Abstract

With the rapid development of sensing, communication, computing technologies, and analytics techniques, today’s manufacturing is marching towards a new generation of sustainability, digitalization, and intelligence. Even though the significance of both sustainability and intelligence is well recognized by academia, industry, as well as governments, and substantial efforts are devoted to both areas, the intersection of the two has not been fully exploited. Conventionally, studies in sustainable manufacturing and smart manufacturing have different objectives and employ different tools. Nevertheless, in the design and implementation of smart factories, sustainability, and energy efficiency are supposed to be important goals. Moreover, big data based decision-making techniques that are developed and applied for smart manufacturing have great potential in promoting the sustainability of manufacturing. In this paper, the state-of-the-art of sustainable and smart manufacturing is first reviewed based on the PRISMA framework, with a focus on how they interact and benefit each other. Key problems in both fields are then identified and discussed. Specially, different technologies emerging in the 4th industrial revolution and their dedications on sustainability are discussed. In addition, the impacts of smart manufacturing technologies on sustainable energy industry are analyzed. Finally, opportunities and challenges in the intersection of the two are identified for future investigation. The scope examined in this paper will be interesting to researchers, engineers, business owners, and policymakers in the manufacturing community, and could serve as a fundamental guideline for future studies in these areas.

1. Introduction

Since James Watt redesigned the steam engines in the 18th century, which was the cornerstone to the 1st industrial revolution, human’s capability to manufacture products has been improved dramatically. The way of manufacturing products has also changed significantly in the following the 2nd and the 3rd industrial revolutions, which arose from the usage and popularity of electric energy and new communication technologies, respectively. Nowadays, with the availability of big data, the advancement of computational capability, and the popularization of smart devices, the manufacturing industries is marching towards a new era, namely, the 4th industrial revolution. The emerging manufacturing paradigm is often referred as “smart manufacturing”, which combines artificial intelligence, communication technology, and then applies them to production and business so that the production efficiency is enhanced, customized needs are satisfied, and the production cost is lowered [1,2].

Compared with traditional manufacturing, the most distinctive features of smart manufacturing are greatly enhanced flexibility, automation, intelligence, high integration, and sustainability [3,4,5]. Big data, smart sensors, Internet of Things (IoT), etc. are all driving forces for smart manufacturing. Smart manufacturing brings such a profound impact to various industry sectors with broad applications including integrated circuit manufacturing, workload rescheduling, and production optimization. For example, modern computer processing techniques, such as deep learning, utilizes big data to characterize, model, and control production processes, leading to enhanced product quality and lowered risk of accidents [6,7,8,9,10,11]. Smart sensor techniques, like radio-frequency identification, enables tracking and identifying the position of a large number of objects accurately [12]. Smart grid system helps to distribute the power adaptively and adjust the power supply intelligently [13]. Combination of cloud computing and high performance computing improves decision making of terminals [14,15]. Additive manufacturing greatly changes the way of fabrication and enhances customization. Those technologies have been increasingly applied to more and more areas, attracting more attention from industry, academia, and governments. Many countries have realized the importance of smart manufacturing and therefore invested hugely in the realization of this paradigm. For example, the U.S. launched two related manufacturing institutes, Digital Manufacturing and Design Innovation Institute (DMDII) and Clean Energy Smart Manufacturing Innovation Institute (CESMII). The U.S. government invests about $50 million and $70 million in DMDII and CESMII, respectively. China devotes three billion dollars in a plan called “Made in China 2025”, the goal of which is to speed up the pace of modernized industries [16]. Complying with the emphasis of government, smart manufacturing draws significant attention in academia. Recent research mainly focuses on the optimization of schedules and adjusting production process regarding the prediction so that the efficiency can be boosted.

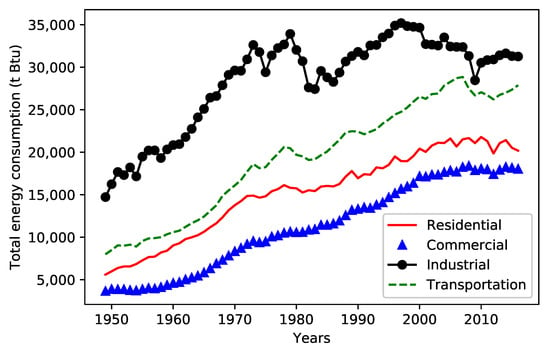

Although industrial revolutions stimulate the improvement of residents’ living standard and bring much convenience in almost every aspect of society, serious issues such as environment pollution and global warming also arose, owing to the combustion of large amount of fossil fuels and noxious in manufacturing. Industries emissions are the main source of greenhouse gases, such as CO. According to an EPA report, annual industrial CO emissions in the U.S. accounts for 21% of overall emissions [17]. In addition, shortage of natural resources, resulting in the increase of energy price is a critical pressing issue that needs to be addressed [18]. Figure 1 illustrates the energy consumption in the U.S. from 1949 to 2016. The data source is from the U.S. Energy Information Administration [19]. It can be concluded that industrial energy consumption is the most important part of the overall energy usage, and it was almost doubled compared with 1949. The demand of balancing ecosystems and leaving enough resources for future generations places significant pressure on manufacturing [20]. In order to deal with environmental problems and conserve energy and natural resources, concept of sustainable manufacturing was proposed and has attracted substantial attention from governments, industry, and academia [21]. Sustainable manufacturing aims at changing the traditional production mode to a less poisonous emission, which is more environment-friendly, less consumption of natural resource and long-term insight style. Many countries promulgated policies related to promote sustainable manufacturing, such as restricting the emissions of factories and encouraging renewable energy. In academia, sustainable manufacturing is also a field of popular interest. Most researchers focus on clean energy solutions, reducing waste, and recycling.

Figure 1.

Consumption trend of different applications in U.S. from 1949-2016. The data is from the U.S. Energy Information Administration [19].

Smart manufacturing and sustainable manufacturing are two important themes in modern industries, and there are many intersections between the two. Sustainability is one of the essential goals of smart manufacturing, which is significant due to current environmental issues and consumption of natural resources. For example, one of the core ideas of smart manufacturing is to improve energy efficiency [22]. Improving energy efficiency means more energy saving and less consumption of natural resources. Therefore, energy efficiency is also a solution to sustainability [23,24]. Rich research results are available in both areas. However, there are a limited number of works in the intersection of sustainable manufacturing and smart manufacturing. Additionally, the overlap of these two areas is not sufficiently addressed in the existing literature.

In order to promote smart factories with sustainability and tackle the aforementioned challenges in the future, we aim at summarizing the existing achievement and drawing more attention to the critical research gap. In the rest of this article, the definition and characteristics of sustainable manufacturing are first presented, followed by a discussion on the current related policies in major industrial countries. Smart manufacturing is then introduced. The hierarchy of smart manufacturing in energy levels as well as the key technologies related to sustainable manufacturing are discussed in detail. The current stage of sustainable energy solutions and the existing smart manufacturing applications related to energy devices are also reviewed. Finally, we summarize the current research gap and possible approaches to further promoting energy sustainability in smart factories.

2. Description of Target Literature

This paper reviews the state-of-the-art of smart manufacturing and notion of sustainability by identifying the significant influcence of smart manufacturing on society, industries as well as environment and innovation achieved in recent years. To conduct the review systematically, we organize our review based on the PRISMA framework [25].

First, a database of the scientific literature and government reports is built based on the search results from Google Scholar, Google Search, and Web of Science. Most of the materials are peer-reviewed scientific literature, while reports from government and other authentic institutions are also included, because national policies and global trends of smart manufacturing are critical topics addressed in this article. To identify the target scientific literature, several key words, “smart manufacturing”, “sustainability”, “intelligent”, “IoT”, and their combinations are chosen.

Second, the papers in the database are filtered using the following rules.

- (1)

- For the papers published within recent three years, only the literature from top journals or conferences in the corresponding field are chosen.

- (2)

- For the papers that have been published more than three years ago, the literature with high citations are considered.

- (3)

- For the papers have been published more than seven years ago, they are only used as an introduction to the key concept or descriptions of conventional technologies.

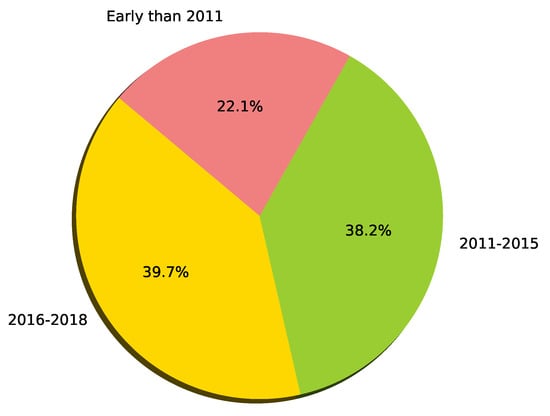

The year distribution of the reviewed papers is illustrated in Figure 2. For studies focused on the same problem, the latest and most recognized papers, which are usually published in more authentic journals, are chosen as major references. In order to have an objective and comprehensive overview of related topics, we have selected the most representative literature for each section. The referred papers have more citations and are recognized for providing better insights of the investigated area.

Figure 2.

Year distribution of reviewed literature.

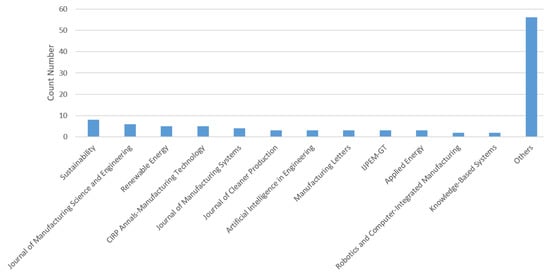

Both smart manufacturing and sustainability are very broad concepts, and they are related to numerous technologies, therefore, the literature from a wide range of sources are chosen. Figure 3 summarize the distribution of journals cited in this paper. It can be noticed that the most cited source journal is Sustainability. Additionally, literature from more than 60 journals are reviewed, including the top journals in sustainability, manufacturing, energy, and top conferences in computer science.

Figure 3.

Journal distribution of reviewed literature.

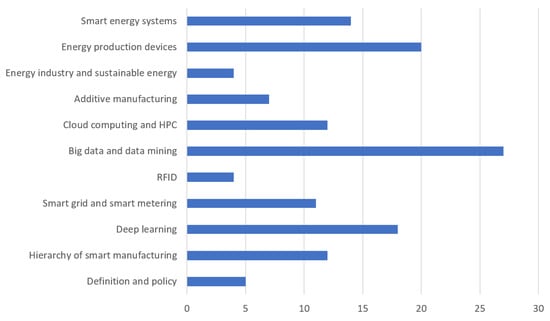

Figure 4 shows the distribution of the literature among different core aspects in our review. Most topics have more than 10 references. Specifically, for promising topics that attract more attention in academia and industry communities, more references are included to capture the quick advancement in recent decades. For example, deep learning is an emerging area that has received more and more attention globally. As a data analysis and prediction tool, deep learning shows its unsurpassed power in many areas and is expected to have wide applications in smart manufacturing. Hence more literature are reviewed to cover the details on this topic.

Figure 4.

Section distribution of reviewed literature.

3. Green and Sustainable Manufacturing

In this section, we first present the definition and characteristics of sustainable manufacturing and then introduce the current development and related policies.

3.1. The Definition and Characterization

Nowadays, the environmental disruption, climate warming, air pollution, and water contamination are increasingly affecting residents’ life and health, and the shortage of energy and resources is also exerting tremendous burden on manufacturing and policymakers. The traditional manufacturing fails to meet current environmental requirements since it consumes the future generations’ resources and harms the environment. Thus, the importance of sustainability is widely recognized, leading to the development of sustainable manufacturing. A large and growing number of manufacturing companies are realizing substantial financial and environmental benefits from sustainable business practices.

In manufacturing, sustainability refers to the creation of manufactured products through economically-sound processes that minimize negative environmental impacts while conserving energy and natural resources. Sustainable manufacturing not only benefits the next generations, but also enhances employee, community, and product safety [26]. The criteria for sustainable manufacturing can be summarized as follows [27]:

- no or little harm to the environment and society

- no reduction of natural resource

- capability of satisfying nowadays and future energy needs

- high efficiency

- no toxic emission to air, land or water

- no or little greenhouse gases emission

- no pressure on future populations

To achieve sustainability in smart factories, a common concept called Source-System-Service route (3S) is proposed [27]. Source step means the energy or resources used is clean, abundant, renewable, inexpensive and environment-friendly. The system includes the enhancement of energy efficiency, integration of machines and factories, multifunction and less energy waste or trash. Service step means recycling, dependable and clean products.

3.2. Current Development and Policy

To prevent climate change, environmental disruption, and promote the advancement of sustainable manufacturing, many countries launched related policies. China sponsored green manufacturing as one of the major projects in manufacturing. In the 12th Five-Year Plan, the industries related to environmental protection, energy saving, biotechnology, new energy, new energy vehicles are emphasized [28].

In the European new seven-year 2020 program, the European Union plans to invest 7.8 billion dollars to a program called “Factories of the Future” to promote smart manufacturing as well as sustainable manufacturing [29]. The goal of this program is to develop clean, environmentally friendly manufacturing [16]. The European Union plans to reduce up to 30% of the current energy consumption, 20% waste and 20% materials consumption in manufacturing processes, as well as integrate novel technologies and develop up to 50 new applications [16].

The U.S. government invested 680 million dollars, of which 240 million is from public investment and 460 from non-federal sources, to boost sustainable manufacturing, specifically clean energy, and smart manufacturing [16]. Other countries, such as the United Kingdom, Australia and Korea, also established policies or plans to promote the advancement of the 4th industries, and environment friendly manufacturing [29].

4. Smart Manufacturing

As the subject of the 4th industrial revolution, smart manufacturing becomes a popular theme. In this section, the definition of smart manufacturing is first presented, and then the role of sustainability is explained. Finally, we state a hierarchy of manufacturing to enable responsive analysis of the impact of different technologies on the production activities.

4.1. The Definition

Smart manufacturing is a very broad concept. Internet of Things (IoT), wireless sensor networks, big data, cloud computing, and embedded system are all key enabling technologies [30]. Additionally, improved measures or methodologies that can be used to modify the production process, increase efficiency or reduce emission are also included in this concept. The aim of smart manufacturing is to maximize profits of factories, nullify the risk of accidents and achieve zero-emission in the production process.

A basic structure of smart manufacturing consists of machines, facilities or resources, communication network, cloud computing, and monitoring or control terminals. Machines exchange information and sensors send signals through the network to the cloud when they are running. In the cloud, data is analyzed with machine learning or other information technologies simultaneously, and then the results or predictions are sent to terminals for decision-making. In this process, the production is optimized so that high efficiency and performance could be achieved. Except for production optimization, the operating conditions of each machine are monitored, and the possible failure or potential errors are predicted in the cloud, and the manager can decide to make adjustments to the facility in advance, which reduces the risk of accidents and avoids energy waste.

Smart manufacturing brings innovation into three aspects: horizontal integration, vertical integration, and end-to-end integration. Horizontal integration means strengthening the cooperation among companies or corporations; vertical integration refers to the integration among different subsystems in each corporation; and end-to-end integration enables the combination of design, customers’ needs, and dynamic adjustment of production. By simultaneously performing horizontal integration, vertical integration, and end-to-end integration, smart manufacturing is able to make the production process more efficient, sustainable, cost-effective, and customized. The differences between smart manufacturing and traditional manufacturing are summarized in Table 1 [30].

Table 1.

Comparison of smart manufacturing and traditional manufacturing.

4.2. The Role of Sustainability in Smart Manufacturing

Smart manufacturing and sustainable manufacturing have many intersections. A critical goal of smart manufacturing is to enhance production sustainability. When performing manufacturing activities, the production cost is an essential factor that affects manufacturers’ managing strategies. If the technology is intelligent in other aspects but energy costly, it can hardly be widely applied. Since the price of energy is continuously increasing, the money spent on the purchase of raw materials and energy, including electricity and fuels, accounts for a significant portion of the production budget. High energy efficiency and low consumption mean more money savings. Thus, in order to maximize the profits, sustainability needs to be taken into consideration by manufacturing companies.

In addition, because of the severe environmental pollution and disruption of natural resources, more and more countries emphasize sustainability, as evidenced by the promulgation of various laws and policies. The larger quantity of money invested, the more technologies and clean energy research sponsored. Environment-friendly techniques will be the future trends both in academia and industries. Consequently, sustainability is one core aspect of smart manufacturing.

4.3. The Hierarchy of Smart Manufacturing

A hierarchy of smart manufacturing process is defined in the existing literature for the convenience of analyzing the energy efficiency of different technologies in the smart factories [31,32]. In this article, a three-level hierarchy is adopted: process level, machine level, and factor and enterprise level. The criteria of such divisions are the hierarchy of interaction and integration in the manufacturing processes. The mechanism of increasing energy efficiency is quite different at different levels. The key feature of one technology is identified by analyzing its impact and its implementation at a given level. At each level, we first present its definition, and then summarize the possible approaches/techniques as well as the potential improvements based on the criteria given in Section 3.1. Finally, following by the list of the achievement at each level, the limitations and research gaps are discussed.

4.3.1. Process Level

Practice belonging to this level includes the research and innovation regarding fundamental physical phenomena, the emerging methods or technologies that are different with the legacy techniques, as well as the applications of new energy. Here, the physical phenomena refer to energy losses brought by physical mechanisms, such as material reflectivity, heat transfer, and heat waste. Some researchers argue that the energy waste at this level is insignificant compared with the total energy usage [32,33]. Nevertheless, the improvement of the fundamental physical process is still remarkable to sustainability and energy efficiency, because many processes are mutually interconnected, and enhancement of one process often results in the advancement of other connected processes. The improvement is even more notable in the 4th industrial revolution, considering that IoT becomes a critical in the smart factories. For example, the performance of electronic devices or machines is greatly dependent on the performance of the cooling system. Studying the basic process of cooling and heat transfer can increase the efficiency of the cooling unit, thus enhancing the machine’s energy efficiency and reducing energy waste. Another example involves tool degradation. Tool degradation almost exists in any manufacturing process and is the source of many undesirable outcomes, e.g., deteriorated product quality, increased production costs due to reworking and refurbishing, and reduced energy efficiency of machines. Some studies indicate that tool degradation greatly influences the machine behavior and defines a limit to the device [31]. Furthermore, research related to the mechanism of energy transformation is also desired. Study of recycling heat waste in a certain process, for example, contributes to the conservation of energy and reduces energy waste. Innovative manufacturing processes that consume less energy are also important for sustainability. For instance, due to its numerous advantages over traditional fusion welding techniques, ultrasonic metal welding has been popularly adopted in various industrial applications, such as lithium-ion battery assembly [34,35,36,37,38], automotive body construction [39], and power device packaging [40]. Two important advantages of this process are its short cycle time and low energy consumption.

4.3.2. Machine/Station Level

Machine/station level focuses on the integration of different processes. The energy usage of this level is the sum of all the processes. The energy efficiency () at this level is given as:

As shown above, the energy efficiency of the machine level is proportional to the energy usage of the processes. As mentioned in Section 4.3.1, the energy waste of single process may not be a large percentage of the overall energy waste. However, the efficiency of the process level has a critical impact on the energy efficiency of the machine level. In fact, doubling energy efficiency at process level will lead to doubling efficiency at the machine level [31,41,42].

4.3.3. Factory Level

Factory level is a level where the efficiency is not just a sum of all the lower levels, but a result of interaction among all subsystems. At this level, the facilities and machines are interconnected. An improvement of a single component may have a significant impact on the others since the whole system is working as an entity. The technologies are applied at this level influence the energy efficiency by vertical and horizontal integration, which is one of the essential features that distinguish smart manufacturing and traditional manufacturing. The mainstream research on smart manufacturing, such as big data analytics and machine learning, mainly optimizes the performance at this level. By adaptively allocating resources, optimally scheduling operations, and improving decision-making, the energy and materials waste is reduced, and sustainability is thus enhanced.

4.4. Smart Manufacturing in the Energy Industry

According to the International Energy Agency (IEA), the manufacturing industry contributed 27% of global final energy consumption in 2014, and the demand for energy resources in the manufacturing industry is expected to keep rising as the development of world economies [43]. Sustainable energy is one solution to reducing the negative impact on the environment and increase energy sustainability. Energy resource is one of the most critical resources for the manufacturing industry. Adopting sustainable energy could reduce pollution and greenhouse gas emissions from the source, and lead to improved energy sustainability during the whole product cycle.

The development of smart manufacturing technologies is very influential in the energy industry and helps facilitate the deployment of sustainable energy. The cost of electricity from solar photovoltaic and windfalls rapidly. Since 2010, prices of new solar photovoltaic have come down by 70%, wind by 25% and battery costs by 40%, and the sustainable energy is affordable to not only developed countries but also developing countries [43,44].

The impacts of smart manufacturing technologies in the energy industry are reflected in two major aspects. First, smart manufacturing technologies could improve the performances or reduce the production cost of energy devices, such as energy collect devices and energy storage devices. Second, energy factories could turn into “smart energy factories” with the help of smart manufacturing technologies. The performance improvements of energy manufacturing devices and energy manufacturing processes could help energy industry meet the drastically increasing demands of energy resources, and thus enhance the energy sustainability from the source. Details of smart manufacturing applications in the energy industry will be discussed in Section 5.

5. Applications of Smart Techniques in Sustainable Manufacturing

In this section, the case studies related to different smart techniques are classified and discussed. For each technique, we first introduce the technique and then analyze its application in sustainable manufacturing.

5.1. Deep Learning

Deep learning, as part of machine learning family, is now attracting increasing attention from both academia and industries. Inspired by the structure of the human brain, deep learning mainly utilities multilayer neural networks to classify data and predict trends. Deep learning needs to be fed a large quantity of data, then typically using backpropagation algorithm to optimize the weights of neurons until convergence. It has been proven to be successful and bring much breakthrough in a wide range of fields, such as automatic speech recognition [45], natural language processing [46,47], computer vision [48], and mobile advertising [49]. Compared with traditional machine learning algorithms, deep learning is characterized by hierarchical learning, which requires more data and higher calculation performance. Some popular deep learning architectures are as follows [50]:

- Convolutional neural networks (CNN)

- Long short-term memory networks (LSTM)

- Deep belief networks (DBN)

- Deep stacking networks (DSN)

The emergence of the IoT trend stimulates the success of deep learning. The popularity of the Internet and automation technology provides a substantial amount of data. Big data provides a sufficient amount of data to feed and train the neuron network, discovering the hidden pattern or intricate structure. Meanwhile, the significant improvement of processing power is another factor that drives the broad application of deep learning. A current single GTX 1080 GPU with computational capability of 8.9 TFLOPS, is approximately twice as powerful as the best supercomputer in 2000, which has only 4.9 TFLOPS computational capability. The rapid revolution of computing performance shortens the time to obtain the outcome, and real-time analytics becomes feasible.

Recently, as a very effective method, deep learning is one of the most active research domains. Many researchers devote their efforts to this area. In manufacturing, the application can be divided into the following aspects:

- Quality inspection [6,51]

- Fault diagnostic (detection, identification, estimation of magnitudes)

- Predictive analytics for defect prognosis [52,53]

- Condition monitoring [54,55]

- Service or operation planning [56,57]

For example, Nijat et al. [6] implemented stacked LSTM to extract features from time series data, which switches the intensive hand-crafted feature extraction way to a more automatic and intelligent way. Their network can also be used in process planning, monitoring the semi-finished products quality and determining the next process step. Leng and Jiang [56] built a decision support system by modifying stacked denoising auto-encoder to extract sentence-level characteristics, which integrates the resources of different enterprises. Ren et al. [52] proposed a generic approach to predict defect area and segment defect. Their network can achieve good performance on a small dataset and can be applied to different types of surface, which reduces the cost of data collection. Chen et al. [58,59] applied a deep neural network to classify rolling/bearing fault and predict remaining useful life of bearing. Yu et al. [54] applied a multistage DBN-based extreme learning machine to credit risk assessment. Leng et al. [57] combined a deep learning method with granular computing to service planning. Zhao et al. [55] proposed a convolutional bi-directional LSTM method to monitor machine health and eliminate noise intervention. Wu et al. [53] implemented LSTM to estimate remaining useful life of machines, aircraft turbofan engines in particular. Xu et al. [51] utilized region proposal network into standard parts inspection. Masci et al. [60] present a max-pooling CNN to inspect steel defect, which obtained twice improvement in performance compared with traditional Support Vector Machine classifiers. Shao et al. [61] developed a Restricted Boltzmann Machine based deep belief networks to extract features from vibration signals and to characterize operation status of motors and conduct fault diagnosis.

5.2. Smart Grid and Smart Metering

The smart grid is an electric network system that distributes the power effectively. This technology implements advanced monitoring methods to capture the actions of consumers and power providers, integrating the power distribution and generation as well as consumption so that the energy losses are reduced, and the reliability of power supply is increased. In this technology, central controlling system, named Supervisory Control and Data Acquisition system, is implemented, which supervises the energy use of machines and factories, adjusting the power supply of the whole system dynamically [62,63,64]. The key technologies or features of smart grid include [13]:

- Smart meters

- State estimation

- Distributed generations

- Renewable energy integrations (REI)

- Bidirectional communication system (BCS)

- Automatic healing capability (AHC)

- Data security/cyber security

- Carbon emission reduction

- Meter data management (MDM)

- Field area networks (FAN)

- IT and back office computing

- Demand response

- Electricity storage devices

- Distribution automation

Mainly, the smart meter is an essential component of smart grid technology. The smart meter is a digital meter that records energy consumption and sends data to the Internet. It not only monitors the performance of all equipment but also visualizes the flow of energy for the ease of understanding the usage manners and consumption patterns. Herrmann et al. [62] propose an application of smart meters in manufacturing. It turns out that by adopting different temporal resolutions in different manufacturing levels, including process level, machine level as well as factory level, smart meters are capable of capturing necessary loads and energy peaks of the production process and improving energy efficiency in each level.

The smart grid has numerous advantages over the traditional grid system, such as high efficiency, reliability, and economics. First, by tracing the energy usage, the energy peaks can be monitored so that the distribution of power can be adjusted correspondingly, which effectively reduces the excessive energy consumption. With a smart meter, the energy consumption is recorded more precisely and virtualized, and the data collected in the cloud can be used to optimize the scheduling, which greatly increases energy efficiency [62,65]. Second, by implementing state estimation and automation technology, the possible fault of an electric net can be diagnosed, and the network is self-healing, which increases the reliability of power supply, as well as the resistance to the damage of natural disasters, such as hurricane and earthquake [66]. Besides, smart grid effectively reduces brownouts or blackouts [67]. Third, energy costs are decreased by monitoring the hourly energy use and performing dynamical adjustments with the help of smart meters. The data collected is transmitted to the Internet or cloud for ease of analysis and managing usage. By arranging the energy-intensive task in the low energy use time, factories can save energy and a large quantity of money [67,68,69]. For energy generators, because the smart grid enables immediate communication with the end-users, they can arrange the power plants more adaptively, so that the number of costly power plants could be decreased. Apart from conventional smart grid technology, micro-grid is more stable and economic and is mainly used in demand side management. Wang [70] proposed an optimization modeling for micro-grid. The integrated genetic algorithm to solve the dilemma where the comfort of users and consumption reduction cannot be both achieved. They conducted a simulation on a smart grid from Tianjin, and the numerical results suggested an enhancement in demand response to the economic operation.

Smart grid plays an important role in sustainable manufacturing. For the traditional grid, one big problem that hinders the popularity of renewable energy, such as wind and solar energy, is that the generation of such electricity is always fluctuating and not stable. Since smart grid can monitor the power demand and adjust the power supply dynamically and the capacity of renewable energy is improved, the utilization of renewable energy can be increased. In addition, by monitoring the performance of machines and optimizing schedule with smart metering, the supply of energy can be adjusted dynamically, reducing energy waste and increasing energy savings, which contributes to the energy sustainability. To evaluate the performance of smart grid on sustainability, Zhao [71] conducted a systematic literature review and proposed a four-sustainability-criterion evaluation framework, which employed stochastic Analytical Hierarchy Process (AHP) and fuzzy Technique for Order Preference by Similarity to Ideal Solution (TOPSIS).

However, there are still some concerns about the smart grid. One concern is the security issue. Since the data is transmitted online, it is vulnerable to attacks from hackers. Smart grid systems rely on the meters and distributed computer agents. If hackers attack these automated control systems, the whole power supply line could be cut off. Therefore, more research is desired on this issue.

5.3. Radio-Frequency Identification (RFID)

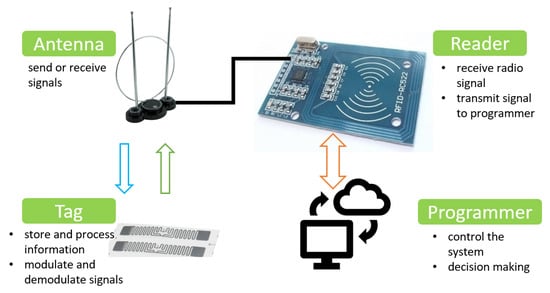

Radio-frequency identification technology (RFID) is used to trace and identify the assigned task of each object. RFID mainly comprises such components: tags (transponders), readers, antenna, printers, information systems, mobile devices, and point of sale with RFID readers. Figure 5 shows the basic structure of RFID. In this technology, each object is attached to a unique tag. The specific information, such as the procedure an object should be processed, is stored in the tag. There are some antennas on the tag so that the communication and identification from a long distance are allowed. The signals sent from antennas are collected by readers, which exchanges information with programmers to accomplish the desired processing task of the item. By RFID, the objects can be tracked very precisely, and even in a wide area and among many objects, each tag can be distinguished, which is far better than the traditional manual identification and classification.

Figure 5.

The structure of RFID.

The tags can be classified into active and passive categories. Active tags need a power source, which is usually an onboard battery. Thus, the power capacity determines the lifetime of the tag. The requirement of power source influences the size, price and lifetime of tags. In contrast, a passive tag doesn’t need batteries, which is made of antennas, semiconductor chips, and some encapsulation. The passive tag is powered by the tag reader. The energy is captured by the antenna. To power up a passive tag, the radiation must be strong enough, and the magnetic induction or electromagnetic wave capture must be implemented to transmit power to the tag. Although passive tags are smaller and cheaper, the wave that a reader emits is much stronger than that of an active tag.

The readers can be divided into two classes, i.e., passive readers and active readers. Passive readers only receive radio wave signals and cannot charge tags. The advantage of passive readers is that the wave range is broad and easy to adjust. The active readers can both charge tags and receive radio waves. However, the reception range of active readers is relatively short compared with passive readers.

RFID technology has been widely used in many areas [12], such as airport’s tracking baggage system, monitoring oil drill pipe, recording insect motions as well as preventing collisions in mines. Specifically, many industries adopt RFID technology to assist the production process and manufacture customized products. For example, the Ford Motor Company used this technology to assemble cars parts automatically, improving the quality and tracking on production line [72]. During the production process, a vehicle is attached to a tag to specify what process to be done at each stage, satisfying different customer needs. Implementing RFID decreases the operator error, and increase the efficiency greatly. Compared with traditional tracking systems, RFID has the following features [73,74]:

- Ease of identification. Because the tag attached to the item is assigned unique information, such as manufacturing conditions and product type, the part is easy to identify and track during the production. This feature is very important in mass production.

- Simultaneous communication. The tag not only specifies what task to be done on the part, but also keep updating during the production, recording the complete task as well as quality diagnostics, which enables real-time inspection and monitoring.

- Automation. By attaching the tags to the item, the production process, including assembling, packaging, and delivery is finished automatically. In addition, the performance history is recorded, so that the manufactures can use such information as feedback to modify the production process and improve the quality of products.

- Improving efficiency at the enterprise level. RFID technology integrates designing, and customer needs as well as manufacturing. Because the information on the tag is constantly updated, the designers can change the production process easily to meet some special customer needs. By shortening the response time, manufacturing efficiency is greatly improved, and the waste (energy consumption and production cost) due to rescheduling induced by different customer needs in mass customization production is minimized.

5.4. Big Data Analytics and Data Mining

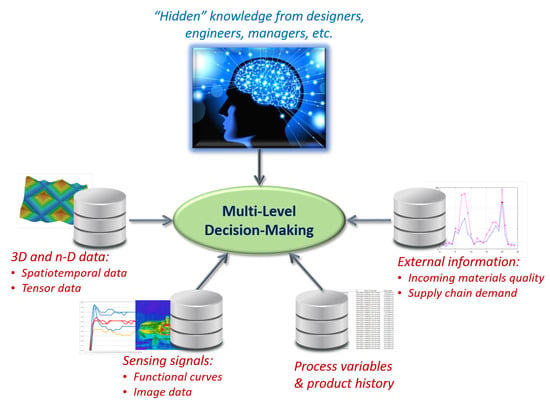

Nowadays, data is being collected at all the levels in the manufacturing sector. The data size in manufacturing is extremely large, and the manufacturing industry is marching towards a big data era. Big data is characterized by four V’s, i.e., volume, variety, velocity, and veracity. High volume means the size of the dataset is huge. High velocity indicates a high speed of data collection is extremely fast. High variety represents there are numerous data sources and types. High veracity refers to the high uncertainty and large noise in the collected data. In manufacturing, a large amount of data is constantly generated, coming from process design, assembly, scheduling, instant communication, quality examination and so on. Moreover, big data in manufacturing is unique and different than other sectors. For example, manufacturing largely depends on human operations, so it is beneficial to model and leverage human intelligence. Nevertheless, human intelligence is extremely abstract, and the digitalization of such knowledge is very difficult. Furthermore, the decision-making processes at different levels are dynamic and interactive with multiple objectives and constraints. Figure 6 illustrates the data sources in a modern manufacturing factory. The challenges brought by big data and the uniqueness of manufacturing make the traditional data processing methodologies no longer capable. Data mining technique offers a feasible solution.

Figure 6.

Data sources in a modern manufacturing factory.

Data mining is a tool that commonly implements machine learning, statistical methods, visualization or other pattern recognition technologies to find useful features or trends. Since it is successful in discovering potential patterns hidden inside big data, data mining can be used to optimize the operation, improve products quality and other aspects, including fault recognition, quality diagnostic, prediction, and scheduling [75,76]. Different from other techniques, data mining does not require specific data collection processes, and because of development of machine learning, especially deep learning, data mining is playing an increasingly important role in big data analytics for manufacturing.

Data mining has been widely used in the industries that require a high precision method to monitor the quality of product and diagnose faults, such as semiconductor manufacturing and integrated circuit manufacturing. Some researchers apply a decision-tree to detect fault and make decisions [77,78,79]. Sebzalli [80] implemented neural networks and c-means clustering to optimize the production process and reduce the waste of product due to changeover, thus increasing energy efficiency and saving energy. Lee et al. [81,82] used self-organized maps and fuzzy networks to improve the performance of the quality examination. New machine learning and statistical techniques were proposed to achieve a balance between measurement cost and precision or enhance interpolation accuracy for high-resolution 3D measurement tasks [76,83,84,85]. Applications include high-precision machining and ultrasonic metal welding. Using these algorithms, not only measurement cost can be saved significantly, but also measurement time is reduced to a great extent. As such, production efficiency can be promoted. These data mining methods or algorithms aim to increase the efficiency at the process level, and they turn out to successfully and effectively promote the efficiency of manufacturing.

At the factory and enterprise level, data mining is also employed in detecting possible problems that may influence the integration of the whole production process and the supply chain. Some researchers proposed an intelligent system to compare and analyze the collected data. After that, the discovered feature is shared so that the overall energy efficiency of manufacturing is improved [86,87,88]. Other applications of data mining include [89]:

- Predicting manufacturing process and minimizing tool wear or other tool defects [83,90,91].

- Improving engineering design and decision-making [92,93].

- Optimizing machine performance.

- Discovering material properties to instruct yield in medical and chemical industries [94].

- Assisting decision making by predicting the outcome of decisions [95].

- Promoting maintenance [96].

Data mining can be applied to sustainable manufacturing [97]. In transportation, some commercial data mining systems such as MineFleet can effectively save energy usage and promote sustainability. Data mining acts in the following aspects.

- Petrol waste analytics. By analyzing the data collected from vehicles, the trend of fuel consumption is predicted to improve combustion efficiency, which saves energy and reduces emissions.

- Emission control. Transportation emissions are the important source of greenhouse and toxic gas in the air. Data mining provides an effective method to develop a decision-making system or set a reference for policy makers.

It is worth noting that computing also consumes energy. When processing big data, the energy consumption resulted by computing facilities cannot be ignored. Many researchers or institutions [98,99,100] have carried out research on energy saving of computing platforms. For instance, Fricke et al. [101] proposed a system that takes advantage of computing ability of mobile phones to save energy. However, this area is relatively insufficiently studied, and more research efforts are necessary.

5.5. Cloud Computing and High-Performance Computing

Cloud computing, as an emerging technology, is defined by National Institute of Standards and Technology [102] as “a model for enabling ubiquitous, convenient, on-demand network access to a shared pool of configurable computing resources (e.g., networks, servers, storage, applications, and services) that can be rapidly provisioned and released with minimal management effort or service provider interaction”. Based on cloud computing, the concept of cloud manufacturing is proposed, which means a kind of customer-centric manufacturing that comes up with customer needs and keeps reconfiguring the resources and schedule so that the energy efficiency is increased, and production costs are reduced [14].

As one of the core enabler technologies of smart manufacturing, cloud computing is now transforming the way of manufacturing analytics. It saves a large quantity of cost by eliminating some traditional processes [103]. For example, some necessary operations to accomplish customization such as tweaks can be optimized by cloud computing. Hence, such changes can happen seamlessly. Elkay Manufacturing company succeeded in applying cloud computing to their production and obtained great benefits [104]. This saves cost mainly at the process level. Cloud computing can also benefit manufacturers at the enterprise level. By accelerating transactions between manufacturers and wholesalers, time can be significantly saved [103]. Other applications involve increasing operation efficiency and strengthening the collaborations, virtualization and product design [104,105].

Cloud manufacturing is a popular research domain. Topics in this domain mainly include automation, control, the platform architecture, and resource sharing and management [103,104]. For example, Valilai et al. [105] proposed a platform, called XML Layered Modular (XMLAYMOD) platform, to support distributed manufacturing systems, which implements cloud computing paradigm and service-oriented approach. Then they successfully applied the platform to product designing, process planning, and CNC machining. Zhang et al. [106] proposed a cloud computing platform to support cloud manufacturing. Yoo and Kim analyzed critical variables in the application of cloud computing regarding technology, organization, and environment. They also pointed out top management support, competitive pressure, and compatibility to be essential factors in employing cloud computing [107].

Since the timely response is required in cloud computing, the end server is required to have excellent computing capabilities. High-performance computing (HPC) on the cloud can serve as a good solution. According to Techopedia’s definition, “HPC is the use of supercomputers and parallel processing techniques for solving complex computational problems. HPC technology focuses on developing parallel processing algorithms and systems by incorporating both administration and parallel computational techniques”. [108] Typically, HPC is utilized to solve some complicated problems, such as large-scale simulation and modeling, which is infeasible to solve in a fast manner with normal computers. The applications of HPC include [108]:

- Oil and gas industry modeling

- Electronic design automation

- Climate modeling

- Media and entertainment

- Biosciences

By involving computer architecture, electronics, and other technologies, HPC on the cloud is a powerful tool for industrial analytics and business management. Many researchers conducted investigations on evaluating and improving the performance of cloud HPC. For example, Gupta et al. [109] evaluated the performance of HPC and showed that for low communication intensive applications, HPC on the cloud is more cost-effective. Hassani et al. [110] proposed a novel approach to enhance the performance and scalability of Amazon’s HPC cloud performance. Their study showed that using their method, Amazon’s HPC cloud can achieve over 20% acceleration compared with Pthreads and OpenMP. Expósito et al. [111] investigated the bottlenecks of HPC cloud on Amazon regarding shared memory, representative HPC codes and new cluster instances. They also proposed some techniques to reduce the cost and energy use.

HPC on the cloud is also an excellent solution to sustainable manufacturing. Because cloud computing is required to be instantly accessible to the computing resources, the data centers are necessary to guarantee the operation. However, when the demand is enormous, the energy consumption increases dramatically, which in return will cause more energy cost and more greenhouse gas emissions [112]. To address this issue, Garg et al. [112] introduced Dynamic Voltage Scaling to the near-optimal scheduling policies which combine the profit analysis and energy sustainability in the resource allocation. Their system leverages heterogeneity to perform computation and reduces 33% of the energy cost by lowering CPUs supply voltage.

5.6. Additive Manufacturing

The definition of additive manufacturing covers a wide field of production techniques that fabricate specially customized products in a layer-by-layer fashion. The development of smart manufacturing technologies is fast changing, and when it is coupled with increasing commercial demand, additive manufacturing (commonly known as 3D printing) shows numerous advantages in providing customized and specifically designed products [113]. With the adoption of additive manufacturing, the design-to-product cycle is shortened significantly, and resources including time, energy, and money are greatly saved. Hence, great industrial sustainability, as well as production efficiency, can be achieved [114].

Commonly adopted additive manufacturing technologies include Fused Deposition Modeling (FDM), Stereo-Lithography (SLA), Selective Laser Sintering (SLS), and Digital Light Processing (DLP) [115]. These manufacturing technologies have tremendous applications in various fields. Table 2 shows a summary of the applications and improvement in different fields with the additive manufacturing technologies [116,117,118].

Table 2.

Applications of Additive Manufacturing.

Some widely recognized characteristics of additive manufacturing technologies include direct production 3D CAD models, designs in the form of shared digital files, customized novel, complex structure, and final products with low porosity [118]. As such, additive manufacturing technology is a more advanced flexibility option that can lead to significant changes in the outcome of the market structure as well as the supply chain.

Through applying additive manufacturing techniques, we observe several outstanding advantages over traditional manufacturing techniques, such as mass customization and enhancing industrial sustainability and extending the lifespan of products [114,119]. This is because, by dematerialization and reconfiguration of the value chain due to redesigning of products, the required materials, components as well as energy consumption are reduced, so that the scale of material flows decreases, saving energy demands and bringing less environmental impact. As additive manufacturing is able to convert the material into customized products and services directly, it is identified as having the great potential to provide many sustainability advantages [119]. These advantages include the impact on the economy, the natural environment, and human society. The influence of environment and economy from additive manufacturing is interconnected.

Furthermore, additive manufacturing can be environmentally compatible with traditional manufacture processes for small to medium batch products with complex structures. Although the cost of additive manufacturing is still expensive, additive manufacturing is expected to be less costly in the future for larger products [114]. While the high performance of additive manufacturing may be most frequently encouraged by creation or capture of economic value, there are cases where behaviors are motivated by social and environmental values. For example, Filabot has the direct aim of commercializing technologies to reduce negative environmental impacts. Through taking something considered as waste, Filabot’s products can add value by supporting localized polymer recycling [114].

In summary, this section has reviewed the characteristics and strengths which can enable a more sustainable model of production as well as consumption in the smart manufacturing area. Given the examples, advantages, and applications mentioned above, it is clear that additive manufacturing will play a vital role in the transition towards a more sustainable industrial system since the applications of additive manufacturing technologies creates opportunities for more sustainable production and consumption. The exploitation of such opportunities will lead to changes in the distribution of manufacturing, reconfiguration of values chains, and simplification of supply chains.

6. Applications in Energy Industry

In this section, the current stage of sustainable energy solutions is first reviewed. Next, several smart manufacturing applications related to energy devices are discussed. Finally, we analyze current research and possible approaches to modeling, monitoring, and decision-making tasks in the energy industry.

6.1. Sustainable Energy

Sustainable energy is a broad concept. It includes renewable energies, such as solar energy, wind energy, hydropower, geothermal energy, bioenergy, marine energy, and all energies that supply the current consumption with insignificant influence on future energy and minimal or no negative impact on ecology, economy, and society [27]. In the following parts of this section, several sustainable energies with greatest shares in the current world energy supply are studied and evaluated based on their natural properties.

6.1.1. Solar Energy

The source of solar energy is the radiant light and heat from the Sun. Generally, solar energy is generated by collecting thermal energy through solar thermal systems and converting to electricity through photovoltaic systems. The most important advantage of solar energy is that it has almost unlimited energy supply with relatively balanced global distribution. Thus, solar energy is a competitive choice for less developed counties without access to other sustainable energies.

6.1.2. Wind Energy

Wind energy is generated by collecting the mechanical energy of the airflow through wind turbines. The cause of large-scale wind in nature is the differences in the atmospheric pressures, which are caused by the differences in absorption of solar energy. Hence, wind energy can be treated as an indirect use of solar energy. Electricity is the primary way of utilizing wind energy. In 2016, wind energy is the second most significant source of renewable electricity [43]. As a clean and renewable energy, wind energy not only produces no water or air pollution but also has low construction cost and maintenance requirements. Moreover, one of the most critical advantages of wind energy is that the land resources occupied by wind farm can be shared with other purposes [27].

6.1.3. Hydropower

Hydropower is harvested from the mechanical energy of falling water or fast running water. Because the water flowing in general changes slowly and has long seasonal patterns, hydropower is relatively stable, unlike unpredictable and rapidly fluctuating solar and wind power. The techniques for hydropower generation are relatively robust and developed. However, the extremely low geographical diversity limits the deployment of the hydropower plant in areas with limited water resources [27]. In 2016, the majority of renewable electricity is supplied by hydropower, which is 16% of the total world electricity. However, the growth of hydropower is slower than other renewable energies, and its share of renewable electricity falls 5.5% since 1990 [43].

6.2. Energy Devices Applications

In recent decades, the cost of sustainable energy system deployment falls dramatically. For example, in 2016, the price of a solar photovoltaic module to generate 1 W of power under a defined illumination intensity of 1 sun is one-sixth of the price in 2008 [120]. In addition to the increasing availability of new materials, smart design and manufacturing techniques is another factor that drives the decline of the manufacturing and deployment cost of energy devices. In the rest part of this section, several smart manufacturing applications related to energy production and storage devices are highlighted.

6.2.1. Energy Production Devices

Computer-aided simulation has been wildly used as a low-cost approach for optimizing product designs, including sustainable energy devices. However, due to the nonlinear effects as well as the complex and highly fluctuating environment the turbines subjected, challenges exist in the design of wind and hydro energy devices, such as blade and other structures of turbines. Software, tools, and frameworks for faster simulation and optimization are also highly desired. Benefited from the advancement of data analytics techniques, several data-driven optimization algorithms are proposed for the design tasks for wind and hydro turbines [121,122,123,124]. Moreover, the development of computational infrastructures, such as HPC, enhances the evaluation efficiency for complex models from hardware-level [125,126].

As mentioned in Section 5.6, additive manufacturing is a powerful tool for the low-cost and rapid production of industrial products or prototypes. For the solar panel industry, Vak et al. developed an additive manufacturing platform as a fabrication tool for solution-processed solar cells, and report three major advantages of adopting additive manufacturing for solar cell manufacturing. First, additive manufacturing enables users to test different device structures or designs without hardware changes. Second, additive manufacturing brings reproducibility and transferability into the solar panel industry, which allows users to share optimized printing conditions from machine to machine and from factory to factory. Third, additive manufacturing significantly reduces the time for the production of new parts and the fabrication of solar cell modules [127]. Wittbrodt et al. evaluated the potential of using additive manufacturing, as a low-cost solution, to accelerate the deployment of solar energy systems in developing conuntries [128]. The similar benefits are shared in wind and hydro energy industries [129,130,131,132]. Additionally, Han et al. discussed the potential of wind energy harvesters at the household level using low-cost and high-efficiency additive manufacturing technology [130]. Kamimura et al. adopted additive manufacturing for a scale-downed experiment to predict the performance of a new turbines design without a large-scale experiment [131].

6.2.2. Energy Storage Devices

Varieties of energy carriers, such as electricity, heat, and cooling, are integrated into the energy systems. The smart manufacturing techniques make the energy storage devices more affordable, more reliable, and cleaner and improve the sustainability in the energy industry.

In 2015, 27% of the final energy consumption in the industry was in the form of electricity, and the share of electricity is expected to rise to 40% by 2040 [43]. In addition, the rapid development of electric vehicles increases the demand for electricity storage in transportation. Among various kinds of energy storage systems, lithium-ion batteries are the most popular form of storage in the world and contribute more than 85% of power capacity in the deployed energy storage system in 2015 [133]. However, the cost, performance, reliability, and safety of batteries remain challenges in the energy industry. Luo et al. summarized the current research and development of crucial electrical energy storage technologies based on the types of energy stored [134]. Saw et al. analyzed the issues of integrating the lithium-ion battery into the electric vehicles battery pack, and provided a guideline for battery cell choice and cell integration approaches selection. Schünemann et al. proposed a cost-oriented model for electrode and cell production [135]. Aiming to improve the assembly quality of lithium-ion batteries in electric vehicles, Smart monitoring, modeling, and control techniques were developed for ultrasonic metal welding [35,83,136]. More research is required on battery manufacturing techniques for the goal of energy storage systems, such as long-term storage durations, reducing battery integration costs, and advanced battery recycling.

6.3. Smart Energy Systems

Benefited from the recent development in smart manufacturing technologies, more and more advanced data analytics techniques are integrated with modeling, monitoring, and decision-making technologies, and adopted in numerous studies related to the energy industry. The improvements are demonstrated by several applications in the rest of the sections.

6.3.1. Modeling

One of the challenges in wind energy system modeling is that wind has low predictability, and the performance of wind turbines is affected mainly by the wind profile. Because airflow is a chaotic aerodynamic system with nonlinear and complex behaviors, it is difficult for the traditional physical models and conventional statistical models to find the relationship between certain explanatory variables and future wind speed efficiently. Recently, several machine learning techniques, such as deep neural networks, show strong efficiencies in time series analysis of wind data for speed forecasting, and the predicted accuracy for both short-term and long-term get improved [137,138,139,140,141]. Hu et al. proposed a deep neural network architecture that transfers the high-level data patterns obtained from data-rich farms to a newly built farm and reduces the prediction errors significantly [142]. For wind power forecast and analysis, it is also crucial to have a model of wind-to-power relationship to describe the response of a turbine under different wind profiles. However, it is almost impossible to provide an analytical expression for such a complex turbine system. To address the challenges in wind turbine operation modeling, Ding et al. proposed sophisticated statistical methodologies to utilize real-world wind data and the corresponding turbine response data. The flexible modeling capability of the nonparametric data analytic methods they adopted is demonstrated by wind industry applications [143].

Similar challenges also exist in the modeling of the photovoltaic power generation system. Because the photovoltaic power is greatly affected by the weather condition, the output power will fluctuate greatly and thus is hard to be forecast accurately. A recent development of data analytic techniques provides powerful tools for the performance prediction of energy systems, such as neural network based modeling approach and ensemble empirical mode decomposition based forecasting method [144,145].

6.3.2. Monitoring

Compared with the traditional power plants that generate power by burning fossil fuels, sustainable energy factories, such as solar farms and wind farms, usually lay over a large area field, which makes generation monitoring a challenging task. Additionally, the growing deployment of self-driven sustainable energy systems, such as rooftop solar photovoltaic systems, increases the demands of remote or distributed monitoring systems. Smart manufacturing technology could be taken as possible approaches to addressing this problem. For example, Adhya et al. proposed an IoT based solar photovoltaic system for remote monitoring, analyzing, and controlling the power plant. This system could improve energy production efficiency by reducing manual supervision and assisting scheduling task of plant management. The potential of integrating solar power into utility grid is also promoted [146]. Han et al. developed a home energy management system using IoT technique, considering both energy consumption and renewable energy generation [147].

6.3.3. Decision-Making

As the development of smart infrastructures, like smart meters and IoT devices, the data volume in the energy industry is experiencing explosive growth. The most critical challenge in an intelligent energy system is how to take advantage of big data to reduce the cost and improve efficiency. Data analytics, HPC, and cloud computing techniques are useful for dynamic energy management in smart grids. Mohammed et al. evaluated the performance of a hybrid artificial neural network for short-term load forecasting [148]. Zhang et al. built a demand response system for energy management with learning-based optimization technique [149]. Lee et al. proposed a comprehensive multiple-criteria decision-making model, which consists of the interpretive structural modeling and fuzzy analytic network process, for the evaluation and selection of photovoltaic solar plant locations [150].

7. Prospective and Conclusion

In this paper, we first introduce the basic concepts of the two manufacturing paradigms and then discuss major promising technologies aiming to the 4th industrial revolution, in which the devotion to the sustainability is highlighted. Then we summarize the existing solutions to sustainable manufacturing, including renewable and clean energy, energy devices and systems. The relationship and gap between smart manufacturing and sustainable manufacturing are particularly discussed. The most remarkable advancement as well as the identified research gaps that need more investigation are summarized below:

- Deep learning and data mining are core techniques that drive the advancement of smart manufacturing and transform traditional manufacturing styles to modern paradigms. Nevertheless, sustainability and energy efficiency have not been fully considered. First, applications on sustainability and energy efficiency problems are less studied. This is partly because that those problems are essentially different with problems popularly studied in the computer science community regarding data types, data volume, and objectives. Furthermore, when developing smart manufacturing techniques, the consideration of energy efficiency and sustainability will yield multi-objective, multi-constraint problems, which can be so complicated that conventional methods are incapable.

- Cloud computing and HPC are key technologies of smart manufacturing. Nevertheless, the deployment of these supercomputing techniques in manufacturing is still at its nascent stage and requires substantial efforts. Particularly, the choice between cloud computing and HPC, how to effectively incorporate supercomputing powers into daily manufacturing practices, and cybersecurity issues need more investigation. Moreover, due to costly computation and maintenance, supercomputing facilities are a major energy consumption source themselves. Thus, research on reducing energy use, reducing maintenance cost, and achieving a tradeoff between performance and energy efficiency remains to be done.

- Additive manufacturing, as an innovative technique, has attracted a lot of interests from both industries and academia. It increases the customization of products and enables producing products with a complicated geometric shape. Although additive manufacturing is compatible with sustainable manufacturing, there are still many things researchers can do to improve sustainability, such as recycling materials. Additionally, the enhancement of product quality using inline sensing and monitoring, real-time control, and sampling inspection methodology also shows great potential in increasing the sustainability of additive manufacturing.

- Smart manufacturing technologies have improved the production efficiency and sustainability of some renewable energies with large shares. However, the applications for bioenergy and the energies with small shares are limited. The existing smart manufacturing approaches for large shares cannot be directly applied to small share applications as a result of different time scales, varied production rates, and different process dynamics. As such, fundamental research on extending existing methods and developing new methods is critically needed.

- The electricity storage devices have drawn many scholars’ attention, and the ongoing research has made some major progress in improving the quality and efficiency of battery manufacturing. To further enhance the sustainability in energy storage systems, research on industrial heat and cooling systems are highly desired. In addition, the deployment of big data based decision-making, such as online process monitoring, real-time control, and battery performance monitoring, is able to greatly promote quality and bring energy saving.

Given the increasing public awareness of environmental issues and the national policies, it is foreseen that more emphasis will be placed on sustainability in the development of techniques in smart manufacturing. The combination of clean energy, recycling materials, and smart manufacturing should receive more attention from researchers, engineers, business owners, and policymakers in the manufacturing community. In order to develop approaches tailored to these applications, we propose that more fundamental research is needed and nontrivial efforts are required in this aspect. For example, exploring the prognostic defects prediction method to avoid defects and save materials. Collective efforts are necessary to develop an integrated decision-making framework for smart and sustainable manufacturing.

Author Contributions

Investigation, Methodology, and Witing Original Draft, Y.M. and Y.Y.; Conceptualization, Writing—Review, and Editing: H.C., P.-H.L., and C.S.; Resources and Supervision, H.C. and C.S.

Funding

This research has been supported by a “Scholar-in-Residence” fund from the National Center for Supercomputing Applications (NCSA) at the University of Illinois at Urbana-Champaign.

Conflicts of Interest

The authors declare no conflict of interest. The funding sponsors had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, and in the decision to publish the results.

References

- Jiang, P.; Ding, K.; Leng, J. Towards a cyber-physical-social-connected and service-oriented manufacturing paradigm: Social Manufacturing. Manuf. Lett. 2016, 7, 15–21. [Google Scholar] [CrossRef]

- Mitsuishi, M.; Ueda, K.; Kimura, F. (Eds.) Manufacturing Systems and Technologies for the New Frontier; Springer: London, UK, 2008. [Google Scholar] [CrossRef]

- Shrouf, F.; Ordieres, J.; Miragliotta, G. Smart factories in Industry 4.0: A review of the concept and of energy management approached in production based on the Internet of Things paradigm. In Proceedings of the 2014 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Bandar Sunway, Malaysia, 9–12 December 2014; pp. 697–701. [Google Scholar]

- Lee, J.; Bagheri, B.; Jin, C. Introduction to cyber manufacturing. Manuf. Lett. 2016, 8, 11–15. [Google Scholar] [CrossRef]

- Davis, J.; Edgar, T.; Porter, J.; Bernaden, J.; Sarli, M. Smart manufacturing, manufacturing intelligence and demand-dynamic performance. Comput. Chem. Eng. 2012, 47, 145–156. [Google Scholar] [CrossRef]

- Mehdiyev, N.; Lahann, J.; Emrich, A.; Enke, D.; Fettke, P.; Loos, P. Time Series Classification using Deep Learning for Process Planning: A Case from the Process Industry. Procedia Comput. Sci. 2017, 114, 242–249. [Google Scholar] [CrossRef]

- Zerehsaz, Y.; Shao, C.; Jin, J. Tool wear monitoring in ultrasonic welding using high-order decomposition. J. Intell. Manuf. 2016, 1–13. [Google Scholar] [CrossRef]

- Baumers, M.; Ozcan, E. Scope for Machine Learning in Digital Manufacturing. arXiv, 2016; arXiv:1609.05835. [Google Scholar]

- Stanisavljevic, D.; Spitzer, M. A Review of Related Work on Machine Learning in Semiconductor Manufacturing and Assembly Lines; SAMI@ iKNOW: Graz, Austria, 18–19 October 2016. [Google Scholar]

- Weimer, D.; Scholz-Reiter, B.; Shpitalni, M. Design of deep convolutional neural network architectures for automated feature extraction in industrial inspection. CIRP Ann. 2016, 65, 417–420. [Google Scholar] [CrossRef]

- Chen, X.W.; Lin, X. Big Data Deep Learning: Challenges and Perspectives. IEEE Access 2014, 2, 514–525. [Google Scholar] [CrossRef]

- Zhekun, L.; Gadh, R.; Prabhu, B. Applications of RFID technology and smart parts in manufacturing. Proc. DETC 2004, 4, 1–7. [Google Scholar]

- Paul, S.; Rabbani, M.S.; Kundu, R.K.; Zaman, S.M.R. A review of smart technology (Smart Grid) and its features. In Proceedings of the 2014 1st International Conference on Non Conventional Energy (ICONCE), Kalyani, India, 16–17 January 2014; pp. 200–203. [Google Scholar]

- Wu, D.; Greer, M.J.; Rosen, D.W.; Schaefer, D. Cloud manufacturing: Strategic vision and state-of-the-art. J. Manuf. Syst. 2013, 32, 564–579. [Google Scholar] [CrossRef]

- Yu, C.; Xu, X.; Lu, Y. Computer-Integrated Manufacturing, Cyber-Physical Systems and Cloud Manufacturing—Concepts and relationships. Manuf. Lett. 2015, 6, 5–9. [Google Scholar] [CrossRef]

- Stephen, J. A Policymaker’s Guide to Smart Manufacturing; Report; Information Technology & Innovation Foundation: Washington, DC, USA, 2016. [Google Scholar]

- United States Environmental Protection Agency. Sources of Greenhouse Gas Emissions. Available online: https://www.epa.gov/ghgemissions/sources-greenhouse-gas-emissions (accessed on 1 September 2018).

- U.S. Energy Information Administration. Annual Energy Review 2011; Government Printing Office: Washington, DC, USA, 2012.

- The U.S. Energy Information Administration. Annual Energy Review. Available online: https://www.eia.gov/totalenergy/data/annual/#consumption (accessed on 1 September 2018).

- Ellabban, O.; Abu-Rub, H.; Blaabjerg, F. Renewable energy resources: Current status, future prospects and their enabling technology. Renew. Sustain. Energy Rev. 2014, 39, 748–764. [Google Scholar] [CrossRef]

- Brunke, J.C.; Johansson, M.; Thollander, P. Empirical investigation of barriers and drivers to the adoption of energy conservation measures, energy management practices and energy services in the Swedish iron and steel industry. J. Clean. Prod. 2014, 84, 509–525. [Google Scholar] [CrossRef]

- Bunse, K.; Vodicka, M.; Schönsleben, P.; Brülhart, M.; Ernst, F.O. Integrating energy efficiency performance in production management—Gap analysis between industrial needs and scientific literature. J. Clean. Prod. 2011, 19, 667–679. [Google Scholar] [CrossRef]

- Lee, C.M.; Choi, Y.H.; Ha, J.H.; Woo, W.S. Eco-friendly technology for recycling of cutting fluids and metal chips: A review. Int. J. Precis. Eng. Manuf. Green Technol. 2017, 4, 457–468. [Google Scholar] [CrossRef]

- Rogers, E.A. The Energy Savings Potential of Smart Manufacturing; American Council for an Energy-Efficient Economy: Washington, DC, USA, 2014. [Google Scholar]

- Liberati, A.; Altman, D.G.; Tetzlaff, J.; Mulrow, C.; Gøtzsche, P.C.; Ioannidis, J.P.; Clarke, M.; Devereaux, P.J.; Kleijnen, J.; Moher, D. The PRISMA statement for reporting systematic reviews and meta-analyses of studies that evaluate health care interventions: Explanation and elaboration. PLoS Med. 2009, 6, e1000100. [Google Scholar] [CrossRef] [PubMed]

- United States Environmental Protection Agency. Sustainable Manufacturing. Available online: https://www.epa.gov/sustainability/sustainable-manufacturing (accessed on 1 September 2018).

- Dincer, I.; Acar, C. A review on clean energy solutions for better sustainability: A review on clean energy solutions for better sustainability. Int. J. Energy Res. 2015, 39, 585–606. [Google Scholar] [CrossRef]

- Forum, W.E. CEO Policy Recommendations for Emerging Economy Nations China. Available online: http://reports.weforum.org/manufacturing-growth/china/?doing_wp_cron=1514099819.9172980785369873046875 (accessed on 1 September 2018).

- Commission, T.E. Key Enabling Technologies: Factories of the Future. Available online: http://ec.europa.eu/research/industrial_technologies/factories-of-the-future_en.html (accessed on 1 September 2018).

- Wang, S.; Wan, J.; Li, D.; Zhang, C. Implementing Smart Factory of Industrie 4.0: An Outlook. Int. J. Distrib. Sens. Netw. 2016, 12, 3159805. [Google Scholar] [CrossRef]

- Apostolos, F.; Alexios, P.; Georgios, P.; Panagiotis, S.; George, C. Energy Efficiency of Manufacturing Processes: A Critical Review. Procedia CIRP 2013, 7, 628–633. [Google Scholar] [CrossRef]

- Duflou, J.R.; Kellens, K.; Guo, Y.; Dewulf, W. Critical comparison of methods to determine the energy input for discrete manufacturing processes. CIRP Ann. Manuf. Technol. 2012, 61, 63–66. [Google Scholar] [CrossRef]