Design and Implementation of a Teaching Model for EESM Using a Modified Automotive Starter-Generator

Abstract

1. Introduction

2. EESM Background

- -

- It is cost-effective because it has no reliance on rare-earth materials

- -

- Because of no magnets, EESM is better in high-temperature environments

- -

- Field weakening is easier to achieve due to active field control

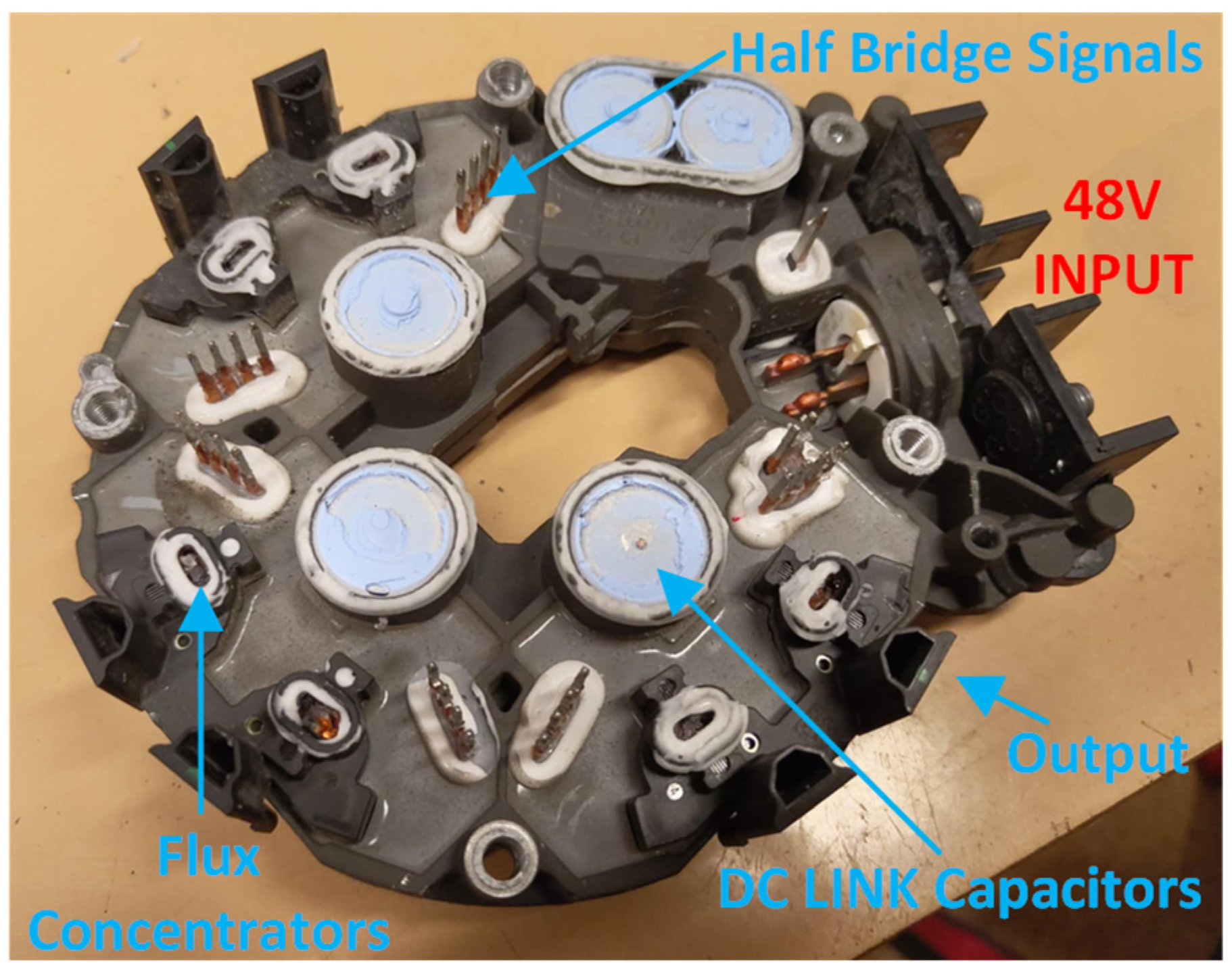

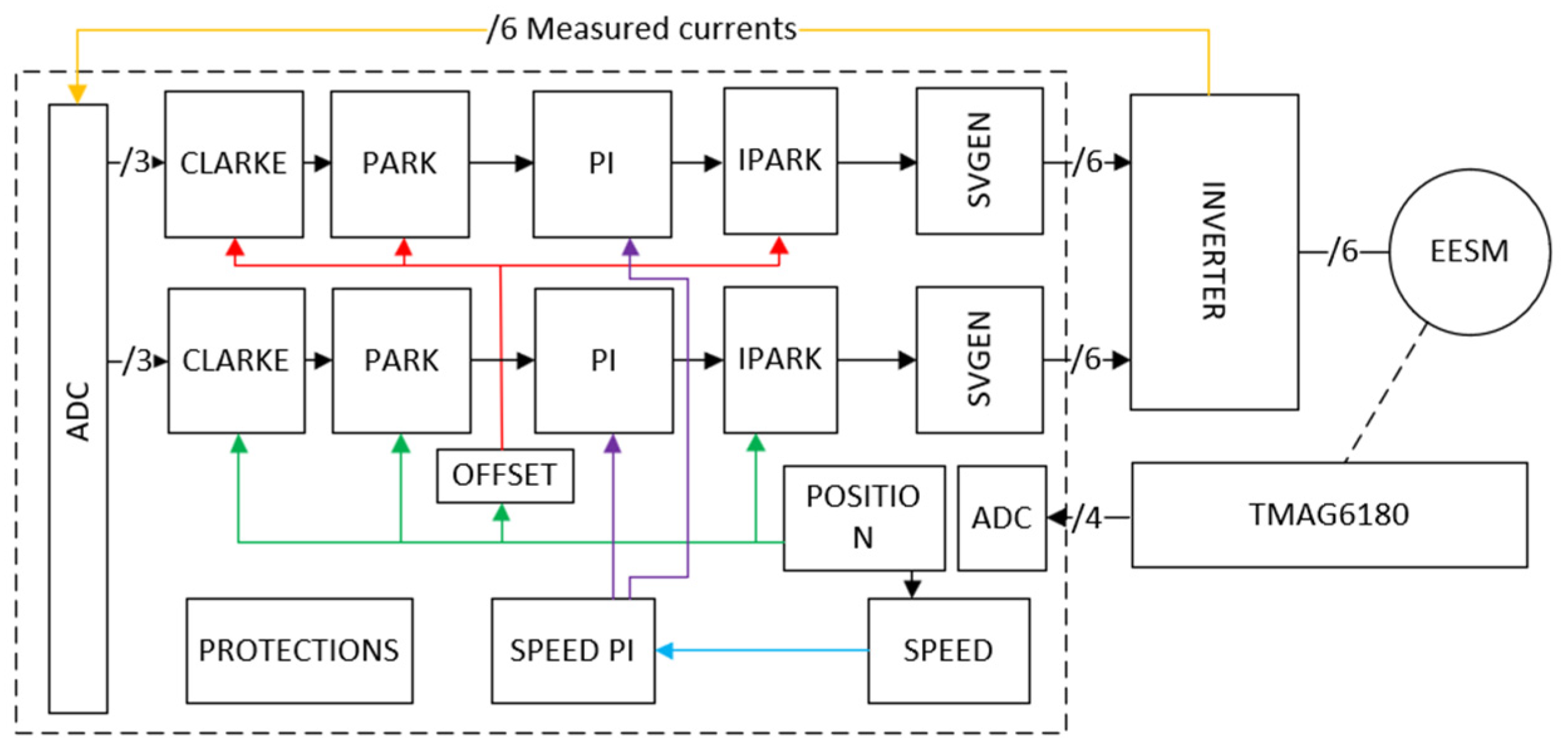

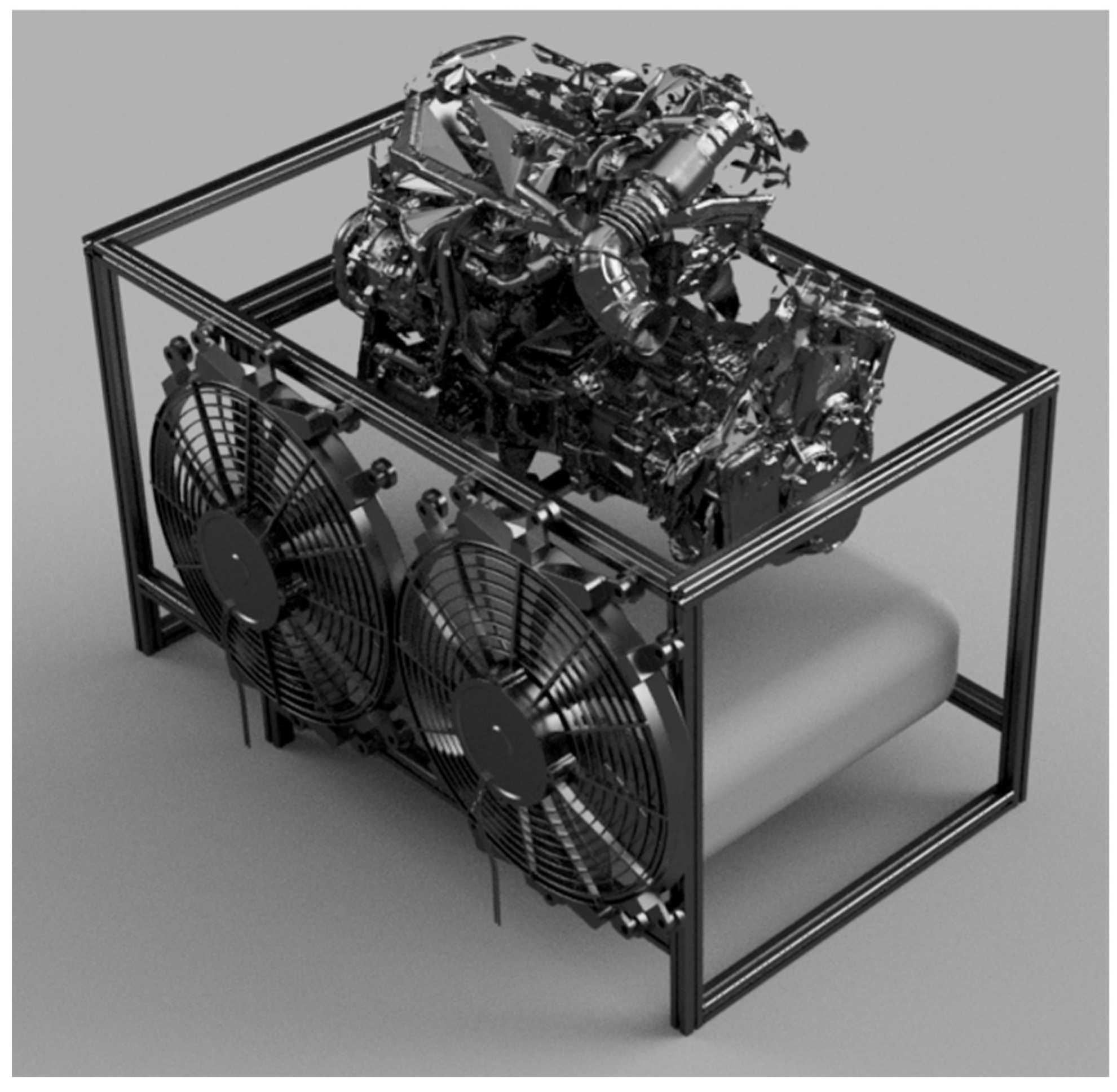

3. Proprietary EESM System

- -

- Increased fault tolerance: In the event of failure in one of the three-phase subsystems, the motor can still be operational, but with reduced power [28].

- -

- Lower per-phase current: Due to the dual three-phase configuration, phase current can be significantly lower while maintaining the same overall torque output.

- -

- Smoother torque production: The 30° shift between three-phase systems contributes to the smoother torque production, reducing torque ripple. This reduces stress on the mechanical components, thereby increasing the system’s performance and lifespan.

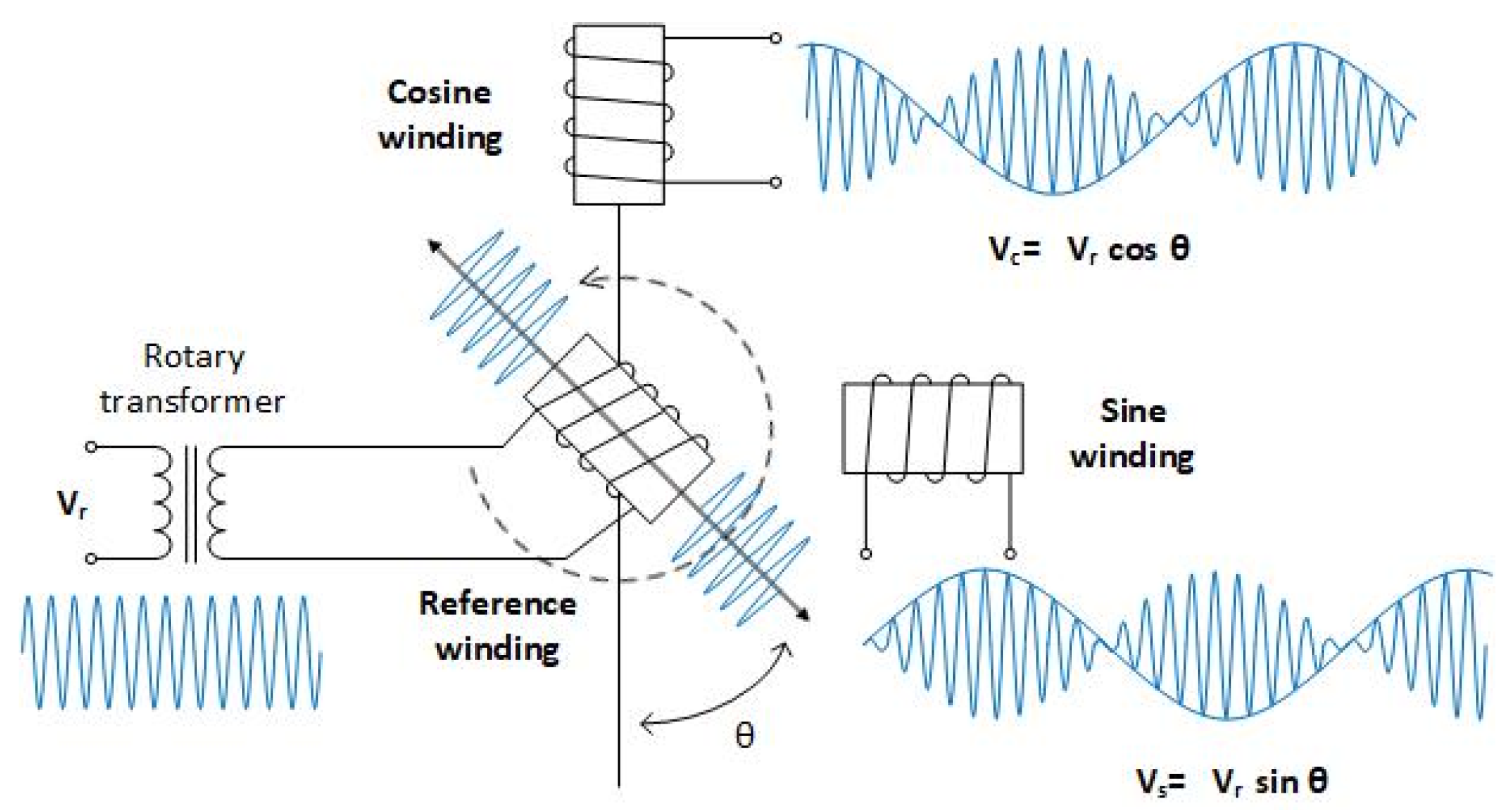

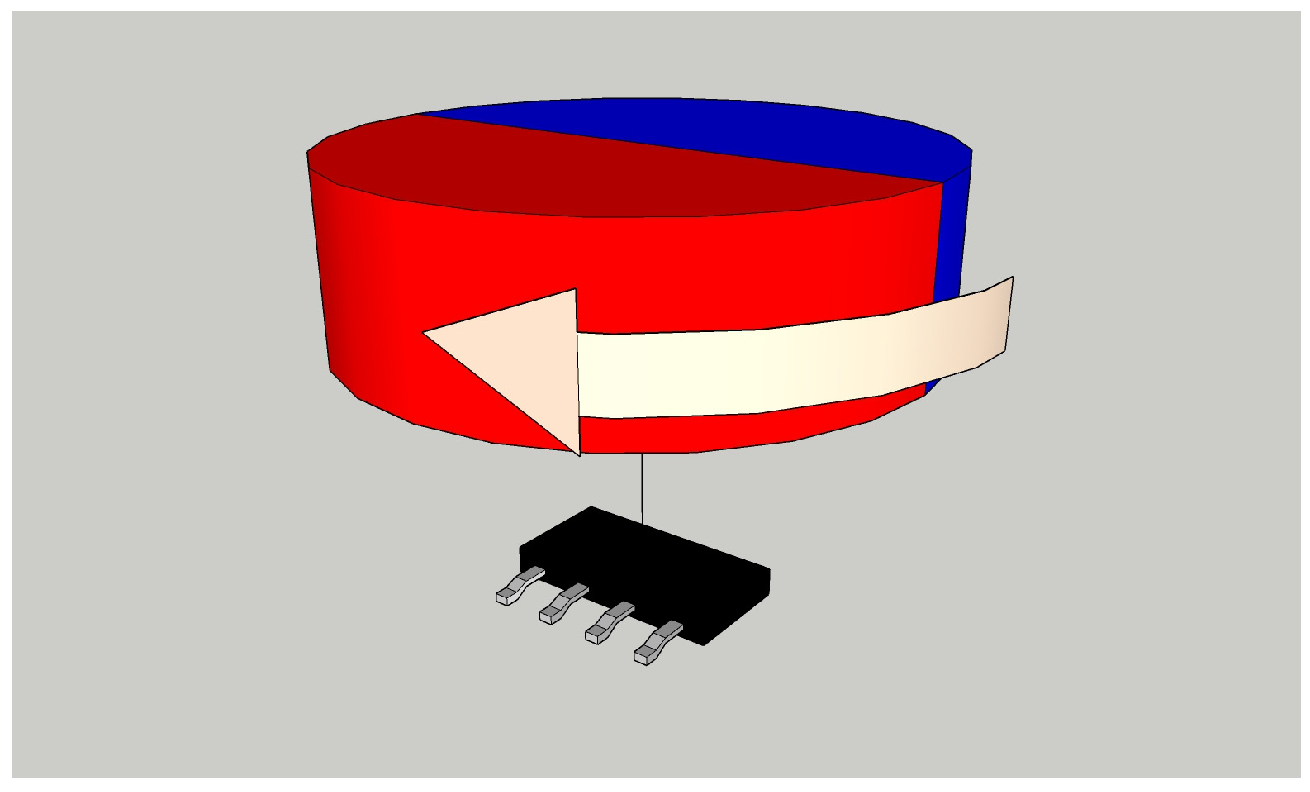

3.1. Rotor Position Sensor Design

- -

- Encoders: Output pulses according to the resolution of the sensor. This sensor is relatively cheap and can be interfaced directly by counting pulses and calculating the time between pulses [29,30]. The disadvantage is that the encoder does not know the absolute position of the rotor, and this position must be detected after every system power-up.

- -

- Resolvers: A more complex solution for position sensing, but it offers absolute rotor position. There are many types of resolvers based on their principle of operation [30].

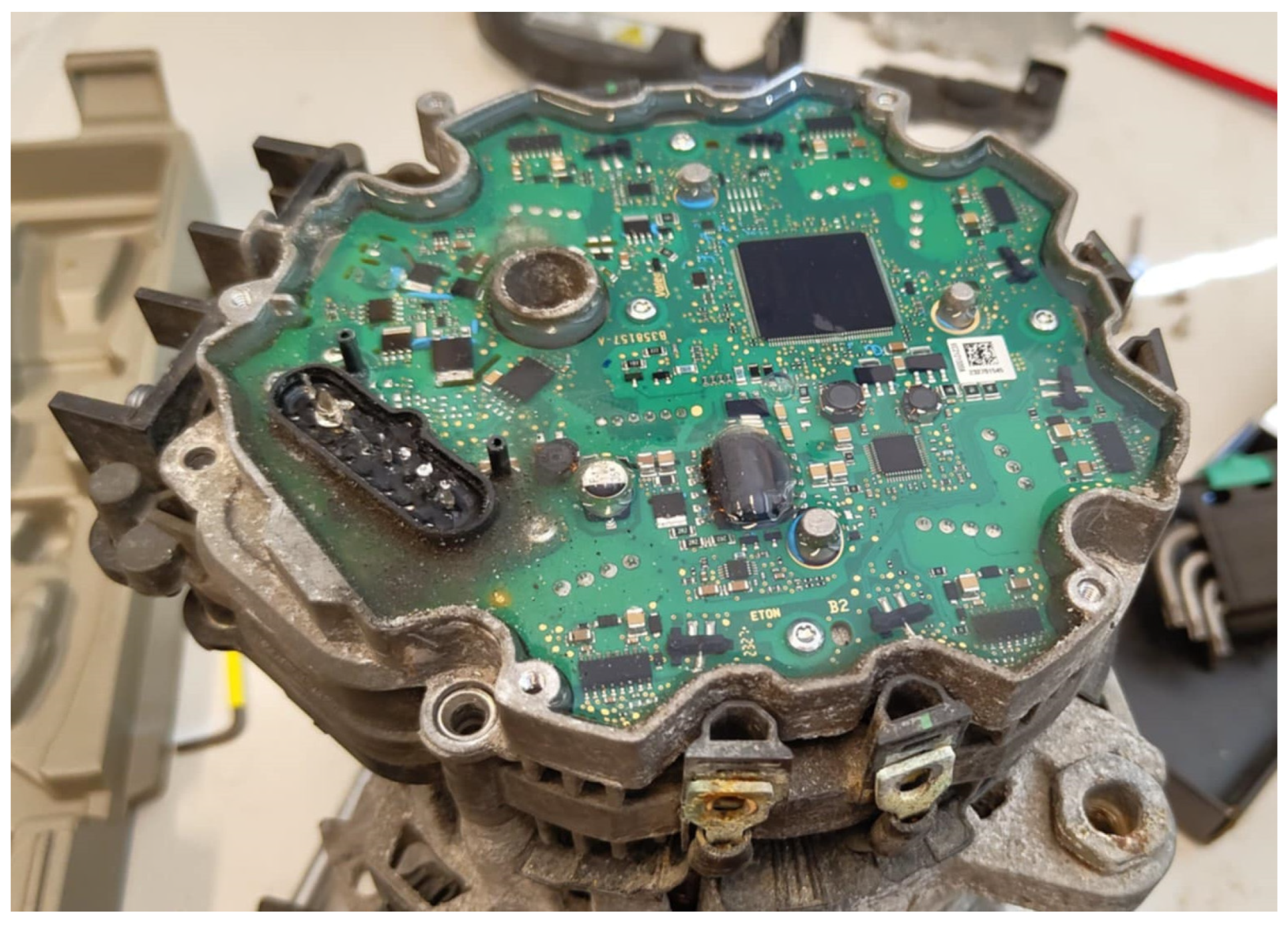

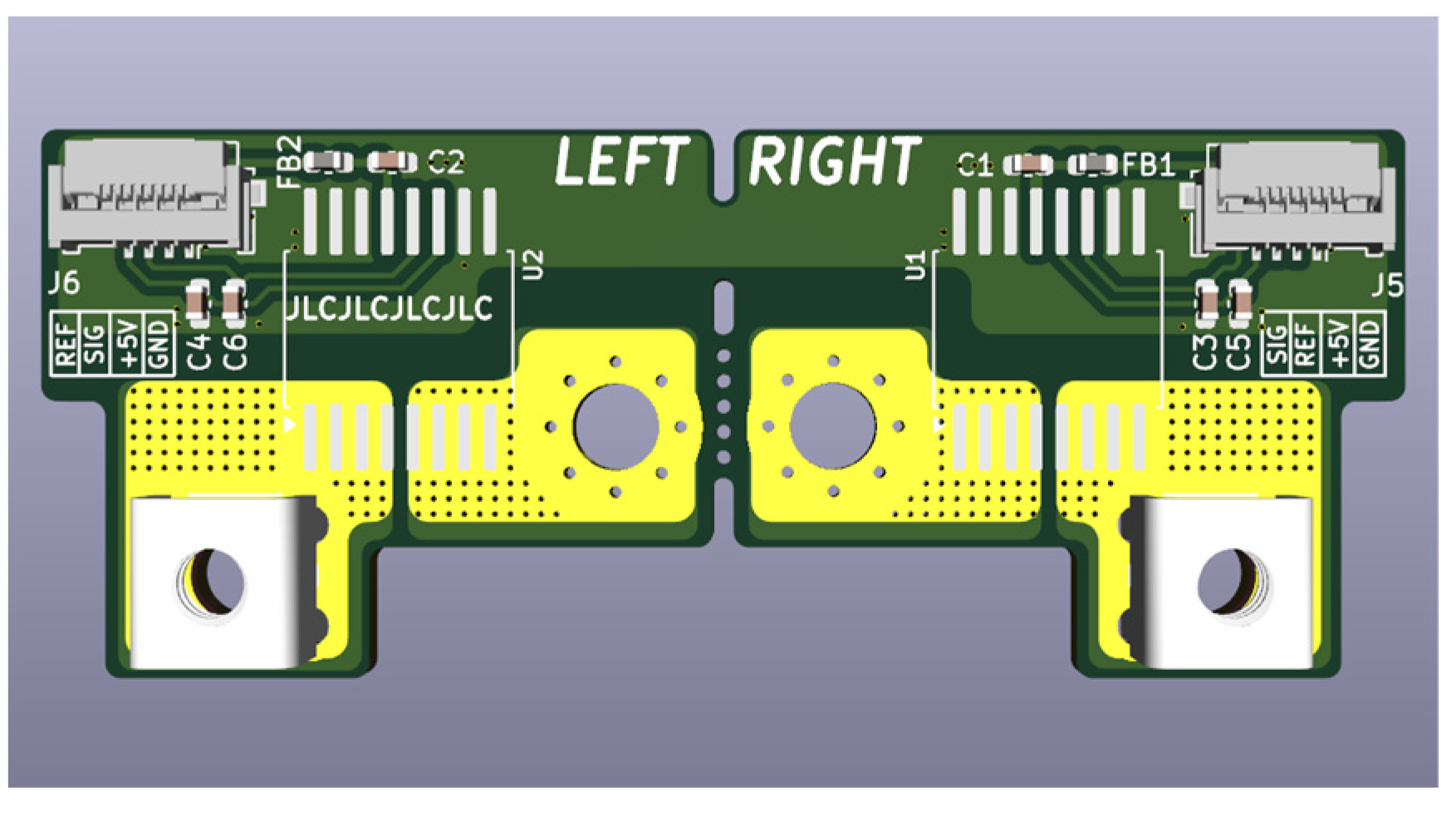

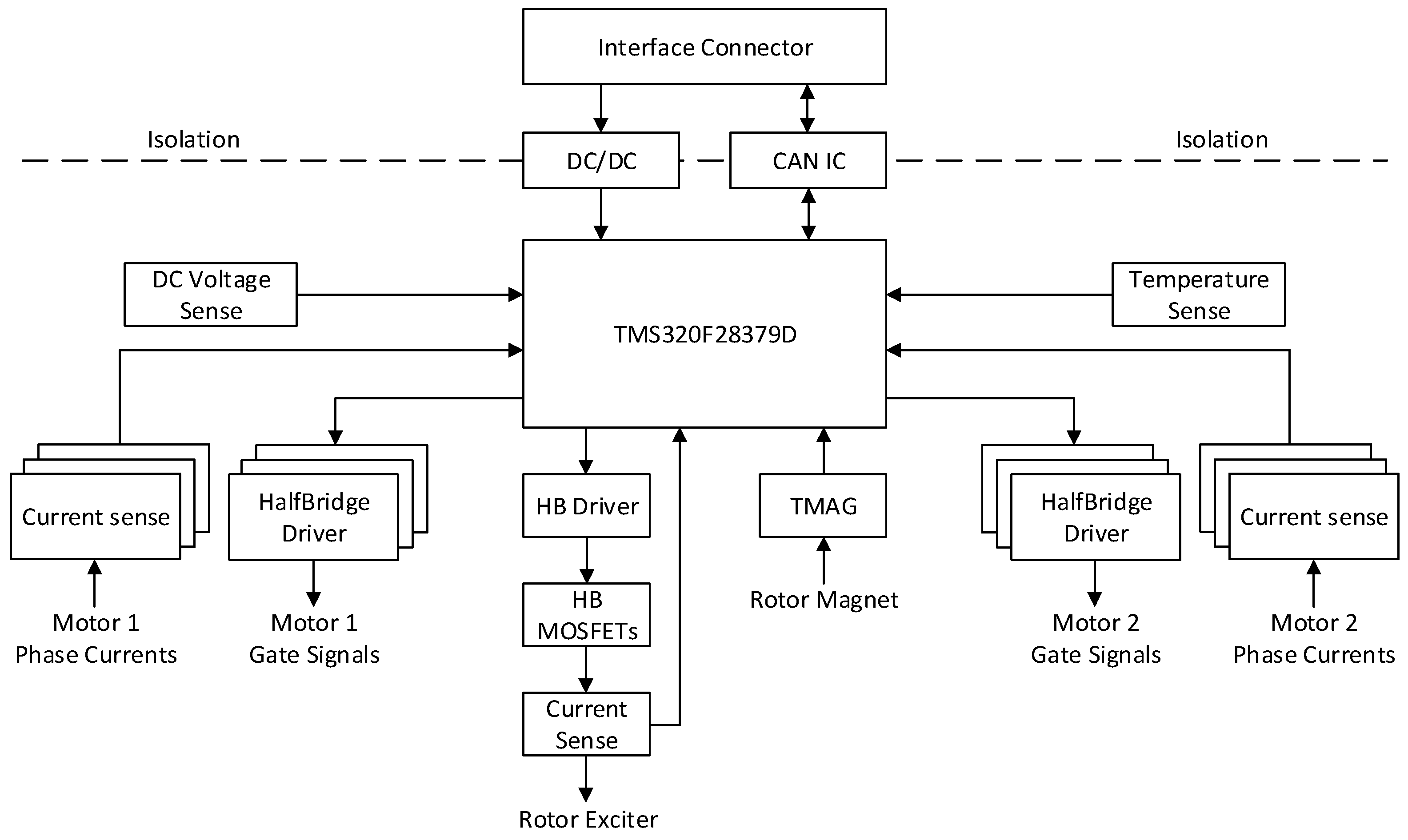

3.2. New Control PCB Design

- -

- 6× Half Bridge drivers

- -

- 1× Half-bridge driver for excitation winding

- -

- Isolated CAN communication

- -

- Implemented AMR position sensor

- -

- Control DSP

- -

- 6× Current measurement for each phase

- -

- Voltage and temperature measurement

- -

- Physical current sensor: The Board has an interface to measure current using a physical HALL current sensor. The sensor is capable of measuring a current of 120 A RMS. The disadvantage of this method is the size and the fact that the sensor is SMD, and all the current must flow through the dedicated PCB of the sensor.

- -

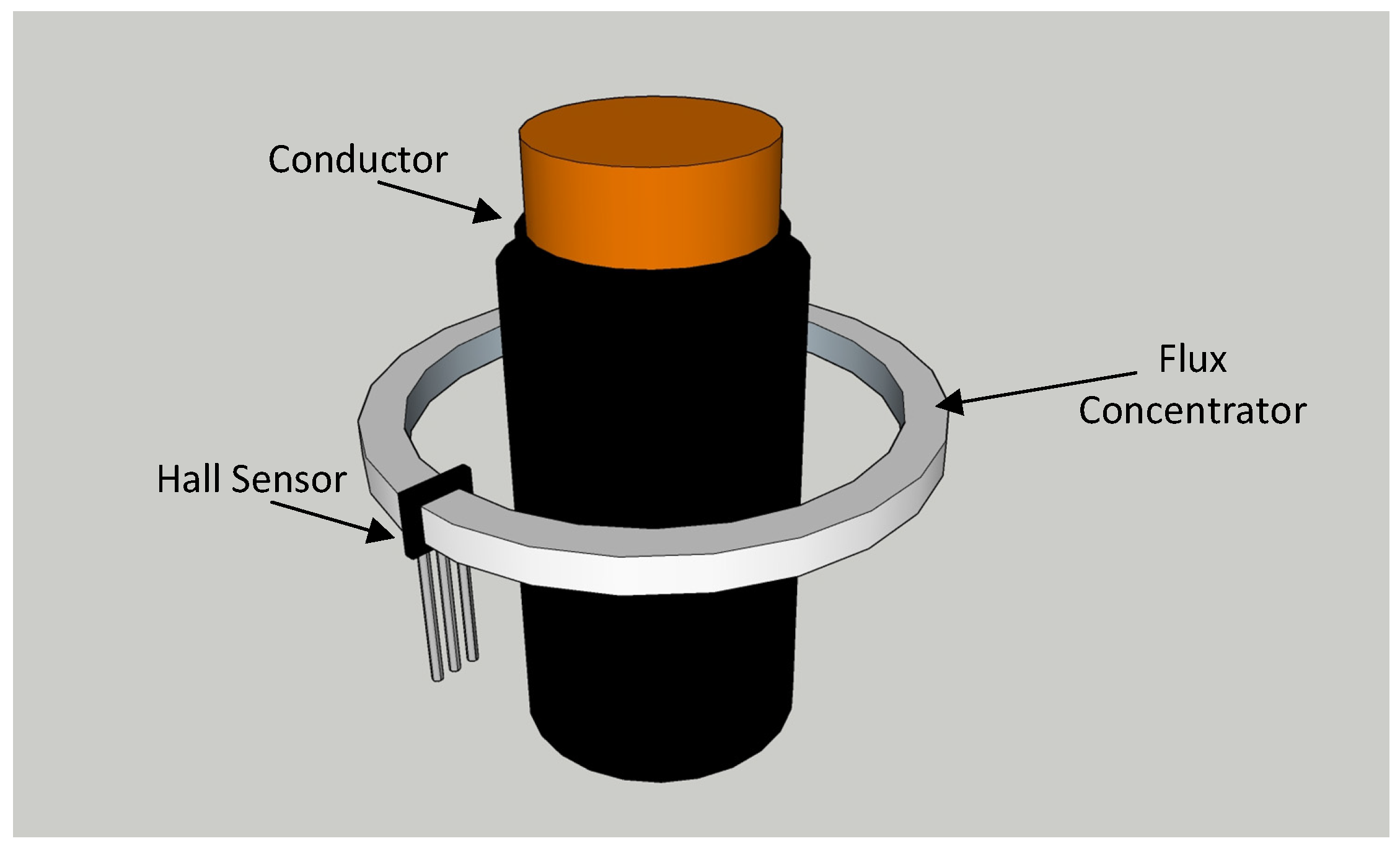

- Ratiometric HALL Effect Sensor: Another ready solution is using a hall sensor with ratio-metric output. This sensor is put directly on the output phase conductor and measures the magnetic field. This value can be directly calculated for the following current. To further increase precision and sensitivity, the output phases have flux concentrators mounted on them, which improves the deployment of this measurement technique [33].

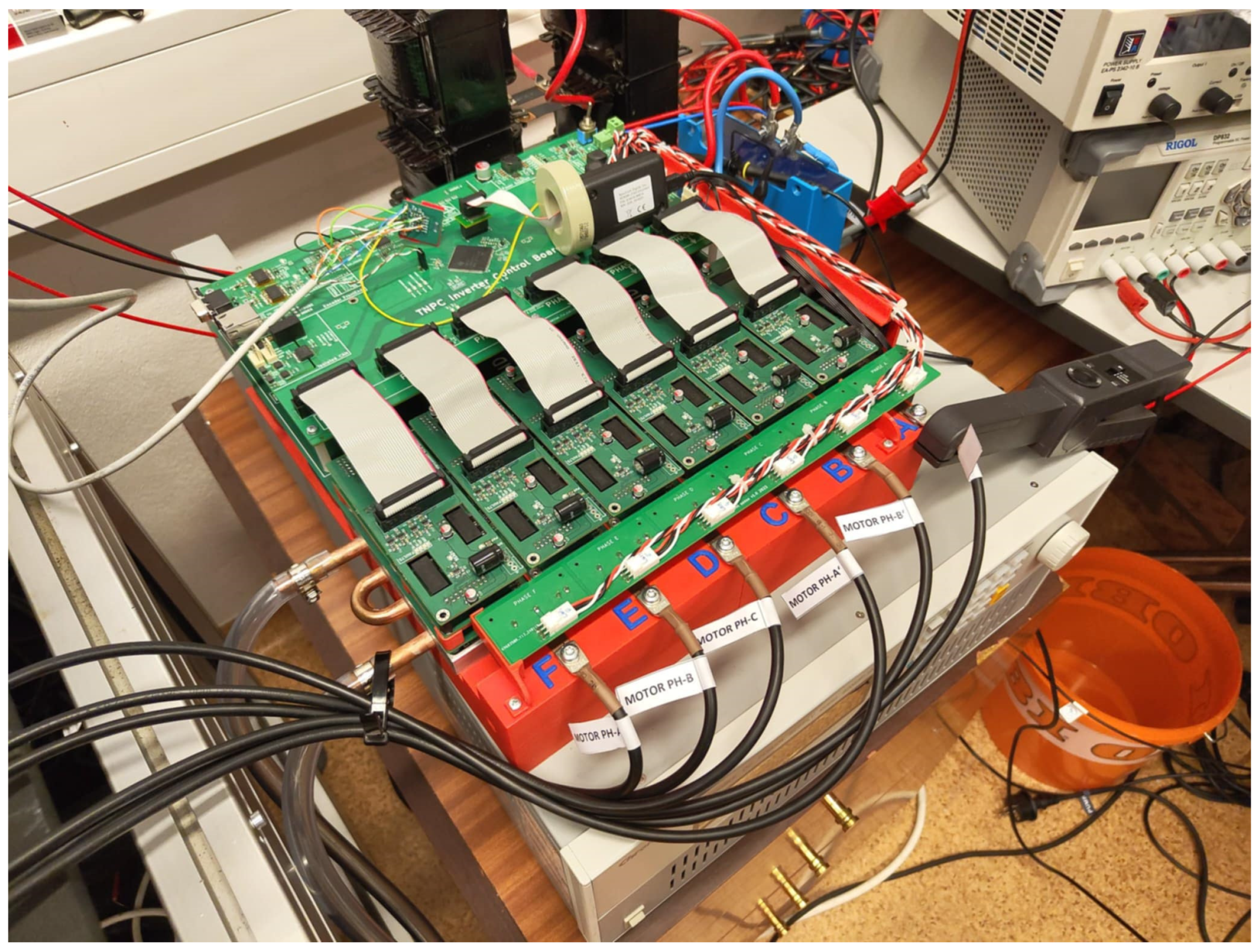

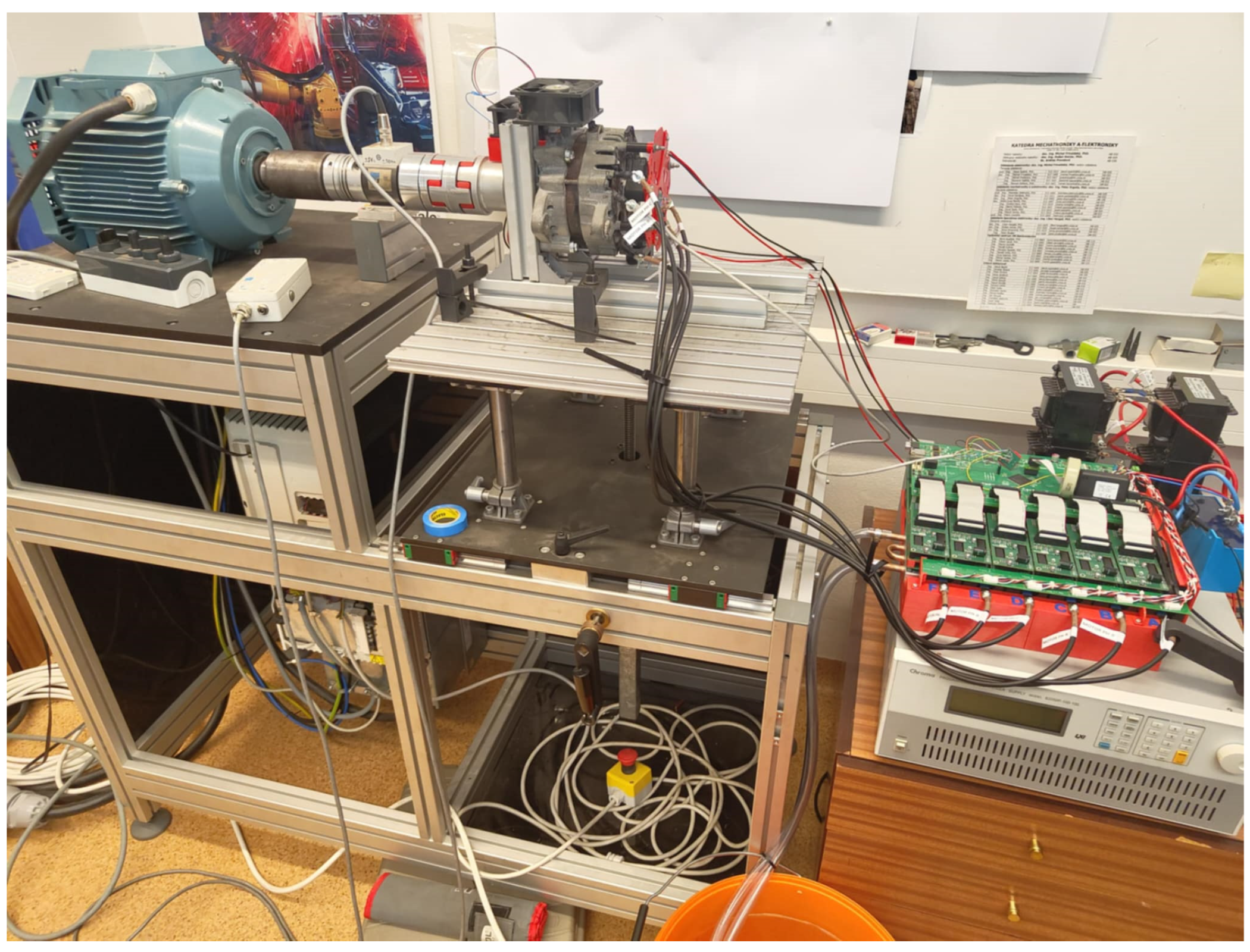

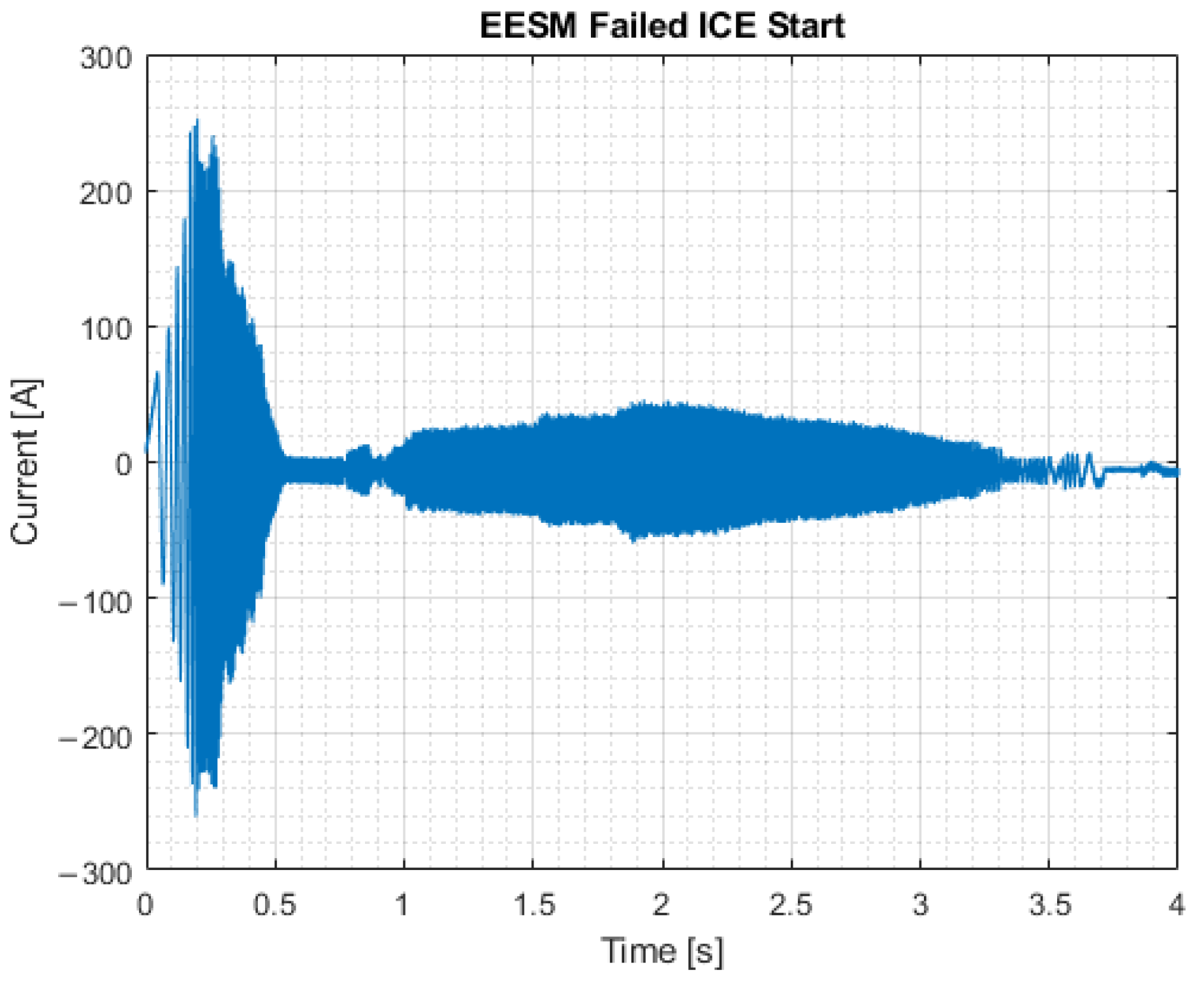

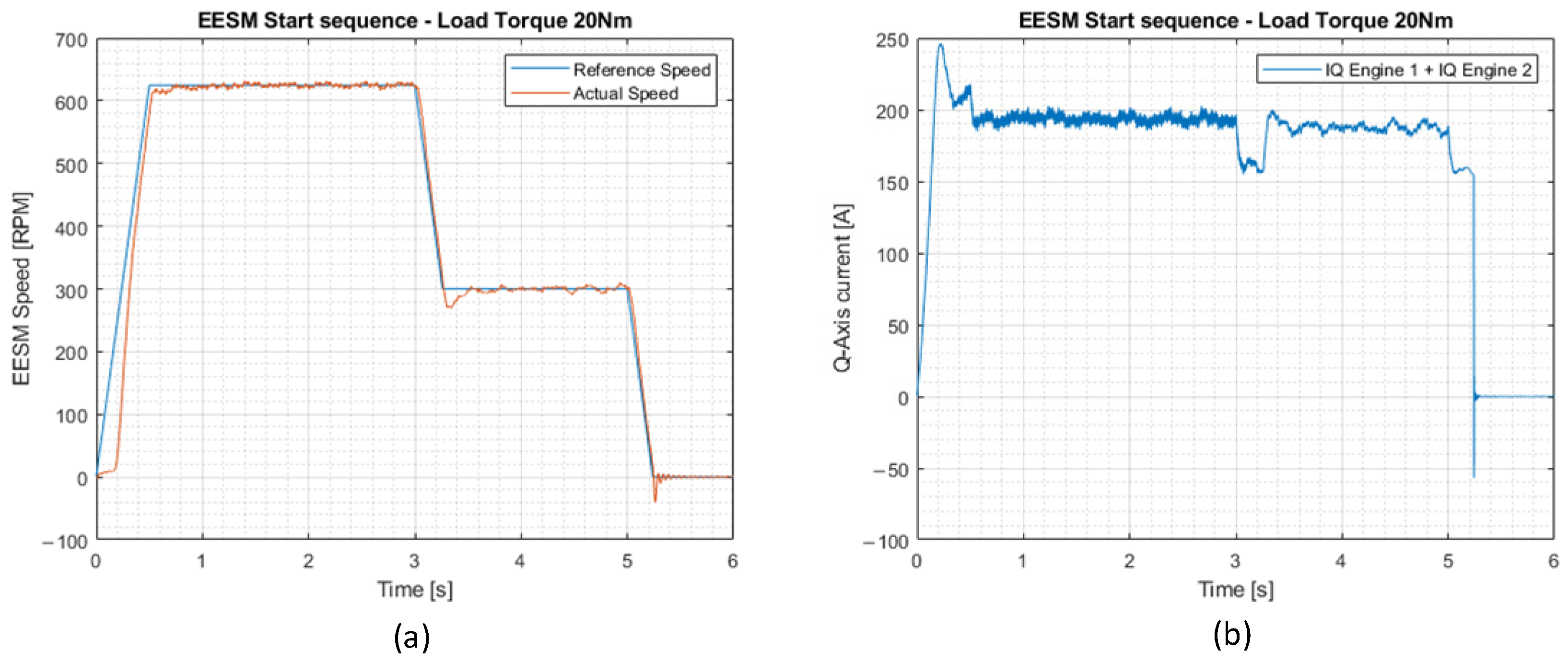

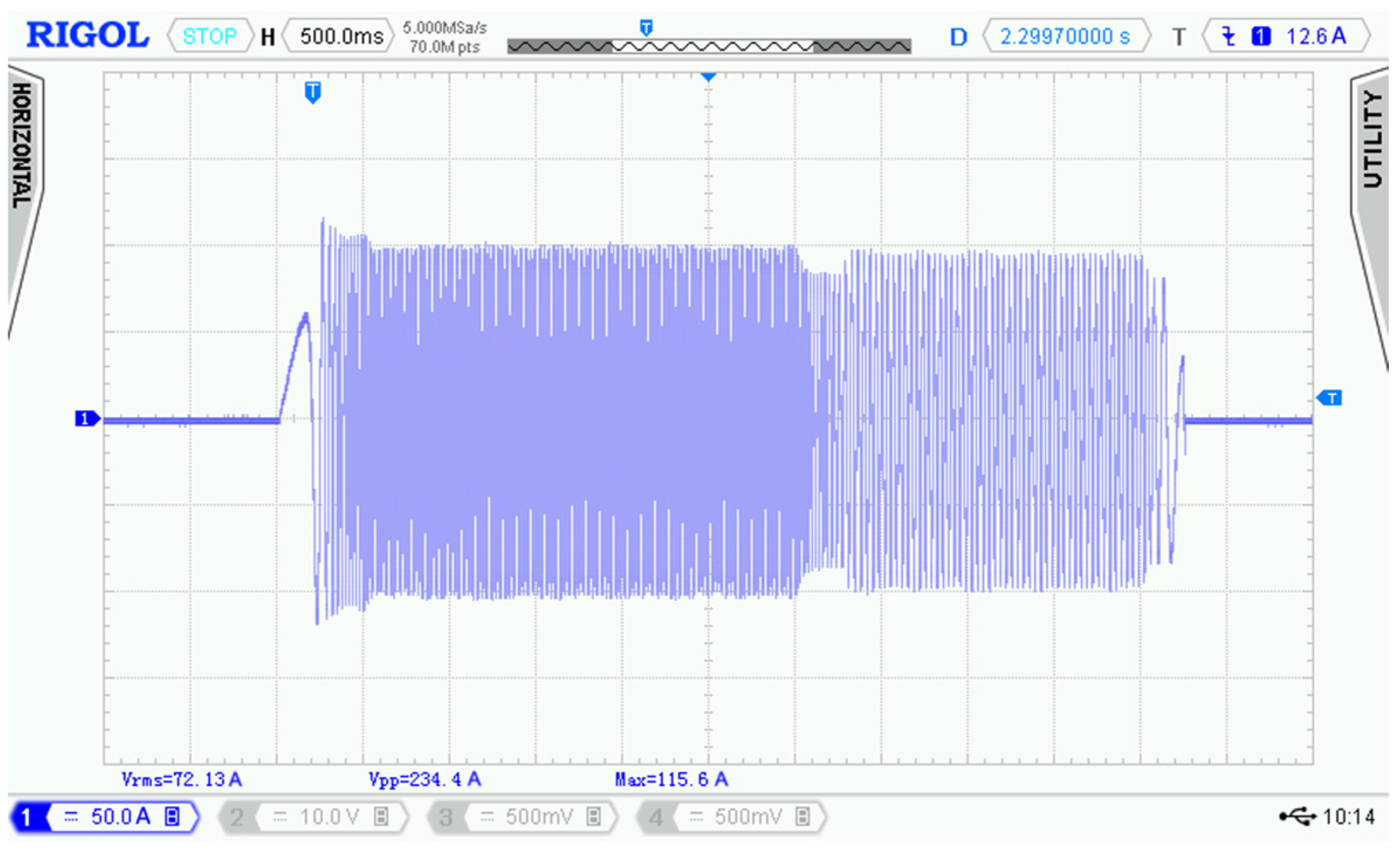

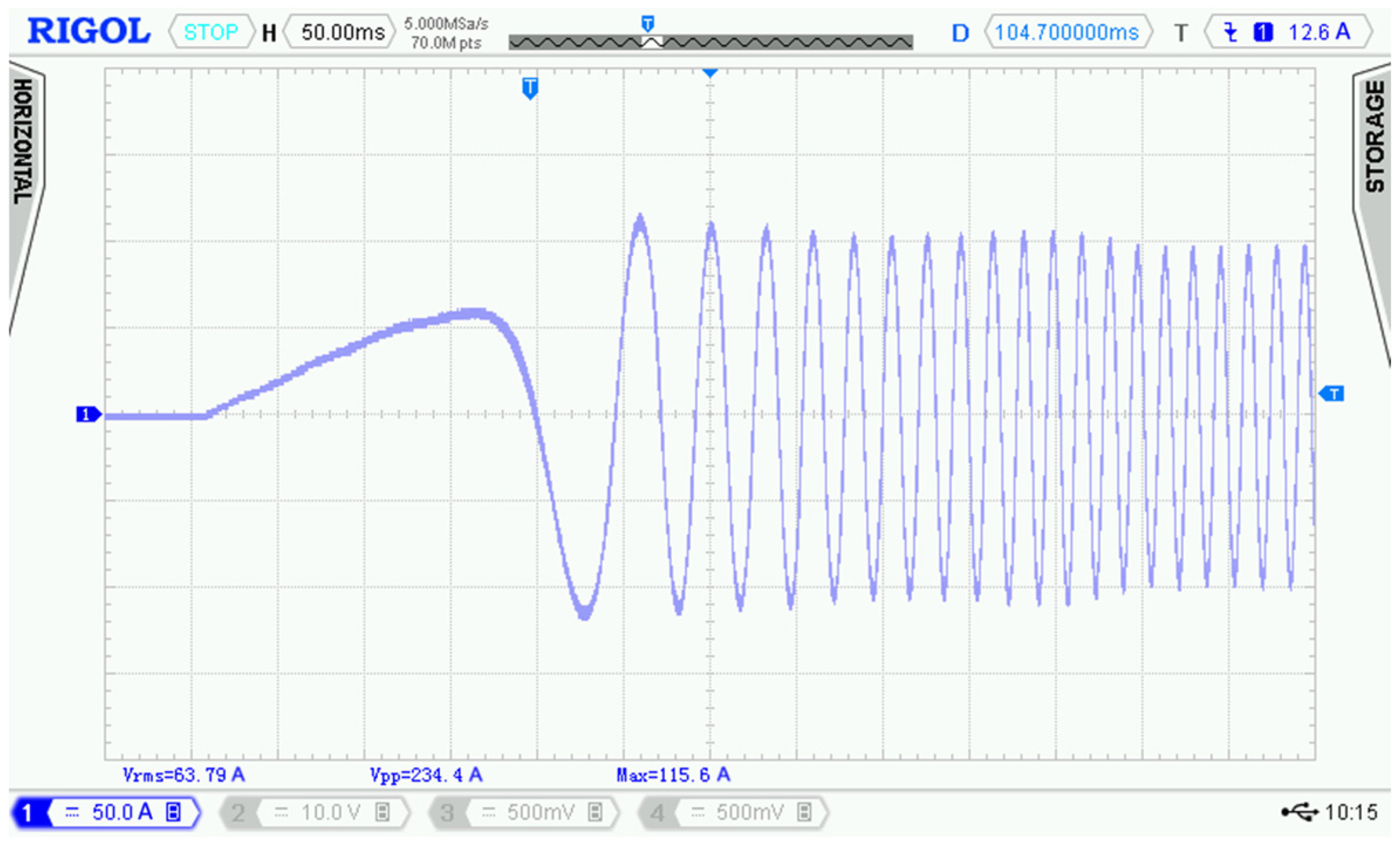

4. EESM Verification with Another Inverter

- -

- Undervoltage protection: If the voltage on the DC bus drops significantly, the TRIP event is triggered, and all ePWMs are turned off to protect the power transistors.

- -

- Overtemperature protection: If the measured temperature of the power modules exceeds 60 °C, the inverter is turned off to prevent transistor destruction.

- -

- Overspeed protection: If the speed of the motor exceeds the set threshold, the inverter is disabled. This protection will safeguard the engine in the event of dynamometer failure or sudden torque drop, preventing RPM from reaching dangerous values.

5. Conclusions

6. Future Work

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Correction Statement

References

- Reddy, M.P.; Aneesh, A.; Praneetha, K.; Vijay, S. Global Warming Analysis and Prediction Using Data Science. In Proceedings of the Fifth International Conference on I-SMAC (IoT in Social, Mobile, Analytics and Cloud) (I-SMAC), Palladam, India, 11–13 November 2021; pp. 1055–1059. [Google Scholar] [CrossRef]

- Abu-Rub, H.; Malinowski, M.; Al-Haddad, K. Energy, Global Warming and Impact of Power Electronics in the Present Century. In Power Electronics for Renewable Energy Systems, Transportation and Industrial Applications; John Wiley & Sons: Hoboken, NJ, USA, 2014; pp. 1–26. [Google Scholar] [CrossRef]

- The Intergovernmental Panel on Climate Change (IPCC). Global Warming of 1.5 °C. Available online: https://www.ipcc.ch/sr15 (accessed on 23 July 2025).

- Zhai, Q.; Cao, H.; Zhao, X.; Yuan, C. Reducing Greenhouse Gas emissions of global automotive manufacturing through clean energy supply: Cost benefit analysis. In Proceedings of the 2011 IEEE International Symposium on Sustainable Systems and Technology, Chicago, IL, USA, 16–18 May 2011; p. 1. [Google Scholar] [CrossRef]

- DeCicco, J. Factor Analysis of Greenhouse Gas Emissions from Automobiles. 26 December 2012. Available online: https://papers.ssrn.com/sol3/papers.cfm?abstract_id=2205144 (accessed on 23 July 2025).

- Zaid, S.A.; Albalawi, H.; Alatwi, A.M.; Elemary, A. Performance Improvement of an Electric Vehicle Charging Station Using Brain Emotional Learning-Based Intelligent Control. Processes 2024, 12, 1014. [Google Scholar] [CrossRef]

- Valeo. 48 Volts Mild Hybrid System, the Affordable Electrification. Available online: https://www.valeo.com/en/48-volts-affordable-electrification/ (accessed on 23 July 2025).

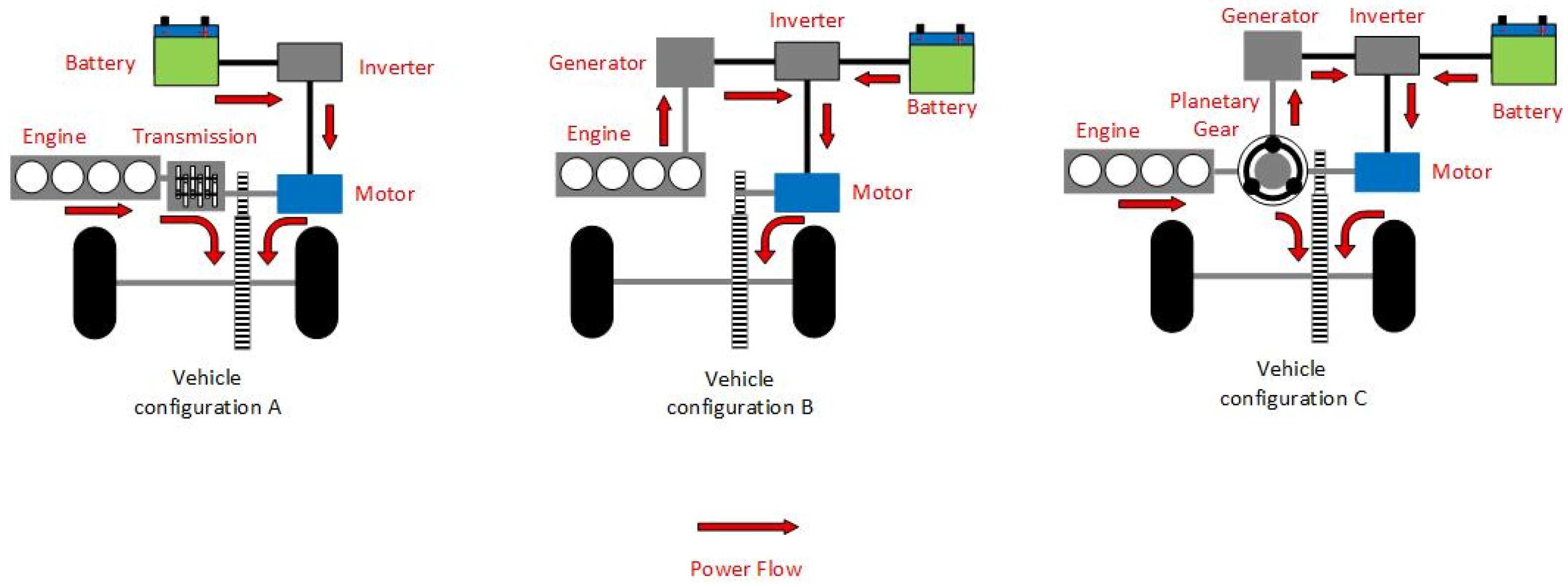

- Liu, J.; Peng, H. Modeling and Control of a Power-Split Hybrid Vehicle. Control Systems Technology. IEEE Trans. Ind. Appl. 2008, 16, 1242–1251. [Google Scholar] [CrossRef]

- Audi Media Center. Drive System. Available online: https://www.audi-mediacenter.com/en/audi-technology-lexicon-7180/drive-system-7227 (accessed on 23 July 2025).

- Ruzimov, S.; Mavlonov, J.; Mukhitdinov, A. Analysis of the Powertrain Component Size of Electrified Vehicles Commercially Available on the Market. Commun. Sci. Lett. Univ. Zilina 2022, 24, B74–B86. [Google Scholar] [CrossRef]

- Pielecha, I.; Cieslik, W.; Szwajca, F. Energy Flow and Electric Drive Mode Efficiency Evaluation of Different Generations of Hybrid Vehicles under Di-versified Urban Traffic Conditions. Energies 2023, 16, 794. [Google Scholar] [CrossRef]

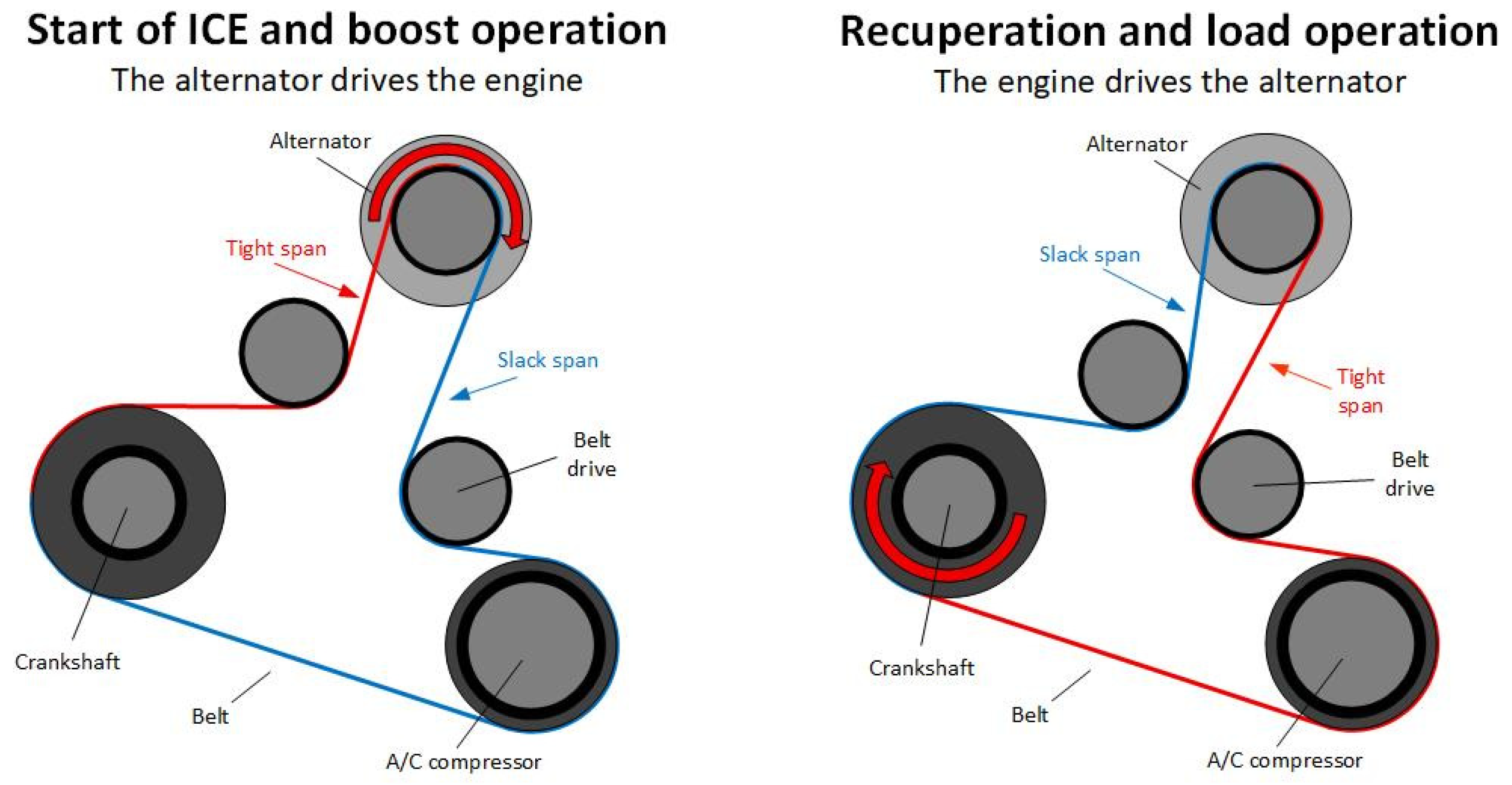

- Electronic Specifier. What Is a Belt or Integrated Starter Generator? Available online: https://www.electronicspecifier.com/industries/automotive/what-is-a-belt-or-integrated-starter-generator (accessed on 23 July 2025).

- Pels, T.; Reitz, D.; Lázló; Vestgård, B.; DevoTek, K. Small starter generator—Big Impact. In Proceedings of the 7th LuK Symposium, Bühl, Germany, 11–12 April 2002. [Google Scholar]

- Viorel, I.A.; Szabo, L.; Löwenstein, L.; Stet, C. Integrated Starter-Generators for Automotive Applications. Acta Electroteh. 2004, 45, 255–260. [Google Scholar]

- Stuffer, A.; Heinrich, D.; Hauck, C.; Schmidt, T.; Stief, H. Introduction of 48 V Belt Drive System: New tensioner and decoupler solutions for belt driven mild hybrid systems. In Proceedings of the 10th Schaeffler Symposium, Baden-Baden, Germany, 3–4 April 2014. [Google Scholar]

- Jacques, D.; Allegro MicroSystems. Common Driver Platform for 12 V and 48 V Systems. Available online: https://www.allegromicro.com/en/insights-and-innovations/technical-documents/12v-48v-bsg (accessed on 23 July 2025).

- Valeo Technical Bulletin, iBSG—Starter Alternator, TSB-VES-202301-1181-VSIN-en. February 2023. Available online: https://api.techassist.valeoservice.systems/sites/default/files/technical-document/assets/TSB-VES-202301-1181-VSIN-en.pdf (accessed on 23 July 2025).

- Nøland, J.K.; Nuzzo, S.; Tessarolo, A.; Alves, E.F. Excitation System Technologies for Wound-Field Synchronous Machines: Survey of Solutions and Evolving Trends. IEEE Access 2019, 7, 109699–109718. [Google Scholar] [CrossRef]

- James; Widmer, D.; Martin, R.; Kimiabeigi, M. Electric vehicle traction motors without rare earth magnets. Sustain. Mater. Technol. 2015, 3, 7–13. [Google Scholar] [CrossRef]

- Graffeo, F.; Vaschetto, S.; Cossale, M.; Kerschbaumer, M.; Bortoni, E.C.; Cavagnino, A. Cylindrical Wound-Rotor Synchronous Machines for Traction Applications. In Proceedings of the International Conference on Electrical Machines (ICEM), Gothenburg, Sweden, 23–26 August 2020; pp. 1736–1742. [Google Scholar] [CrossRef]

- Tang, J.; Liu, Y.; Sharma, N. Modeling and Experimental Verification of High-Frequency Inductive Brushless Exciter for Electrically Excited Synchronous Machines. IEEE Trans. Ind. Appl. 2019, 55, 4613–4623. [Google Scholar] [CrossRef]

- Graffeo, F.; Stiscia, O.; Vaschetto, S.; Cavagnino, A.; Tenconi, A. Doubly Excitated Synchronous Machines for Traction Applications. In Proceedings of the IEEE 30th International Symposium on Industrial Electronics (ISIE), Kyoto, Japan, 20–23 June 2021; pp. 1–8. [Google Scholar] [CrossRef]

- Müller, S.; Maier, D.; Parspour, N. Inductive Electrically Excited Synchronous Machine for Electrical Vehicles—Design, Optimization and Measurement. Energies 2023, 16, 1657. [Google Scholar] [CrossRef]

- Rubino, S.; Bojoi, R.; Cavagnino, A.; Vaschetto, S. Asymmetrical twelve-phase in-duction starter/generator for more electric engine in aircraft. In Proceedings of the IEEE Energy Conversion Congress and Exposition (ECCE), Milwaukee, WI, USA, 18–22 September 2016; pp. 1–8. [Google Scholar] [CrossRef]

- Long, Q.; Zhou, Z.; Lin, X.; Liao, J. Investigation of a novel brushless electrically excited synchronous machine with arc-shaped rotor structure. Energy Rep. 2020, 6 (Suppl. 9), 608–617. [Google Scholar] [CrossRef]

- Valeo Service. 48 V Mild Hybrid Systems. Available online: https://www.valeoservice.com/en-com/48v-mild-hybrid-systems (accessed on 23 July 2025).

- Choi, K.-S. Method of Controlling Energy Regeneration for Mild Hybrid Vehicle. US Patent Number US10787163B2, 29 September 2020. [Google Scholar]

- Kellner, J.; Kaščák, S.; Praženica, M.; Resutík, P.; Ferková, Ž. Implementation of New Fault Tolerant Control for Five-Phase Induction Motor in Fault Operation. In Proceedings of the 2022 ELEKTRO, Krakow, Poland, 23–26 May 2022; pp. 1–6. [Google Scholar] [CrossRef]

- Kumar, A.S.A.; George, B.; Mukhopadhyay, S.C. Technologies and Applications of Angle Sensors: A Review. IEEE Sens. 2021, 21, 7195–7206. [Google Scholar] [CrossRef]

- Wang, S.; Ma, R.; Cao, F.; Luo, L.; Li, X. A Review: High-Precision Angle Measurement Technologies. Sensors 2024, 24, 1755. [Google Scholar] [CrossRef] [PubMed]

- Texas Instruments. TMAG6180-Q1 Automotive High-Precision Analog AMR 360° Angle Sensor Datasheet; Revised March 2024; Texas Instruments: Dallas, TX, USA, 2024; Available online: https://www.ti.com/lit/ds/symlink/tmag6180-q1.pdf?ts=1755612449953 (accessed on 23 July 2025).

- Resutík, P.; Praženica, M.; Kaščák, S. Design and Verification of Multiphase Multilevel Traction Inverter. Appl. Sci. 2024, 14, 10562. [Google Scholar] [CrossRef]

- Allegro Microsystems Application Information AN296245, Material Selection and Geometry Considerations for High Current Sensing Magnetic Flux Concentrator Designs. Available online: https://www.allegromicro.com/-/media/files/application-notes/an296245-high-current-sensing-flux-concentrator-design.pdf?sc_lang=en (accessed on 23 July 2025).

| Position | P0 | P1 | P2 | P3 | P4/P5 |

|---|---|---|---|---|---|

| e-machine type | BSG | ISG | BSG/ISG | ISG | ISG |

| Main functions | Start-Stop and Energy Recovery | Start-Stop and Energy Recovery | Enhanced Start-Stop, Improved Energy Recovery and Electric Drive | Enhanced Start-Stop, Improved Energy Recovery and Electric Drive | Enhanced Start-Stop, Improved Energy Recovery and Electric Drive |

| Powertrain connection | Engine via toothed belt | Engine to Crankshaft | Transmission Input–either side connected Toothed Belt or built-in Gear Mesh | Transmission output via Gear Mesh | Rear Axle or Differential via Gear Mesh |

| Ability to disconnect from ICE | No | No | Yes | Yes | Yes |

| Integration Cost | Low | Medium | High | High | High |

| Braking energy recovery | Good | Better | Best | Best | Best |

| Energy recovery with engine off | No | No | Yes | Yes | Yes |

| Electric drive capability | No | No | Yes | Yes | Yes |

| Electric boost capability | Yes | Yes | Yes | Yes | Yes |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Published by MDPI on behalf of the World Electric Vehicle Association. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Resutík, P.; Danko, M.; Praženica, M. Design and Implementation of a Teaching Model for EESM Using a Modified Automotive Starter-Generator. World Electr. Veh. J. 2025, 16, 480. https://doi.org/10.3390/wevj16090480

Resutík P, Danko M, Praženica M. Design and Implementation of a Teaching Model for EESM Using a Modified Automotive Starter-Generator. World Electric Vehicle Journal. 2025; 16(9):480. https://doi.org/10.3390/wevj16090480

Chicago/Turabian StyleResutík, Patrik, Matúš Danko, and Michal Praženica. 2025. "Design and Implementation of a Teaching Model for EESM Using a Modified Automotive Starter-Generator" World Electric Vehicle Journal 16, no. 9: 480. https://doi.org/10.3390/wevj16090480

APA StyleResutík, P., Danko, M., & Praženica, M. (2025). Design and Implementation of a Teaching Model for EESM Using a Modified Automotive Starter-Generator. World Electric Vehicle Journal, 16(9), 480. https://doi.org/10.3390/wevj16090480