A Demand Factor Analysis for Electric Vehicle Charging Infrastructure

Abstract

1. Introduction

2. The Current State of Knowledge

- (1)

- The main factors influencing DF, in descending order of significance, are as follows:

- -

- Charging control strategy—tariff-based regulation risks significantly increasing DF due to synchronization of charging for large numbers of EVs. According to [16], DF can increase by 2.5–10 times.

- -

- EVCS location type (residential, workplace, public, etc.)—differences in DF can exceed 400% [15].

- -

- -

- Average power consumption per session—higher consumption increases DF (up to 100%).

- -

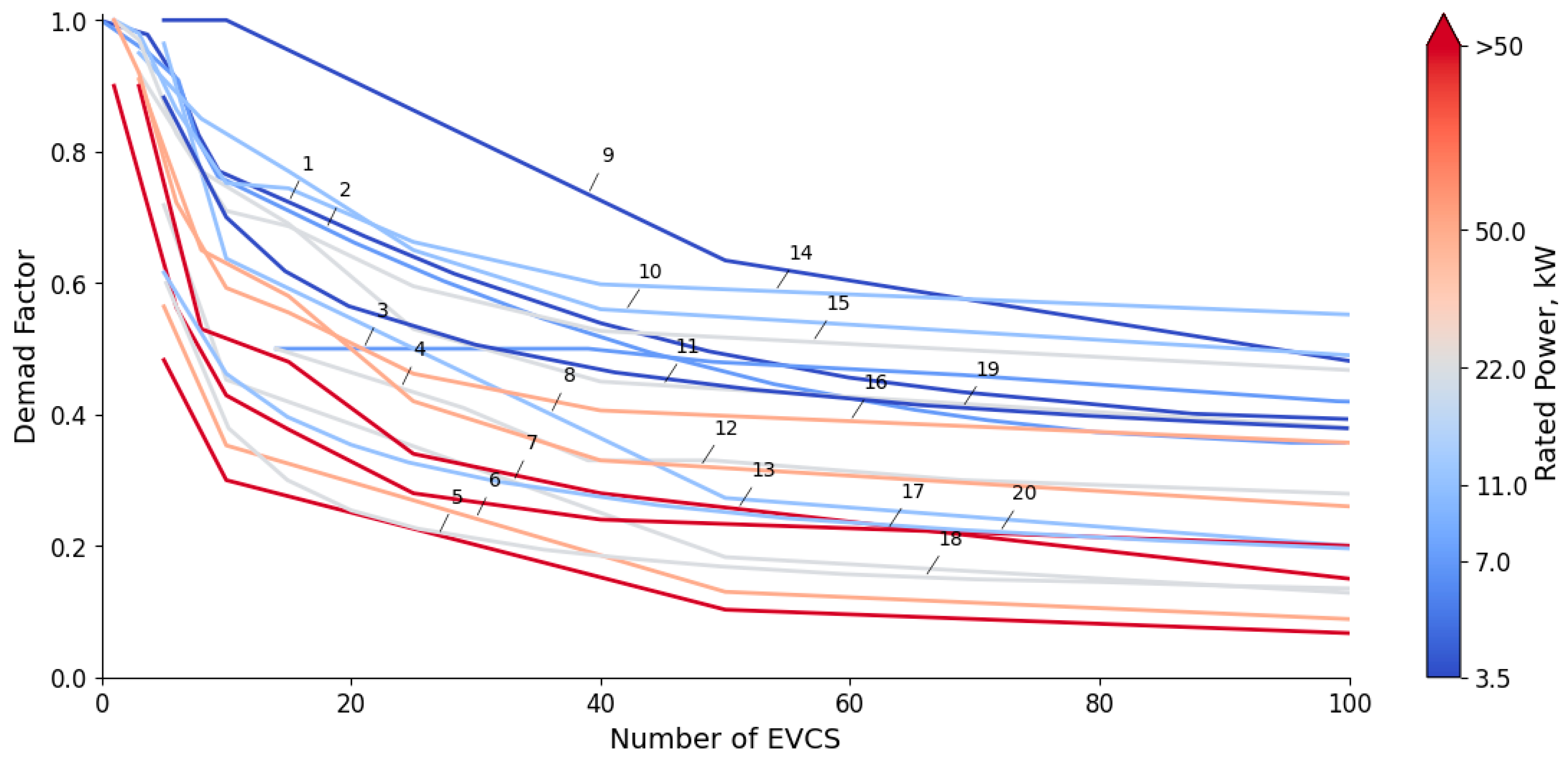

- Number of EVCSs—more EVCSs lead to lower DF (average reduction of 33–95%).

- -

- Rated power of EVCSs—higher power reduces DF (approximately 50%).

- -

- Settlement size—smaller cities have higher DF (average increase of 18.1%).

- -

- EV parameters—battery capacity has a minor effect on DF, but this factor has received insufficient attention in the literature.

- -

- Geographical location—hilly areas have higher DF than flat regions.

- (2)

- -

- Nominal technical parameters and number of EVCS charging ports;

- -

- Nominal technical parameters of charged EVs;

- -

- EV plug-in time probability distribution;

- -

- EV initial SOC probability distribution;

- -

- Charging session durations probability distribution;

- -

- Average number of charging sessions per day.

3. Materials and Methods

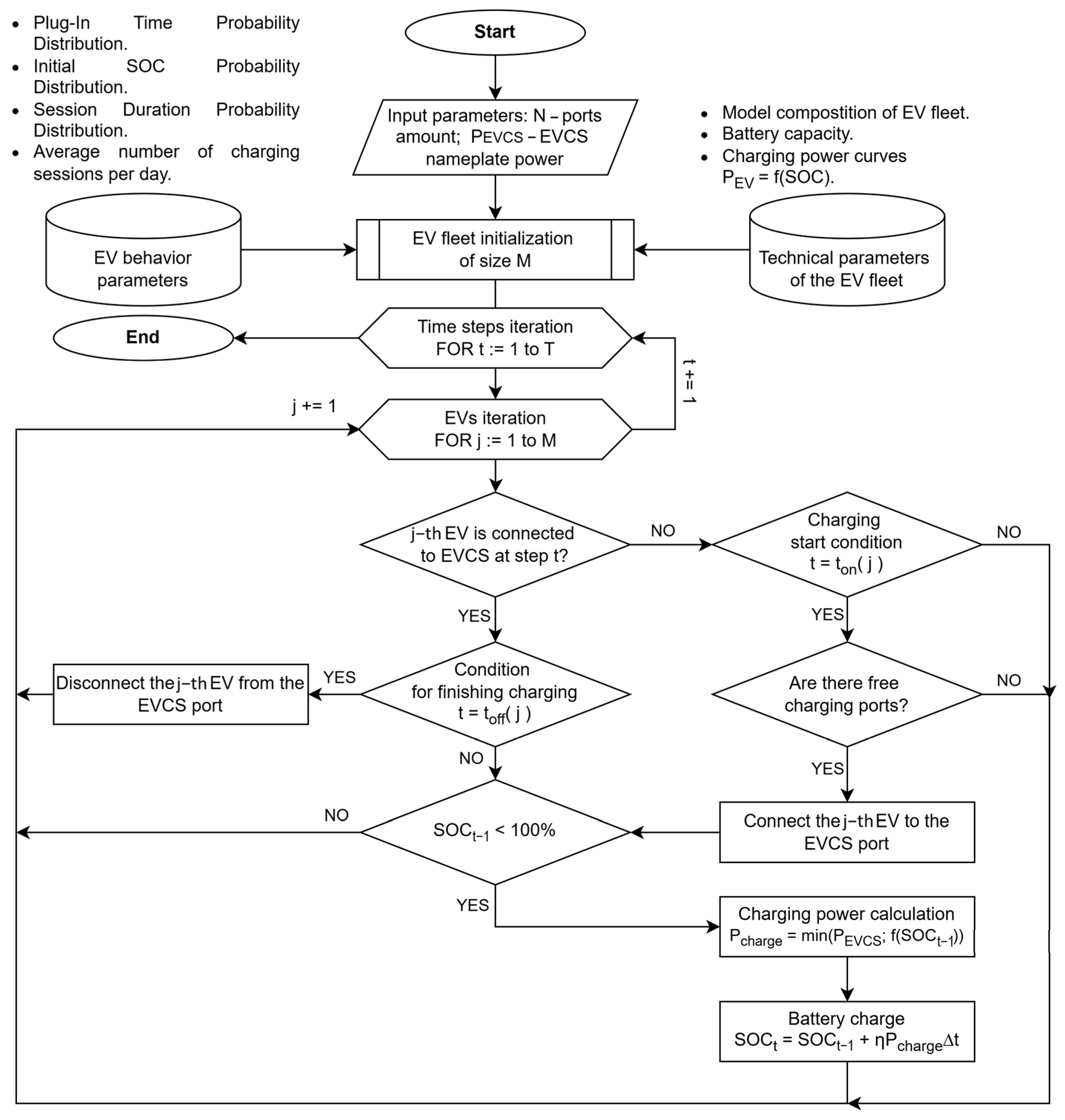

- (1)

- EVCS type: fast or slow.

- (2)

- Number of charging ports: 5 to 50.

- (3)

- Rated power of charging ports: for slow EVCSs: 3.7, 11, 22 kW; for fast EVCSs: 50, 120, 180 kW.

- (4)

- EV parameters: two variants of model fleet structures were considered: (a) current structure corresponding to the actual EV model distribution in the Russian Federation according to [35] (Table 3); (b) prospective structure: parameters of all EVs were conventionally set equal to those of Zeekr 001. EV parameters were based on data from [36].

- (5)

- Average daily charging sessions: for slow EVCSs: 0.5, 2, 4; for fast EVCSs: 2, 6, 12. The number of daily charging sessions followed a Poisson distribution.

- -

- One and a half sessions per day corresponds to typical home EVCS usage: surveys of EV owners [37] show average home charging frequency of about four sessions/week (~0.6 sessions per day);

- -

- Four sessions per day represents the theoretical maximum usage for slow EVCSs; given the parameters of the modeled EV fleet, 3–5 EVs could be fully charged (0–100%) per day.

- (6)

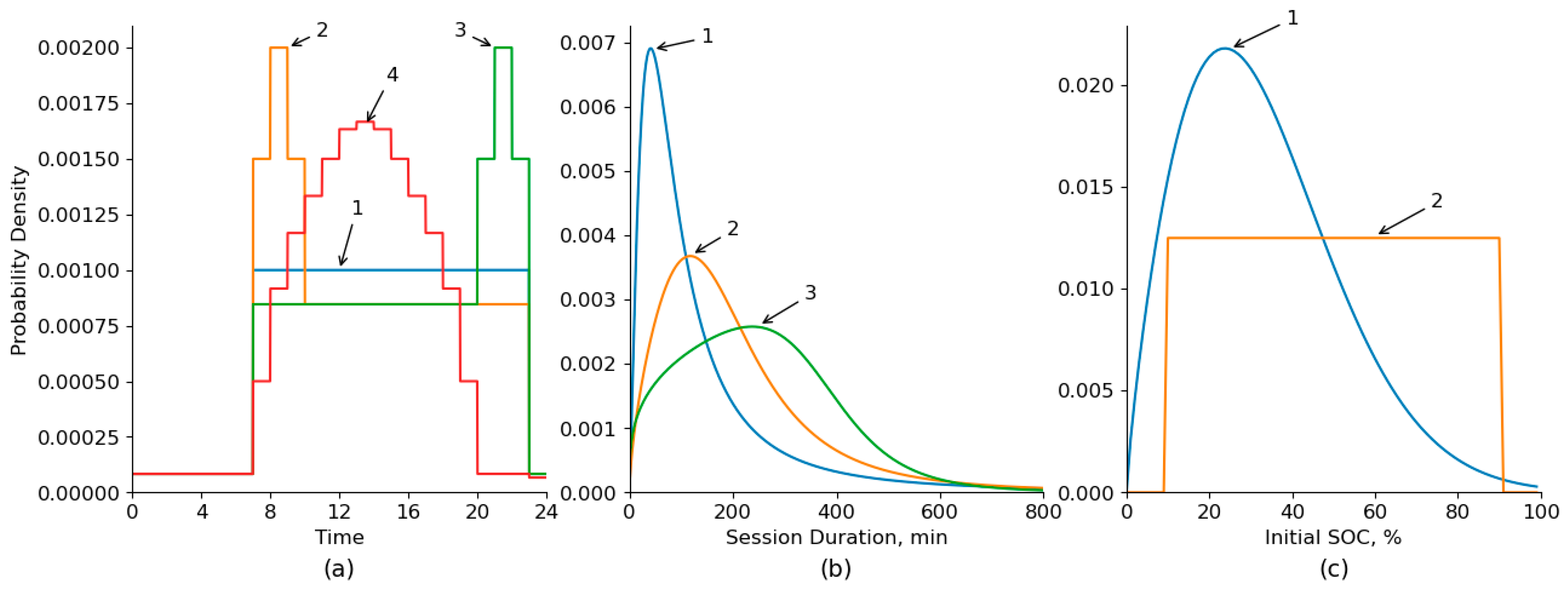

- EV plug-in times. Based on the analysis of open EVCS usage data [39], four characteristic types of daily plug-in time distributions were identified (Figure 4a) as follows: 1—uniform distribution during working hours (typical for public areas and restaurants); 2—morning peak distribution (typical for stores and offices); 3—evening peak distribution (typical for residential areas and hotels); 4—afternoon peak distribution (typical for public parking lots).

- (7)

- Charging session duration (only for slow EVCSs). Based on the analysis of open EVCS utilization data [39] (data on 14,953 sessions of 990 EVCSs), three types of Burr distributions were adopted (Figure 4b) (the distribution parameters, as well as the KS-statistics (D) and p-value are given in brackets) as follows: 1—short sessions (median 88 min, typical for stores; distribution parameters: c = 1.50, d = 1.45, scale = 67.60 (D = 0.077, p > 0.05)); 2—medium sessions (median 169 min, typical for residential areas; parameters: c = 2.66, d = 0.62, scale = 225.48 (D = 0.0245, p > 0.05)); 3—long sessions (median 235 min, typical for campgrounds; parameters: c = 5.77, d = 0.23, scale = 406.23 (D = 0.053, p > 0.05)). For all distributions p > 0.05, there is therefore no reason to reject the hypothesis that the data follow a Burr distribution.

- (8)

- Initial battery SOC. Two distributions were used (Figure 4c) as follows: 1—Weibull distribution (parameters: c = 1.81, scale = 37.85 (D = 0.0236, p > 0.05)), based on the analysis of open data from [40,41,42] (in total, these papers present an analysis of data from 53,377 sessions of 882 EVCS); 2—uniform distribution between 10% and 90%.

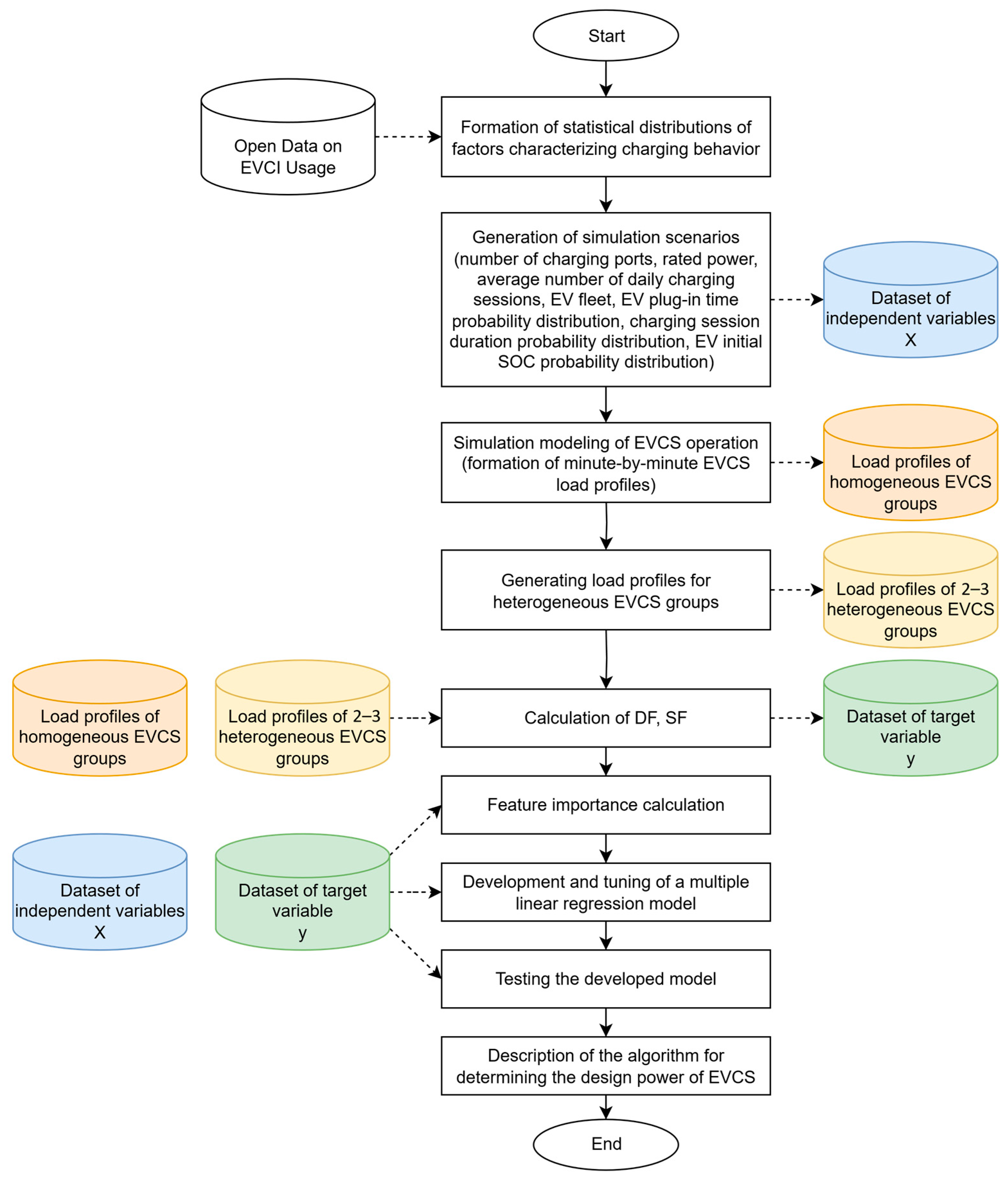

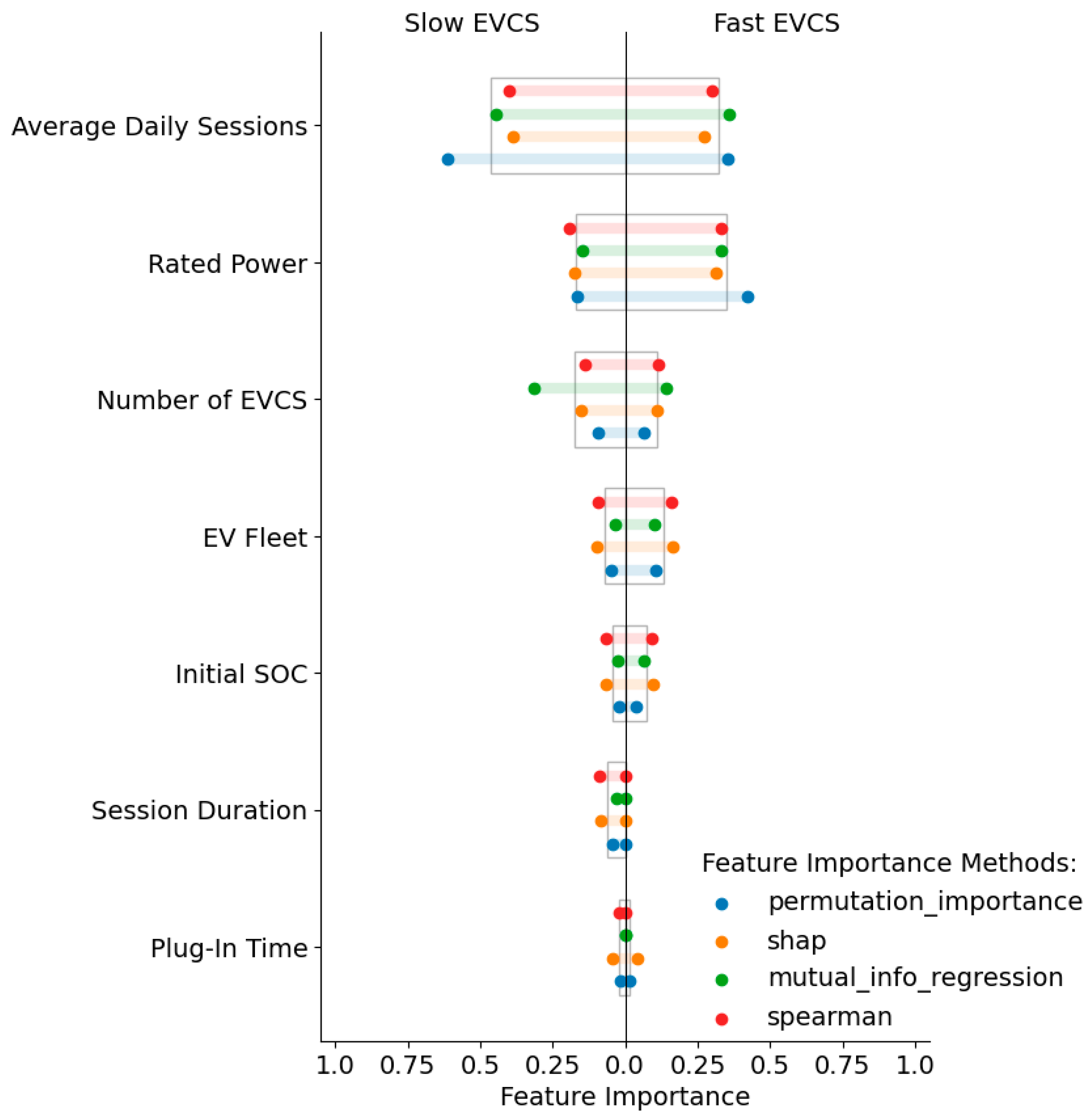

- -

- Filter methods: Spearman correlation coefficient, mutual information (Mutual_Info_Regression);

- -

- Wrapper methods: permutation feature importance, Shapley values.

- -

- This combination of methods provides a comprehensive assessment of the feature contributions to the DF value by identifying both monotonic and non-linear relationships between a feature and the target variable, as well as the overall predictive importance of the feature. The following approach is used for feature importance analysis and selection:

- -

- High values for all four metrics—a significant feature;

- -

- Filter methods: high score; wrapper methods: low score—a redundant feature (it has a statistical association with the target variable but is not actually used by the model in determining the DF value);

- -

- Filter methods: low score; wrapper methods: high score—the feature’s significance is only revealed through interaction with other features;

- -

- Low values for all four metrics—an insignificant feature.

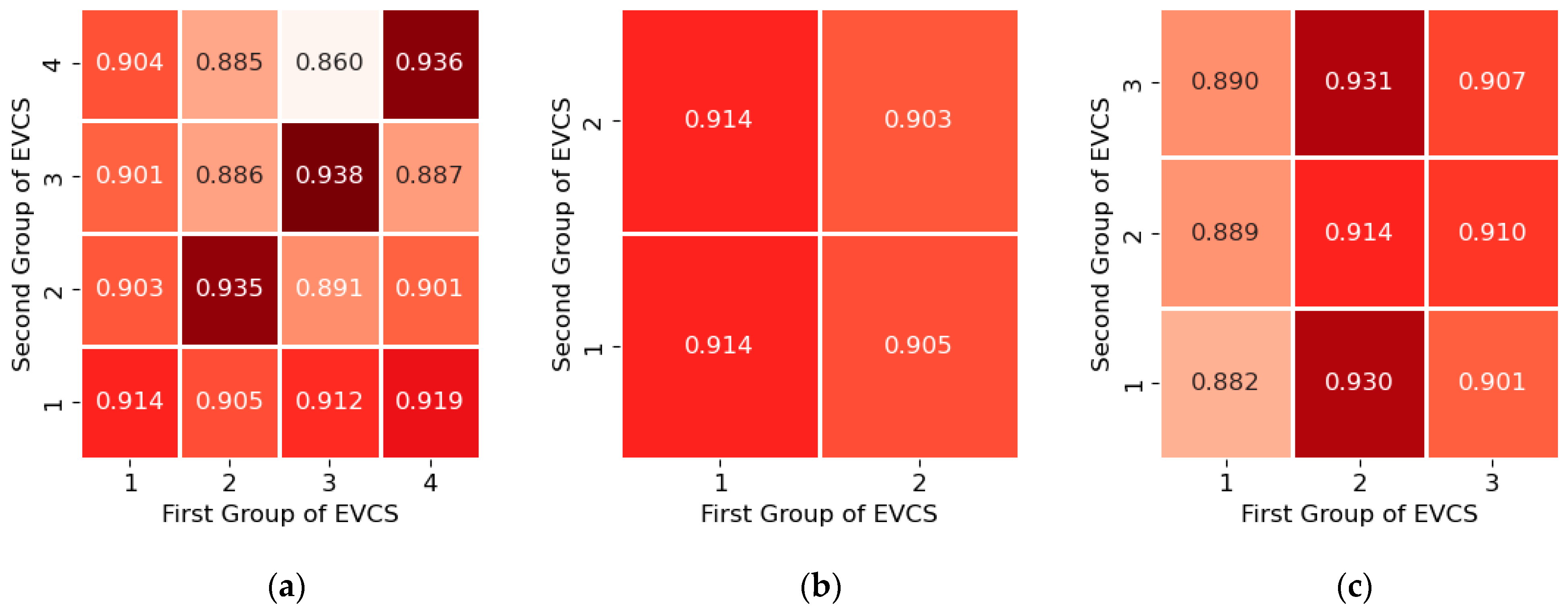

- (1)

- Simulation of power consumption profiles for homogeneous EVCS groups under various influencing factors, with DF calculation for each group;

- (2)

- Generation of power consumption profiles for heterogeneous EVCS groups by summing profiles from stage 1, with SF determination. All possible combinations of two and three EVCS groups were considered.

- -

- Statistical distributions characterizing EVCS usage patterns in different countries, climate zones, and location types fall within the boundaries of the adopted distribution ranges;

- -

- A common rule for ending a charging session is adopted for all EVs at fast EVCSs: reaching a battery SOC of 90%;

- -

- A limited set of EV models, presented in Table 3, is used;

- -

- Smart charging capabilities (V1G, V2G) are not considered;

- -

- Ultra-fast charging stations with a charging port power exceeding 180 kW are not accounted for.

4. Significance Analysis of Factors Affecting the Diversity Factor

5. EVCI Design Load Estimation Algorithm

- -

- s ± 5%—increase in DF calculation error: from 0.36% to 0.72%;

- -

- s ± 10%—increase in DF calculation error: from 1.87% to 2.43%;

- -

- s ± 20%—increase in DF calculation error: from 6.05% to 8.40%.

- Determine parameters for homogeneous EVCS groups: number of charging ports; rated power of charging ports; average number of daily charging sessions.

- Calculate demand factors using Equation (5) and design power using Equation (6) for each homogeneous EVCS group.

- Determine the design power for heterogeneous EVCS groups using Equation (7).

- -

- Subgroup 1: 3.7 kW, 30 units, 2 sessions per day.

- -

- Subgroup 2: 22 kW, 50 units, 4 sessions per day.

- -

- Subgroup 3: 50 kW, 10 units, 6 sessions per day.

- -

- Home charging: s = 0.4–0.6 (charge once every 2–3 days);

- -

- Lowload public EVCSs: s = 1–2;

- -

- Mediumload public EVCSs: s = 3–6;

- -

- Highload public EVCSs: s = 7–12.

6. Conclusions

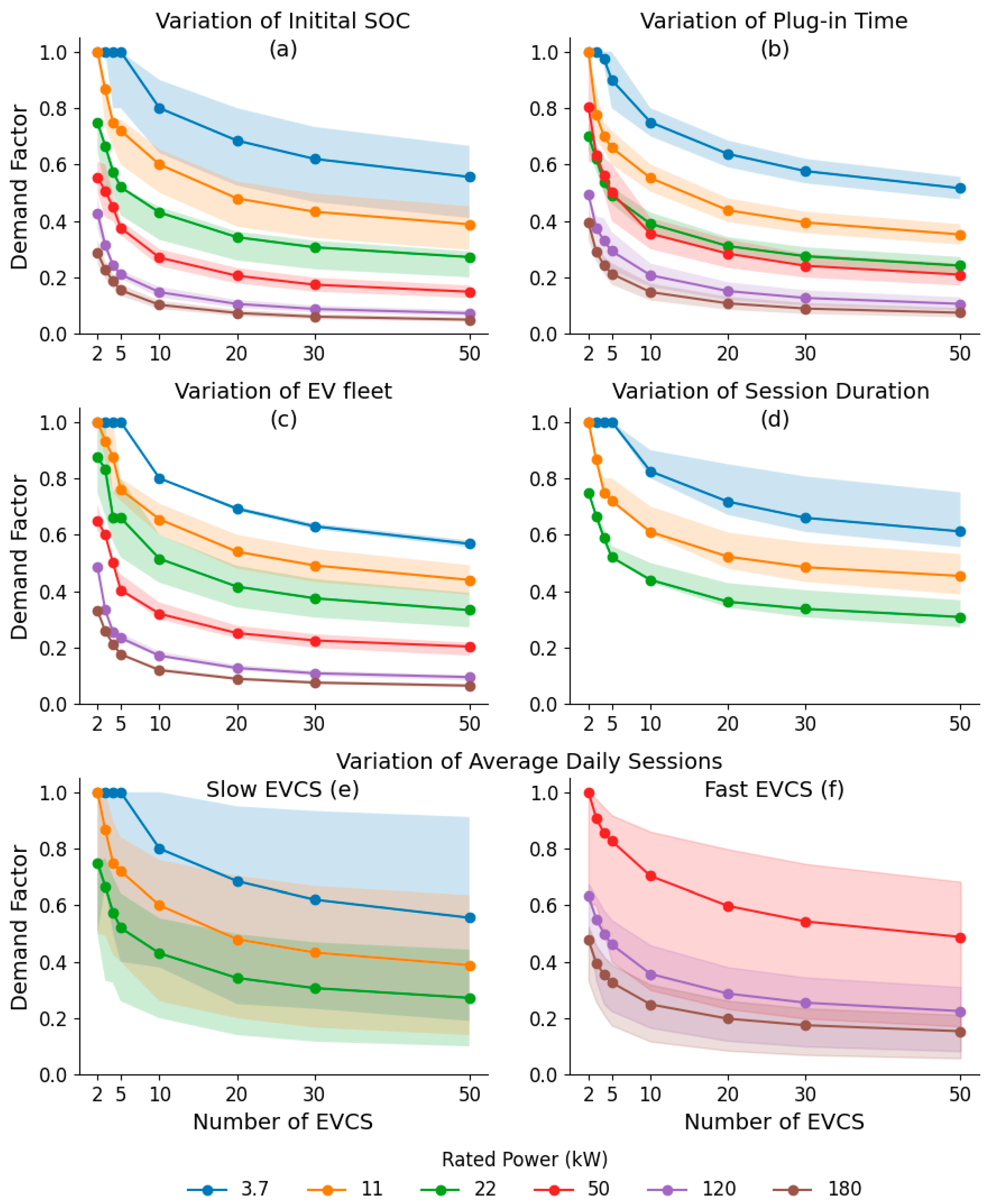

- The average number of daily charging sessions was identified as the most significant factor affecting the DF, a parameter largely overlooked in state-of-the-art (SOTA) methodologies. An increase in daily sessions from 0.5 to 4 led to a 2.4-fold rise in DF, underscoring that charging behavior is a primary driver of peak load, not just station hardware.

- The rated power of EVCSs is a critical technical factor, with higher power ratings substantially reducing DF due to shorter charging sessions and decreased probability of load coincidence. Increasing the power of slow EVCSs from 3.7 kW to 22 kW reduced the average DF by 32%, while for fast EVCSs (50 kW to 180 kW), the reduction was more pronounced at 56%.

- The number of charging ports remains a crucial parameter, consistent with the existing literature. However, our model quantifies its effect in conjunction with behavioral factors. Increasing the number of ports from 5 to 50 reduced the average DF by 38%, confirming the expected diversification effect but with greater accuracy.

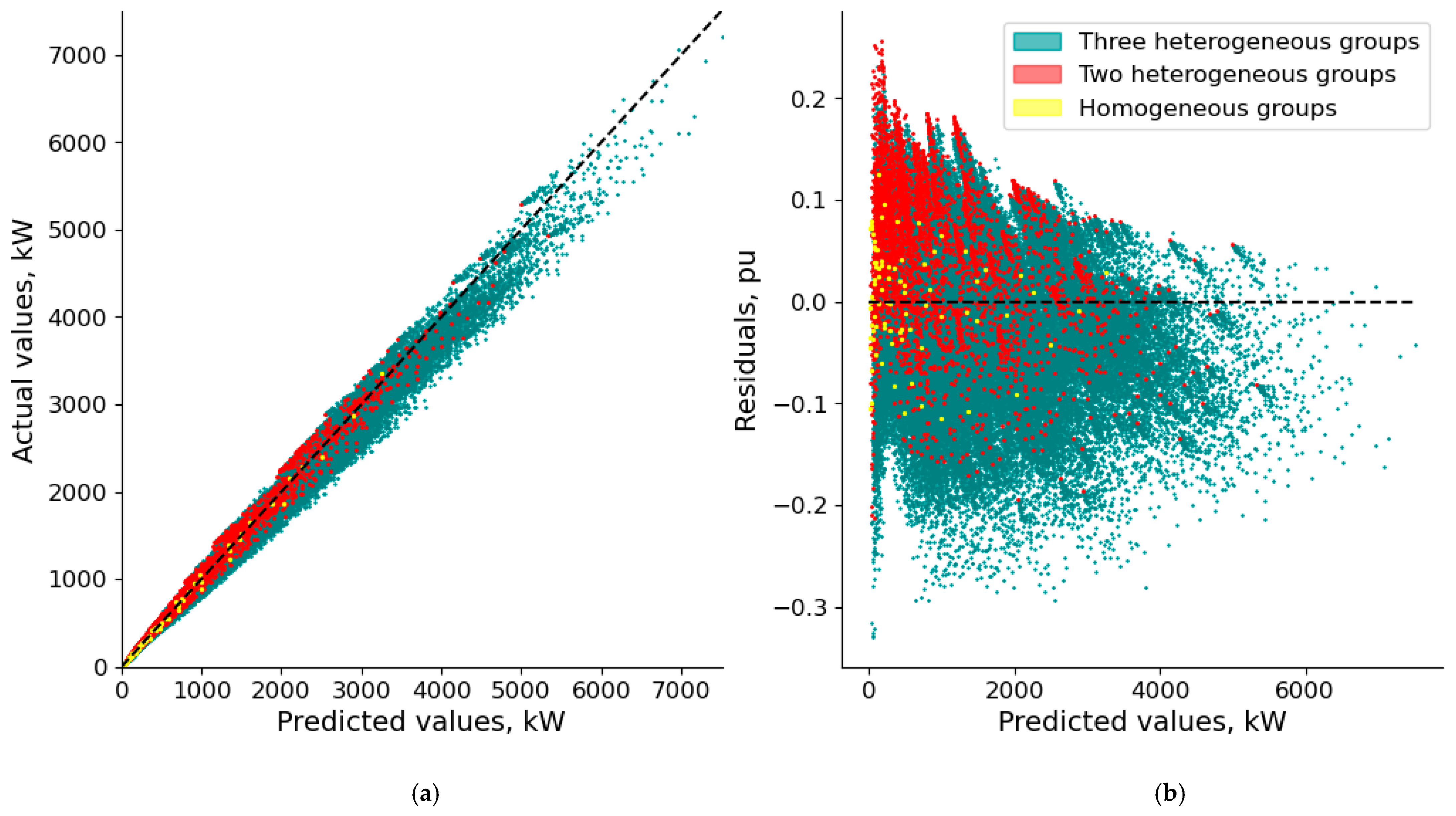

- The proposed algorithm and the regression model (5)–(7) demonstrate a superior performance compared with SOTA approaches. Validation results showed high accuracy (MAPE = 6.01%, R2 = 0.987) in calculating design loads for both homogeneous and heterogeneous EVCS groups. In stark contrast, applying the DF values and methods from the reviewed SOTA literature to our dataset yielded unacceptably high errors (MAPE of 50.36–67.72%). This significant improvement in accuracy is directly attributable to the inclusion of the average number of daily sessions alongside technical parameters. However, it should be taken into account that, due to the omission of all behavioral factors, the proposed algorithm provides an estimate of the EVCS design power with the deviations shown in Table 5 and Figure 9.

- The practical relevance of this work is substantial. The derived expressions provide grid planners and utilities with a simple yet accurate tool to determine design loads without resorting to complex simulations in most cases. This minimizes the overestimation of infrastructure requirements, leading to direct capital expenditure (CAPEX) savings by avoiding the unnecessary reinforcement of distribution networks. The proposed methodology has been formalized into a practical step-by-step procedure for direct application in planning and design stages.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| AC | Alternating Current |

| DC | Direct Current |

| DF | Demand Factor |

| DSO | Distribution System Operator |

| EV | Electric Vehicle |

| EVCI | Electric Vehicle Charging Infrastructure |

| EVCS | Electric Vehicle Charging Station |

| EVSE | Electric Vehicle Supply Equipment |

| MAPE | Mean Absolute Percentage Error |

| NHTS | National Household Travel Survey |

| RRMSE | Relative Root Mean Square Error |

| SF | Simultaneity Factor |

| SOC | State of Charge |

| SOTA | State-of-the-Art |

| V2G | Vehicle-to-Grid |

References

- On the Concept for the Development of Production and Use of Electric Vehicle Transport in the Russian Federation for the Period Until 2030—ConsultantPlus. Available online: https://www.consultant.ru/document/cons_doc_LAW_393496/2cc3e7a044fad83b4255225febe023d7c743e4a0 (accessed on 1 August 2025). (In Russian).

- IRENA. Innovation Landscape for Smart Electrification: Decarbonising End-Use Sectors with Renewable Power; International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2023; p. 212. Available online: https://digital-energy.eu/en/studies/irena-innovation-landscape-smart-electrification (accessed on 17 September 2025).

- ESIG’s Report. Charging Ahead. Grid Planning for Vehicle Electrification. A Report of the Energy Systems Integration Group’s Grid Planning for Vehicle Electrification Task Force. Available online: https://www.esig.energy/grid-planning-for-vehicle-electrification (accessed on 17 August 2025).

- Li, Y.; Jenn, A. Impact of Electric Vehicle Charging Demand on Power Distribution Grid Congestion. Proc. Natl. Acad. Sci. USA 2024, 121, e2317599121. [Google Scholar] [CrossRef]

- Lukuyu, J.; Shirley, R.; Taneja, J. Managing Grid Impacts from Increased Electric Vehicle Adoption in African Cities. Sci. Rep. 2024, 14, 24320. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, S.I.; Salehfar, H.; Selvaraj, D.F. Impact of Electric Vehicle Charging on the Performance of Distribution Grid. In Proceedings of the 2021 IEEE 12th International Symposium on Power Electronics for Distributed Generation Systems (PEDG), Chicago, IL, USA, 28 June–1 July 2021; pp. 1–8. [Google Scholar] [CrossRef]

- Huang, L.; Li, H.; Lai, C.S.; Zobaa, A.F.; Zhong, B.; Zhao, Z.; Lai, L.L. Electric Vehicle Cluster Scheduling Model for Distribution Systems Considering Reactive-Power Compensation of Charging Piles. Energies 2024, 17, 2541. [Google Scholar] [CrossRef]

- Ilyushin, P.V.; Shepovalova, O.V.; Filippov, S.P.; Nekrasov, A.A. The Effect of Complex Load on the Reliable Operation of Solar Photovoltaic and Wind Power Stations Integrated into Energy Systems and into Off-Grid Energy Areas. Energy Rep. 2022, 8, 1515–1529. [Google Scholar] [CrossRef]

- Kulikov, A.; Ilyushin, P.; Suslov, K.; Filippov, S. Organization of Control of the Generalized Power Quality Parameter Using Wald’s Sequential Analysis Procedure. Inventions 2023, 8, 17. [Google Scholar] [CrossRef]

- Kulikov, A.L.; Shepovalova, O.V.; Ilyushin, P.V.; Filippov, S.P.; Chirkov, S.V. Control of Electric Power Quality Indicators in Distribution Networks Comprising a High Share of Solar Photovoltaic and Wind Power Stations. Energy Rep. 2022, 8, 1501–1514. [Google Scholar] [CrossRef]

- Kulikov, A.L.; Ilyushin, P.V.; Suslov, K.V.; Karamov, D.N. Coherence of Digital Processing of Current and Voltage Signals at Decimation for Power Systems with a Large Share of Renewable Power Stations. Energy Rep. 2022, 8, 1464–1478. [Google Scholar] [CrossRef]

- Glover, J.D.; Sarma, M.S.; Overbye, T. Power Systems Analysis and Design, 6th ed.; Cengage Learning: Boston, MA, USA, 2015; ISBN 978-1-305-63213-4. [Google Scholar]

- Bollerslev, J.; Andersen, P.B.; Jensen, T.V.; Marinelli, M.; Thingvad, A.; Calearo, L.; Weckesser, T. Coincidence Factors for Domestic EV Charging From Driving and Plug-In Behavior. IEEE Trans. Transp. Electrif. 2022, 8, 808–819. [Google Scholar] [CrossRef]

- Hecht, C.; Figgener, J.; Sauer, D.U. Simultaneity Factors of Public Electric Vehicle Charging Stations Based on Real-World Occupation Data. World Electr. Veh. J. 2022, 13, 129. [Google Scholar] [CrossRef]

- Jokinen, I.; Lehtonen, M. Modeling of Electric Vehicle Charging Demand and Coincidence of Large-Scale Charging Loads in Different Charging Locations. IEEE Access 2023, 11, 114291–114315. [Google Scholar] [CrossRef]

- Unterluggauer, T.; Hipolito, F.; Klyapovskiy, S.; Andersen, P.B. Impact of Electric Vehicle Charging Synchronization on the Urban Medium Voltage Power Distribution Network of Frederiksberg. World Electr. Veh. J. 2022, 13, 182. [Google Scholar] [CrossRef]

- Fani, H.; Hashmi, M.U.; Deconinck, G. Impact of Electric Vehicle Charging Simultaneity Factor on the Hosting Capacity of LV Feeder. Sustain. Energy Grids Netw. 2024, 40, 101581. [Google Scholar] [CrossRef]

- Gardholm, E. Dimensioning of the Electricity Distribution Network as the Share of Electric Vehicles Increases. 2024. Available online: http://www.diva-portal.org/smash/record.jsf?pid=diva2:1894764 (accessed on 13 February 2025).

- Zakaria, A.; Duan, C.; Djokic, S.Z. Hosting Capacity of Distribution Networks for Controlled and Uncontrolled Residential EV Charging with Static and Dynamic Thermal Ratings of Network Components. Electr. Veh. Integr. Impacts Power Syst. 2024, 18, 1283–1301. [Google Scholar] [CrossRef]

- Ali, S.; Wintzek, P.; Zdrallek, M. Development of Demand Factors for Electric Car Charging Points for Varying Charging Powers and Area Types. Electricity 2022, 3, 410–441. [Google Scholar] [CrossRef]

- Mason, J. Engineering Design Standard EDS 08-5050 Electric Vehicle Connections. Available online: https://media.umbraco.io/uk-power-networks/baik5mop/eds-08-5050-electric-vehicle-connections.pdf (accessed on 14 February 2024).

- Burges, K.; Schlösser, T.; Tröster, E. Handbook on Planning and Operating an E-Mobility Infrastructure; Deutsche Energie-Agentur: Berlin, Germany, 2022; p. 41. Available online: https://energypedia.info/wiki/File:025_Handbook_on_Planning_and_Operating_an_E-Mobility_Infrastructure.pdf (accessed on 19 August 2025).

- Opstad, A.; Bakken, B.H.; Nygård, H.S.; Doorman, G.; Sevdari, K. Flexibility from Electric Vehicles—Residential Charging Coincidence Factors in Norway. CSE 2024, 35, 1–17. Available online: https://cse.cigre.org/cse-n035/c1-flexibility-from-electric-vehicles-residential-charging-coincidence-factors-in-norway.html (accessed on 20 August 2025).

- Silber, F.; Scheubner, S.; Märtz, A. Analysis of the Simultaneity Factor of Fast-Charging Sites Using Monte-Carlo Simulation. Int. J. Electr. Power Energy Syst. 2024, 155, 109540. [Google Scholar] [CrossRef]

- Bong, A.; Cisneiros e Faria, L.A.; Leier, E.; Vertgewall, C.M.; Kortmann, S.; Ulbig, A. Grid Impacts by Providing Flexibility of Electric Vehicles Based on Simultaneity Factors. In Proceedings of the 2024 International Conference on Smart Energy Systems and Technologies (SEST), Torino, Italy, 10–12 September 2024; pp. 1–6. [Google Scholar] [CrossRef]

- Rosstandart. Notification on the Development of Draft Amendment No. 7 to SP 256.1325800.2016 “Electrical Installations of Residential and Public Buildings. Design and Installation Rules”. Available online: https://www.gost.ru/portal/gost/home/activity/standardization/notification/notificationssetrules (accessed on 8 February 2025). (In Russian).

- Zhang, Y.; Yang, J.; Li, Q.; Deng, W.; Xie, X. Special transformer sharing mode: Utilizing special transformers of buildings to supply power for charging stations. IET Gener. Transm. Distrib. 2023, 17, 1021–1034. [Google Scholar] [CrossRef]

- Carvalhosa, S.; Ferreira, J.R.; Araújo, R.E. Fuzzy Logic Estimation of Coincidence Factors for EV Fleet Charging Infrastructure Planning in Residential Buildings. Energies 2025, 18, 4679. [Google Scholar] [CrossRef]

- Rosstandart. Notification on the Development of SP “Electrical Networks of Urban Microdistricts. Design Rules”. Available online: https://www.rst.gov.ru/portal/gost/home/activity/standardization/notification/notificationssetrules (accessed on 5 February 2025). (In Russian)

- Palomino, A.; Parvania, M. Probabilistic Impact Analysis of Residential Electric Vehicle Charging on Distribution Transformers. In Proceedings of the 2018 North American Power Symposium (NAPS), Fargo, ND, USA, 9–11 September 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Ali, S.; Wintzek, P.; Zdrallek, M.; Böse, C.; Monscheidt, J.; Gemsjäger, B.; Slupinski, A. Demand Factor Identification of Electric Vehicle Charging Points for Distribution System Planning. In Proceedings of the CIRED 2021—The 26th International Conference and Exhibition on Electricity Distribution, Online, 20–23 September 2021; Volume 2021, pp. 2574–2578. [Google Scholar] [CrossRef]

- Märtz, A.; Held, L.; Wirth, J.; Jochem, P.; Suriyah, M.; Leibfried, T. Development of a Tool for the Determination of Simultaneity Factors in PEV Charging Processes; Zenodo: Dublin, Ireland, 14 October 2019; Available online: https://www.ieh.kit.edu/veroeffentlichungen_3464.php (accessed on 22 August 2025).

- Stahleder, D.; Übermasser, S.; Reihs, D.; Ledinger, S.; Lehfuss, S. Electric Vehicle Car Park Charging Simultaneity and Grid Connection Power Requirement Analysis. In Proceedings of the CIRED 2021—The 26th International Conference and Exhibition on Electricity Distribution, Online, 20–23 September 2021; Volume 2021, pp. 2183–2187. [Google Scholar] [CrossRef]

- Voronin, V.A. Analysis of Open Data on the Use of DC Electric Charging Stations for Electric Vehicles. In Proceedings of the All-Russian School of Young Scientists “Digitalization, Decarbonization and Decentralization of Modern Electric Power Industry”, Sevastopol, Russia, 29–30 May 2024; SevSU: Sevastopol, Russia, 2024; pp. 218–227. Available online: https://www.elibrary.ru/item.asp?id=69918879 (accessed on 20 August 2025). (In Russian).

- There Are Almost 60 Thousand Electric Vehicles in Russia. Available online: https://www.autostat.ru/news/59463/ (accessed on 23 February 2025). (In Russian).

- EV Database. Available online: https://ev-database.org/ (accessed on 19 May 2025).

- Bonfiglio, A.; Minetti, M.; Loggia, R.; Mascioli, L.F.; Golino, A.; Moscatiello, C.; Martirano, L. Integrated Vehicle-to-Building and Vehicle-to-Home Services for Residential and Worksite Microgrids. Smart Cities 2025, 8, 101. [Google Scholar] [CrossRef]

- PJSC “Rosseti Moscow Region” Summarizes the Work of Electric Vehicle Charging Stations in 2024. Available online: https://xn--80aoda2algca.xn--p1ai/pao-rosseti-moskovskij-region-podvelo-itogi-raboty-zaryadnyx-stancij-dlya-elektromobilej-za-2024-god/ (accessed on 25 February 2025). (In Russian).

- Baek, K.; Lee, E.; Kim, J. A Dataset for Multi-Faceted Analysis of Electric Vehicle Charging Transactions. Sci. Data 2024, 11, 262. [Google Scholar] [CrossRef] [PubMed]

- Level-3-EV-Charging-Dataset. Available online: https://github.com/DESL-EPFL/Level-3-EV-charging-dataset (accessed on 21 March 2024).

- Siddique, C.; Afifah, F.; Guo, Z.; Zhou, Y. Data Mining of Plug-in Electric Vehicles Charging Behavior Using Supply-Side Data. Energy Policy 2022, 161, 112710. [Google Scholar] [CrossRef]

- Jonas, T.; Daniels, N.; Macht, G. Electric Vehicle User Behavior: An Analysis of Charging Station Utilization in Canada. Energies 2023, 16, 1592. [Google Scholar] [CrossRef]

- Energetics, EV WATTS Charging Station Dashboard Q4-23’. Available online: https://www.energetics.com/evwatts (accessed on 25 March 2024).

- Roy, B.; Ivanic, Z.; Windover, P.; Ruder, A.; Shirk, M. New York State EV Charging Station Deployment. World Electr. Veh. J. 2016, 8, 877–887. [Google Scholar] [CrossRef]

- Voronin, V.A.; Nepsha, F.S. Enhancing the Process for Connecting EV Charging Stations to the Power Grid. In Proceedings of the 2024 IEEE 3rd International Conference on Problems of Informatics, Electronics and Radio Engineering (PIERE), Novosibirsk, Russian, 15–17 November 2024; pp. 1240–1244. [Google Scholar] [CrossRef]

- Visakh, A.; Selvan, M. Smart Charging of Electric Vehicles to Minimize the Cost of Chargingand the Rate of Transformer Aging in a Residential Distribution Network. Turk. J. Electr. Eng. Comput. Sci. 2022, 30, 927–942. [Google Scholar] [CrossRef]

- van Sambeek, H.L.; Zweistra, M.; Hoogsteen, G.; Varenhorst, I.A.M.; Janssen, S. GridShield—Optimizing the Use of Grid Capacity during Increased EV Adoption. World Electr. Veh. J. 2023, 14, 68. [Google Scholar] [CrossRef]

- Boyko, E.; Byk, F.; Ilyushin, P.; Myshkina, L.; Suslov, K. Methods to Improve Reliability and Operational Flexibility by Integrating Hybrid Community Mini-Grids into Power Systems. Energy Rep. 2023, 9, 481–494. [Google Scholar] [CrossRef]

- Voronin, V.; Nepsha, F.; Ilyushin, P. Determining Volt/Var Characteristics of Electric Vehicle Charging Station Inverters for Voltage Regulation in Distribution Networks. World Electr. Veh. J. 2024, 15, 553. [Google Scholar] [CrossRef]

- Guia, T.; M’Hamdi, B.; Khechekhouche, A. Electric vehicle charging stations load impact on the distribution network. J. Eng. Exact Sci. 2024, 10, 20813. [Google Scholar] [CrossRef]

- Pierro, G.D.; Bitsanis, E.; Tansini, A.; Bonato, C.; Martini, G.; Fontaras, G. Fuel Cell Electric Vehicle Characterisation under Laboratory and In-use Operation. Energy Rep. 2024, 11, 611–623. [Google Scholar] [CrossRef]

- Jia, C.; Liu, W.; He, H.; Chau, K.T. Health-Conscious Energy Management for Fuel Cell Vehicles: An Integrated Thermal Management Strategy for Cabin and Energy Source Systems. Energy 2025, 333, 137330. [Google Scholar] [CrossRef]

- Dai, S.; Shen, P.; Deng, W.; Yu, Q. Hydrogen Energy in Electrical Power Systems: A Review and Future Outlook. Electronics 2024, 13, 3370. [Google Scholar] [CrossRef]

| Ref. | Description | Factors | Results |

|---|---|---|---|

| [13] | Home charging, slow AC EVCSs, Monte Carlo simulation (based on the Danish National Travel Survey and plug-in behavior data from >10,000 Nissan Leafs) | Number of EVs (5–100), EVCS power (3.7–22 kW), EV battery capacity (24–60 kWh), charging behavior |

|

| [14] | Public charging, AC EVCSs (11 kW, 22 kW), real-world data from roaming maps (26,951 connectors observed, subsample of 1562 connectors with 45,487 charge events), Dec 2019–Mar 2020 | Number of EVCSs (1–1000), consumption per session (8–60 kWh), charging control strategy |

|

| [15] | Home, workplace, public, and fast charging stations, simulation modeling (based on Finnish NHTS 2016 data: 12,773 respondents, 40,321 trips) | EVCS power (3.68–100 kW), location type, air temperature (−20–15 °C) |

|

| [16] | Home and workplace charging, 11 kW AC EVCSs, real data (Danish National Travel Survey, 2006–2019) + Monte Carlo simulation (24,252 resident EVs + 34,818 visitor EVs) | Charge management by reducing the price during certain hours of the day |

|

| [17] | Home charging, slow AC EVCSs, real-world data from smart meters in 300 Belgian households (Dec 2022–Dec 2023) | EVCS power (2.7–11 kW), average daily consumption (0–10… >30 kWh), power grid scheme (number of consumers from 12 to 69) |

|

| [18] | Home charging, slow AC EVCSs, Monte Carlo simulation (based on travel data in Stockholm) | EVCS power (3.7 and 11 kW), number of EVCSs (5–50) |

|

| [19] | Home charging, slow AC EVCSs, Monte Carlo simulation (based on real UK field trial data from ~200 EVs over 1 year, extended to 3000 EVs) | EVCS power (3.7 and 7 kW), number of EVCSs (1–3000), season of the year |

|

| [20] | Private and public charging, stochastic simulation (based on mobility data from 316,000 individuals and >1 million routes in Germany, 2008–2018). | EVCS power (3.7–350 kW), number of EVCSs (1–500), city size |

|

| [22] | Home/public charging, AC/DC EVCSs, real-world monitoring and synthetic data (modeling based on German mobility patterns, simultaneity factors) | Number of EVs (10–10,000), EVCS power (3.7–11 kW), EVCS type (home, workplace, public) | DF ranges from 0.6–0.8 to 0.1–0.2 for 10–10,000 EVs (EVCS power 3.7–11 kW) |

| [23] | Home charging, slow AC EVSEs, real data from 216 Tesla households in Norway (Nov 2020–Mar 2021), including temperature and electricity price data | Geographical location (mountainous, hilly, flat area), time of day and day of the week, charging price, air temperature |

|

| [30] | Home charging, AC EVCSs. Real data: residential load from 112 homes (2015, Salt Lake City), EV charging from 8000 vehicles (INL, 2011–2013). | Number of EVs (1–6) |

|

| [31] | Private, public, and fast EV charging points, Monte Carlo simulation (based on mobility data from “Mobilität in Deutschland” and real grid data from six German DSOs), 2000 EVs simulated over 1000 weeks (19 years) (EV battery capacity 45 kWh). | Number of EVCSs (1–2000), EVCS power (3.7–150 kW) |

|

| [32] | Home charging, AC EVCSs, Monte Carlo simulation (based on real data and synthetic household load profiles from a database of 365,000 entries). Simulated days: 1000–100,000. | Number of EVCSs (1–10), EVCSs power (3.7–11 kW) |

|

| [33] | Home/work/shop charging, Monte Carlo simulation (based on Austrian mobility study with 93,175 car trips). | Number of EVCSs (1–100), EVCS power (11, 22 kW), location type (home, workplace), charging control strategy, parking duration (0.5–2 h) |

|

| [25] | Home charging, slow AC EVSEs, simulation modeling (based on historical user behavior and driving profiles), 10,000 EVs (scaled to 15M for analysis). | Number of EVCSs (1–50), charging control strategy |

|

| References | Number of DF Curves | EVCS Power, kW | Mean Inter-Curve Deviation (RRMSE), % |

|---|---|---|---|

| [13,19,20] | 3 | 3.5 | 15.73 ± 5.90 |

| [19,21] | 2 | 7 | 11.43 ± 0.23 |

| [13,20,26,29] | 4 | 11 | 37.90 ± 17.35 |

| [13,20,21,26,29] | 5 | 22 | 41.12 ± 27.55 |

| [20,26,29] | 3 | 50 | 40.70 ± 30.88 |

| [20,26,29] | 3 | >50 | 31.70 ± 19.76 |

| No | EV Model | Battery Capacity, kWh | Max and Average Power of Fast Charging, kW | Onboard Charger Power, kW | Relative Share, % |

|---|---|---|---|---|---|

| 1 | Nissan Leaf | 39 | 50/40 | 6.6 | 36.8 |

| 2 | Zeekr 001 | 94 | 200/135 | 22 | 25.0 |

| 3 | Tesla Model 3, Tesla Model Y | 57.5 | 170/100 | 11 | 14.47 |

| 4 | Volkswagen ID.4 | 52 | 115/70 | 11 | 7.89 |

| 5 | Evolute i-PRO * | 53 | 100/80 | 6.6 | 7.89 |

| 6 | Moskvich 3E * | 65.7 | 90/67 | 11 | 5.26 |

| 7 | Porsche Taycan | 71 | 223/183 | 11 | 2.63 |

| Coefficient | Value | se | T | p | S1 | St |

|---|---|---|---|---|---|---|

| β0 | 977.625 × 10−3 | 12.764 × 10−3 | 76.59 | <0.01 | - | - |

| β1 | −277.223 × 10−3 | 4.088 × 10−3 | −67.79 | <0.01 | 0.243 | 0.242 |

| β2 | −41.738 × 10−3 | 1.281 × 10−3 | −32.57 | <0.01 | 0.085 | 0.085 |

| β3 | 0.389 × 10−3 | 0.051 × 10−3 | 7.60 | <0.01 | 0.034 | 0.032 |

| β4 | 194.337 × 10−3 | 4.031 × 10−3 | 48.95 | <0.01 | 0.618 | 0.617 |

| β5 | −2.714 × 10−6 | 0.459 × 10−6 | −5.91 | <0.01 | 0.022 | 0.023 |

| Dataset | Number of Observations | RRMSE, % | MAPE, % | R2, pu |

|---|---|---|---|---|

| All data | 193,025 | 8.74 [8.67, 8.80] | 6.01 [5.99, 6.04] | 0.987 [0.985, 0.987] |

| Homogeneous EVCS groups | 85 | 6.93 [5.04, 9.11] | 4.18 [3.53, 4.82] | 0.997 [0.995, 0.999] |

| Two heterogeneous EVCS groups | 3570 | 9.4 [9.10, 9.70] | 7.51 [7.36, 7.68] | 0.988 [0.988, 0.989] |

| Three heterogeneous EVCS groups | 98,770 | 8.71 [8.65, 8.77] | 5.96 [5.94, 5.99] | 0.986 [0.985, 0.986] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Published by MDPI on behalf of the World Electric Vehicle Association. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Voronin, V.; Nepsha, F.; Ilyushin, P. A Demand Factor Analysis for Electric Vehicle Charging Infrastructure. World Electr. Veh. J. 2025, 16, 537. https://doi.org/10.3390/wevj16090537

Voronin V, Nepsha F, Ilyushin P. A Demand Factor Analysis for Electric Vehicle Charging Infrastructure. World Electric Vehicle Journal. 2025; 16(9):537. https://doi.org/10.3390/wevj16090537

Chicago/Turabian StyleVoronin, Vyacheslav, Fedor Nepsha, and Pavel Ilyushin. 2025. "A Demand Factor Analysis for Electric Vehicle Charging Infrastructure" World Electric Vehicle Journal 16, no. 9: 537. https://doi.org/10.3390/wevj16090537

APA StyleVoronin, V., Nepsha, F., & Ilyushin, P. (2025). A Demand Factor Analysis for Electric Vehicle Charging Infrastructure. World Electric Vehicle Journal, 16(9), 537. https://doi.org/10.3390/wevj16090537