Evaluating the Role of Vehicle-Integrated Photovoltaic (VIPV) Systems in a Disaster Context

Abstract

1. Introduction

2. Methodology

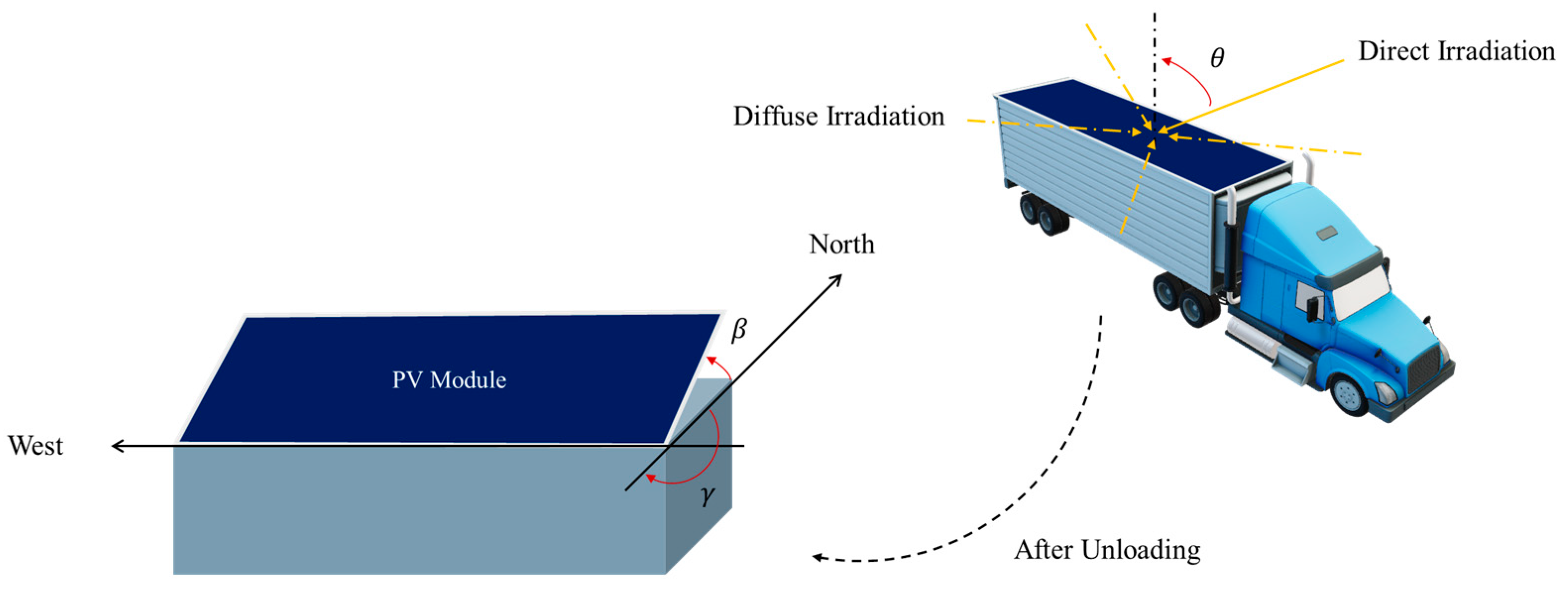

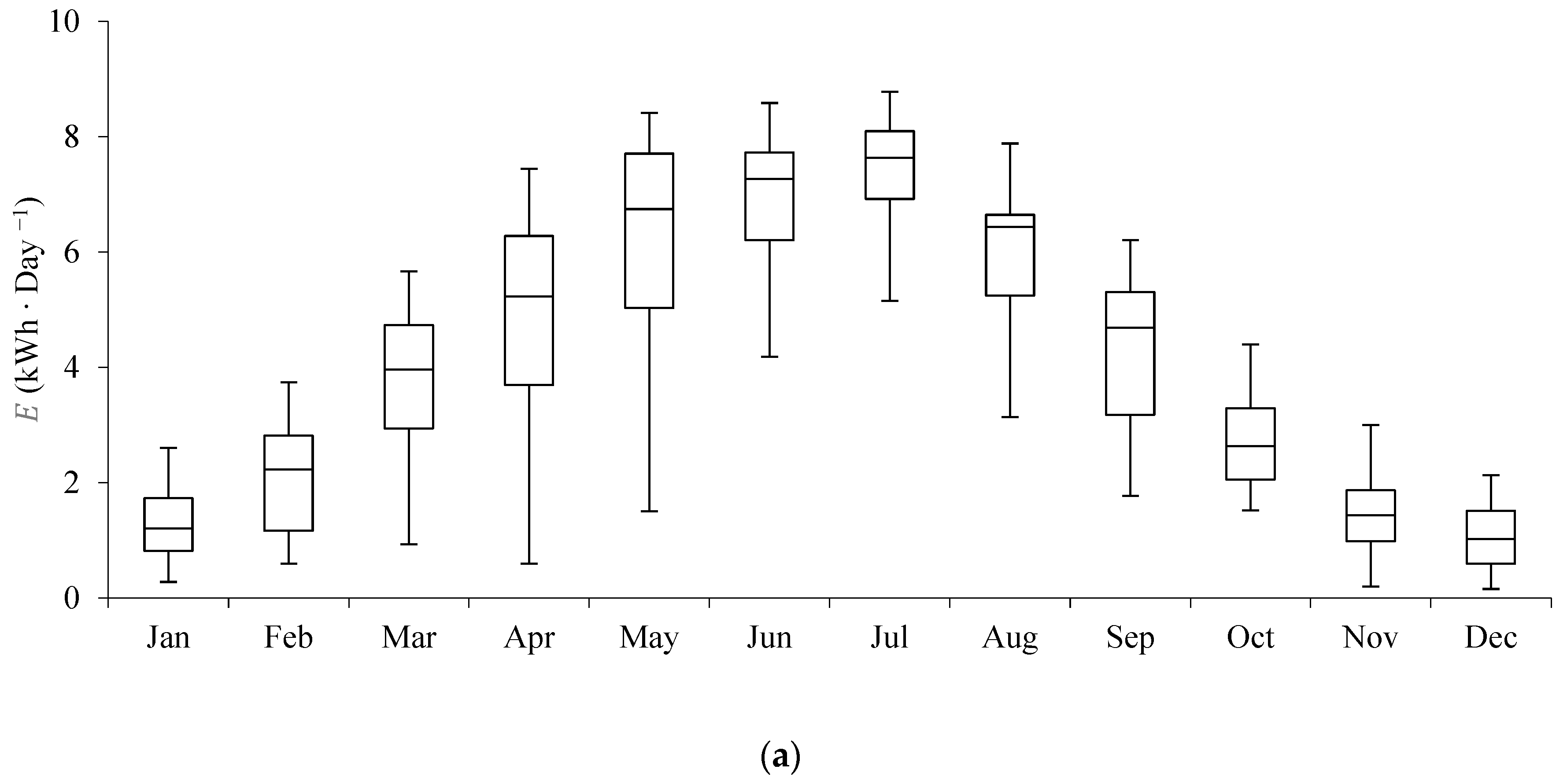

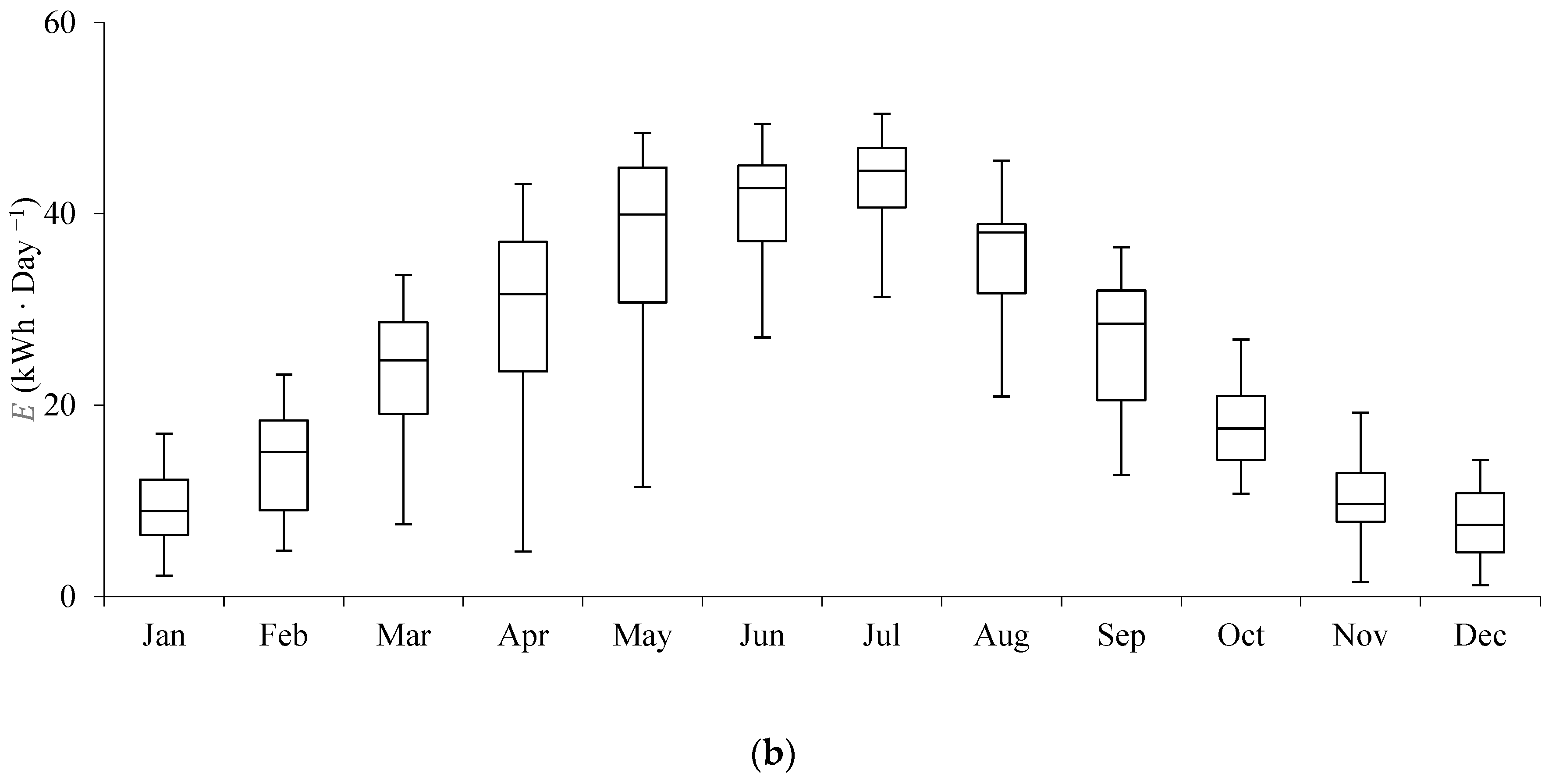

2.1. Solar Irradiance

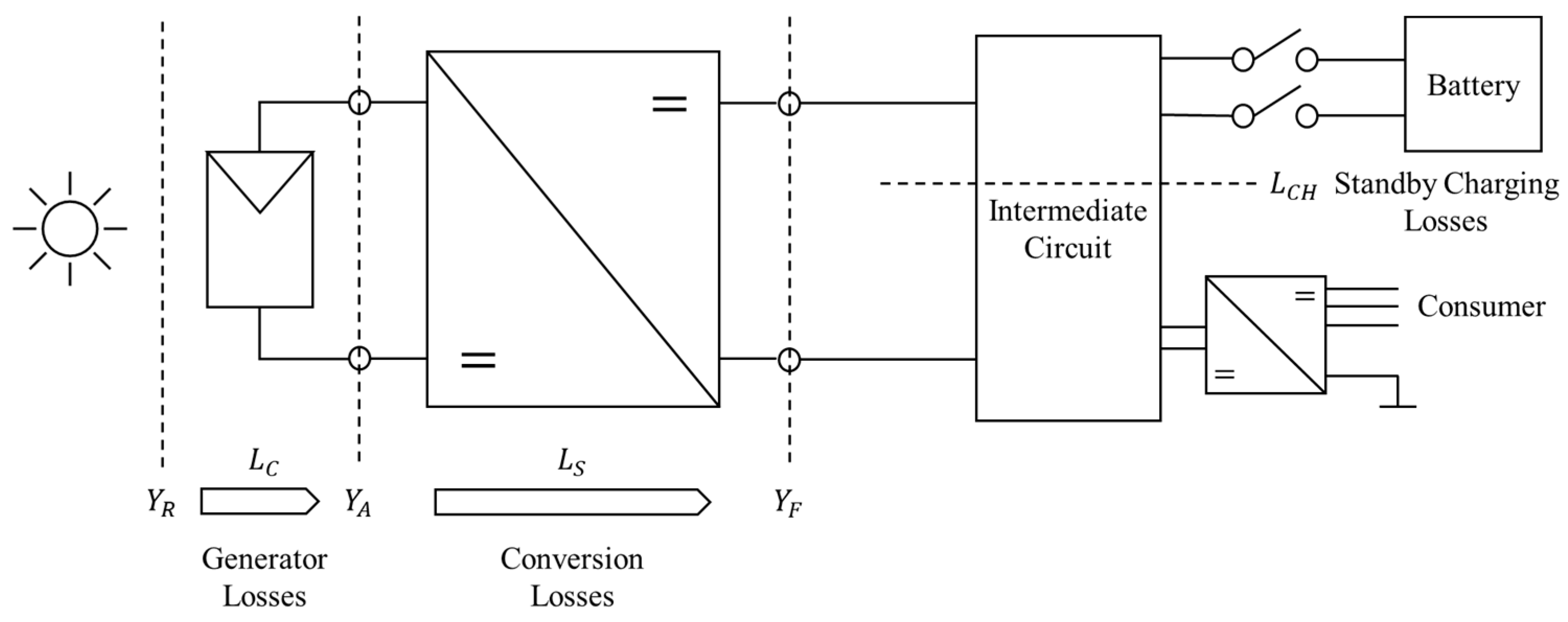

2.2. Performance Ratio

3. Case Studies

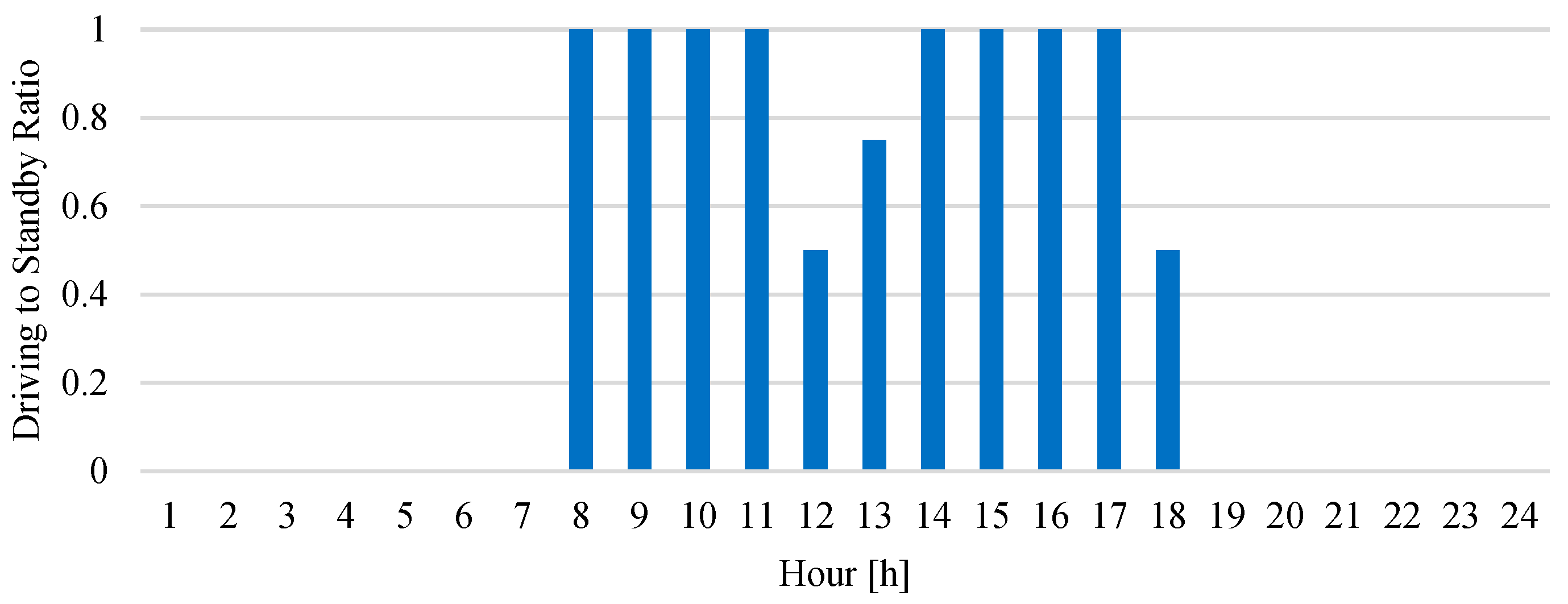

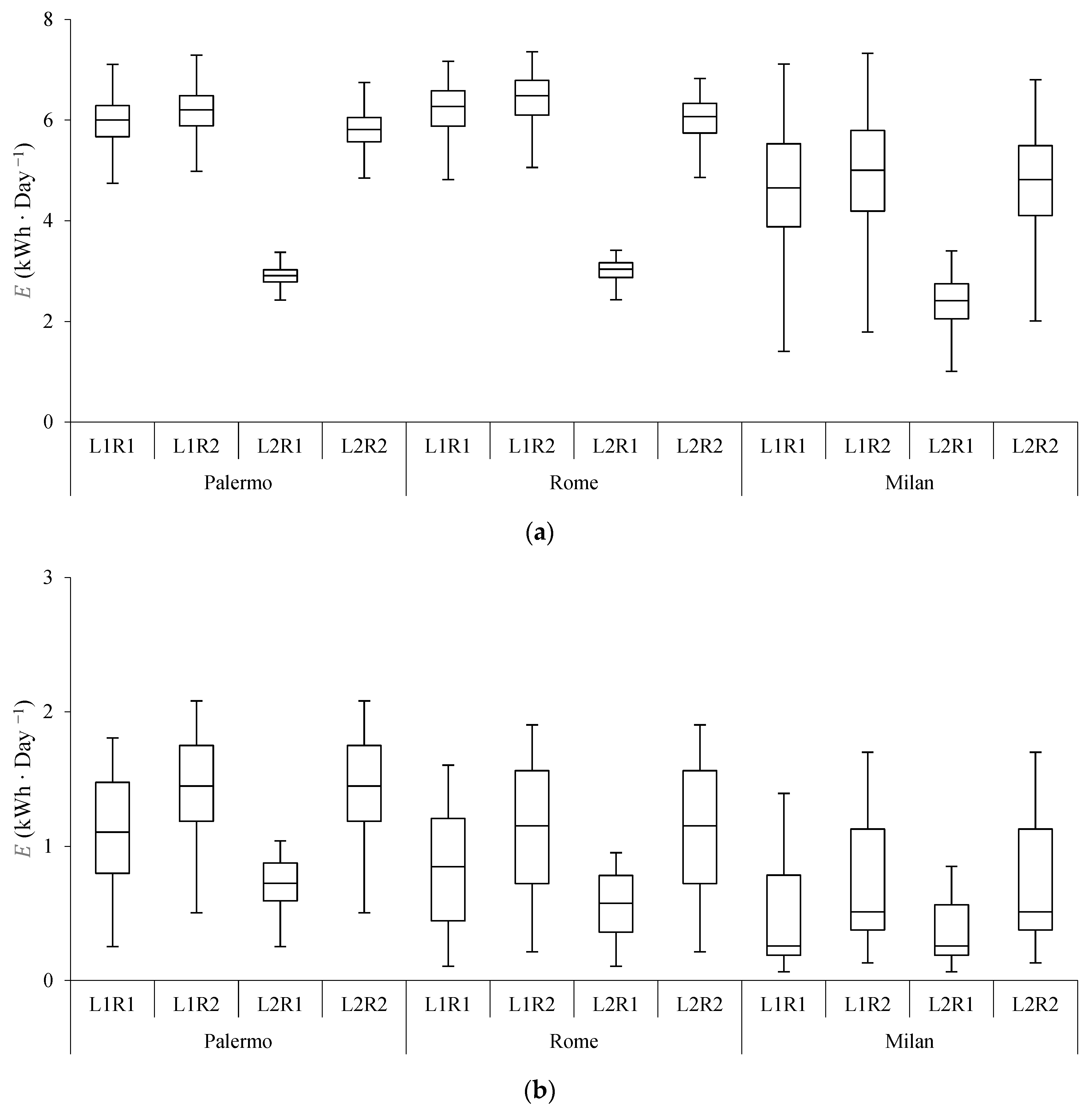

3.1. Ambulance and Truck

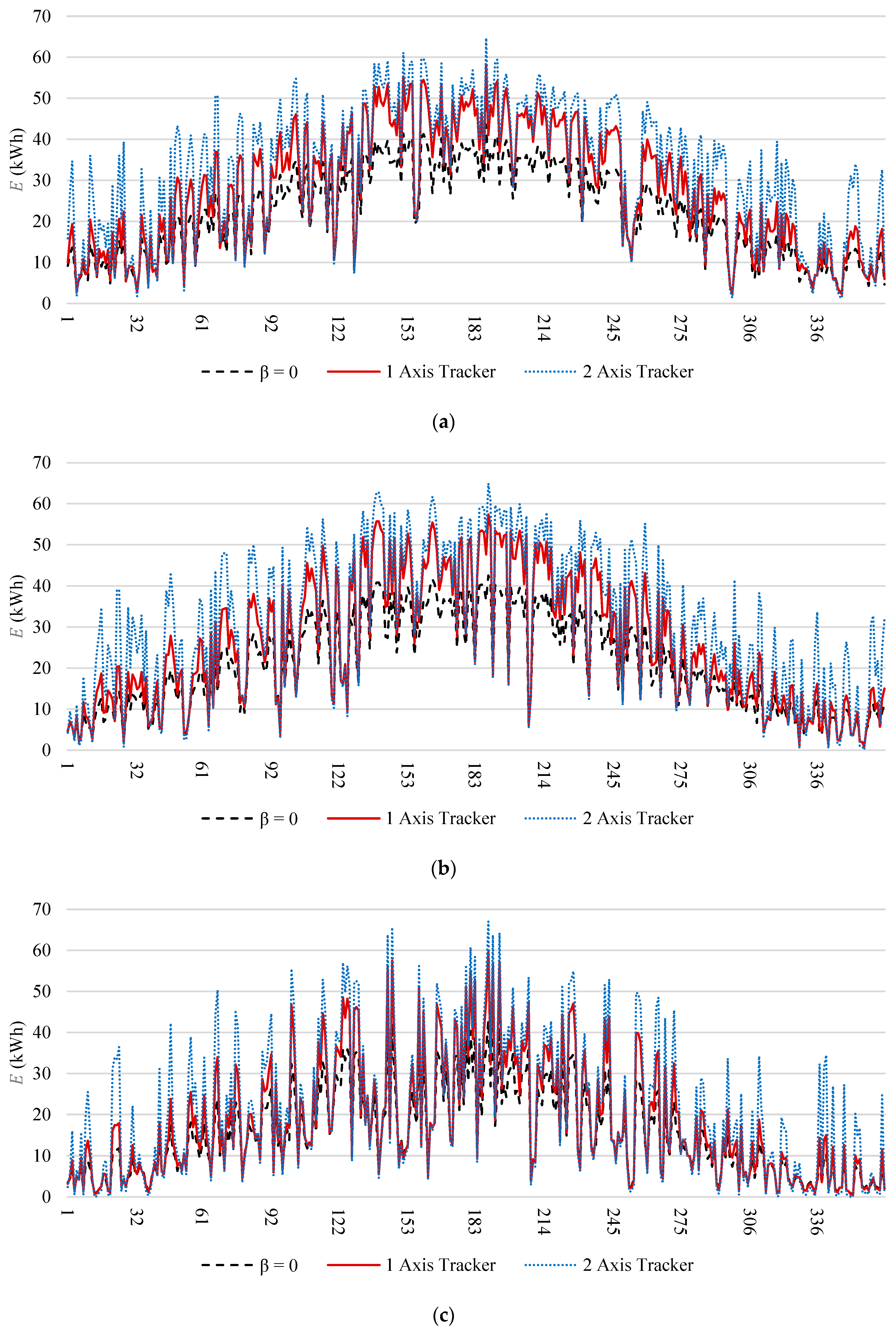

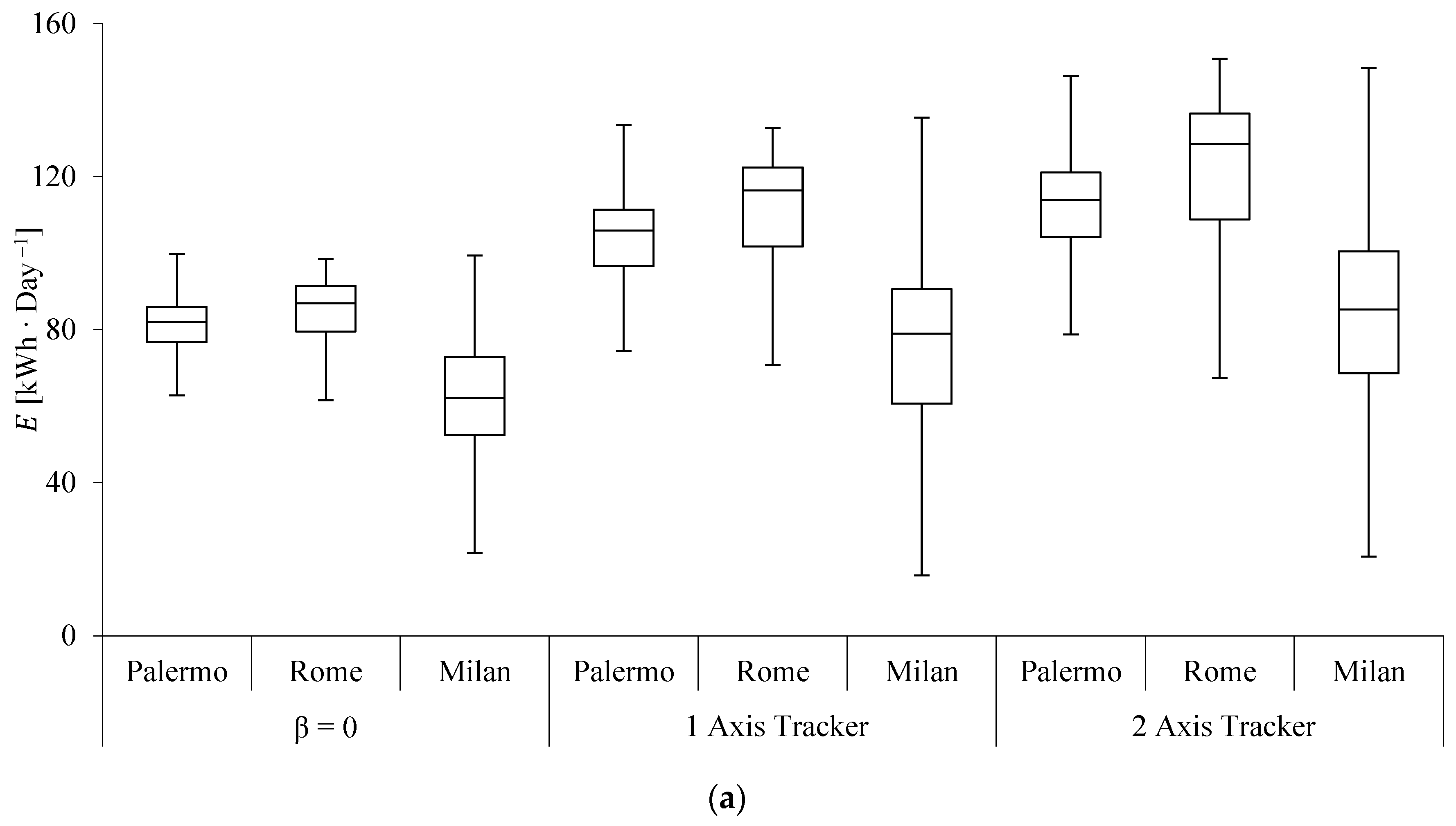

3.2. Container and Mobile Operating Room

3.3. Solar Module

4. Results

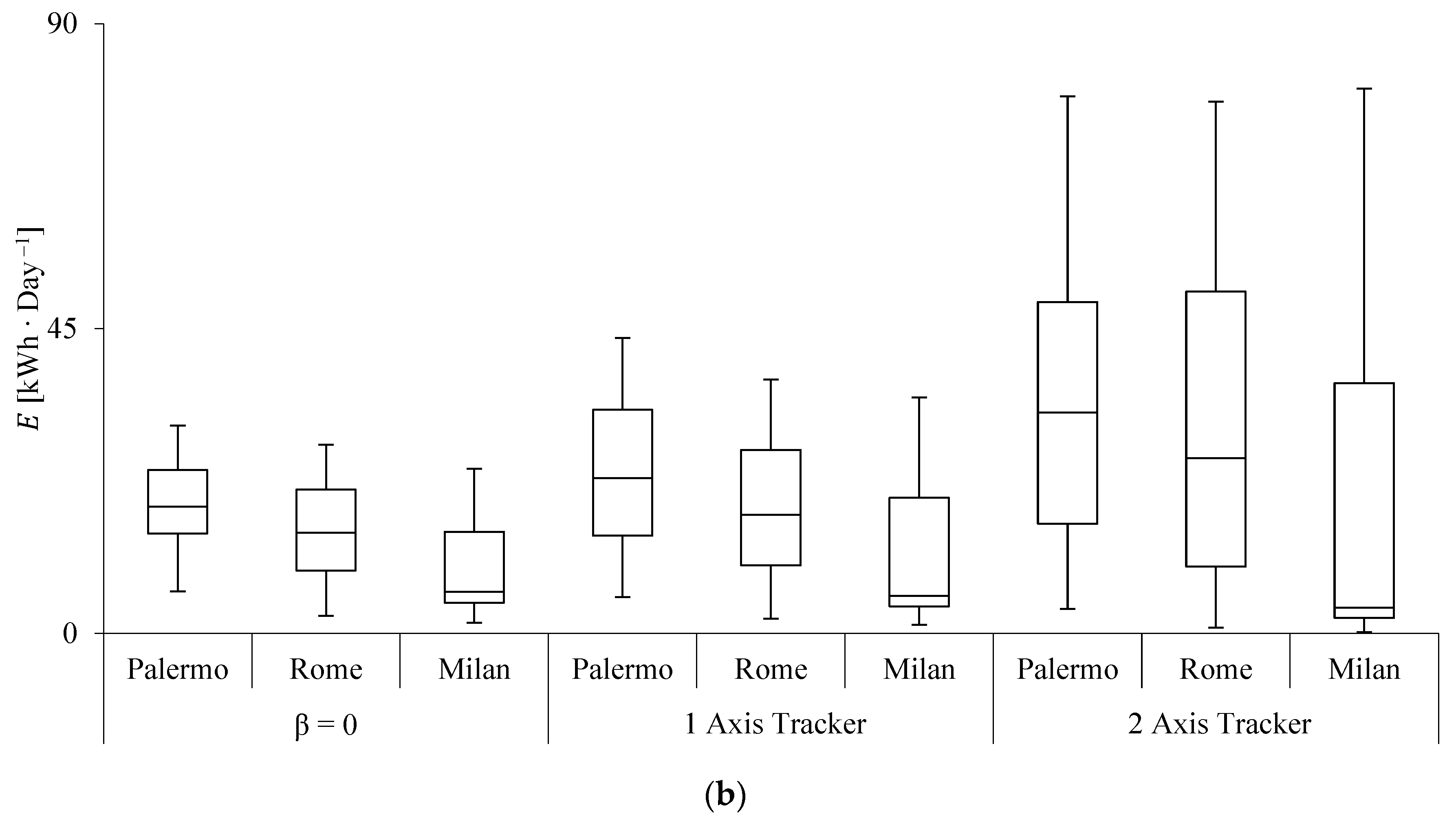

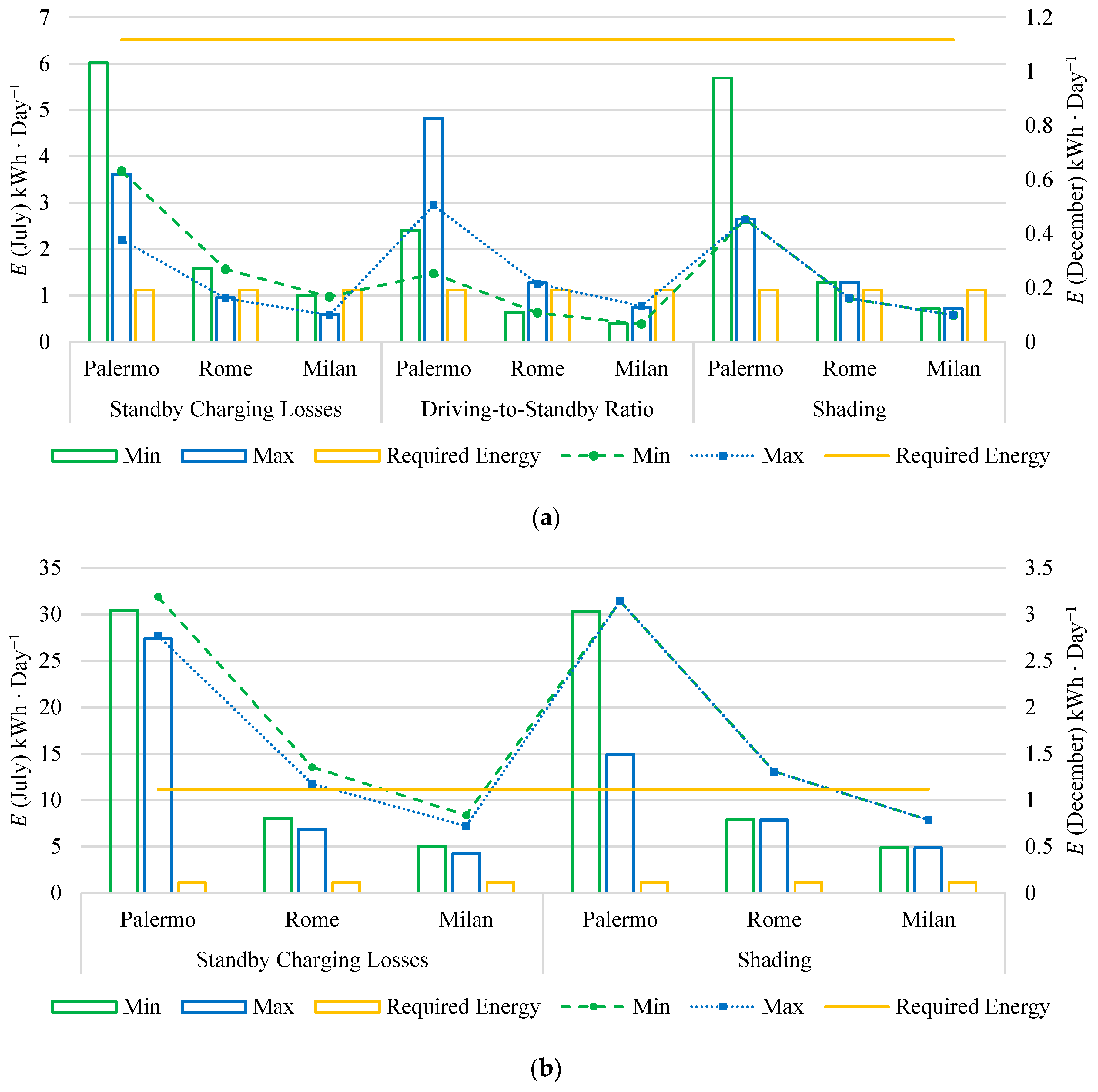

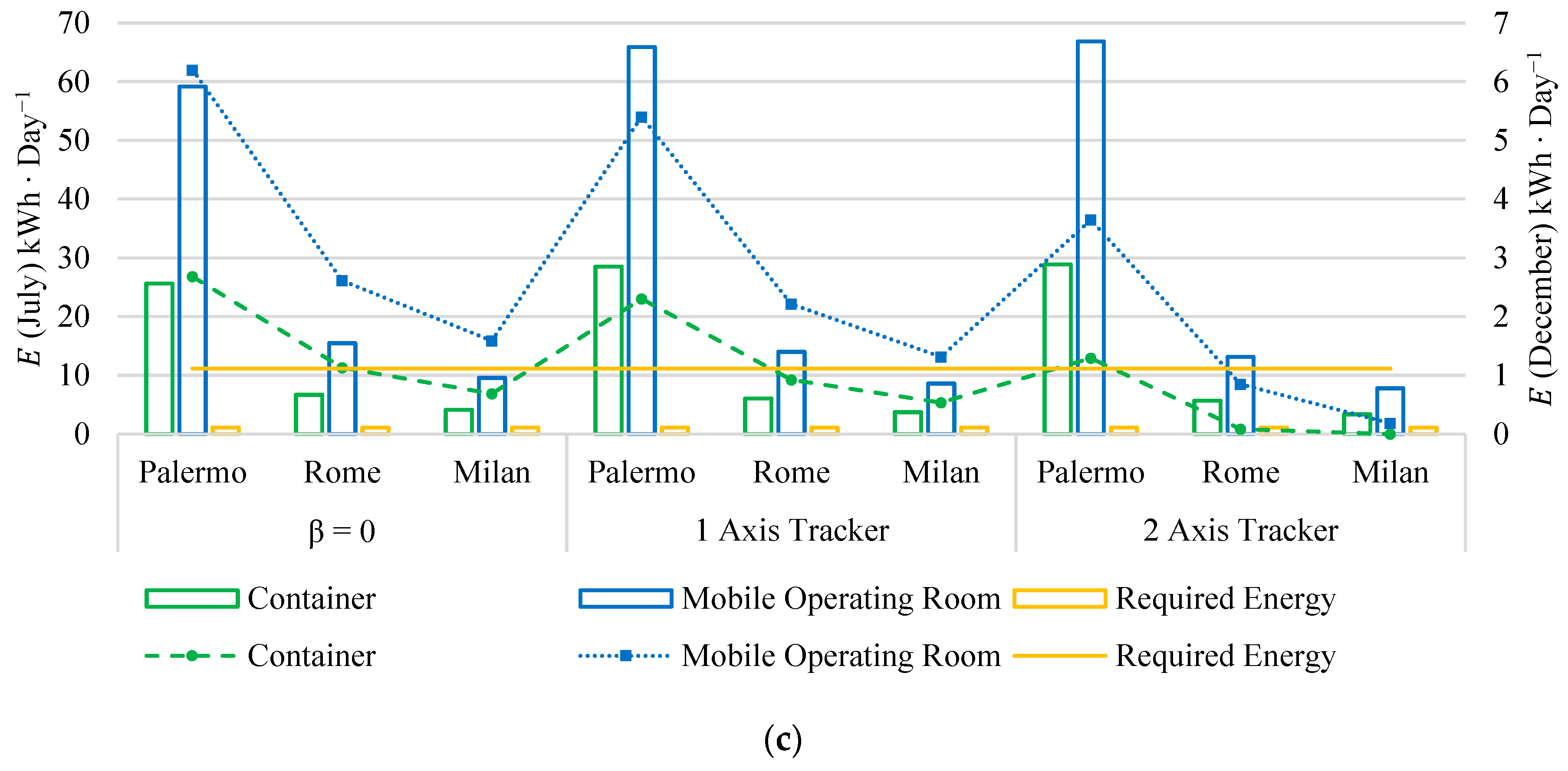

4.1. Energy Production and Solar Range

4.2. Battery Sizing

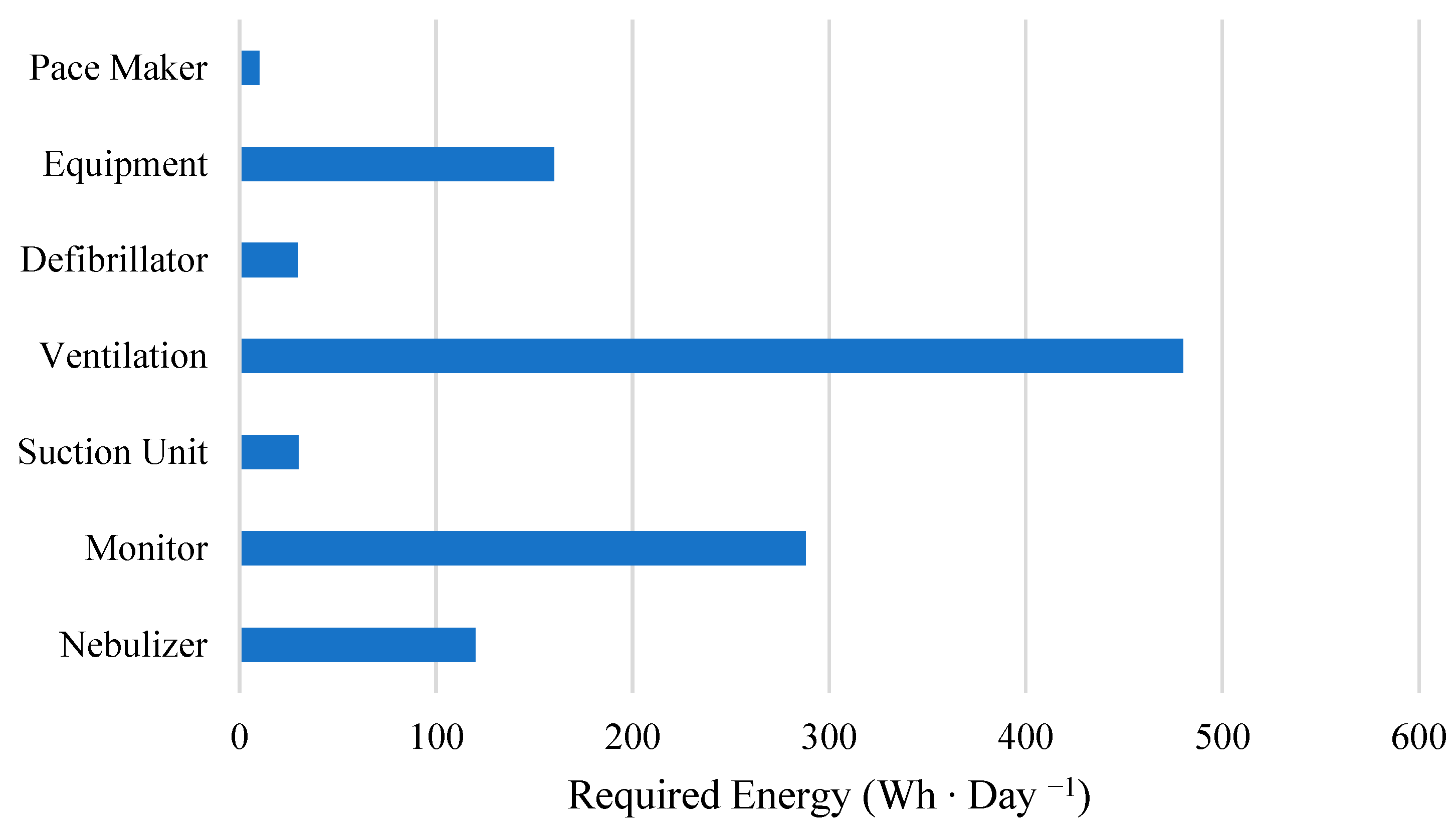

4.3. Load Analysis of Critical Healthcare Equipment

4.4. CO2 Emissions

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Román, M.O.; Stokes, E.C.; Shrestha, R.; Wang, Z.; Schultz, L.; Carlo, E.A.S.; Sun, Q.; Bell, J.; Molthan, A.; Kalb, V.; et al. Satellite-based assessment of electricity restoration efforts in Puerto Rico after Hurricane Maria. PLoS ONE 2019, 14, e0218883. [Google Scholar] [CrossRef]

- Popke, J.; Harrison, C. Energy, resilience, and responsibility in post-hurricane Maria Dominica: Ethical and historical perspectives on ‘Building Back Better’. J. Extrem. Events 2018, 5, 1840003. [Google Scholar] [CrossRef]

- Der Sarkissian, R.; Dabaj, A.; Diab, Y.; Vuillet, M. Evaluating the implementation of the “build-back-better” concept for critical infrastructure systems: Lessons from saint-martin’s island following hurricane irma. Sustainability 2021, 13, 3133. [Google Scholar] [CrossRef]

- Miranda, M.R.; Catalán, D.P.; Menéndez, A.F.; Barbosa, R. Analysis of the economic feasibility of a PV system with hydrogen and supercapacitors-based hybrid energy storage for rural community shelter in Yucatán, México. Int. J. Hydrogen Energy 2024, 108, 171–184. [Google Scholar] [CrossRef]

- Unal, S.; Dagteke, S.E. Enhancement of fuel cell based energy sustainability for cell on wheels mobile base stations used in disaster areas. Int. J. Hydrogen Energy 2024, 75, 567–577. [Google Scholar] [CrossRef]

- Candan, A.K.; Boynuegri, A.R.; Onat, N. Home energy management system for enhancing grid resiliency in post-disaster recovery period using Electric Vehicle. Sustain. Energy Grids Netw. 2023, 34, 101015. [Google Scholar] [CrossRef]

- Rad, M.A.V.; Shahsavari, A.; Rajaee, F.; Kasaeian, A.; Pourfayaz, F.; Yan, W.M. Techno-economic assessment of a hybrid system for energy supply in the affected areas by natural disasters: A case study. Energy Convers. Manag. 2020, 221, 113170. [Google Scholar] [CrossRef]

- Saboori, H. Enhancing resilience and sustainability of distribution networks by emergency operation of a truck-mounted mobile battery energy storage fleet. Sustain. Energy Grids Netw. 2023, 34, 101037. [Google Scholar] [CrossRef]

- Li, Q.; Li, T.; Zanelli, A. Performance evaluation of flexible photovoltaic panels for energy supply in post-disaster emergency shelters. J. Build. Eng. 2024, 98, 111285. [Google Scholar] [CrossRef]

- He, G.; Michalek, J.; Kar, S.; Chen, Q.; Zhang, D.; Whitacre, J.F. Utility-scale portable energy storage systems. Joule 2021, 5, 379–392. [Google Scholar] [CrossRef]

- Saboori, H.; Jadid, S. Optimal scheduling of mobile utility-scale battery energy storage systems in electric power distribution networks. J. Energy Storage 2020, 31, 101615. [Google Scholar] [CrossRef]

- Borodinecs, A.; Zajecs, D.; Lebedeva, K.; Bogdanovics, R. Mobile off-grid energy generation unit for temporary energy supply. Appl. Sci. 2022, 12, 673. [Google Scholar] [CrossRef]

- Samadi, H.; Ala, G.; Brano, V.L.; Romano, P.; Viola, F.; Miceli, R. Potential and Methods of Integrating Solar Cells into Vehicles. In Proceedings of the 2023 International Conference on Clean Electrical Power (ICCEP), Terrasini, Italy, 27–29 June 2023; pp. 715–720. [Google Scholar] [CrossRef]

- Ben Said-Romdhane, M.; Skander-Mustapha, S. A Review on Vehicle-Integrated Photovoltaic Panels. In Advanced Technologies for Solar Photovoltaics Energy Systems; Springer: Cham, Switzerland, 2021; pp. 349–370. [Google Scholar] [CrossRef]

- Samadi, H.; Ala, G.; Lo Brano, V.; Romano, P.; Viola, F. Investigation of Effective Factors on Vehicles Integrated Photovoltaic (VIPV) Performance: A Review. World Electr. Veh. J. 2023, 14, 154. [Google Scholar] [CrossRef]

- Almonacid, G.; Muñoz, F.J.; De La Casa, J.; Aguilar, J.D. Integration of PV systems on health emergency vehicles. The FIVE project. Prog. Photovolt. Res. Appl. 2004, 12, 609–621. [Google Scholar]

- Hasan, T.; Jamaludin, S.; Nik, W.W. Analysis of intelligent solar ICU water ambulance to optimize energy. Ann. Med. Surg. 2022, 80, 104141. [Google Scholar] [CrossRef]

- Araki, K.; Ota, Y.; Maeda, A.; Kumano, M.; Nishioka, K. Solar Electric Vehicles as Energy Sources in Disaster Zones: Physical and Social Factors. Energies 2023, 16, 3580. [Google Scholar] [CrossRef]

- Roudbari, A.; Nateghi, A.; Yousefi-khanghah, B.; Asgharpour-Alamdari, H.; Zare, H. Resilience-oriented operation of smart grids by rescheduling of energy resources and electric vehicles management during extreme weather condition. Sustain. Energy Grids Netw. 2021, 28, 100547. [Google Scholar] [CrossRef]

- Rahimi, K.; Chowdhury, B. A hybrid approach to improve the resiliency of the power distribution system. In Proceedings of the 2014 North American Power Symposium (NAPS), Pullman, WA, USA, 7–9 September 2014; pp. 1–6. [Google Scholar] [CrossRef]

- Kim, H.; Ku, J.; Kim, S.M.; Park, H.D. A new GIS-based algorithm to estimate photovoltaic potential of solar train: Case study in Gyeongbu line, Korea. Renew. Energy 2022, 190, 713–729. [Google Scholar] [CrossRef]

- Oh, M.; Kim, S.M.; Park, H.D. Estimation of photovoltaic potential of solar bus in an urban area: Case study in Gwanak, Seoul, Korea. Renew. Energy 2020, 160, 1335–1348. [Google Scholar] [CrossRef]

- Kutter, C.; Alanis, L.E.; Neuhaus, D.H.; Heinrich, M. Yield potential of vehicle integrated photovoltaics on commercial trucks and vans. In Proceedings of the 38th European PV Solar Energy Conference and Exhibition, Online, 6–10 September 2021; Volume 6, p. 10. [Google Scholar]

- Araki, K.; Ota, Y.; Nagaoka, A.; Nishioka, K. 3D solar irradiance model for non-uniform shading environments using shading (aperture) matrix enhanced by local coordinate system. Energies 2023, 16, 4414. [Google Scholar] [CrossRef]

- Tiwari, A.; Darbari, M. (Eds.) Emerging Trends in Computer Science and Its Application, 1st ed.; CRC Press: Boca Raton, FL, USA, 2025. [Google Scholar] [CrossRef]

- Almajali, Z.S.; Aldmour, S.A. Single-Axis Solar Tracker System for Maintaining Southward Orientation of Solar Cells in Solar Cars. In Proceedings of the 2023 IEEE Jordan International Joint Conference on Electrical Engineering and Information Technology (JEEIT), Amman, Jordan, 22–24 May 2023; pp. 211–216. [Google Scholar] [CrossRef]

- Efficiency and Decarbonization Indicators in Italy and in the Biggest European Countries. Edition 2023. 2023. Available online: https://www.isprambiente.gov.it/files2023/pubblicazioni/rapporti/r386-2023.pdf (accessed on 15 June 2024).

- Kumar, N.M.; Chopra, S.S.; Malvoni, M.; Elavarasan, R.M.; Das, N. Solar cell technology selection for a PV leaf based on energy and sustainability indicators—A case of a multilayered solar photovoltaic tree. Energies 2020, 13, 6439. [Google Scholar] [CrossRef]

- Yamaguchi, M.; Nakamura, K.; Ozaki, R.; Kojima, N.; Ohshita, Y.; Masuda, T.; Okumura, K.; Mabuchi, T.; Satou, A.; Tanimoto, T.; et al. Analysis of Climate Conditions Upon Driving Distance of Vehicle Integrated Photovoltaics-Powered Vehicles. Energy Technol. 2024, 12, 2300692. [Google Scholar] [CrossRef]

- Ota, Y.; Araki, K.; Nagaoka, A.; Nishioka, K. Facilitating vehicle-integrated photovoltaics by considering the radius of curvature of the roof surface for solar cell coverage. Clean. Eng. Technol. 2022, 7, 100446. [Google Scholar] [CrossRef]

- Duffie, J.A.; Beckman, W.A. Solar Engineering of Thermal Processes; John Wiley & Sons: Hoboken, NJ, USA, 2013. [Google Scholar] [CrossRef]

- Remund, J.; Müller, S.C.; Schmutz, M.; Graf, P. Meteonorm Version 8. In Proceedings of the EU PVSEC 2020, Lisbon, Portugal, 7–11 September 2020. [Google Scholar] [CrossRef]

- European Commission; Joint Research Centre. Photovoltaic Geographical Information System (PVGIS). 2024. Available online: https://ec.europa.eu/jrc/en/pvgis (accessed on 7 February 2025).

- Brito, M.C.; Santos, T.; Moura, F.; Pera, D.; Rocha, J. Urban solar potential for vehicle integrated photovoltaics. Transp. Res. Part D Transp. Environ. 2021, 94, 102810. [Google Scholar] [CrossRef]

- Brito, M.C.; Amaro e Silva, R.; Pera, D.; Costa, I.; Boutov, D. Effect of urban shadowing on the potential of solar-powered vehicles. Prog. Photovolt. Res. Appl. 2024, 32, 73–83. [Google Scholar] [CrossRef]

- Mallon, K.R.; Assadian, F.; Fu, B. Analysis of on-board photovoltaics for a battery electric bus and their impact on battery lifespan. Energies 2017, 10, 943. [Google Scholar] [CrossRef]

- Abdelhamid, M.; Pilla, S.; Singh, R.; Haque, I.; Filipi, Z. A comprehensive optimized model for on-board solar photovoltaic system for plug-in electric vehicles: Energy and economic impacts. Int. J. Energy Res. 2016, 40, 1489–1508. [Google Scholar] [CrossRef]

- Kanz, O.; Reinders, A.; May, J.; Ding, K. Environmental impacts of integrated photovoltaic modules in light utility electric vehicles. Energies 2020, 13, 5120. [Google Scholar] [CrossRef]

- Araki, K.; Karr, A.J.; Chabuel, F.; Commault, B.; Derks, R.; Ding, K.; Duigou, T.; Ekins-Daukes, N.J.; Gaume, J.; Hirota, T.; et al. State-of-the-Art and Expected Benefits of PV-Powered Vehicles. 2021. Available online: https://iea-pvps.org/wp-content/uploads/2021/07/IEA_PVPS_T17_State-of-theart-and-expected-benefits-of-VIPV_report.pdf (accessed on 6 June 2024).

- Mertens, K. Photovoltaics: Fundamentals, Technology, and Practice; John Wiley & Sons: Hoboken, NJ, USA, 2018. [Google Scholar]

- Leloux, J.; Taylor, J.; Moretón, R.; Narvarte, L.; Trebosc, D.; Desportes, A.; Solar, S. Monitoring 30,000 PV systems in Europe: Performance, faults, and state of the art. In Proceedings of the 31st European Photovoltaic Solar Energy Conference and Exhibition, Hamburg, Germany, 14–18 September 2015; pp. 1574–1582. [Google Scholar]

- WAS 500 E-RTW. 2023. Available online: https://www.was-vehicles.com/de/innovation/was-500-e-rtw.html (accessed on 20 November 2023).

- Semi. The Future of Trucking Is Electric. 2023. Available online: https://www.tesla.com/semi (accessed on 20 November 2023).

- Mobile Surgery Unit. Available online: https://www.expandable-trailers.com/applications/mobile-surgery-unit (accessed on 10 April 2024).

- Types of Containers, Dimensions and Characteristics of Containers. 2023. Available online: https://www.groupe-rdt.com/en/useful-information/types-of-containers/ (accessed on 20 November 2023).

- Global Solar Atlas. 2024. Available online: https://globalsolaratlas.info/map/ (accessed on 28 December 2024).

- Yamaguchi, M.; Ota, Y.; Masuda, T.; Thiel, C.; Tsakalidis, A.; Jaeger-Waldau, A.; Araki, K.; Nishioka, K.; Takamoto, T.; Nakado, T.; et al. Analysis for effects of temperature rise of PV modules upon driving distance of vehicle integrated photovoltaic electric vehicles. Energy Power Eng. 2024, 16, 131–150. [Google Scholar] [CrossRef]

- Park, C.; Park, H.; Jeon, H.; Choi, K.; Suh, J. Evaluation and Validation of Photovoltaic Potential Based on Time and Pathway of Solar-Powered Electric Vehicle. Appl. Sci. 2023, 13, 1025. [Google Scholar] [CrossRef]

- REGULATION (EC) No 561/2006 OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL on the Harmonisation of Certain Social Legislation Relating to Road Transport and Amending Council Regulations (EEC) No 3821/85 and (EC) No 2135/98 and Repealing Council Regulation (EEC) No 3820/85. 2023. Available online: https://eur-lex.europa.eu/resource.html?uri=cellar:5cf5ebde-d494-40eb-86a7-2131294ccbd9.0005.02/DOC_1&format=PDF (accessed on 10 November 2023).

- Lodi, C.; Seitsonen, A.; Paffumi, E.; De Gennaro, M.; Huld, T.; Malfettani, S. Reducing CO2 emissions of conventional fuel cars by vehicle photovoltaic roofs. Transp. Res. Part D Transp. Environ. 2018, 59, 313–324. [Google Scholar] [CrossRef]

- Ota, Y.; Masuda, T.; Araki, K.; Yamaguchi, M. Curve-correction factor for characterization of the output of a three-dimensional curved photovoltaic module on a car roof. Coatings 2018, 8, 432. [Google Scholar] [CrossRef]

- Hirota, T.; Kamiya, Y.; Komoto, K. Feasibility Study of Onboard PV for Passenger Vehicle Application. Trans. Soc. Automot. Eng. Jpn. 2020, 51. [Google Scholar] [CrossRef]

- Commault, B.; Duigou, T.; Maneval, V.; Gaume, J.; Chabuel, F.; Voroshazi, E. Overview and perspectives for vehicle-integrated photovoltaics. Appl. Sci. 2021, 11, 11598. [Google Scholar] [CrossRef]

- Le Series. 2023. Available online: https://www.sungoldsolar.com/flexible-solar-panel/le/ (accessed on 30 December 2023).

- Kutter, C.; Basler, F.; Alanis, L.E.; Markert, J.; Heinrich, M.; Neuhaus, D.H. Integrated lightweight, glass-free PV module technology for box bodies of commercial trucks. In Proceedings of the 37th European PV Solar Energy Conference and Exhibition, Lisbon, Portugal, 7–11 September 2020; Volume 7, p. 11. [Google Scholar]

- Martins, A.C.; Chapuis, V.; Virtuani, A.; Ballif, C. Robust glass-free lightweight photovoltaic modules with improved resistance to mechanical loads and impact. IEEE J. Photovolt. 2018, 9, 245–251. [Google Scholar] [CrossRef]

- Kim, S.; Holz, M.; Park, S.; Yoon, Y.; Cho, E.; Yi, J. Future options for lightweight photovoltaic modules in electrical passenger cars. Sustainability 2021, 13, 2532. [Google Scholar] [CrossRef]

- Kuttybay, N.; Mekhilef, S.; Koshkarbay, N.; Saymbetov, A.; Nurgaliyev, M.; Dosymbetova, G.; Orynbassar, S.; Yershov, E.; Kapparova, A.; Zholamanov, B.; et al. Assessment of solar tracking systems: A comprehensive review. Sustain. Energy Technol. Assess. 2024, 68, 103879. [Google Scholar] [CrossRef]

- Single Axis Tracker. 2025. Available online: https://lumaxenergy.com/assets/datasheets/single-axis-tracker/SAT.pdf (accessed on 15 February 2025).

- Duo Series Dual Axis Solar Tracking Systems. 2025. Available online: https://www.pvsolarfirst.com/Products_details/Duo_Series_Dual_Axis_Solar_Tracking_Systems.html (accessed on 15 February 2025).

- Jogunuri, S.; Kumar, R.; Kumar, D. Sizing an off-grid photovoltaic system (A case study). In Proceedings of the 2017 International Conference on Energy, Communication, Data Analytics and Soft Computing (ICECDS), Chennai, India, 1–2 August 2017; pp. 2618–2622. [Google Scholar] [CrossRef]

- Mat, F.C.; Mokhtar, S.E.B.; Hisyam, M.B.; Harun, S.W. Smart Power Management System for Ambulance. IOP Conf. Ser. Mater. Sci. Eng. 2020, 854, 012070. [Google Scholar] [CrossRef]

- Drinhaus, H.; Schumacher, C.; Drinhaus, J.; Wetsch, W.A. W(h)at(t) counts in electricity consumption in the intensive care unit. Intensive Care Med. 2023, 49, 437–439. [Google Scholar] [CrossRef]

- Dieleman, N.A.; Jagtenberg, C.J. Electric ambulances: Will the need for charging affect response times? SSRN 2024. [Google Scholar] [CrossRef]

- New Energy and Industrial Technology Development Organization. NEDO, PV-Powered Vehicle Strategy Committee. 2018. Available online: https://www.nedo.go.jp/content/100885778.pdf (accessed on 29 June 2024).

| Type | Model | Roof Area (m2) | Area Usage (%) |

|---|---|---|---|

| Ambulance | WAS E 500 | 8.17 | 79 |

| Truck | Tesla Semi | 34.00 | 96 |

| Container | Dry Cargo | 28.30 | 95 |

| Mobile Operating Room | Expandable | 66.12 | 94 |

| Palermo | Rome | Milan | |

|---|---|---|---|

| () | 1564.20 | 1520.30 | 1382.80 |

| () | 1943.10 | 1870.70 | 1681.50 |

| (%) | 80.50 | 81.27 | 82.24 |

| (%) | 98.00 | 98.00 | 98.00 |

| (%) | 78.89 | 79.64 | 80.60 |

| Value (%) | |

|---|---|

| Temperature Losses | 9 |

| MPPT Losses | 5 |

| DC/DC Conversion Losses | 5 |

| Battery Charging Losses | 2 |

| Model | Power (Wp) | Cell Efficiency (%) | Number of Cells | Cell Dimension (mm) | Module Size (mm) |

|---|---|---|---|---|---|

| LE-M2 |

| Parameters Value | ) | ) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| WAS E 500 | Tesla Semi | WAS E 500 | Tesla Semi | ||||||||||

| PA | RO | MI | PA | RO | MI | PA | RO | MI | PA | RO | MI | ||

| (W) | 0 | 1.89 | 1.79 | 1.34 | 9.54 | 9.05 | 6.75 | 3253 | 3085 | 2302 | 7633 | 7238 | 5402 |

| 700 | 1.13 | 1.07 | 0.80 | 8.79 | 8.28 | 6.09 | 1952 | 1851 | 1381 | 7030 | 6628 | 4873 | |

| (%) | 40 | 1.51 | 1.42 | 1 | - | - | - | 2611 | 2451 | 1730 | - | - | - |

| 80 | 1.60 | 1.51 | 1.11 | - | - | - | 2757 | 2607 | 1917 | - | - | - | |

| Shading (%) | 0 | 1.79 | 1.69 | 1.24 | 9.50 | 9.01 | 6.71 | 3078 | 2911 | 2136 | 7603 | 7207 | 5371 |

| 80 | 0.92 | 0.86 | 0.76 | 5.13 | 4.81 | 4.30 | 1588 | 1481 | 1315 | 4104 | 3849 | 3444 | |

| ) | ) | ||||||

|---|---|---|---|---|---|---|---|

| Palermo | Rome | Milan | Palermo | Rome | Milan | ||

| Container | 21.91 | 20.58 | 15.18 | 87.64 | 82.32 | 60.72 | |

| 1 Axis Tracker | 27.71 | 26.11 | 18.42 | 110.82 | 104.45 | 73.67 | |

| 2 Axis Tracker | 32.28 | 31.15 | 21.46 | 129.13 | 124.62 | 85.84 | |

| Mobile Operating Room | 50.66 | 47.58 | 35.09 | 202.64 | 190.32 | 140.36 | |

| 1 Axis Tracker | 64.1 | 60.45 | 42.66 | 256.4 | 241.8 | 170.64 | |

| 2 Axis Tracker | 75.3 | 72.69 | 50.27 | 301.2 | 290.76 | 201.08 | |

| Parameters | Value | WAS E 500 | Tesla Semi | ||||

|---|---|---|---|---|---|---|---|

| ) | |||||||

| Palermo | Rome | Milan | Palermo | Rome | Milan | ||

| (W) | 0 | 0.49 | 0.47 | 0.35 | 2.48 | 2.35 | 1.75 |

| 700 | 0.29 | 0.28 | 0.21 | 2.28 | 2.15 | 1.58 | |

| (%) | 40 | 0.45 | 0.43 | 0.30 | - | - | - |

| 80 | 0.48 | 0.45 | 0.33 | - | - | - | |

| Shading (%) | 0 | 0.46 | 0.44 | 0.32 | 2.47 | 2.34 | 1.74 |

| 80 | 0.24 | 0.22 | 0.20 | 1.33 | 1.25 | 1.19 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Published by MDPI on behalf of the World Electric Vehicle Association. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Samadi, H.; Ala, G.; Imburgia, A.; Licciardi, S.; Romano, P.; Viola, F. Evaluating the Role of Vehicle-Integrated Photovoltaic (VIPV) Systems in a Disaster Context. World Electr. Veh. J. 2025, 16, 190. https://doi.org/10.3390/wevj16040190

Samadi H, Ala G, Imburgia A, Licciardi S, Romano P, Viola F. Evaluating the Role of Vehicle-Integrated Photovoltaic (VIPV) Systems in a Disaster Context. World Electric Vehicle Journal. 2025; 16(4):190. https://doi.org/10.3390/wevj16040190

Chicago/Turabian StyleSamadi, Hamid, Guido Ala, Antonino Imburgia, Silvia Licciardi, Pietro Romano, and Fabio Viola. 2025. "Evaluating the Role of Vehicle-Integrated Photovoltaic (VIPV) Systems in a Disaster Context" World Electric Vehicle Journal 16, no. 4: 190. https://doi.org/10.3390/wevj16040190

APA StyleSamadi, H., Ala, G., Imburgia, A., Licciardi, S., Romano, P., & Viola, F. (2025). Evaluating the Role of Vehicle-Integrated Photovoltaic (VIPV) Systems in a Disaster Context. World Electric Vehicle Journal, 16(4), 190. https://doi.org/10.3390/wevj16040190