Battery Management System for Electric Vehicles: Comprehensive Review of Circuitry Configuration and Algorithms

Abstract

1. Introduction

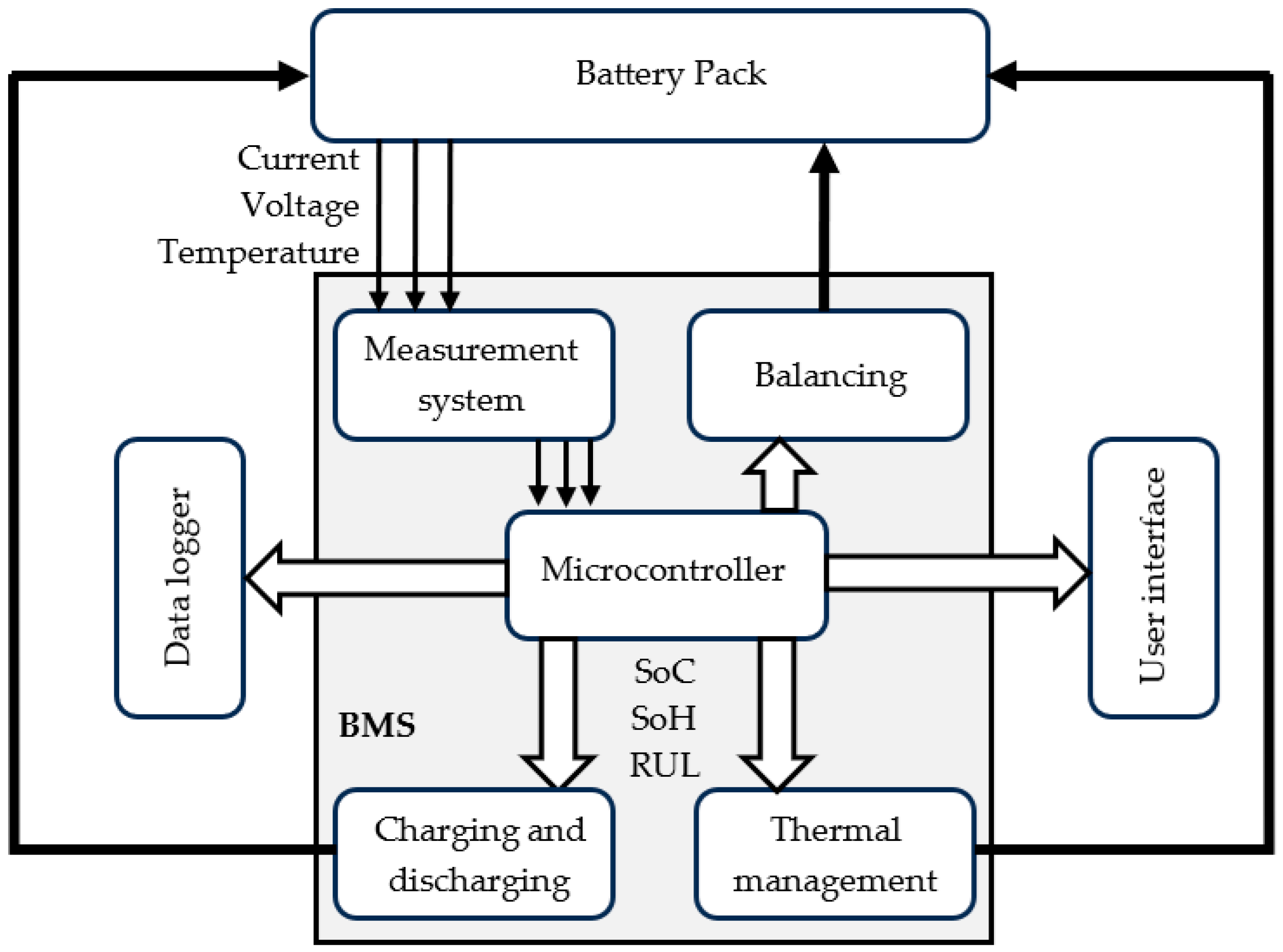

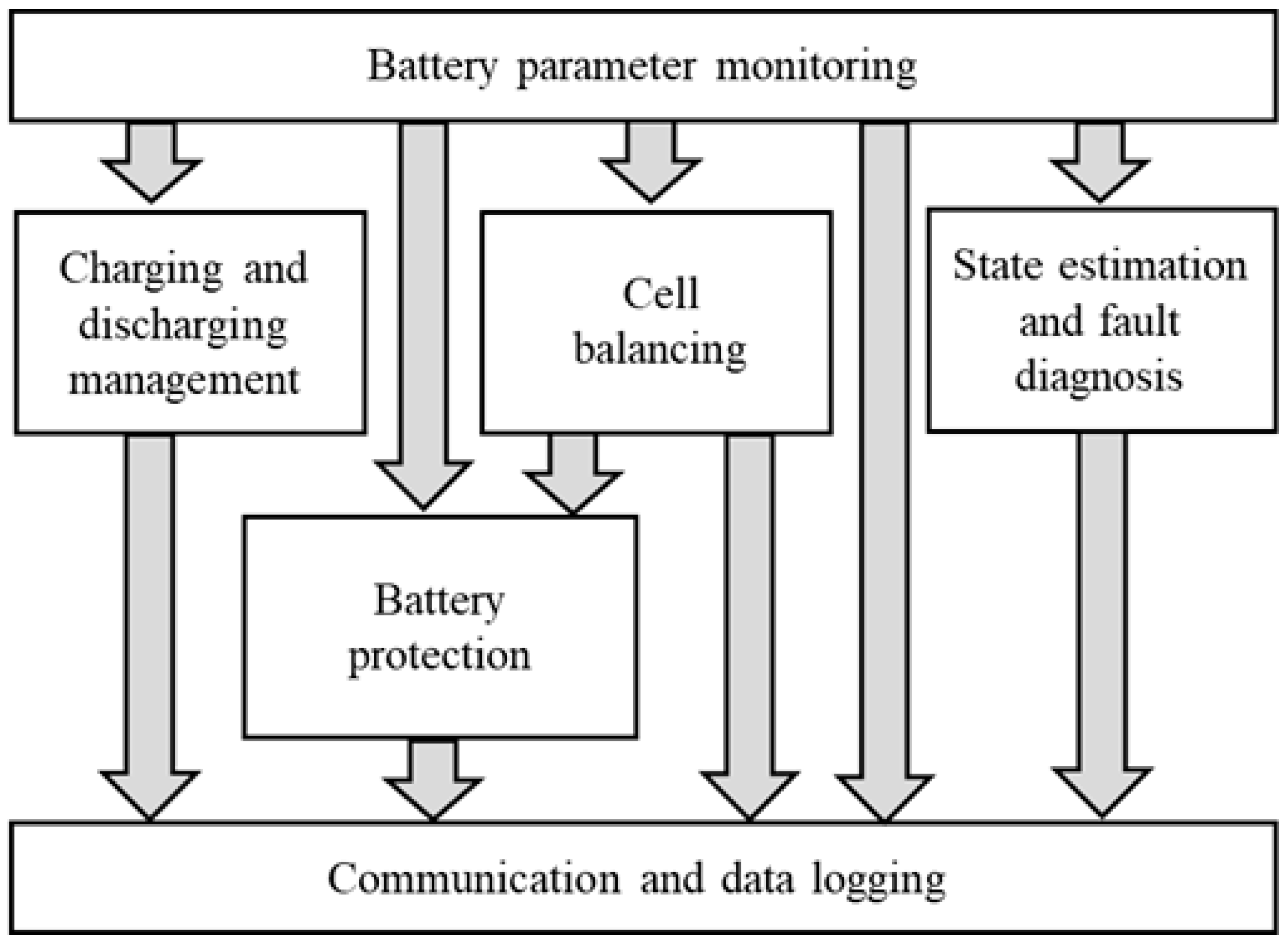

- Battery cell parameter monitoring—the BMS mainly focuses on monitoring voltage, current, and temperature.

- Battery cell protection—the BMS must ensure protection against battery system hazards (charge and discharge control; overcurrent).

- Cell balancing—the BMS must use a passive or active equalization method, minimizing the irregularity of cells.

- State estimation (SoC, SoH) and fault diagnosis (insulation)— the BMS estimates and predicts the state of charge (SoC) and the state of health (SoH); the BMS is also responsible for detecting faults, such as fires, thermal runaways, and explosions, and for minimizing the consequences of fault effects.

- Charging and discharging management—to ensure a long service life for the battery pack, the BMS must sustain the corresponding SoC and provide the most efficient method for charging and discharging procedures.

- Communication and data logging—the BMS must govern and filer battery pack data, as well as accumulate crucial information.

2. Battery Cell Parameter Monitoring

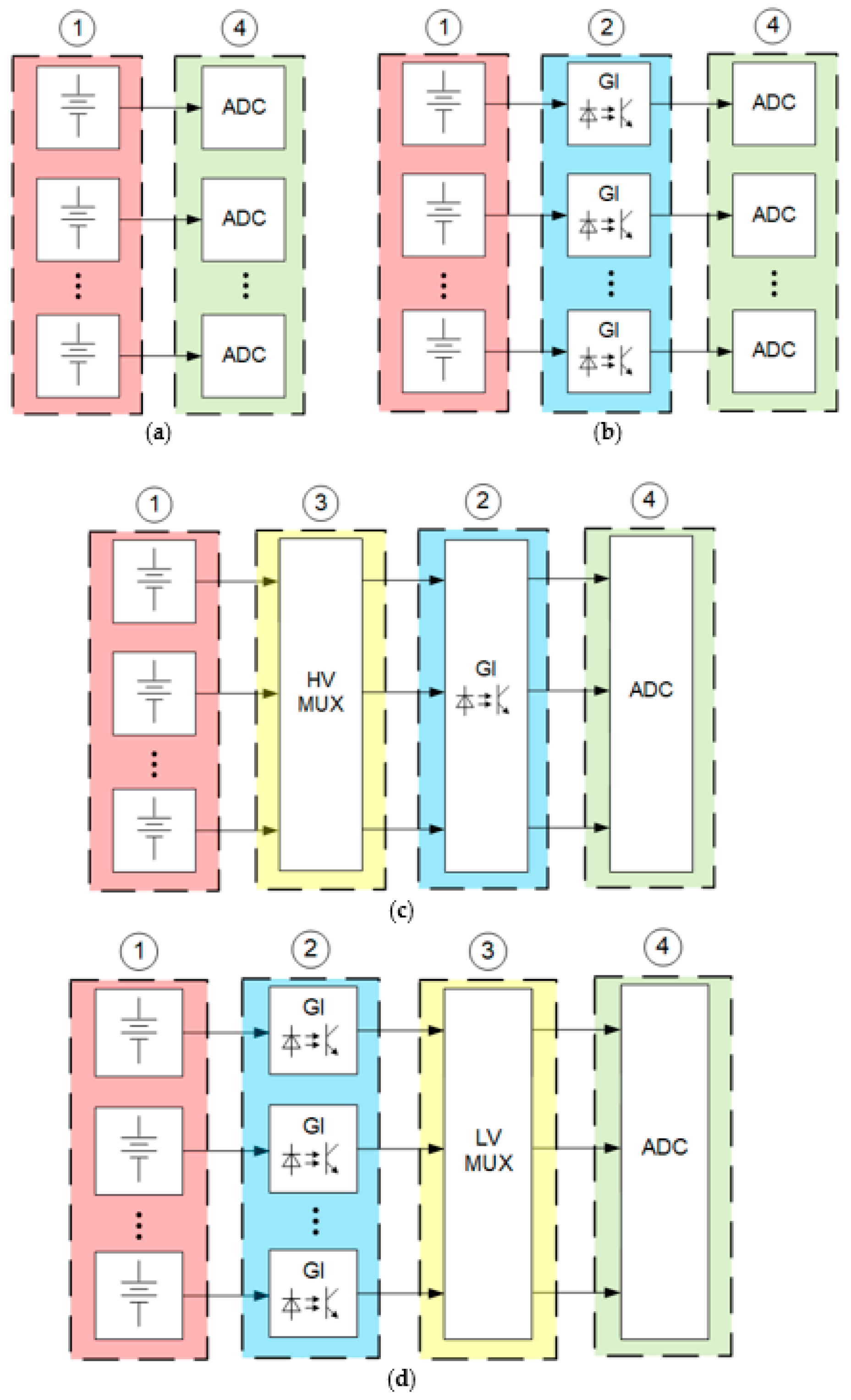

2.1. Voltage Measurement

- MCP3008, which enables one to measure the voltage of eight battery cells;

2.2. Current Measurement

2.3. Temperature Measurement

2.4. Strain Measurement

2.5. Analysis Results

3. Battery Cell Protection

3.1. Protection from Overcurrent and Short Circuits

3.2. Overvoltage and Undervoltage Protection

3.3. Temperature Protection

3.4. Analysis Results

4. Cell Balancing

4.1. Passive Balancing

4.2. Active Balancing

4.3. Development Trends of Cell Balancing Methods

4.4. Analysis Results

5. State Estimation

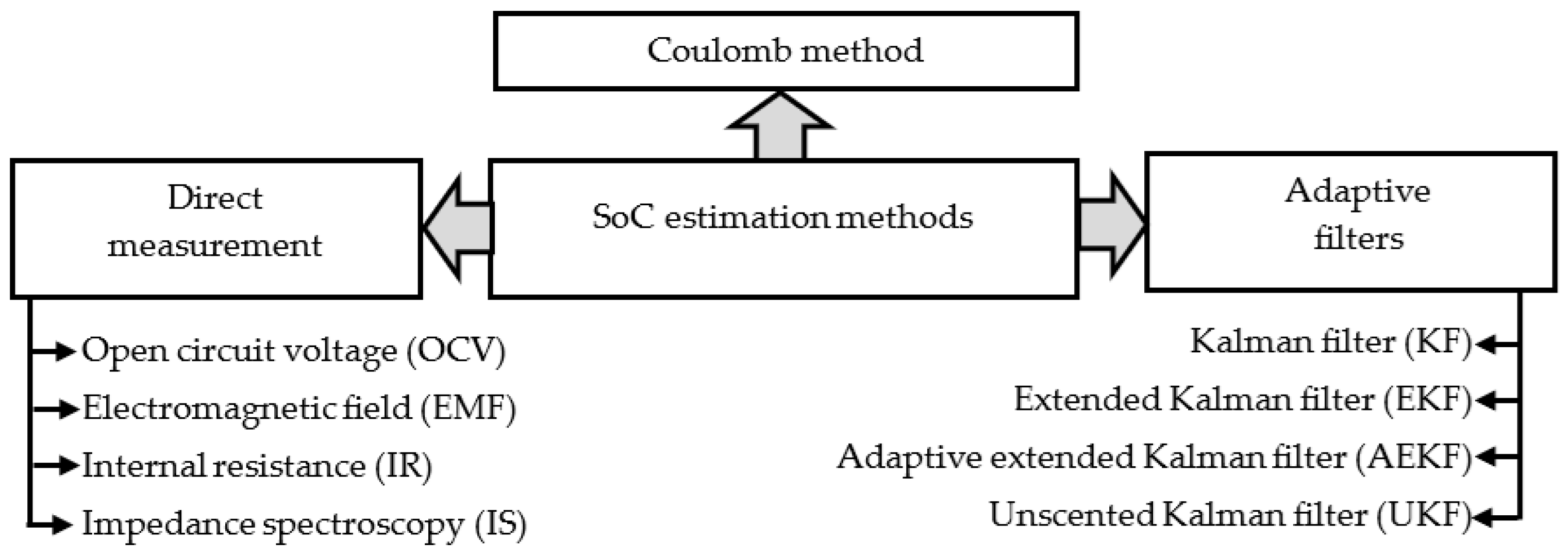

5.1. Determining SoC

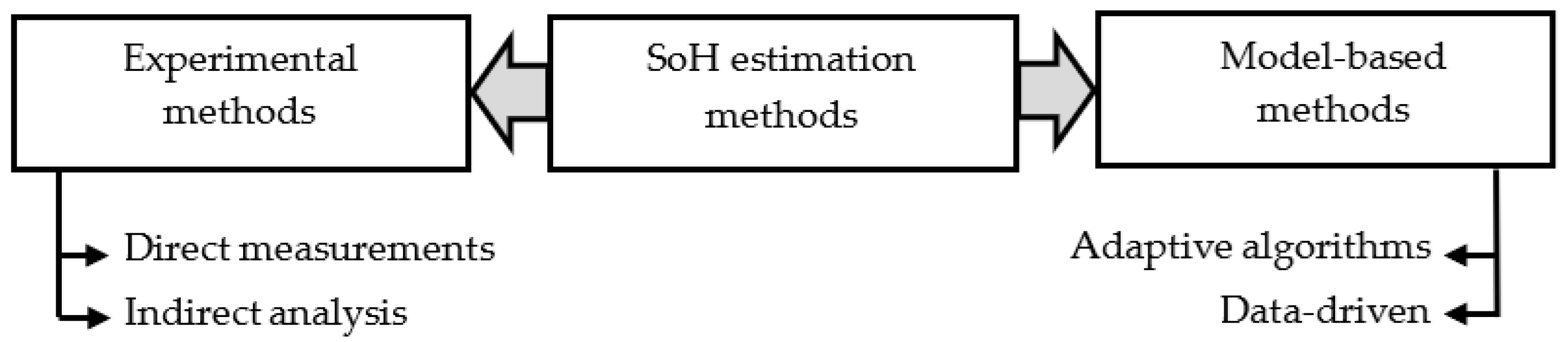

5.2. Determining SoH

5.3. Determining RUL

5.4. Determining SoF

5.5. Determining EIS

5.6. Analysis Results

6. Artificial Intelligence and Big Data Technologies

6.1. Enhancing Cell Balancing Efficiency

6.2. Improving State Estimation Efficiency

6.3. Real-World Data

7. Charging and Discharging Management

7.1. Charging and Discharging Management Considering Battery PACK Lifespan

7.2. Step-by-Step Charging and Discharging with Direct Current

7.3. Managing Charging and Discharging in an SMES/Battery Hybrid Energy Storage System

7.4. Analysis Results

8. Communication and Data Logging

8.1. Data Storage Methods in BMS

8.2. Methods of Data Transfer in BMSs

8.3. Data Acquisition

8.4. Summarizing the Results

9. Prospective Research Avenues

10. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| ADC | Analog-digital converter |

| AEKF | Adaptive extended Kalman filter |

| AMR | Anisotropic magnetoresistance |

| AR | Augmented reality |

| BLE | Bluetooth Low Energy |

| BMS | Battery management system |

| BTMS | Battery temperature management system |

| CAN | Controller Area Network |

| CID | Current Interruption Device |

| CMU | Cell management unit |

| DAQ | Data Acquisition System |

| DoD | Depth of discharge |

| D-S | AI Data Science |

| EEPROM | Electrically Erasable Programmable Read-Only Memory |

| EIS | Electrochemical impedance spectroscopy |

| EKF | Extended Kalman filter |

| EMF | Electromagnetic field |

| EV | Electric vehicle |

| FBG | Fiber Bragg grating |

| GMR | Giant magnetoresistance |

| HV | High voltage |

| I2C | Inter-Integrated Circuit |

| IoT | Internet of Things |

| IR | Internal resistance |

| IS | Impedance spectroscopy |

| KF | Kalman filter |

| LV | Low voltage |

| MCU | Microcontroller Unit |

| NFC | Near-Field Communication |

| NN | Neural network |

| OC | Overcurrent |

| OCV | Open-circuit voltage |

| OV | Overvoltage |

| PCM | Phase-change material |

| PF | Particle filter |

| PSO | Particle swarm optimization |

| RTD | Resistive temperature detector |

| RUL | Remaining useful life |

| RVM | Relevance vector machine |

| SoC | State of charge |

| SoF | State of function |

| SoH | State of health |

| SPI | Serial Peripheral Interface |

| SRAM | Static Random Access Memory |

| SVM | Support vector machine |

| TMR | Tunnel magnetoresistance |

| UART | Universal Asynchronous Receiver-Transmitter |

| UKF | Unscented Kalman filter |

| UPF | Unscented particle filter |

| UV | Undervoltage |

| wBMS | Wireless Battery Management System |

References

- Raj, K.V.; Rayudu, K.; Battapothula, G. Critical Review on Battery Management Systems. In Proceedings of the 2022 International Conference on Applied Artificial Intelligence and Computing (ICAAIC), Salem, India, 9–11 May 2022. [Google Scholar]

- Chen, X.; Yang, Y.; Wang, J.; Song, J. Hybrid Portable and Stationary Energy Storage Systems with Battery Charging and Swapping Coordination. In Proceedings of the 2022 IEEE IAS Industrial and Commercial Power System Asia (I&CPS Asia), Shanghai, China, 6–9 July 2022. [Google Scholar]

- Mishra, S.; Swain, S.C.; Samantaray, R.K. A Review on Battery Management System and Its Application in Electric Vehicle. In Proceedings of the 2021 International Conference on Advances in Computing and Communications (ICACC), Kochi, India, 21–23 October 2021. [Google Scholar]

- Darwish, M.; Ioannou, S.; Janbey, A.; Amreiz, H.; Marouchos, C.C. Review of Battery Management Systems. In Proceedings of the 2021 International Conference on Electrical, Computer, Communications and Mechatronics Engineering (ICECCME), Mauritius, 7–8 October 2021. [Google Scholar]

- Bashir, H.; Yaqoob, A.; Jawaid, I.; Khalid, W.; Javed, M.Y.; Sultan, W. A Review of Battery Management System and Modern State Estimation Approaches in Lithium-ion Batteries for Electric Vehicle. In Proceedings of the 2022 5th International Conference on Energy Conservation and Efficiency (ICECE), Lahore, Pakistan, 1–2 March 2022. [Google Scholar]

- Long, L.C.; Jeyabalan, N.G. Review on Techniques used in Battery Management System. In Proceedings of the 2023 IEEE 21st Student Conference on Research and Development (SCOReD), Kuala Lumpur, Malaysia, 13–14 December 2023. [Google Scholar]

- Chothani, N.; Kumar, S. Enhancements in Active Cell Balancing and Integration of Protective Systems for Electric Vehicle Battery. In Proceedings of the 2024 International Conference on Modeling, Simulation & Intelligent Computing (MoSICom), Dubai, United Arab Emirates, 29–31 January 2024. [Google Scholar]

- Vaideeswaran, V.; Bhuvanesh, S.; Devasena, M. Battery Management Systems for Electric Vehicles using Lithium-Ion Batteries. In Proceedings of the 2019 Innovations in Power and Advanced Computing Technologies (i-PACT), Vellore, India, 22–23 March 2019. [Google Scholar]

- Gabbar, H.A.; Othman, A.M.; Abdussami, M.R. Review of Battery Management Systems (BMS) Development and Industrial Standards. Technologies 2021, 9, 28. [Google Scholar] [CrossRef]

- Spoorthi, B.; Pradeepa, P. Review on Battery Management System in EV. In Proceedings of the 2022 International Conference on Intelligent Controller and Computing for Smart Power (ICICCSP), Hyderabad, India, 21–23 July 2022. [Google Scholar]

- Devi, B.; Kumar, V.S. Lithium-ion Battery Management System: A review. In Proceedings of the 2022 International Conference on Power, Energy, Control and Transmission Systems (ICPECTS), Chennai, India, 8–9 December 2022. [Google Scholar]

- Bhat, S. Sudharshana Battery Management System for Electrical Devices: A Review. In Proceedings of the 2024 5th International Conference on Image Processing and Capsule Networks (ICIPCN), Dhulikhel, Nepal, 3–4 July 2024. [Google Scholar]

- Vijaychandra, J.; Knypiński, Ł. A Comprehensive Review on Challenges and Possible Solutions of Battery Management Systems in Electric Vehicles. In Proceedings of the 2024 Progress in Applied Electrical Engineering (PAEE), Koscielisko, Poland, 24–28 June 2024. [Google Scholar]

- Niu, H.; Luo, B. Research on Digital Calibration of Voltage Measurement for Automotive Battery Management Systems. In Proceedings of the 2024 13th International Conference on Communications, Circuits and Systems (ICCCAS), Xiamen, China, 14–16 June 2024. [Google Scholar]

- Niu, H.; Luo, B. Research on Switched-Capacitor Based Voltage Measurement for Multi-Cell Battery Management Systems. In Proceedings of the 2024 6th International Conference on Circuits and Systems (ICCS), Chengdu, China, 26–28 April 2024. [Google Scholar]

- Lee, J.-K.; Woo, S.; Jeong, W.; Oh, K.-S.; Kim, D.; Ko, Y.; Jeon, J.Y.; Lee, J.; Son, Y.-S.; Lee, S.-G.; et al. ASIL-D Compliant Battery Monitoring IC with High Measurement Accuracy and Robust Communication. In Proceedings of the 2023 IEEE International Solid-State Circuits Conference (ISSCC), San Francisco, CA, USA, 19–23 February 2023. [Google Scholar]

- Xu, D.; Wang, L.; Yang, J. Research on Li-ion Battery Management System. In Proceedings of the 2010 International Conference on Electrical and Control Engineering, Wuhan, China, 25–27 June 2010. [Google Scholar]

- Man, X.-C.; Wu, L.-J.; Zhang, X.-M.; Ma, T.-K.; Jia, W. A High Precision Multi-Cell Battery Voltage Detecting Circuit for Battery Management Systems. In Proceedings of the 2016 IEEE 83rd Vehicular Technology Conference (VTC Spring), Nanjing, China, 15–18 May 2016. [Google Scholar]

- Mörtel, R.; Franz, J.; Rindelaub, S.; Wijayawardhana, C.; Langnes, E.; Burger, A.; Würsig, A.; Müller-Groeling, A. Smart Cells—Battery Monitoring via Internal Sensors. In Proceedings of the 2022 IEEE 13th International Symposium on Power Electronics for Distributed Generation Systems (PEDG), Kiel, Germany, 26–29 June 2022. [Google Scholar]

- Zhu, K.; Liu, X.; Pong, P.W.T. Performance Study on Commercial Magnetic Sensors for Measuring Current of Unmanned Aerial Vehicles. IEEE Trans. Instrum. Meas. 2020, 69, 1397–1407. [Google Scholar] [CrossRef]

- Jun, Z.; Liqun, W.; Xuefei, C.; Yi, J. Research and Design of a New Type of High Current Bidirectional Hall Current Sensor. In Proceedings of the 2021 IEEE Asia Conference on Information Engineering (ACIE), Sanya, China, 15–17 January 2021. [Google Scholar]

- Marsic, V.; Faramehr, S.; Maini, I.; Moran, D.A.J.; Igic, P. Study of GaN Hall Effect Magnetic Sensors. IEEE Access 2025, 13, 25622–25636. [Google Scholar] [CrossRef]

- Sysoeva, S. XMR-Microsystems as an Alternative to Hall Sensors in Motion and Current Control Systems. Kompon. I Tekhnologii 2012, 129, 33–42. [Google Scholar]

- Qi, Z.; Wei, P.; Liu, C.; Huang, H.; Xu, H.; Li, X. A Novel Tunneling Magnetoresistive Current Sensor Based on Reference Magnetic Field Source. IEEE Sens. Lett. 2024, 8, 5500304. [Google Scholar] [CrossRef]

- García-Miquel, H.; Cebrián, L.; Madrigal, J.; Sales, S. Current Sensor Based on a Fiber Bragg Grating Coated by Electroplated Magnetostrictive Material. In Proceedings of the 2020 IEEE SENSORS, Rotterdam, Netherlands, 25–28 October 2020. [Google Scholar]

- Kurosawa, K.; Shirakawa, K.; Kikuchi, T. Development of Optical Fiber Current Sensors and Their Applications. In Proceedings of the 2005 IEEE/PES Transmission & Distribution Conference & Exposition: Asia and Pacific, Dalian, China, 14–18 August 2005. [Google Scholar]

- Guo, D.; Li, W.; Pan, T.; Lin, Y. Implantable Flexible Temperature Sensor for In-Operando Sensing of Lithium-Ion Batteries. In Proceedings of the 2023 24th International Conference on Electronic Packaging Technology (ICEPT), Shihezi, China, 11–14 August 2023. [Google Scholar]

- Yongqing, W.; Zongqing, G.; Shuonan, W.; Ping, H. The Temperature Measurement Technology of Infrared Thermal Imaging and Its Applications Review. In Proceedings of the 2017 13th IEEE International Conference on Electronic Measurement & Instruments (ICEMI), Yangzhou, China, 20–22 October 2017. [Google Scholar]

- Knobloch, A.; Karp, J.; Plotnikov, Y.; Kapusta, C.; Siegel, J.; Samad, N.; Stefanopoulou, A. Novel Thin Temperature and Expansion Sensors for Li-Ion Battery Monitoring. In Proceedings of the 2017 IEEE SENSORS, Glasgow, UK, 29 October–1 November 2017. [Google Scholar]

- Vincent, T.A.; Gulsoy, B.; Sansom, J.E.H.; Marco, J. In-Situ Instrumentation of Cells and Power Line Communication Data Acquisition Towards Smart Cell Development. J. Energy Storage 2022, 50, 104218. [Google Scholar] [CrossRef]

- Gulsoy, B.; Vincent, T.A.; Sansom, J.E.H.; Marco, J. In-Situ Temperature Monitoring of a Lithium-Ion Battery Using an Embedded Thermocouple for Smart Battery Applications. J. Energy Storage 2022, 54, 105260. [Google Scholar] [CrossRef]

- Wang, D.; Gulsoy, B.; Marco, J. Development of Dual Temperature Sensing Approach for In-Situ Temperature Monitoring of a Lithium-Ion Battery. In Proceedings of the 2023 IEEE 17th International Conference on Industrial and Information Systems (ICIIS), Peradeniya, Sri Lanka, 25–26 August 2023. [Google Scholar]

- Shen, Z.-W.; Zhang, Y.; Li, M.; Wang, J.; Song, R.; Chen, W.; Zhang, S.; Ming, Z. Research on Internal Temperature and Strain of Soft-Packed Batteries under Overcharging Conditions Based on Built-In Fiber Bragg Grating Sensors. In Proceedings of the 2024 IEEE International Conference on High Voltage Engineering and Applications (ICHVE), Berlin, Germany, 2–6 September 2024. [Google Scholar]

- Huang, F.; Yang, H.; Liu, B.; Liu, J.; Hu, Y.; Fu, Y.; Xiao, W.; He, X.; Wu, Q. Real-Time Monitoring of Temperature Field Distribution of Three-Element LiB Lithium Battery Using FBG Arrays. IEEE Sens. J. 2023, 23, 30473–30480. [Google Scholar] [CrossRef]

- Sethuraman, V.A.; Chon, M.J.; Shimshak, M.; Srinivasan, V.; Guduru, P.R. In Situ Measurements of Stress Evolution in Silicon Thin Films during Electrochemical Lithiation and Delithiation. J. Power Sources 2010, 195, 5062–5066. [Google Scholar] [CrossRef]

- Nascimento, M.; Novais, S.; Ding, M.S.; Ferreira, M.S.; Koch, S.; Passerini, S.; Pinto, J.L. Internal Strain and Temperature Discrimination with Optical Fiber Hybrid Sensors in Li-Ion Batteries. J. Power Sources 2019, 410–411, 1–9. [Google Scholar] [CrossRef]

- Wu, Y.; Wang, Y.; Yung, W.K.C.; Pecht, M. Ultrasonic Health Monitoring of Lithium-Ion Batteries. Electronics 2019, 8, 751. [Google Scholar] [CrossRef]

- Sauerteig, D.; Hanselmann, N.; Arzberger, A.; Reinshagen, H.; Ivanov, S.; Bund, A. Electrochemical-Mechanical Coupled Modeling and Parameterization of Swelling and Ionic Transport in Lithium-Ion Batteries. J. Power Sources 2018, 378, 235–247. [Google Scholar] [CrossRef]

- Palumbo, A.; Li, Z.; Yang, E.-H. Trends on Carbon Nanotube-Based Flexible and Wearable Sensors via Electrochemical and Mechanical Stimuli: A Review. IEEE Sens. J. 2022, 22, 20102–20125. [Google Scholar] [CrossRef]

- Choi, W.; Seo, Y.; Yoo, K.; Ko, T.J.; Choi, J. Carbon Nanotube-Based Strain Sensor for Excessive Swelling Detection of Lithium-Ion Battery. In Proceedings of the 2019 20th International Conference on Solid-State Sensors, Actuators and Microsystems & Eurosensors XXXIII (TRANSDUCERS & EUROSENSORS XXXIII), Berlin, Germany, 23–27 June 2019. [Google Scholar]

- Puviwatnangkurn, W.; Tanboonjit, B.; Fuengwarodsakul, N.H. Overcurrent Protection Scheme of BMS for Li-Ion Battery Used in Electric Bicycles. In Proceedings of the 2013 10th International Conference on Electrical Engineering/Electronics, Computer, Telecommunications and Information Technology, Krabi, Thailand, 15–17 May 2013. [Google Scholar]

- Makuvara, T.M.; Gill, A.; Gupta, S.; Chauhan, S. Protection Circuits for Optimal Battery Management of Battery Electric Vehicle Scooters. In Proceedings of the 2023 3rd Asian Conference on Innovation in Technology (ASIANCON), Ravet, India, 25–27 August 2023. [Google Scholar]

- Mikhaylov, V.V. Protection of Storage Batteries against Short-Circuit Currents in Alternative Power Systems. In Proceedings of the 2022 International Conference on Industrial Engineering, Applications and Manufacturing (ICIEAM), Sochi, Russian Federation, 16–20 May 2022. [Google Scholar]

- Heidary, A.; Popov, M.; Moghim, A.; Niasar, M.G.; Lekić, A. The Principles of Controlled DC-Reactor Fault Current Limiter for Battery Energy Storage Protection. IEEE Trans. Ind. Electron. 2024, 71, 1525–1534. [Google Scholar] [CrossRef]

- Pradeep, K.; Amaragatti, A.V.; Yugendra, G.L.; Manohar, P.; Kulkarni, S.V.; Ramanujan, K.S. Real Time Battery Monitoring and Protection System with CAN Bus Communication and Data Logging. In Proceedings of the 2024 IEEE 4th International Conference on Sustainable Energy and Future Electric Transportation (SEFET), Hyderabad, India, 9–11 January 2024. [Google Scholar]

- Anonto, H.Z.; Emon, M.M.H.; Nandi, A.; Islam, S.; Hossain, M.I.; Shufian, A. Protecting Battery Health During Charge and Discharge for Electric Vehicles. In Proceedings of the 2025 IEEE Texas Power and Energy Conference (TPEC), College Station, TX, USA, 3–5 March 2025. [Google Scholar]

- Xu, H.; Cheng, L.; Xu, S.; Liu, C.; Paizulamu, D. Operating Performance Evaluation and Improvement Method of Reconfigurable Battery Energy Storage System. In Proceedings of the 2022 12th International Conference on Power and Energy Systems (ICPES), Guangzhou, China, 23–25 December 2022. [Google Scholar]

- Wu, K.; Wang, H.; Chen, C. A Protection Chip for Three Lithium Cells. In Proceedings of the 2021 IEEE International Conference on Integrated Circuits, Technologies and Applications (ICTA), Zhuhai, China, 24–26 November 2021. [Google Scholar]

- Ramesh, P.; Gouda, P.K.; Sandhya, S.; Dhanush, C.N.; Pavithra, Y.C.; Simran, S. Intelligent Charging System for Electric Vehicle Batteries. In Proceedings of the 2024 International Conference on Electronics, Computing, Communication and Control Technology (ICECCC), Bengaluru, India, 12–14 July 2024. [Google Scholar]

- Gektidis, K.M.; Tsovilis, T. The Challenge of Surge Protection for LiFePO4 Batteries Using Varistors. IEEE Lett. Electromagn. Compat. Pract. Appl. 2025, 7, 25–29. [Google Scholar] [CrossRef]

- Adasah, S.N.; Wang, Z.; Hu, S.; Capezza, S.; Shao, J.; Chow, M.-Y. Review of Fault Diagnosis Based Protection Mechanisms for Battery Energy Storage Systems. In Proceedings of the 2024 IEEE 33rd International Symposium on Industrial Electronics (ISIE), Ulsan, South Korea, 2–5 June 2024. [Google Scholar]

- Kasniya, B.; Kanumuri, T.; Shrivastava, V.; Sharma, V. A Review of Li-Ion Battery’s Thermal Runaway Mitigation Strategies with an Eye Towards a Smarter BTMS. In Proceedings of the 2022 IEEE 10th Power India International Conference (PIICON), New Delhi, India, 25–27 November 2022. [Google Scholar]

- Sabarimuthu, M.; Radha, J.; Gomathy, S.; Eswaran, R.; Kaushik, A.U.; Koushika, S. Integrated Battery Management and Thermal Control System for Lithium-Ion Battery Pack in Electric Vehicle. In Proceedings of the 2024 2nd International Conference on Self Sustainable Artificial Intelligence Systems (ICSSAS), Erode, India, 15–16 May 2024. [Google Scholar]

- Zhang, J.; Zhang, L.; Sun, F.; Wang, Z. An Overview on Thermal Safety Issues of Lithium-Ion Batteries for Electric Vehicle Application. IEEE Access 2018, 6, 23848–23863. [Google Scholar] [CrossRef]

- Mishra, S.P.; Padhi, P.P.; Ch, M. EV’s Battery Thermal Management Analysis Using Various Cooling Techniques—A Case Study. In Proceedings of the 2023 International Conference in Advances in Power, Signal, and Information Technology (APSIT), Bhubaneswar, India, 8–10 June 2023. [Google Scholar]

- Li, A.; Weng, J.; Yuen, A.C.Y.; Wang, W.; Liu, H.; Lee, E.W.M.; Wang, J.; Kook, S.; Yeoh, G.H. Machine learning assisted advanced battery thermal management system: A state-of-the-art review. J. Energy Storage 2023, 60, 106688. [Google Scholar] [CrossRef]

- Shao, D.; Hu, L.; Zhang, J.; Hu, R.; Zhang, G.; Jiang, L.; Wang, X.; Wen, Y. Advanced low-temperature preheating strategies for power lithium-ion batteries applied in electric vehicles: A review. Int. J. Electrochem. Sci. 2024, 19, 100817. [Google Scholar] [CrossRef]

- Kumar, M.; Yadav, V.K.; Mathuriya, K.; Verma, A.K. A Brief Review on Cell Balancing for Li-Ion Battery Pack (BMS). In Proceedings of the 2022 IEEE 10th Power India International Conference (PIICON), New Delhi, India, 25–27 November 2022. [Google Scholar]

- Jiang, B.; Liu, Y.; Huang, X.; Prakash, R.R.R. A New Battery Active Balancing Method with Supercapacitor Considering Regeneration Process. In Proceedings of the IECON 2020—46th Annual Conference of the IEEE Industrial Electronics Society, Singapore, 18–21 October 2020. [Google Scholar]

- Alam, M.M.; Lu, D.D.-C.; Aguilera, R.P. Review of Battery Balancing Techniques Based on Structure and Control Strategy. In Proceedings of the 2021 31st Australasian Universities Power Engineering Conference (AUPEC), Perth, Australia, 26–30 September 2021. [Google Scholar]

- Daowd, M.; Omar, N.; Van Den Bossche, P.; Van Mierlo, J. Passive and Active Battery Balancing Comparison Based on MATLAB Simulation. In Proceedings of the 2011 IEEE Vehicle Power and Propulsion Conference, Chicago, IL, USA, 6–9 September 2011. [Google Scholar]

- Qi, J.; Lu, D.D.-C. Review of Battery Cell Balancing Techniques. In Proceedings of the 2014 Australasian Universities Power Engineering Conference (AUPEC), Perth, WA, Australia, 28 September–1 October 2014. [Google Scholar]

- Pascual, C.; Krein, P.T. Switched Capacitor System for Automatic Series Battery Equalization. In Proceedings of the APEC 97—Applied Power Electronics Conference, Atlanta, GA, USA, 23–27 February 1997. [Google Scholar]

- Hong, W.; Ng, K.-S.; Hu, J.-H.; Moo, C.-S. Charge Equalization of Battery Power Modules in Series. In Proceedings of the 2010 International Power Electronics Conference—ECCE ASIA, Sapporo, Japan, 21–24 June 2010. [Google Scholar]

- Bhaumik, D.; Barik, J. Capacitor-Based Cell Balancing: A Comprehensive Review. In Proceedings of the 2024 International Conference on Intelligent Systems and Advanced Applications (ICISAA), Pune, India, 25–27 January 2024. [Google Scholar]

- Kaushik, A.; Mittal, A.; Sinha, A.; Singh, A. Analysis and Comparative Study of Inductor-Based Active Cell Balancing Technique for EV. In Proceedings of the 2024 IEEE Third International Conference on Power Electronics, Intelligent Control and Energy Systems (ICPEICES), Delhi, India, 17–19 July 2024. [Google Scholar]

- Thiruvonasundari, K.; Deepa, D. Optimized Passive Cell Balancing for Fast Charging in Electric Vehicle. IETE J. Res. 2021, 69, 2089–2097. [Google Scholar] [CrossRef]

- Daowd, M.; Antoine, M.; Omar, N.; Lataire, P.; Van Den Bossche, P.; Van Mierlo, J. Battery Management System—Balancing Modularization Based on a Single Switched Capacitor and Bidirectional DC/DC Converter with the Auxiliary Battery. Energies 2014, 7, 2897–2937. [Google Scholar] [CrossRef]

- Vardhan, R.K.; Selvathai, T.; Reginald, R.; Sivakumar, P.; Sundaresh, S. Modeling of Single Inductor Based Battery Balancing Circuit for Hybrid Electric Vehicles. In Proceedings of the IECON 2017—43rd Annual Conference of the IEEE Industrial Electronics Society, Beijing, China, 29 October–1 November 2017. [Google Scholar]

- Lee, E.-S.; Lee, S.-W.; Kim, C.-S.; Han, J.-K. A New Chain-Structured Cell-Balancing Circuit with a Coupled-Inductor Based Modules. In Proceedings of the 2024 3rd International Conference on Power Systems and Electrical Technology (PSET), Tokyo, Japan, 21–23 March 2024. [Google Scholar]

- Thakkar, R.R.; Rao, Y.S.; Sawant, R.R. Comparative Performance Analysis on Passive and Active Balancing of Lithium-Ion Battery Cells. In Proceedings of the 2021 IEEE 18th India Council International Conference (INDICON), Guwahati, India, 19–21 December 2021. [Google Scholar]

- Naguib, M.; Kollmeyer, P.; Emadi, A. Lithium-Ion Battery Pack Robust State of Charge Estimation, Cell Inconsistency, and Balancing: Review. IEEE Access 2021, 9, 50570–50582. [Google Scholar] [CrossRef]

- Koutsouvelis, D.C.; Vokas, G.A.; Ioannidis, G.C. Cell Balancing Using a Modified Cuk Converter. In Proceedings of the 12th Mediterranean Conference on Power Generation, Transmission, Distribution and Energy Conversion (MEDPOWER 2020), Online Conference, 8–11 November 2020. [Google Scholar]

- Nishijima, K.; Sakamoto, H.; Harada, K. A PWM Controlled Simple and High-Performance Battery Balancing System. In Proceedings of the 2000 IEEE 31st Annual Power Electronics Specialists Conference (PESC 2000), Galveston, TX, USA, 18–23 June 2000. [Google Scholar]

- Kim, C.H.; Park, H.S.; Kim, C.E.; Moon, G.W.; Lee, J.H. Individual Charge Equalization Converter with Parallel Primary Winding of Transformer for Series Connected Lithium-Ion Battery Strings in an HEV. J. Power Electron. 2009, 9, 472–480. [Google Scholar]

- Kulsangcharoen, P.; Klumpner, C.; Rashed, M.; Asher, G. Evaluation of a Flyback Regenerative Voltage Equalisation Circuit for Series-Connected Supercapacitor Stacks. In Proceedings of the 14th European Conference on Power Electronics and Applications (EPE 2011), Birmingham, UK, 30 August–1 September 2011. [Google Scholar]

- Kutkut, N.H.; Divan, D.M.; Novotny, D.W. Charge Equalization for Series Connected Battery Strings. IEEE Trans. Ind. Appl. 1995, 31, 562–568. [Google Scholar] [CrossRef]

- Kim, C.; Kim, M.; Moon, G. Individual Cell Equalizer Using Active-Clamp Flyback Converter for Li-Ion Battery Strings in an Electric Vehicle. In Proceedings of the IEEE Vehicle Power and Propulsion Conference (VPPC), Seoul, Korea, 9–12 October 2012. [Google Scholar]

- Yang, D.; Li, S.; Qi, G. A Bidirectional Flyback Cell Equalizer for Series-Connected Lithium Iron Phosphate Batteries. In Proceedings of the IEEE 6th International Conference on Power Electronics Systems and Applications (PESA), Hong Kong, China, 15–17 December 2015. [Google Scholar]

- Zhan, H.; Xiang, X.; Lambert, S.M.; Pickert, V.; Wu, H.; Lu, X. A Cascaded Transformer-Based Equalisation Converter for Series Connected Battery Cells. In Proceedings of the 8th IET International Conference on Power Electronics, Machines and Drives (PEMD), Glasgow, UK, 19–21 April 2016. [Google Scholar]

- Park, H.-S.; Kim, C.-E.; Kim, C.-H.; Moon, G.-W.; Lee, J.-H. A Modularized Charge Equalizer for an HEV Lithium-Ion Battery String. IEEE Trans. Ind. Electron. 2009, 56, 1464–1476. [Google Scholar] [CrossRef]

- Ye, Y.; Jiang, J.; Zhao, E.; Li, P.; Li, Z.; Hui, X. An Improved Balancing Strategy for Inductor-Based Balancing Circuit. In Proceedings of the 2023 IEEE International Conference on Power Science and Technology (ICPST), Kunming, China, 12–14 May 2023. [Google Scholar]

- Ekanayake, E.M.A.G.N.C.; Hemapala, K.T.M.U.; Jayathunga, U. Active and Passive Based Hybrid Cell Balancing Approach to Series Connected Lithium-Ion Battery Pack. In Proceedings of the 2022 Moratuwa Engineering Research Conference (MERCon), Moratuwa, Sri Lanka, 27–29 July 2022. [Google Scholar]

- Alamgir, M.; Ashraf, M.H.; Zeeshan, M.; Shehzad Hassan, M.A.; Shah, S.H.; Farooq, U. A Hybrid Approach to Balance Lithium-ion Cells by Implementing SoC Using Kalman Filter. In Proceedings of the 2024 International Conference on Engineering & Computing Technologies (ICECT), Islamabad, Pakistan, 23 May 2024. [Google Scholar]

- Imran, S.A.; Ali Kazmi, S.N.; Sakandar, H.; Ulasyar, A.; Khalid, A. A Distributive Hybrid Cell Balancing Technique for Series-Connected Lithium-Ion Cells. In Proceedings of the 2024 3rd International Conference on Emerging Trends in Electrical, Control, and Telecommunication Engineering (ETECTE), Lahore, Pakistan, 26–27 November 2024. [Google Scholar]

- Alamin, K.S.S.; Chen, Y.; Macii, E.; Poncino, M.; Vinco, S. Digital Twins for Electric Vehicle SoX Battery Modeling: Status and Proposed Advancements. In Proceedings of the 2023 AEIT International Conference on Electrical and Electronic Technologies for Automotive (AEIT AUTOMOTIVE), Modena, Italy, 5–7 July 2023. [Google Scholar]

- Hasib, S.A.; Islam, S.; Chakrabortty, R.K.; Ryan, M.J.; Saha, D.K.; Ahamed, M.H.; Moyeen, S.I.; Das, S.K.; Ali, M.F.; Islam, M.R.; et al. A Comprehensive Review of Available Battery Datasets, RUL Prediction Approaches, and Advanced Battery Management. IEEE Access 2021, 9, 86166–86193. [Google Scholar] [CrossRef]

- Shete, S.; Jog, P.; Kumawat, R.K.; Palwalia, D.K. Battery Management System for SOC Estimation of Lithium-Ion Battery in Electric Vehicle: A Review. In Proceedings of the 2021 6th IEEE International Conference on Recent Advances and Innovations in Engineering (ICRAIE), Kedah, Malaysia, 1–3 December 2021. [Google Scholar]

- Saji, D.; Babu, P.S.; Ilango, K. SoC Estimation of Lithium Ion Battery Using Combined Coulomb Counting and Fuzzy Logic Method. In Proceedings of the 2019 4th International Conference on Recent Trends on Electronics, Information, Communication & Technology (RTEICT), Bangalore, India, 17–18 May 2019. [Google Scholar]

- Suryoatmojo, H.; Anam, S.; Rahmawan, Z.; Asfani, D.A.; Faurahmansyah, M.A.; Prabowo, P. State of Charge (SOC) Estimation on Lead-Acid Batteries Using the Coulomb Counting Method. In Proceedings of the 2022 10th International Conference on Smart Grid and Clean Energy Technologies (ICSGCE), Kuala Lumpur, Malaysia, 12–14 October 2022. [Google Scholar]

- Ahmed, M.S.; Balasingam, B. A Scaling Approach for Improved Open Circuit Voltage Modeling in Li-Ion Batteries. In Proceedings of the 2019 IEEE Electrical Power and Energy Conference (EPEC), Montreal, QC, Canada, 16–18 October 2019. [Google Scholar]

- Hou, W.; Shi, Q.; Liu, Y.; Guo, L.; Zhang, X.; Wu, J. State of Charge Estimation for Lithium-Ion Batteries at Various Temperatures by Extreme Gradient Boosting and Adaptive Cubature Kalman Filter. IEEE Trans. Instrum. Meas. 2024, 73, 2504611. [Google Scholar] [CrossRef]

- Al-Smadi, M.K.; Abu Qahouq, J.A. SOH Estimation Algorithm and Hardware Platform for Lithium-Ion Batteries. In Proceedings of the 2024 IEEE Vehicle Power and Propulsion Conference (VPPC), Washington, DC, USA, 9–12 September 2024. [Google Scholar]

- Dung, L.-R.; Wu, S.-H.; Yuan, H.-F. An SOH Estimation System Based on Time-Constant-Ratio Measurement. In Proceedings of the 2014 IEEE 23rd International Symposium on Industrial Electronics (ISIE), Istanbul, Turkey, 1–4 June 2014. [Google Scholar]

- Xiao, A.; Liu, W. Review of SOH Prediction Methods for Lithium-Ion Batteries. In Proceedings of the 2024 7th Asia Conference on Energy and Electrical Engineering (ACEEE), Chengdu, China, 10–12 May 2024. [Google Scholar]

- Yang, A.; Wang, Y.; Tsui, K.L.; Zi, Y. Lithium-Ion Battery SOH Estimation and Fault Diagnosis with Missing Data. In Proceedings of the 2019 IEEE International Instrumentation and Measurement Technology Conference (I2MTC), Auckland, New Zealand, 20–23 May 2019. [Google Scholar]

- Dongsheng, J.; Haiyun, W. EV Battery SOH Diagnosis Method Based on Discrete Fréchet Distance. In Proceedings of the 2015 5th International Conference on Electric Utility Deregulation and Restructuring and Power Technologies (DRPT), Changsha, China, 26–29 November 2015. [Google Scholar]

- Gou, B.; Xu, Y.; Feng, X. State-of-Health Estimation and Remaining-Useful-Life Prediction for Lithium-Ion Battery Using a Hybrid Data-Driven Method. IEEE Trans. Veh. Technol. 2020, 69, 10854–10867. [Google Scholar] [CrossRef]

- Wu, L.; Fu, X.; Guan, Y. Review of the Remaining Useful Life Prognostics of Vehicle Lithium-Ion Batteries Using Data-Driven Methodologies. Appl. Sci. 2016, 6, 166. [Google Scholar] [CrossRef]

- Henley, S.S.; Golden, R.M.; Kashner, T.M. Statistical Modeling Methods: Challenges and Strategies. Biostat. Epidemiol. 2019, 4, 105–139. [Google Scholar] [CrossRef]

- Song, Y.; Liu, D.; Yang, C.; Peng, Y. Data-Driven Hybrid Remaining Useful Life Estimation Approach for Spacecraft Lithium-Ion Battery. Microelectron. Reliab. 2017, 75, 142–153. [Google Scholar] [CrossRef]

- Noh, T.-W.; Ahn, J.-H.; Lee, B.K. An Advanced SOF Estimation Algorithm for LiFePO4 SLI Battery of Vehicle with Online Update of Cranking Resistance. In Proceedings of the 2017 IEEE Energy Conversion Congress and Exposition (ECCE), Cincinnati, OH, USA, 1–5 October 2017. [Google Scholar]

- Balagopal, B.; Chow, M.-Y. The State of the Art Approaches to Estimate the State of Health (SOH) and State of Function (SOF) of Lithium-Ion Batteries. In Proceedings of the 2015 IEEE 13th International Conference on Industrial Informatics (INDIN), Cambridge, UK, 22–24 July 2015. [Google Scholar]

- Ouyang, J.; Xiang, D.; Li, J. State-of-Function Evaluation for Lithium-Ion Power Battery Pack Based on Fuzzy Logic Control Algorithm. In Proceedings of the 2020 IEEE 9th Joint International Information Technology and Artificial Intelligence Conference (ITAIC), Chongqing, China, 11–13 December 2020. [Google Scholar]

- Juang, L.W.; Kollmeyer, P.J.; Jahns, T.M.; Lorenz, R.D. Implementation of Online Battery State-of-Power and State-of-Function Estimation in Electric Vehicle Applications. In Proceedings of the 2012 IEEE Energy Conversion Congress and Exposition (ECCE), Raleigh, NC, USA, 15–20 September 2012. [Google Scholar]

- Shen, P.; Ouyang, M.; Lu, L.; Li, J.; Feng, X. The Co-Estimation of State of Charge, State of Health, and State of Function for Lithium-Ion Batteries in Electric Vehicles. IEEE Trans. Veh. Technol. 2018, 67, 92–103. [Google Scholar] [CrossRef]

- Peng, S.; Ling, Q.; Yang, M.; Bao, C.; Zhong, X.; Wang, P. A High-Precision and Fast Measurement Method for Li-Ion Battery EIS. IEEE Trans. Instrum. Meas. 2025, 74, 2005313. [Google Scholar] [CrossRef]

- Lu, P.; Li, M.; Zhang, L.; Zhou, L. A Novel Fast-EIS Measuring Method and Implementation for Lithium-Ion Batteries. In Proceedings of the 2019 Prognostics and System Health Management Conference (PHM-Qingdao), Qingdao, China, 25–27 October 2019. [Google Scholar]

- Crescentini, M.; De Angelis, A.; Ramilli, R.; De Angelis, G.; Tartagni, M.; Moschitta, A.; Traverso, P.A.; Carbone, P. Online EIS and Diagnostics on Lithium-Ion Batteries by Means of Low-Power Integrated Sensing and Parametric Modeling. IEEE Trans. Instrum. Meas. 2021, 70, 2001711. [Google Scholar] [CrossRef]

- Yu, F.; Zhang, L.; Lu, P.; Li, M. Design of Multi-Channel EIS Measurement System for Lithium-Ion Batteries. In Proceedings of the 2020 11th International Conference on Prognostics and System Health Management (PHM-Jinan), Jinan, China, 23–25 October 2020. [Google Scholar]

- La, P.-H.; Choi, S.-J. Integrated On-Line EIS Measurement Scheme Utilizing Flying Capacitor Equalizer for Series Battery String. In Proceedings of the 2021 IEEE Applied Power Electronics Conference and Exposition (APEC), Phoenix, AZ, USA, 14–17 June 2021. [Google Scholar]

- Duraisamy, T.; Kaliyaperumal, D. Machine learning-based optimal cell balancing mechanism for electric vehicle battery management system. IEEE Access 2021, 9, 132846–132861. [Google Scholar] [CrossRef]

- Harwardt, K.; Jung, J.-H.; Beiranvand, H.; Nowotka, D.; Liserre, M. Lithium-ion battery management system with reinforcement learning for balancing state of charge and cell temperature. In Proceedings of the 2023 IEEE Belgrade PowerTech, Belgrade, Serbia, 25–29 June 2023. [Google Scholar]

- Chen, J.; Behal, A.; Li, C. Active battery cell balancing by real time model predictive control for extending electric vehicle driving range. IEEE Trans. Autom. Sci. Eng. 2024, 21, 4003–4015. [Google Scholar] [CrossRef]

- Finegan, D.; Zhu, J.; Feng, X.; Keyser, M.; Ulmefors, M.; Li, W.; Bazant, M.; Cooper, S. The Application of Data-Driven Methods and Physics-Based Learning for Improving Battery Safety. Joule 2021, 5, 319–329. [Google Scholar] [CrossRef]

- Tong, S.; Lacap, J.H.; Park, J.W. Battery state of charge estimation using a load-classifying neural network. Energy Storage 2016, 7, 236–243. [Google Scholar] [CrossRef]

- Ragone, M.; Yurkiv, V.; Ramasubramanian, A.; Kashir, B.; Mashayek, F. Data driven estimation of electric vehicle battery state-of-charge informed by automotive simulations and multi-physics modeling. J. Power Sources 2020, 483, 229108. [Google Scholar] [CrossRef]

- Song, S.; Wei, Z.; Xia, H.; Cen, M.; Cai, C. State-of-charge (SOC) estimation using T-S Fuzzy Neural Network for Lithium Iron Phosphate Battery. In Proceedings of the 2018 26th International Conference on Systems Engineering (ICSEng), Sydney, NSW, Australia, 18–20 December 2018. [Google Scholar]

- Pushpavanam, B.; Akilan, T.; Kalyani, S.; Swedheetha, C.; Naveen, P.; Manikandan, P. Machine Learning Algorithms for Estimation of State-of-Charge of Li-Ion Batteries. In Proceedings of the 2023 7th International Conference on Electronics, Communication and Aerospace Technology (ICECA), Coimbatore, India, 22–24 November2023. [Google Scholar]

- Tingbari, V.M. Machine Learning Approach for Accurate Lithium-Ion Battery Temperature Prediction Using Electrochemical Features Independent of Battery SOC and SOH. In Proceedings of the 2025 IEEE Applied Power Electronics Conference and Exposition (APEC), Atlanta, GA, USA, 16 March 2025. [Google Scholar]

- Li, L. Battery Health Management Based on Digital Twin Technology. In Proceedings of the 2024 3rd International Conference on Energy and Power Engineering, Control Engineering (EPECE), Chengdu, China, 23–24 February 2024. [Google Scholar]

- Njoku, J.N.; Nwakanma, C.I.; Lee, J.-M.; Kim, D.-S. Trustworthy Battery Management: A Digital Twin Approach Leveraging XAI and Blockchain. In Proceedings of the 2025 International Conference on Artificial Intelligence in Information and Communication (ICAIIC), Fukuoka, Japan, 18–21 February 2025. [Google Scholar]

- Tian, J.; Liu, X.; Li, S.; Wei, Z.; Zhang, X.; Xiao, G.; Wang, P. Lithium-ion battery health estimation with real-world data for electric vehicles. Energy 2023, 270, 126855. [Google Scholar] [CrossRef]

- Zhang, M.; Miao, Z.; Fan, L. Battery identification based on real-world data. In Proceedings of the 2017 North American Power Symposium (NAPS), Morgantown, WV, USA, 17–19 September 2017. [Google Scholar]

- Jia, Z.; Zhang, Z.; Sun, Z.; Liu, P.; Wang, Z.; Zhang, Z. Estimation of Battery Capacity Fade using Real-World Vehicle Data for Diagnosis of Abnormal Capacity Loss. In Proceedings of the 2023 IEEE Energy Conversion Congress and Exposition (ECCE), Nashville, TN, USA, 29 October–2 November 2023. [Google Scholar]

- Karnehm, D.; Pohlmann, S.; Wiedenmann, A.; Kuder, M.; Neve, A. Introduction of a Cloud Computing Architecture for the Condition Monitoring of a Reconfigurable Battery System for Electric Vehicles. In Proceedings of the 2023 6th Conference on Cloud and Internet of Things (CIoT), Lisbon, Portugal, 20–23 March 2023. [Google Scholar]

- Xu, T. Energy Storage System Control Strategy Considering Battery Lifespan. In Proceedings of the 2024 IEEE 7th Information Technology, Networking, Electronic and Automation Control Conference (ITNEC), Chongqing, China, 15–17 March 2024. [Google Scholar]

- Zhijie; Wei, Z. Power Battery Charging Device Design. In Proceedings of the 2023 IEEE 7th Information Technology and Mechatronics Engineering Conference (ITOEC), Chongqing, China, 15–17 September 2023. [Google Scholar]

- Sun, Q.; Lv, H.; Wang, S.; Gao, S.; Wei, K. Optimized State of Charge Estimation of Lithium-Ion Battery in SMES/Battery Hybrid Energy Storage System for Electric Vehicles. IEEE Trans. Appl. Supercond. 2021, 31, 5700606. [Google Scholar] [CrossRef]

- Zhang, Y. Research on SoC Architecture Model and Its Application in BMS Scenario. In Proceedings of the 2023 IEEE IAS Industrial and Commercial Power System Asia (I&CPS Asia), Xi’an, China, 14–16 July 2023. [Google Scholar]

- Tran, M.-K.; Panchal, S.; Khang, T.D.; Panchal, K.; Fraser, R.; Fowler, M. Concept Review of a Cloud-Based Smart Battery Management System for Lithium-Ion Batteries: Feasibility, Logistics, and Functionality. Batteries 2022, 8, 19. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, H. Digital Twin for Battery Systems: Cloud Battery Management System with Online State-of-Charge and State-of-Health Estimation. J. Energy Storage 2020, 30, 101557. [Google Scholar] [CrossRef]

- Moharm, K.; Eltahan, M.; Immonen, E. Big Data Driven Battery Management Systems. In Proceedings of the 2020 2nd International Conference on Control Systems, Mathematical Modeling, Automation and Energy Efficiency (SUMMA), Lipetsk, Russia, 11–13 November 2020. [Google Scholar]

- Karmawijaya, M.I.; Haq, I.N.; Leksono, E.; Widyotriatmo, A. Development of Big Data Analytics Platform for Electric Vehicle Battery Management System. In Proceedings of the 2019 6th International Conference on Electric Vehicular Technology (ICEVT), Bali, Indonesia, 18–21 November 2019. [Google Scholar]

- Cheah, M.; Stocker, R. Cybersecurity of Battery Management Systems. HORIBA Readout 2019, 53, 82–89. [Google Scholar]

- Gorenflo, C.; Golab, L.; Keshav, S. Mitigating Trust Issues in Electric Vehicle Charging Using a Blockchain. In Proceedings of the Tenth ACM International Conference on Future Energy Systems (e-Energy ‘19), Phoenix, AZ, USA, 25–28 June 2019. [Google Scholar]

- Krishna, T.N.V.; Kumar, S.V.S.V.P.D.; Srinivasa Rao, S.; Chang, L. Powering the Future: Advanced Battery Management Systems (BMS) for Electric Vehicles. Energies 2024, 17, 3360. [Google Scholar] [CrossRef]

- Arslan, M.B.; Özdemir, Ş. Review of the Charging System and Communication Protocols of the Electric Vehicles. Artvin Çoruh Üniversitesi Mühendislik Ve Fen Bilim. Derg. 2024, 2, 50–79. [Google Scholar]

- Lee, M.; Lee, J.; Lee, I.; Lee, J.; Chon, A. Wireless Battery Management System. In Proceedings of the 2013 World Electric Vehicle Symposium and Exhibition (EVS27), Barcelona, Spain, 17–20 November 2013. [Google Scholar]

- Shell, C.; Henderson, J.; Verra, H.; Dyer, J. Implementation of a Wireless Battery Management System (WBMS). In Proceedings of the 2015 IEEE International Instrumentation and Measurement Technology Conference (I2MTC), Pisa, Italy, 11–14 May 2015. [Google Scholar]

- Cao, Z.; Gao, W.; Fu, Y.; Mi, C. Wireless Battery Management Systems: Innovations, Challenges, and Future Perspectives. Energies 2024, 17, 3277. [Google Scholar] [CrossRef]

- Samanta, A.; Williamson, S.S. A Survey of Wireless Battery Management System: Topology, Emerging Trends, and Challenges. Electronics 2021, 10, 2193. [Google Scholar] [CrossRef]

- Christakis, I.; Orfanos, V.A.; Chalkiadakis, P.; Rimpas, D. Real-Time Monitoring of a Lithium-Ion Battery Module to Enhance Safe Operation and Lifespan. Eng. Proc. 2024, 82, 66. [Google Scholar] [CrossRef]

- Pannerselvam, S.; Narayanan, V.; Gireesh Kumar, T. Energy Efficient Machine Learning Based SMART-A-BLE Implemented Wireless Battery Management System for Both Hybrid Electric Vehicles and Battery Electric Vehicles. Procedia Comput. Sci. 2023, 218, 235–248. [Google Scholar] [CrossRef]

- Ismail, M.; Ahmed, R. A Comprehensive Review of Cloud-Based Lithium-Ion Battery Management Systems for Electric Vehicle Applications. IEEE Access 2024, 12, 116259–116273. [Google Scholar] [CrossRef]

- Na, S.-J.; Sim, J.-U.; Kim, B.-J.; Kwon, D.-H.; Cho, I.-H. Design of Bluetooth Communication-Based Wireless Battery Management System for Electric Vehicles. IEEE Access 2024, 12, 185946–185957. [Google Scholar] [CrossRef]

- Bansal, P.; Nagaraj, P.R. Wireless Battery Management System for Electric Vehicles. In Proceedings of the 2019 IEEE Transportation Electrification Conference (ITEC-India), Bengaluru, India, 17–19 December 2019. [Google Scholar]

- Ghazali, A.K.; Aziz, N.A.A.; Hassan, M.K. Advanced Algorithms in Battery Management Systems for Electric Vehicles: A Comprehensive Review. Symmetry 2025, 17, 321. [Google Scholar] [CrossRef]

- Murlidharan, V.R.; Karnati, J.; Malik, H. Battery Management System: Threat Modeling, Vulnerability Analysis, and Cybersecurity Strategy. IEEE Access 2025, 13, 37198–37220. [Google Scholar] [CrossRef]

| Reference | Year | Description |

|---|---|---|

| Vaideeswaran et al. [8] | 2019 | Overview of the main BMS functions |

| Darwish et al. [4] | 2021 | Overview of diagnostic functions and charging algorithms |

| Gabbar et al. [9] | 2021 | Analysis of BMS structures used in EV and stationary energy storage |

| Mishra et al. [3] | 2021 | Overview of the BMS functions; lithium-ion battery modeling analysis |

| Spoorthi et al. [10] | 2022 | Overview of BMS balancing and diagnostic functions |

| Long et al. [6] | 2023 | Overview of BMS technological improvement directions |

| Devi et al. [11] | 2023 | Overview of BMS functions |

| Bhat et al. [12] | 2024 | BMS modeling |

| Vijaychandra et al. [13] | 2024 | Methods to improve battery safety |

| Reference | Battery Parameter Monitoring | Battery Protection | Cell Balancing | State Estimation and Fault Diagnosis | Charging and Discharging Management | Communication and Data Logging | Artificial Intelligence and Big Data Technologies |

|---|---|---|---|---|---|---|---|

| [8] | ∨ | ∨ | ∨ | ∨ | ∨ | ∨ | - |

| [4] | - | - | ∨ | ∨ | ∨ | - | - |

| [9] | ∨ | ∨ | - | ∨ | - | ∨ | - |

| [3] | - | - | - | ∨ | - | ∨ | - |

| [10] | ∨ | - | ∨ | ∨ | - | - | - |

| [6] | - | - | ∨ | ∨ | - | ∨ | - |

| [11] | ∨ | ∨ | ∨ | ∨ | - | - | - |

| [12] | - | - | - | ∨ | - | - | ∨ |

| [13] | - | ∨ | - | ∨ | - | - | ∨ |

| Method | Measurement Accuracy | Measurement Linearity | Problems for Integrating into EVs | Cost |

|---|---|---|---|---|

| Voltage measurement | ||||

| Voltage dividers | Depends on resistors | High | Impossible due to low operating voltage | Low |

| Individual galvanic decoupling | Depends on galvanic decoupling microcircuits | High | Absent | High |

| Low-voltage multiplexors | Depends on galvanic decoupling microcircuits and multiplexors | High | Absent | High |

| High-voltage multiplexors | Depends on galvanic decoupling microcircuits | high | Difficulty concerning high-voltage multiplexor reliability | Medium |

| Current measurement | ||||

| Shunt resistance | Medium | High | Absent | Low |

| Hall effect sensors | Medium | Medium | Absent | Low |

| Magnetoresistance effect-based sensors | Depends on individual magnetoresistance effects | Medium | Absent | High |

| Fiber-optic sensors | Low | Low | Construction complexity | Medium |

| Temperature measurement | ||||

| Thermoresistors | High within a narrow range | Low | Absent | Low |

| Thermocouples | Medium | Medium | Absent | Medium |

| Fiber-optic sensors | High | Medium | Construction complexity | High |

| Method | Response Rate | Selectivity | Difficulties of Integrating into EV | Cost |

|---|---|---|---|---|

| Voltage measurement | ||||

| Comparator circuit | High | Absent | Absent | Low |

| Multi-level protection | High | Present | Absent | Low |

| Time-current protection | Medium | Present | Absent | Medium |

| Controllable reactors | Low | Present | Weight–size parameters | High |

| Voltage protection | ||||

| Comparator circuit | High | Present | Absent | Low |

| Varistors | High | Absent | Absent | Medium |

| Temperature protection | ||||

| Passive protection | High | Absent | Re-implementation requirement | Low |

| Passive management | Not assessed | Present | Absent | Medium |

| Active management | Not assessed | Present | Absent | High |

| Method | Advantages | Disadvantages |

|---|---|---|

| Fixed resistor balancing | Simplicity and low cost of realization | Low efficiency; low rate of balancing |

| Switched resistor balancing | Higher rate of balancing and efficiency compared to fixed resistor balancing | Higher realization cost compared to fixed resistor balancing |

| Basic switched capacitor | Simplicity of operation | Big number of switch keys, low efficiency, low rate of balancing |

| Single switched capacitor | Simplicity of operation, high efficiency | Low rate of balancing |

| Double-tiered switched capacitor | Relatively high rate of balancing; simplicity of operation | Large number of switch keys; high realization cost |

| Single-inductor balancing | Relatively high rate of balancing; high efficiency | Complexity of operation; high realization cost |

| Multi-inductor balancing | High rate of balancing | The number of inductors increases when the cells are connected in series; high realization cost |

| Chain structure multi-inductor balancing | High rate of balancing | The circuit size and realization cost are higher |

| Single-winding transformer (switched transformer) balancing | Relative compactness | High realization cost |

| Multiple-winding transformer balancing | Relative compactness | Number of cells limited by the number of secondary windings; low efficiency |

| Multiple-transformer balancing | High rate of balancing | Low efficiency, large dimensions, and high realization cost |

| Cuk converter balancing | High rate of balancing and efficiency | Complexity of operation; relatively large dimensions |

| Buck-boost converter balancing | High rate of balancing and efficiency | Complexity of operation, relatively large dimensions, and high realization cost |

| Flyback converter balancing | High rate of balancing | Transformer needed |

| Full-bridge converter balancing | High rate of balancing | Complexity of operation, relatively large dimensions, and high realization cost |

| Method | Accuracy | Disadvantages | Requirements for Computational Resources | Cost |

|---|---|---|---|---|

| Determining SoC | ||||

| Coulomb method | High | Initial point required | Low | Low |

| OCV | Medium | Disregards loss of capacity | Low | Low |

| Adaptive filters | High | Preliminary calculations required | Medium | Medium |

| Determining SoH | ||||

| Direct measurements | Medium | Experiment required | Low | Low |

| Adaptive algorithms | High | Big data required | Medium | Medium |

| Digital twins | High | Big data and computation capacities required | High | High |

| Determining RUL | ||||

| AI | High | Big data and computation capacities required | High | High |

| Adaptive filters | Medium | Data required during whole operational phase | Medium | Medium |

| Stochastic methods | Medium | Data required during whole operational phase | Medium | Medium |

| Method | Advantages | Disadvantages | Cost | Energy Efficiency |

|---|---|---|---|---|

| Management considering battery life | Reduces depreciation of individual cells; service life extension | Complex management system; high computation load | Medium (requires advanced BMS) | High |

| Step-by-step direct-current charging | Increases charging process efficiency; reduces polarization and gas evolution; overheating protection | Precise analysis of battery state required; extended time of algorithm implementation | Medium (requires precise current control) | High |

| SMES/battery hybrid system | Reduces the number of battery charge/discharge cycles; more uniform load distribution; service life extension | Construction and management complexity; high equipment cost; limited applicability outside specialized systems | High (complex technologies and materials) | Extra high |

| Memory Classification | Characteristics | |

|---|---|---|

| Volatile memory | SRAM | High read and record rate, high cost, and is basically used in low cache memory |

| DRAM | Low read and record rate, needs regular updates, and often used in high-capacity RAM | |

| Non-volatile memory | PROM | Memory can be programmed only once and cannot be changed after programming |

| EPROM | Electrically erasable programmable read-only memory only for constant use; can perform multiple programming processes | |

| EEPROM | Multiple programming support and high data-erasing speed | |

| PCRAM | Non-volatility, high read rate, low static power consumption, and byte addressability | |

| FLASH (divided into Nor Flash and Nand Flash) | High read and record efficiency, stability, packet writing and deletion support, and is often used for external memory expansion | |

| Technology | Advantages | Disadvantages | Cost | Energy Efficiency/Interference Immunity/Scalability |

|---|---|---|---|---|

| CAN | Multipoint connection; wide application in the automotive industry | Limited bandwidth (up to 1 Mbit/s) | Low | High/extra high/medium |

| I2C | Simplicity, economic efficiency, and is a good communication method between sensors inside a module | Short distances, low bandwidth (up to 400 Kbit/s), and the limited number of nodes | Low | Extra high/medium/low |

| SPI | High data transfer rate | Many wires required, inapplicable to long connections, and no addressing is provided | Medium | Medium/medium/medium |

| UART | Connection simplicity; asynchronous mode | Speed and coverage range limitations; inapplicable to complex networks | Low | High/low/low |

| Ethernet | Very high bandwidth (up to 10 Gbit/s); IoT and cloud technology support | High energy consumption; complexity of implementation | High | Low/high/extra high |

| BLE | Wireless connection within short distances (up to 40 m) | Limited bandwidth (up to 2 Mbit/s) | Low | Extra high/low/medium |

| Zigbee | Stable connection up to 100 m | Difficult network setup; limited bandwidth (up to 250 Kbit/s) | Low | Extra high/medium/high |

| Wi-Fi | High bandwidth (up to 600 Mbit/s), access to the cloud, and remote monitoring | High energy consumption; sensitive to interferences | Medium | Low/low/extra high |

| NFC | Very simple identification of modules | Very small range of coverage (~10 cm); limited volume of data | Low | Extra high/high/low |

| Cellular networks (4G/5G LTE) | High rate (up to several hundred Mbit/s) and coverage range (up to several kilometers), access to the cloud, and remote control | High energy consumption, Depends on coverage, Expensive traffic | High | Low/medium/extra high |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Published by MDPI on behalf of the World Electric Vehicle Association. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kurkin, A.; Chivenkov, A.; Aleshin, D.; Trofimov, I.; Shalukho, A.; Vilkov, D. Battery Management System for Electric Vehicles: Comprehensive Review of Circuitry Configuration and Algorithms. World Electr. Veh. J. 2025, 16, 451. https://doi.org/10.3390/wevj16080451

Kurkin A, Chivenkov A, Aleshin D, Trofimov I, Shalukho A, Vilkov D. Battery Management System for Electric Vehicles: Comprehensive Review of Circuitry Configuration and Algorithms. World Electric Vehicle Journal. 2025; 16(8):451. https://doi.org/10.3390/wevj16080451

Chicago/Turabian StyleKurkin, Andrey, Alexander Chivenkov, Dmitriy Aleshin, Ivan Trofimov, Andrey Shalukho, and Danil Vilkov. 2025. "Battery Management System for Electric Vehicles: Comprehensive Review of Circuitry Configuration and Algorithms" World Electric Vehicle Journal 16, no. 8: 451. https://doi.org/10.3390/wevj16080451

APA StyleKurkin, A., Chivenkov, A., Aleshin, D., Trofimov, I., Shalukho, A., & Vilkov, D. (2025). Battery Management System for Electric Vehicles: Comprehensive Review of Circuitry Configuration and Algorithms. World Electric Vehicle Journal, 16(8), 451. https://doi.org/10.3390/wevj16080451