1. Introduction

Despite the fact that sustainable development has been considered a topic of interest since the 1980s [

1,

2], the transport sector has been one of the last sectors to develop relevant initiatives aimed at optimizing its operations from the environmental perspective. The road freight sector has been more concerned with minimizing the time and costs of its activity with the application of vehicle routing models since the 1950s [

3], or developing their own mathematical algorithms for the optimization of their activity based on the specific variables on the types of products, clients, type of fleet, geographical situation, etc. [

4]. These improvements have led, without it being its main objective, to fuel savings per ton-kilometer (tkm) transported and reductions of their environmental impacts. However, taking Europe as an example, while all sectors reduced a quarter of their greenhouse gas (GHG) emissions between 1990 and 2009, the transport sector increased almost a third of its emissions in the same period [

5]. This was mainly due to the increase in the domestic truck traffic, which despite representing only 3% of the vehicle fleet in the European Union (EU), produces almost a quarter of the total CO

2 emissions generated by the road transport sector [

6]. The CO

2 emissions produced by road freight increased by 36% between 1990 and 2010 [

7]. This increase stopped in 2010 due to the European economic crisis that began between 2008 and 2009. However, some projections have suggested that under this perspective, without the intervention of governments, GHG emissions produced by trucks will be, with respect to the 1990 levels, around 35% higher for the years, 2030 and 2050 [

8].

The energy consumption and GHG emissions of the sector are not being reduced as expected, mainly due to the difficulties in implementing energy efficiency measures in the road freight subsector and the difficulty of finding alternatives to diesel fuel [

9]. In contrast to the industrial sector where real-time emissions can be easily measured and thus different emission regulation and trading mechanisms can be established [

10], in the transport sector, due to its diffuse nature, the establishment of these mechanisms has been hampered. Policy planning for traffic emissions has commonly consisted of sub-national or municipal strategies, such as the implementation of low-emission zones or the improvement of traffic flow to reduce the concentration of air pollutants in specific areas, but these types of measures, instead of reducing them, are dispersing these air pollutants over a bigger geographical area [

11]. Measures to effectively reduce the environmental impacts in this sector have consisted in limiting, through regulations, the emissions of air pollutants, such as carbon monoxide (CO), nitrogen oxides (NOx), volatile organic compounds (VOC), and particulate matter (PM), of newly manufactured vehicles prior to entering the market [

12]. The existing regulations for the control of air polluting emissions around the world are based almost generally on the European standards [

13], US Environmental Protection Agency (EPA) [

14], or Japanese regulations [

15], from which most countries directly take the established limits for the specific standard or reference the limitation values of different standards [

16,

17]. Truck manufacturers have concentrated efforts into meeting these demanding standards by modifying engines and installing devices for the post-treatment of exhaust gases, such as exhaust gas recirculation valves and particulate filters, in order to reduce NOx and PM emissions, respectively. However, these efforts have negatively affected the fuel efficiency [

18,

19,

20]. In recent years, some manufacturers have shown technological improvements to meet the Euro VI standards by using selective catalytic reduction systems that use urea to reduce NOx emissions without significantly affecting the fuel consumption, obtaining a diesel consumption of up to 28 L/100 km for articulated trucks under optimal road and driving conditions during efficiency tests [

21,

22].

Although countries, such as Japan, the United States, Canada, and China [

8,

23], have incorporated legislative measures for the control of CO

2 emissions, the EU has yet to establish limits for these emissions from road freight heavy vehicles. In the EU, among the first initiatives to tackle GHG emissions was the Communication 2014/285 [

8] “Strategy to reduce fuel consumption and CO

2 emissions in heavy vehicles”. In addition, the series of documents that accompanied this communication highlighted the absence of GHG control measures as well as common and internationally recognized standards for their measurement. Recently, a surveillance system for heavy vehicles in the EU was proposed through a regulation that is expected to be published in 2019, which requires manufacturers to provide accurate data on the CO

2 emissions of their new trucks in order to collect information that will allow the future establishment of limits to GHG truck emissions in a suitable and uniform way [

23]. Despite the absence of measures to control CO

2 emissions during vehicle operation, the transport sector, particularly, freight transport, has voluntarily adopted standards to account for these emissions and energy consumption. Freight companies have been prompted by other sectors that have demanded a reduction in their contribution to the carbon footprint of their products, goods, or services. In Europe, the carbon footprint calculation has become popular since the entry into force of Directive 2003/87/EC [

24], which requires mandatory GHG reporting by companies in the energy and industrial subsectors with the highest energy use. Companies in other diffuse sectors, who were not included until 2009 in the Emissions Trading Scheme [

25], began to take an interest in their carbon footprint due to the benefits that it could bring to their organization and their products, such as higher market value, an increase in brand value, corporate image improvement, reduced insurance fees as well as an improvement in their credit ratings [

26]. Among these initiatives for fuel consumption and emissions accounting, they can be referenced to the related general tools for life cycle analysis, such as SimaPro [

27], GaBi [

28], Gemis [

29]; specific tools for the transport sector include Tremove [

30], COPERT [

31], MOVES [

32], GREET [

33], the decarbonization prediction model [

34], EcoTransIT [

35], the GHG Protocol tool for mobile combustion [

36], the World Ports Climate Initiative (WPCI) Carbon Footprinting Calculator [

37], the Third Party Road Freight CO

2 emissions pilot model [

38], the Network for Transport Measures (NTM) basic Freight Calculator [

39], Planung Transport Verkehr (PTV) Map & Guide [

40], Logistics Emissions Calculator (LogEC) [

41], Versit+ [

42]; and databases, reports, or methodologies, such as the European standard (EN) 16258 [

43], the GHG Protocol Corporate Standard [

44], the European Association for Forwarding, Transport, Logistics and Customs Services (CLECAT) guide [

45], Odette [

46], Panteia and Duoinlog [

47], the Intergovernmental Panel on Climate Change (IPCC) [

48], Ecoinvent [

49], IDEMAT [

50], the Handbook of Emission Factors for Road Transport (HBEFA) [

51], Lipasto [

52], the GHG Reporting Database [

53], the Department for Environment, Food and Rural Affairs (DEFRA) GHG conversion factors [

54], the European Monitoring and Evaluation Programme and the Environmental European Agency (EMEP/EEA) emission inventory guidebook [

55], the Joint Research Centre (JRC) technical reports [

56], and the Netherlands Organisation for applied scientific research (TNO) reports [

57].

Most of the aforementioned tools are currently based on the standard EN-16258 [

43] “Methodology for the calculation and declaration of energy consumption and greenhouse gases emissions in transport services (transport of goods and passengers)”. This standard is the first international standard to harmonize and standardize the procedures for the calculation and reporting of emissions and energy for the transport sector. This standard has been fully accepted among the European transport companies [

58] and represents a possible basis for future international standardization initiatives [

59]. The EN-16258 [

43] focuses the reporting of energy consumption and GHG emissions on the fuel life cycle analysis (Well-to-Wheels, WTW). The WTW analysis includes the generated impacts by the energy use in the vehicle (Tank-to-Wheels, TTW), plus the impacts of the extraction of the raw materials, transportation, transformation, and distribution of the fuel to the service station (Well-to-Tank, WTT). However, limiting the emissions accounting just to the GHGs narrows the analysis only to the climate change impact, leaving aside other environmental impacts associated with road freight services. Although accounting the energy consumption during the vehicle operation can calculate the fuel-dependent pollutants other than CO

2, such as emissions of sulfur dioxide (SO

2) and heavy metals contained in the fuel, the emissions of CO, NOx, methane (CH

4), nitrous oxide (N

2O), ammonia (NH

3), PM, and non-methane volatile organic compounds (NMVOC) do not depend proportionally on fuel consumption, but on other factors, such as the emission control technology and operating conditions. The emissions estimation through the mentioned tools for road transport commonly base the results on factors that only consider operation parameters, such as vehicle size, emission control technology, and some also look at the load factor, except for tools [

31,

32] that consider other important factors, such as the vehicle speed and the road gradients. However, the main limitation using even the most comprehensive available tools is the impossibility of considering the variations in speed and road gradients in the different slopes during a specific freight service. Therefore, it is necessary to use emission factors and a methodology that provides accurate results for each assessed case. Until there is a procedure for measuring pollutant emissions for diffuse sectors, its estimation is the only way to establish the objectives for its reduction and measure its degree of achievement. The emission factors and the fuel consumption calculation models that are incorporated in the different tools must be susceptible to improvements and updates based on experimentally obtained information.

This work aimed to advance research along that line. On the one hand, a method was proposed for the calculation of fuel consumption and TTW emissions during a road freight service. The method was based on the proposed procedure in the EMEP/EEA air pollutant emission inventory guidebook of 2016 [

55] and incorporated variables related to the characteristics of the route and the service itself that were identified from the study of three experiments. These adjustments allowed us to estimate more accurately fuel consumption to the actual measured figures, and consequently reduce the error of the proportional emissions. On the other hand, the emission factors were adjusted based on the inventory analysis for fuels other than 100% diesel fossil fuel, which affects the reliability of the estimation of the WTW emissions [

60]. From the results of the emission inventories for the WTT and TTW phases obtained with the new calculation method, an environmental impact assessment was performed for the three cases under study through the ReCiPe 2016 [

61] method with the tool for life cycle analysis SimaPro 8.5.0 [

27] and the Ecoinvent v3.4 [

49] database. Given that the production of fuels can generate impacts in categories other than those mainly affected by emissions from the operation of the vehicles, such as climate change, acidification, eutrophication, ozone depletion, and energy consumption [

62,

63], the 18 impact categories of the assessment method were considered.

2. Materials and Methods

In 2017, the EEA published the “EMEP/EEA air pollutant emission inventory guidebook 2016” [

55], which details the calculation methods and factors for fuel consumption and emissions with three levels of precision (tiers) for the vehicle operation phase or TTW analysis. These emission factors compiled in the EMEP/EEA [

55] guide were based on previous initiatives, such as Artemis [

64], Corinair [

65], the Methodologies to Estimate Emissions from Transport (MEET) project [

66], and HBEFA emission factors [

51].

The calculation model proposed by EMEP/EEA [

55] offers three approaches with different consumption and emission factors, depending on the data availability. Tier 1 provides emission factors based on the amount (kg) of fuel; Tier 2 provides emissions and fuel consumption factors per km traveled for different vehicle types and emission control technologies; and Tier 3 establishes a series of equations and factors to incorporate, in addition to the variables included in the Tier 2 method, others, such as the speed, the load factor, and the road gradient.

It should be noted that the Tier 2 and Tier 3 emission factors available for freight vehicles are only for diesel and gasoline engines, considering the correction factors for biodiesel and bioethanol mixtures, respectively. The considered emissions by the EMEP/EEA [

55] guide can be classified into four groups:

Group 1: Pollutants not directly dependent on fuel consumption, such as CO, NOx, CH4, N2O, NH3, NMVOC, and PM2.5.

Group 2: Estimated emissions based on the fuel, lube oil, and urea consumption, such as CO2, SO2, and heavy metals.

Group 3: Emissions of polycyclic aromatic hydrocarbons (PAHs), persistent organic pollutants (POPs), and dioxins and furans.

Group 4: NMVOC emissions, such as alkanes, cycloalkanes, alkenes, alkynes, aldehydes, and aromatics, calculated as a fraction of the total NMVOC.

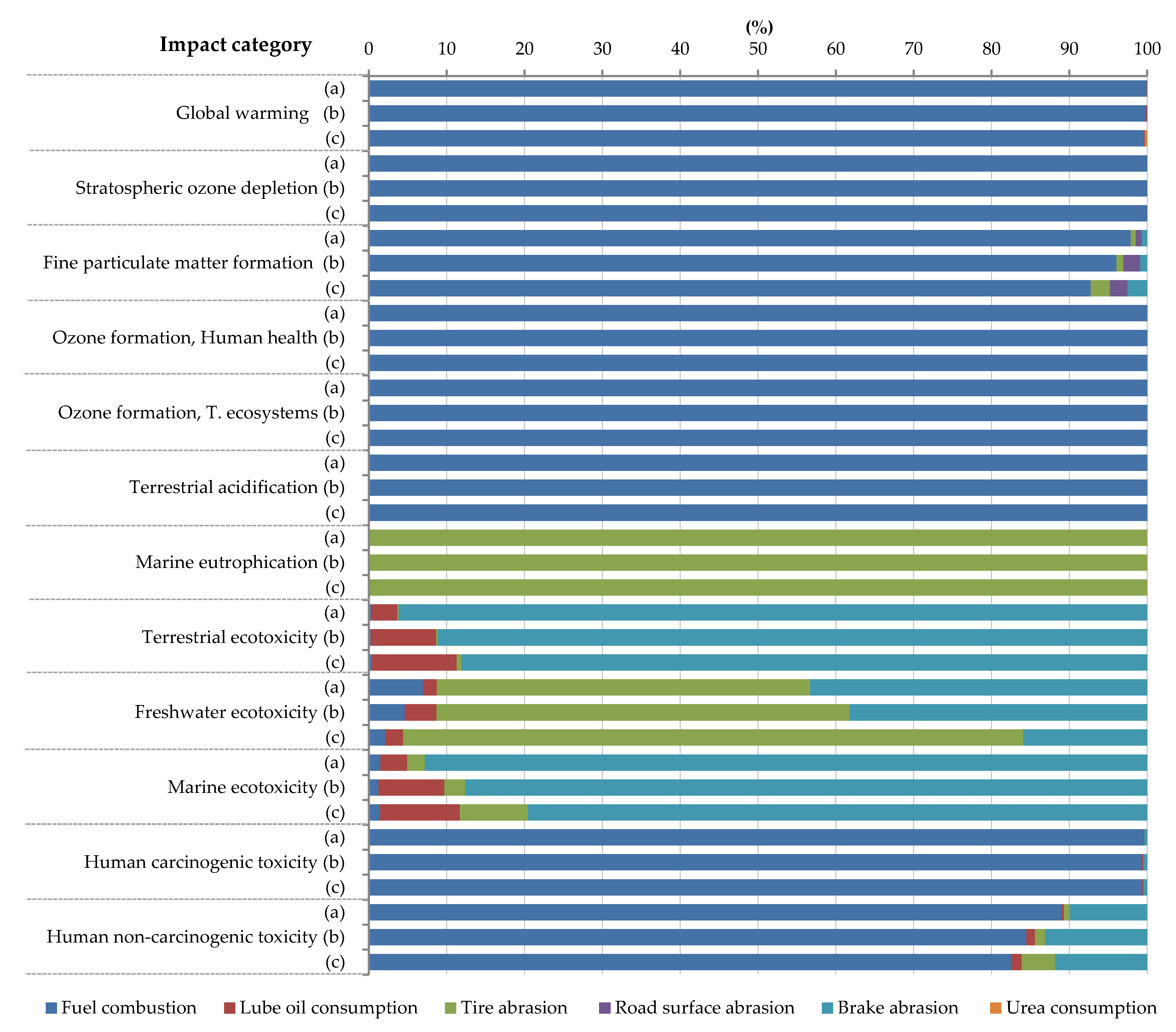

In addition to these pollutants derived from fuel, lube oil, and urea consumption, emissions from tires, brakes, and road surface abrasion were considered.

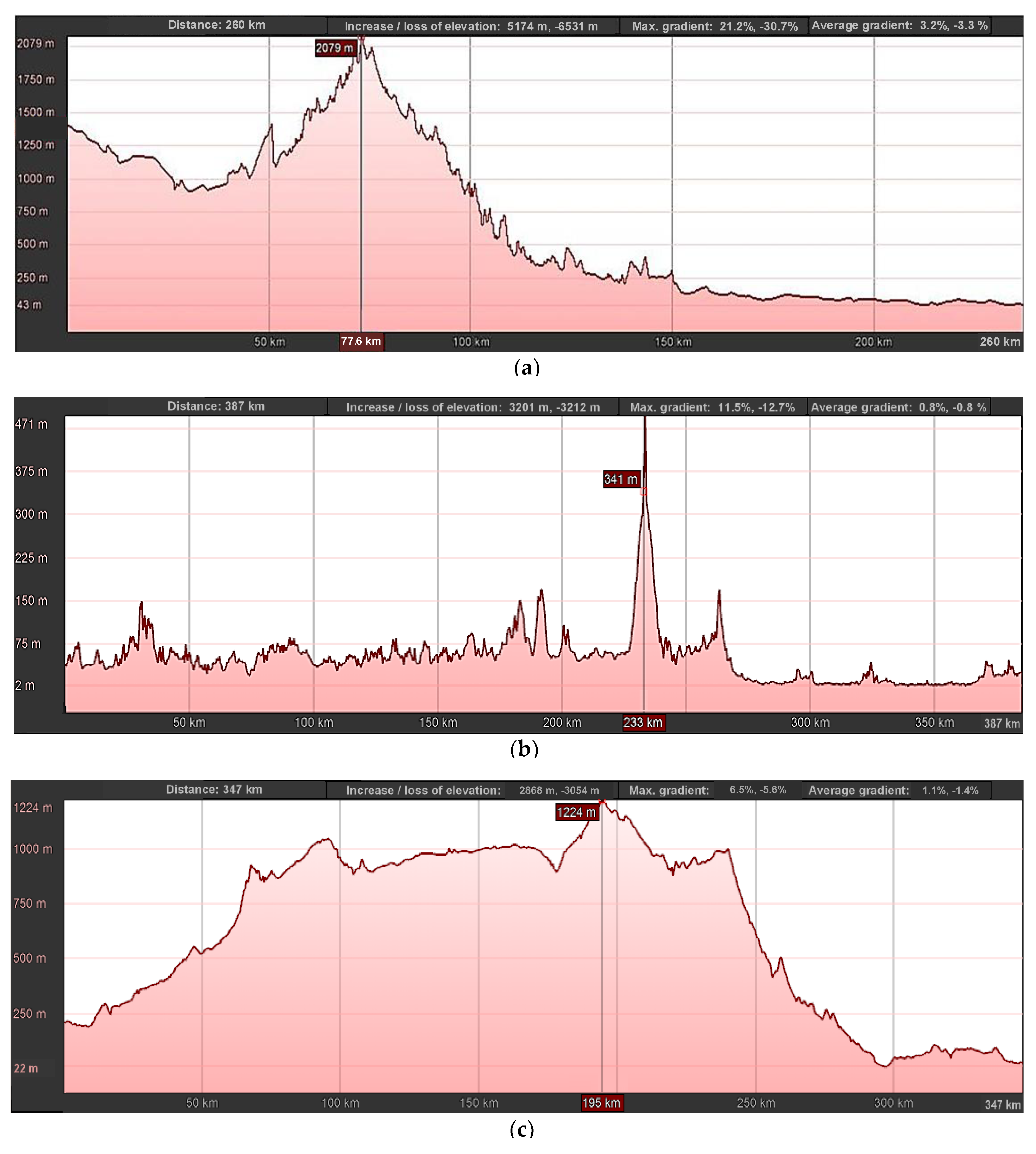

The proposed method for the energy consumption and emissions estimation for a specific road freight service basically seeks to individually analyze different sections of the route considering changes in the operating parameters, such as average speed and road gradient, as determined through the Google Earth Pro software [

67]. The accounting of emissions was elaborated based on the Tier 3 factors, equations, and coefficients from the EMEP/EEA [

55] guide.

The calculation of each of these pollutants was performed for each section of the route, which was divided considering significant changes in the circulation area (urban or interurban), number of lanes, traffic density, average speed, topology, or trend in the road gradient. The energy consumption, emission factors, and calculation equations for each group of pollutants are detailed in the following subsections.

2.1. Pollutants of Group 1

For the estimation of CO, NOx, VOC, and PM2.5 emissions and energy consumption, the Tier 3 method was used. For the CH4, N2O, and NH3 emissions, the Tier 2 emission factors were used, which are available by vehicle type, control emissions technology, and type of road circulation.

The Tier 3 method provides the coefficients for each type of vehicle and the emission control technology (conventional, Euro I–VI), load factor (0%, 50%, and 100%), and the road gradient (0%, ±2%, ±4%, and ±6%), based on the speed in each route section to be applied in Equation (1) [

55]:

where

EC is the Energy Consumption (MJ/km);

EF is the emission factor of CO, PM

2.5, NOx, and VOC (g/km);

V is the vehicle speed (km/h); and

RF a reduction factor. Coefficients (

α,

β,

γ,

δ,

ε,

ζ,

η) and the

RF are obtained from the 1.A.3.b.i-iv Road transport hot EFs Annex 2017, attached in the EMEP/EEA report [

55].

Based on the obtained results using the EMEP/EEA Equation (1) and the coefficients for 0% and 100% load factors, it is possible to calculate the energy consumption or emission factor for a partial load using the Equation (2), where the specific load factor,

LF, is from 0 to 1.

For the estimation of CH

4, N

2O, NO

2, and NH

3 gases, the emission factors per km were directly applied from

Table A1,

Table A2,

Table A3 and

Table A4. For the effect of biodiesel blends on emissions, the average emissions of CO, PM

2.5, NOx, and VOC were determined by the application of the variation rates presented in

Table A5, which are only recommended for Euro III or earlier vehicles, since for more modern vehicles, the variation is more difficult to predict due to the implementation of exhaust gas treatment systems [

55].

2.2. Pollutants of Group 2

2.2.1. Pollutants from fuel consumption

For the estimation of CO

2 and SO

2 emissions, the fuel characteristics were considered, such as the content of sulfur (

s), carbon (

c), hydrogen (

h), oxygen (

o), and nitrogen (

n). From these characteristics in mass terms, for the CO

2 calculation, Equations (3)–(5) were applied [

55]:

where

are the CO

2 emissions (kg) and

is the energy consumption (kg). If biofuel blends are used, the calculation of CO

2 emissions should be made by only considering the fraction of fossil diesel.

For the SO

2 calculation, Equations (6) and (7) were applied [

55]:

where

s is the sulfur content in parts per million (ppm).

where

are the SO

2 emissions (g), and

is the sulfur content (g/g).

The emission factors of heavy metals in ppm contained in the consumed fuel by heavy vehicles are presented in

Table A6.

2.2.2. Pollutants from lube oil consumption

The consumption of engine lube oil for heavy diesel trucks is on average 1.56 kg/10,000 km with an average CO

2 emissions of 0.486 g/km [

55]. From this consumption, the content of heavy metals in the lube oil used by heavy vehicles are presented in

Table A6.

2.2.3. Pollutants from urea consumption

In Euro V and Euro VI heavy-duty diesel engines, urea is used as a catalyst to reduce NOx emissions. The urea consumption generates CO

2 emissions, whose average emission factor is 0.26 kg CO

2/L or 0.238 kg CO

2/kg of urea solution [

55]. The urea solution has an urea content of 32.5% [

68]. If the amount of consumed urea is unknown, this consumption is assumed to be 6% or 3.5% of the diesel consumption in Euro V or Euro VI heavy vehicles, respectively [

55].

2.3. Other Pollutants

For the estimation of pollutants included in Group 3, the emission factors for diesel heavy vehicles for PAHs and POPs are presented in

Table A7, and those for the polychlorinated dibenzo dioxins (PCDDs), polychlorinated dibenzo furans (PCDFs), and polychlorinated biphenyls (PCBs) are presented in

Table A8.

For the pollutants included in Group 4, the fractions of alkanes, cycloalkanes, alkenes, alkynes, aldehydes, and aromatics, corresponding to 96.71% of the total NMVOC, are presented in

Table A9. The residual amount, that is, 3.29% of the total NMVOC, were considered HAPs.

The abrasion of brakes, tires, and the road surface generates particulate matter (PM>10, PM2.5–10, and PM<2.5) that contains metal and non-metal particles that are released into the air, water, and soil. The emission of particles from tire and brake abrasion was calculated based on the weight, number of axes, and speed in each section of the route; hence, this method was considered as Tier 2+.

For the calculation of the total particulate matter (TPM) of the tire abrasion of heavy vehicles, Equations (8) and (9) were applied [

55]:

where

is the load correction factor for tire abrasion;

is the number of axes;

is the total PM emission of tire abrasion (g/km); and

is the speed correction factor for tire abrasion. If V < 40 km/h, then

; if 40 km/h ≤ V ≤ 90 km/h, then

; and if V > 90 km/h, then

.

For the calculation of the TPM of brake abrasion in heavy vehicles, Equations (10) and (11) were applied [

55]:

where

is the load correction factor for brake abrasion;

is the total PM emissions of brake abrasion (g/km); and

is the speed (V) correction factor for brake abrasion. If V < 40 km/h, then

; if 40 km/h ≤ V ≤ 95 km/h, then

; and if V > 95 km/h, then

.

For the calculation of the TPM from road surface abrasion by heavy vehicles, an average factor of 0.076 g/km was used [

55]. From the TPM emissions calculated for each origin, it is necessary to specify what type of particles are contained in this total by the fractions shown in

Table A10. Additionally, in the TPM emissions of tires and brakes, there is a content of different metal and non-metal elements and PAHs, which are presented in

Table A11. Of the TPM produced by brake abrasion, 100% is released into the air, while of the total produced by tire abrasion, 14% goes into air, 43% into water, and 43% into soil [

27,

49].

4. Discussion

The application of the proposed method for the accounting of TTW emissions for road freight services in the three different locations demonstrates the increase in the accuracy and reliability of this type of calculation through route sections, especially in roads on rugged terrains and with high gradients as in the assessed case in Colombia. In this analyzed service in Colombia, the use of Tier 2 fuel consumption and emission factors from databases or generic tools, developed with data for standard conditions in European or North American countries, generated very high uncertainties when they were applied in different geographies. The diesel consumption on mountainous roads for a fully loaded rigid truck in Colombia was 45 L/100 km, compared to averages between 22–26 L/100 km that are usually applied from other sources. In contrast, the diesel consumption for an articulated truck on a hilly road in Spain from both the proposed method and generic databases coincided with an average of 31 L/100 km. These figures coincided with the average European road type, with traffic at a speed limit of 90 km/h, which is why this journey obtained a similar fuel consumption to the average calculated for the factors in Tier 2. The estimated figure through the Tier 3 method by sections was the closest to the average for this route, which can vary up to 5%, according to the company’s technical director. It is noteworthy that the average consumption for trucks in Europe varies only approximately 10% between a flat and a mountainous road [

87] due to the developed infrastructure with several tunnels and viaducts, something nonexistent for the analyzed route in Colombia between two capital cities. In this route, trucks must travel the Western mountain range on narrow roads with fog, sharp curves, high gradients, and unpaved or damaged sections due to landslides. For this reason, the distance of the analyzed route could be done in approximately 4 h in Europe, while the Pereira–Quibdo route takes more than 8 h. In the case of Malaysia, the fuel consumption figures obtained by both the Tier 2 and Tier 3 methods by sections were very similar, but both were also below the actual average for the route. This uncertainty could be produced mainly because none of the methods can account for the extra consumption in dense traffic conditions in urban areas, a variable that affected the analyzed service given that the truck must cross Kuala Lumpur City from south to north through streets with very dense traffic.

The results through the Tier 3 method by sections, despite being closer to the actual consumption than the results obtained with the Tier 2 and Tier 3 method for the entire journey, might have omitted the additional consumption that is generated in the gear shift on each of the slopes in each section, plus many of these slopes have gradients above the average gradient of each analyzed section. On the other hand, the method does not consider the altitude, the age of the truck, or the driving style, factors that significantly influence the actual fuel consumption [

6,

88,

89,

90,

91]. It is estimated that an efficient driving style can save on average between 5 and 12% [

92], and even up to 25% of fuel [

93].

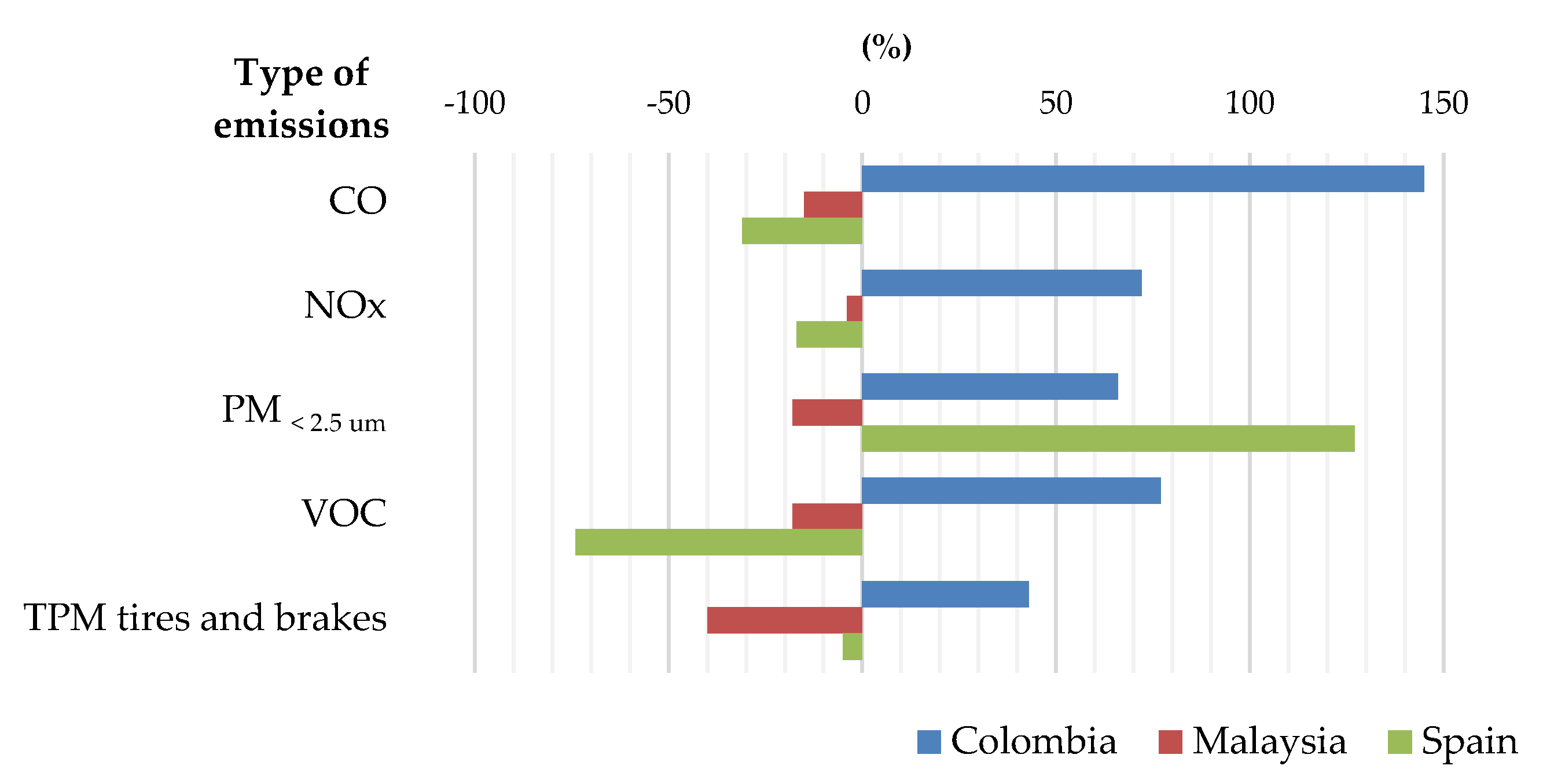

For the assessed case in Spain, due to the similarity in fuel consumption estimations from both the Tier 2 and Tier 3 methods, it could be thought that the use of Tier 2 factors for the estimation of emissions from vehicle operation could be acceptable. However, there are emissions that greatly vary depending on operating parameters, such as air pollutants and tire and brake abrasion emissions. This was demonstrated by the proposed calculation method by sections, where for the loaded truck for the outward journey, a consumption of 35.7 L/100 km was obtained compared to the return of 26.6 L/100 km, which indicates that the quantity of released polluting gases can also vary significantly in each journey. Analyzing the variation rate in the generation of air pollutants obtained by the Tier 3 method by sections compared to the Tier 2 method, very significant changes of up to 145% can be observed in

Figure 4.

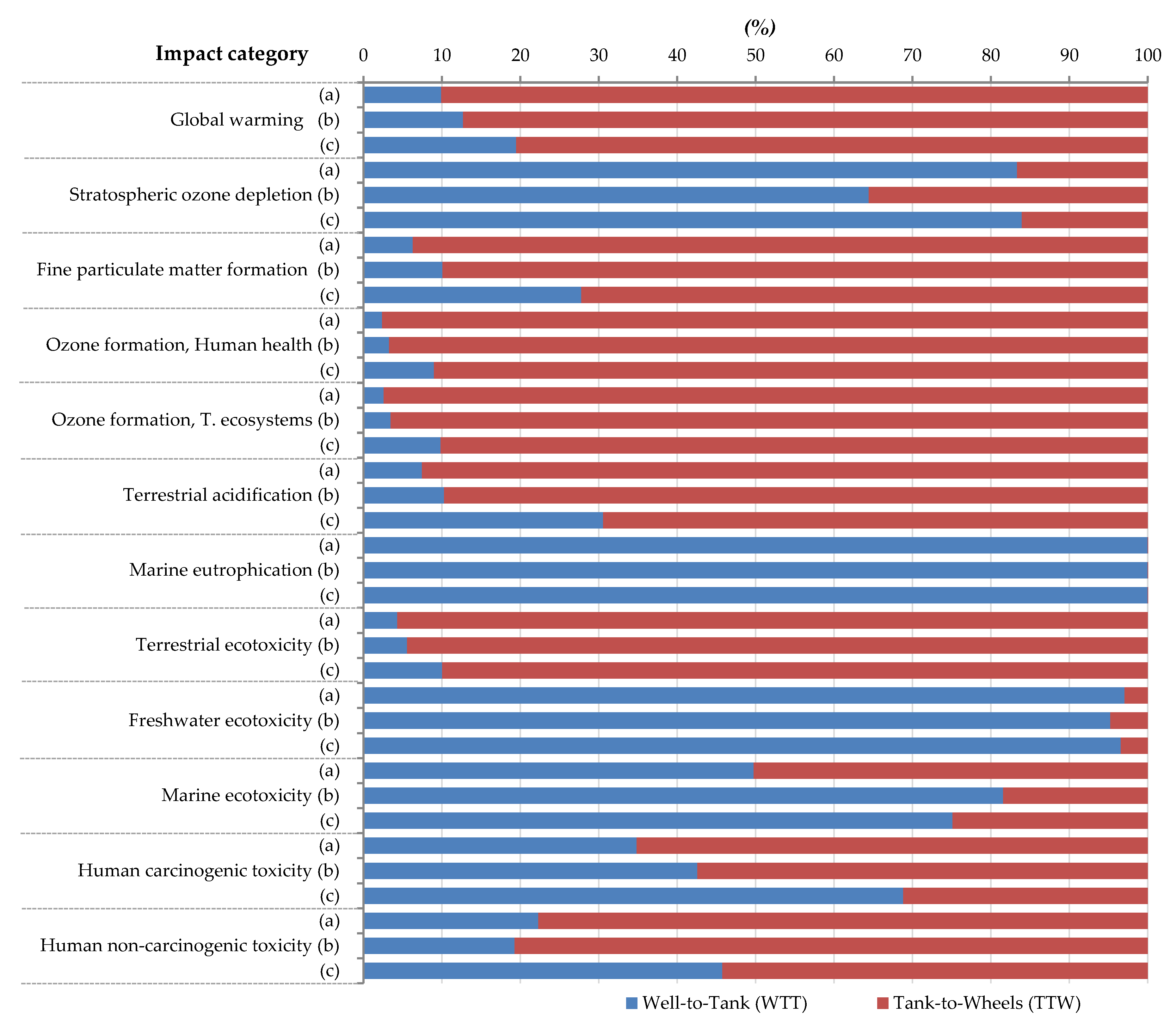

Although the obtained figures from the three studied cases should not be compared, basically because in one of them only the outward journey was considered, and in the other cases, the type of vehicles and load factors were different, important conclusions can be obtained from the analysis of the contribution shares of each phase of the WTW analysis. In general, the environmental impact of the TTW phase was an order of magnitude higher than that of the WTT, so the models used to estimate the corresponding emissions must be as reliable as possible if they are to be used as planning tools or for the environmental reporting of freight transport services.

In particular, for all three cases, the TTW phase mainly affected the impact categories related to human health and ecosystems, while the WTT phase affected the categories related to resource availability. The contribution of each phase to the impact categories was mainly influenced by the type of road and by the emission control technology of the vehicle. This can be observed in Spain where the route was carried out by motorway and with a Euro VI vehicle, hence the TTW phase had greater responsibility in seven of the 18 impact categories, compared to the case in Colombia where this phase had responsibility in nine impact categories and with very high contributions, especially in the categories of ozone and particulate matter formation and in human toxicity. Additionally, in the Colombian case, the TTW contribution share was about 50% in marine ecotoxicity impacts, in contrast to shares of 18% and 25% for the Malaysian and Spanish cases, respectively. The high contribution in marine ecotoxicity due to the vehicle operation in the Colombian case was because of the high copper emissions from brake abrasion, which was influenced by the high load factor and low average speed on the mountainous road, generating around three times more brake abrasion particles than those generated in the Malaysian and Spanish cases.

It can also be observed that in each case, there were different contributions in the climate change category, which was not influenced by vehicle technology, but was affected by the fuel production process in each country. In the case of Spain, the WTT phase for B5 diesel at the station generated 0.74 kg CO

2 eq/kg, compared to 0.32 kg CO

2 eq/kg of B10 diesel in Colombia and 0.43 kg CO

2 eq/kg of B7 diesel in Malaysia; which means GHG emissions of 17.3, 7.5, and 10 g CO

2 eq/MJ, respectively. This is because the ULSD in Spain needs higher energy expenditure than the conventional diesel production used in Colombia. Additionally, the electricity used in Colombia is 76% produced by hydroelectric power [

94], contributing less CO

2 to the process. Furthermore, the petroleum used in Spain is transported from different continents, compared to the local petroleum used in Colombia. In addition, there is a very important factor that increases the amount of CO

2 to each kg of B5 diesel in Spain, which is related to the production of palm oil biodiesel. In the case of Colombia, the 10% of palm oil biodiesel in the fuel generated a reduction of CO

2 emissions in this WTT phase. However, the 5% of biodiesel incorporated in the fuel in Spain increased the CO

2 emissions by more than 30%. This is because the palm oil production in Malaysia and, mainly in Indonesia, has been grown in tropical forests and peatlands, whose preparation for cultivation releases large amounts of CO

2 [

95,

96]. In consequence, the total GHG, including combustion emissions, were 88.5, 75.6, and 78.5 g CO

2 eq/MJ of B5, B10, and B7 diesel in the respective countries. Despite this environmental impact of fuel in Spain, the use of Euro VI vehicles and ULSD achieved relatively low impacts against cases, such as Colombia, in the categories related to human health. For example, WTW emissions for the categories of fine particulate matter formation, ozone formation, and terrestrial acidification per km, in the case of Spain, were 1.26 g PM

2.5 eq, 5.80 g NOx eq, and 3.08 g SO

2 eq, respectively, when compared to 15.8 g PM

2.5 eq, 16.1 g NOx eq, and 7.38 g SO

2 eq in the studied case in Colombia, which shows the importance of fuel and vehicle emissions regulations.

The application of the Tier 3 method for the estimation of emission factors is considered a reliable method since for diesel heavy vehicles, the data has been based on a sufficiently large set of experimental data [

55]. However, in addition to the experiments that have been conducted under European driving conditions, these factors did not consider the error caused by the mileage age of the vehicles and the cold-start overemissions, therefore, increasing the uncertainty for all estimated gases, especially for CO and VOC emissions. To verify the uncertainty of the obtained estimations, basically, a soft verification method was used by comparing the estimations with the results from the Tier 2 factors and other GHG calculation tools. A ground truth verification method was applied only for the fuel consumption figures due to the impossibility of applying on-board measurements since two of the tested vehicles had pre-Euro and Euro I technology, which lacked on-board diagnostic (OBD-II) connectors for the use of instrumentation for the collection of operation data, consumption, and emissions during the journeys, being practical and necessary for the theoretical estimation by the proposed method for companies that have these types of old technology vehicles. Another parameter that can change the uncertainty in the estimations is the average speed caused by dense traffic, heavy meteorological conditions, or incidents on the road, such as landslides or accidents. This parameter more significantly affected freight transport on single lane roads on mountainous topology than on motorways. In this sense, a sensitivity analysis of the freight transport in the Colombian case was conducted for three scenarios: A fast service where the journey time was reduced by half an hour in optimal road conditions and low traffic; a slightly delayed service, which lasted half an hour more due to the traffic; and a very delayed service that could take up to two hours more due to heavy rain conditions. In the fast service scenario, due to the reduction of 6–7% in the journey time, the fuel consumption and the respective fuel-dependent emissions were reduced by 3.4%, while the emissions of air pollutant gases were reduced between 2.4% and 9%. In the slightly delayed service, the 6–7% increased time produced an increase of 3.9% in fuel consumption and fuel-dependent emissions, and between 3% and 11% of the air pollutant emissions. In the 2-h delay scenario, the 23% increased time produced an increase of 17% in the fuel consumption and fuel-dependent emissions, and between 12% and 47% of the air pollutant emissions. These assessed scenarios show that variation in the journey time and, consequently, the average speed does not cause a direct proportional variation in the fuel consumption and emissions. This is mainly because the fuel consumption and emissions are more affected by other parameters, such as the road section gradients. For this reason, to increase the accuracy of the results, it is important to elaborate new estimations by applying the proposed method every time a freight service parameter changes, since extrapolating previously calculated average emission factors could increase the uncertainty in the results.

5. Conclusions

The proposed emissions estimation method in this paper, unlike most similar methods where only the type of vehicle and the emission control technology are considered, also considers the load factor, gradients, and speed for the different slopes that can be found on a specific route. Through this method, companies, in addition to being able to estimate GHG emissions for journeys in which fuel consumption is unknown, can estimate other emissions, such as air pollutant gases and particles from the abrasion of tires, brakes, and road surface. From these estimations, companies can calculate the carbon footprint of the transported products as well as analyze the different environmental impacts related to the operation of the vehicle and the corresponding fuel used for a specific route. From these analyses, measures can be taken to reduce the impacts of the operation, such as load limits, speed, fleet modernization, or change of type and fuel supplier. It is worth mentioning that this estimation method by sections of the route, supported by information of open source software for the elaboration of elevation profiles, is mainly useful for small and medium companies with limited resources to establish environmental accounting through tools or commercial equipment, which are commonly not adapted to the actual conditions of their operation.

The results of the case studies showed the high uncertainties by using fuel consumption and emission factors from databases developed in a different region to where the freight service took place. Specifically, the diesel consumption on mountainous roads in Colombia was 45 L/100 km, compared to averages between 22–26 L/100 km from generic factors from European sources. In contrast, the diesel consumption for an articulated truck on a hilly motorway in Spain from both the proposed method and generic factors coincided at 31 L/100 km, because this route has similar characteristics to the average European road type and driving conditions. However, even for the Spanish route, the estimated air pollutant emissions by the proposed method differed up to 127% when compared to the generic factors, since the vehicle speed, load, and road gradient have a relevant impact in these emissions. Similarly, for the Colombian route, the variation in air pollutant estimations was up to 145%, while the Malaysian route was up to 40%. The differences in the obtained results in each country were basically because of the topology and characteristics of the roads and the emission control technologies of vehicles. In general, the consideration of air pollutants and tire, brake, and road surface emissions and specific parameters of the operation revealed the importance of emission sources other than diesel combustion and different impact categories to climate change. Specifically, we can highlight the impact generated by the vehicle operation in the terrestrial and marine ecotoxicity categories, where the main reason is the released copper particles by the brake abrasion. The results also showed that the fuel consumption and emissions, depending on the type and condition of the road, could increase more than double when compared to a motorway in good condition. It can be seen that the more rugged the terrain, the greater the variation of non-dependent gases on fuel consumption considering the different operating parameters when compared to the average Tier 2 emission factors, which were established according to the type of vehicle and the emission control technology. In this sense, the investment made in the construction of infrastructure, despite generating environmental impacts, can generate reductions in vehicle operation that would compensate for the impacts in some of the assessed categories. Therefore, it is interesting to include infrastructure construction processes in the life cycle analysis associated with transport services.

In conclusion, the relevance of the different emission sources that must be taken into account was demonstrated, being necessary to apply estimation methods for specific sections of the route, given that the quantity of pollutant emissions is extremely influenced by the speed, load factors, and road gradients. These factors are decisive when evaluating the environmental impacts associated with a specific transport service and the various strategies that are intended to be implemented to improve the sustainability of the sector in different territories.