Operation Optimization in a Smart Micro-Grid in the Presence of Distributed Generation and Demand Response

Abstract

1. Introduction

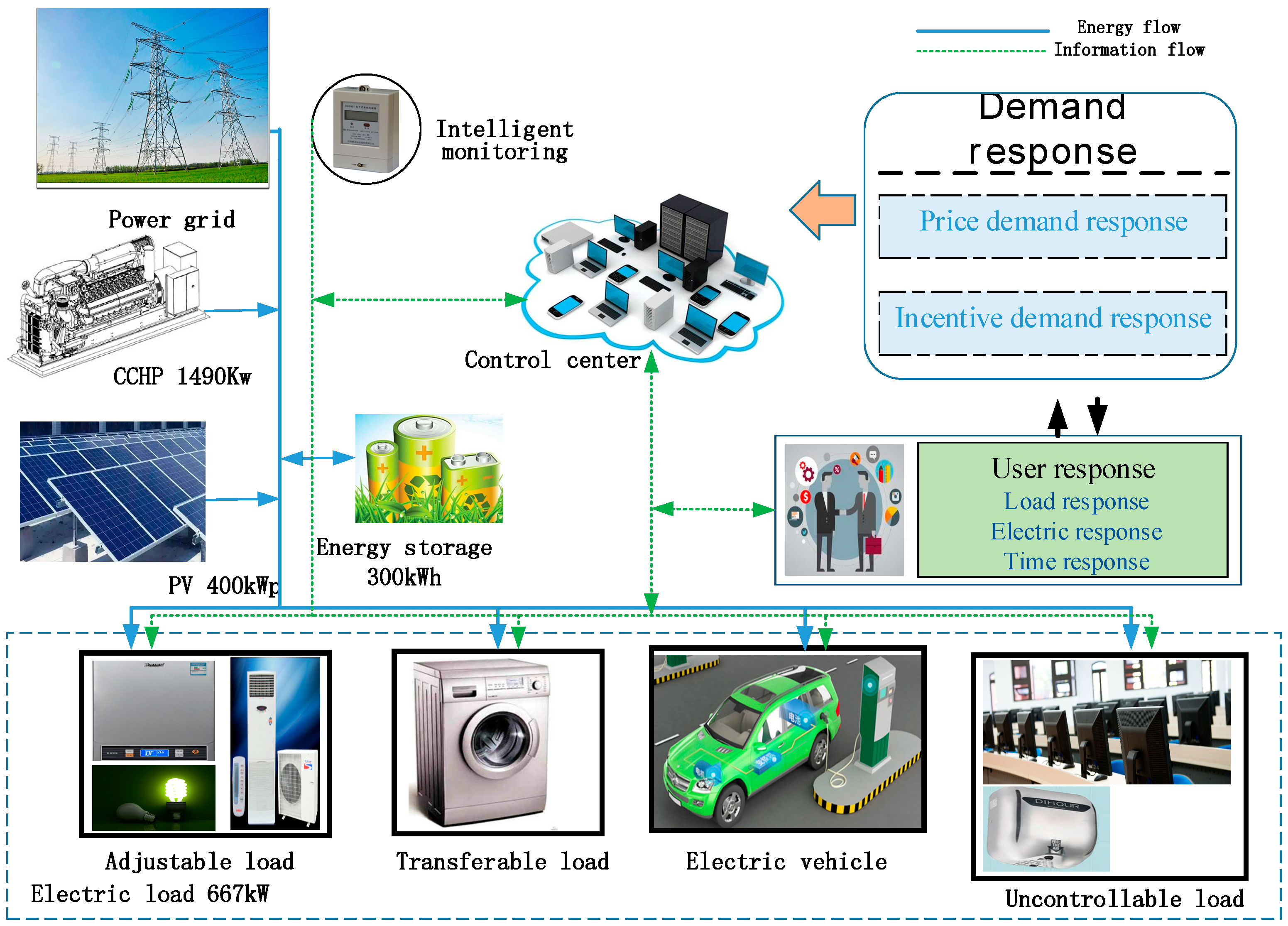

2. Demand Response and Micro-Grid

2.1. Response Resources

2.2.1. Photovoltaic Power Generation

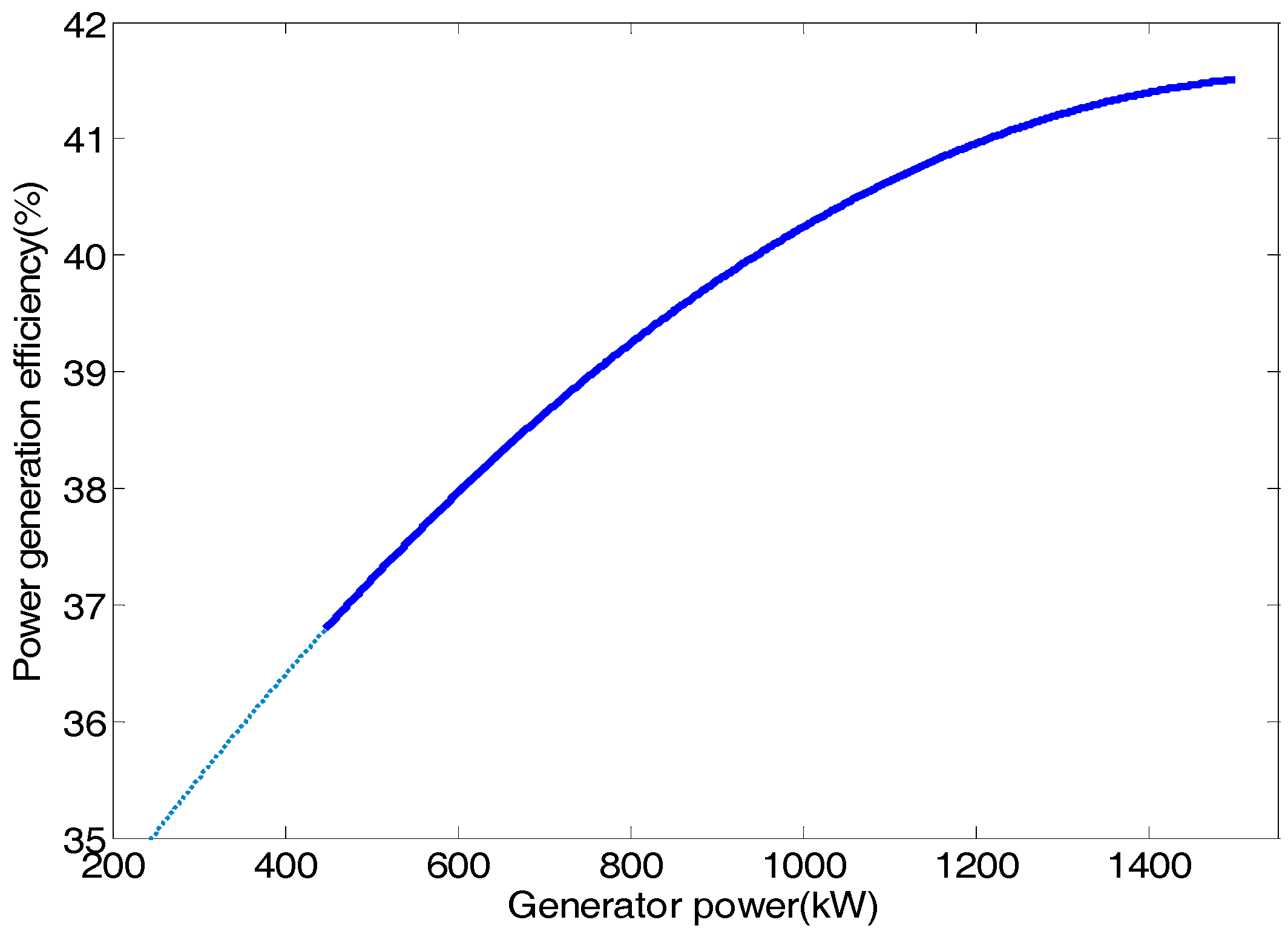

2.2.2. CCHP System

2.2.3. Energy Storage System

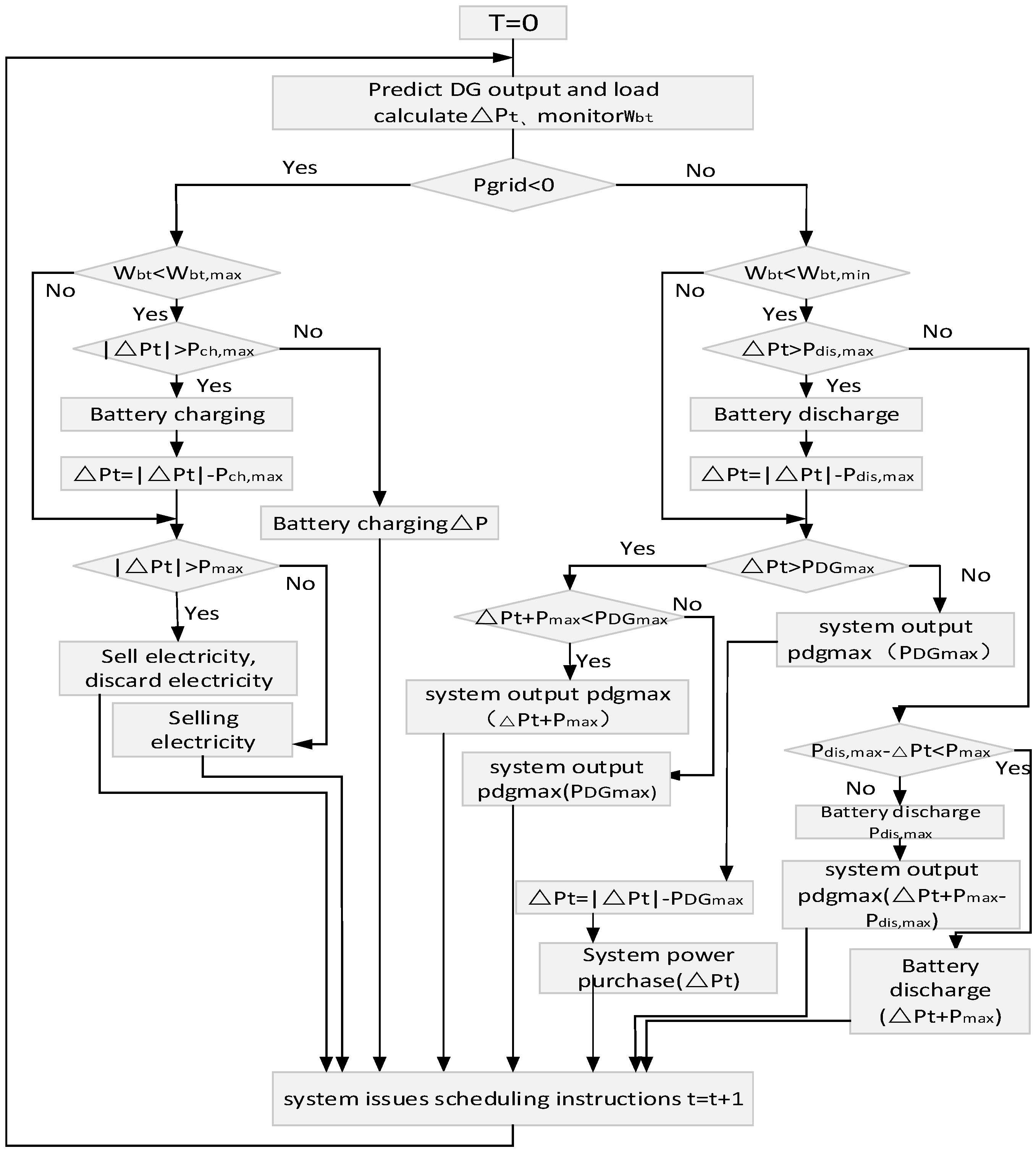

2.2. Operation Strategy

3. Optimization Model

3.1. Objective Function

3.2. Constraints

3.2.1. Load Resource Constraints

3.2.2. Run Constraints

3.2.3. Energy Storage Constraint

3.2.4. Customer Comfort Constraints

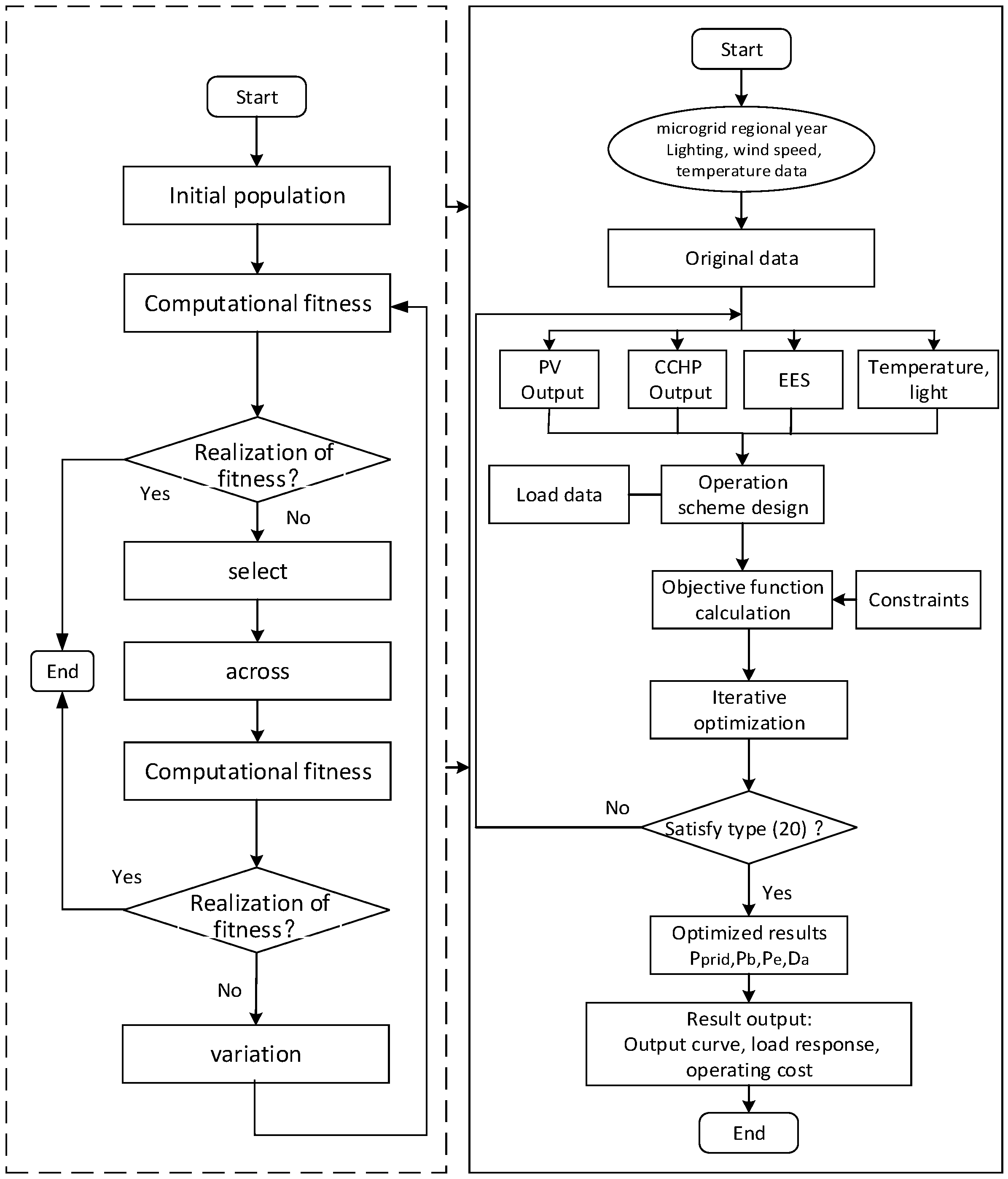

4. Solution Method

4.1. Algorithm Introduction

- (1)

- The genetic algorithm starts the search from the string set of the problem solution, instead of starting from a single solution. This is a great difference between the genetic algorithm and the traditional optimization algorithm. The traditional optimization algorithm is to obtain the optimal solution from a single initial value iteration, and it is easy to get into the local optimal solution. The genetic algorithm is searched from the set of sets, and its coverage is large. These attributes are beneficial to the global optimization.

- (2)

- The algorithm itself is easy to parallelize. Genetic algorithm can simultaneously manage multiple individuals in a group. In this process, GA can evaluate multiple solutions in the search space to reduce the risk of falling into the local optimal solution.

- (3)

- Genetic algorithm performs individual evaluation by fitness function value. The whole process basically does not need other knowledge or auxiliary information of search space. The fitness function in the algorithm is not only restricted by continuous and differentiable, but also the domain of its definition can be set arbitrarily. This feature makes the application scope of genetic algorithm greatly expanded.

- (4)

- The genetic algorithm uses the rule of probability instead of deterministic rule in determining the direction of search.

- (5)

- When genetic algorithm organizes search by information obtained from evolutionary process, individuals with large fitness have higher survival probability and get more adapted genetic structure. It has self-organization, self-adaptive and self-learning habits.

4.2. Solution Flow

- (1)

- Determine the system optimization variables. System optimization variables include photovoltaic output , the charging and discharging current of the storage battery , discharge depth , gas turbine output , tie-line power and electricity price information.

- (2)

- Input the basic data of case analysis. Optimization objectives, system control strategies, optimization period T = 5 min, optimization time interval , DER unit in the micro-grid system, energy storage unit parameters, the initial optimization time , etc.

- (3)

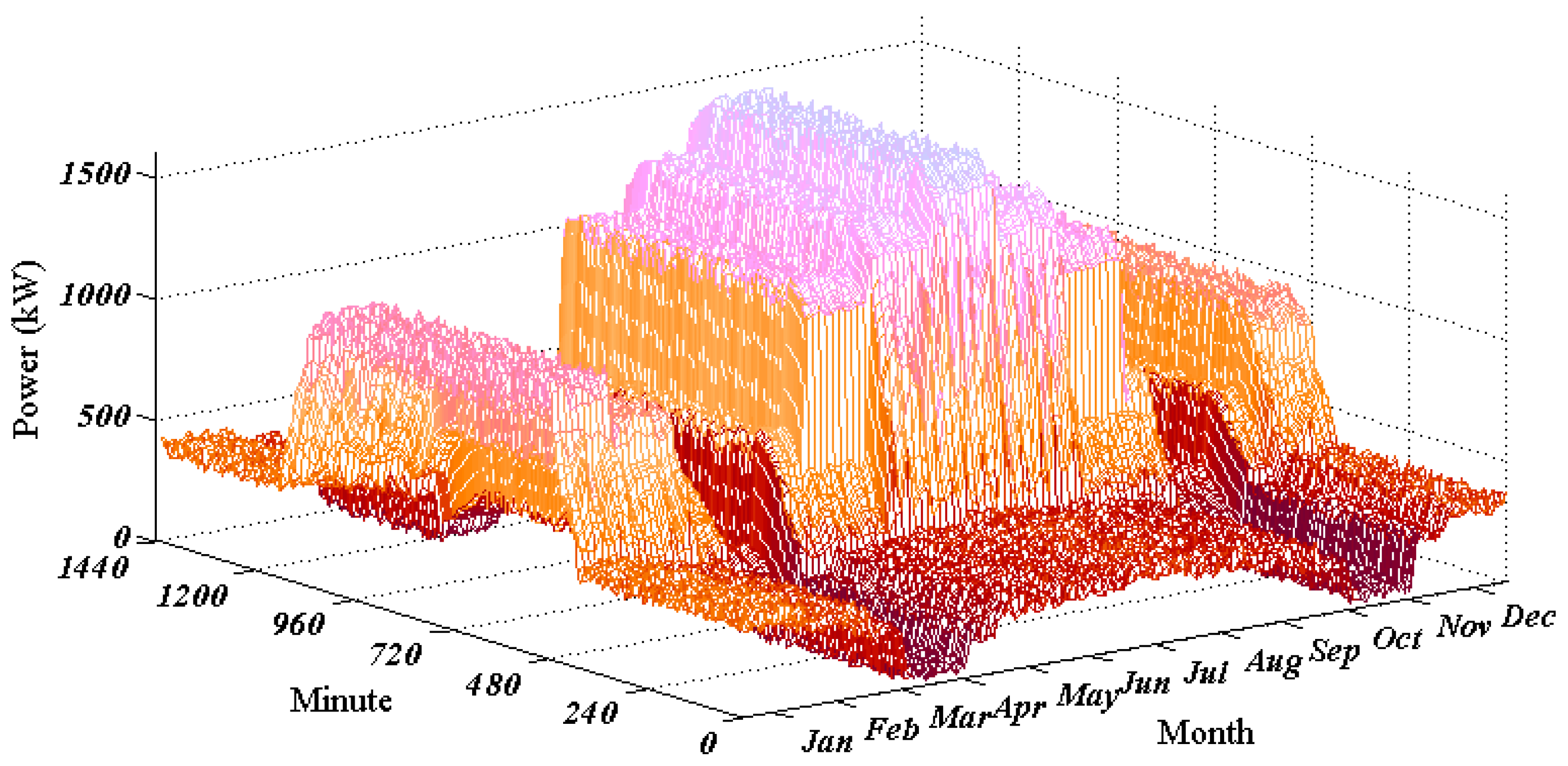

- According to the system operation scheme and annual load data in the previous section, the system operation simulation for 1440 min a day is completed, and the daily output of the photovoltaic, the gas turbine unit, the discharge depth of the storage battery, the charging and discharging current, and the tie-line power are obtained.

- (4)

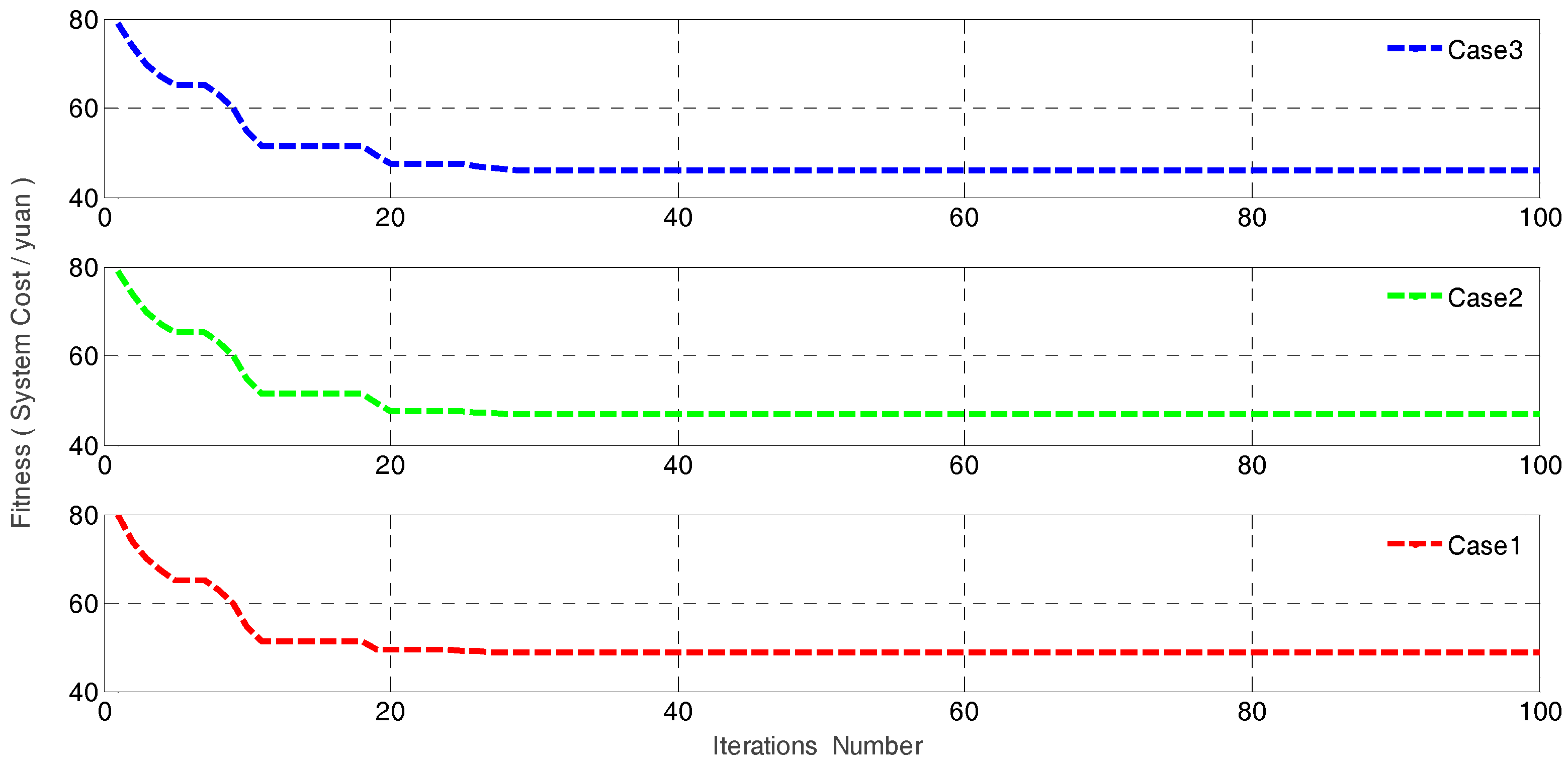

- According to the obtained optimization results and the set constraints, the objective function is calculated and iterative optimization is carried out.

- (5)

- Output results: Output the optimal decision variable result (optimization curve and calculation result) and the optimal value of the problem to be optimized, and the algorithm ends.

5. Simulation

5.1. Scenario Introduction

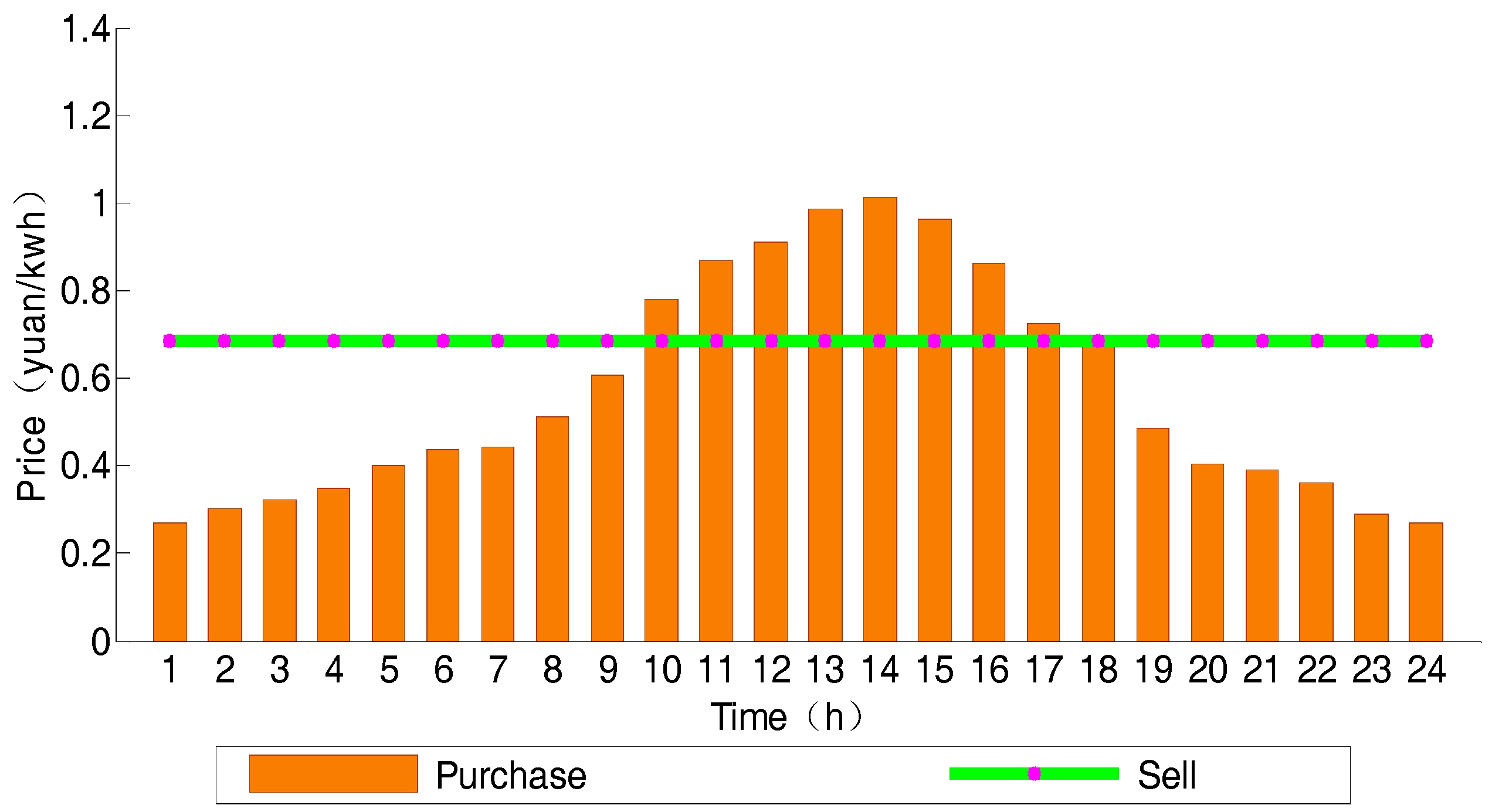

5.2. Basic Data

5.2.1. Electric Load

5.2.2. Energy Storage Parameter

5.2.3. CCHP Parameter

5.3. Operational Optimization

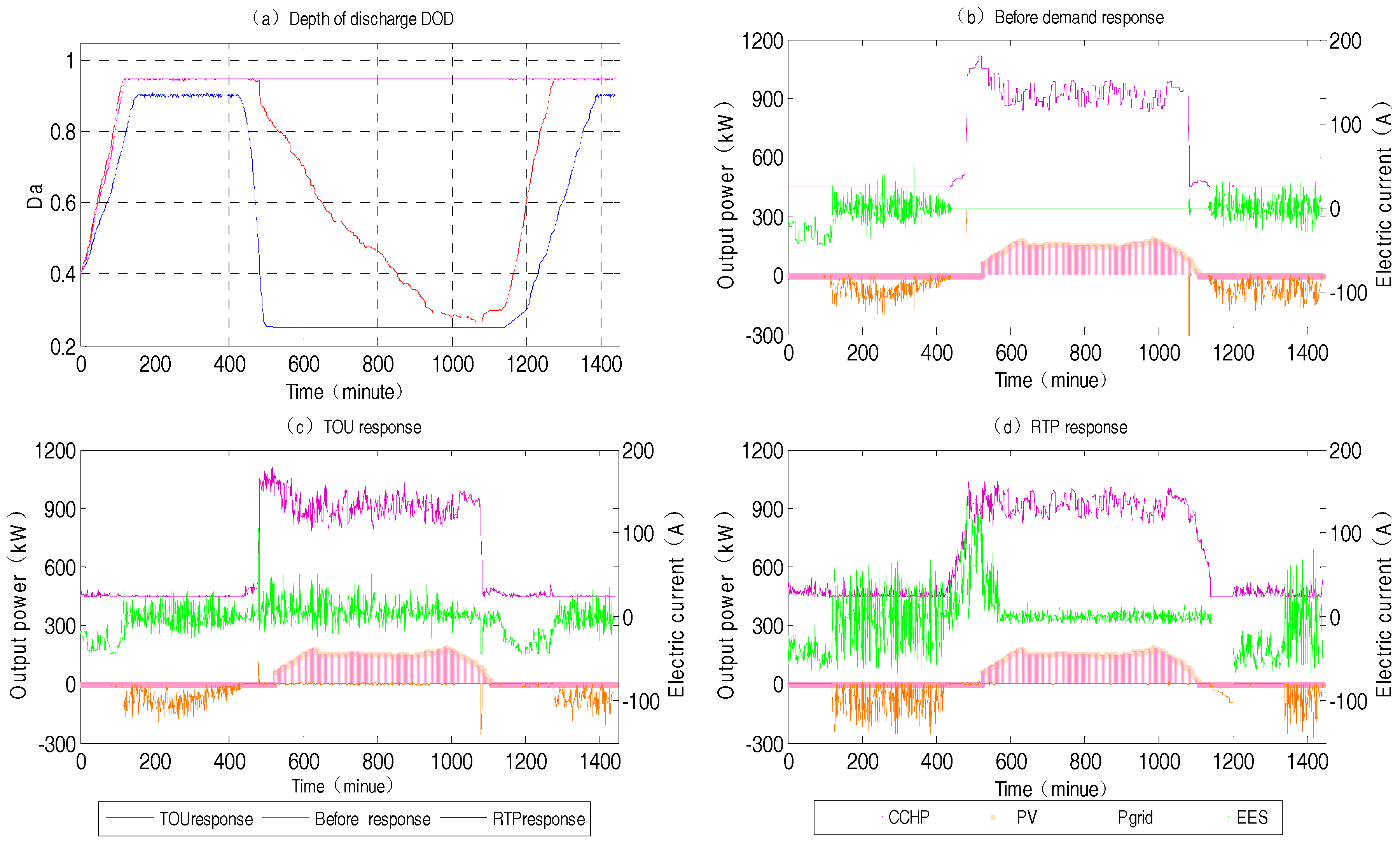

5.3.1. Power Output

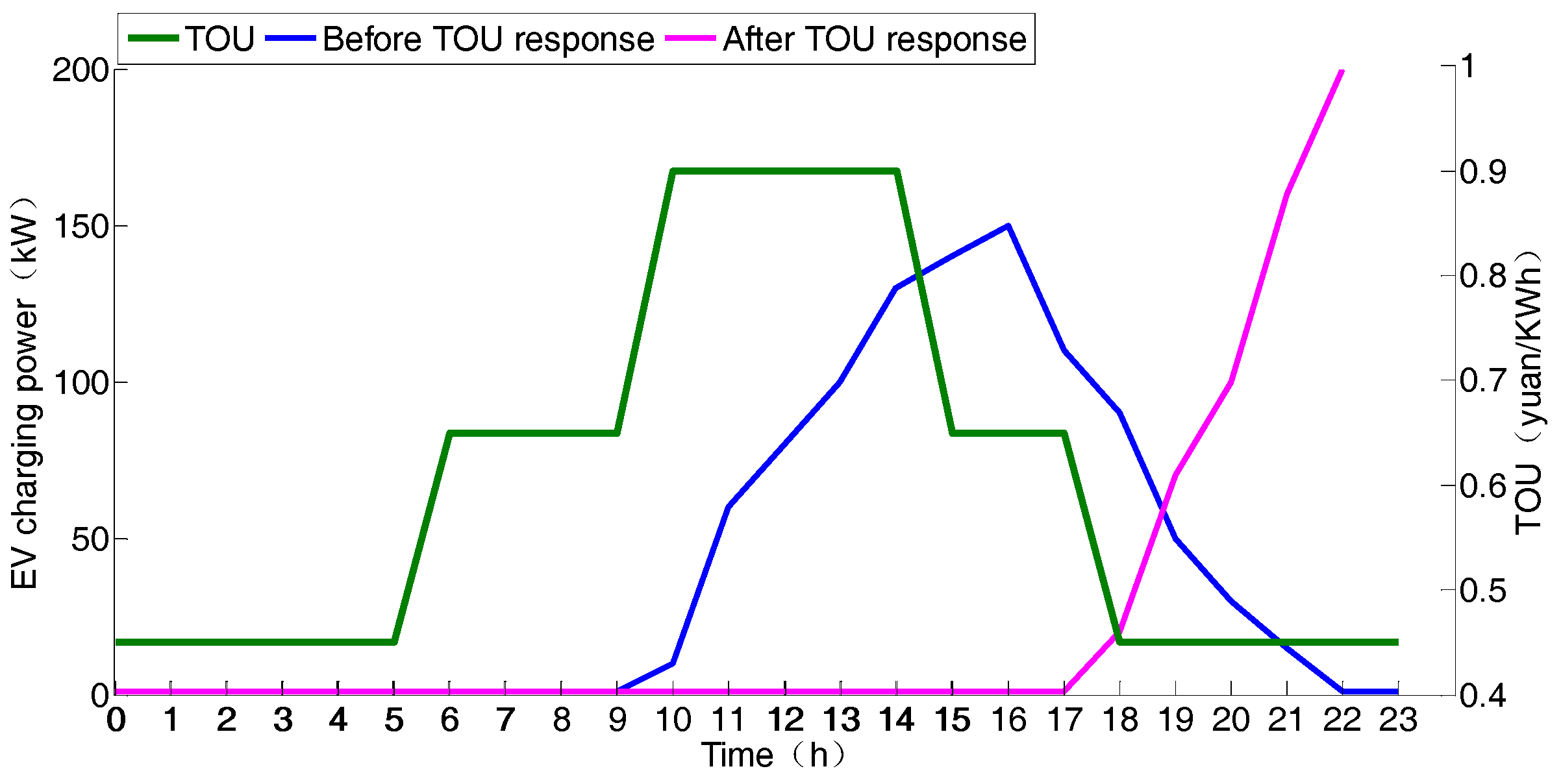

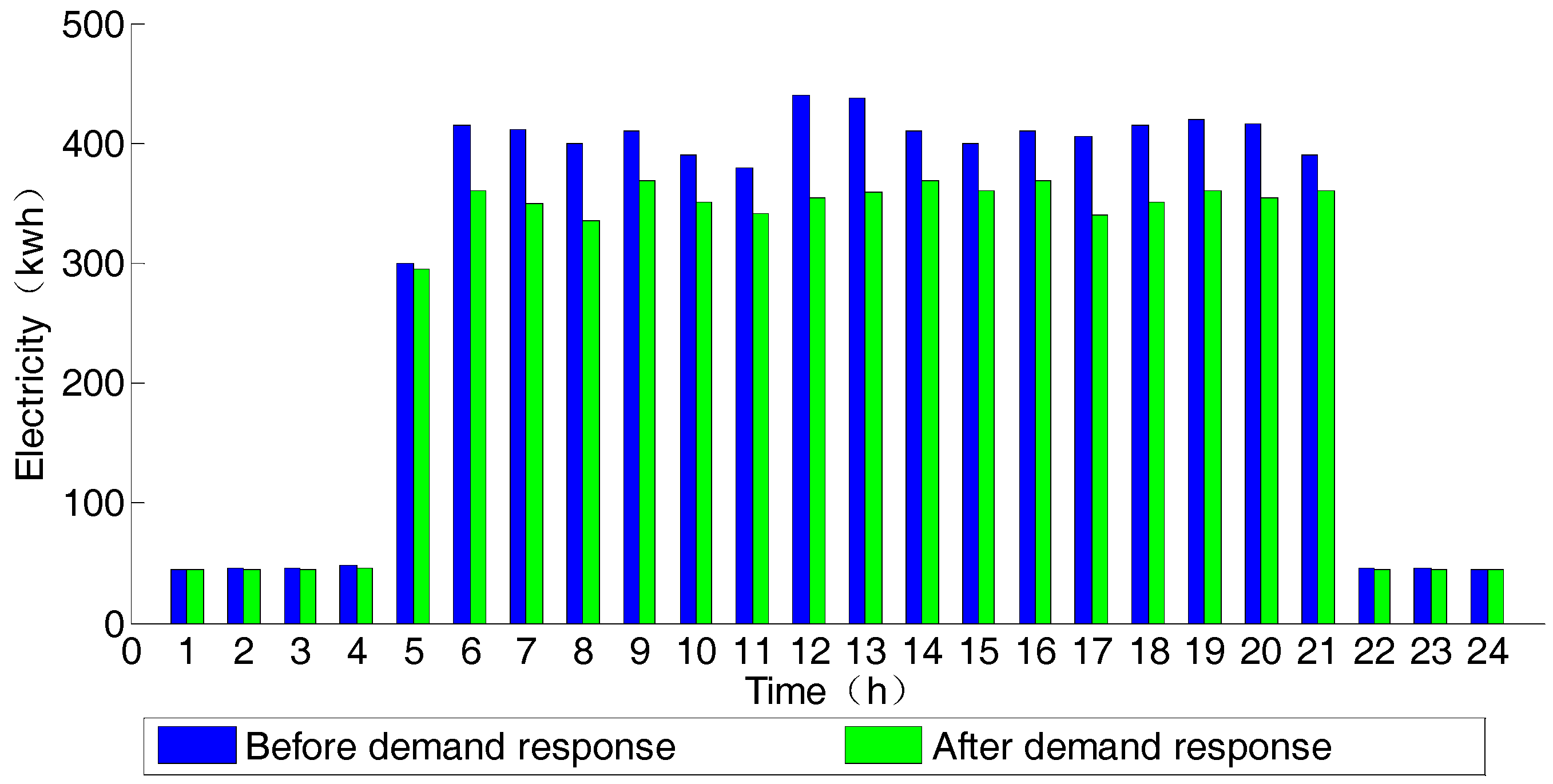

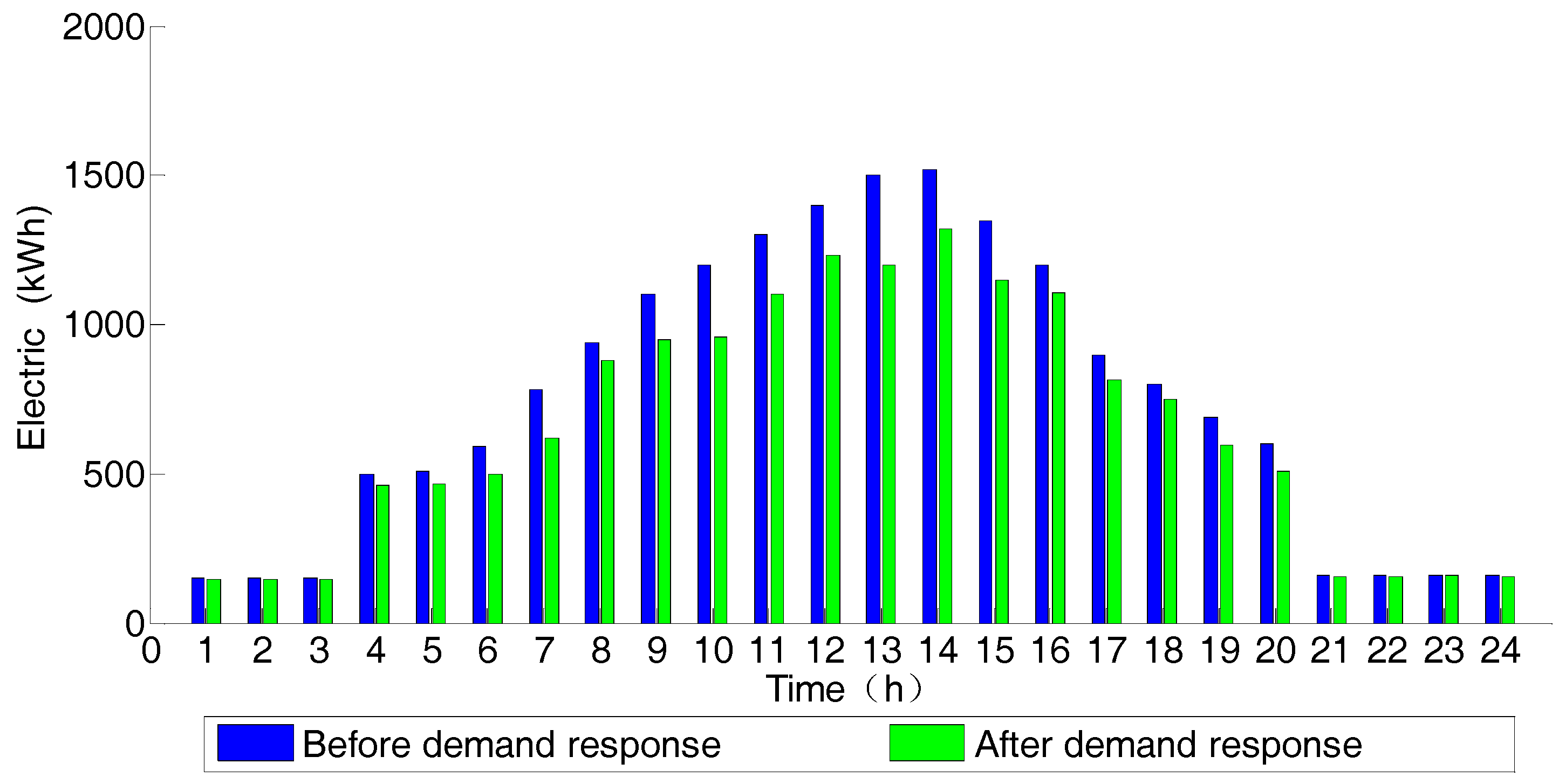

5.3.2. Load Response

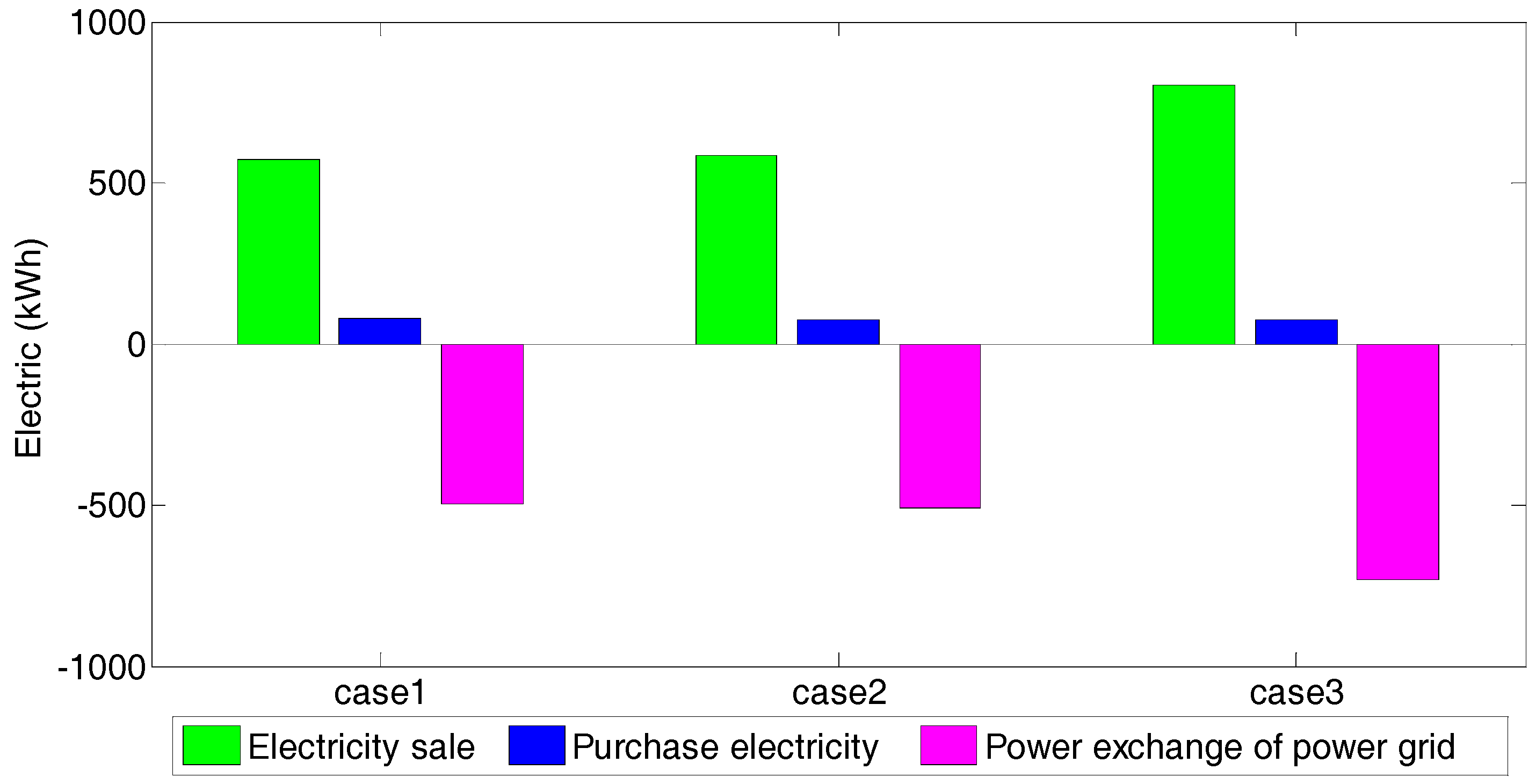

6. Result and Discussion

7. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Nomenclature

| the rated output of the solar panel, kW | |

| intensity of solar radiation, W/m3 | |

| power temperature coefficient | |

| the rated thermoelectric ratio of CCHP system | |

| the heat and power production of gas turbine | |

| the exhaust residual heat of the gas turbine at time t, kW | |

| the output of the gas turbine at time t, kW | |

| the power generation efficiency of the gas turbine | |

| the heat loss coefficient of the gas turbine | |

| the natural gas consumption per unit time, Nm3/h | |

| the low calorific value of natural gas, kWh/m3 | |

| the rated capacity of the battery, kWh | |

| the charging power of the battery, kW | |

| the discharging power of the battery, kW | |

| the remainder of the battery after the T period | |

| the remaining amount of electricity of the battery after the T period | |

| the charge and discharge efficiency of the battery | |

| the battery’s own discharge rate, percent per hour | |

| the difference between the micro-grid load and the micro-grid output | |

| upper limit of the interactive power | |

| the current maximum allowed charging rates of the battery | |

| the current maximum allowed discharging rates of the battery | |

| the maximum allowed electric energy of the battery | |

| the minimum allowed electric energy of the battery | |

| the converted objective function | |

| the total heat consumption | |

| environmental costs | |

| the pollutant discharge level | |

| the sum of the current maximum output of each micro power | |

| the overall cost of building system | |

| the operating costs, Yuan/kW | |

| gas price, Yuan/m3 | |

| the output of distributed generation during the response period, kw | |

| the charge/discharge depreciation cost per unit time of energy storage, Yuan/kWh | |

| the electricity cost of the micro-grid during the response period, Yuan/kWh | |

| the purchase price, Yuan/kWh | |

| the selling price, Yuan/kWh | |

| the tie-line switching power, kW | |

| the actual photovoltaic output/kW | |

| the actual power of the interruptible load/kW | |

| the upper limits of the curtailable load reduction/kw | |

| the state of the load at time | |

| the reduction of the curtailable load/kW | |

| the active power of the load/kW | |

| the core load power/kW | |

| the controllable load power/kW | |

| the line loss during power transmission/kW | |

| the storage battery charging and discharging power/kW | |

| the upper limits of the remaining capacity/kW | |

| the operational state of the transferable load | |

| the time the device starts running | |

| the device scheduling period | |

| the result of iteration i | |

| the low calorific value of natural gas | |

| environmental value for the pollutant j | |

| penalties for the punishment of pollutants |

References

- Lasseter, R.; Akhil, A.; Marnay, C.; Stephens, J.; Dagle, J.; Guttromson, R.; Meliopoulous, A.S.; Yinger, R.; Eto, J. Integration of Distributed Energy Resources. The CERTS Micro-Grid Concept. 2002. Available online: https://cloudfront.escholarship.org/dist/prd/content/qt9w88z7z1/qt9w88z7z1.pdf (accessed on 20 December 2017).

- Zhu, W.; Xu, W.; Zhou, Z. Development status of micro-grid and its prospect in China. Electr. Age 2012, 10, 42–4346. [Google Scholar]

- Karthikeyan, R.; Parvathy, A.K. Peak Load reduction in micro Smart Grid using Non-Intrusive Load monitoring and Hierarchical Load scheduling. In Proceedings of the IEEE International Conference on Smart Sensors and Systems, Bangalore, India, 21–23 December 2015; pp. 1–6. [Google Scholar]

- Fabrizio, E.; Branciforti, V.; Costantino, A.; Filippi, M.; Barbero, S.; Tecco, G.; Mollo, P.; Molino, A. Monitoring and managing of a micro-smart grid for renewable sources exploitation in an agro-industrial site. Sustain. Cities Soc. 2017, 28, 88–100. [Google Scholar] [CrossRef]

- Nasraoui, K.; Lakhoua, N.; Amraoui, L.E. Study and analysis of micro smart grid using the modeling language SysML. In Proceedings of the IEEE International Conference on Green Energy Conversion Systems, Hammamet, Tunisia, 23–25 March 2017; pp. 1–8. [Google Scholar]

- Kumar, M.; Srivastava, S.C.; Singh, S.N. Control Strategies of a DC micro-grid for Grid Connected and Islanded Operations. IEEE Trans. Smart Grid 2017, 6, 1588–1601. [Google Scholar] [CrossRef]

- Guo, Y.; Xiong, J.; Xu, S.; Su, W. Two-Stage Economic Operation of micro-grid-Like Electric Vehicle Parking Deck. IEEE Trans. Smart Grid 2017, 7, 1703–1712. [Google Scholar] [CrossRef]

- Morozumi, S. Micro-grid Demonstration Projects in Japan. In Proceedings of the IEEE, Power Conversion Conference—Nagoya, Nagoya, Japan, 2–5 April 2007; pp. 635–642. [Google Scholar]

- Morozumi, S.; Kikuchi, S.; Chiba, Y.; Kishida, J.; Uesaka, S.; Arashiro, Y. Distribution technology development and demonstration projects in Japan. In Proceedings of the IEEE Power and Energy Society General Meeting-Conversion and Delivery of Electrical Energy in the 21st Century, Pittsburgh, PA, USA, 20–24 July 2008; pp. 1–7. [Google Scholar]

- Gao, Z.; Teng, X.; Zhang, X. Solution of active power dispatch and control scheme for inter-connected power grids with large-scale wind power integration. Autom. Electr. Power Syst. 2010, 34, 37–41. (In Chinese) [Google Scholar]

- Huang, Y.; Fang, B.; Sun, J. Simulation research on the micro-grid with flywheel energy storage system. Power Syst. Prot. Control 2011, 39, 83–87. (In Chinese) [Google Scholar]

- Li, O.; Ge, X. Intellgent Micro-Grid Technology for Island. Electr. Energy Manag. Technol. 2014, 10, 56–66. (In Chinese) [Google Scholar]

- Pei, W.; Du, Y.; Li, H.; Yang, Y.; Deng, W.; Qi, Z. Novel Solution and Key Technology of Interconnection and Interaction for Large Scale micro-grid Cluster Integration. High Volt. Eng. 2015, 41, 3193–3203. (In Chinese) [Google Scholar]

- Jimeno, J.; Anduaga, J.; Oyarzabal, J.; de Muro, A.G. Architecture of a micro-grid energy management system. Int. Trans. Electr. Energy Syst. 2011, 21, 1142–1158. [Google Scholar]

- Palma-Behnke, R.; Benavides, C.; Lanas, F.; Severino, B.; Reyes, L.; Llanos, J.; Sáez, D. A micro-grid Energy Management System Based on the Rolling Horizon Strategy. IEEE Trans. Smart Grid 2013, 4, 996–1006. [Google Scholar] [CrossRef]

- Kanchev, H.; Lu, D.; Colas, F.; Lazarov, V.; Francois, B. Energy Management and Operational Planning of a micro-grid With a PV-Based Active Generator for Smart Grid Applications. IEEE Trans. Ind. Electron. 2011, 58, 4583–4592. [Google Scholar] [CrossRef]

- Wu, X.; Wang, X.; Liu, S. Summary of research on micro-grid energy management system. Electr. Power Autom. Equip. 2014, 34, 7–14. (In Chinese) [Google Scholar]

- Chen, C.; Duan, S.; Cai, T.; Liu, B. Micro-grid energy management model based on improved genetic arithmetic. Trans. China Electrotech. Soc. 2013, 28, 196–201. (In Chinese) [Google Scholar]

- Wang, X.; Ai, Q.; Xu, W.; Peng, H. Multi-objective optimal energy management of micro-grid with distributed generation. Power Syst. Prot. Control 2009, 37, 79–83. (In Chinese) [Google Scholar]

- Niu, H.; Huang, X.; Yang, R.; Tang, Y.; Feng, X.; Yang, M. Research and design of functional architecture system in micro-grid energy management system. Renew. Energy Resour. 2013, 31, 47–51. (In Chinese) [Google Scholar]

- Fu, Y.; Jiang, Y.; Li, Z.; Wei, C. Optimal economic dispatch for micro-grid considering shiftable loads. Proc. CSEE 2014, 34, 2612–2620. (In Chinese) [Google Scholar]

- Chen, J.; Wang, C.; Zhao, B.; Zhang, X. Economic operation optimization of a stand-alone micro-grid system considering characteristics of energy storage system. Autom. Electr. Power Syst. 2012, 36, 25–31. (In Chinese) [Google Scholar]

- Wang, R.; Gu, W.; Wu, Z. Economic and optimal operation of a combined heat and power micro-grid with renewable energy resources. Autom. Electr. Power Syst. 2011, 35, 22–27. (In Chinese) [Google Scholar]

- Yang, P.; Ai, X.; Cui, M.; Lei, Z. Particle Swarm Optimization Based Economic Operation Analysis of micro-grid Containing Multi Energy Supply System. Power Syst. Technol. 2009, 20, 38–42. (In Chinese) [Google Scholar]

- Javaid, N.; Javaid, S.; Abdul, W.; Ahmed, I.; Almogren, A.; Alamri, A.; Niaz, I.A. A Hybrid Genetic Wind Driven Heuristic Optimization Algorithm for Demand Side Management in Smart Grid. Energies 2017, 10, 319. [Google Scholar] [CrossRef]

- Bharathi, C.; Rekha, D.; Vijayakumar, V. Genetic Algorithm Based Demand Side Management for Smart Grid. Wirel. Pers. Commun. 2017, 93, 481–502. [Google Scholar] [CrossRef]

- Gao, C.; Li, Q.; Li, H.; Zhai, H.; Zhang, L. Integration method and operation mechanism of demand response resources based on load aggregator business. Autom. Electr. Power Syst. 2013, 37, 78–86. [Google Scholar] [CrossRef]

- Lu, X.; Sun, K.; Huang, L.; Xiao, X. Improved droop control method in distributed energy storage systems for autonomous operation of AC micro-grid. Autom. Electr. Power Syst. 2013, 37, 180–185. (In Chinese) [Google Scholar]

- Elbaset, A.A.; Hassan, M.S.; Ali, H. Performance analysis of grid-connected PV system. In Proceedings of the IEEE, Power Systems Conference, Cairo, Egypt, 27–29 December 2016. [Google Scholar]

- Thirugnanam, K.; Kerk, S.K.; Yuen, C.; Liu, N.; Zhang, M. Energy Management for Renewable Micro-Grid in Reducing Diesel Generators Usage with Multiple Types of Battery. IEEE Trans. Ind. Electron. 2018. [Google Scholar] [CrossRef]

- Yousefi, H.; Ghodusinejad, M.H.; Kasaeian, A. Multi-objective Optimal Component Sizing of a Hybrid ICE+PV/T Driven CCHP micro-grid. Appl. Heat Eng. 2017, 122, 126–138. [Google Scholar] [CrossRef]

- Lee, S.J.; Kim, J.H.; Kim, C.H.; Kim, S.K.; Kim, E.S.; Kim, D.U.; Mehmood, K.K.; Khan, S.U. Coordinated Control Algorithm for Distributed Battery Energy Storage Systems for Mitigating Voltage and Frequency Deviations. IEEE Trans. Smart Grid 2017, 7, 1713–1722. [Google Scholar] [CrossRef]

- Mao, X.; Chen, S.; Wu, J. Optimal dispatch of implicit battery microgrid under tou price mechanism. Power Grid Technol. 2015, 39, 1192–1197. [Google Scholar]

- Qian, K.; Zhou, C.; Yuan, Y.; Shi, X.; Allan, M. Analysis of environmental benefits of distributed generation. J. Electr. Eng. China 2008, 28, 11–15. [Google Scholar]

- Wei, X.; Zhou, H. Assessment of environmental value standards for pollutant emission reduction in China’s thermal power generation industry. Environ. Sci. Res. 2003, 16, 53–56. [Google Scholar]

- Zhang, N.; Cai, R. SO2, NOx and CO2 exhaust fines should be of the order of magnitude. Chin. J. Electr. Eng. 1997, 4, 286–288. [Google Scholar]

- Liu, Y.; Yuen, C.; Huang, S.; Hassan, N.U.; Wang, X.; Xie, S. Peak-to-Average Ratio Constrained Demand-Side Management With Consumer’s Preference in Residential Smart Grid. IEEE J. Sel. Top. Signal Process. 2014, 8, 1084–1097. [Google Scholar] [CrossRef]

- Li, W.T.; Yuen, C.; Hassan, N.U.; Tushar, W.; Wen, C.K.; Wood, K.L.; Hu, K.; Liu, X. Demand Response Management for Residential Smart Grid: From Theory to Practice. IEEE Access 2015, 3, 2431–2440. [Google Scholar] [CrossRef]

- Madraswala, H.S.; Deshpande, A.S. Genetic algorithm solution to unit commitment problem. In Proceedings of the IEEE International Conference on Nascent Technologies in Engineering, Delhi, India, 4–6 July 2016; pp. 1–6. [Google Scholar]

- Jenkins, D.P.; Fletcher, J.; Kane, D. Lifetime prediction and sizing of lead-acid batteries for microgeneration storage applications. Renew. Power Gener. IET 2008, 2, 191–200. [Google Scholar] [CrossRef]

- He, B.; Yang, Y.; Duan, L. A study of the off-design performance of a micro gas turbine-based combined cooling, heating and power (CCHP) cogenration system. J. Eng. Heat Energy Power. 2008, 6, 615–619, 689–690. (In Chinese) [Google Scholar]

- Lopes, J.A.P.; Soares, F.J.; Almeida, P.M.R. Integration of Electric Vehicles in the Electric Power System. Proc. IEEE 2010, 99, 168–183. [Google Scholar] [CrossRef]

- Zeng, B. Forecasting the relation of supply and demand of natural gas in China during 2015-2020 using a novel grey model. J. Intell. Fuzzy Syst. 2017, 32, 141–155. [Google Scholar] [CrossRef]

- Liu, C.; Lin, B. Evaluating Design of Increasing Block Tariffs for Residential Natural Gas in China: A Case Study of Henan Province. Comput. Econom. 2017, 1, 1–17. [Google Scholar] [CrossRef]

- Li, R.; Li, P. Economical Optimal Operation of CCHP Micro-grid System Based on Improved Artificial Fish Swarm Algorithm. In Proceedings of the 2014 China Electrical Equipment Innovation and Development Forum, Beijing, China, 21 June 2014. [Google Scholar]

| Time(h) | Electricity Price (Yuan/kWh) |

|---|---|

| 0:00–6:00 | 0.45 |

| 6:00–10:00 | 0.65 |

| 10:00–15:00 | 0.90 |

| 15:00–18:00 | 0.65 |

| 18:00–24:00 | 0.45 |

| Transferable Load | Rated Power (kW) | Run Time (h) | Time Window | |

|---|---|---|---|---|

| Start Time (h) | Stop Time (h) | |||

| Washing machine | 0.8 | 1 | 9 | 17 |

| Rice cooker | 1.5 | 2 | 16 | 20 |

| EV | 100 | 5 | 10 | 24 |

| Parameter | Value |

|---|---|

| Maximum charge and discharge power/kW | 65 |

| Rated capacity/(kW·h) | 300 |

| SOC operating range | 0.25–0.95 |

| SOC overcharge protection threshold | 0.9 |

| SOC overdischarge protection threshold | 0.3 |

| Charge–discharge conversion efficiency/percent | 90% |

| Self-discharge rate/(%·s−1) | 0 |

| longevity | 5–15 |

| Cycle times | 2000 (90% DOD) |

| Parameter | Value | ||

|---|---|---|---|

| Load rate (%) | 100 | 75 | 50 |

| electric power (kW) | 1490 | 1118 | 742 |

| output power (kW) | 1528 | 1146 | 765 |

| power factor | 1 | 1 | 1 |

| Voltage (V) | 400 | 399 | 403 |

| Electric current (A) | 2146 | 1613 | 1064 |

| Frequency (HZ) | 50 | 50 | 50 |

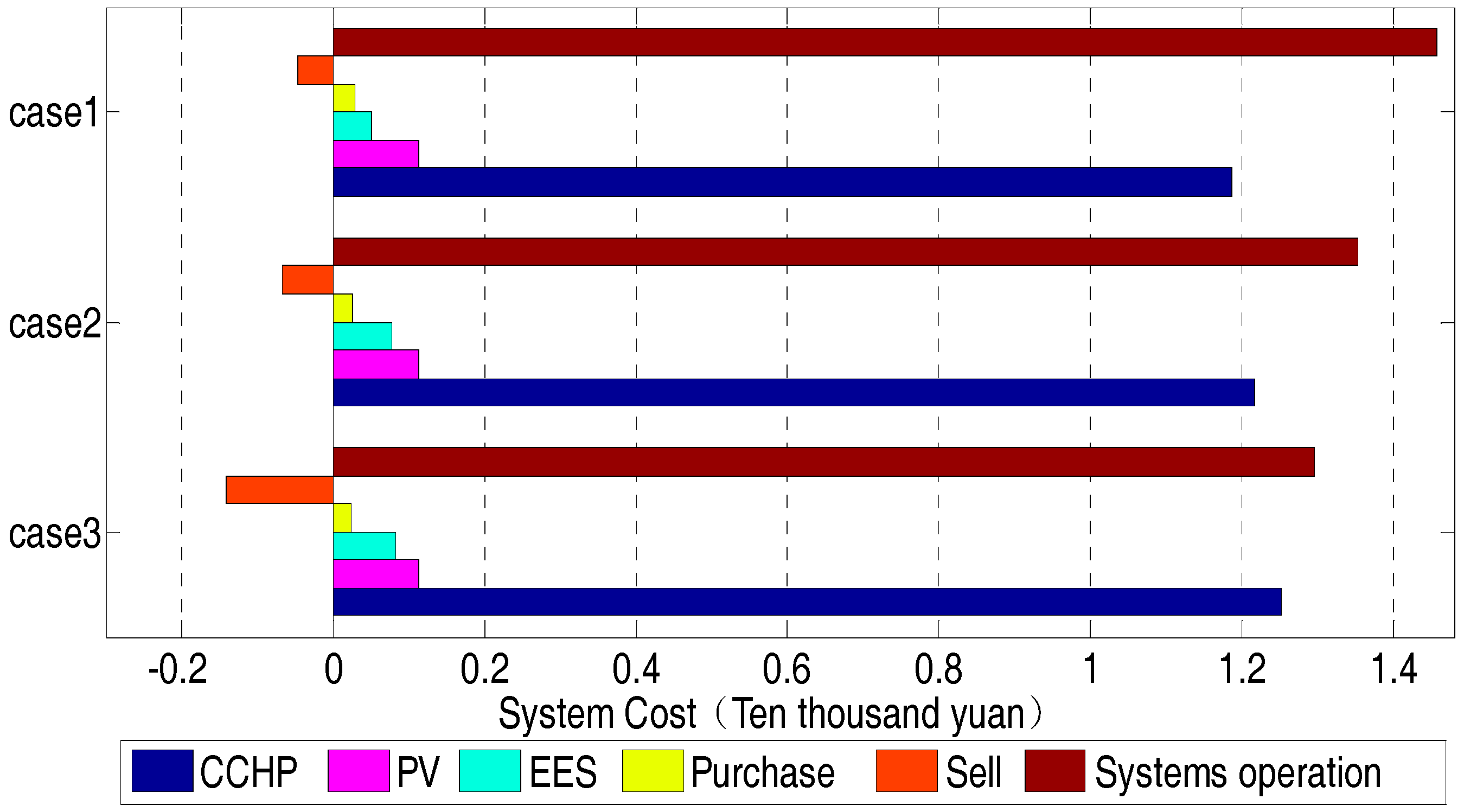

| Scene | Case 1 | Case 2 | Case 3 | ||

|---|---|---|---|---|---|

| CCHP | Daily gas consumption/m3 | 3645.812 | 3773.154 | 3849.980 | |

| Daily operation cost/Yuan | 12,170 | 12,260 | 12,510 | ||

| PV | Daily operation cost/Yuan | 1120 | 1120 | 1120 | |

| EES | Daily operation cost/Yuan | 600 | 770 | 820 | |

| Grid interaction | Purchase | Daily Electricity/kWh | 78.627 | 75.344 | 74.179 |

| Daily operation cost/Yuan | 290 | 250 | 240 | ||

| Sell | Daily Electricity/kWh | 574.20 | 583.051 | 803.302 | |

| Daily profit/Yuan | 460 | 871 | 1200 | ||

| Economics operation | operation cost/Yuan | 13,720 | 13,530 | 13,490 | |

| Environmental | environmental cost/Yuan | 27.74 | 27.77 | 36.62 | |

| F | Daily cost/Yuan | 13,747.74 | 13,557.77 | 13,526.62 | |

| NOX | CO2 | SO2 | |

|---|---|---|---|

| CCHP | 4.7954 | 170.1607 | 0.0232 |

| Thermal power plant | 0.1547–3.0938 | 86.4725 | 0.1083–3.9446 |

| NOX | CO2 | SO2 | |||

|---|---|---|---|---|---|

| Price (Yuan/kg) | 2 | 1 | 0.01 | ||

| Calculation results/Yuan | Case 1 | 4.9690 | 2.795910373 | 1.782395122 | 0.390732044 |

| Case 2 | 4.9741 | 2.798799982 | 1.78423725 | 0.391135871 | |

| Case 3 | 6.5576 | 3.689783444 | 2.352239927 | 0.515651947 | |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Huang, Y.; Wang, Y.; Li, F.; Zhang, Y.; Tian, C. Operation Optimization in a Smart Micro-Grid in the Presence of Distributed Generation and Demand Response. Sustainability 2018, 10, 847. https://doi.org/10.3390/su10030847

Wang Y, Huang Y, Wang Y, Li F, Zhang Y, Tian C. Operation Optimization in a Smart Micro-Grid in the Presence of Distributed Generation and Demand Response. Sustainability. 2018; 10(3):847. https://doi.org/10.3390/su10030847

Chicago/Turabian StyleWang, Yongli, Yujing Huang, Yudong Wang, Fang Li, Yuanyuan Zhang, and Chunzheng Tian. 2018. "Operation Optimization in a Smart Micro-Grid in the Presence of Distributed Generation and Demand Response" Sustainability 10, no. 3: 847. https://doi.org/10.3390/su10030847

APA StyleWang, Y., Huang, Y., Wang, Y., Li, F., Zhang, Y., & Tian, C. (2018). Operation Optimization in a Smart Micro-Grid in the Presence of Distributed Generation and Demand Response. Sustainability, 10(3), 847. https://doi.org/10.3390/su10030847