Experimental Investigation of the Impact of Coal Fines Migration on Coal Core Water Flooding

Abstract

1. Introduction

2. Materials and Methods

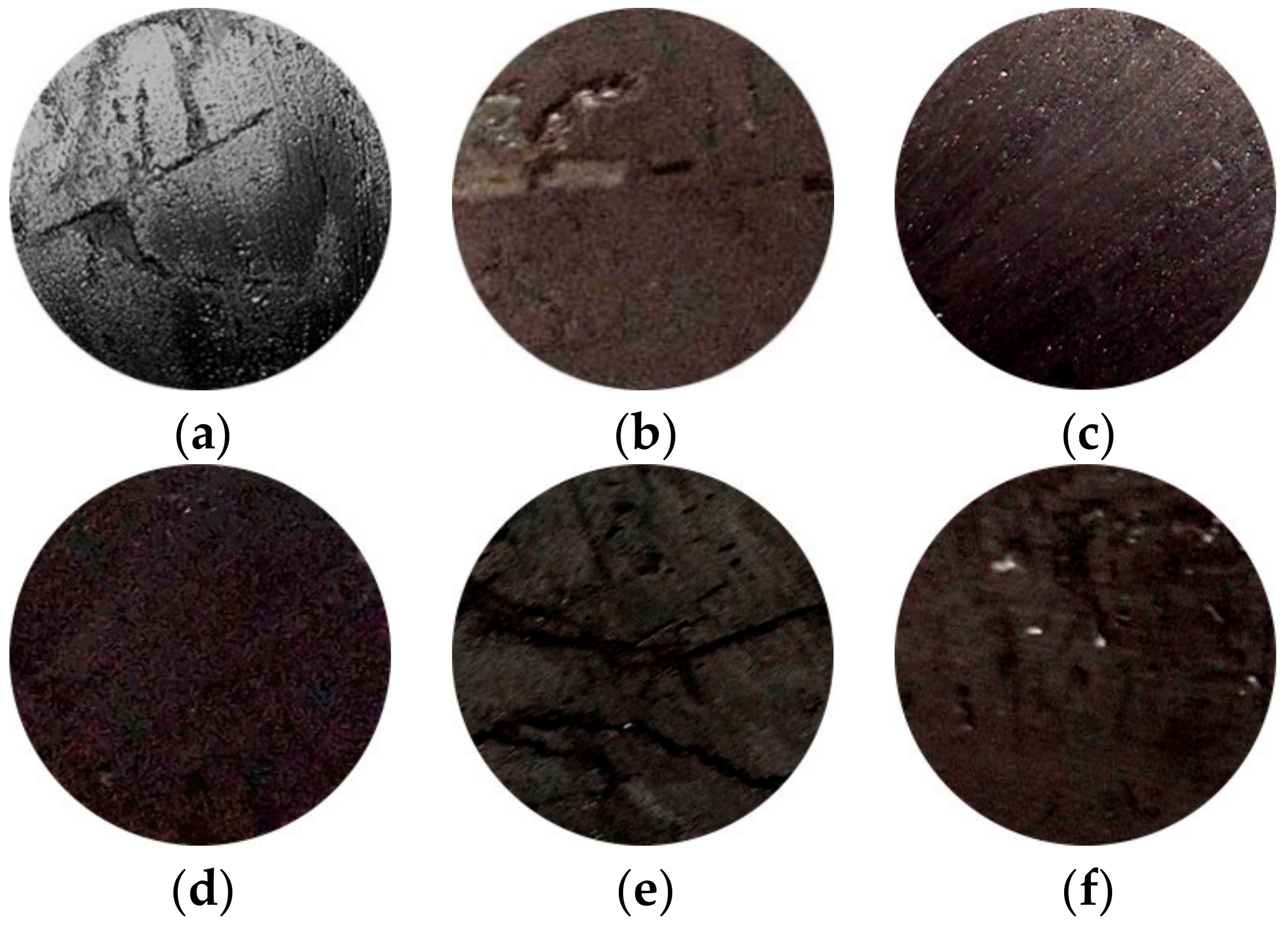

2.1. Sample Preparation and Characterization

2.1.1. Coal Rocks

2.1.2. Coal Fines

2.1.3. Displacement Fluids

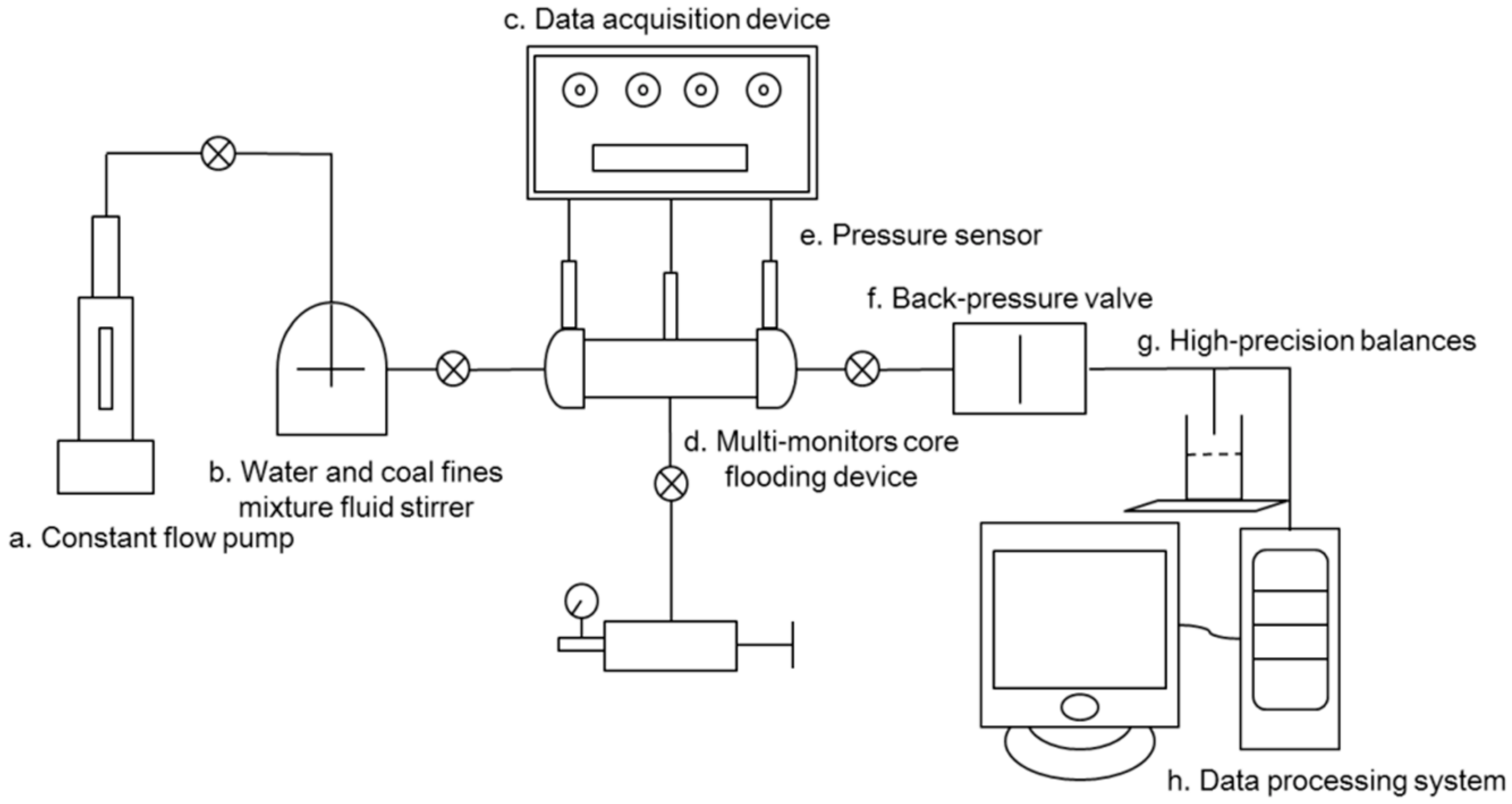

2.2. Experimental Equipment and System

2.3. Experimental Schemes and Workflow

3. Results and Discussion

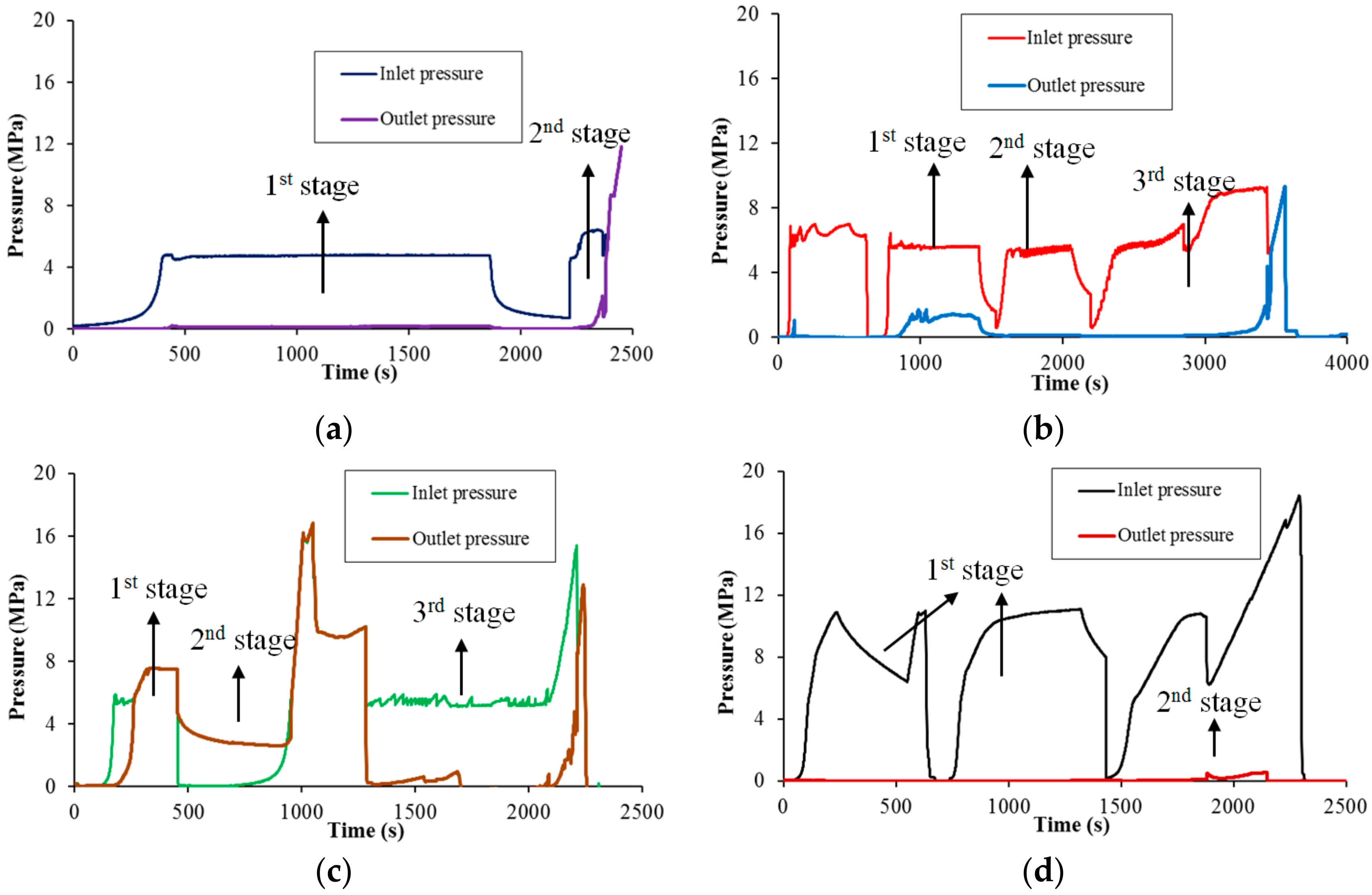

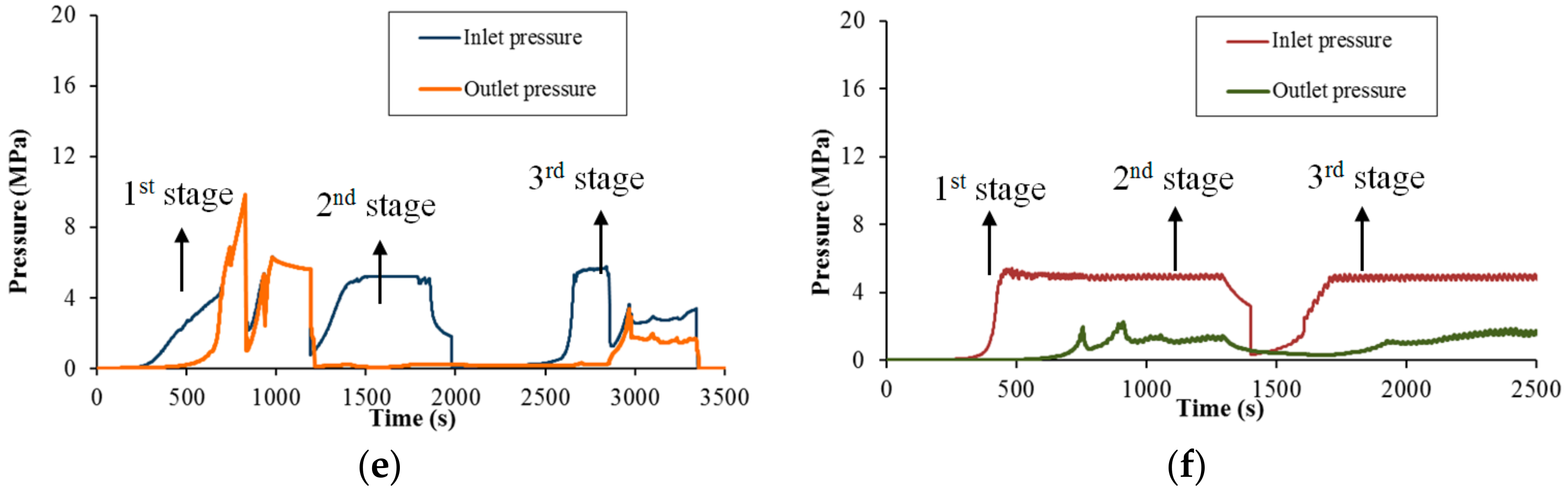

3.1. Analysis of Pressures Variation

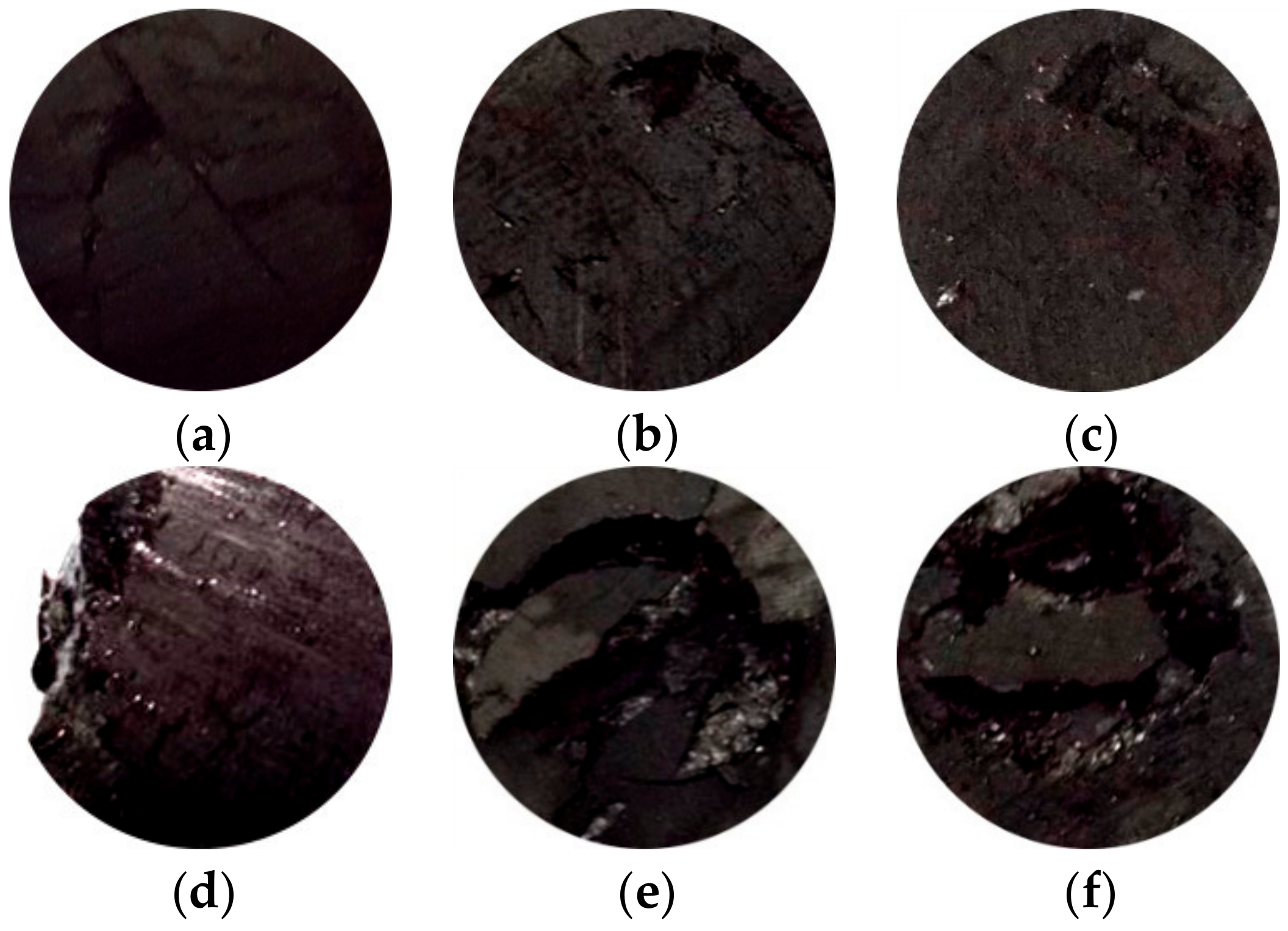

3.2. Analysis of Pore and Cleat Change

3.3. Analysis of Permeability Variation

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Moore, T.A. Coalbed methane: A review. Int. J. Coal Geol. 2012, 101, 36–81. [Google Scholar] [CrossRef]

- Salmachi, A.; Yarmohammadtooski, Z. Production data analysis of coalbed methane wells to estimate the time required to reach to peak of gas production. Int. J. Coal Geol. 2015, 141, 33–41. [Google Scholar] [CrossRef]

- Magill, D.P.; Ramurthy, M.; Jordan, R.; Nguyen, P.D. Controlling coal-fines production in massively cavitated openhole coalbed-methane wells. In Proceedings of the SPE Asia Pacific Oil and Gas Conference and Exhibition Society of Petroleum Engineers, Brisbane, Australia, 18–20 October 2010. [Google Scholar]

- Bai, T.; Chen, Z.; Aminossadati, S.M.; Li, L.; Liu, J.; Lu, H. Dimensional analysis and prediction of coal fines generation under two-phase flow conditions. Fuel 2017, 194, 460–479. [Google Scholar] [CrossRef]

- Bai, T.; Chen, Z.; Aminossadati, S.M.; Pan, Z.; Liu, J.; Li, L. Characterization of coal fines generation: A micro-scale investigation. J. Nat. Gas Sci. Eng. 2015, 27, 862–875. [Google Scholar] [CrossRef]

- Guo, Z.; Hussain, F.; Cinar, Y. Permeability variation associated with fines production from anthracite coal during water injection. Int. J. Coal Geol. 2015, 147–148, 46–57. [Google Scholar] [CrossRef]

- Liu, H.L.; Wang, H.Y.; Liu, R.H.; Zhao, Q.; Zhang, X.W.; Yong, H. Unconventional oil and gas resources development status and key issues. Nat. Gas Ind. 2009, 29, 113–116. [Google Scholar]

- Okotie, V.U.; Moore, R.L. Well production challenges and solutions in a mature, very low-pressure coalbed methane reservoir. In Proceedings of the SPE Annual Technical Conference and Exhibition, Calgary, AB, Canada, 19–21 October 2010. [Google Scholar]

- Zhong, Z.Y.; Wu, X.D.; Han, G.Q.; He, L.P.; Xiong, X.F.; Wang, S.L. Experimental investigation on particle transport of coal fines in unsteady terrain slug flow. J. Pet. Sci. Eng. 2018, 166, 747–758. [Google Scholar] [CrossRef]

- Chen, Z.H.; Wang, Y.B.; Sun, P. Destructive influences and effectively treatments of coal powder to high rank coal bed methane production. J. China Coal Soc. 2009, 34, 229–232. [Google Scholar]

- Zou, Y.S.; Zhang, S.C.; Zhang, J. Experimental method to simulate coal fines migration and coal fines aggregation prevention in the hydraulic fracture. Transp. Porous Med. 2014, 101, 17–34. [Google Scholar] [CrossRef]

- Nouri, A.; Vaziri, H.; Belhaj, H.; Islam, R. Sand-production prediction: A new set of criteria for modeling based on large-scale transient experiments and numerical investigation. SPE J. 2006, 11, 227–237. [Google Scholar] [CrossRef]

- Liu, C.H.; Liu, X.F.; Zhou, C. Migration patterns of pulverized coal in coal reservoirs during the well drainage. Coal Geol. Explor. 2015, 43, 23–26. [Google Scholar]

- Liu, S.G.; Hu, A.M.; Song, B.; Li, H.F. Early warning and prevention and control measures of coal dust concentration in coal bed gas wells. J. China Coal Soc. 2012, 37, 86–89. [Google Scholar]

- Zou, J.; Rezaee, R. Effect of particle size on high-pressure methane adsorption of coal. Pet. Res. 2016, 1, 53–58. [Google Scholar] [CrossRef]

- Liu, S.G.; Zhang, X.L.; Yuan, W.F.; Tian, X.Y. Pulverized coal output law of coal-bed methane wells and practice of drainage control and management. J. China Coal Soc. 2012, 37, 412–415. [Google Scholar]

- Wang, Q.W.; Cao, D.Y.; Wang, T. Relationship between the stress-concentrated zone caused by cavity-completed wells and the coal powder output. Coal Geol. Explor. 2013, 41, 35–37. [Google Scholar]

- Liu, X.F. Prediction of flowing bottom hole pressures for two-phase coalbed methane wells. Acta Geol. Sin. Engl. Ed. 2013, 87, 1412–1420. [Google Scholar]

- Wei, Y.C.; Cao, D.Y.; Yuan, Y. Characteristics and controlling factors of pulverized coal during coalbed methane drainage in Hancheng area. J. China Coal Soc. 2013, 38, 1424–1429. [Google Scholar]

- Zhang, G.S.; Tian, W.T.; Tao, S.; Bai, J.M.; Shi, H.N.; Cheng, H. Experimental research of coal grain migration rules of Coalbed Methane. J. Oil Gas Technol. 2011, 33, 105–108. [Google Scholar]

- Cao, D.Y.; Yao, Z.; Li, X.M.; Wei, Y.C.; Hu, A.M.; Song, B. Rules of coal powder output under physical simulation experiments of single-phase water flow displacement. J. China Coal Soc. 2013, 38, 624–628. [Google Scholar]

- Li, X.M.; Cao, D.Y.; Yao, Z.; Xiang, X.R.; Wang, X.L.; Wei, Y.C. Study on mechanism of pulverized coal discharge based on flow-state physical simulation. Coal Sci. Technol. 2015, 43, 76–79. [Google Scholar]

- Lan, W.J.; Wang, H.X.; Yang, S.Y.; Zheng, C.; Liu, Y.X.; Chen, S.S. Study on the migration of pulverized coal in CBM wellbore. J. Pet. Sci. Eng. 2017, 156, 740–747. [Google Scholar] [CrossRef]

- Shi, Q.M.; Qin, Y.; Zhou, B.Y.; Zhang, M.J.; Wu, M.; Wang, L.N. An experimental study of the agglomeration of coal fines in suspensions: Inspiration for controlling fines in coal reservoirs. Fuel 2018, 211, 110–120. [Google Scholar] [CrossRef]

- Bai, T.; Chen, Z.; Aminossadati, S.M.; Rufford, T.E.; Liang, L. Experimental investigation on the impact of coal fines generation and migration on coal permeability. J. Pet. Sci. Eng. 2017, 159, 257–266. [Google Scholar] [CrossRef]

- Gash, B.W. Measurement of rock properties in Coal for Coalbed Methane Production. In Proceedings of the 66th Annual Technical Conference and Exhibition of the Society of Petroleum Engineers, Society of Petroleum Engineers, Dallas, TX, USA, 6–9 October 1991. [Google Scholar]

- Yao, Z.; Cao, D.; Wei, Y.; Li, X.; Wang, X.; Zhang, X. Experimental analysis on the effect of tectonically deformed coal types on fines generation characteristics. J. Pet. Sci. Eng. 2016, 146, 350–359. [Google Scholar] [CrossRef]

- Wei, C.; Zou, M.; Sun, Y.; Cai, Z.; Qi, Y. Experimental and applied analyses of particle migration in fractures of coalbed methane reservoirs. J. Nat. Gas Sci. Eng. 2015, 23, 399–406. [Google Scholar] [CrossRef]

- Guo, Z.H.; Hussain, F.; Cinar, Y. Physical and analytical modelling of permeability damage in bituminous coal caused by fines migration during water production. J. Nat. Gas Sci. Eng. 2016, 35, 331–346. [Google Scholar] [CrossRef]

- Han, G.; Ling, K.; Wu, H.; Gao, F.; Zhu, F.; Zhang, M. An experimental study of coal-fines migration in Coalbed-methane production wells. J. Nat. Gas Sci. Eng. 2015, 26, 1542–1548. [Google Scholar] [CrossRef]

- Mitchell, T.R.; Leonardi, C.R. Micromechanical investigation of fines liberation and transport during coal seam dewatering. J. Nat. Gas Sci. Eng. 2016, 35, 1101–1120. [Google Scholar] [CrossRef]

- Reydick, D.B.; Luc, G.; Turner, K.M. Steel X-ray μCT investigations of the effects of cleat demineralization by HCl acidizing on coal permeability. J. Nat. Gas Sci. Eng. 2018, 55, 206–218. [Google Scholar]

- Niu, C.K.; Xia, W.C.; Peng, Y.L. Analysis of coal wettability by inverse gas chromatography and its guidance for coal flotation. Fuel 2018, 228, 290–296. [Google Scholar] [CrossRef]

- Wang, Q.G.; Yin, W.D.; Yang, H.R.; Lu, J.F.; Zhao, B. Numerical study on the effect of fine coal accumulation in a coal beneficiation fluidized bed. Powder Technol. 2015, 283, 570–578. [Google Scholar] [CrossRef]

- Zhang, N.; Chen, X.M.; Nicholson, T.; Peng, Y.J. The effect of froth on the dewatering of coals—An oscillatory rheology study. Fuel 2018, 222, 362–369. [Google Scholar] [CrossRef]

- Zhang, S.H.; Tang, S.H.; Zhang, J.P.; Pan, Z.J. Pore structure characteristics of China sapropelic coal and their development influence factors. J. Nat. Gas Sci. Eng. 2018, 53, 370–384. [Google Scholar] [CrossRef]

- Othman, F.; Yu, M.; Kamali, F.; Hussain, F. Fines migration during supercritical CO2 injection in sandstone. J. Nat. Gas Sci. Eng. 2018, 56, 344–357. [Google Scholar] [CrossRef]

| Schemes | No.1 | No.2 | No.3 | No.4 | No.5 | No.6 |

|---|---|---|---|---|---|---|

| Gas permeability/mD | 0.33 | 0.27 | 0.20 | 0.02 | 0.46 | 0.24 |

| Schemes | 1st Stage | 2nd Stage | 3rd Stage |

|---|---|---|---|

| (Single-Phase Water Flow) | (Two-Phase Water and Coal Fines Flow) | (Two-Phase Water and Coal Fines Flow) | |

| Water Flow Rate (mL/min) | Water Flow Rate (mL/min), Coal Fines Concentration (g/cc) | Water Flow Rate (mL/min), Coal Fines Concentration (g/cc) | |

| No.1 | 2 | 5, 0.01 | × |

| No.2 | 2 | 2, 0.004 | 2, 0.01 |

| No.3 | 5 | 5, 0.004 | 1, 0.01 |

| No.4 | 1 | 1, 0.004 | × |

| No.5 | 1 | 1, 0.004 | 5, 0.01 |

| No.6 | 1 | 1, 0.004 | 2, 0.01 |

| Schemes | Items | 1st Stage (Single-Phase Water Flow) | 2nd Stage (Two-Phase Water and Coal Fines Flow) | 3rd Stage (Two-Phase Water and Coal Fines Flow) | |||

|---|---|---|---|---|---|---|---|

| Pseudo-Steady Flow | Cleat-Open | Pseudo-Steady Flow | Cleat-Open | Pseudo-Steady Flow | Cleat-Open | ||

| 1 | Flow rate (mL/min) | 2 | × | 5 | 5 | × | × |

| Coal fines concentration (g/cc) | 0 | 0.01 | 0.01 | ||||

| Permeability (mD) | 0.30 | 0.23 | / | ||||

| 2 | Flow rate (mL/min) | 2 | × | 2 | × | 2 | 2 |

| Coal fines concentration (g/cc) | 0 | 0.004 | 0.01 | 0.01 | |||

| Permeability (mD) | 0.16 | 0.13 | 0.08 | / | |||

| 3 | Flow rate (mL/min) | × | 5 | × | 5 | 1 | 1 |

| Coal fines concentration (g/cc) | 0 | 0.004 | 0.004 | 0.004 | |||

| Permeability (mD) | / | / | 0.13 | / | |||

| 4 | Flow rate (mL/min) | 1 | × | 1 | × | × | × |

| Coal fines concentration (g/cc) | 0 | 0.004 | |||||

| Permeability (mD) | 0.06 | 0.06 | |||||

| 5 | Flow rate (mL/min) | × | 1 | 1 | × | 2 | 2 |

| Coal fines concentration (g/cc) | 0 | 0.004 | 0.01 | 0.01 | |||

| Permeability (mD) | / | 0.14 | 0.13 | / | |||

| 6 | Flow rate (mL/min) | 1 | × | 1 | × | 2 | 5 |

| Coal fines concentration (g/cc) | 0 | 0.004 | 0.01 | 0.01 | |||

| Permeability (mD) | 0.19 | 0.20 | 0.16 | / | |||

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, D.; Liu, Y.; Wang, T.; Wang, D. Experimental Investigation of the Impact of Coal Fines Migration on Coal Core Water Flooding. Sustainability 2018, 10, 4102. https://doi.org/10.3390/su10114102

Gao D, Liu Y, Wang T, Wang D. Experimental Investigation of the Impact of Coal Fines Migration on Coal Core Water Flooding. Sustainability. 2018; 10(11):4102. https://doi.org/10.3390/su10114102

Chicago/Turabian StyleGao, Dapeng, Yuewu Liu, Tianjiao Wang, and Daigang Wang. 2018. "Experimental Investigation of the Impact of Coal Fines Migration on Coal Core Water Flooding" Sustainability 10, no. 11: 4102. https://doi.org/10.3390/su10114102

APA StyleGao, D., Liu, Y., Wang, T., & Wang, D. (2018). Experimental Investigation of the Impact of Coal Fines Migration on Coal Core Water Flooding. Sustainability, 10(11), 4102. https://doi.org/10.3390/su10114102