1. Introduction

Conservation agriculture involves no-till systems based on minimum soil disturbance, which is able to recover soil quality, improve the soil organic content, precipitation utilization rate, and crop yields, and facilitate the sustainability of agriculture development [

1,

2,

3]. Unlike traditional tillage, at least 30% of crop straws or residues after harvest are covered on the ground in this tillage mode, but in real production, up to 100% of straws are crushed and returned. The straw residues in fields complicate sowing works, block the furrowing and sowing devices of seeders, reduce the sowing quality, working efficiency, and soil temperatures, and interfere with emergence rate and emergence time, thereby reducing crop yields [

4,

5,

6]. Therefore, some degree of soil disturbance is required in the form of planting strips for seeding.

The northeast China farming region includes one of the most important commodity grains in China. Corn is the main crop there, which holds a particularly prominent position. In particular, the planting area of maize is about 8.9 × 10

6 ha, accounting for more than 29% of maize acreage in China [

7], and the maize yield in this region accounts for 30% of the total corn yield in China [

8]. The use of conservation agriculture for corn cultivation has been well promoted in the region, and the area planted has increased year by year [

9]. Due to differences in climate and soil conditions, no-till planting mode and strip-seeding mode were commonly used in the region when planting corn in the fields covered by corn straw and stubble [

10,

11]. The no-till planting is a conservation agriculture mode that uses a no-tillage seeder equipped with straw cutting and row-cleaning tools, and adopts coulters to cut residues on the sowing rows. While cutting straws, the coulter also creates rudiment furrows for sowing units, and the uniform furrows can increase seeding quality (including row distance variation coefficient, sowing depth consistency, seed spacing uniformity) and emergence rate, thereby promoting crop growth [

12,

13]. Compared with traditional tillage, the no-tillage sowing mode reduces working costs and prolongs crop growing time, and provides the best energy efficiency ratio [

14,

15,

16]. Another planting mode of the conservation agriculture system is strip seeding, in which a strip-till machine is used, after harvest or before sowing, to cut and clean straws and loosen soils, so that the seeder can operate on the newly-formed seedbed. In this operation, different types of coulters are used to cut straws on the soil surface with residue coverage and loosen soils on the soil surface with no residue coverage. Compared with traditional tilling, this mode is more ideal for soil and water conservation [

17]. Compared with the no-tillage mode, it increases the plant population and yield, and enhances the lodging resistance of crops [

18]. Numerical simulation showed vertical farming can successfully delay rainfall runoff [

19]. Coulters are very important in conservation agriculture, but there is little research on their working performances.

The working performances of coulters are affected by soil properties, crop residue level, geometrical shape, and rotation velocity [

20,

21]. Mion et al. [

22] and Seida et al. [

23] tested the performances of different coulters under no-residue conditions and found that the furrow characteristics and soil disturbance changed along with the variation of coulter geometric shape, and usually, fluted coulters intensified seedbed soil disturbance compared with planar coulters. This view was proved by Zeng and Chen [

24], who compared two types of fluted coulters at high-speed operation on wheat residue-covered lands and found that coulter types did not significantly affect the straw disturbance. Sarauskis et al. [

25] and Bianchini and Magalhães [

1] compared different notched coulters in cutting winter wheat and sugar cane residues, and found that the coulters with notched structures or sharp-fanged structures performed better. By comparing two types of fluted coulters at high-speed operation on wheat fields, Zeng and Chen [

24] confirmed that the increase of coulter velocity significantly enlarged furrow width, and found that working velocity was more effective than coulter geometric shape on soil disturbance; the 8W-fluted coulter at high-speed operation could more efficiently solve the problem of long-term no-tillage with excessive wheat straw residues. When single-disk or double-disc openers were used to cut ripe straw residues, the rise of coulter velocity would increase the ripe residue cutting efficiency, but the cutting force was also strengthened [

26]. During real work, the skid of coulters is inevitable [

27]. The skid of coulters reduces the cutting linear velocity, which negatively affects the soil disturbance and residue cutting rate [

28]. There is a lack of information on whether or not corn residue coverage affects the working performance of the coulters. Such information is very critical for guiding the design and popularization of high-performance no-tillage seeders and strip-till machines.

Generally, previous studies on coulters were based on a single working condition. There is rare research on the effects of corn residue coverage on the working performance of coulters, or research on the cutting force or skid at different coulters. Thus, this study aimed to investigate the working performance of coulters (four types of fluted coulters, one type of flat coulter) in the conservation agriculture system, and evaluate the effects from soil disturbance, residue coverage change, cutting force, and skid rate at with or without corn residue coverage and different working velocities. It also aimed to recommend suitable coulter types for the planting tools of different planting modes under the conservation agriculture system that is commonly in northeast China, and solve the problems against the further popularization of conservation agriculture techniques due to residue coverage.

2. Materials and Methods

2.1. Study Site Description

The experiments were conducted in the agriculture experiment field (43.84° N, 125.33° E; altitude 228 m) of Jilin University, Changchun, Jilin province. This study site belonged to the continental seasonal climate, and was located at the transition from the wet zone to semi-arid zone. The temperatures gradually rose westwards, and the precipitation slowly declined westwards. The annual average precipitation was 522–615 mm, and the sunlight duration was 2500–2700 h. In the past 30 years, the average summer temperature (June to August) was 15.2–23.1 °C, and the precipitation was 300–350 mm, which was about 60% of total annual precipitation. The soils in the field belonged to the typical black clay of northeast China.

The field tests lasted from 16 to 27 October 2017 (from the third to fourth week after the corn harvest), with the daily average temperature of 12–16 °C, but nearly no precipitation. The study site was corn stubble field; the aboveground corn straws were crushed by a combine harvester and evenly covered on soil surface. The physiochemical properties of soils and corn straws before trials are shown in

Table 1.

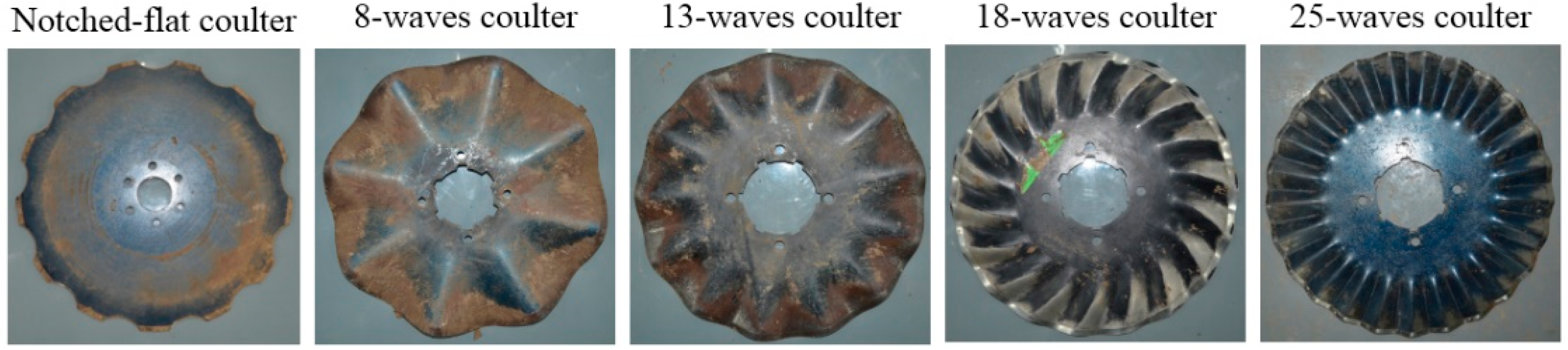

2.2. Coulters Tested

Four types of fluted coulters (8, 13, 18, 25 equidistant waves) and one type of notched-flat (NF) coulter commonly used in Northeast China were used and named as 8 W, 13 W, 18 W, 25 W and NF, respectively (

Figure 1). All of the coulters had a diameter of 406 mm. The fluted coulters formed flutes radiating from the outer periphery toward the center, and consisted of equal-spaced waves along the thrust direction.

The geometric parameters of these coulters were listed in

Table 2, which are very important influence factors on the working performance. Working width was defined as the largest width around a coulter. Effective waves were defined as the total wavenumber in the coulter–soil contact under specific working depth, which was set as 80 mm here.

For each test, a single coulter was mounted to a hanger through a sliding shank for adjusting the tillage depth. The hanger had a three-point hitch and two limited depth wheels for controlling the tillage depth (

Figure 2).

2.3. Experimental Design and Treatment Methods

Each plot was 3 m wide, which ensured that the tractor did not affect the other working procedures. These plots were 50 m long perpendicular to the crop sowing direction, and included the 10-m adjustment zone reserved at each end, and a 30-m data acquisition zone with stable working in the middle. Such setting ensured that the tractor could travel at a set velocity in the zone. A completely randomized design was adopted. The test factors included two field conditions (no residue, whole residue), five types of coulters (NF, 8 W, 13 W, 18 W, and 25 W), and three working velocities (8 km/h, 10 km/h, and 12 km/h), for a total of 30 factor combinations. Each combination was repeated three times, which resulted in a total of 90 plots in the field. All of the treatments were provided with traction by a John Deere 504 tractor, and the working depth of the coulters was set constantly at 80 mm.

2.4. Measurements

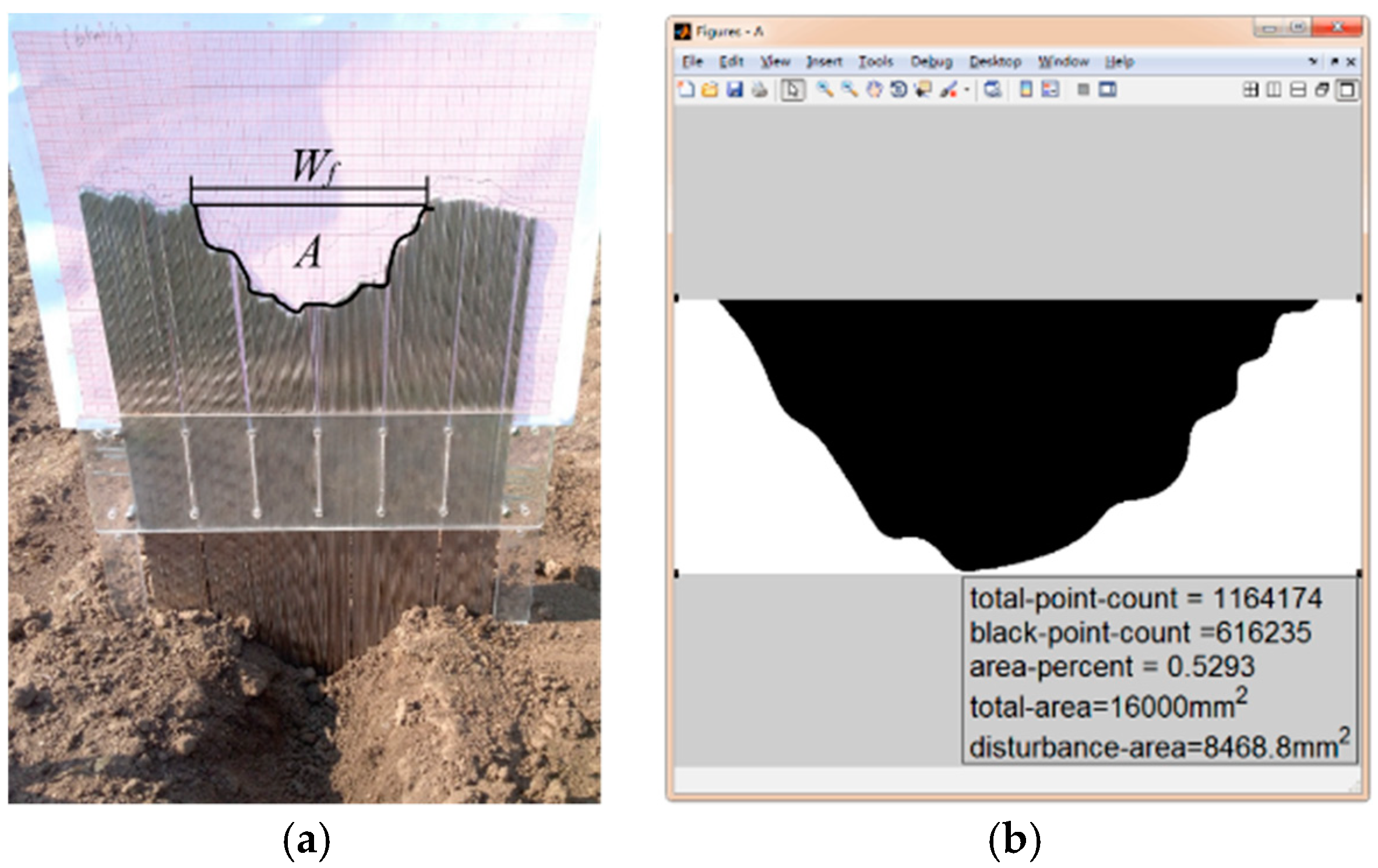

2.4.1. Furrow Profile

Furrow profiles were measured using a profile meter consisting of movable metal pins (

Figure 3). Before measurements, the straw residues on the soil surfaces and the coulter-loosened soils inside the furrows were carefully removed. The profile meter was placed perpendicular to the ground, at the advancing direction of the machine and into the center of the furrow. The skidable profiling drill rod was released freely, so that its lower end contacted the furrow surfaces. In this way, the outline formed on the upper end of the profiling pin was exactly the furrow outline. The outlines were plotted on engineering sheets, and digital pictures were acquired by scanning on a computer. The furrow outlines were extracted on Matlab, and maximum furrow width (W

f) and furrow disturbance area (A) were calculated. All of the data above were measured relative to original soil surfaces. For each test, three furrow cross-sections were randomly measured along the furrow, and the three measurements were averaged [

29].

2.4.2. Residue Coverage Change

The residue coverage change under the ground condition of whole residue coverage was measured, and the data were analyzed. Since the row spacing of corn planted on the test plots was 0.65 m, the size of a test zone was set as 0.65 m × 1 m. The ground residue coverage rate was detected by photographing the digital images right above the test zone before and after tillage. On the undisturbed soil ground, the samples were placed randomly in the field (

Figure 4a), but on the disturbed surfaces, the samples were centered at the route of a coulter (

Figure 4b). The percent of residues on soil surface was determined via image threshold analysis on Matlab [

30]. The difference in residue coverage rates before and after tests was calculated and considered as the change in residue coverage (C).

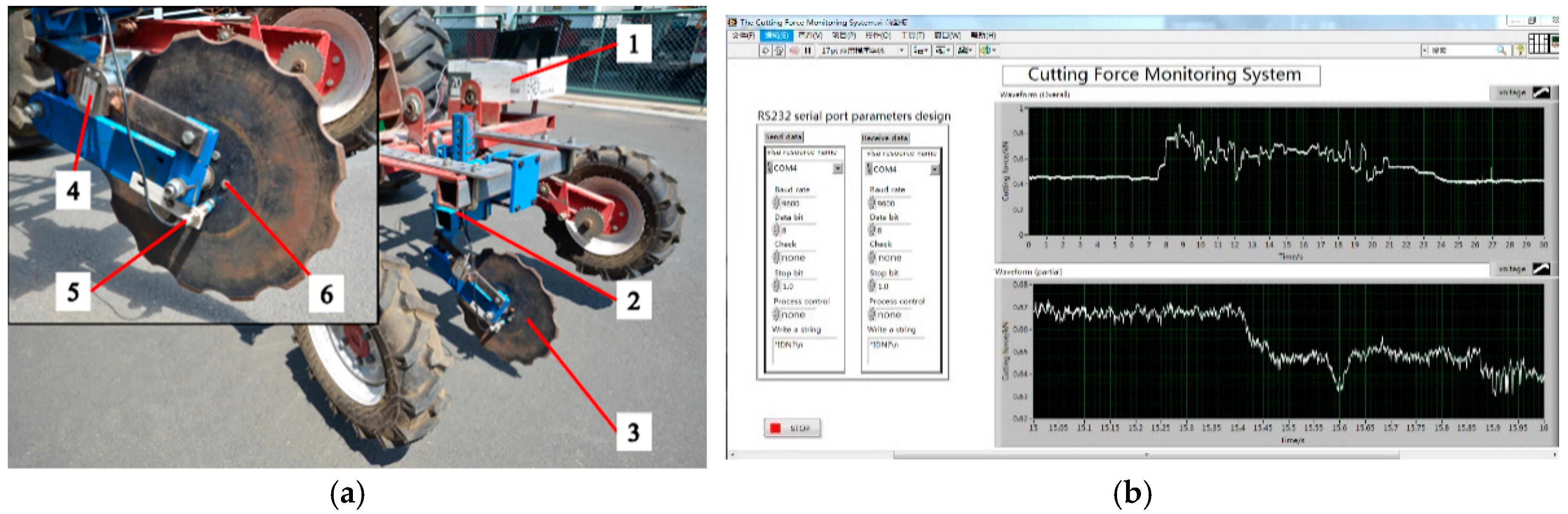

2.4.3. Cutting Forces

The cutting force (F) was tested in real-time by a MIK-LCS1 S-shaped pressure sensor (Hangzhou Meacon Automation Techology Co., Ltd., Hangzhou, China). The voltage signals of the sensor were acquired by a USB66530 data acquisition card (National Instruments, Austin, TX, USA). A LabVIEW (National Instruments, Austin, TX, USA) program was developed for data display and storage. The voltages were stored in the form of Excel tables and then converted to cutting force. Prior to experiments, the sensor was calibrated. The data acquisition device was illustrated in

Figure 5a, and the cutting force monitoring program was shown in

Figure 5b.

2.4.4. Skid Rate

The skid rate (S) was tested at six sensing points uniformly distributed around each coulter (

Figure 5a). The number of sensing at each measuring point was recorded in a contactless way during the coulter rotation process by a NJ5200-N Holzer switch series (Omdhon (Shanghai) Industrial Co., Ltd., Shanghai, China). Then, the skid rate was determined as follows [

31]:

where

(%) is the skid rate;

D (mm) is the real distance from the testing zone;

R (mm) is the radius of the coulter;

n is the real number of rotations of the coulter (

,

p is the number of sensings at a measuring point).

2.5. Statistical Analyses

Analysis of variance (ANOVA) is appropriate for randomized complete block design, and was used to analyze the variance of the obtained data. Means were compared using the Least Significant Difference (LSD).

3. Results

Analysis of variance (ANOVA) of the variables, with the respective means, levels, and results of the F-tests shown in

Table 3.

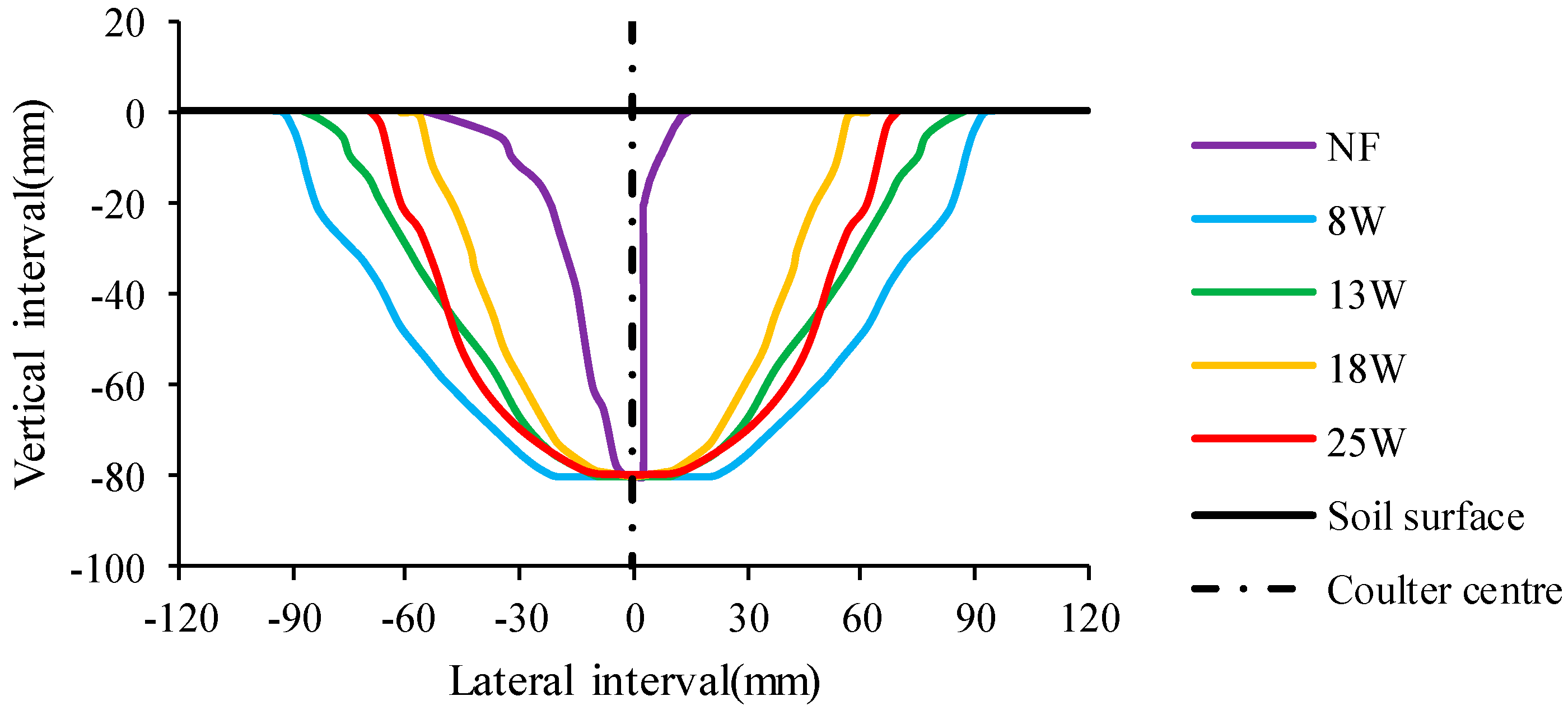

3.1. Furrow Cross-Sectional Profile

Figure 6 shows the furrow cross-sectional profile of the five types of coulters. The flat coulter formed an asymmetrical furrow cross-section profile; it imposed outward strain on the soils at the chamfered side, and made the soils within the cutting depth fail and led to the formation of furrows. Moreover, the soils at the side without chamfer were transversally extruded by the discs, forming flat surfaces. These results are consistent with Solhjou et al. [

32] and Matin et al. [

33] that the unilateral chamfered openers had a similar cross-sectional profile to rotating straight blades. All of the fluted coulters formed a nearly symmetrical furrow cross-sectional profile, the geometrical data of which were mirror-imaged for analysis. Fluted coulters had more complex geometrical shapes than the flat coulter, and thus produced more complicated soil kinetics. The fluted surfaces of fluted coulters provide a discontinuous digging function for soil crushing and residue cutting, but not for soil progression or acting, and avoided excessive soil disturbance, which was what expected from conservation agriculture. In addition, the waves of the coulter potentially twist soil from side to side when they travel in the soil. This twisting action favors fracturing the soil and mixing residue with the soil, resulting in uniform soil bulk density and rapid residue decomposition.

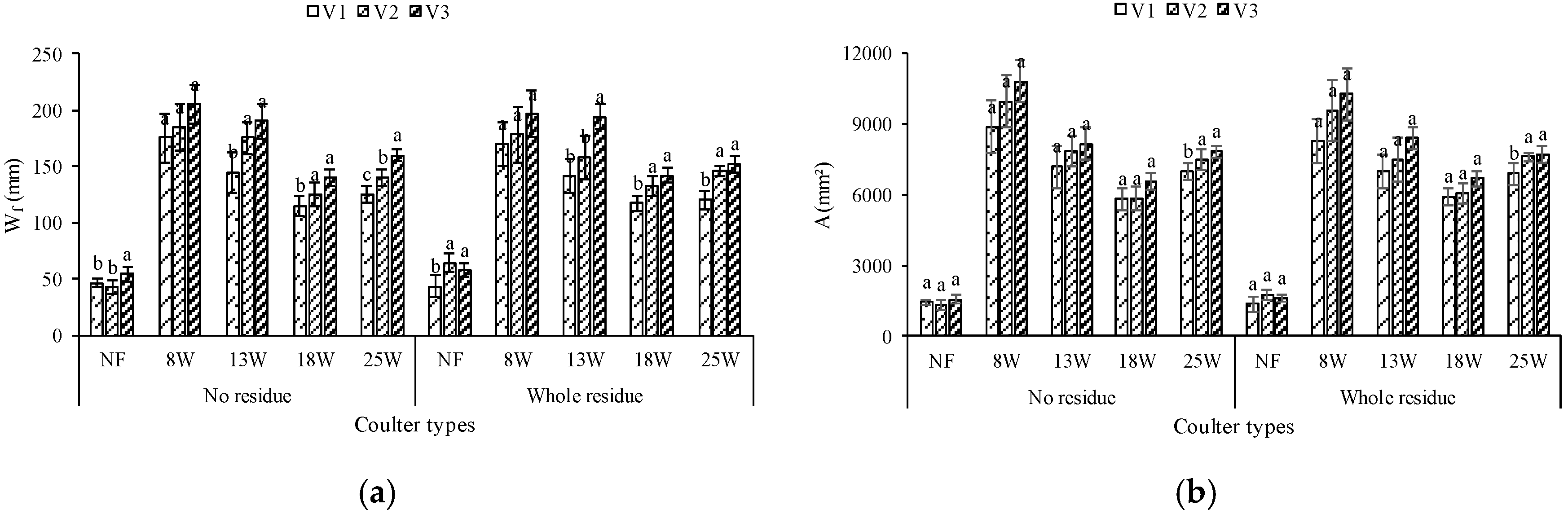

The field conditions did not significantly affected maximum furrow width (W

f) or disturbance area (A) (

p < 0.05), which were 134.4 mm and 6462.4 mm

2 on average, respectively (

Table 3), indicating that the residual did not affect the furrow profile formed by the coulters. The reason was that a working coulter cut off the residual, and was always operating at the preset working depth. These results are similar to Hasumu and Chen [

29] in that the furrow outline was decided by the working depth when other conditions were unchanged.

The working velocity significantly affected both the W

f and the A (

p < 0.05), and larger furrows were formed at higher working velocity. Compared with V1, the W

f at V2 and V3 values increased by 12.4% and 22.5%, respectively, and the A values were enlarged by 8.7% and 16.5%, respectively (

Table 3). These results are consistent with Zeng and Yang [

24]. However, these results are different from Francetto et al. [

34], which may be because they installed furrow openers at the back of coulters, and the soil-disturbed areas were subsequently affected by the furrow openers.

The coulter type significantly affected both the W

f and the A (

p < 0.05), and the NF created the furrows with the smallest width and disturbance area among all of the tested coulters. Among the fluted coulters, the W

f maximized at 8 W and minimized at 18 W. Compared with the 8 W, the W

f from the 13 W, 18 W, and 25 W decreased by 9.6%, 30.5%, and 24.0%, respectively. The effect of the fluted coulters on the A has the same trend, with 8 W forming the largest A and 18 W forming the smallest A. Compared with 8 W, the A from 13 W, 18 W, and 25 W furrows were reduced by 20.2%, 36.1%, and 22.8%, respectively (

Table 3). This conclusion is consistent with Francetto et al. [

34], who found that when used together with furrow openers, the flat coulters compared with fluted coulters disturbed soil areas by 12.26%. The difference in working breadth led to the difference in furrow width, since a narrower tool created smaller furrows [

35]. Zeng and Yang [

24] concluded similarly that the working width of the 13-W coulter was smaller than that of the 8-W coulter. Mion et al. [

22] and Seidaet al. [

23] also found the differences in soil disturbance and drift that were induced by different types of coulters also led to more disturbance compared with smooth coulters. They were either forming the same furrow width, yet a different furrow disturbance area, or forming the same furrow disturbance area, yet a different furrow width, which could be attributable to the different shapes of furrow outlines formed by coulters (

Figure 7).

The furrow cross-section area reflects the soil area disturbed by the coulter. The larger furrows facilitate the smooth operation of the planters; however, when the coulter-created furrows are excessively wide, negative effects also appear, leading to the accelerated loss of soil moisture; the soils around seeds are loosened and cannot fully contact with soils, leading to a reduction in emergence rate and an increase in emergence time, which affect the crop yields.

3.2. Change in Residue Coverage (C)

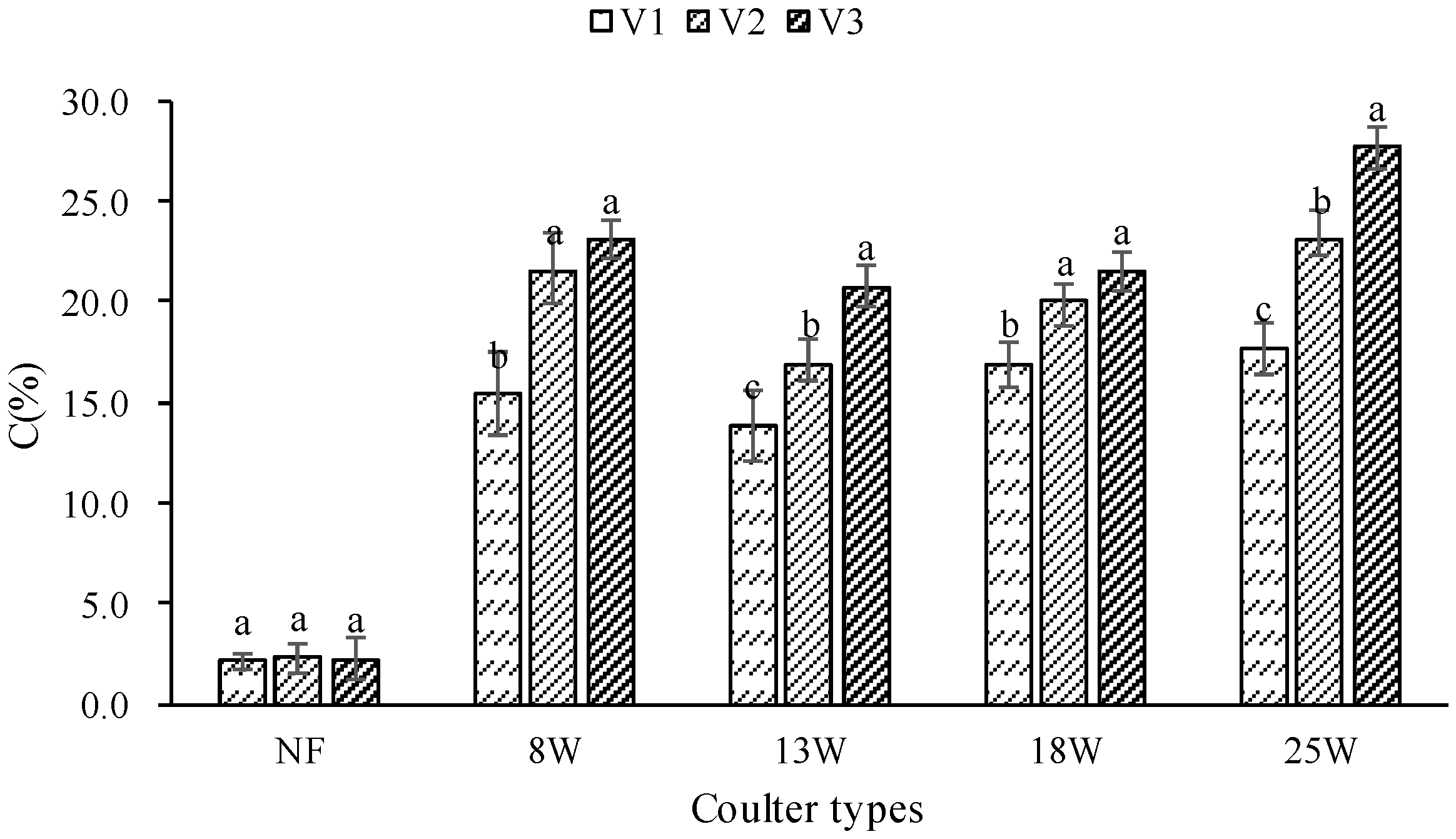

The working velocity significantly affected the change in residue coverage (C) (

p < 0.05), and the C at 12 km/h increased significantly by 13.7% compared with that at 10 km/h. Similarly, the C at 10 km/h significantly rose by 26.5% compared with that at 8 km/h (

Table 3). The C of the NF was not significantly affected by the working velocity, but the C of the fluted coulters significantly increased with the rise of velocity, which was maximized at V3 and minimized at V1 (

Figure 8). Zeng and Yang [

24] reported similar conclusions when they studied the residue changes of fluted coulters after high-velocity working in a wheat stubble field.

The coulter type significantly affected the C (

p < 0.05); the C minimized to 2.2% in the NF among all of the tested coulters; among the fluted coulters, the C maximized at the 25-W coulter and minimized at the 13-W coulter. Compared with the 25-W coulter, the C in the 8 W, 13 W and 28 W decreased by 12.4%, 24.8%, and 14.7%, respectively (

Table 3). This conclusion was different from Zeng and Yang [

24], which may be because the high working velocity weakened the effect of coulter type on residue cover. It should be noted the C at small wavenumbers—8 W and 13 W—were slightly lower than the furrow widths, but those at large wavenumbers—18 W and 25 W—were slightly higher than the furrow widths, which shows that the wavenumbers and the width of the coulter affect the straw disturbance (

Figure 8).

The change in residue coverage indicates the change of exposed soil after tillage, and could indicate the amount of residue incorporation or burial. Excessive residue coverage change would lead to the accelerated loss of soil moisture; on the contrary, it would reduce the sowing quality, which in turn was associated with the results of the furrow cross-sectional profile.

3.3. Cutting Force (F)

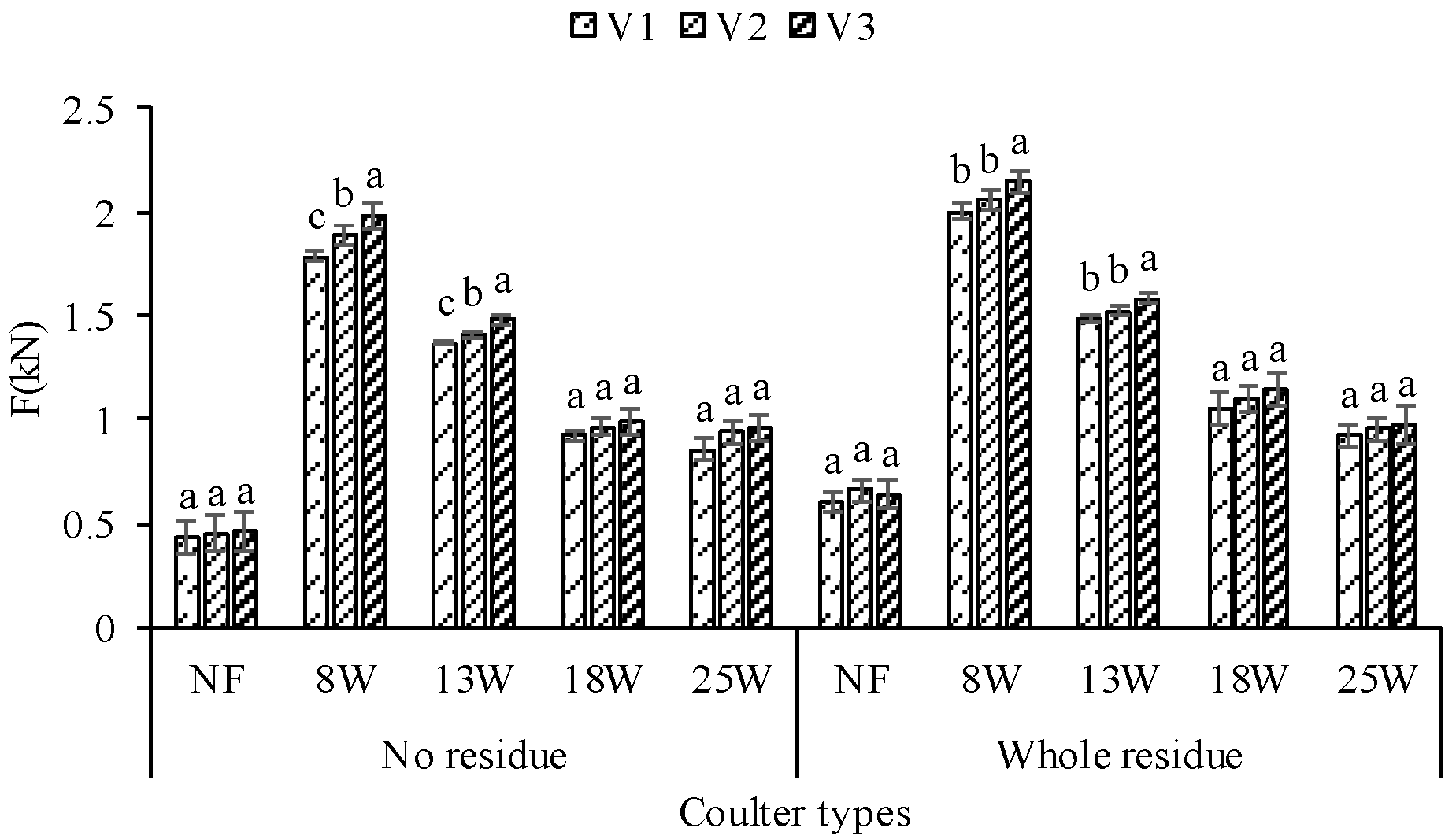

The field conditions significantly affected the cutting force (

p < 0.05); the average cutting forces in the WR and NR treatments were 1.265 KN and 1.125 KN, respectively, with an increase of about 11.6% (

Table 3). As reported, given the high toughness of straws, the cutting force of straws surpassed that of soils [

36]. The differences in soil conditions most affected the variation of cutting force in NF coulter plates, with a difference of 33% between the two types of field conditions, which was higher than all of the fluted coulters. Among the fluted coulters, with the rise of wavenumber, the cutting force from the field conditions gradually decreased, and the differences in the 8 W and 25 W were 9.7% and 3.4%, respectively (

Figure 9).

The working velocity significantly affected cutting force (

p < 0.05); with the rise of working velocity, the cutting force was significantly strengthened, and compared with that at V1, those at V2 and V3 increased by 4.5% and 9.4%, respectively (

Table 3). Kushwaha et al. [

37] and Sahu and Raheman [

38] reported similarly that the cutting force was increased with the increase in the working velocity of the coulters. The increase in the cutting force with the increase in speed was due to a high amount of soil resistance and the higher force that was needed to achieve the soil acceleration. Greater tool penetration was responsible for the increase of soil resistance on the implement. Further experiments showed that the cutting force of the flat coulter or the coulters with nearly planar surfaces (18 W, 25 W) was less affected by the working velocity, but the coulters with small wavenumbers were largely affected by the velocity (

Figure 9).

The coulter type significantly affected the cutting force (

p < 0.05), but the cutting force of NF was lower than those of the fluted coulters. Among the fluted coulters, with the increase in wavenumber, the cutting force was gradually weakened, as the cutting forces at wavenumbers 13 W, 18 W, and 25 W were 24.5%, 47.9%, and 52.7% lower, respectively, than that at 8 W (

Table 3). The possible reason is that the blade length and area of the fluted coulters in contact with soils and straws were larger, forming larger furrows and leading to a larger cutting force. The test results validate the soil cutting theory that tools with a larger working width produce larger cutting resistance [

35]. Darmora and Pandey [

39], Hasimu and Chen [

29], and Ahmad et al. [

28] found the same results when they tested different types of furrow openers.

The cutting force reflects the ease with which the coulter cut off the residue and cut into the soil, as well as the minimum load required to work smoothly within the expected working depth. The coulter with a lower cutting force was easy to cut off the straw residue; flat coulters and large-wavenumber fluted coulters were beneficial for cutting straw residue in the fields covered by corn straw and stubble. The cutting capacity of a coulter was affected by the load applied to it, and a suitable load is necessary. An insufficient load applied to the coulter can cause the coulter to fail to cut the straw, which in turn causes excessive energy consumption and wastes resources.

3.4. Skid Rate (S)

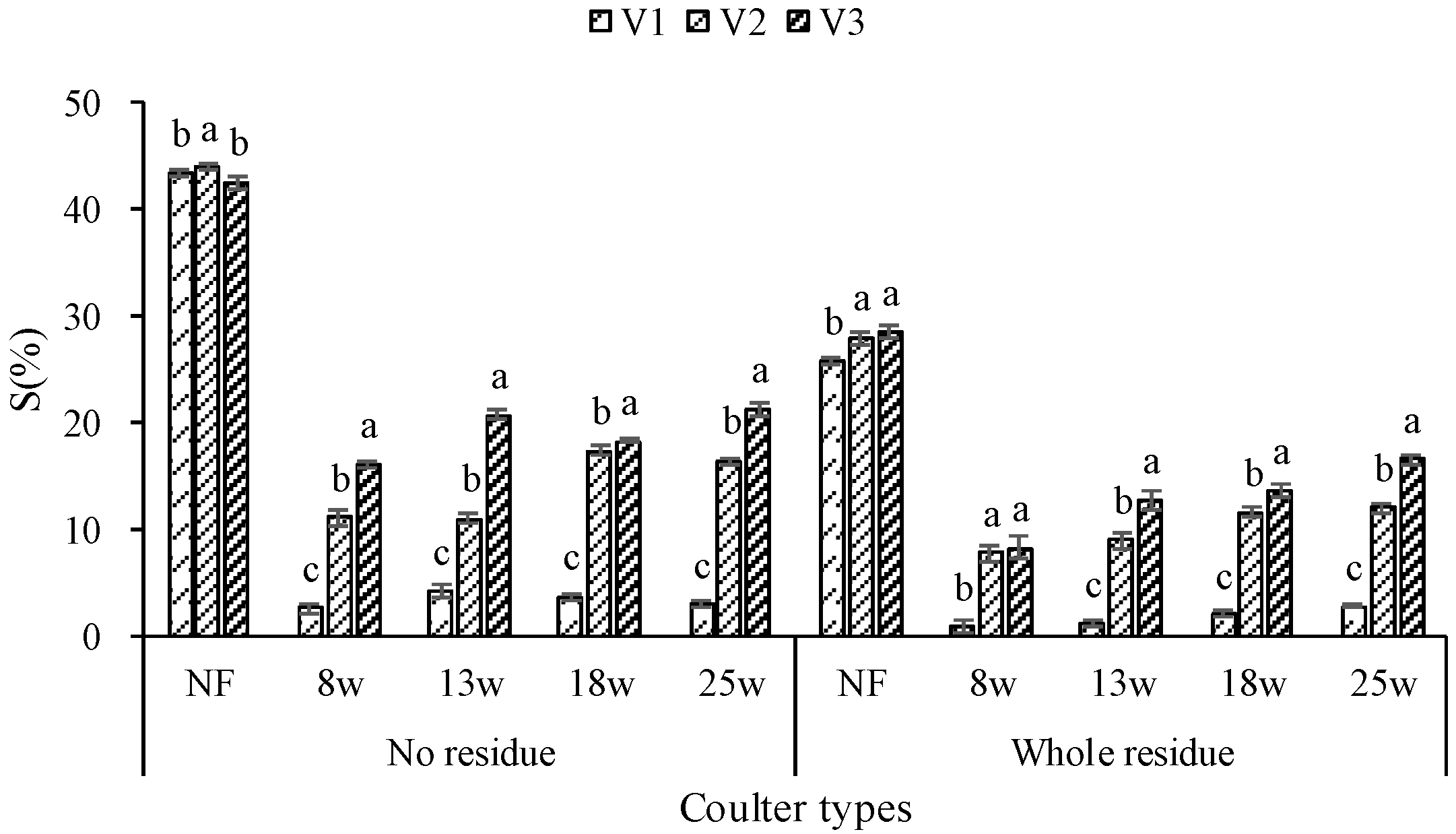

The field conditions significantly affected the skid rate of coulters (S) (

p < 0.05), as the NR plots generated larger skid rates by 20.9% compared to WR ones (

Table 3). When the coulter was working on fields with residue coverage, a larger cutting force was generated, which was equal to the larger external load imposed on the coulter, but a larger load was favorable for reducing the skid rate of the revolving part, as reported by Gao [

27] and Zhao [

40].

The working velocity significantly affected the skid rate of the coulters (

p < 0.05); with the rise of the working velocity, the skid rate of the coulters was strengthened, and those at V2 and V3 compared with that at V1 increased by 88.4% and 122.7%, respectively (

Table 3). Further experiments showed the skid rate of the flat coulter was less affected by the working velocity, but all of the fluted coulters were largely affected by the velocity (

Figure 10). The working velocity more significantly affected the skid rate of the coulters compared with the straw residues (or namely the cutting force), and thus, when the working velocity increased, the skid rate of the coulters rose.

The coulter type significantly affected the skid rate of the coulters (

p < 0.05), as the skid rate of the NF was higher than all of the fluted coulters. Among the fluted coulters, with the increase of wavenumber, the skid rate gradually increased, as the skid rates of 13 W, 18 W, and 25 W were 26.6%, 42.9%, and 54.6% higher, respectively than at 8 W (

Table 3). The reasons were attributed to the different cutting forces among the different types of the coulters, as the skid rate of the coulters decreased with a larger cutting force, and increased with a smaller cutting force.

The skid rate affects the actual rotational speed of the coulter; the increase in skid rate reduces the rotational speed and the cutting linear velocity of the coulter, which reduces the cutting and throwing action of the coulter on residue and soil, resulting in reduced soil disturbance and residue coverage. The skid rate was also closely related to the load applied to the coulter; a sufficient load can reduce the slip rate of the coulter.

4. Discussion

In this study, the presence of corn residue coverage, working velocity, and coulter types on the soil disturbance, residue coverage change, cutting force, and skid rate were investigated. While not all of the test factors have significant differences in tillage performance indicators, the overall direction of the results showed that it is feasible to achieve desired tillage performance by selecting different coulters for conservation agriculture.

Under the no-tillage mode, the coulters of a no-tillage planter cut off the straw residues that were covered on the ground, forming a certain furrow, which is the rudiment furrow opened by the furrow opener. Flat coulters and large-wavenumber fluted coulters (18 W and 25 W) have less cutting force for cutting straw residue in the fields covered by corn straw and stubble; therefore, they were competent. The larger coulter-created furrow width and disturbance area help the furrowing devices create more uniform seed furrows; however, when the coulter-created furrows are excessively wide, negative effects also appear, leading to the accelerated loss of soil moisture. As a result, the soils around seeds are loosened, which then cannot fully contact with soils, leading to a reduction in the emergence rate and an increase in the emergence time, which affect the crop yields. Meanwhile, the formation of wide furrows requires a larger cutting force and consumes more power. In all, given the soil disturbed amount and cutting resistance, the coulters installed on the no-tillage planter should be selected according to the breadth of the furrow openers. The furrow width formed by the coulters should not exceed the seed furrow width formed by the furrow openers, which means that coulters with as large a wavenumber as possible should be selected when the furrowing width conditions are satisfied.

Under the strip-seeding mode, it is necessary to install coulters at the front and back of the row cleaner of the strip-till machine. Such coulters could cut off straws and loosen soils, and the furrowing and planting in the newly formed strips will be completed. The coulters installed in the front are mainly responsible for cutting crop residues, and thus, coulters with small cutting force work on residue-covered fields are more suitable and can reduce the power loss. In this way, the flat coulter NF or large-wavenumber coulters (18 W or 25 W) are more suitable. The coulters installed at the back mainly function to loosen the shallow soils at the fixed depth (5–10 cm). Since their working environment is equivalent to a ground without residue coverage, we think that coulters with a large furrow width and soil disturbed area are more suitable. In this way, the large-wavenumber coulters (8 W or 13 W) are more suitable, but the wavenumber should be decided by the working breadth of the strip-till machine and the effect of the cutting force. Moreover, the inclined installation of flat coulters or large-wavenumber coulters can enlarge the working breadth. In the future, relevant studies will be conducted, aiming to reach the working parameter combination of target breadth and small cutting force by adjusting the working leaning angle.

In addition, increasing the working velocity led to the increment of all of the tested indicators; during all of the works, it is always expected to generate a smaller cutting force and skid rate. The coulters work better at lower working velocity, but the work efficiency and theoretical rotation speed all decrease, indicating that the working velocity should be selected according to real work demands. The load applied to the coulters has a significant effect on their performance; therefore, an appropriate load should be applied in order to improve the coulters’ performance.

5. Conclusions

Coulters were required for corn sowing in conservation agriculture systems where the fields were covered by corn straw and stubble. In this study, the working performances of five types of coulters (NF, 8 W, 13 W, 18 W, and 25 W) under two ground conditions (with or without straw residue coverage) and at three working velocities were investigated. The residue coverage had a significant effect on the cutting force and skid rate, and the working velocity and coulter type both significantly affected the tested indicators. Among all of the tested coulter types, the flat coulter was found to have the smallest furrow outline, residue disturbance change, cutting force, and the largest skid rate. The wavenumbers and the work width both affect the performance of the work; among the tested fluted coulters, as the wavenumber rose, the cutting force, furrow width, and furrow disturbance area all gradually decreased, while the skid rate and residue disturbance were gradually enhanced. For soil disturbance and residue management, the coulter type has a greater impact than the working velocity under the same conditions; therefore, the coulter type is the main consideration to improve the tillage performance.

This study contributes to selecting suitable coulters for different corn planting modes in the conservation agriculture system in northeast China. Among the five coulters, the flat coulter and large-wavenumber fluted coulters (18 W and 25 W) had less cutting force, and in this regard, they would be beneficial for cutting straw residue in fields and should be installed at the front of a no-tillage planter or the row cleaner of a strip-till machine. From the perspective of loosening soil and constructing seedbeds, the small-wavenumber fluted coulters (8 W and 13 W) were more desirable tools to be installed at the back of the row cleaner of the strip-till machine, as they resulted in more soil and residue disturbance. Notably, the coulter should be subjected to sufficient load, regardless of the planting mode to which it was applied. The inclined installation of flat coulters or large-wavenumber coulters can enlarge the working breadth. In the future, relevant studies will be conducted that aim to reach the working parameter combination of target breadth and small cutting force by adjusting the working leaning angle.