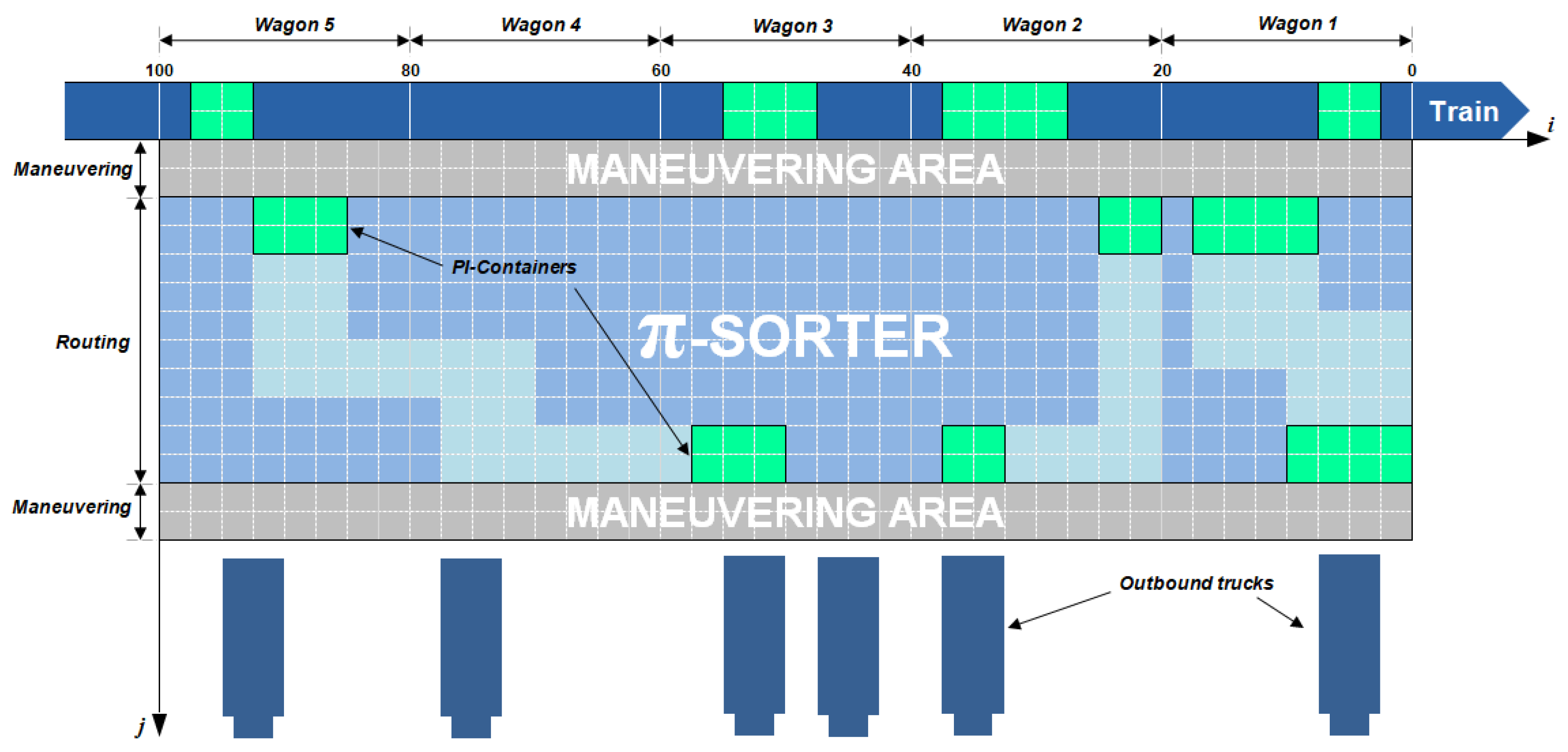

- Road–Road PI-hubs: Cross-docking terminals used to efficiently transfer the PI-containers between inbound and outbound trucks through PI-sorters. They are composed of PI-sorters connected to the PI-docks using maneuvering areas that arrange the PI-containers after being unloaded from inbound trucks to be routed in the PI-sorters and then grouped and loaded into the outgoing trucks [15].

- Road–Rail PI-hubs: Use the same mechanism as the Road–Road PI-hubs. However, the PI-containers are transferred between trucks and trains and between trains and other trains using PI-sorters for routing and maneuvering areas to arrange containers. The interested reader can refer to [16] for a detailed functional design of the Road–Rail PI-hubs.

- Water–Road PI-hubs: Are designed to transfer the PI-containers between boats and trucks in a port terminal [10].

2. Literature Review

2.1. Classical Cross-Docking Terminals

2.2. Physical Internet Cross-Docking Hubs

2.3. Sustainability in Supply Chains and Cross-Docks

2.4. Multi-Objective Optimization Techniques

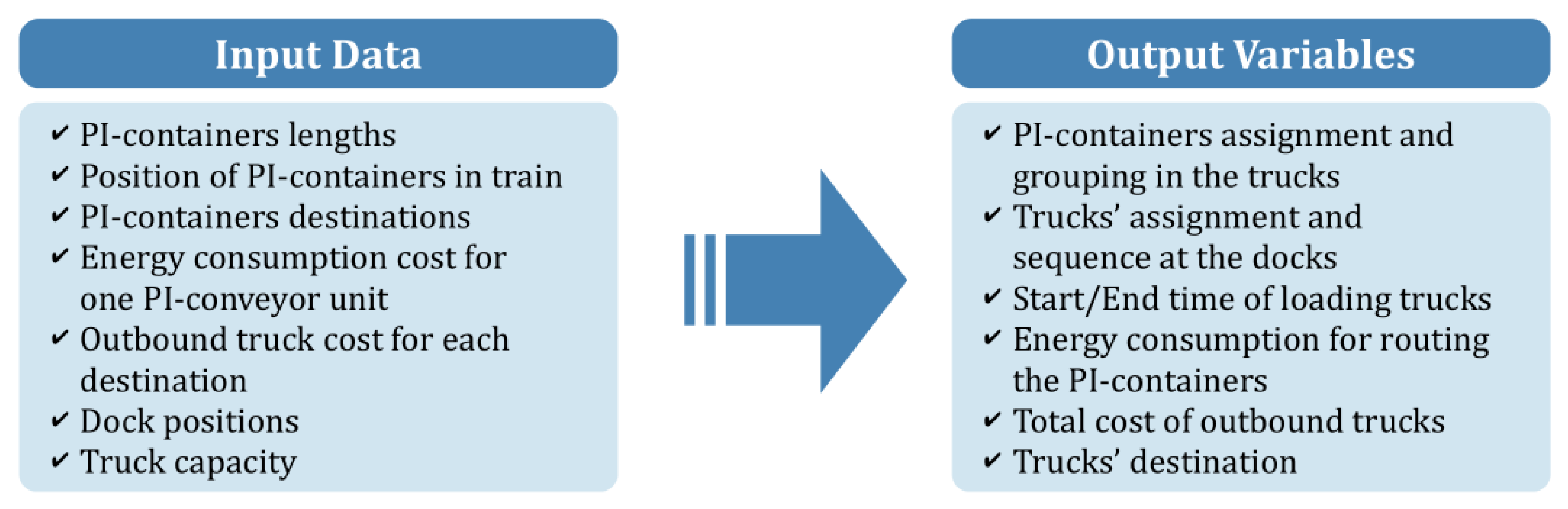

3. Problem Description and Working Assumptions

- There are two objective functions to minimize: (the cost of using outbound trucks) and (the energy consumption cost for the PI-conveyors).

- The two objective functions are arranged in some order defined by the decision maker: minimizing and then in this study for example.

- The train unloads PI-containers that have different lengths and destinations.

- Each outbound truck must load only PI-containers that have the same destination.

4. Mathematical Formulation

4.1. Problem Data and Parameters

| N | Total number of PI-containers in the train |

| K | Total number of the outbound docks in the Rail→Road section |

| D | Total number of destinations of PI-containers |

| H | Total number of available outbound trucks |

| i, j | Indices of PI-containers to transfer from the train to the inbound trucks () |

| k | Index of the outbound docks in the Rail→Road section () |

| d | Index of the destinations of PI-containers to load into the outbound trucks () |

| h, g | Indices of the outbound trucks () |

| CE | Cost of energy consumption for one unit of PI-conveyors |

| Cost of using an outbound truck for destination d | |

| I | Time to load one PI-container into an outbound truck |

| V | Truck changeover time |

| Y | Vertical length of the Rail→Road section |

| Pi | Position of the bottom left corner of the PI-containers in the wagons of the train starting from the right axis of the Rail→Road section |

| Rk | Position of the outbound dock k starting from the right axis of the Road→Rail section |

| Li | Length of a PI-container i to unload from the train |

| Gdi | Two dimension binary matrix () containing the destination of each PI-container, where: |

| Q | Truck capacity |

| M | A sufficient big positive number. The minimum value of M must be above: |

4.2. Decision Variables

4.2.1. Binary Variables

4.2.2. Integer Variables

| zih | The area (Number of PI-conveyor units) swept by PI-container i to arrive at its destination at the outbound truck h |

4.2.3. Continuous Variables

| bh | Start time for loading outbound truck h |

| qh | End time for loading outbound truck h (completion time) |

4.3. Objective Function

| F1 | The total cost of trucks used for all destination |

| F2 | The total energy consumption cost for PI-conveyors |

4.4. Constraints

4.5. Constraints Description

5. Solving Methods

5.1. Construction Heuristic

| Algorithm 1 Overview of the heuristic () algorithm for the initial solution |

|

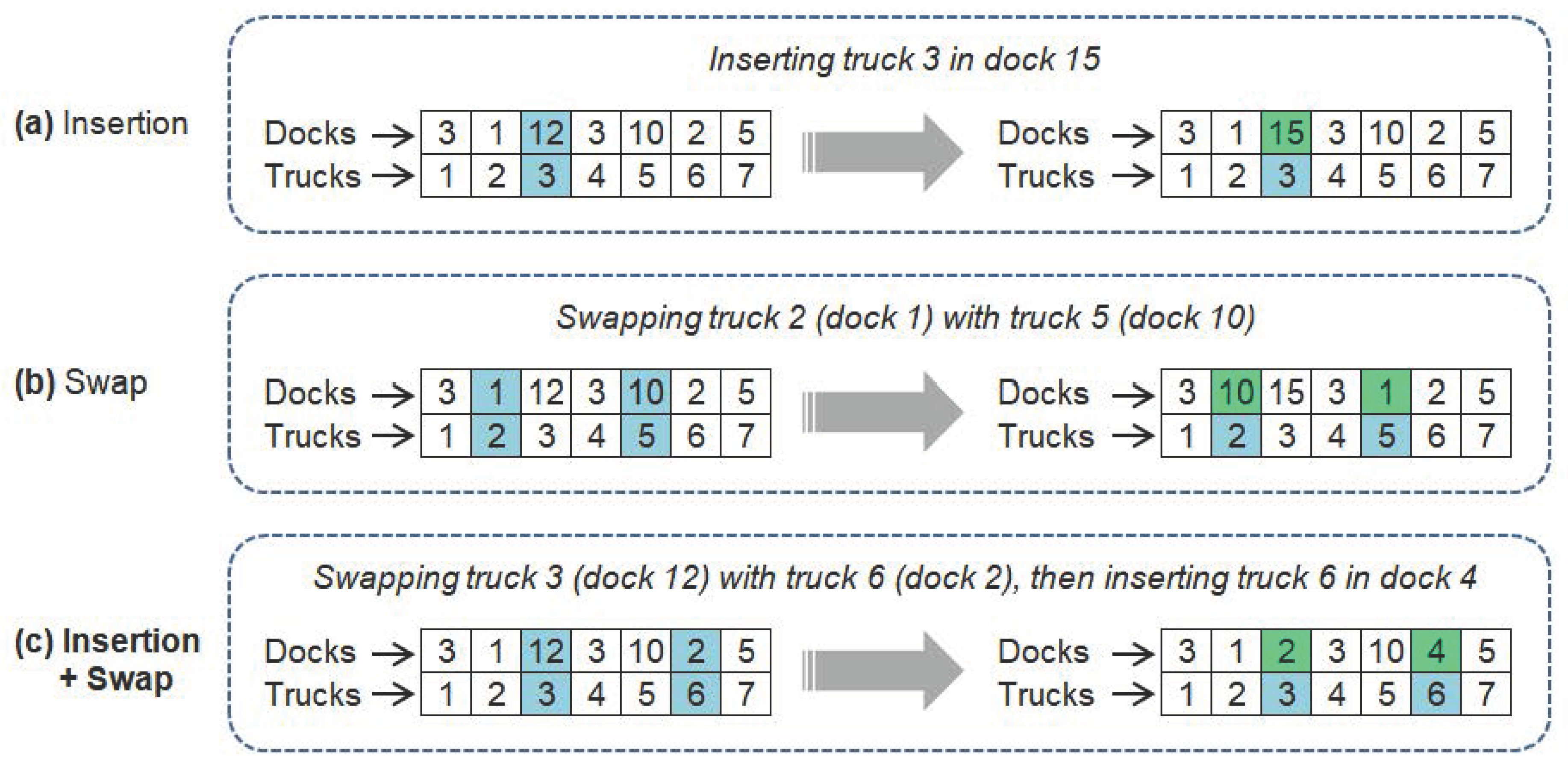

5.2. Neighborhood Operators

5.3. MO-VNSSA

| Algorithm 2 Overview of the hybrid MO-VNSSA algorithm |

|

5.4. MO-VNSTS

| Algorithm 3 Overview of the hybrid MO-VNSTS algorithm |

|

6. Computational Experiments

6.1. Implementation and Instances

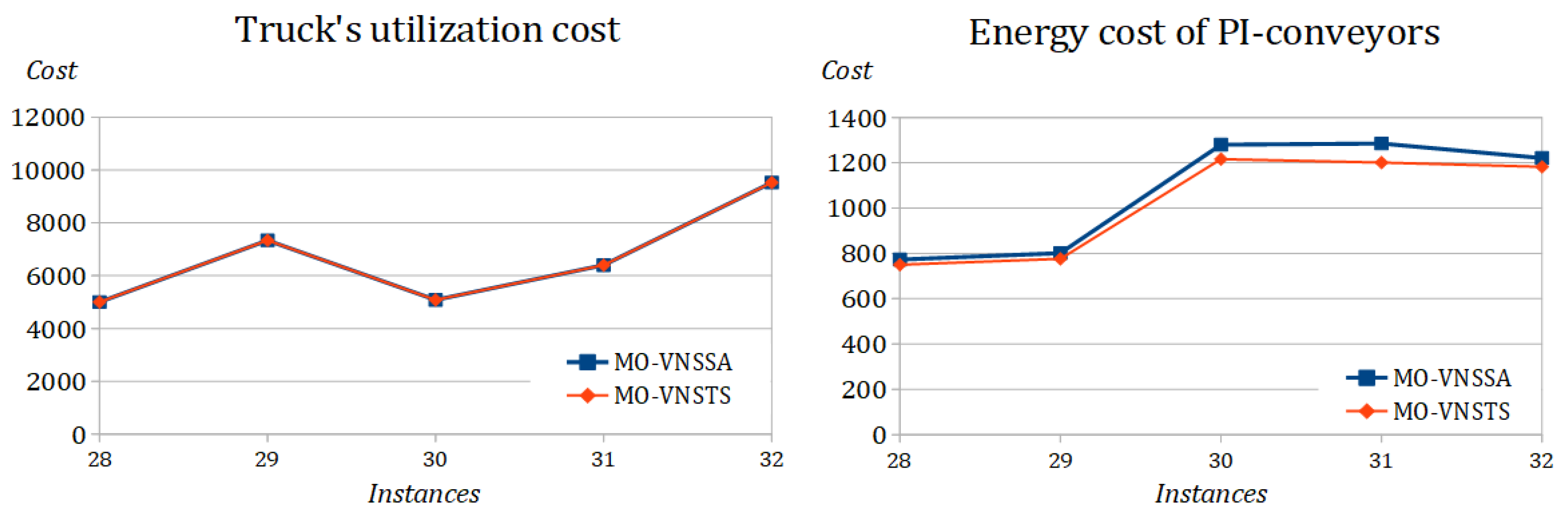

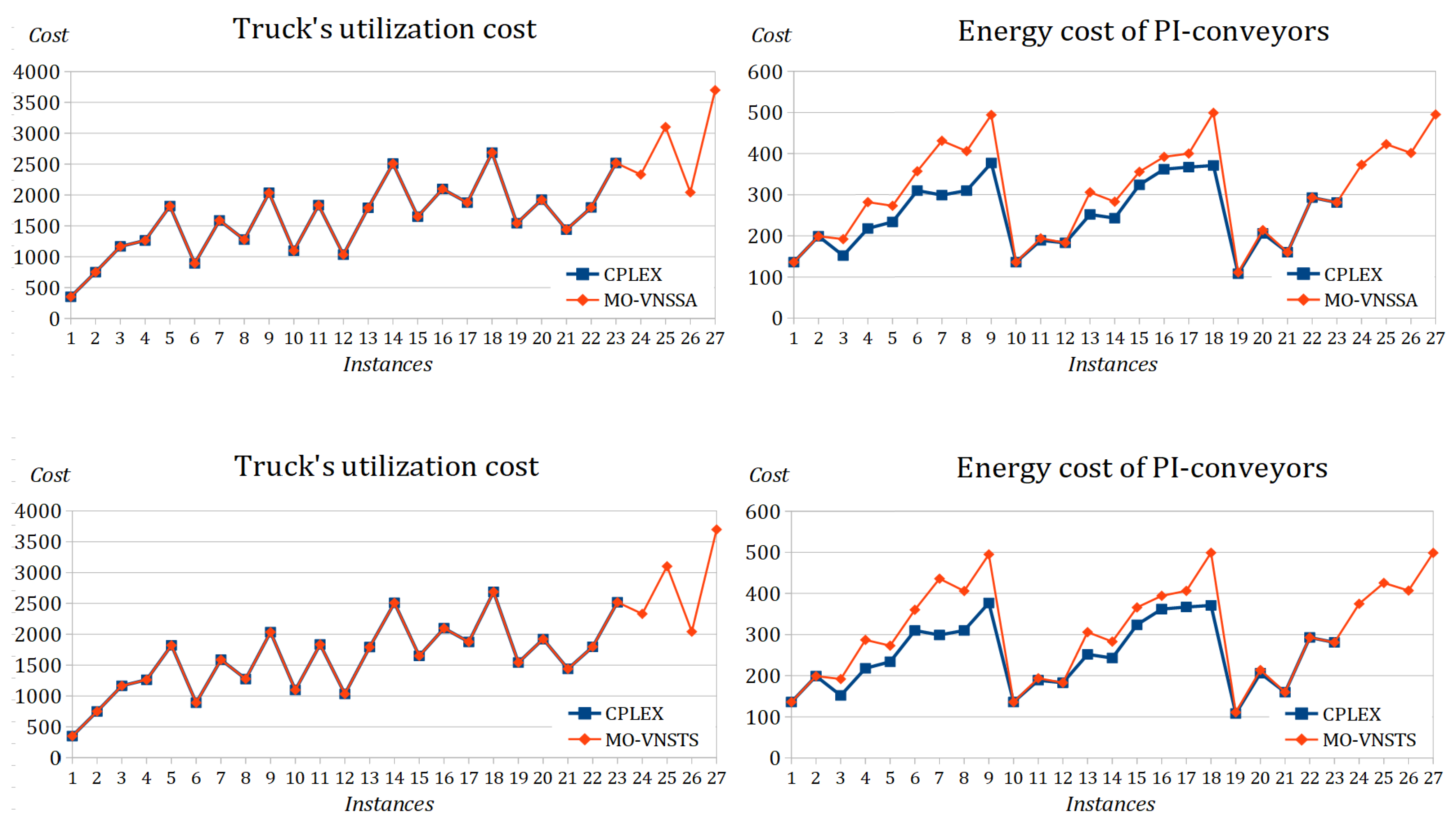

6.2. Numerical Results

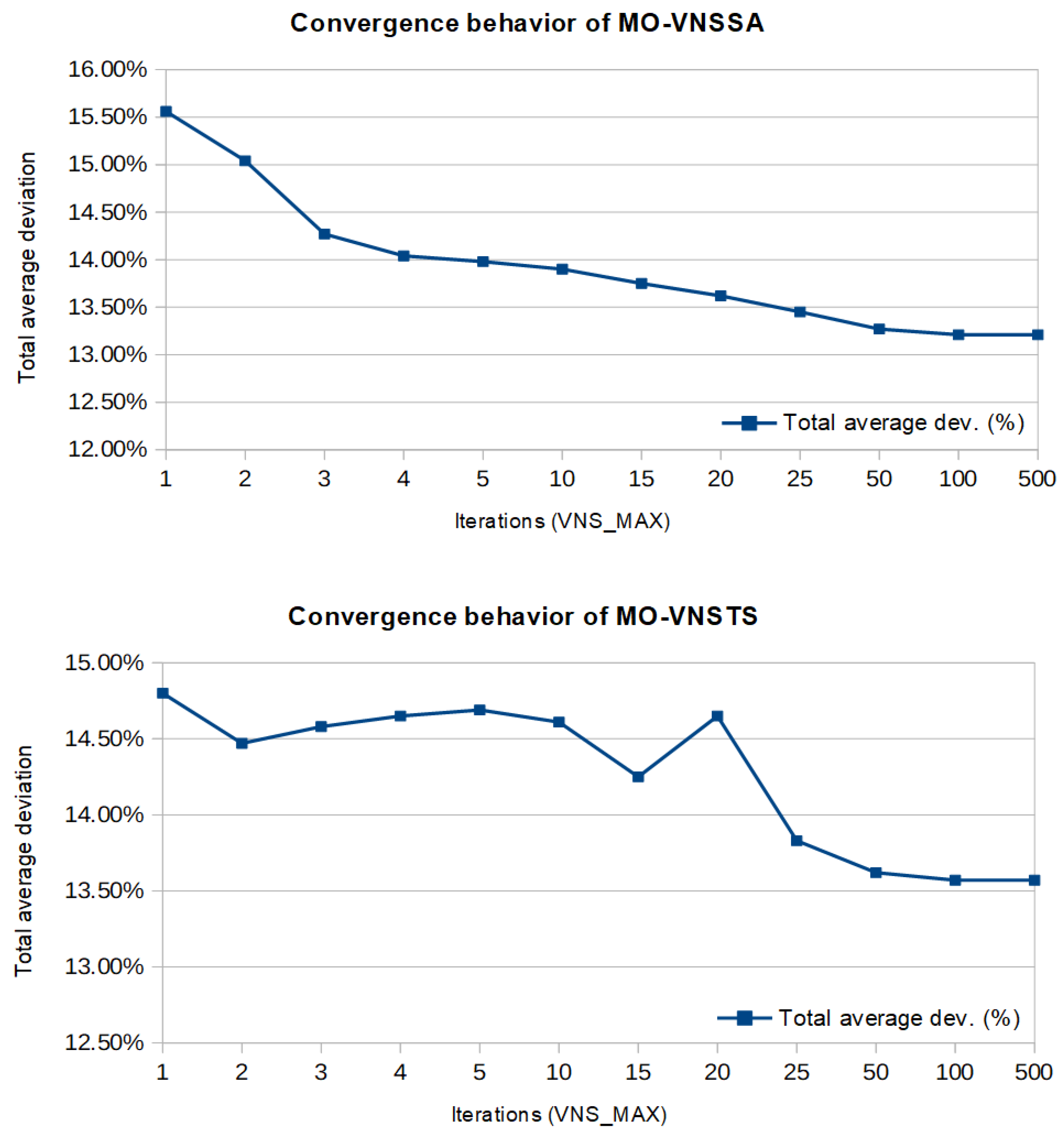

6.3. Sensitivity Analysis

6.3.1. ANOVA Measures

6.3.2. Convergence Behavior

6.4. Discussion

7. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

Abbreviations

| ACO | Ant Colony Optimization |

| GA | Genetic Algorithm |

| GLS | Guided Local Search |

| GRASP | Greedy Randomized Adaptive Search Procedure |

| LS | Local Search |

| MOGA | Multi-Objective Genetic Algorithm |

| MO-MIP | Multi-Objective Mixed Integer Programming Model |

| MOPSO | Multi-Objective Particle Swarm Optimization |

| MO-VNSSA | Multi-Objective Variable Neighborhood Search - Simulated Annealing |

| MO-VNSTS | Multi-Objective Variable Neighborhood Search - Tabu Search |

| NSGA | Non-dominated Sorting Genetic Algorithm |

| PI | Physical Internet |

| PMA | Pareto Memetic Algorithm |

| PSO | Particle Swarm Optimization |

| SA | Simulated Annealing |

| SCBM | Simulated Constraint Boundary Method |

| TL | Tabu List |

| TS | Tabu Search |

| VNS | Variable Neighborhood Search |

References

- Stock, J.R.; Boyer, S.L.; Harmon, T. Research opportunities in supply chain management. J. Acad. Mark. Sci. 2010, 38, 32–41. [Google Scholar] [CrossRef]

- Christopher, M. Logistics & Supply Chain Management; Pearson: London, UK, 2016. [Google Scholar]

- Croom, S.; Vidal, N.; Spetic, W.; Marshall, D.; McCarthy, L. Impact of social sustainability orientation and supply chain practices on operational performance. Int. J. Oper. Prod. Manag. 2018, 38, 2344–2366. [Google Scholar] [CrossRef] [Green Version]

- Ciccullo, F.; Pero, M.; Caridi, M.; Gosling, J.; Purvis, L. Integrating the environmental and social sustainability pillars into the lean and agile supply chain management paradigms: A literature review and future research directions. J. Clean. Prod. 2018, 172, 2336–2350. [Google Scholar] [CrossRef]

- Centobelli, P.; Cerchione, R.; Esposito, E. Environmental Sustainability and Energy-Efficient Supply Chain Management: A Review of Research Trends and Proposed Guidelines. Energies 2018, 11, 275. [Google Scholar] [CrossRef]

- Koberg, E.; Longoni, A. A systematic review of sustainable supply chain management in global supply chains. J. Clean. Prod. 2019, 207, 1084–1098. [Google Scholar] [CrossRef]

- Jadhav, A.; Orr, S.; Malik, M. The role of supply chain orientation in achieving supply chain sustainability. Int. J. Prod. Econ. 2018. [Google Scholar] [CrossRef]

- Ladier, A.L.; Alpan, G. Cross-docking operations: Current research versus industry practice. Omega 2016, 62, 145–162. [Google Scholar] [CrossRef]

- Van Belle, J.; Valckenaers, P.; Cattrysse, D. Cross-docking: State of the art. Omega 2012, 40, 827–846. [Google Scholar] [CrossRef] [Green Version]

- Montreuil, B.; Meller, R.D.; Ballot, E. Towards a Physical Internet: The impact on logistics facilities and material handling systems design and innovation. In Proceedings of the International Material Handling Research Colloquium (IMHRC), Milwaukee, WI, USA, 21–24 June 2010; pp. 1–23. [Google Scholar]

- Montreuil, B.; Meller, R.D.; Ballot, E. Physical Internet Foundations. In Service Orientation in Holonic and Multi Agent Manufacturing and Robotics; Studies in Computational Intelligence; Borangiu, T., Thomas, A., Trentesaux, D., Eds.; Springer: Berlin/Heidelberg, Geramny, 2013; Volume 472, pp. 151–166. [Google Scholar]

- Pan, S.; Nigrelli, M.; Ballot, E.; Sarraj, R.; Yang, Y. Perspectives of inventory control models in the Physical Internet: A simulation study. Comput. Ind. Eng. 2015, 84, 122–132. [Google Scholar] [CrossRef]

- Treiblmaier, H.; Mirkovski, K.; Lowry, P. Conceptualizing the Physical Internet: Literature Review, Implications and Directions for Future Research. In Proceedings of the 11th CSCMP Annual European Research Seminar Conference, Vienna, Austria, 12–13 May 2016. [Google Scholar]

- Sternberg, H.; Norrman, A. The Physical Internet–review, analysis and future research agenda. Int. J. Phys. Distrib. Logist. Manag. 2017, 47, 736–762. [Google Scholar] [CrossRef]

- Meller, R.D.; Montreuil, B.; Thivierge, C.; Montreuil, Z. Functional design of physical internet facilities: A road-based transit center. In 12th IMHRC Proceedings, Gardanne, France; Georgia Southern University: Statesboro, GA, USA, 2012. [Google Scholar]

- Ballot, E.; Montreuil, B.; Thivierge, C. Functional design of physical internet facilities: A road–rail hub. In 12th IMHRC Proceedings, Gardanne, France; Georgia Southern University: Statesboro, GA, USA, 2012. [Google Scholar]

- Boysen, N.; Fliedner, M. Cross dock scheduling: Classification, literature review and research agenda. Omega 2010, 38, 413–422. [Google Scholar] [CrossRef] [Green Version]

- Yu, W.; Egbelu, P.J. Scheduling of inbound and outbound trucks in cross docking systems with temporary storage. Eur. J. Oper. Res. 2008, 184, 377–396. [Google Scholar] [CrossRef]

- Khalili-Damghani, K.; Tavana, M.; Santos-Arteaga, F.J.; Ghanbarzad-Dashti, M. A customized genetic algorithm for solving multi-period cross-dock truck scheduling problems. Measurement 2017, 108, 101–118. [Google Scholar] [CrossRef]

- Keshtzari, M.; Naderi, B.; Mehdizadeh, E. An improved mathematical model and a hybrid metaheuristic for truck scheduling in cross-dock problems. Comput. Ind. Eng. 2016, 91, 197–204. [Google Scholar] [CrossRef]

- Vahdani, B.; Zandieh, M. Scheduling trucks in cross-docking systems: Robust meta-heuristics. Comput. Ind. Eng. 2010, 58, 12–24. [Google Scholar] [CrossRef]

- Boloori-Arabani, A.; Ghomi, S.F.; Zandieh, M. Meta-heuristics implementation for scheduling of trucks in a cross-docking system with temporary storage. Expert Syst. Appl. 2011, 38, 1964–1979. [Google Scholar] [CrossRef]

- Amini, A.; Tavakkoli-Moghaddam, R. A bi-objective truck scheduling problem in a cross-docking center with probability of breakdown for trucks. Comput. Ind. Eng. 2016, 96, 180–191. [Google Scholar] [CrossRef]

- Shakeri, M.; Low, M.Y.H.; Turner, S.J.; Lee, E.W. A robust two-phase heuristic algorithm for the truck scheduling problem in a resource-constrained crossdock. Comput. Oper. Res. 2012, 39, 2564–2577. [Google Scholar] [CrossRef]

- Konur, D.; Golias, M.M. Cost-stable truck scheduling at a cross-dock facility with unknown truck arrivals: A meta-heuristic approach. Transp. Res. Part E Logist. Transp. Rev. 2013, 49, 71–91. [Google Scholar] [CrossRef]

- Agustina, D.; Lee, C.; Piplani, R. A review: Mathematical modles for cross docking planning. Int. J. Eng. Bus. Manag. 2010, 2, 47–54. [Google Scholar] [CrossRef]

- Gelareh, S.; Glover, F.; Guemri, O.; Hanafi, S.; Nduwayo, P.; Todosijević, R. A comparative study of formulations for a cross-dock door assignment problem. Omega 2018, in press. [Google Scholar] [CrossRef]

- Assadi, M.T.; Bagheri, M. Differential evolution and Population-based simulated annealing for truck scheduling problem in multiple door cross-docking systems. Comput. Ind. Eng. 2016, 96, 149–161. [Google Scholar] [CrossRef]

- Molavi, D.; Shahmardan, A.; Sajadieh, M.S. Truck scheduling in a cross docking systems with fixed due dates and shipment sorting. Comput. Ind. Eng. 2018, 117, 29–40. [Google Scholar] [CrossRef]

- Dulebenets, M. A diploid evolutionary algorithm for sustainable truck scheduling at a cross-docking facility. Sustainability 2018, 10, 1333. [Google Scholar] [CrossRef]

- Wisittipanich, W.; Hengmeechai, P. Truck scheduling in multi-door cross docking terminal by modified particle swarm optimization. Comput. Ind. Eng. 2017, 113, 793–802. [Google Scholar] [CrossRef]

- Van Belle, J.; Valckenaers, P.; Berghe, G.V.; Cattrysse, D. A tabu search approach to the truck scheduling problem with multiple docks and time windows. Comput. Ind. Eng. 2013, 66, 818–826. [Google Scholar] [CrossRef] [Green Version]

- Kuo, Y. Optimizing truck sequencing and truck dock assignment in a cross docking system. Expert Syst. Appl. 2013, 40, 5532–5541. [Google Scholar] [CrossRef]

- Boysen, N.; Briskorn, D.; Tschöke, M. Truck scheduling in cross-docking terminals with fixed outbound departures. OR Spectr. 2013, 35, 479–504. [Google Scholar] [CrossRef]

- Golias, M.M.; Saharidis, G.K.; Boile, M.; Theofanis, S. Scheduling of inbound trucks at a cross-docking facility: Bi-objective vs bi-level modeling approaches. Int. J. Inf. Syst. Supply Chain Manag. 2012, 5, 20–37. [Google Scholar] [CrossRef]

- Mohtashami, A.; Tavana, M.; Santos-Arteaga, F.J.; Fallahian-Najafabadi, A. A novel multi-objective meta-heuristic model for solving cross-docking scheduling problems. Appl. Soft Comput. 2015, 31, 30–47. [Google Scholar] [CrossRef]

- Heidari, F.; Zegordi, S.H.; Tavakkoli-Moghaddam, R. Modeling truck scheduling problem at a cross-dock facility through a bi-objective bi-level optimization approach. J. Intell. Manuf. 2018, 29, 1155–1170. [Google Scholar] [CrossRef]

- Pach, C.; Sallez, Y.; Berger, T.; Bonte, T.; Trentesaux, D.; Montreuil, B. Routing Management in Physical Internet Crossdocking Hubs: Study of Grouping Strategies for Truck Loading. In Advances in Production Management Systems. Innovative and Knowledge-Based Production Management in a Global-Local World; IFIP Advances in Information and Communication Technology; Grabot, B., Vallespir, B., Gomes, S., Bouras, A., Kiritsis, D., Eds.; Springer: Berlin/Heidelberg, Germany, 2014; Volume 438, pp. 483–490. [Google Scholar]

- Sallez, Y.; Pan, S.; Montreuil, B.; Berger, T.; Ballot, E. On the activeness of intelligent Physical Internet containers. Comput. Ind. 2016, 81, 96–104. [Google Scholar] [CrossRef]

- Sallez, Y.; Berger, T.; Bonte, T.; Trentesaux, D. Proposition of a hybrid control architecture for the routing in a Physical Internet cross-docking hub. IFAC-PapersOnLine 2015, 48, 1978–1983. [Google Scholar] [CrossRef]

- Vo, N.V.; Berger, T.; Bonte, T.; Sallez, Y. Control of Rail–Road PI-Hub: The ORCA Hybrid Control Architecture. In Service Orientation in Holonic and Multi-Agent Manufacturing; Studies in Computational Intelligence; Borangiu, T., Trentesaux, D., Thomas, A., Cardin, O., Eds.; Springer International Publishing: New York, NY, USA, 2018; Volume 762, pp. 291–302. [Google Scholar]

- Walha, F.; Bekrar, A.; Chaabane, S.; Loukil, T.M. A Rail–Road PI-hub allocation problem: Active and reactive approaches. Comput. Ind. 2016, 81, 138–151. [Google Scholar] [CrossRef]

- Walha, F.; Bekrar, A.; Chaabane, S.; Loukil, T. A Rail–Road PI-hub allocation problems: Model and heuristic. In Proceedings of the IPIC 2014, Quebec, QC, Canada, 28–30 May 2014. [Google Scholar]

- Chargui, T.; Bekrar, A.; Reghioui, M.; Trentesaux, D. A Mathematical Formulation and Tabu Search Approach for the Road–Rail Assignment Problem. In Proceedings of the 5th IPIC Conference 2018, Groningen, The Netherlands, 18–22 June 2018. [Google Scholar]

- Taylor, K.M.; Vachon, S. Empirical research on sustainable supply chains: IJPR’s contribution and research avenues. Int. J. Prod. Res. 2018, 56, 950–959. [Google Scholar] [CrossRef]

- Mota, B.; Gomes, M.I.; Carvalho, A.; Barbosa-Povoa, A.P. Towards supply chain sustainability: Economic, environmental and social design and planning. J. Clean. Prod. 2015, 105, 14–27. [Google Scholar] [CrossRef]

- Kong, L.; Li, H.; Luo, H.; Ding, L.; Zhang, X. Sustainable performance of just-in-time (JIT) management in time-dependent batch delivery scheduling of precast construction. J. Clean. Prod. 2018, 193, 684–701. [Google Scholar] [CrossRef]

- Demartini, M.; Pinna, C.; Aliakbarian, B.; Tonelli, F.; Terzi, S. Soft Drink Supply Chain Sustainability: A Case Based Approach to Identify and Explain Best Practices and Key Performance Indicators. Sustainability 2018, 10, 3540. [Google Scholar] [CrossRef]

- Guo, F.; Liu, Q.; Liu, D.; Guo, Z. On Production and Green Transportation Coordination in a Sustainable Global Supply Chain. Sustainability 2017, 9, 2071. [Google Scholar] [CrossRef]

- Shahram fard, S.; Vahdani, B. Assignment and scheduling trucks in cross-docking system with energy consumption consideration and trucks queuing. J. Clean. Prod. 2019, 213, 21–41. [Google Scholar] [CrossRef]

- Marler, R.T.; Arora, J.S. Survey of multi-objective optimization methods for engineering. Struct. Multidiscip. Optim. 2004, 26, 369–395. [Google Scholar] [CrossRef]

- Duarte, A.; Pantrigo, J.J.; Pardo, E.G.; Mladenovic, N. Multi-objective variable neighborhood search: An application to combinatorial optimization problems. J. Glob. Optim. 2015, 63, 515–536. [Google Scholar] [CrossRef]

- Glover, F. Tabu search—Part 1. ORSA J. Comput. 1989, 1, 190–206. [Google Scholar] [CrossRef]

- Feo, T.A.; Resende, M.G. Greedy randomized adaptive search procedures. J. Glob. Optim. 1995, 6, 109–133. [Google Scholar] [CrossRef]

- Kirkpatrick, S.; Gelatt, C.D.; Vecchi, M.P. Optimization by simulated annealing. Science 1983, 220, 671–680. [Google Scholar] [CrossRef] [PubMed]

- Mladenović, N.; Hansen, P. Variable neighborhood search. Comput. Oper. Res. 1997, 24, 1097–1100. [Google Scholar] [CrossRef]

- Voudouris, C. Guided Local Search for Combinatorial Optimisation Problems. Ph.D. Thesis, University of Essex, Colchester, UK, 1997. [Google Scholar]

- Davis, L. Handbook of Genetic Algorithms; Van Nostrand Reinhold: New York, NY, USA, 1991. [Google Scholar]

- Kennedy, J.; Eberhart, R. Particle swarm optimization. In Proceedings of the ICNN’95—International Conference on Neural Networks, Perth, Western Australia, 27 November–1 December 1995; Volume 4, pp. 1942–1948. [Google Scholar] [CrossRef]

- Dorigo, M.; Blum, C. Ant colony optimization theory: A survey. Theor. Comput. Sci. 2005, 344, 243–278. [Google Scholar] [CrossRef]

- Konak, A.; Coit, D.W.; Smith, A.E. Multi-objective optimization using genetic algorithms: A tutorial. Reliab. Eng. Syst. Saf. 2006, 91, 992–1007. [Google Scholar] [CrossRef]

- Parsopoulos, K.E.; Vrahatis, M.N. Particle swarm optimization method in multiobjective problems. In Proceedings of the 2002 ACM Symposium on Applied Computing, Madrid, Spain, 11–14 March 2002; pp. 603–607. [Google Scholar]

- Jones, D.F.; Mirrazavi, S.K.; Tamiz, M. Multi-objective meta-heuristics: An overview of the current state-of-the-art. Eur. J. Oper. Res. 2002, 137, 1–9. [Google Scholar] [CrossRef]

- Jaeggi, D.M.; Parks, G.T.; Kipouros, T.; Clarkson, P.J. The development of a multi-objective Tabu Search algorithm for continuous optimisation problems. Eur. J. Oper. Res. 2008, 185, 1192–1212. [Google Scholar] [CrossRef]

- Bandyopadhyay, S.; Saha, S.; Maulik, U.; Deb, K. A simulated annealing-based multiobjective optimization algorithm: AMOSA. IEEE Trans. Evol. Comput. 2008, 12, 269–283. [Google Scholar] [CrossRef]

- Geiger, M.J. Randomised variable neighbourhood search for multi objective optimisation. In Proceedings of the EU/ME Workshop: Design and Evaluation of Advanced Hybrid Meta-heuristics, Nottingham, UK, 4–5 November 2004; pp. 34–42. [Google Scholar]

- Arroyo, J.E.C.; dos Santos Ottoni, R.; de Paiva Oliveira, A. Multi-objective variable neighborhood search algorithms for a single machine scheduling problem with distinct due windows. Electron. Notes Theor. Comput. Sci. 2011, 281, 5–19. [Google Scholar] [CrossRef]

- Lu, P.; Tolliver, D. Multiobjective pavement-preservation decision making with simulated constraint boundary programming. J. Transp. Eng. 2013, 139, 880–888. [Google Scholar] [CrossRef]

- Jaszkiewicz, A. A Comparative Study of Multiple-Objective Metaheuristics on the Bi-Objective Set Covering Problem and the Pareto Memetic Algorithm. Ann. Oper. Res. 2004, 131, 135–158. [Google Scholar] [CrossRef] [Green Version]

- Sun, Y.; Li, X.; Liang, X.; Zhang, C. A Bi-Objective Fuzzy Credibilistic Chance-Constrained Programming Approach for the Hazardous Materials Road–Rail Multimodal Routing Problem under Uncertainty and Sustainability. Sustainability 2019, 11, 2577. [Google Scholar] [CrossRef]

- Jones, D.; Tamiz, M. A review of goal programming. In Multiple Criteria Decision Analysis; Springer: New Yrok, NY, USA, 2016; pp. 903–926. [Google Scholar]

- Gandibleux, X.; Ehrgott, M. 1984–2004—20 Years of Multiobjective Metaheuristics. But What About the Solution of Combinatorial Problems with Multiple Objectives? In Evolutionary Multi-Criterion Optimization; Coello Coello, C.A., Hernández Aguirre, A., Zitzler, E., Eds.; Springer: Berlin/Heidelberg, Germany, 2005; pp. 33–46. [Google Scholar]

- Romero, C. Handbook of Critical Issues in Goal Programming; Elsevier: Amsterdam, The Netherlands, 2014. [Google Scholar]

- Palacios, J.J.; González-Rodríguez, I.; Vela, C.R.; Puente, J. Swarm lexicographic goal programming for fuzzy open shop scheduling. J. Intell. Manuf. 2015, 26, 1201–1215. [Google Scholar] [CrossRef]

- Ngatchou, P.; Zarei, A.; El-Sharkawi, A. Pareto multi objective optimization. In Proceedings of the 13th International Conference on Intelligent Systems Application to Power Systems, Avlington, VA, USA, 6–10 November 2005; pp. 84–91. [Google Scholar]

| Data | Abbreviations | Values |

|---|---|---|

| Number of PI-containers | N | [4, 12] |

| Number of destinations | D | [1, 3] |

| Number of docks | K | 15 |

| Lengths of PI-containers | {1, 2, 3, 4, 5, 10} | |

| Cost of energy consumption for one PI-conveyor | 0.5 | |

| Cost of using a truck for each destination | [200, 800] | |

| Positions of PI-containers in the train | [1, 75] | |

| Destination of PI-containers in the train | Random (Binary) |

| Algorithm Parameters | Abbreviations | Values |

|---|---|---|

| Number of iterations for each neighborhood | Max_VNS | 500 |

| Number of generated neighborhoods | Nb_N | 3 |

| Number of iterations before shaking PI-containers’ assignments in trucks | Max_Shake | 10 |

| Simulated Annealing temperature decreasing step | 0.01 | |

| Initial temperature in the Simulated Annealing | T_Max | 1 |

| Tabu List Size | TL_Size | 10 |

| Number of iterations for the Tabu Search process | Max_TS | 100 |

| Instances | CPLEX | MO-VNSSA | MO-VNSTS | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| # | D | N | H | F | F | Time (s) | F | F | Time (s) | F | F | Time (s) | |||

| 1 | 1 | 4 | 4 | 351 | 136 | 0.11 | 351 | 136 | 0.078 | 351 | 136 | 0.081 | |||

| 2 | 1 | 5 | 4 | 750 | 199 | 0.42 | 750 | 199 | 0.087 | 750 | 199 | 0.091 | |||

| 3 | 1 | 6 | 5 | 1166 | 152 | 0.69 | 1166 | 192 | 0.088 | 1166 | 192 | 0.081 | |||

| 4 | 1 | 7 | 5 | 1263 | 218 | 11.36 | 1263 | 282 | 0.084 | 1263 | 287 | 0.094 | |||

| 5 | 1 | 8 | 5 | 1821 | 234 | 2.78 | 1821 | 273 | 0.094 | 1821 | 273 | 0.100 | |||

| 6 | 1 | 9 | 7 | 891 | 310 | 14.86 | 891 | 357 | 0.116 | 891 | 360.2 | 0.144 | |||

| 7 | 1 | 10 | 7 | 1588 | 299 | 10.86 | 1588 | 431 | 0.134 | 1588 | 436 | 0.138 | |||

| 8 | 1 | 11 | 7 | 1276 | 310 | 13.36 | 1276 | 406 | 0.122 | 1276 | 406 | 0.138 | |||

| 9 | 1 | 12 | 7 | 2035 | 377 | 38.28 | 2035 | 494 | 0.140 | 2035 | 495 | 0.143 | |||

| 10 | 2 | 4 | 4 | 1096 | 136 | 0.14 | 1096 | 136 | 0.056 | 1096 | 136 | 0.078 | |||

| 11 | 2 | 5 | 4 | 1835 | 189 | 0.28 | 1835 | 194 | 0.066 | 1835 | 194 | 0.078 | |||

| 12 | 2 | 6 | 5 | 1033 | 183 | 0.30 | 1033 | 183 | 0.081 | 1033 | 183 | 0.091 | |||

| 13 | 2 | 7 | 5 | 1792 | 252 | 0.52 | 1792 | 306 | 0.084 | 1792 | 306 | 0.091 | |||

| 14 | 2 | 8 | 5 | 2510 | 243 | 1.69 | 2510 | 283 | 0.091 | 2510 | 283 | 0.112 | |||

| 15 | 2 | 9 | 7 | 1650 | 324 | 453.09 | 1650 | 355.8 | 0.112 | 1650 | 366 | 0.125 | |||

| 16 | 2 | 10 | 7 | 2098 | 362 | 277.84 | 2098 | 392 | 0.194 | 2098 | 394.2 | 0.131 | |||

| 17 | 2 | 11 | 7 | 1876 | 367 | 40.52 | 1876 | 400 | 0.147 | 1876 | 406.2 | 0.138 | |||

| 18 | 2 | 12 | 7 | 2688 | 371 | 186.89 | 2688 | 499 | 0.159 | 2688 | 499 | 0.153 | |||

| 19 | 3 | 4 | 4 | 1542 | 108 | 0.16 | 1542 | 111 | 0.059 | 1542 | 111 | 0.078 | |||

| 20 | 3 | 5 | 4 | 1923 | 206 | 2.09 | 1923 | 214 | 0.069 | 1923 | 214 | 0.094 | |||

| 21 | 3 | 6 | 5 | 1440 | 160 | 0.25 | 1440 | 160 | 0.084 | 1440 | 160 | 0.094 | |||

| 22 | 3 | 7 | 5 | 1797 | 293 | 17.17 | 1797 | 293 | 0.084 | 1797 | 293 | 0.094 | |||

| 23 | 3 | 8 | 5 | 2520 | 281 | 164.42 | 2520 | 281 | 0.091 | 2520 | 281 | 0.106 | |||

| 24 | 3 | 9 | 7 | * | * | * | 2331 | 372.8 | 0.106 | 2331 | 374.8 | 0.128 | |||

| 25 | 3 | 10 | 7 | * | * | * | 3102 | 422.6 | 0.116 | 3102 | 425.6 | 0.144 | |||

| 26 | 3 | 11 | 7 | * | * | * | 2042 | 401.4 | 0.122 | 2042 | 407 | 0.141 | |||

| 27 | 3 | 12 | 7 | * | * | * | 3699 | 495 | 0.141 | 3699 | 498.6 | 0.150 | |||

| Instances | MO-VNSSA | MO-VNSTS | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| # | D | N | H | F | F | Time (s) | F | F | Time (s) | ||

| 28 | 7 | 20 | 15 | 5001 | 772.6 | 4.322 | 5001 | 750 | 4.503 | ||

| 29 | 10 | 20 | 15 | 7338 | 801.2 | 4.5872 | 7338 | 776 | 4.7218 | ||

| 30 | 7 | 30 | 20 | 5081 | 1279.8 | 7.4594 | 5081 | 1216 | 7.3938 | ||

| 31 | 10 | 30 | 20 | 6401 | 1284.8 | 7.35 | 6401 | 1201 | 7.4782 | ||

| 32 | 15 | 30 | 20 | 9529 | 1220.4 | 8.1656 | 9529 | 1182 | 8.2032 | ||

| Meta-Heuristics | F | p-Value |

|---|---|---|

| MO-VNSSA | 1.623 | 0.209 |

| MO-VNSTA | 0.726 | 0.196 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chargui, T.; Bekrar, A.; Reghioui, M.; Trentesaux, D. Multi-Objective Sustainable Truck Scheduling in a Rail–Road Physical Internet Cross-Docking Hub Considering Energy Consumption. Sustainability 2019, 11, 3127. https://doi.org/10.3390/su11113127

Chargui T, Bekrar A, Reghioui M, Trentesaux D. Multi-Objective Sustainable Truck Scheduling in a Rail–Road Physical Internet Cross-Docking Hub Considering Energy Consumption. Sustainability. 2019; 11(11):3127. https://doi.org/10.3390/su11113127

Chicago/Turabian StyleChargui, Tarik, Abdelghani Bekrar, Mohamed Reghioui, and Damien Trentesaux. 2019. "Multi-Objective Sustainable Truck Scheduling in a Rail–Road Physical Internet Cross-Docking Hub Considering Energy Consumption" Sustainability 11, no. 11: 3127. https://doi.org/10.3390/su11113127

APA StyleChargui, T., Bekrar, A., Reghioui, M., & Trentesaux, D. (2019). Multi-Objective Sustainable Truck Scheduling in a Rail–Road Physical Internet Cross-Docking Hub Considering Energy Consumption. Sustainability, 11(11), 3127. https://doi.org/10.3390/su11113127