From Cell to Pack: Empirical Analysis of the Correlations Between Cell Properties and Battery Pack Characteristics of Electric Vehicles

Abstract

1. Introduction

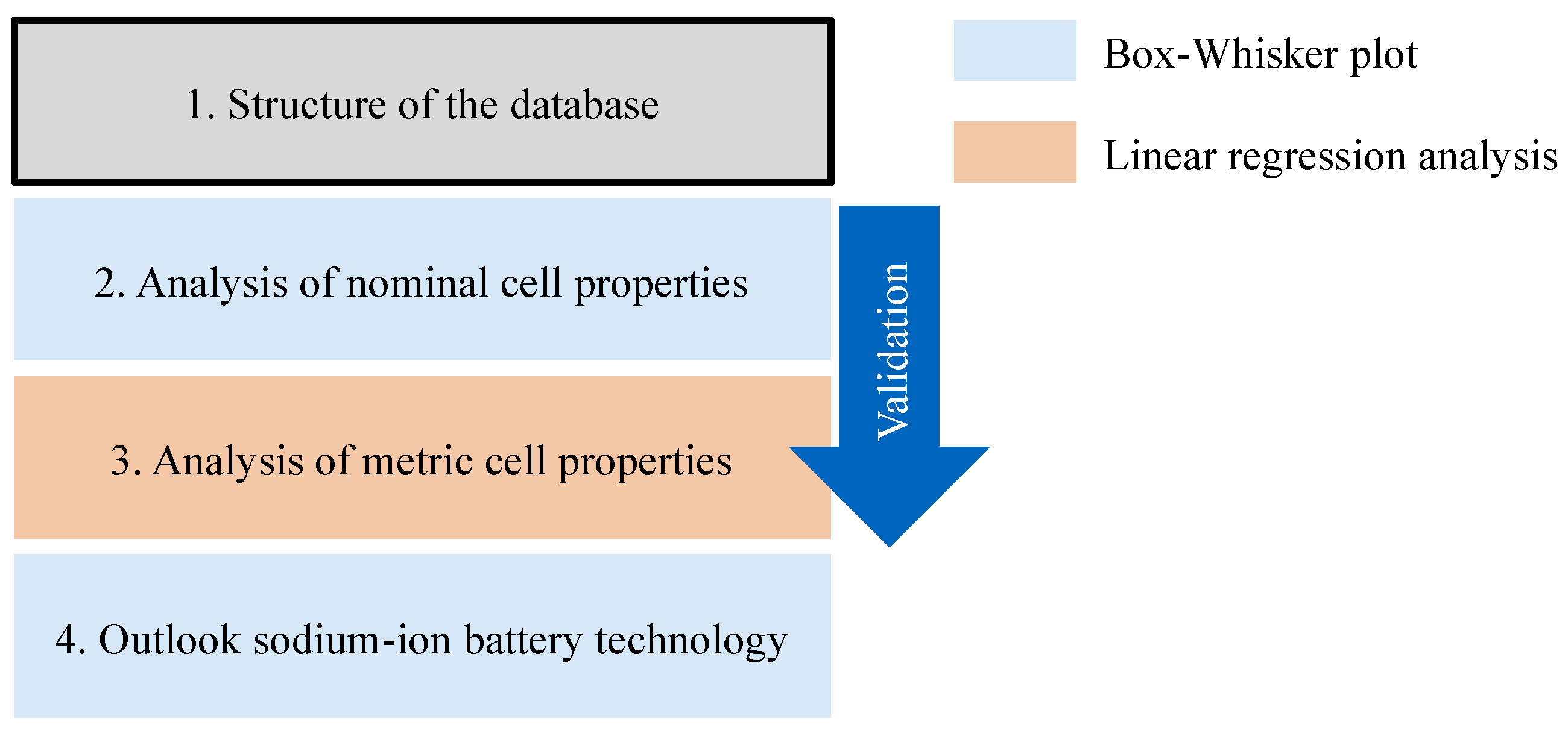

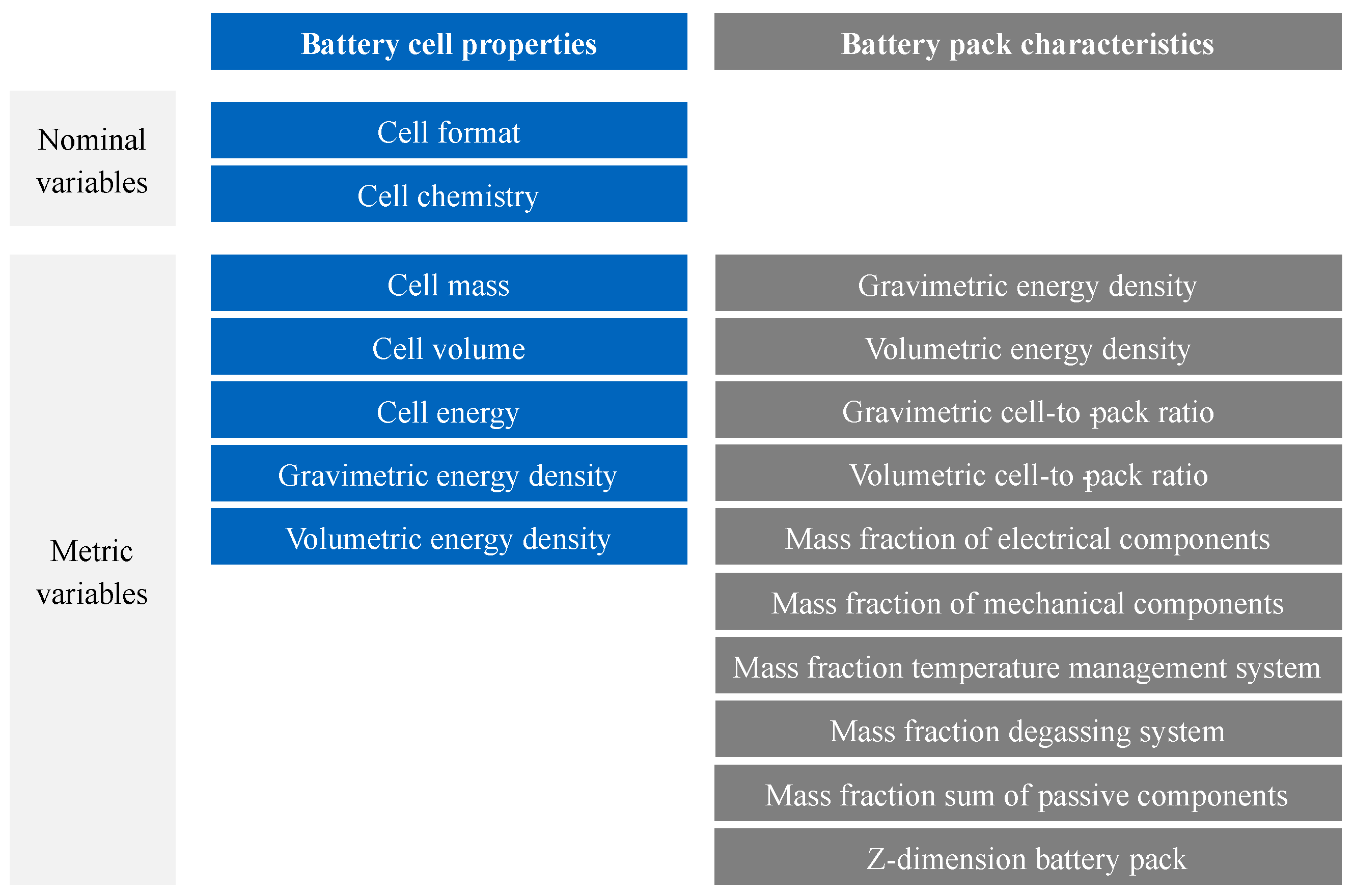

2. Methodology

3. Results

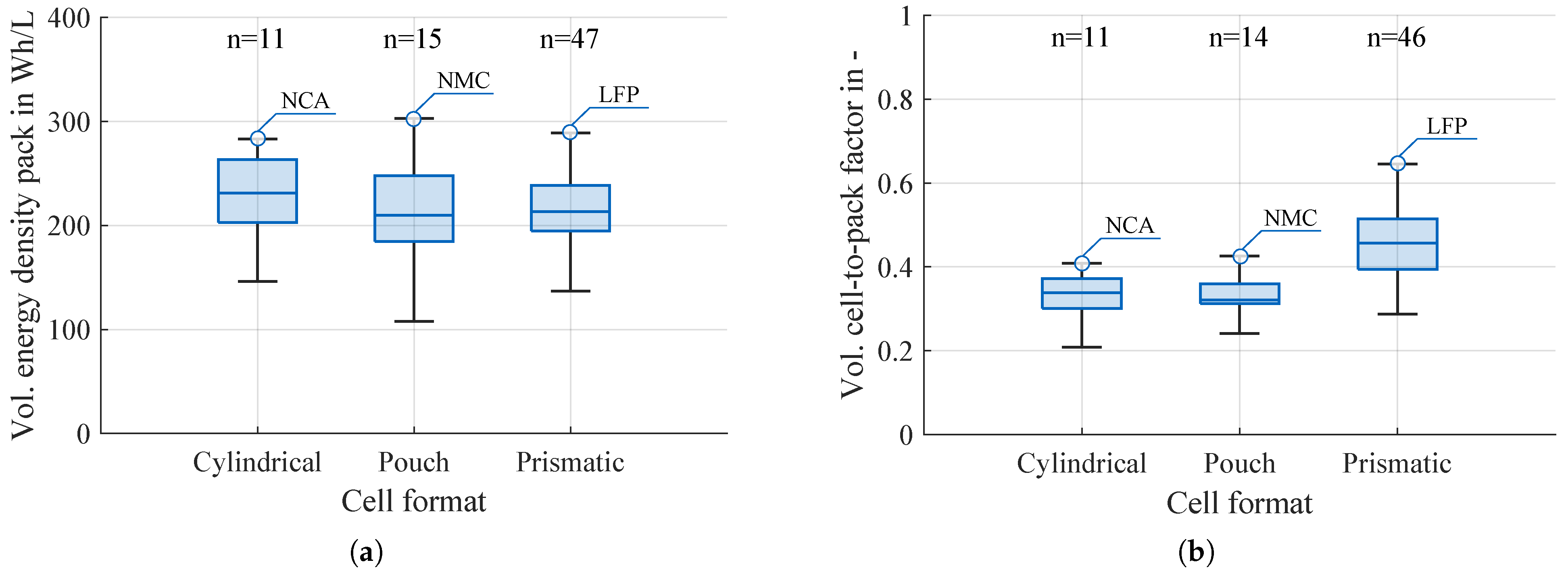

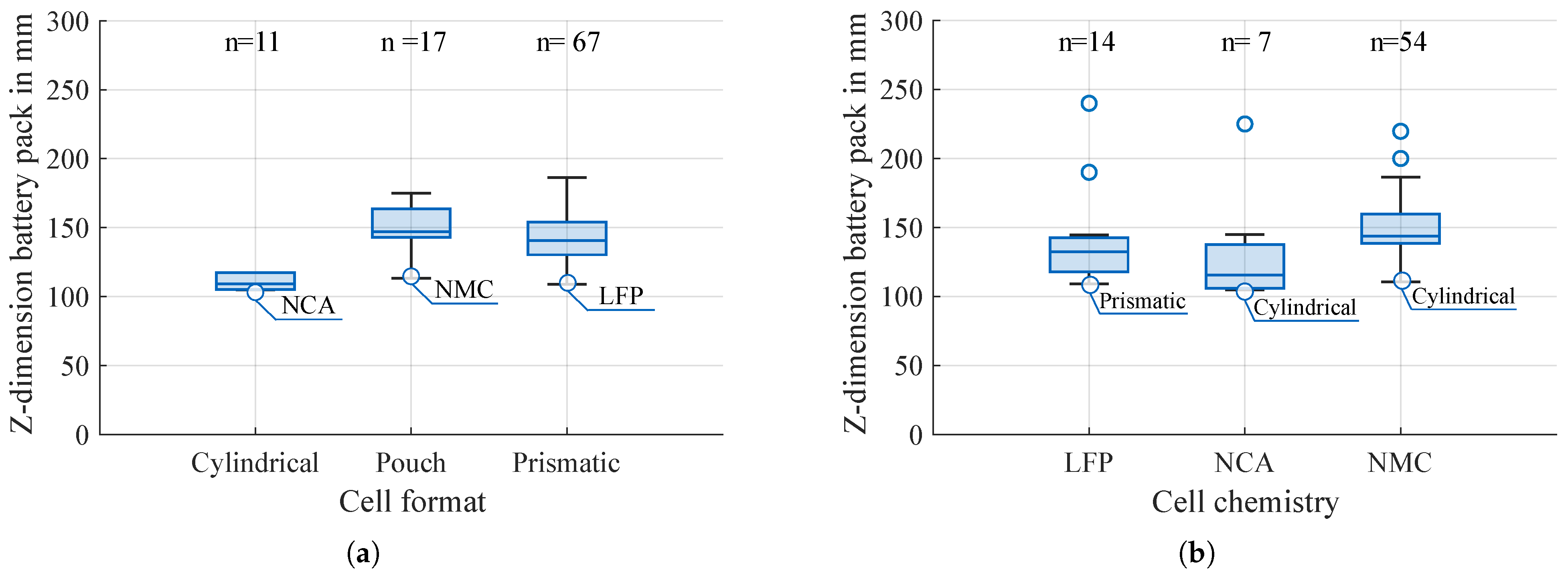

3.1. Results of the Nominal Analysis

3.2. Results of the Metric Analysis

3.3. Outlook Sodium-Ion Battery Technology

4. Discussion and Outlook

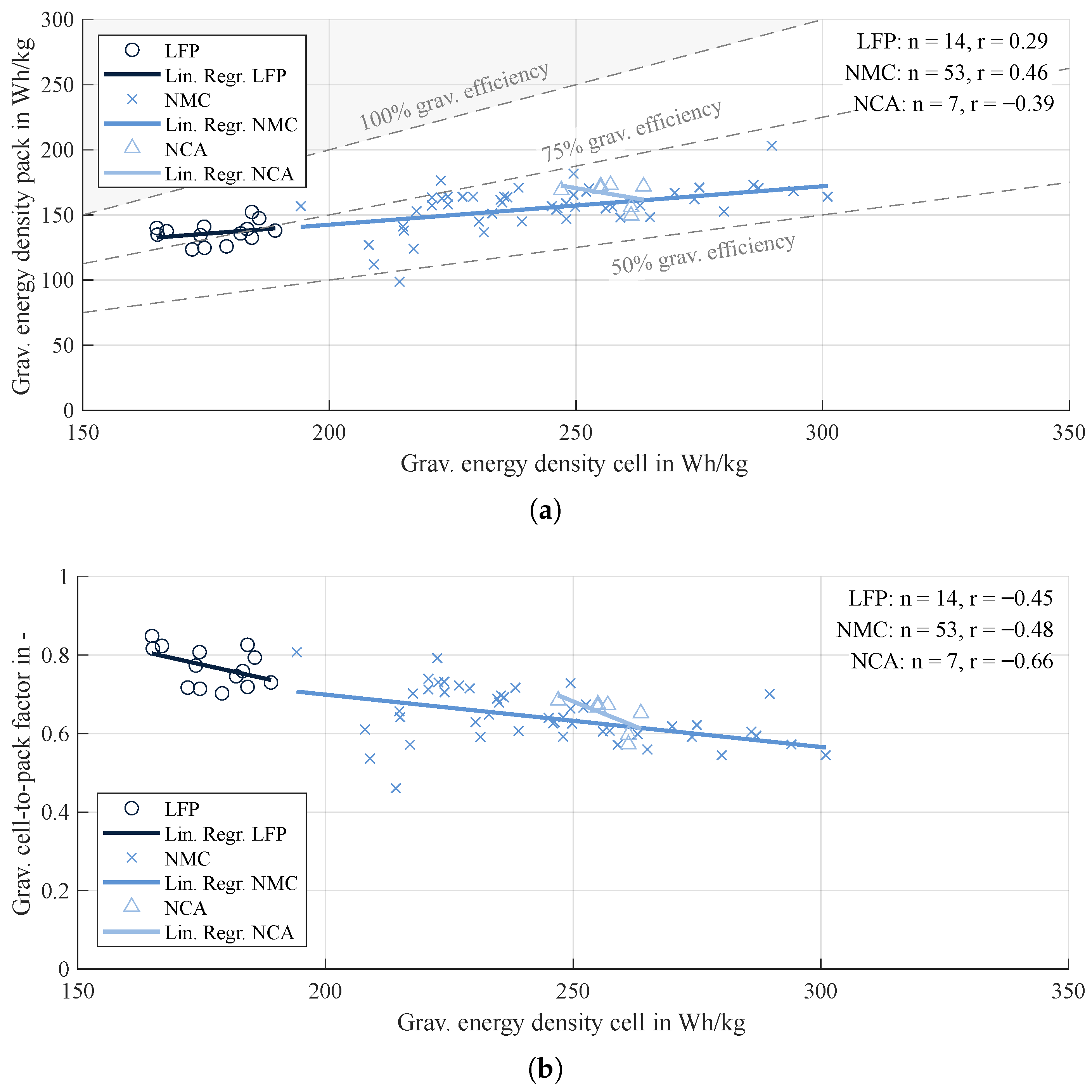

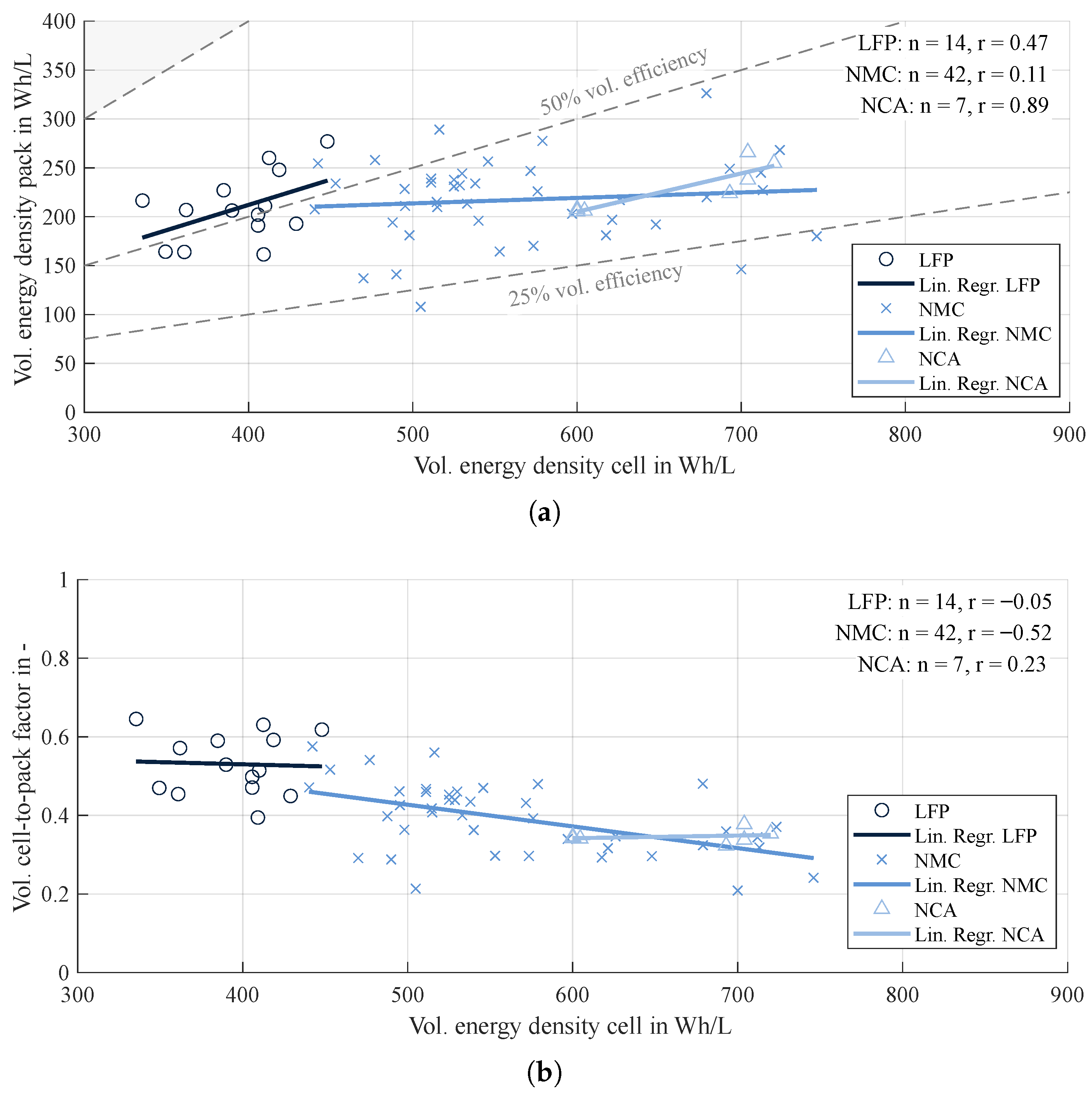

- Analysis of nominal cell characteristics suggests that volumetric energy densities at the pack level exhibit comparable values across all cell formats. The results indicate that this comparable behavior of cell formats is attributed to pack factors being higher for prismatic cells than cylindrical and pouch cells. Regarding cell chemistries, NMC and NCA cells show higher gravimetric energy densities than LFP cells at both cell and pack levels. However, these differences at the pack level are reduced due to the advantageous pack factors of LFP cells. The analysis of battery pack z-dimensions suggests no significant influence of the used cell chemistry on the vertical dimensions of a battery pack; however, it shows the linkage between pack height and cell format. The highest z-dimension values are observed in packs using prismatic cells, whereas cylindrical cells are used in battery packs of smaller heights.

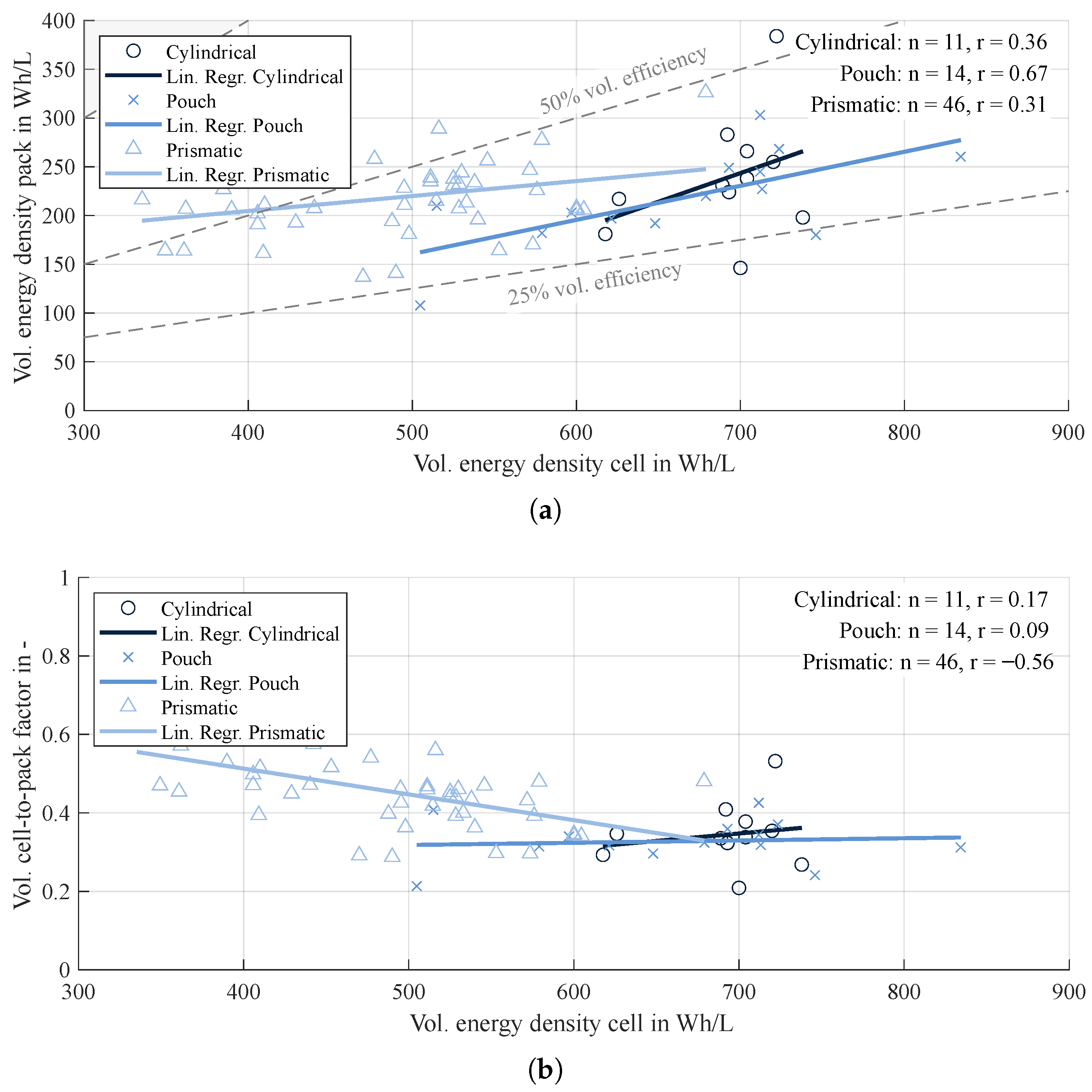

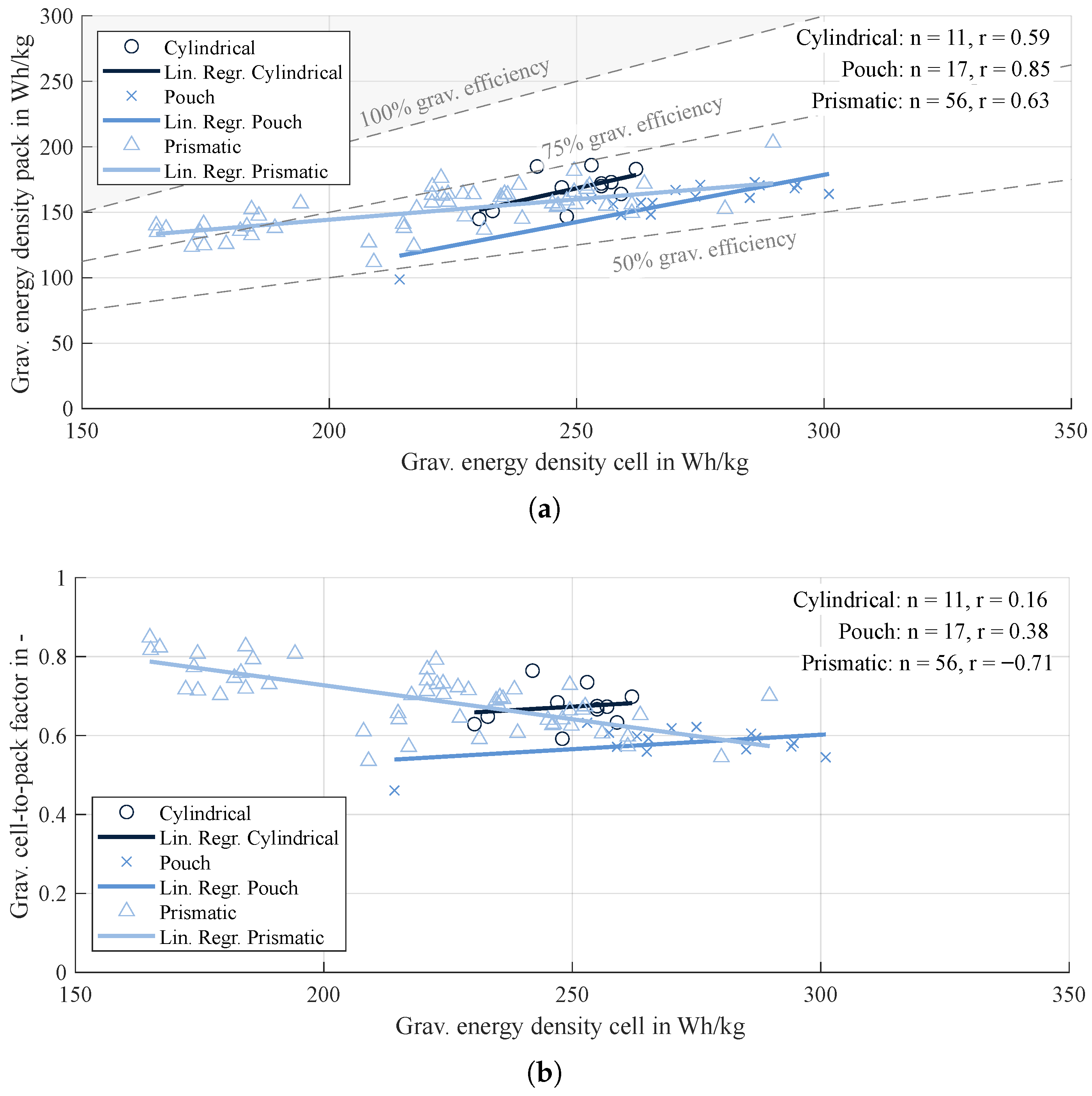

- Analysis of metric cell characteristics indicate that increases in volumetric and gravimetric cell-level energy density lead to proportionally smaller increases in corresponding pack-level energy density. This effect is particularly pronounced in prismatic cells, where the volumetric cell-to-pack factor significantly decreases with increasing volumetric cell energy density. A similar trend is observed in the progression of the gravimetric cell-to-pack factor for NMC and LFP cells. These correlations can be attributed to the growing proportion of passive components required as cell-level energy density increases. Furthermore, cells with lower energy density are predominantly implemented in CtP architectures, with the database showing this approach is primarily represented by vehicles using prismatic LFP cells. This architectural choice results in superior cell-to-pack factors for this specific cell format and chemistry combination in gravimetric and volumetric terms.

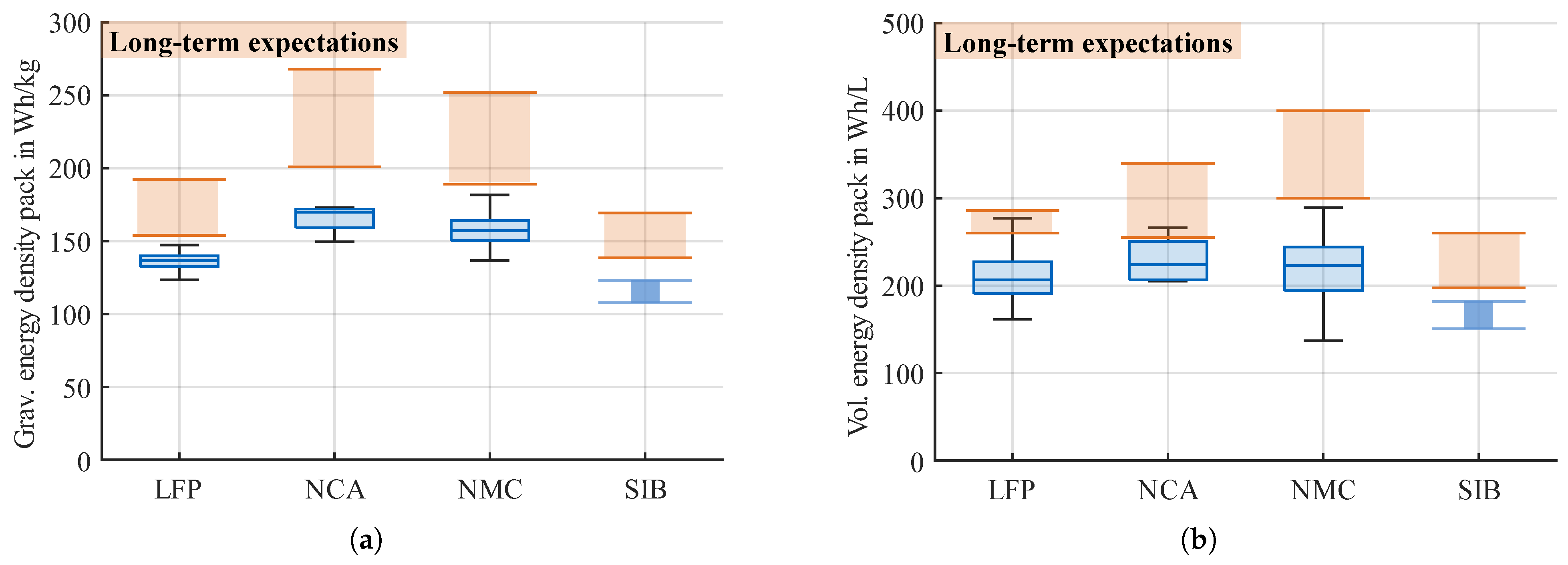

- The outlook for SIBs shows that, due to the lack of pack factors for SIBs, these can only be estimated based on pack factors of LFP cells. This approach is justified by the similar thermal characteristics exhibited by sodium-ion and LFP cells. Results indicate that SIBs position themselves at the lower boundary of LIB energy densities at both cell and pack levels. As both technologies are expected to advance, similar relative performance levels are projected for the long term.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| BEV | Battery electric vehicle |

| NMC | Nickel cobalt manganese oxide |

| NCA | nickel cobalt aluminum oxide |

| LFP | lithium iron phosphate |

| SIB | Sodium-ion battery |

| LIB | Lithium-ion battery |

| MtP | Module-to-pack |

| CtP | Cell-to-pack |

References

- Gnann, T. Elektromobilität; Fraunhofer ISI: Karlsruhe, Germany, 2025; Available online: https://www.isi.fraunhofer.de/de/themen/elektromobilitaet.html (accessed on 29 January 2025).

- Klimaschutz im Verkehr. Umweltbundesamt. 2025. Available online: https://www.umweltbundesamt.de/themen/verkehr/klimaschutz-im-verkehr (accessed on 29 January 2025).

- Bergk, F.; Knörr, W.; Lambrecht, U. Klimaschutz im Verkehr: Neuer Handlungsbedarf Nach dem Pariser Klimaschutzabkommen; Umweltbundesamt: Dessau-Roßlau, Germany, 2017. [Google Scholar]

- Klimavorteil für E-Autos Bestätigt. Umweltbundesamt. 2024. Available online: https://www.umweltbundesamt.de/presse/pressemitteilungen/klimavorteil-fuer-e-autos-bestaetigt (accessed on 29 January 2025).

- Frieske, B.; van den Adel, B.; Schwarz-Kocher, M.; Stieler, S.; Schnabel, A.; Tözün, B. Strukturstudie BWe Mobil 2019: Transformation Durch Elektromobilität und Perspektiven der Digitalisierung; e-mobil BW GmbH: Stuttgart, Germany, 2019. [Google Scholar]

- Koloch, J.; Schneider, J.; Seidenfus, M.; Lienkamp, M. Beyond lithium: A comprehensive use-case-analysis of sodium-ion-battery technology in battery electric vehicles. e-Prime-Adv. Electr. Eng. Electron. Energy 2025, 12, 100995. [Google Scholar] [CrossRef]

- Hettesheimer, T.; Thielmann, A.; Neef, C.; Möller, K.-C.; Wolter, M.; Lorentz, V.; Gepp, M.; Wenger, M.; Prill, T.; Zausch, J.; et al. Entwicklungsperspektiven für Zellformate von Lithium-Ionen-Batterien in der Elektromobilität; Fraunhofer-Gesellschaft: Munich, Germany, 2017. [Google Scholar]

- Baazouzi, S.; Feistel, N.; Wanner, J.; Landwehr, I.; Fill, A.; Birke, K.P. Design, Properties, and Manufacturing of Cylindrical Li-Ion Battery Cells—A Generic Overview. Batteries 2023, 9, 309. [Google Scholar] [CrossRef]

- Koloch, J.; Heienbrok, M.; Rosenberger, N.; Lienkamp, M. From Cell to Pack: Empirical Analysis of the Correlations Between Cell Properties and Battery Pack Characteristics of Electric Vehicles. In Proceedings of the EVS38—International Electric Vehicle Symposium and Exhibition, Göteborg, Sweden, 15–18 June 2025. [Google Scholar]

- Schöberl, J.; Ank, M.; Schreiber, M.; Wassiliadis, N.; Lienkamp, M. Thermal runaway propagation in automotive lithium-ion batteries with NMC-811 and LFP cathodes. eTransportation 2024, 19, 100305. [Google Scholar] [CrossRef]

- Löbberding, H.; Wessel, S.; Offermanns, C.; Kehrer, M.; Rother, J.; Heimes, H.; Kampker, A. From Cell to Battery System in BEVs: Analysis of System Packing Efficiency and Cell Types. World Electr. Veh. J. 2020, 11, 77. [Google Scholar] [CrossRef]

- A2MAC1. 2024. Available online: https://www.a2mac1.com/ (accessed on 29 January 2024).

- Nicoletti, L.; Köhler, P.; König, A.; Heinrich, M.; Lienkamp, M. Parametric Modelling of Weight and Volume Effects in Battery Electric Vehicles, with Focus on the Gearbox. Proc. Des. Soc. 2021, 1, 2389–2398. [Google Scholar] [CrossRef]

- Völkl, K.; Korb, C. Deskriptive Statistik: Eine Einführung für Politikwissenschaftlerinnen und Politikwissenschaftler; Springer VS: Wiesbaden, Germany, 2018. [Google Scholar]

- Kühnel, S.; Krebs, D. Statistik für die Sozialwissenschaften: Grundlagen, Methoden, Anwendungen; Rowohlt Taschenbuch Verlag: Reinbek bei Hamburg, Germany, 2018. [Google Scholar]

- König, A.; Nicoletti, L.; Schröder, D.; Wolff, S.; Waclaw, A.; Lienkamp, M. An Overview of Parameter and Cost for Battery Electric Vehicles. World Electr. Veh. J. 2021, 12, 21. [Google Scholar] [CrossRef]

- Pampel, F.; Pischinger, S.; Teuber, M. A systematic comparison of the packing density of battery cell-to-pack concepts at different degrees of implementation. Results Eng. 2022, 13, 100310. [Google Scholar] [CrossRef]

- Deng, Y.; Lu, K.; Liu, T.; Wang, X.; Shen, H.; Gong, J. Numerical Simulation of Aerodynamic Characteristics of Electric Vehicles with Battery Packs Mounted on Chassis. World Electr. Veh. J. 2023, 14, 216. [Google Scholar] [CrossRef]

- Belingardi, G.; Scattina, A. Battery Pack and Underbody: Integration in the Structure Design for Battery Electric Vehicles—Challenges and Solutions. Vehicles 2023, 5, 498–514. [Google Scholar] [CrossRef]

- Gerlitz, E.; Botzem, D.; Weinmann, H.; Ruhland, J.; Fleischer, J. Cell-to-Pack-Technologie für Li-Ionen-Batterien: Aktueller Entwicklungsstand, Marktakteure in der Automobilindustrie und Auswirkungen auf eine nachhaltige Produktionstechnik unter dem Aspekt der Kreislaufwirtschaft. Z. FüR Wirtsch. Fabr. 2021, 116, 689–694. [Google Scholar] [CrossRef]

- Arora, S.; Kapoor, A.; Shen, W. Application of Robust Design Methodology to Battery Packs for Electric Vehicles: Identification of Critical Technical Requirements for Modular Architecture. Batteries 2018, 4, 30. [Google Scholar] [CrossRef]

- Reid, H.T.; Singh, G.; Palin, E.; Dai, Y.; Zong, W.; Somerville, L.; Shearing, P.R.; Robinson, J.B. Key considerations for cell selection in electric vertical take off and landing vehicles: A perspective. EES Batter. 2025, 1, 227–241. [Google Scholar] [CrossRef]

- Ohneseit, S.; Finster, P.; Floras, C.; Lubenau, N.; Uhlmann, N.; Seifert, H.J.; Ziebert, C. Thermal and Mechanical Safety Assessment of Type 21700 Lithium-Ion Batteries with NMC, NCA and LFP Cathodes–Investigation of Cell Abuse by Means of Accelerating Rate Calorimetry (ARC). Batteries 2023, 9, 237. [Google Scholar] [CrossRef]

- Epp, A.; Sauer, D.U. Multiperspective Optimization of Cell and Module Dimensioning for Different Lithium-Ion Cell Formats on Geometric and Generic Assumptions. Energy Technol. 2022, 10, 2100874. [Google Scholar] [CrossRef]

- Hasselwander, S.; Meyer, M.; Österle, I. Techno-Economic Analysis of Different Battery Cell Chemistries for the Passenger Vehicle Market. Batteries 2023, 9, 379. [Google Scholar] [CrossRef]

- Gao, Y.; Yu, Q.; Yang, H.; Zhang, J.; Wang, W. The Enormous Potential of Sodium/Potassium-Ion Batteries. Adv. Mater. 2024, 36, e2405989. [Google Scholar] [CrossRef] [PubMed]

- Zhao, L.; Zhang, T.; Li, W.; Li, T.; Zhang, L.; Zhang, X.; Wang, Z. Engineering of Sodium-Ion Batteries: Opportunities and Challenges. Engineering 2023, 24, 172–183. [Google Scholar] [CrossRef]

- Tapia-Ruiz, N.; Armstrong, A.R.; Alptekin, H.; Amores, M.A.; Au, H.; Barker, J.; Boston, R.; Brant, W.R.; Brittain, J.M.; Chen, Y.; et al. 2021 roadmap for sodium-ion batteries. J. Phys. Energy 2021, 3, 031503. [Google Scholar] [CrossRef]

- Nagmani; Pahari, D.; Verma, P.; Puravankara, S. Are Na-ion batteries nearing the energy storage tipping point? J. Energy Storage 2022, 56, 105961. [Google Scholar] [CrossRef]

- Chen, Y.; Ye, C.; Zhang, N.; Liu, J.; Li, H.; Davey, K.; Qiao, S. Prospects for practical anode-free sodium batteries. Mater. Today 2024, 73, 260–274. [Google Scholar] [CrossRef]

- Rostami, H.; Valio, J.; Suominen, P.; Tynjälä, P.; Lassi, U. Advancements in cathode technology, recycling strategies, and market dynamics: A comprehensive review of sodium ion batteries. Chem. Eng. J. 2024, 495, 153471. [Google Scholar] [CrossRef]

- Rudola, A.; Rennie, A.J.R.; Heap, R.; Meysami, S.S.; Lowbridge, A.; Mazzali, F.; Sayers, R.; Wright, C.J.; Barker, J. Commercialisation of high energy density sodium-ion batteries: Faradion’s journey and outlook. J. Mater. Chem. A 2021, 9, 8279–8302. [Google Scholar] [CrossRef]

- Liang, X.; Hwang, J.Y.; Sun, Y.K. Practical Cathodes for Sodium-Ion Batteries: Who Will Take The Crown? Adv. Energy Mater. 2023, 13, 2023. [Google Scholar] [CrossRef]

- Yao, A.; Benson, S.M.; Chueh, W.C. Critically assessing sodium-ion technology roadmaps and scenarios for techno-economic competitiveness against lithium-ion batteries. Nat. Energy 2025, in press. [Google Scholar] [CrossRef]

- Hirsh, H.S.; Li, Y.; Tan, D.H.S.; Zhang, M.; Zhao, E.; Meng, Y.S. Sodium-Ion Batteries Paving the Way for Grid Energy Storage. Adv. Energy Mater. 2020, 10, 2020. [Google Scholar] [CrossRef]

- Stephan, A.; Hettesheimer, T.; Neef, C.; Schmaltz, T.; Link, S.; Stephan, M.; Heizmann, J.L.; Thielmann, A. Alternative Battery Technologies Roadmap 2030+; Fraunhofer-Gesellschaft: Munich, Germany, 2023. [Google Scholar]

- Mei, W.; Cheng, Z.; Wang, L.; Teng, A.; Li, Z.; Jin, K.; Sun, J.; Wang, Q. Thermal hazard comparison and assessment of Li-ion battery and Na-ion battery. J. Energy Chem. 2025, 102, 18–26. [Google Scholar] [CrossRef]

- Kim, H. Sodium-Ion Battery: Can It Compete with Li-Ion? ACS Mater. Au 2023, 3, 571–575. [Google Scholar] [CrossRef]

- Rudola, A.; Sayers, R.; Wright, C.J.; Barker, J. Opportunities for moderate-range electric vehicles using sustainable sodium-ion batteries. Nat. Energy 2023, 8, 215–218. [Google Scholar] [CrossRef]

- Dorau, F.A.; Sommer, A.; Koloch, J.; Röß-Ohlenroth, R.; Schreiber, M.; Neuner, M.; Abo Gamra, K.; Lin, Y.; Schöberl, J.; Bilfinger, P.; et al. Comprehensive Analysis of Commercial Sodium-Ion Batteries: Structural and Electrochemical Insights. J. Electrochem. Soc. 2024, 171, 090521. [Google Scholar] [CrossRef]

| Unit | LFP | NMC | NCA | SIB | ||

|---|---|---|---|---|---|---|

| Grav. cell energy density | / | Current: Expected: | 165–190 200–250 [25] | 195–300 300–400 [25] | 250–265 300–400 [25] | 140–160 [25,26,27,28,29,30,31] 180–220 [25,27,28,29,31,32,33,34] |

| Vol. cell energy density | / | Current: Expected: | 340–450 500–550 [25] | 440–750 750–1000 [25] | 600–720 750–1000 [36] | 290–350 [25,28,35] 380–500 [25,28,34] |

| Grav. cell-to-pack factor | - | 0.77 | 0.63 | 0.67 | 0.77 1 | |

| Vol. cell-to-pack factor | - | 0.52 | 0.40 | 0.34 | 0.52 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Published by MDPI on behalf of the World Electric Vehicle Association. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Koloch, J.; Heienbrok, M.; Kasperek, M.; Lienkamp, M. From Cell to Pack: Empirical Analysis of the Correlations Between Cell Properties and Battery Pack Characteristics of Electric Vehicles. World Electr. Veh. J. 2025, 16, 484. https://doi.org/10.3390/wevj16090484

Koloch J, Heienbrok M, Kasperek M, Lienkamp M. From Cell to Pack: Empirical Analysis of the Correlations Between Cell Properties and Battery Pack Characteristics of Electric Vehicles. World Electric Vehicle Journal. 2025; 16(9):484. https://doi.org/10.3390/wevj16090484

Chicago/Turabian StyleKoloch, Jan, Mats Heienbrok, Maksymilian Kasperek, and Markus Lienkamp. 2025. "From Cell to Pack: Empirical Analysis of the Correlations Between Cell Properties and Battery Pack Characteristics of Electric Vehicles" World Electric Vehicle Journal 16, no. 9: 484. https://doi.org/10.3390/wevj16090484

APA StyleKoloch, J., Heienbrok, M., Kasperek, M., & Lienkamp, M. (2025). From Cell to Pack: Empirical Analysis of the Correlations Between Cell Properties and Battery Pack Characteristics of Electric Vehicles. World Electric Vehicle Journal, 16(9), 484. https://doi.org/10.3390/wevj16090484