Effects of Industrial Operations on Socio-Environmental and Public Health Degradation: Evidence from a Least Developing Country (LDC)

Abstract

1. Introduction

2. Institutional Pressure and Environmental Management Practices

- To examine the extent to which human health related factors are affected by the firms’ operations in an industrial zone at Chittagong, Bangladesh.

- To examine the extent to which natural environment-related factors are affected by the firms’ operations in an industrial zone at Chittagong, Bangladesh.

- To examine the extent to which socio-economic factors are affected by the firms’ operations in an industrial zone at Chittagong, Bangladesh.

3. Institutional Pressures and Environmental Management Practices in Bangladesh

3.1. Regulative Pressure

3.2. Normative Pressure

3.3. Cognitive Pressure

4. Environmental Harm of Industrial Firms’ Operations: A Socio-Ecological Problem in Bangladesh

5. Research Methods

5.1. Choice of Methodology

5.2. Data Collection and Analysis

5.3. Validity and Reliability of the Qualitative Study

6. Results

6.1. Environmental Harm of Tanning Operations

6.2. Environmental Harm of Pulp Operations

6.3. Environmental Harm of Fertilizer Operations

6.4. Environmental Harm of Textile Operations

6.5. Environmental Harm of Cement Plant Operations

6.6. Comparison of Health Hasards from Polluting Tannery, Pulp & Paper, Fertilizer, Textile, and Cement Industries

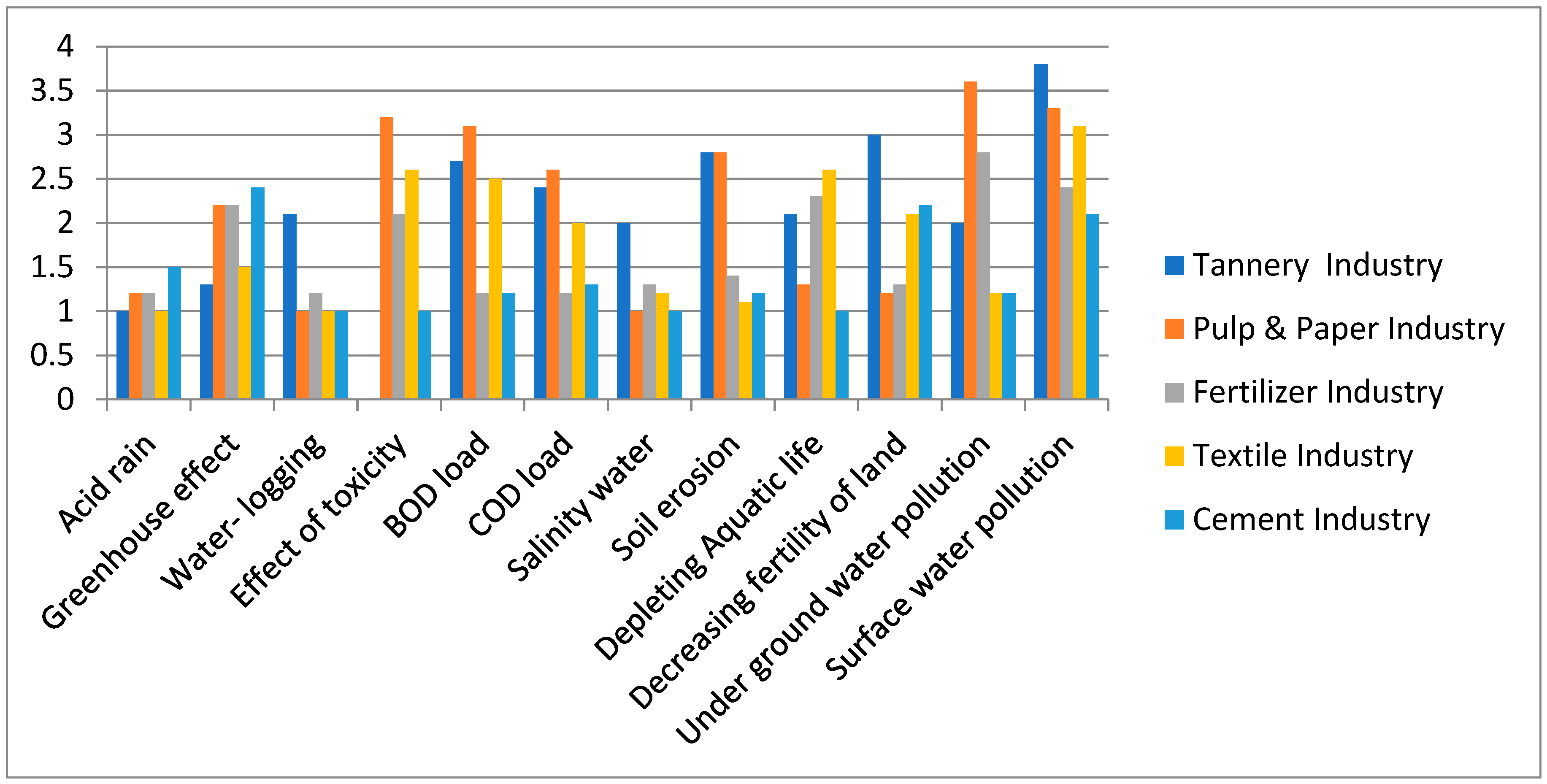

6.7. Comparison of Environmental Hazards from Polluting Tannery, Pulp & Paper, Fertilizer, Textile, and Cement Industries

6.8. Comparison of Socio-Economic Hazards from Polluting Tannery, Pulp & Paper, Fertilizer, Textile, and Cement Industries

7. Discussion

8. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Boons, F. Organizing Within Dynamic Ecosystems: Conceptualizing Socio-Ecological Mechanisms. Organ. Environ. 2013, 26, 281–297. [Google Scholar] [CrossRef]

- Driscoll, C.; Starik, M. The Primordial Stakeholder: Advancing the Conceptual Consideration of Stakeholder Status for the Natural Environment. J. Bus. Ethics 2004, 49, 55–73. [Google Scholar] [CrossRef]

- Starik, M.; Kanashiro, P. Toward a Theory of Sustainability Management: Uncovering and Integrating the Nearly Obvious. Organ. Environ. 2013, 26, 7–30. [Google Scholar] [CrossRef]

- Dauvergne, P.; Lister, J. The Prospects and Limits of Eco-Consumerism: Shopping Our Way to Less Deforestation? Organ. Environ. 2007, 23, 132–154. [Google Scholar] [CrossRef]

- Asian Development Bank. Emerging Asia: Changes and Challenges; Asian Development Bank: Manila, Philippines, 1997. [Google Scholar]

- Ling, L.; Issac, D. Environmental Management Issues in China: Problems and Strategies. Prop. Manag. 1996, 14, 17–26. [Google Scholar] [CrossRef]

- Bashar, A.; Reazuddin, M. Towards Sustainable Development: Issues of Environmental Pollution in Bangladesh; Department of Environment: Dhaka, Bangladesh, 1990.

- Hoque, A.; Clarke, A. Greening of Industries in Bangladesh: Pollution Prevention Practices. J. Clean. Prod. 2013, 51, 47–56. [Google Scholar] [CrossRef]

- Mastaller, M.; Montgomery, R.; Weinstocks, J. Bangladesh: Towards an Environmental Strategy; Asian Development Bank (ADB): Manila, Philippines, 2000. [Google Scholar]

- Verma, A.K.; Dash, R.R.; Bhunia, P. A Review on Chemical Coagulation/Flocculation Technologies for Removal of Colour from Textile Wastewaters. J. Environ. Manag. 2012, 93, 154–168. [Google Scholar] [CrossRef] [PubMed]

- Rabbani, G.M.; Chowdhury, M.; Khan, N.A. Impacts of Industrial Pollution on Human Health: Empirical Evidences from an Industrial Hotspot (Kaliakoir) in Bangladesh. Asian J. Water Environ. Pollut. 2009, 7, 27–33. [Google Scholar]

- Murillo-Luna, J.L.; Garcés-Ayerbe, C.; Rivera-Torres, P. Barriers to the Adoption of Proactive Environmental Strategies. J. Clean. Prod. 2011, 19, 1417–1425. [Google Scholar] [CrossRef]

- Angelidis, J.; Ibrahim, N. An Exploratory Study of the Impact of Degree of Religiousness Upon an Individual’s Corporate Social Responsiveness Orientation. J. Bus. Ethics 2004, 51, 119–128. [Google Scholar] [CrossRef]

- Schwartz, M.; Carroll, A. Integrating and Unifying Competing and Complementary Frameworks: The Search for a Common Core in the Business and Society Field. Bus. Soc. 2008, 47, 148–186. [Google Scholar] [CrossRef]

- Corbett, M.; Cutler, D.J. Environmental Management Systems in the New Zealand Plastics Industry. Int. J. Oper. Prod. Manag. 2000, 20, 204–224. [Google Scholar] [CrossRef]

- Post, J.E.; Lawrence, A.T.; Webber, J. Business and Society: Corporate Strategy, Public Policy, and Ethics; McGraw Hill: New York, NY, USA, 2003. [Google Scholar]

- Berrone, P.; Gomez-Mejia, L. Environmental Performance and Executive Compensation: An Integrated Agency-Institiutional Perspective E. Acad. Manag. J. 2009, 52, 103–126. [Google Scholar] [CrossRef]

- Winn, M.I.; Pogutz, S. Business, Ecosystems, and Biodiversity: New Horizons for Management Research. Organ. Environ. 2013, 26, 203–229. [Google Scholar] [CrossRef]

- Bansal, P.; Roth, K. Why Companies Go Green: A Model of Ecological Responsiveness. Acad. Manag. J. 2000, 43, 717–736. [Google Scholar]

- Bansal, P. Evolving Sustainability: A longitudinal Study of Corporate Sustainable Development. Strateg. Manag. J. 2005, 26, 197–218. [Google Scholar] [CrossRef]

- Colwell, S.; Joshi, A. Corporate Ecological Responsiveness: Antecedent Effects of Institutional Pressure and Top Management Commitment and Their Impact on Organizational Performance. Bus. Strategy Environ. 2013, 22, 73–91. [Google Scholar] [CrossRef]

- Sharma, S.; Vredenburg, H. Proactive Corporate Environmental Strategy and the Development of Competitively Valuable Organizational Capabilities. Strateg. Manag. J. 1998, 19, 729–753. [Google Scholar] [CrossRef]

- Wartick, S.; Cochran, P. The Evolution of the Corporate Social Performance Model. Acad. Manag. Rev. 1985, 10, 758–769. [Google Scholar] [CrossRef]

- Tumin, V.M.; Koryakov, A.G.; Nikiforova, E.P. The main factors of socio-ecological-economic stability and development of industrial enterprises. World Appl. Sci. J. 2013, 25, 945–949. [Google Scholar]

- Hoffman, A. Linking Oranizational and Field-Level Analyses: The Diffusion of Corporate Environmental Practice. Organ. Environ. 2001, 14, 133–156. [Google Scholar] [CrossRef]

- Christmann, P.; Taylor, G. Globalization and the Environment: Determinants of Firm Self-Regulation in China. J. Int. Bus. Stud. 2001, 32, 439–458. [Google Scholar] [CrossRef]

- Dacin, M.; Oliver, C.; Roy, J. The Legitimacy of Strategic Alliances: An InstItutional Perspective. Strateg. Manag. J. 2007, 28, 169–187. [Google Scholar] [CrossRef]

- Scott, W.R. Institutions and Organizations: Ideas and Interests; Sage: London, UK, 2008. [Google Scholar]

- Stanwick, P.; Stanwick, S. The Relationship Between Corporate Social Performance, and Organizational Size, Financial Performance, and Environmental Performance: An Empirical Examination. J. Bus. Ethics 1998, 17, 195–204. [Google Scholar] [CrossRef]

- Wood, D. Corporate Social Performance Revisited. Acad. Manag. Rev. 1991, 16, 691–718. [Google Scholar] [CrossRef]

- Bourgeois, L.J.I. Strategy and Environment: A Conceptual Integration. Acad. Manag. Rev. 1980, 5, 25–39. [Google Scholar] [CrossRef]

- Lin, H. Strategic Alliances for Environmental Improvements. Bus. Soc. 2012, 51, 335–348. [Google Scholar] [CrossRef]

- Baum, J.; Oliver, C. Institutional Linkages and Organizational Mortality. Adm. Sci. Quartariy 1991, 36, 187–218. [Google Scholar] [CrossRef]

- Oliver, C. Sustainabe Competitive Advantage: Combining Institutional and Resource Based Views. Strateg. Manag. J. 1997, 18, 697–713. [Google Scholar] [CrossRef]

- DiMaggio, P.; Powell, W. The Iron Cage Revisited: Institutional Isomorphism and Collective Rationality in Organizational Fields. Am. Sociol. Rev. 1983, 83, 147–160. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J. The Moderating Effects of Institutional Pressures on Emergent Green Supply Chain Practices and Performance. Int. J. Prod. Res. 2007, 45, 4333–4355. [Google Scholar] [CrossRef]

- Child, J.; Tsai, T. The Dynamic between Firms’ Environmental Strategies and Institutional Constraints in Emerging Economies: Evidence from China and Taiwan. J. Manag. Stud. 2005, 42, 95–125. [Google Scholar] [CrossRef]

- Mohiuddin, M.; Al Mamun, A.; Syed, F.A.; Masud, M.M.; Su, Z. Environmental Knowledge, Awareness, and Business School Students’ Intentions to Purchase Green Vehicles in Emerging Countries. Sustainability 2018, 10, 1534. [Google Scholar] [CrossRef]

- Peng, M. Institutional Transitions and Strategic Choices. Acad. Manag. Rev. 2003, 28, 275–296. [Google Scholar] [CrossRef]

- North, D. Institutions, Institutional Change and Economic Performance; Press Syndicate: Cambridge, UK, 1990. [Google Scholar]

- Berrone, P.; Fosfuri, A.; Gelabert, L.; Gomez-Mejia, L. Necessity as the Mother of ‘Green’ Inventions: Institutional Pressures and Environmental Innovations. Strateg. Manag. J. 2013, 34, 891–909. [Google Scholar] [CrossRef]

- Hoffman, A.; Ventresca, M. The Institutional Framing of Policy Debates: Economics Versus the Environment. Am. Behav. Sci. 1999, 42, 1368–1392. [Google Scholar] [CrossRef]

- Hoffman, A. Institutional Evolution and Change: Environmentalism and The U.S. Chemical Industry. Acad. Manag. J. 1999, 42, 351–371. [Google Scholar]

- Delmas, M.; Toffel, M.W. Stakeholders and Environmental Management Practices: An Institutional Framework. Bus. Strategy Environ. 2004, 13, 209–222. [Google Scholar] [CrossRef]

- Jennings, P.; Zandbergen, P. Ecologically Sustainable Organizations: An Institutional Approach. Acad. Manag. Rev. 1995, 20, 1015–1052. [Google Scholar] [CrossRef]

- Sharma, S.; Henriques, I. Stakeholder Influences on Sustainability Practices in the Canadian Forest Products Industry. Strateg. Manag. J. 2005, 26, 159–180. [Google Scholar] [CrossRef]

- Berrone, P.; Gelabert, L.; Fosfuri, A.; Gomez-Mejia, L.R. Can institutional forces create competitive advantage? An empirical examination of environmental innovation. In Proceedings of the Academy of Management Conference, Anaheim, CA, USA, 8–13 August 2008; pp. 1–6. [Google Scholar]

- Hoffman, A. From Heresy to Dogma: An Institutional History of Corporate Environmentalism; Stanford University Press: Standford, CA, USA, 1997. [Google Scholar]

- Bansal, P.; Clelland, I. Talking Trash: Legitimacy, Impression Management, and Unsystematic Risk in the Context of the Natural Environment. Acad. Manag. J. 2004, 47, 93–103. [Google Scholar]

- Dalmas, M. The diffusion of environmental management standards in Europe and in the United States: An institutional perspective. Policy Sci. 2002, 35, 91–119. [Google Scholar] [CrossRef]

- Montiel, I.; Delgado-Ceballos, J. Defining and Measuring Corporate Sustainability: Are We There Yet? Organ. Environ. 2014. [Google Scholar] [CrossRef]

- Jensen, J.C.; Berg, N. Determinants of Traditional Sustainability Reporting Versus Integrated Reporting. An Institutionalist Approach. Bus. Strategy Environ. 2012, 21, 299–316. [Google Scholar] [CrossRef]

- Pérez-Batres, L.; Miller, V.V.; Pisani, M.J. CSR, Sustainability and the Meaning of Global Reporting for Latin American Corporations. J. Bus. Ethics 2010, 91, 193–209. [Google Scholar] [CrossRef]

- Smith, W.K.; Lewis, M.W. Toward a theory of paradox: A dynamic equilibrium model of organizing. Acad. Manag. Rev. 2011, 36, 381–403. [Google Scholar]

- Delmas, M.; Montes-Sancho, M.J. An Institutional Perspective on the Diffusion of International Management System Standards: The Case of the Environmental Management Standard ISO 14001. Bus. Ethics Q. 2011, 21, 103–132. [Google Scholar] [CrossRef]

- King, A.; Lenox, M.; Terlaak, A. The strategic use of decentralized institutions: Exploring certification with the ISO 14001 management standard. Acad. Manag. J. 2005, 48, 1091–1106. [Google Scholar] [CrossRef]

- Aguilera-Caracuel, J.; Ortiz-de-Mandojana, N. Green Innovation and Financial Performance: An Institutional Approach. Organ. Environ. 2013, 26, 365–385. [Google Scholar] [CrossRef]

- Khan, M.R. The Green Agenda in Bangladesh; Forum of Environmental Journalists of Bangladesh (FEJB): Dhaka, Bangladesh, 2000. [Google Scholar]

- Reazuddin, M.; Hoque, Z. Environmental Management System (EMS) for Industries in Bangladesh; Government of Bangladesh: Dhaka, Bangladesh, 2002.

- Chowdhury, Q.I. National Environmental Legislations; Forum of Environmental Journalists of Bangladesh (FEJB): Dhaka, Bangladesh, 1999. [Google Scholar]

- Mahjabeen, Z. Environmental Movement in Bangladesh: Some Case Studies; Bangladesh Paribesh Andolon (BAP): Dhaka, Bangladesh, 2002. [Google Scholar]

- Belal, A.R.; Roberts, R.W. Stakeholders’ Perceptions of Corporate Social Reporting in Bangladesh. J. Bus. Ethics 2010, 97, 311–324. [Google Scholar] [CrossRef]

- Mohammad, N. The Role of Global Governance Mechanisms to Protect the Environment for Sustainability: A Study on Bangladesh Perspective. Aust. J. Basic Appl. Sci. 2011, 5, 1175–1186. [Google Scholar]

- Belal, A.R. A Study of Corporate Social Disclusures in Bangladesh. Manag. Audit. J. 2001, 16, 224–289. [Google Scholar]

- Gain, P. Bangladesh Environment Facing the 21st Century, 2nd ed.; Society for Environment and Human Development (SEHD): Dhaka, Bangladesh, 2002. [Google Scholar]

- Government of Bangladesh. Pollution: Industrial Sector; Bangladesh Bureau of Statistics: Dhaka, Bangladesh, 1999.

- Sunny, F.; Karimanzira, T.; Huang, Z. Environment Security: An Empirical Study of Industrialization and the Impact on Environment in the Dhaka Division, Bangladesh. Environ. Dev. Sustain. 2012, 14, 885–900. [Google Scholar] [CrossRef]

- Gain, P. Leather Industry: Environmental Pollution and Mitigation Measures; Society for Environment and Human Development (SEHD): Dhaka, Bangladesh, 2001. [Google Scholar]

- Gain, P. Bangladesh Environment: Facing the 21st Century; Society for Environment and Human Development (SEHD): Dhaka, Bangladesh, 1998. [Google Scholar]

- Hoque, A.; Clarke, A.; MacDonald, A. Implementing a Developing Country’s Global Environmental Commitments: Industry Perspectives on Potential Pollution Prevention Programs in Bangladesh. In Cross-Border Partnerships for Sustainability and Innovation: A Role for South-Driven Sustainability? Vazquez, D.A., Sarkis, J., Cordeiro, J., Eds.; Springer Publishing Company: New York, NY, USA, 2014. [Google Scholar]

- Holt, D. The Percieved Benefit of an Environmental Management. Bus. Process. Manag. J. 1998, 1, 204–213. [Google Scholar] [CrossRef]

- Davis, P.R.; McGregor, J.A. Civil Society, International Donors and Poverty in Bangladesh. Commonw. Comp. Politics 2000, 38, 47–64. [Google Scholar] [CrossRef]

- Zafarullah, H.; Rahman, M.H. Human Rights, Civil Society and Nongovernmental Organizations: The Nexus in Bangladesh. Hum. Rights Q. 2002, 24, 1011–1034. [Google Scholar] [CrossRef]

- Hoque, A.; Clarke, A.; Huang, L. Lack of stakeholder influence on pollution prevention: A developing country perspective. Organ. Environ. 2016, 29, 367–385. [Google Scholar] [CrossRef]

- Khan, M.R. The Green-Agenda in Bangladesh: A Policy-Management Framework; Forum of Environmental Journalists of Bangladesh: Dhaka, Bangladesh, 2000. [Google Scholar]

- Islam, R. West Minimization Practices; Asian Productivity Organization: Tokyo, Japan, 2000. [Google Scholar]

- Islam, N. Public Awareness about Environmental Issues: Perspective Bangladesh. Asian Aff. 2008, 30, 30–56. [Google Scholar]

- Aminuzzaman, S.M. Environment Policy of Bangladesh: A Case Study of an Ambitious Policy with Implementation Snag. Available online: http://gsdl.ewubd.edu/greenstone/collect/admin-mprhgdco/index/assoc/HASHa973.dir/P0200.pdf (accessed on 26 October 2018).

- Muhith, A. Protecting the Fragile Environment in Bangladesh. In Bangladesh in the Twenty-First Century: Towards an Industrial Society; University Press Limitted (UPL): Dhaka, Bangladesh, 1999. [Google Scholar]

- Rahman, A.; Chowdhury, F. People’s Report on Bangladesh Environment, 2001: Main Report; Unnayan Shamannay: Dhaka, Bangladesh, 2001; Volume 1. [Google Scholar]

- Bala, S.K.; Yusuf, M.A. Corporate Environmental Reporting in Bangaldesh: A Study of Listed Public Limited Companies. J. Bus. Stud. 2003, 24, 31–45. [Google Scholar]

- Quader, A.K. Environmental Rules and Regulations of Bangladesh; Poribash Andolon: Dhaka, Bangladesh, 2000; pp. 667–671. [Google Scholar]

- Nishat, A.; Shammin, P.; Faisal, I.; Junaid, J. Industrial Pollution. In Bangladesh Environment OutLook—2001; Nishat, A., Ullah, M., Haque, A.K.E., Eds.; Centre for Sustainable Development (CSD): Dhaka, Bangladesh, 2001. [Google Scholar]

- Observer, T.B. The Adjoining Area of Hazaribagh. The Bangaldesh Observer, 9 July 2002. [Google Scholar]

- Ullah, M. Environmental Politics in Bangladesh; Centre for Sustainable Development (CFSD): Dhaka, Bangladesh, 1999; p. 224. [Google Scholar]

- Roy, P. Vast Swath of Saver Farmland Washed with Toxic Waste. The Daily Star, 7 February 2007; 24. [Google Scholar]

- Star, T.D. Four Textile Firms Fined for Polluting Rive’. The Daily Star, 22 March 2007; 1. [Google Scholar]

- World Bank. World Development Report 2000: Entering the 21st Century; The World Bank: Washington, DC, USA; Oxford University Press: New York, NY, USA, 2000. [Google Scholar]

- Bakht, D. A Environmental Study on Urea Fertilizer Factory in Ghorashal; Bangladesh University of Engineering and Technology (BUET): Dhaka, Bangladesh, 1996. [Google Scholar]

- Shakil, M. Fertilizer Plants Rains Toxin on Pleople. The Daily Star, 22 June 2007. [Google Scholar]

- Shakil, M. Toxic Textile Waste Polluting Louhajang River in Tangail. The Daily Star, 3 July 2006. [Google Scholar]

- Star, T.D. The Untreated Liquid Waste from the Dying Industries. The Daily Star, 24 February 2005. [Google Scholar]

- Islam, A. Toxic Water from Dying Units Polluting Rivers, Cannals: Fish Resources, Crops and Greenery Threatened in Bhaluka. The Daily Star, 15 August 2005. [Google Scholar]

- Star, T.D. Liquid Waste from a Dying Factory Polluting the Shitalakhya Near Kanchpur Bridge on the Outskirts of the Capital. The Daily Star, 19 January 2008. [Google Scholar]

- Islam, S.; Miah, S. Banglapedia (National Encyclopedia of Bangladesh); Asiatic Society of Bangladesh: Dhaka, Bangladesh, 2003; Volume 4. [Google Scholar]

- Government of the People’s Republic of Bangladesh. The Environment Conservation Rules (ECR), 1997; Government of the People’s Republic of Bangladesh: Dhaka, Bangladesh, 1997.

- Patton, M.Q. Qualitative Research and Evaluation Methods; SAGE Publication: Thousands Oaks, CA, USA, 2002. [Google Scholar]

- Glaser, B.G.; Strauss, A.L. Discovery of Grounded Theory: Strategies for Qualitative Research. Available online: http://www.sxf.uevora.pt/wp-content/uploads/2013/03/Glaser_1967.pdf (accessed on 26 October 2018).

- Stuart, I.; McCutcheon, D.; Handfield, R.; McLachlin, R.; Samson, D. Effective case research in operations management: A process perspective. J. Oper. Manag. 2002, 20, 419–433. [Google Scholar] [CrossRef]

- Thietart, R.-A.; Girod-Séville, M.; Perret, V.; Allard-Poesi, F.; Charreire, S.; Durieux, S.; Baumard, P. Doing Management Research: A Comprehensive Guide. J. Oper. Res. Soc. 2003, 54, 1123. [Google Scholar]

- Belay, A.A. Impacts of Chromium from Tannery Effluent and Evaluation of Alternative Treatment Options. J. Environ. Prot. 2010, 1, 53–58. [Google Scholar] [CrossRef]

- Schuman, H.; Presser, S. The Open and Closed Question. American Sociological Review; American Sociological Association: Washington, DC, USA, 1979. [Google Scholar]

- Saldana, J. Fundamentals of Qualitative Research; Oxford University Press: Oxford, UK, 2011. [Google Scholar]

- Eisenhardt, K.M. Building theories from case study research. Acad. Manag. Rev. 1989, 14, 532–550. [Google Scholar] [CrossRef]

- Bouma, G.D.; Ling, R. The Research Process; Oxford University Press: Oxford, UK, 2004. [Google Scholar]

- Creswell, J.W. Research Design: Qualitative, Quantitative, and Mixed Methods Design; Sage: London, UK, 2003. [Google Scholar]

- Jones, M.; Irit, A. Guiding the Use of Grounded Theory in Doctoral Studies—An Example from the Australian Film Industry. Available online: https://ro.uow.edu.au/cgi/viewcontent.cgi?referer=https://www.google.com/&httpsredir=1&article=1842&context=commpapers (accessed on 26 October 2018).

- Downe-Wamboldt, B. Content analysis: Method, applications, and issues. Health Care Women Int. 1992, 13, 313–321. [Google Scholar] [CrossRef] [PubMed]

- Hsieh, H.-F.; Shannon, S.E. Three approaches to qualitative content analysis. Qual. Health Res. 2005, 15, 1277–1288. [Google Scholar] [CrossRef] [PubMed]

- Maxime, L.; Karuranga, E.G.; Lebouc, M.F.; Mohiuddin, M. Ethnic entrepreneurship in OECD countries: A systematic review of performance determinants of ethnic ventures. Int. Bus. Econ. Res. J. 2013, 12, 1199. [Google Scholar]

- Sultana, M.A.; Rashid, M.M.; Mohiuddin, M.; Mazumder, M.N.H. Cross-cultural management and organizational performance: A content analysis perspective. Int. J. Bus. Manag. 2013, 8, 133–146. [Google Scholar] [CrossRef]

- Yin, R.K. Validity and generalization in future case study evaluations. Eval. 2013, 19, 321–332. [Google Scholar] [CrossRef]

- Merriam, S.B. Qualitative Research and Case Study Applications in Education. Revised and Expanded from Case Study Research in Education; Jossey-Bass Publishers: San Francisco, CA, USA, 1998. [Google Scholar]

- Ingle, K.N.; Harada, K.; Wei, C.N.; Minamoto, K.; Ueda, A. Policy Framework for Formulating Environmental Management Strategy for Sustainable Development of Tanneries in India. Environ. Health Prev. Med. 2011, 16, 123–128. [Google Scholar] [CrossRef] [PubMed]

- Kanagaraj, J.; Babu, N.K.C.; Mandal, A.B. Recovery and Reuse of Chromium from Chrome Tanning Waste Water Aiming towards Zero Discharge of Pollution. J. Clean. Prod. 2008, 16, 1807–1813. [Google Scholar] [CrossRef]

- Kafiluddin, A.K. Population Research, Environmental Conservation and Economic Development; Prof. Shamin Ahamed: Dhaka, Bangladesh, 2001; p. 850. [Google Scholar]

- Khan, M.A. Fish Losing Final Fight with Tannery Waste: Buriganga Southwest of Dhaka Area Polluted. The Daily Star, 12 December 2004. [Google Scholar]

- Star, T.D. Toxic, Untreated Tannery Wastes of Hazaribagh Tannery Units are Pumped Out into the Highly-Polluted Buriganga, Putting the River’s Ecosystem in Peril. The Daily Star, 8 August 2004. [Google Scholar]

- Star, T.D. Tones of Chemical Waste are Dumped into the Karnaphuli River. The Daily Star, 2 March 2007. [Google Scholar]

- Ibrahim, N.A.; Moneim, N.M.A.; Halim, E.S.A.; Hosni, M.M. Pollution Prevention of Cotton-cone Reactive Dyeing. J. Clean. Prod. 2008, 16, 1321–1326. [Google Scholar] [CrossRef]

- Ozturk, E.; Yetis, U.; Dilek, F.B.; Demirer, G.N. A Chemical Substitution Study for a Wet Processing Textile Mill in Turkey. J. Clean. Prod. 2009, 17, 239–247. [Google Scholar] [CrossRef]

- Rahman, K. Industrial Pollution and Control for Sustainable Development; Department of Environment: Dhaka, Bangladesh, 1992.

- Ali, Y. Water Pollution; The University Press Limited (UPL): Dhaka, Bangladesh, 1997. [Google Scholar]

- Star, T.D. Fertilizer Factory Gas Leaks Kills 100 Cattle. The Daily Star, 18 February 2004. [Google Scholar]

- Bal, P. Environmental Hazards on Karnafuly River. Prothom Alo, 16 February 2007; 1. [Google Scholar]

- Starik, M.; Rands, G. Weaving an Integrated Web: MuItlevel and Multisystem Perspectives of Ecologically Sustainable Organizations. Acad. Manag. Rev. 1995, 20, 908–935. [Google Scholar] [CrossRef]

- de Abreu, M.C.; de Castro, F.; de Assis Soares, F.; da Silva Filho, J.C. A comparative understanding of corporate social responsibility of textile firms in Brazil and China. J. Clean. Prod. 2012, 1, 119–126. [Google Scholar] [CrossRef]

- Logsdon, J.M.; Husted, B.W. Mexico’s environmental performance under NAFTA: The first 5 years. J. Environ. Dev. 2000, 9, 370–383. [Google Scholar] [CrossRef]

- Jeswani, H.K.; Wehrmeyer, W.; Mulugetta, Y. How warm is the corporate response to climate change? Evidence from Pakistan and the UK. Bus. Strategy Environ. 2008, 17, 46–60. [Google Scholar] [CrossRef]

- Boons, F.; Lüdeke-Freund, F. Business models for sustainable innovation: State-of-the-art and steps towards a research agenda. J. Clean. Prod. 2013, 45, 9–19. [Google Scholar] [CrossRef]

- Bansal, P.; Bertels, S.; Ewart, T.; MacConnachie, P.; O’Brien, J. Bridging the research-practice gap. Acad. Manag. Perspect. 2013, 26, 73–93. [Google Scholar] [CrossRef]

- Hart, S.; Dowell, G. A natural-resource-based view of the firm: Fifteen years after. J. Manag. 2011, 37, 1464–1479. [Google Scholar]

- Sandelowski, M.; Barroso, J. Finding the findings in qualitative studies. J. Nurs. Scholarsh. 2002, 34, 213–219. [Google Scholar] [CrossRef] [PubMed]

| Name of Sample Industry | Number of Sample Industrial Plants | Number of Sample Respondents |

|---|---|---|

| Tannery Industry | 02 | (5/each plant × 2) = 10 |

| Pulp and Paper Industry | 02 | (5 × 2) = 10 |

| Fertilizer Industry | 02 | (5 × 2) = 10 |

| Textile Industry | 02 | (5 × 2) = 10 |

| Cement Industry | 02 | (5 × 2) = 10 |

| Total | 10 | 50 |

| Human Health Factors | Score | Environmental Factors | Score | Socio-Economic Factors | Score |

|---|---|---|---|---|---|

| Skin disease | 4.0 | Acid rain | 1.0 | Livelihood | 3.3 |

| Respiratory illness | 3.6 | Greenhouse effect | 1.3 | Livestock | 1.2 |

| Children respiratory disease | 1.4 | Water-logging | 2.1 | Forest resources | 1.1 |

| Brain and nervous system effect | 3.5 | Effect of toxicity | 0.0 | Water resources | 3.6 |

| Diarrhea and stomach related disease | 1.3 | BOD * load | 2.7 | Export market | 1.0 |

| Waterborne disease | 1.2 | COD ** load | 2.4 | Quality of life | 3.5 |

| Effect of poisonous gas | 1.3 | Salinity of water | 2.0 | Grazing land | 3.4 |

| Bad smell | 3.4 | Soil erosion | 2.8 | Productivity of land | 3.5 |

| Effect of toxicity | 3.8 | Depletion of aquatic life | 2.1 | Discoloring and eroding buildings | 2.6 |

| Decrease in fertility of land | 3.0 | ||||

| Underground water pollution | 2.0 | ||||

| Surface water pollution | 3.8 |

| Human Health Factors | Score | Environmental Factors | Score | Socio-Economic Factors | Score |

|---|---|---|---|---|---|

| Skin disease | 3.8 | Acid rain | 1.2 | Livelihood | 2.4 |

| Respiratory illness | 2.6 | Greenhouse effect | 2.2 | Livestock | 1.6 |

| Children respiratory disease | 2.4 | Water-logging | 1.0 | Forest resource | 2.8 |

| Brain and nervous system effect | 1.2 | Effect of toxicity | 3.2 | Water resource | 3.0 |

| Diarrhea and stomach related disease | 1.3 | BOD load | 3.1 | Export market | 1.0 |

| Water-borne disease | 1.2 | COD load | 2.6 | Quality of life | 2.5 |

| Effect of poisonous gas | 1.2 | Salinity of water | 1.0 | Grazing land | 2.1 |

| Bad smell | 2.5 | Soil erosion | 2.8 | Productivity of land | 2.3 |

| Effect of toxicity | 1.4 | Depletion of aquatic life | 1.3 | Discoloring and eroding building | 1.2 |

| Decrease in fertility of land | 1.2 | ||||

| Underground water pollution | 3.6 | ||||

| Surface water pollution | 3.3 |

| Human Health Factors | Score | Environmental Factors | Score | Socio-Economic Factors | Score |

|---|---|---|---|---|---|

| Skin disease | 1.4 | Acid rain | 1.2 | Livelihood | 2.1 |

| Respiratory illness | 3.6 | Greenhouse effect | 2.2 | Livestock | 2.5 |

| Children respiratory disease | 2.4 | Water-logging | 1.2 | Forest resources | 1.2 |

| Brain and nervous system effect | 1.2 | Effect of toxicity | 2.1 | Water resources | 3.2 |

| Diarrhea and stomach related disease | 1.2 | BOD load | 1.2 | Export market | 1.2 |

| Water-borne disease | 1.3 | COD load | 1.2 | Quality of life | 2.5 |

| Effect of poisonous gas | 1.2 | Salinity of water | 1.3 | Grazing land | 2.5 |

| Bad smell | 2.5 | Soil erosion | 1.4 | Productivity of land | 2.2 |

| Effect of toxicity | 1.0 | Depletion of aquatic life | 2.3 | Discoloring and eroding buildings | 1.0 |

| Irritation of the mucous membranes of nose, throat, eyes. | 3.5 | Decrease in fertility of land | 1.3 | Extraction of ground water | 2.6 |

| Underground water pollution | 2.8 | ||||

| Surface water pollution | 2.4 |

| Human Health Factors | Score | Environmental Factors | Score | Socio-Economic Factors | Score |

|---|---|---|---|---|---|

| Skin disease | 3.8 | Acid rain | 1.0 | Livelihood | 1.7 |

| Respiratory illness | 3.4 | Greenhouse effect | 1.5 | Livestock | 1.3 |

| Children respiratory disease | 1.7 | Water-logging | 1.0 | Forest resources | 1.0 |

| Brain and nervous system effect | 2.5 | Effect of toxicity | 2.6 | Water resources | 2.8 |

| Diarrhea and stomach related disease | 1.1 | BOD load | 2.5 | Export market | 2.7 |

| Water-borne disease | 1.0 | COD load | 2.0 | Quality of life | 2.3 |

| Effect of poisonous gas | 1.2 | Salinity of water | 1.2 | Grazing land | 1.5 |

| Bad smell | 1.3 | Soil erosion | 1.1 | Productivity of land | 2.0 |

| Effect of toxicity | 2.1 | Depletion of aquatic life | 2.6 | Discoloring and eroding buildings | 1.2 |

| Decrease in fertility of land | 2.1 | ||||

| Underground water pollution | 1.2 | ||||

| Surface water pollution | 3.1 |

| Human Health Factors | Score | Environmental Factors | Score | Environmental Factors | Score |

|---|---|---|---|---|---|

| Skin disease | 2.3 | Acid rain | 1.5 | Livelihood | 1.0 |

| Respiratory illness | 2.8 | Greenhouse effect | 2.4 | Livestock | 2.1 |

| Children respiratory disease | 2.4 | Water- logging | 1.0 | Forest resources | 2.1 |

| Brain and nervous system effect | 1.0 | Effect of toxicity | 1.0 | Water resources | 2.2 |

| Diarrhea and stomach related disease | 2.2 | BOD load | 1.2 | Export market | 1.0 |

| Water-borne disease | 2.1 | COD load | 1.3 | Quality of life | 2.8 |

| Effect of poisonous gas | 1.2 | Salinity of water | 1.0 | Grazing land | 2.2 |

| Bad smell | 1.2 | Soil erosion | 1.2 | Productivity of land | 1.2 |

| Effect of toxicity | 1.0 | Depletion of aquatic life | 1.0 | Discoloring and eroding buildings | 2.2 |

| Decrease in fertility of land | 2.2 | ||||

| Underground water pollution | 1.2 | ||||

| Surface water pollution | 2.1 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hoque, A.; Mohiuddin, M.; Su, Z. Effects of Industrial Operations on Socio-Environmental and Public Health Degradation: Evidence from a Least Developing Country (LDC). Sustainability 2018, 10, 3948. https://doi.org/10.3390/su10113948

Hoque A, Mohiuddin M, Su Z. Effects of Industrial Operations on Socio-Environmental and Public Health Degradation: Evidence from a Least Developing Country (LDC). Sustainability. 2018; 10(11):3948. https://doi.org/10.3390/su10113948

Chicago/Turabian StyleHoque, Asadul, Muhammad Mohiuddin, and Zhan Su. 2018. "Effects of Industrial Operations on Socio-Environmental and Public Health Degradation: Evidence from a Least Developing Country (LDC)" Sustainability 10, no. 11: 3948. https://doi.org/10.3390/su10113948

APA StyleHoque, A., Mohiuddin, M., & Su, Z. (2018). Effects of Industrial Operations on Socio-Environmental and Public Health Degradation: Evidence from a Least Developing Country (LDC). Sustainability, 10(11), 3948. https://doi.org/10.3390/su10113948