A Sustainable Decision-Making Framework for Transitioning to Robotic Welding for Small and Medium Manufacturers

Abstract

:1. Introduction and Literature Review

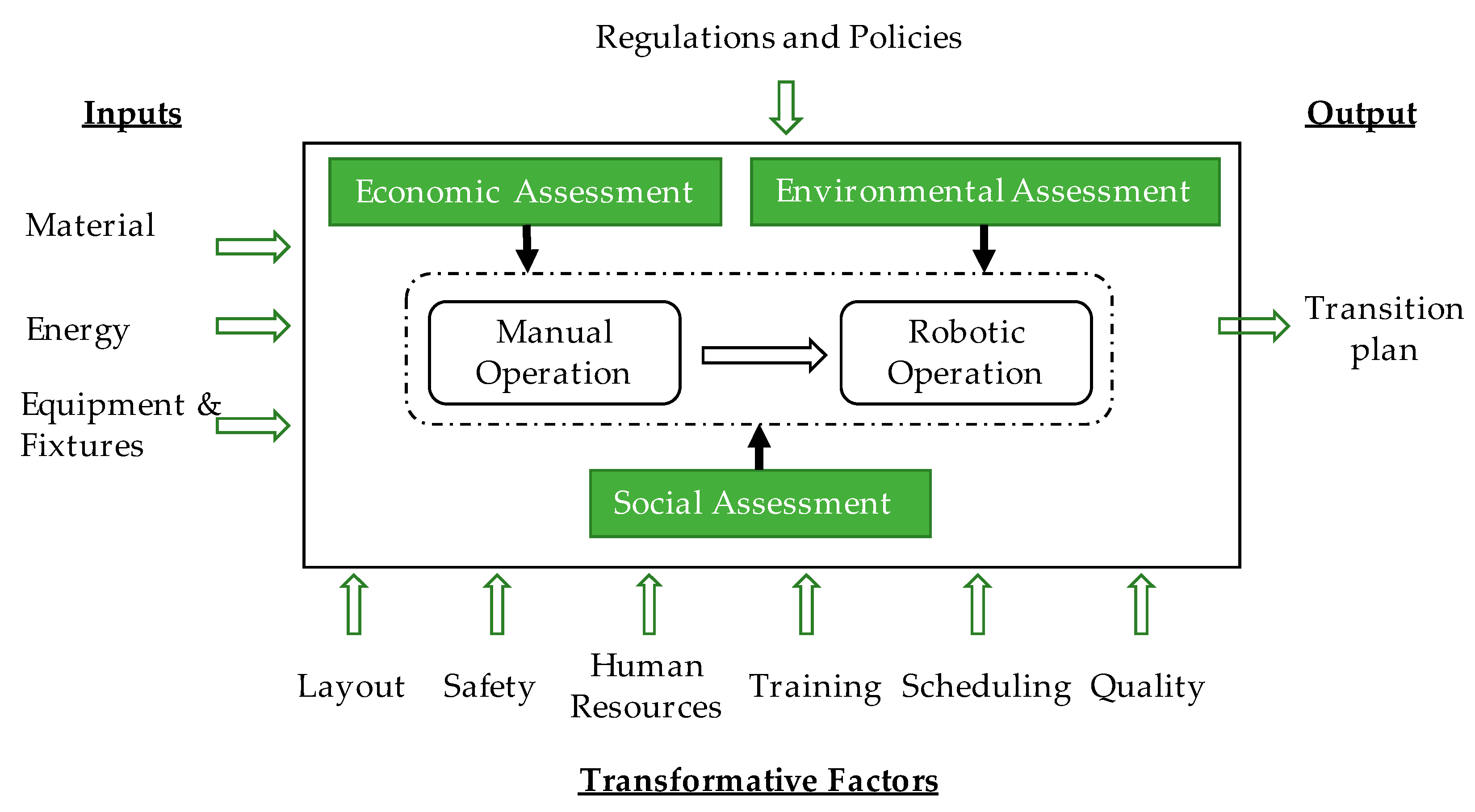

2. Methodology

2.1. Inputs and Transformative Factors

- Startup and command or programming procedures

- Location and installation requirements

- Possible human errors

- Typical robot malfunctions

- Scheduled and unscheduled maintenance

- Structural obstructions

- Energy drop in locations (electrical, air)

- Clear height below the structure, piping, fire protections

- Forklift travel aisles

- Raw material delivery locations

- Current machine layouts

- It must be functional for its required lifespan.

- It must be manufactured with specified materials along with design specifications for the process.

- It must be maintained properly throughout its required lifespan.

2.2. Economic Assessment

2.3. Environmental Impact Assessment

2.4. Social Impact Assessment

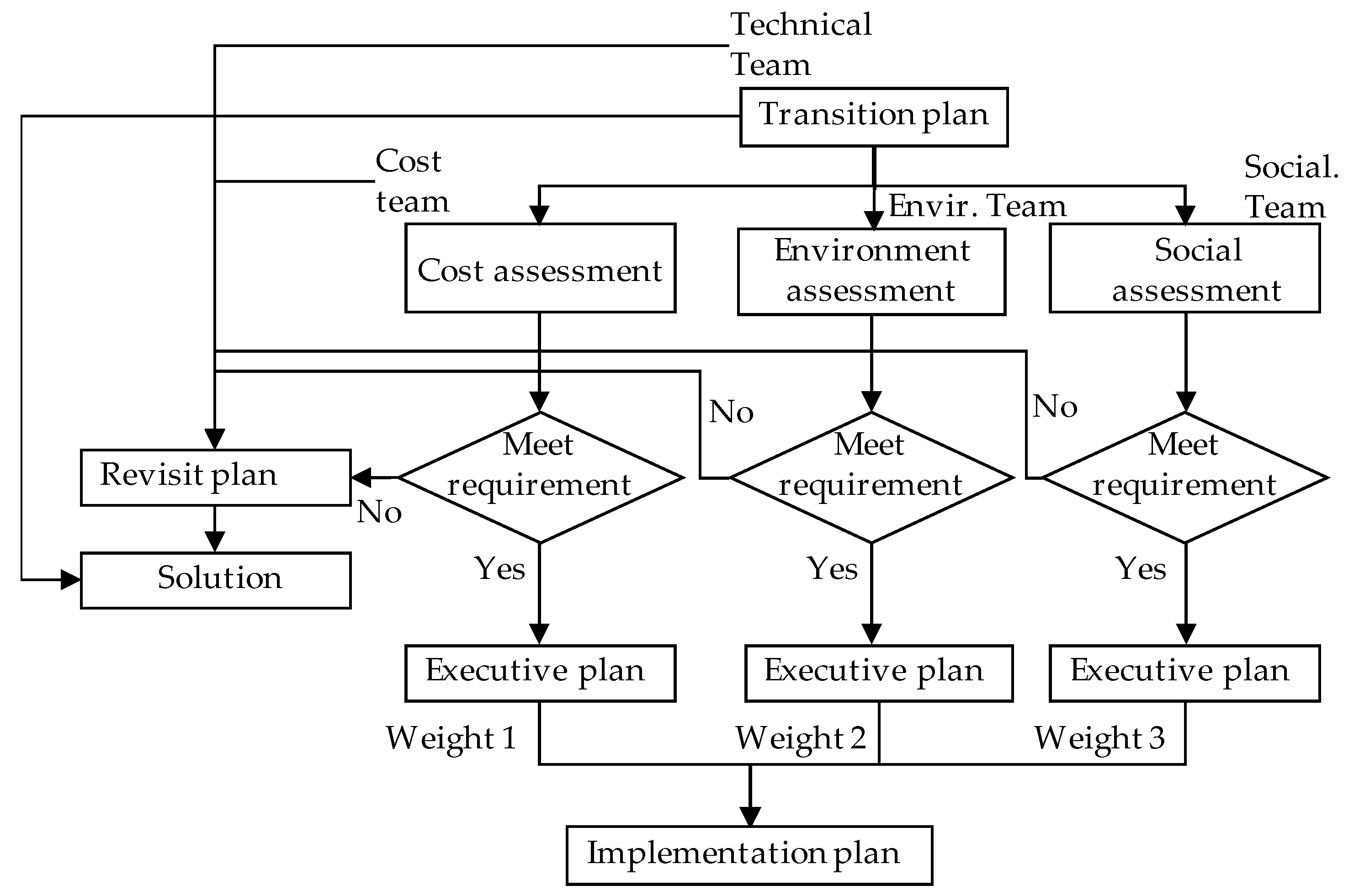

2.5. Application and Decision-Making of the Framework

3. Case Study

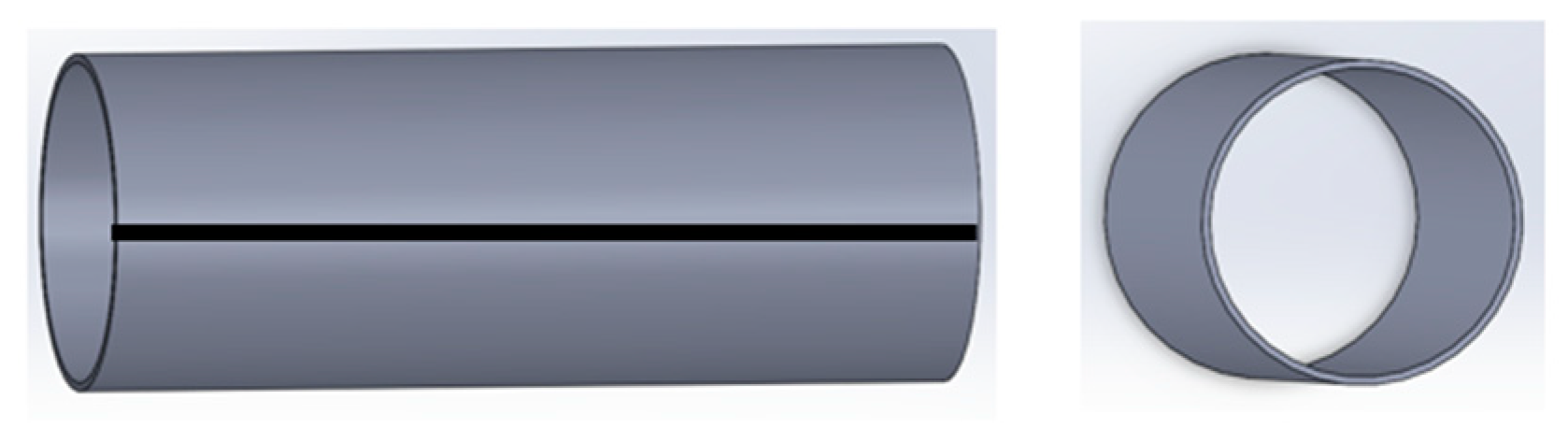

3.1. Case Background

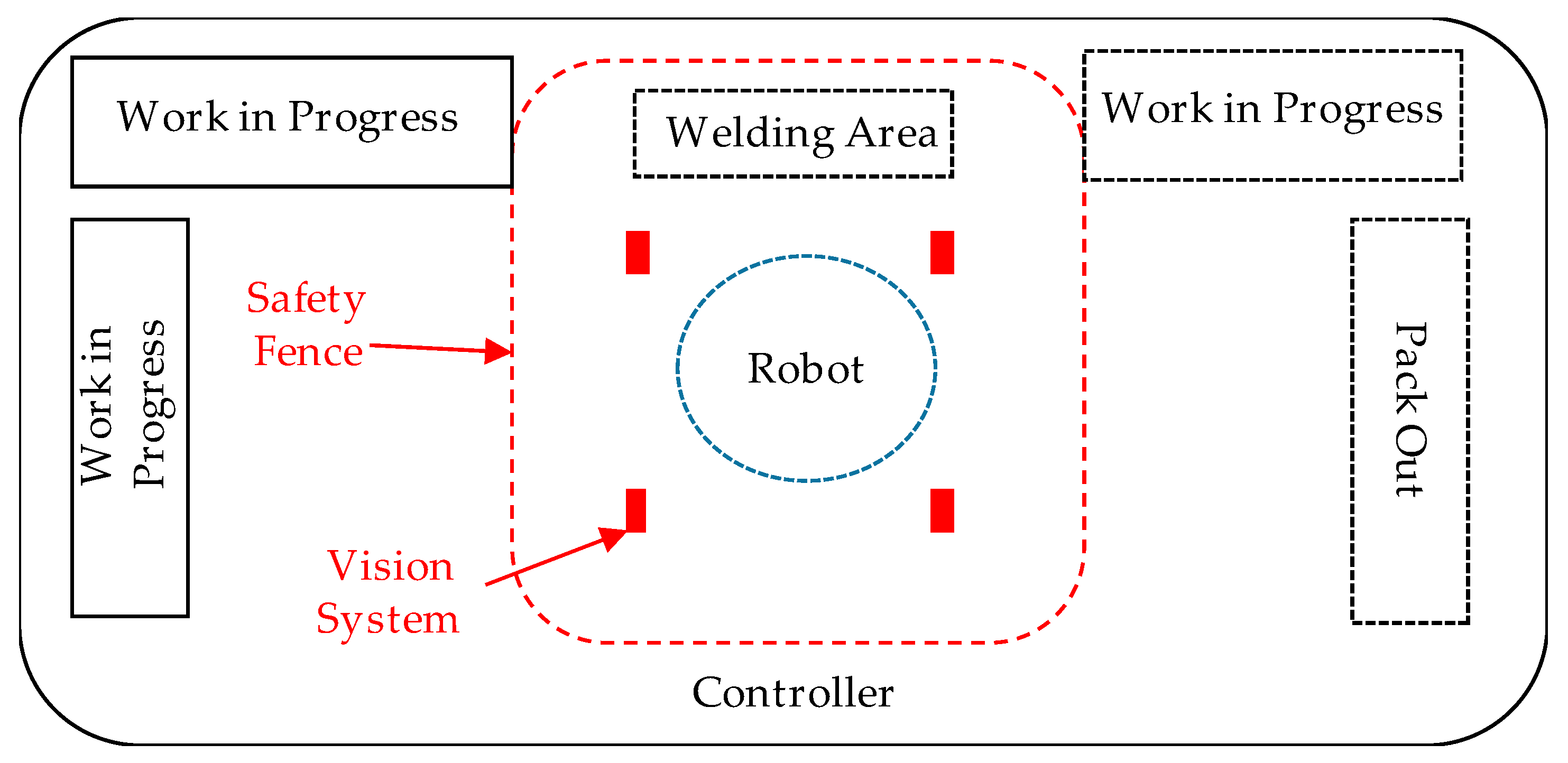

3.2. Inputs

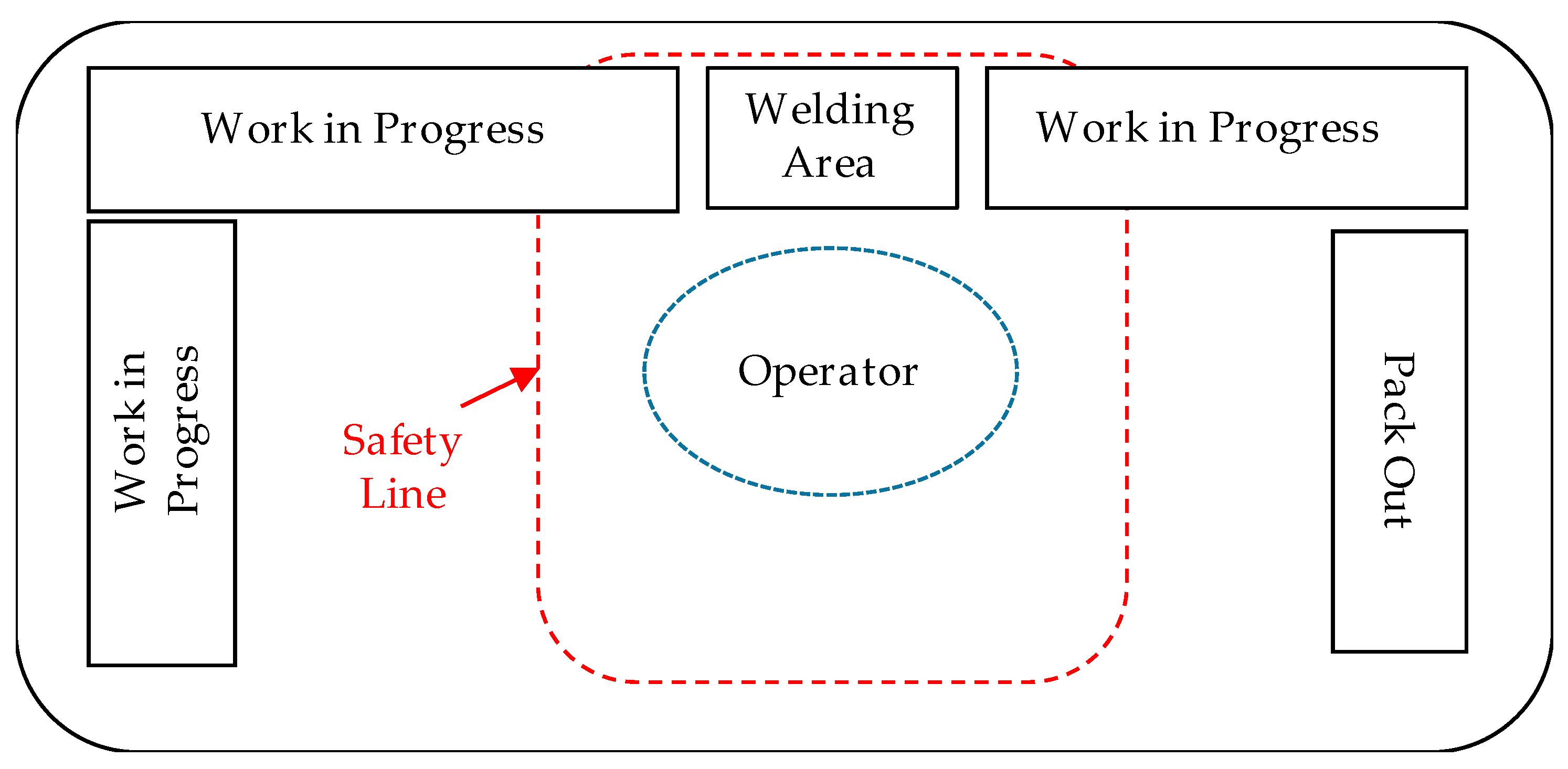

3.3. Transformative Factors

- Be retrained to operate and maintain the robot;

- Be retrained to work in a different area of the factory; or

- Leave the company.

3.4. Economic Assessment

3.5. Environmental Impact Assessment

3.6. Social Impact Assessment

3.7. Decision-Making

- The environmental impact of the robotic process does not violate regulations.In this case, the implementation plan can be carried out and use the new robotic process.

- The environmental impact violates regulations.

4. Discussion and Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Schröder, C. The Challenges of Industry 4.0 for Small and Medium-sized Enterprises; Friedrich Ebert Foundation: Bonn, Germany, 2015; pp. 1–28. [Google Scholar]

- Marvel, J.A.; Messina, E.R.; Antonishek, B.; Wyk, K.V.; Fronczek, L.J. Tools for Robotics in SME Workcells: Challenges and Approaches for Calibration and Registration; NIST Interagency Internal Report NISTIR-8093; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2015. [Google Scholar]

- Zhang, H.; Haapala, K.R. Integrating sustainable manufacturing assessment into decision making for a production work cell. J. Clean. Prod. 2015, 105, 52–63. [Google Scholar] [CrossRef]

- IFR (International Federation of Robotics). Executive Summary World Robotics 2017 Industrial Robots; International Federation of Robotics: Frankfurt, Germany, 2017; pp. 1–10. [Google Scholar]

- OECD. OECD Glossary of Statistical Terms—Small and Medium-Sized Enterprises (SMEs) Definition. Available online: https://stats.oecd.org/glossary/detail.asp?ID=3123 (accessed on 9 May 2018).

- Seidel, M.; Seidel, R.; Tedford, D.; Cross, R.; Wait, L. A Systems Modeling Approach to Support Environmentally Sustainable Business Development in Manufacturing SMEs. Int. J. Ind. Syst. Eng. 2008, 2, 1305–1313. [Google Scholar]

- McKeiver, C.; Gadenne, D. Environmental Management Systems in Small and Medium Businesses. Int. Small Bus. J. 2005, 23, 513–537. [Google Scholar] [CrossRef]

- Deuse, J.; Roßmann, J.; Kuhlenkötter, B.; Hengstebeck, A.; Stern, O.; Klöckner, M. A Methodology for the Planning and Implementation of Service Robotics in Industrial Work Processes. Procedia CIRP 2014, 23, 41–46. [Google Scholar] [CrossRef]

- Talalaev, R.; Sarkans, M.; Laansoo, A.; Veinthal, R. Methodology for Configuration of Robot Welding Cell for SMEs under Conditions of Small and Medium Sized Production Using MIG/MAG Process. In Proceedings of the 8th International DAAAM Baltic Conference, Tallinn, Estonia, 19–21 April 2012. [Google Scholar]

- Sarkans, M.; Roosimölder, L. Implementation of robot welding cells using modular approach. Est. J. Eng. 2010, 16, 317. [Google Scholar] [CrossRef]

- Ben-Horin, P.; Shoham, M. Singularity analysis of a class of parallel robots based on Grassmann–Cayley algebra. Mech. Mach. Theory 2006, 41, 958–970. [Google Scholar] [CrossRef]

- Bhangale, P.P.; Agrawal, V.P.; Saha, S.K. Attribute based specification, comparison and selection of a robot. Mech. Mach. Theory 2004, 39, 1345–1366. [Google Scholar] [CrossRef] [Green Version]

- Bruccoleri, M. Reconfigurable control of robotized manufacturing cells. Robot. Comput.-Integr. Manuf. 2007, 23, 94–106. [Google Scholar] [CrossRef]

- Dolinsky, J.U.; Jenkinson, I.D.; Colquhoun, G.J. Application of genetic programming to the calibration of industrial robots. Comput. Ind. 2007, 58, 255–264. [Google Scholar] [CrossRef]

- González-Galván, E.J.; Loredo-Flores, A.; Jesús Cervantes-Sánchez, J.; Antonio Aguilera-Cortés, L.; Skaar, S.B. An optimal path-generation algorithm for manufacturing of arbitrarily curved surfaces using uncalibrated vision. Robot. Comput.-Integr. Manuf. 2008, 24, 77–91. [Google Scholar] [CrossRef]

- Gultekin, H.; Ekin Karasan, O.; Akturk, M.S. Pure cycles in flexible robotic cells. Comput. Oper. Res. 2009, 36, 329–343. [Google Scholar] [CrossRef] [Green Version]

- Kim, I.-S.; Son, J.-S.; Yarlagadda, P.K.D.V. A study on the quality improvement of robotic GMA welding process. Robot. Comput.-Integr. Manuf. 2003, 19, 567–572. [Google Scholar] [CrossRef]

- Zacharia, P.T.; Aspragathos, N.A. Optimal robot task scheduling based on genetic algorithms. Robot. Comput.-Integr. Manuf. 2005, 21, 67–79. [Google Scholar] [CrossRef]

- Groover, M.P. Fundamentals of Modern Manufacturing, Binder Ready Version: Materials, Processes, and Systems, 6th ed.; Wiley: Hoboken, NJ, USA, 2015; ISBN 978-1-119-12869-4. [Google Scholar]

- Khan, I. Welding Science and Technology; New Age International Pvt Ltd. Publishers: New Delhi, India, 2009; ISBN 978-81-224-2073-9. [Google Scholar]

- DuPont, J.N.; Babu, S.; Liu, S. Welding of Materials for Energy Applications. Metall. Mater. Trans. A 2013, 44, 3385–3410. [Google Scholar] [CrossRef]

- Alkahla, I.; Pervaiz, S. Sustainability assessment of shielded metal arc welding (SMAW) process. IOP Conf. Ser. Mater. Sci. Eng. 2017, 244, 12001. [Google Scholar] [CrossRef] [Green Version]

- Moon, H.-S.; Na, S.-J. A neuro-fuzzy approach to select welding conditions for welding quality improvement in horizontal fillet welding. J. Manuf. Syst. 1996, 15, 392–403. [Google Scholar] [CrossRef]

- Lim, D.-C.; Gweon, D.-G. In-Process joint strength estimation in pulsed laser spot welding using artificial neural networks. J. Manuf. Syst. 1999, 18, 31–42. [Google Scholar] [CrossRef]

- Datta, S.; Nandi, G.; Bandyopadhyay, A. Application of entropy measurement technique in grey based Taguchi method for solution of correlated multiple response optimization problems: A case study in welding. J. Manuf. Syst. 2009, 28, 55–63. [Google Scholar] [CrossRef]

- Zhang, Y.; Gao, X.; Katayama, S. Weld appearance prediction with BP neural network improved by genetic algorithm during disk laser welding. J. Manuf. Syst. 2015, 34, 53–59. [Google Scholar] [CrossRef]

- Sharma, A. A fundamental study on qualitatively viable sustainable welding process maps. J. Manuf. Syst. 2018, 46, 221–230. [Google Scholar] [CrossRef]

- Chang, Y.-J.; Sproesser, G.; Neugebauer, S.; Wolf, K.; Scheumann, R.; Pittner, A.; Rethmeier, M.; Finkbeiner, M. Environmental and Social Life Cycle Assessment of Welding Technologies. Procedia CIRP 2015, 26, 293–298. [Google Scholar] [CrossRef]

- Nakhla, H.; Shen, J.Y.; Bethea, M. Environmental impacts of using welding gas. J. Technol. Manag. Appl. Eng. 2012, 28, 1–11. [Google Scholar]

- Sproesser, G.; Pittner, A.; Rethmeier, M. Increasing Performance and Energy Efficiency of Gas Metal Arc Welding by a High Power Tandem Process. Procedia CIRP 2016, 40, 642–647. [Google Scholar] [CrossRef]

- Sangwan, K.S.; Herrmann, C.; Egede, P.; Bhakar, V.; Singer, J. Life Cycle Assessment of Arc Welding and Gas Welding Processes. Procedia CIRP 2016, 48, 62–67. [Google Scholar] [CrossRef]

- Sproesser, G.; Chang, Y.-J.; Pittner, A.; Finkbeiner, M.; Rethmeier, M. Life Cycle Assessment of welding technologies for thick metal plate welds. J. Clean. Prod. 2015, 108, 46–53. [Google Scholar] [CrossRef]

- Vimal, K.E.K.; Vinodh, S.; Raja, A. Modelling, assessment and deployment of strategies for ensuring sustainable shielded metal arc welding process—A case study. J. Clean. Prod. 2015, 93, 364–377. [Google Scholar] [CrossRef]

- Jármai, K.; Snyman, J.A.; Farkas, J. Minimum cost design of a welded orthogonally stiffened cylindrical shell. Comput. Struct. 2006, 84, 787–797. [Google Scholar] [CrossRef]

- Patrick, C.W.; Newell, J.; William, F. Understanding Welding Cost: Using Flux-Cored Arc Welding (FCAW) for Cost Reduction and Productivity Improvement. ASME Proc. 2014. [Google Scholar] [CrossRef]

- Antonini, J.M.; Stone, S.; Roberts, J.R.; Chen, B.; Schwegler-Berry, D.; Afshari, A.A.; Frazer, D.G. Effect of short-term stainless steel welding fume inhalation exposure on lung inflammation, injury, and defense responses in rats. Toxicol. Appl. Pharmacol. 2007, 223, 234–245. [Google Scholar] [CrossRef] [PubMed]

- Mistry, P.K.J. Impact of Welding Processes on Environment and Health. Int. J. Adv. Res. Mech. Eng. Technol. 2015, 1, 17–20. [Google Scholar]

- Fard, M.H.; Fard, M.H. Impacts of weldiing on environmental problems and health and solutions to overcome these problems. In Proceedings of the 41st IASTEM International Conference, Paris, France, 15–16 December 2016. [Google Scholar]

- Hutchins, M.J.; Robinson, S.L.; Dornfeld, D. Understanding life cycle social impacts in manufacturing: A processed-based approach. J. Manuf. Syst. 2013, 32, 536–542. [Google Scholar] [CrossRef]

- Robotics Industries Association Robotics and Energy Cost Reduction. Available online: https://www.robotics.org/content-detail.cfm/Industrial-Robotics-Industry-Insights/Robotics-and-Energy-Cost-Reduction/content_id/1047 (accessed on 15 May 2018).

- OSHA Authority for 1910 Subpart Q—1910 Subpart Q|Occupational Safety and Health Administration. Available online: https://www.osha.gov/pls/oshaweb/owadisp.show_document?p_table=STANDARDS&p_id=10133 (accessed on 15 May 2018).

- Myhre, B.A.; McRuer, D. Human error—A significant cause of transfusion mortality. Transfusion 2000, 40, 879–885. [Google Scholar] [CrossRef] [PubMed]

- Wilson, M. Implementation of Robot Systems: An Introduction to Robotics, Automation, and Successful Systems Integration in Manufacturing; Butterworth-Heinemann: Oxford, UK, 2014; ISBN 978-0-12-404749-5. [Google Scholar]

- Dawande, M.; Geismar, H.N.; Pinedo, M.; Sriskandarajah, C. Throughput optimization in dual-gripper interval robotic cells. IIE Trans. 2009, 42, 1–15. [Google Scholar] [CrossRef]

- Rajapakshe, T.; Dawande, M.; Sriskandarajah, C. Quantifying the Impact of Layout on Productivity: An Analysis from Robotic-Cell Manufacturing. Oper. Res. 2011, 59, 440–454. [Google Scholar] [CrossRef]

- Yap, H.J.; Taha, Z.; Md Dawal, S.Z.; Chang, S.-W. Virtual Reality Based Support System for Layout Planning and Programming of an Industrial Robotic Work Cell. PLoS ONE 2014, 9. [Google Scholar] [CrossRef] [PubMed]

- ISO. ISO 9000:2015(EN), Quality Management Systems—Fundamentals and Vocabulary. Available online: https://www.iso.org/obp/ui/#iso:std:45481:en (accessed on 15 May 2018).

- Cole, R.J.; Sterner, E. Reconciling theory and practice of life-cycle costing. Build. Res. Inf. 2000, 28, 368–375. [Google Scholar] [CrossRef]

- Naval Education & Training Center. Navy Steelworker: Volume 1—Navedtra 14250—(Nonresident Training Course); Lulu.com: Morrisville, NC, USA, 2013; ISBN 978-1-304-27337-6. [Google Scholar]

- Kopacek, P.; Kopacek, B. End of Life Management of Automation and IT Devices. IFAC Proc. Vol. 2014, 47, 3503–3508. [Google Scholar] [CrossRef]

- ISO (International Organization for Standardization). ISO 14040:2006 Environmental Management—Life Cycle Assessment—Principles and Framwork; International Organization for Standardization: Geneva, Switzerland, 2006. [Google Scholar]

- Heijungs, R.; Guinée, J.B.; Huppes, G.; Lankreijer, R.M.; Udo de Haes, H.A.; Wegener Sleeswijk, A.; Ansems, A.M.M.; Eggels, P.G.; van Duin, R.; de Goede, H.P. Environmental Life Cycle Assessment of Products: Guide and Backgrounds (Part 1). Available online: https://openaccess.leidenuniv.nl/handle/1887/8061 (accessed on 7 August 2018).

- Guinée, J. (Ed.) Handbook on Life Cycle Assessment: Operational Guide to the ISO Standards; Eco-Efficiency in Industry and Science; Springer: Dordrecht, The Netherlands, 2002; ISBN 978-1-4020-0228-1. [Google Scholar]

- Goedkoop, M.; Heijungs, R.; Huijbregts, M.; Schryver, A.D.; Struijs, J.; van Zelm, R. ReCiPe 2008 A Life Cycle Assessment Method Which Comprises Harmonised Category Indicators at the Midpoint and the Endpoint Level; PRé Consultants: Amersfoort, The Netherlands, 2009. [Google Scholar]

- Keoleian, G.A. The application of life cycle assessment to design. J. Clean. Prod. 1993, 1, 143–149. [Google Scholar] [CrossRef]

- Benoît, C.; Norris, G.A.; Valdivia, S.; Ciroth, A.; Moberg, A.; Bos, U.; Prakash, S.; Ugaya, C.; Beck, T. The guidelines for social life cycle assessment of products: Just in time! Int. J. Life Cycle Assess. 2010, 15, 156–163. [Google Scholar] [CrossRef]

- Lee, W.-T.; Haapala, K.R.; Edwards, M.E.; Funk, K.H. A Framework for the Evaluation and Redesign of Human Work Based on Societal Factors. In Leveraging Technology for a Sustainable World; Springer: Berlin/Heidelberg, Germany, 2012; pp. 575–580. ISBN 978-3-642-29068-8. [Google Scholar]

- Sproesser, G.; Chang, Y.-J.; Pittner, A.; Finkbeiner, M.; Rethmeier, M. Sustainable Technologies for Thick Metal Plate Welding. In Sustainable Manufacturing; Sustainable Production, Life Cycle Engineering and Management; Springer: Cham, Switzerland, 2017; pp. 71–84. ISBN 978-3-319-48513-3. [Google Scholar] [Green Version]

- ASPE Poverty Guidelines. Available online: https://aspe.hhs.gov/poverty-guidelines (accessed on 6 August 2018).

- Spiegel-Ciobanu, V.E. Occupational health and safety regulations with regard to welding and assessment of the exposure to welding fumes and of their effect. Weld. Cut. 2012, 11, 61. [Google Scholar]

- Lincoln Electric. Aluminum GMAW—Gas Metal Welding for Aluminum Guide; The Lincoln Electric Company: Cleveland, OH, USA, 2016. [Google Scholar]

- Decker, M.; Fischer, M.; Ott, I. Service Robotics and Human Labor: A first technology assessment of substitution and cooperation. Robot. Autom. Syst. 2017, 87, 348–354. [Google Scholar] [CrossRef] [Green Version]

- Ecoinvent Ecoinvent Version 3. Available online: https://www.ecoinvent.org/database/database.html (accessed on 15 May 2018).

- Bureau of Labor Statistics Harrisonburg, VA—May 2017 OES Metropolitan and Nonmetropolitan Area Occupational Employment and Wage Estimates. Available online: https://www.bls.gov/oes/current/oes_25500.htm#(8) (accessed on 6 August 2018).

- Zhang, H.; Haapala, K.R. Integrating Sustainability Assessment into Manufacturing Decision Making. In Leveraging Technology for a Sustainable World; Dornfeld, D.A., Linke, B.S., Eds.; Springer: Berlin/Heidelberg, Germany, 2012; pp. 551–556. ISBN 978-3-642-29068-8. [Google Scholar]

- Mahbub, N.; Oyedun, A.O.; Zhang, H.; Kumar, A.; Poganietz, W.-R. A life cycle sustainability assessment (LCSA) of oxymethylene ether as a diesel additive produced from forest biomass. Int. J. Life Cycle Assess. 2018. [Google Scholar] [CrossRef]

- Zhang, H.; Calvo-Amodio, J.; Haapala, K.R. A conceptual model for assisting sustainable manufacturing through system dynamics. J. Manuf. Syst. 2013, 32, 543–549. [Google Scholar] [CrossRef]

- Zhang, H.; Amodio-Calvo, J.; Haapala, K. A Systems Thinking Approach for Modeling Sustainable Manufacturing Problems in Enterprises. In Proceedings of the International Annual Conference (IAC) of the American Society for Engineering Management (ASEM), Minneapolis, MI, USA, 17–20 October 2013. [Google Scholar]

- Schenker, S.; Vierhaus, I.; Borndörfer, R.; Fügenschuh, A.; Skutella, M. Optimisation Methods in Sustainable Manufacturing. In Sustainable Manufacturing; Sustainable Production, Life Cycle Engineering and Management; Springer: Cham, Switzerland, 2017; pp. 239–253. ISBN 978-3-319-48513-3. [Google Scholar] [Green Version]

- Turki, S.; Rezg, N.; Turki, S.; Rezg, N. Impact of the Quality of Returned-Used Products on the Optimal Design of a Manufacturing/Remanufacturing System under Carbon Emissions Constraints. Sustainability 2018, 10, 3197. [Google Scholar] [CrossRef]

| Dimension | Value | Unit |

|---|---|---|

| Part area (Al) | 30,000 | mm2 |

| Rod length | 1000 | mm |

| Workpiece length | 300 | mm |

| Workpiece diameter | 100 | mm |

| Wall thickness of workpiece | 3 | mm |

| Volume of cylinder | 23.55 | cm3 |

| Manual | Robotic | ||||

|---|---|---|---|---|---|

| Material | Value (%) | Weight (kg) | Material | Value (%) | Weight (kg) |

| Al | 99.8 | 0.42415 | Al | 94.35 | 0.42796 |

| Fe | 0.13 | 0.00055 | Fe | 0.8 | 0.00363 |

| Si | 0.02 | 0.00008 | Si | 4.5 | 0.02041 |

| Cu | 0.01 | 0.00004 | Cu | 0.3 | 0.00136 |

| Mn | 0.05 | 0.00021 | Mn | 0.05 | 0.00023 |

| Manual | Robotic | Unit | |

|---|---|---|---|

| Arc time | 78.7402 | 28.3465 | s |

| Gas flow rate | N/A | 0.0003 | m3/s |

| Cost of gas per cubic meter | N/A | 0.1060 | $ |

| Electrode costs | 1 | 1.21 | $/part |

| Total shielding gas cost | N/A | 0.0008 | $/part |

| Manual | Robotic | Unit | |

|---|---|---|---|

| Welding current | 250.00 | 350.00 | Amps |

| Welding voltage | 25.00 | 24.00 | Volts |

| Idle power | 50 | 60 | w |

| Power source efficiency | 0.50 | 0.80 | % |

| Arc time | 78.74 | 28.35 | s |

| Power cost rate (kW hour) | 0.12 | 0.12 | $/kWh |

| Idle power cost per part | 0.00049 | 0.000017 | $/part |

| Electric power total cost | 0.33 | 0.01 | $/part |

| Manual | Robotic | Unit | |

|---|---|---|---|

| Arc time | 78.74 | 28.34 | s |

| Deposition rate | 0.00061 | 0.0017 | kg/s |

| Operator factor | 0.35 | 0.8 | % |

| Kilograms of weld deposit | 0.048 | 0.048 | kg |

| Labor and overhead cost per part | 0.005 | 0.00008 | $/s |

| Total welding time | 224.9 | 35.4 | s |

| Total labor and overhead cost | 1.13 | 0.003 | $ |

| Manual | Robotic | Unit | |

|---|---|---|---|

| Annual parts produced | 91,440 | 254,000 | parts |

| Equipment cost | 489 | 50,000 | $ |

| Total equipment cost (per part) | 0.0053 | 0.197 | $/part |

| Characteristic | Manual | Robotic |

|---|---|---|

| Shielding gas cost | $- | $0.0008 |

| Electrical power cost | $0.33 | $0.01 |

| Labor and overhead cost | $1.13 | $0.003 |

| Electrode costs | $1.00 | $1.20 |

| Equipment cost | $0.01 | $0.197 |

| Total cost per part | $2.47 | $1.42 |

| Impact Category | Manual | Robotic |

|---|---|---|

| Climate change (kg CO2-equiv) | 3.39 × 10−1 | 5.79 × 10−1 |

| Terrestrial acidification (kg SO2 eq.) | 6.84 × 10−4 | 1.76 × 10−3 |

| Freshwater eutrophication (kg P eq.) | 5.22 × 10−7 | 6.20 × 10−7 |

| Ozone depletion (kg CFC-11 eq.) | 1.23 × 10−11 | 9.5 × 10−12 |

| Fossil depletion (kg oil eq.) | 1.14 × 10−1 | 7.16 × 10−4 |

| Freshwater ecotoxicity (kg 1, 4 DB eq.) | 6.35 × 10−5 | 8.84 × 10−5 |

| Human toxicity (kg 1, 4 DB eq.) | 6.22 × 10−3 | 4.18 × 10−2 |

| Ionizing radiation (kg U235 eq.) | 5.64 × 10−2 | 5.92 × 10−2 |

| Marine ecotoxicity (kg 1, 4 DB eq.) | 4.19 × 10−6 | 3.80 × 10−4 |

| Marine eutrophication (kg N-equiv) | 3.69 × 10−5 | 6.49 × 10−5 |

| Metal depletion (kg Fe eq.) | 3.72 × 10−2 | 1.24 × 10−1 |

| Natural land transformation (m2) | −1.91 × 10−6 | 2.12 × 10−5 |

| Particulate matter formation (kg PM10 eq.) | 2.61 × 10−4 | 9.21 × 10−4 |

| Photochemical oxidant formulation (kg NMVOC) | 8.38 × 10−4 | 1.50 × 10−3 |

| Terrestrial ecotoxicity (kg 1, 4 DB eq.) | 3.45 × 10−6 | 2.54 × 10−5 |

| Water depletion (m3) | 1.17 | 1.51 |

| Income Comparison Standards (Plocal) | ||||||

|---|---|---|---|---|---|---|

| National Welder Mean ($/hour) | Virginia Welder Mean ($/hour) | Local Welder Mean ($/hour) | Local Annual Mean Income ($/year) | National Poverty Level ($/year) | Mean Virginia Income ($/year) | |

| Work cell: Pj = $18 | 18.69 | 21.58 | 17.97 | 41,080 | 25,100 | 53,980 |

| Pdifference | −0.69 | −3.58 | 0.03 | −3640 | 12,340 | −16,540 |

| Supervisor | Metal Fabricator | Assembler | Machinist | Inspector | Painting | |

|---|---|---|---|---|---|---|

| Local mean | $26.65 | $18.49 | $16.12 | $20.96 | $17.82 | $18.75 |

| Salary increase | $8.65 | $0.49 | –$1.88 | $2.96 | –$0.18 | $0.75 |

| Ep | Wp | L | R | Kb | GZ | |

|---|---|---|---|---|---|---|

| Manual | 3.48 | 1 | 1 | 1 | 4 | 13.92 |

| Robotic | 1.08 | 1 | 1 | 1 | 1 | 1.08 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Epping, K.; Zhang, H. A Sustainable Decision-Making Framework for Transitioning to Robotic Welding for Small and Medium Manufacturers. Sustainability 2018, 10, 3651. https://doi.org/10.3390/su10103651

Epping K, Zhang H. A Sustainable Decision-Making Framework for Transitioning to Robotic Welding for Small and Medium Manufacturers. Sustainability. 2018; 10(10):3651. https://doi.org/10.3390/su10103651

Chicago/Turabian StyleEpping, Kyle, and Hao Zhang. 2018. "A Sustainable Decision-Making Framework for Transitioning to Robotic Welding for Small and Medium Manufacturers" Sustainability 10, no. 10: 3651. https://doi.org/10.3390/su10103651

APA StyleEpping, K., & Zhang, H. (2018). A Sustainable Decision-Making Framework for Transitioning to Robotic Welding for Small and Medium Manufacturers. Sustainability, 10(10), 3651. https://doi.org/10.3390/su10103651