LSTM-Based State-of-Charge Estimation and User Interface Development for Lithium-Ion Battery Management

Abstract

1. Introduction

- A Long Short-Term Memory (LSTM) neural network optimized via Hyperband hyperparameter tuning, ensuring robust performance across diverse operating conditions;

- An intuitive, real-time user interface (UI) that visualizes SOC predictions, increasing user trust and facilitating practical deployment in commercial BMSs.

2. Materials and Methods

2.1. Experimental Configuration

2.1.1. Experimental Setup

2.1.2. Battery Specifications

2.1.3. Sensor Calibration and Data Quality

2.2. Database Development

2.2.1. Experimental Conditions

- Ambient Temperature (25 °C): this condition served as the baseline for evaluating standard battery performance.

- Low Temperature (−10 °C): battery performance was evaluated under cold conditions, where increased internal resistance is expected to affect capacity and power output.

- High Temperature (40 °C): the impact of elevated temperatures on battery performance and potential accelerated degradation was assessed.

- Urban Driving: This cycle simulates urban driving conditions characterized by frequent stops, accelerations, and braking. It reflects typical city driving conditions where batteries experience rapid changes in power demand.

- Highway Driving: This cycle simulates steady highway driving, with fewer stops and power demand variations. It allows for the evaluation of battery performance during prolonged, continuous use at relatively constant operating conditions.

- Mixed Driving Conditions: this cycle combines urban and highway driving elements, providing a more comprehensive assessment of battery performance under varied operating conditions.

2.2.2. Data Collection and Preprocessing

- Data Acquisition System: Data from sensors were collected using a specialized data acquisition system capable of accurately managing large volumes of data. The system was connected to interface software for the real-time control of sensors and data recording, ensuring reliability and consistency in the acquired measurements. Figure 1 illustrates the acquisition equipment.

- Raw Data Collection: Critical battery parameters, such as current, voltage, and temperature, were collected at a high sampling frequency. The data were recorded in real time during simulated driving cycles, capturing rapid variations in battery performance. Preliminary data quality checks ensured that the collected data were consistent and free of significant anomalies.

- Preprocessing Steps:

- -

- Filtering and Smoothing: To ensure data quality, filtering techniques were used to remove sensor noise. Smoothing methods, such as exponential smoothing and Kalman filters, were applied to reduce irrelevant fluctuations while retaining significant trends in the data.

- -

- Normalization: The data were normalized to bring different variables to a comparable scale. Variables like current and voltage were specifically normalized to facilitate analysis and improve model performance during prediction. This step prevents certain variables from dominating the model’s learning due to their larger numerical values.

- -

- Segmentation: The dataset was segmented according to various operating and temperature conditions. This segmentation divided the data into sections corresponding to specific operational cycles of the electric vehicle at given temperatures. Each segment was analyzed independently to assess the impact of different conditions on battery performance.

- Variables:

- -

- Voltage: battery voltage at different times, crucial for evaluating the state of charge.

- -

- Current: current flowing through the battery during operation, used to understand both consumption and recharge.

- -

- Temperature: battery temperature during tests, affecting performance and lifespan.

- -

- Time: timestamps associated with measurements, used to track variable changes over time.

- Labels: The target variable in this dataset is the state of charge (SoC), which represents the remaining energy in the battery as a proportion of its total capacity. SoC is the main indicator that prediction models aim to estimate based on measured characteristics such as voltage, current, and temperature.

- Data Format: The data are provided as CSV files or time-series data files. CSV files are commonly used for tabular data, while time-series data can be organized in specific formats for temporal analysis. Data files contain columns corresponding to the measured variables (voltage, current, temperature) and labels (SoC). Each row represents a measurement taken at a specific time, including timestamps for synchronization. Files may also include metadata that describe experimental conditions and sensor configuration.

- Challenges and Considerations:

- Data quality is crucial to ensure reliable results in battery analysis. However, several challenges related to data quality were encountered:

- -

- Sensor Inaccuracies: sensors used to measure voltage, current, and temperature may have inaccuracies or drifts, which can affect the precision of the measurements and, consequently, the quality of the collected data.

- -

- Environmental Factors: Environmental conditions, such as temperature variations or humidity, can influence sensor performance and the battery itself. Accounting for these factors is essential to correctly interpreting the data.

- -

- Noise in the Data: Noise, or random measurement fluctuations, may originate from various sources, such as electromagnetic interference or measurement errors. Filtering and smoothing techniques are often necessary to reduce noise and improve data quality.

- Although the dataset provides a solid basis for analysis, some limitations should be noted:

- -

- Limited Number of Operational Conditions: The dataset may not include a sufficient variety of operating conditions to cover all possible scenarios. This limitation may hinder the generalizability of results to conditions not represented in the dataset.

- -

- Uncovered Conditions: Certain conditions, such as extreme temperatures beyond the tested ranges or atypical operating scenarios, may not be covered. These gaps could influence the model’s ability to predict SoC in situations not represented by the dataset.

- -

- Sampling Frequency: this is a critical factor in data acquisition, as an inadequate rate may fail to capture rapid fluctuations in key battery parameters such as voltage, current, and temperature, potentially leading to inaccuracies in SOC estimation.

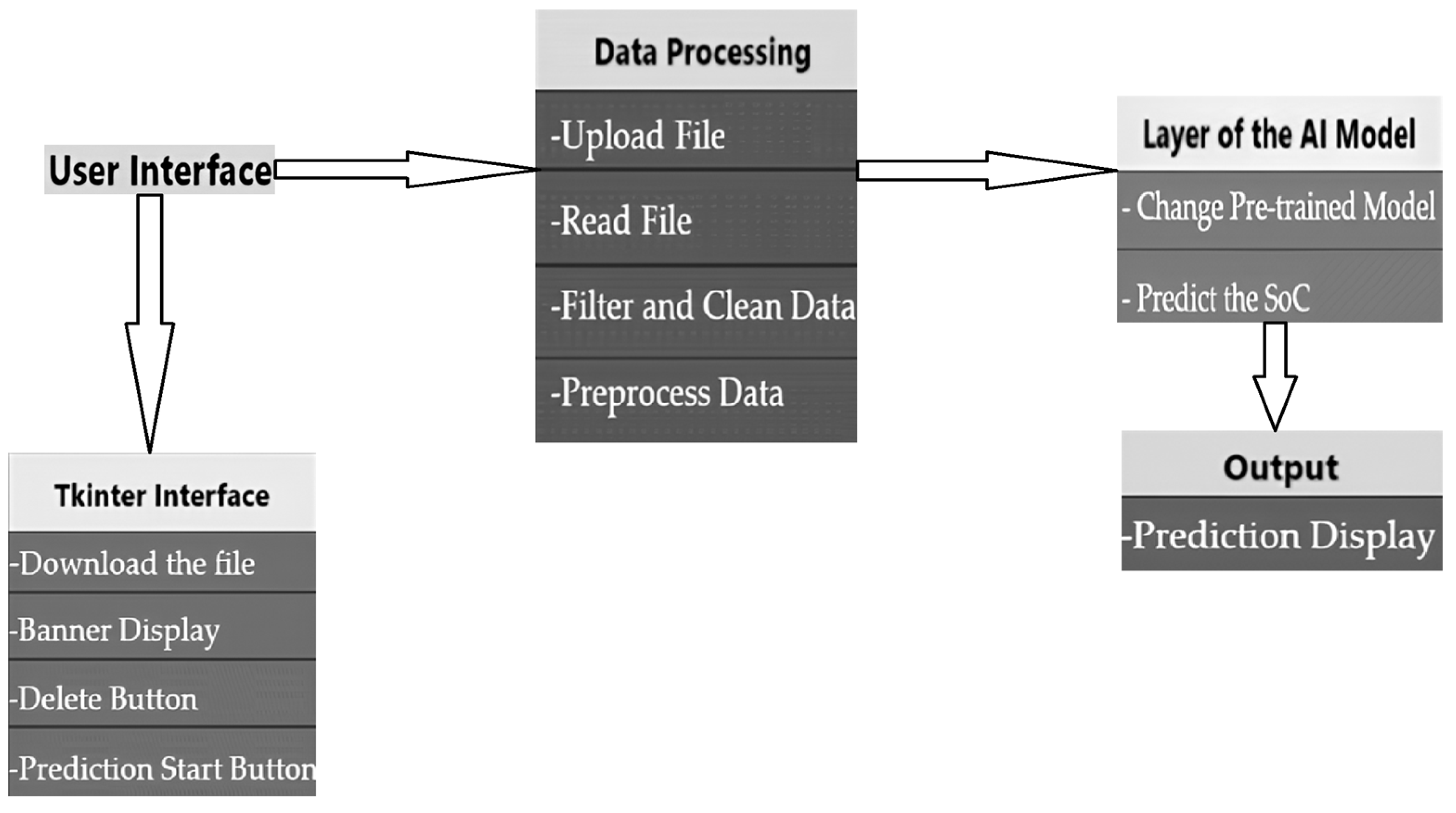

2.3. Interface Development

2.3.1. Application Flowchart

2.3.2. Application Page Description

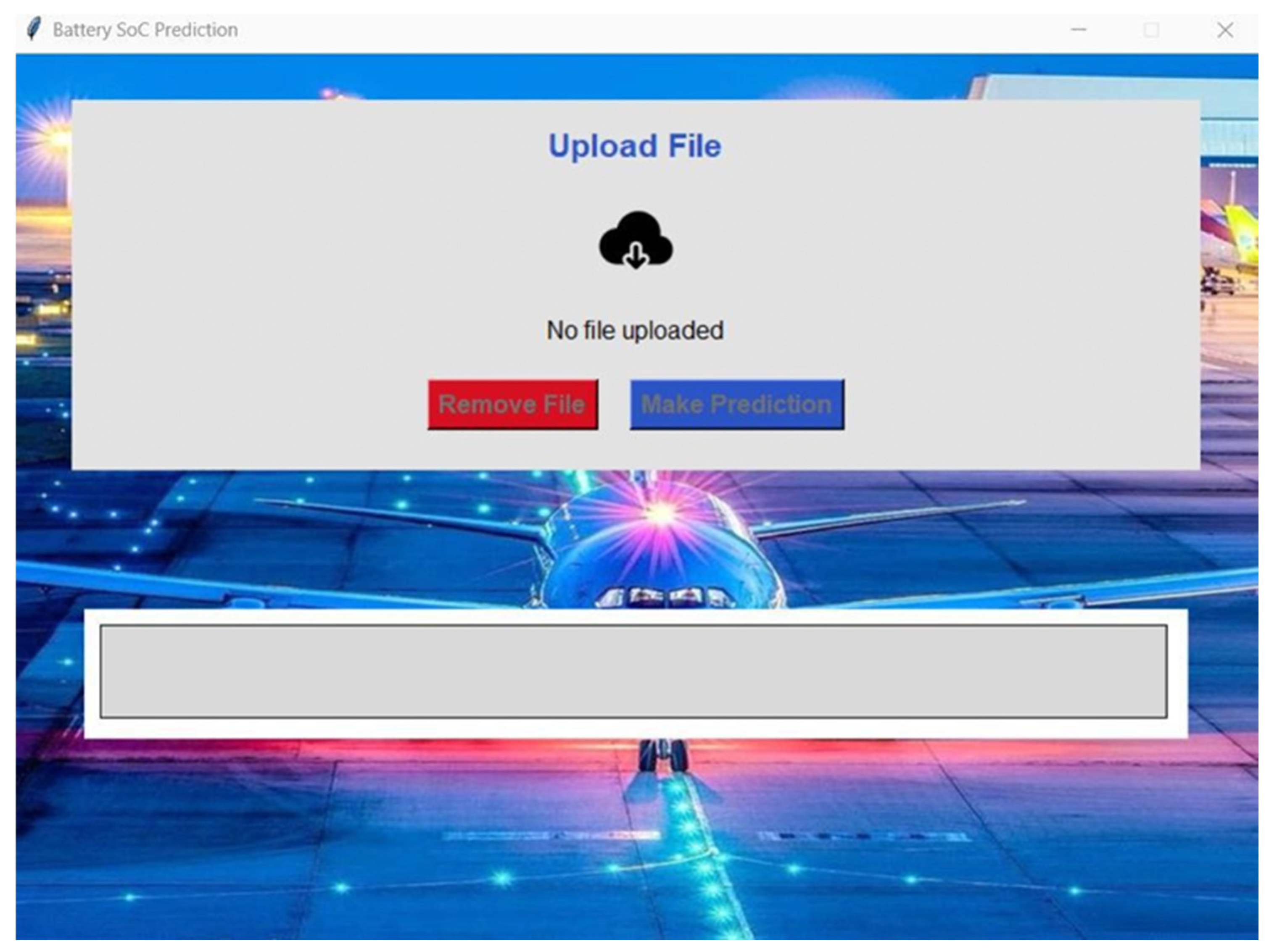

- Unique Structure: The application consists of a single main window designed to be simple, straightforward, and intuitive. All interface elements are organized to guide the user easily through the prediction process.

- File Upload: A button labeled “Upload File” is at the top of the interface. The user clicks this button to upload the file containing the data necessary for battery SoC prediction.

- Control Buttons:

- -

- Remove File Button: Located next to the upload button, this button allows the user to remove the uploaded file, resetting the interface for a new attempt. By default, this button is disabled and is only activated when a file is uploaded.

- -

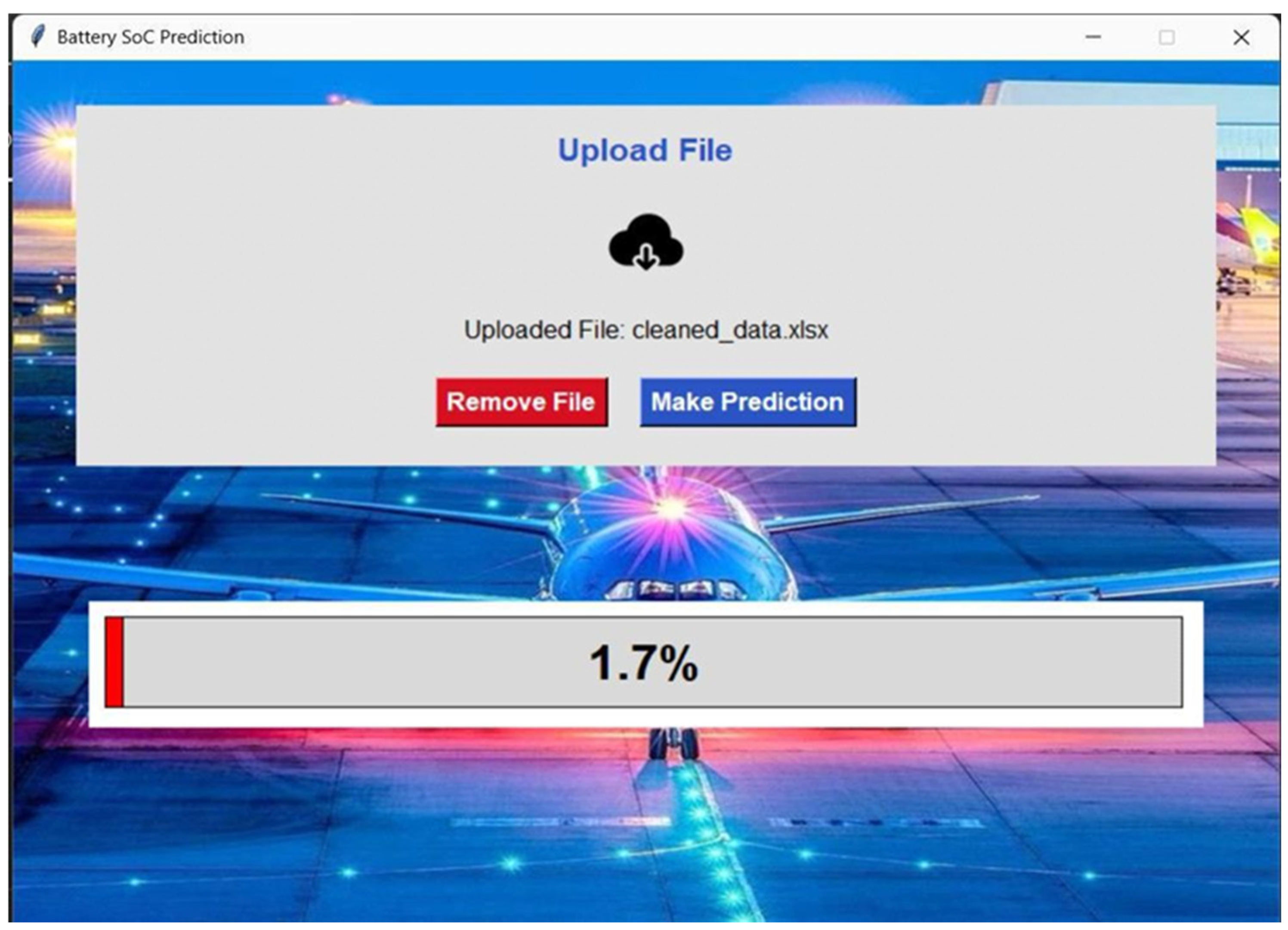

- Make Prediction Button: This button is activated after a file is uploaded. By clicking it, the user initiates the prediction of SoC based on the data from the file.

- Prediction Display (SOC Tape): Below the buttons, a horizontal tape is present to visually display the SoC of the battery. The tape is initially empty and fills or changes color based on the prediction result, with a clear display of the SoC percentage.

2.3.3. Key Features and User Interactions

- Simple Interaction: the interface is designed for smooth interaction, allowing the user to easily upload a file, click a button to make a prediction, and instantly view the visual and numerical SoC result.

- Accessibility and Clarity: Buttons are clearly labeled and accessible, with dynamic states that help users understand available actions at each step. The SoC display is central and visible, providing an optimal user experience.

- Layout:

- -

- File Upload: the application includes an “Upload File” button for uploading a data file in Excel format.

- -

- File Removal: the “Remove File” button deletes the uploaded file and resets the user interface.

- -

- Prediction: the “Make Prediction” button initiates the SoC prediction process by applying the deep learning model to the data from the uploaded file.

- -

- SoC Display: a tape (SOC tape) is integrated to visually display the predicted SoC, represented graphically and numerically.

- File Upload: When the user uploads an Excel file, the model first verifies the validity of the data and then activates the “Remove File” button for a quick reset if necessary.

- Prediction: Clicking “Make Prediction” triggers the analysis of the uploaded Excel file to extract the necessary data. These data are then passed through the model, which predicts the SoC. The result is immediately displayed on the SOC tape.

- File Removal: the user can remove the CSV file at any time, which turns off the prediction button until a new file is uploaded.

2.3.4. Safety-Driven Features in the User Interface

- Threshold-Based Alerts: a color-coded SOC indicator provides immediate visual feedback on battery health:

- -

- Green (20–80%): optimal operating range;

- -

- Yellow (10–20% or 80–90%): warning levels where preventive actions may be needed;

- -

- Red (<10% or >90%): critical SOC levels, where battery lifespan and safety could be compromised.

- Overcharge and Deep Discharge Warnings: the system generates real-time alerts if SOC levels exceed safe operational limits (e.g., below 10% or above 95%), preventing excessive degradation and safety hazards.

- Temperature-Sensitive SOC Adjustments: The interface includes a dynamic SOC correction mechanism since battery performance varies with temperature. If the temperature falls outside the safe range (−10 °C to 40 °C), the system flags the SOC estimation as potentially inaccurate and recommends adjustments.

- Historical Data Visualization for Predictive Maintenance: Users can track SOC trends over time, helping to identify anomalies such as sudden drops in capacity. This enables predictive maintenance, allowing the early detection of battery aging or faults before they cause failures.

2.4. Model Development

2.4.1. Types of Neural Networks Used

- Multi-Layer Perceptron (MLP) is a type of neural network architecture commonly used for regression and classification problems. It consists of an input layer, multiple hidden layers, and an output layer. In this project, the MLP was configured with two hidden layers. Each neuron in the hidden layers applies an activation function to a weighted sum of its inputs, represented by the following equation [14,36]:

- W: weight matrix connecting neurons between layers;

- x: input vector;

- b: bias;

- f: activation function.

- Long Short-Term Memory (LSTM) is an advanced type of recurrent neural network (RNN) designed to handle sequential data, such as time series. This project used an LSTM layer with 50 units to capture temporal dependencies in the battery data. The unique structure of LSTM includes a memory cell and three gates (forget, input, and output) that help regulate the flow of information [37,38].

- ft: the forget gate’s output (a vector with values between 0 and 1, indicating the extent of forgetting for each element in the memory cell);

- σ: the sigmoid activation function, which maps values to the range [0,1];

- Wf: the weight matrix for the forget gate;

- [ht−1, xt]: the concatenated vector of the previous hidden state ht−1 and the current input xt;

- bf: the bias vector for the forget gate.

- it: input at time t (values between 0 and 1, determining how much information to add to the cell state);

- Wi: weight matrix for the input gate;

- bi: bias vector for the input gate.

- : candidate cell state, generated as a potential update to the cell state;

- tanh: hyperbolic tangent function, which scales the cell state to a range between −1 and 1;

- Wc: weight matrix for the candidate cell state;

- bc: bias vectors for the candidate cell state.

- ct: updated cell state;

- ⊙: element-wise multiplication;

- ct−1: previous cell state.

- ot: output gate’s activation (values between 0 and 1, determining how much of the cell state contributes to the output);

- Wo: weight matrix for the output gate;

- bo: Bias vector for the output gate.

- ht: updated hidden state (output of the LSTM cell at time t).

- Fully connected layers (dense layers) are a key component of neural networks. Each neuron in a fully connected layer is connected to every neuron in the previous layer. In this project, two fully connected layers were used after the LSTM to process the output further. The equation for the output of a neuron in a fully connected layer is [37,38]

- W: weight matrix;

- x: input from the previous layer;

- b: bias vector.

- Activation functions introduce non-linearity into neural networks, enabling them to learn complex relationships. The following activation functions were used:

- -

- ReLU (Rectified Linear Unit): ReLU was used in the hidden layers of the MLP and the first dense layer of the model. ReLU is commonly used because it helps mitigate the vanishing gradient problem that often affects deep networks.

- -

- Sigmoid: The sigmoid activation function was used in the output layer to normalize the SoC predictions between 0 and 1. This function is ideal for tasks where the output needs to be within a specific range, such as predicting SoC as a percentage.

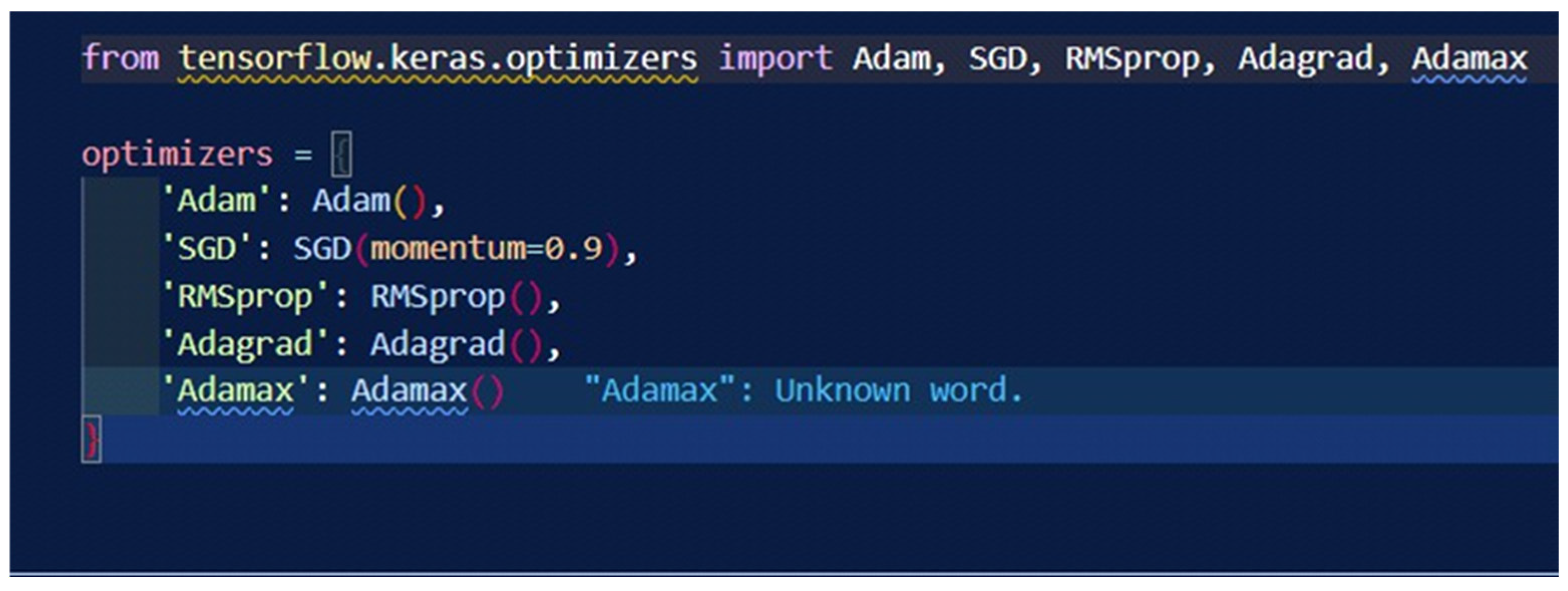

2.4.2. Learning Methods

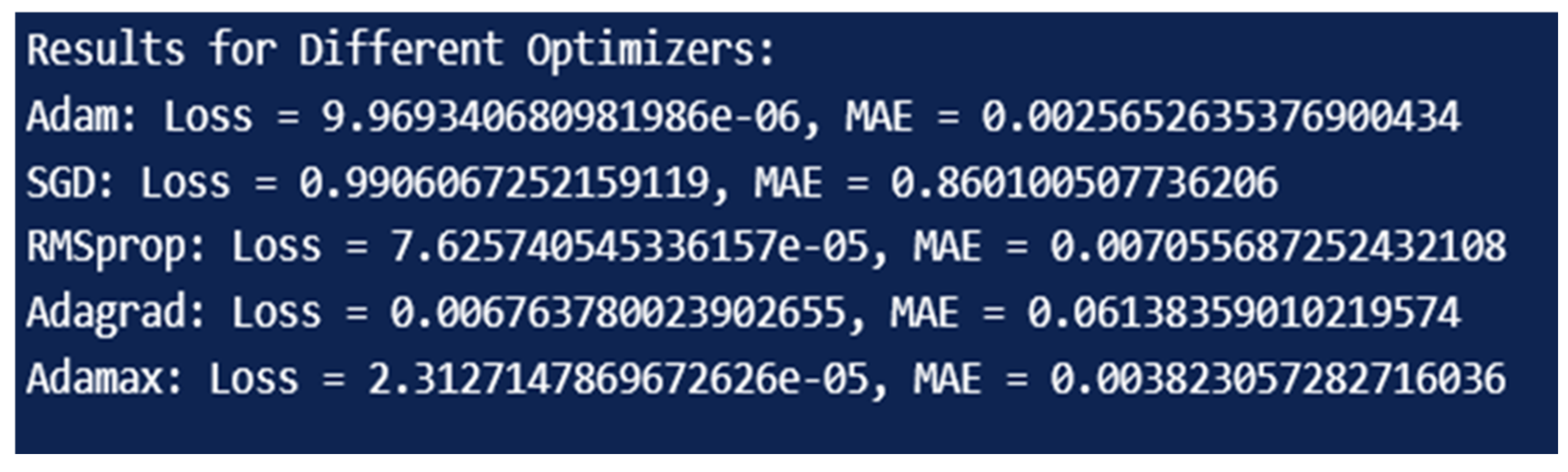

- Adam (Adaptive Moment Estimation) is an adaptive learning rate optimization algorithm that combines the benefits of Adagrad and RMSprop.

- Stochastic Gradient Descent (SGD) is a classical optimization method that updates model parameters for each training sample or batch.

- RMSprop adapts the learning rate for each parameter based on the recent magnitude of the gradients, which helps stabilize the training process.

- Adagrad adapts learning rates based on historical gradient information.

- Adamax is a variant of Adam based on the infinity norm of the gradients, offering increased stability.

2.4.3. Weight Adjustment and Back-Propagation

- Weight Adjustment: neural networks begin with random initial weights.

- Back-Propagation: this is a fundamental technique used to adjust weights.

- -

- Forward Propagation: input data are passed through the network layer by layer, producing an output at each layer.

- -

- Backward Propagation: the error between the predicted and actual values is computed and propagated backward through the network, updating weights to minimize this error.

2.4.4. Model Construction

- Data Preparation: the dataset used for model training includes four key parameters.

- -

- Voltage: the voltage of the battery (in volts).

- -

- Temperature: the temperature of the battery (in degrees Celsius).

- -

- Current: the current passing through the battery (in amperes).

- -

- Capacity: the remaining capacity of the battery (in ampere-hours).

- Data Format: the data were initially provided in .mat format and converted to CSV files for easier manipulation in Python v 3.11.5.

- Preprocessing

- -

- Normalization: the Min-Max normalization technique normalized each feature to a range between 0 and 1, ensuring that all features contribute equally during training.

- -

- Data Splitting: the dataset was divided into training (80%) and validation (20%) sets to evaluate the model’s generalization ability on unseen data.

- Model Architecture

- -

- Input Layer: the model starts with an input layer that accepts a feature vector of size 4, corresponding to the four parameters—voltage, temperature, current, and capacity.

- -

- Hidden Layers: The model includes three hidden layers, determined after experimentation using keras_tuner. The first hidden layer has 64 neurons, the second has 32 neurons, and the third has 16 neurons. The ReLU activation function was used in all hidden layers, allowing the model to learn complex, non-linear relationships in the data.

- -

- Output Layer: a single dense layer without an activation function was used as the output layer, producing a continuous prediction of SoC.

- Model Compilation

- -

- Optimizer: the Adam optimizer was selected for its ability to dynamically adjust the learning rate during training, which is particularly useful in deep learning models with variable hyperparameters.

- -

- Loss Function: The mean_squared_error function was used as the loss metric, calculating the mean of the squared differences between the predicted and actual SoC values. This function penalizes more significant errors, making it ideal for regression tasks.

- Hyperparameter Tuning

- -

- Keras Tuner and Hyperband: hyperparameter tuning was performed using keras_tuner and the Hyperband method, efficiently exploring the hyperparameter space to find the optimal configuration.

- -

- Number of Trials: up to 50 trials were conducted, testing combinations of hidden layer numbers, neuron counts per layer, and learning rates.

- -

- Selection Criterion: the best model was chosen based on the lowest validation loss (val_loss), ensuring robust performance on unseen data.

- -

- Training Details: The model was trained for 100 epochs with a batch size of 32. These settings ensured a balance between training time and convergence to a solution.

2.4.5. Embedded Deployment Considerations

- Model Optimization for Embedded Systems

- -

- Model Quantization: We reduced the precision of weights and activations from 32-bit floating-point to 8-bit integers using TensorFlow Lite post-training quantization. This significantly decreases memory usage and computation time while maintaining model accuracy.

- -

- Pruning and Weight Sharing: redundant neurons and connections were eliminated to reduce the model size, minimizing inference latency.

- -

- Efficient Memory Allocation: memory-efficient data structures were used to optimize storage, particularly for sequential input processing.

- Future Work and Deployment Prospects

- -

- Deployment on microcontrollers with ARM Cortex-M series to further minimize power consumption;

- -

- Integration into an onboard battery management system (BMS) for real-world validation;

- -

- Implementation of edge AI techniques to enhance adaptability to varying battery conditions.

3. Results and Discussion

3.1. Tests and Results

3.1.1. Model Performance

- -

- Mean Squared Error (MSE): 0.0023, or a percentage of 0.23%.

- -

- Mean Absolute Error (MAE): 0.0043, or a percentage of 0.43%

3.1.2. User Interaction

- Functional Testing: Due to the limited data availability, the application was tested once using an Excel file containing battery data. This test validated that all interactions, from file upload to SoC prediction, functioned correctly.

- Result Display: the SoC tape proved to be an effective visual tool for displaying the SoC prediction, offering immediate and user-friendly feedback.

3.1.3. Summary of Results

3.1.4. Challenges and Solutions

- -

- Hyperparameter Tuning: ensuring maximum model accuracy required iterative optimization using tools like keras_tuner.

- -

- Model Integration: the smooth integration of the predictive model with the user interface was achieved through continuous validation and iterative refinement.

3.2. Result Analysis

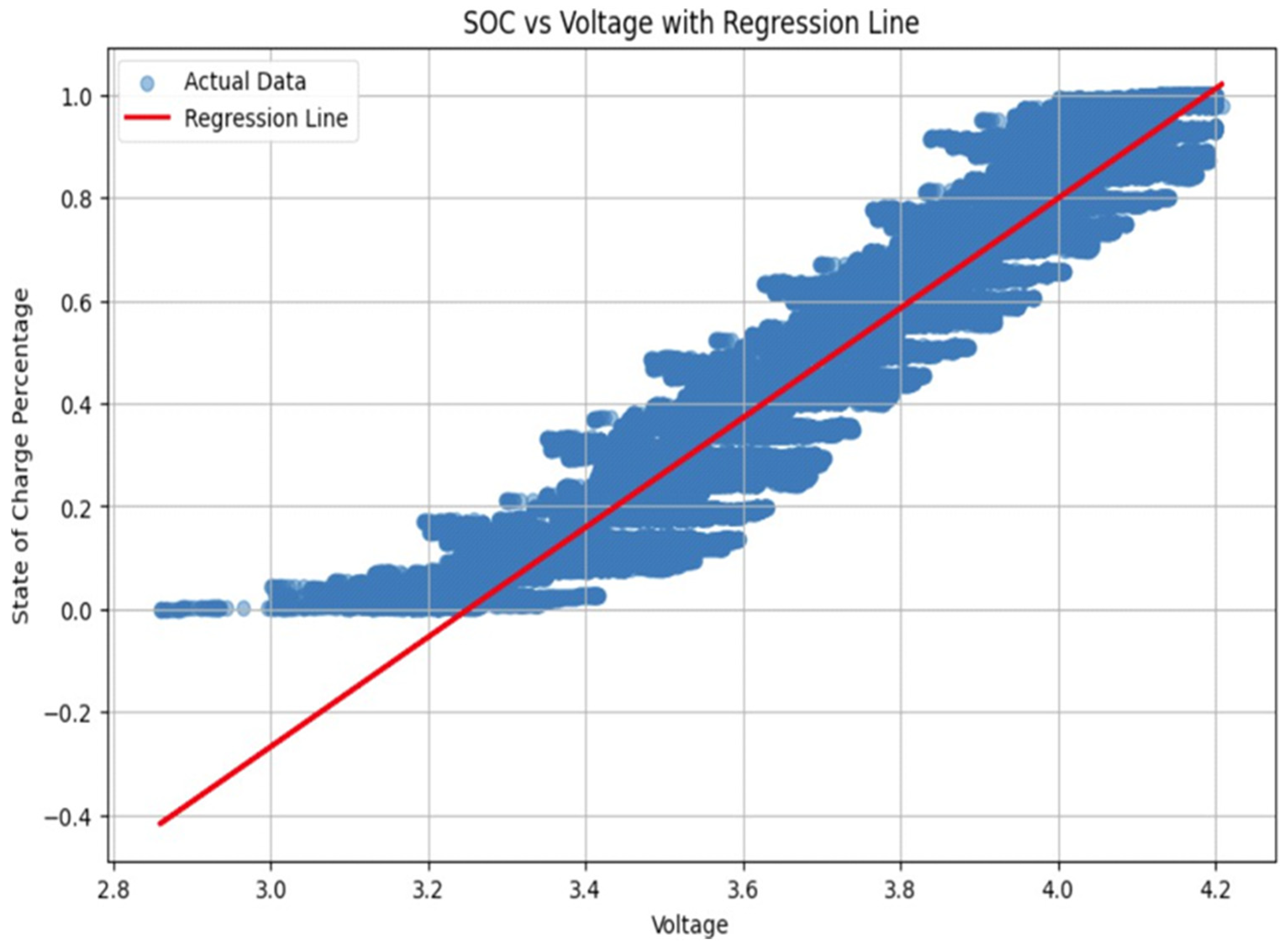

3.2.1. Regression Curves

- X-Axis (Voltage): this axis represents battery voltage in volts.

- Y-Axis (SoC): this axis represents SoC as a percentage.

- Blue Data Points: these points reflect actual battery performance data, showing a general increase in SoC with voltage despite some dispersion.

- Red Regression Line: this line represents the linear regression model, defined by the equation

- Slope: the positive slope indicates a direct relationship between voltage and SoC.

- Intercept: the intercept at −3.46 provides the baseline SoC when voltage is zero, though it is not practically meaningful.

3.2.2. Learning Curves

- X-Axis (Epochs): this axis represents the number of training iterations.

- Y-Axis (Loss): this axis represents the Mean Squared Error (MSE).

- Training Loss (Blue Line): the rapid decrease to near-zero levels within five epochs indicates fast convergence.

- Validation Loss (Orange Line): this mirrors training loss and stabilizes near zero, indicating strong generalization with no overfitting.

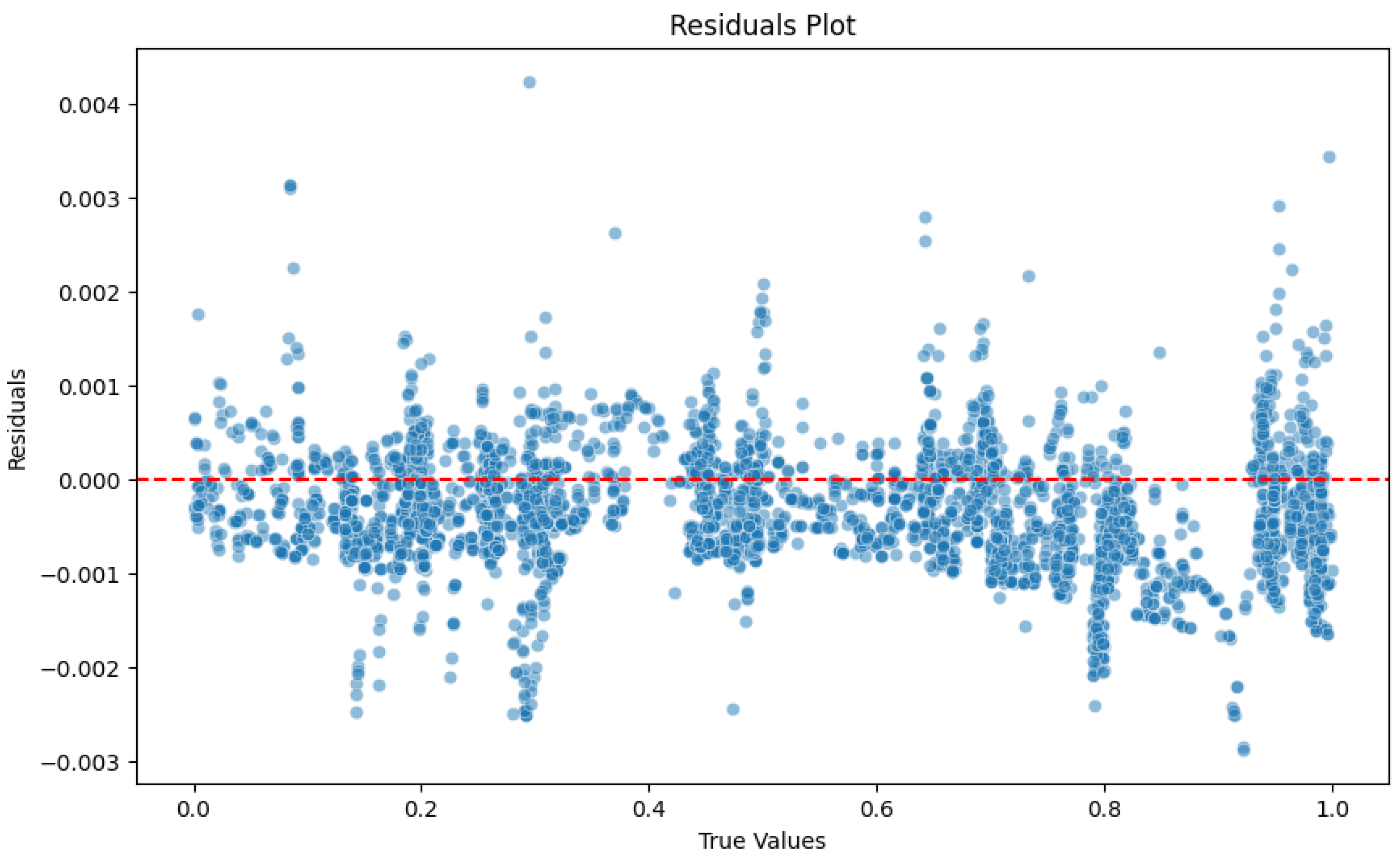

3.2.3. Residual Analysis

- X-Axis (Iterations): this axis represents actual SoC values (%).

- Y-Axis (Residuals): this axis represents prediction errors.

- Red Dotted Line (y = 0): this line represents perfect predictions.

- Dispersion: residuals are evenly distributed around zero, with consistent variance, suggesting no systematic bias.

- Residual Homogeneity: consistent residual dispersion indicates uniform model performance across all true value ranges.

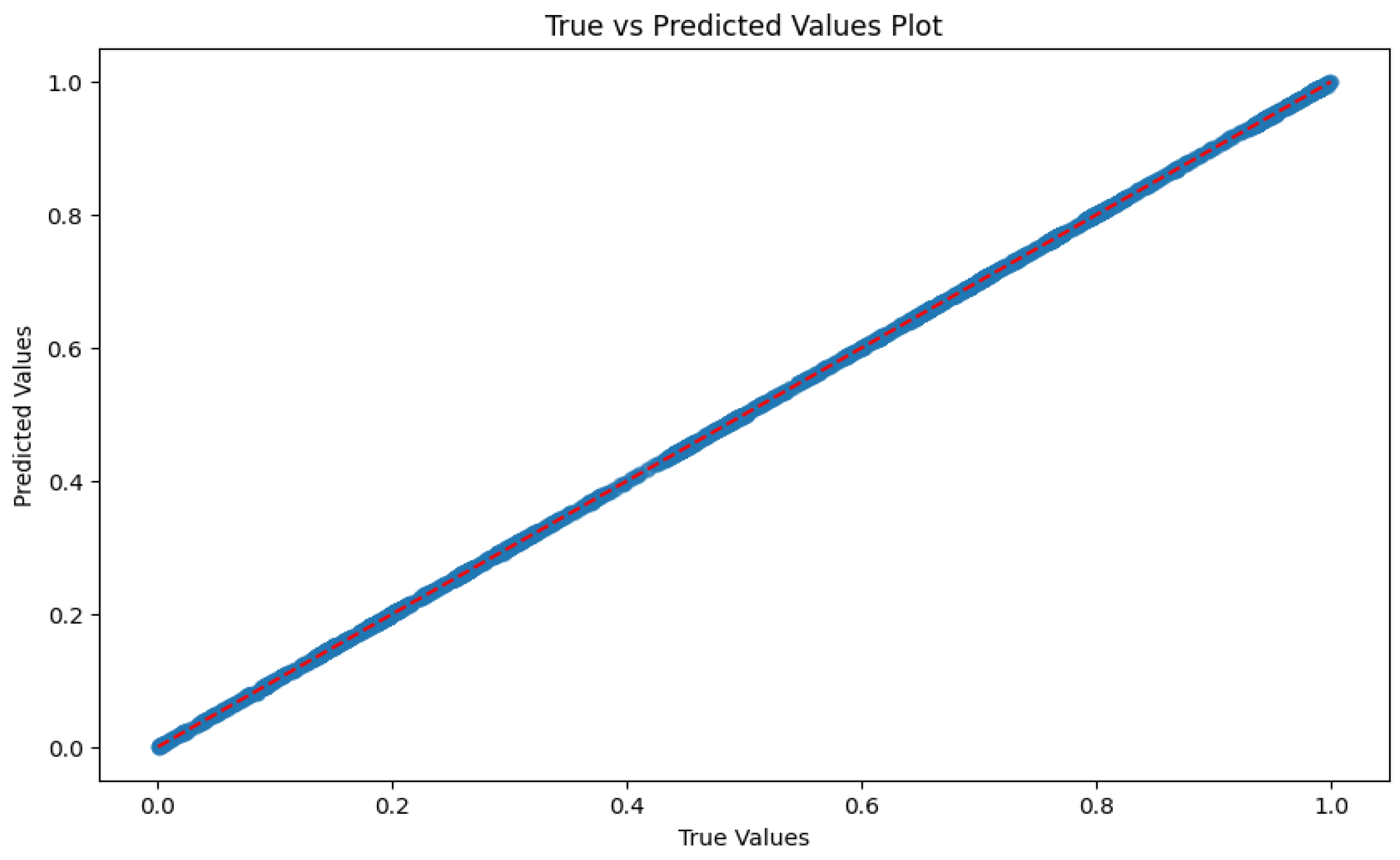

3.2.4. Real vs. Predicted Values

- X-Axis (True Values): this axis represents actual SoC values (%).

- Y-Axis (Predicted Values): this axis represents model-predicted SoC (%).

- Red Dotted Line (y = x): this line represents perfect agreement.

- Dispersion Points: the tight clustering of points around the red line is evident.

3.2.5. Comparison of Results with Existing Models

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Das, P.K. Battery Management in Electric Vehicles—Current Status and Future Trends. Batteries 2024, 10, 174. [Google Scholar] [CrossRef]

- Ghani, F.; An, K.; Lee, D. A Review on Design Parameters for the Full-Cell Lithium-Ion Batteries. Batteries 2024, 10, 340. [Google Scholar] [CrossRef]

- Adnan, M. The Future of Energy Storage: Advancements and Roadmaps for Lithium-Ion Batteries. Int. J. Mol. Sci. 2023, 24, 7457. [Google Scholar] [CrossRef] [PubMed]

- Lundberg, S.; Lee, S.-I. A Unified Approach to Interpreting Model Predictions. arXiv 2017, arXiv:1705.07874. [Google Scholar] [CrossRef]

- Xu, K.; Ba, J.L.; Kiros, R.; Cho, K.; Courville, A.; Salakhutdinov, R.; Zemel, R.S.; Bengio, Y. Show, Attend and Tell: Neural Image Caption Generation with Visual Attention. In Proceedings of the ICML’15: Proceedings of the 32nd International Conference on Machine Learning, Lille, France, 6–11 July 2015; pp. 2048–2055. Available online: https://arxiv.org/abs/1502.03044 (accessed on 29 January 2025).

- Meng, D.; Weng, J.; Wang, J. Experimental Investigation on Thermal Runaway of Lithium-Ion Batteries under Low Pressure and Low Temperature. Batteries 2024, 10, 243. [Google Scholar] [CrossRef]

- Sorensen, A.; Utgikar, V.; Belt, J. A Study of Thermal Runaway Mechanisms in Lithium-Ion Batteries and Predictive Numerical Modeling Techniques. Batteries 2024, 10, 116. [Google Scholar] [CrossRef]

- Sorouri, H.; Oshnoei, A.; Che, Y.; Teodorescu, R. A Comprehensive Review of Hybrid Battery State of Charge Estimation: Exploring Physics-Aware AI-Based Approaches. J. Energy Storage 2024, 100, 113604. [Google Scholar] [CrossRef]

- Zhao, F.; Guo, Y.; Chen, B. A Review of Lithium-Ion Battery State of Charge Estimation Methods Based on Machine Learning. World Electr. Veh. J. 2024, 15, 131. [Google Scholar] [CrossRef]

- Movassagh, K.; Raihan, A.; Balasingam, B.; Pattipati, K. A Critical Look at Coulomb Counting Approach for State of Charge Estimation in Batteries. Energies 2021, 14, 4074. [Google Scholar] [CrossRef]

- Errifai, N.; Rachid, A.; Khamlichi, S.; Saidi, E.; Mortabit, I.; El Fadil, H.; Abbou, A. Combined Coulomb-Counting and Open-Circuit Voltage Methods for State of Charge Estimation of Li-Ion Batteries. In Automatic Control and Emerging Technologies; ACET 2023; Lecture Notes in Electrical Engineering; El Fadil, H., Zhang, W., Eds.; Springer: Singapore, 2024; Volume 1141. [Google Scholar] [CrossRef]

- Bonfitto, A.; Feraco, S.; Tonoli, A.; Amati, N.; Monti, F. Estimation Accuracy and Computational Cost Analysis of Artificial Neural Networks for State of Charge Estimation in Lithium Batteries. Batteries 2019, 5, 47. [Google Scholar] [CrossRef]

- Zhang, D.; Zhong, C.; Xu, P.; Tian, Y. Deep Learning in the State of Charge Estimation for Li-Ion Batteries of Electric Vehicles: A Review. Machines 2022, 10, 912. [Google Scholar] [CrossRef]

- Lin, C.; Xu, J.; Jiang, D.; Hou, J.; Liang, Y.; Zou, Z.; Mei, X. Multi-Model Ensemble Learning for Battery State-of-Health Estimation: Recent Advances and Perspectives. J. Energy Chem. 2025, 100, 739–759. [Google Scholar] [CrossRef]

- Lehmam, O.; El Fallah, S.; Kharbach, J.; Rezzouk, A.; Ouazzani Jamil, M. State of Charge Estimation of Lithium-Ion Batteries Using Extended Kalman Filter and Multi-Layer Perceptron Neural Network. In Artificial Intelligence and Industrial Applications; Springer: Cham, Switzerland, 2023; pp. 59–72. [Google Scholar] [CrossRef]

- Tamilselvi, S.; Gunasundari, S.; Karuppiah, N.; Razak RK, A.; Madhusudan, S.; Nagarajan, V.M.; Sathish, T.; Shamim, M.Z.M.; Saleel, C.A.; Afzal, A. A Review on Battery Modelling Techniques. Sustainability 2021, 13, 10042. [Google Scholar] [CrossRef]

- Graham, J.; Wade, W. Reducing Greenhouse Emissions from Light-Duty Vehicles: Supply-Chain and Cost-Effectiveness Analyses Suggest a Near-Term Role for Hybrids. SAE J. STEEP 2024, 5, 151–168. [Google Scholar] [CrossRef]

- Rudner, T.G.J.; Toner, H. Key Concepts in AI Safety: Interpretability in Machine Learning. CSET Issue Brief 2021, 1–8. [Google Scholar] [CrossRef]

- Benallal, A.; Cheggaga, N.; Ilinca, A.; Tchoketch-Kebir, S.; Ait Hammouda, C.; Barka, N. Bayesian Inference-Based Energy Management Strategy for Techno-Economic Optimization of a Hybrid Microgrid. Energies 2024, 17, 114. [Google Scholar] [CrossRef]

- Pau, D.P.; Aniballi, A. Tiny Machine Learning Battery State-of-Charge Estimation Hardware Accelerated. Appl. Sci. 2024, 14, 6240. [Google Scholar] [CrossRef]

- Giazitzis, S.; Sakwa, M.; Leva, S.; Ogliari, E.; Badha, S.; Rosetti, F. A Case Study of a Tiny Machine Learning Application for Battery State-of-Charge Estimation. Electronics 2024, 13, 1964. [Google Scholar] [CrossRef]

- Bin Kaleem, M.; Zhou, Y.; Jiang, F.; Liu, Z.; Li, H. Fault detection for Li-ion batteries of electric vehicles with segmented regression method. Sci. Rep. 2024, 14, 31922. [Google Scholar] [CrossRef]

- Omojola, A.F.; Ilabija, C.O.; Onyeka, C.I.; Ishiwu, J.I.; Olaleye, T.G.; Ozoemena, I.J.; Nzereogu, P.U. Artificial Intelligence-Driven Strategies for Advancing Lithium-Ion Battery Performance and Safety. Int. J. Adv. Eng. Manag. 2024, 6, 452–484. [Google Scholar] [CrossRef]

- Liu, S.; Zhang, G.; Wang, C. Challenges and Innovations of Lithium-Ion Battery Thermal Management Under Extreme Conditions: A Review. ASME. J. Heat Mass Transfer. 2023, 145, 080801. [Google Scholar] [CrossRef]

- Ortiz, Y.; Arévalo, P.; Peña, D.; Jurado, F. Recent Advances in Thermal Management Strategies for Lithium-Ion Batteries: A Comprehensive Review. Batteries 2024, 10, 83. [Google Scholar] [CrossRef]

- Llamas-Orozco, J.A.; Meng, F.; Walker, G.S.; Abdul-Manan, A.F.N.; MacLean, H.L.; Posen, I.D.; McKechnie, J. Estimating the environmental impacts of global lithium-ion battery supply chain: A temporal, geographical, and technological perspective. PNAS Nexus 2023, 2, pgad361. [Google Scholar] [CrossRef]

- Machín, A.; Morant, C.; Márquez, F. Advancements and Challenges in Solid-State Battery Technology: An In-Depth Review of Solid Electrolytes and Anode Innovations. Batteries 2024, 10, 29. [Google Scholar] [CrossRef]

- Sarker, I.H. Machine Learning: Algorithms, Real-World Applications and Research Directions. SN Comput. Sci. 2021, 2, 160. [Google Scholar] [CrossRef]

- Kollmeyer, P.; Vidal, C.; Naguib, M.; Skells, M. LG 18650HG2 Li-ion Battery Data and Example Deep Neural Network xEV SOC Estimator Script. Mendeley Data 2020. [Google Scholar] [CrossRef]

- Editorial Team. LG HG2 Battery Review 18650 Test 20A 3000mAh Part 1. Batteries18650.com. 2016. Available online: https://www.batteries18650.com/2016/05/lg-hg2-review-18650-battery-test.html (accessed on 2 March 2025).

- Goumopoulos, C. A High Precision, Wireless Temperature Measurement System for Pervasive Computing Applications. Sensors 2018, 18, 3445. [Google Scholar] [CrossRef]

- Taye, M.M. Theoretical Understanding of Convolutional Neural Network: Concepts, Architectures, Applications, Future Directions. Computation 2023, 11, 52. [Google Scholar] [CrossRef]

- Cheggaga, N.; Benallal, A.; Tchoketch Kebir, S. A New Neural Networks Approach Used to Improve Wind Speed Time Series Forecasting. Alger. J. Renew. Energy Sustain. Dev. 2021, 3, 151–156. [Google Scholar] [CrossRef]

- Cervellieri, A. A Feed-Forward Back-Propagation Neural Network Approach for Integration of Electric Vehicles into Vehicle-to-Grid (V2G) to Predict State of Charge for Lithium-Ion Batteries. Energies 2024, 17, 6107. [Google Scholar] [CrossRef]

- Khalid, A.; Sundararajan, A.; Acharya, I.; Sarwat, A.I. Prediction of Li-Ion Battery State of Charge Using Multilayer Perceptron and Long Short-Term Memory Models. In Proceedings of the 2019 IEEE Transportation Electrification Conference and Expo (ITEC), Detroit, MI, USA, 19–21 June 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Zhou, Y.; Wang, S.; Xie, Y.; Feng, R.; Fernandez, C. An Enhanced Bidirectional Long Short Term Memory-Multilayer Perceptron Hybrid Model for Lithium-Ion Battery State of Charge Estimation at Multi-Temperature Ranges. 2024. [CrossRef]

- Yalçın, O.G. Convolutional Neural Networks. In Applied Neural Networks with TensorFlow 2; Apress: Berkeley, CA, USA, 2021. [Google Scholar] [CrossRef]

- Babu, P.S.; Indragandhi, V.; Vedhanayaki, S. Enhanced SOC estimation of lithium ion batteries with RealTime data using machine learning algorithms. Sci. Rep. 2024, 14, 16036. [Google Scholar] [CrossRef]

- Jafari, S.; Byun, Y.C. Efficient state of charge estimation in electric vehicles batteries based on the extra tree regressor: A data-driven approach. Heliyon 2024, 10, e25949. [Google Scholar] [CrossRef] [PubMed]

- Sreekumar, A.V.; Lekshmi, R.R. Comparative Study of Data Driven Methods for State of Charge Estimation of Li-ion Battery. In Proceedings of the 2023 2nd International Conference on Paradigm Shifts in Communications Embedded Systems, Machine Learning and Signal Processing (PCEMS), Nagpur, India, 5–6 April 2023; pp. 1–6. [Google Scholar] [CrossRef]

- RamPrakash, S.; Sivraj, P. Performance Comparison of FCN, LSTM and GRU for State of Charge Estimation. In Proceedings of the 2022 3rd International Conference on Smart Electronics and Communication (ICOSEC), Trichy, India, 20–22 October 2022; pp. 47–52. [Google Scholar] [CrossRef]

- Hannan, M.A.; How, D.N.T.; Lipu, M.S.H.; Mansor, M.; Ker, P.J.; Dong, Z.Y.; Sahari, K.S.M.; Tiong, S.K.; Muttaqi, K.M.; Mahlia, T.M.I.; et al. Deep learning approach towards accurate state of charge estimation for lithium-ion batteries using self-supervised transformer model. Sci. Rep. 2021, 11, 19541. [Google Scholar] [CrossRef]

| Component | Description | Specifications |

|---|---|---|

| Battery | LG 18650HG2 Li-Ion | 3000 mAh, 3.6 V |

| Current Sensor | XYZ Model | Accuracy: ±0.1% |

| Voltage Sensor | ABC Model | Range: 0–5 V |

| Data Acquisition System | DEF System | Sampling Rate: 1000 Hz |

| Specifications | Value | Unit |

|---|---|---|

| Nominal Capacity | 3000 | mAh |

| Nominal Voltage | 3.6 | V |

| Chemistry | LiNiMnCoO2 | - |

| Maximum Charge Rate | 4.2 | A |

| Maximum Discharge Rate | 20 | A |

| Operating Temperature Range | −20 to 75 | °C |

| Sensor Type | Model | Measurement Range | Accuracy |

|---|---|---|---|

| Current Sensor | XYZ-100 | 0–100 A | ±0.1% |

| Voltage Sensor | ABC-50 | 0–5 V | ±0.05% |

| Temperature Sensor | LM35 | −55 °C to 150 °C | ±0.2 °C |

| Feature | Description | Units |

|---|---|---|

| Voltage | Battery Terminal Voltage | Volts (V) |

| Current | Battery Discharge–Charge Current | Amperes (A) |

| Temperature | Battery Temperature | Degrees Celsius (°C) |

| SOC | State of Charge | Percentage (%) |

| Model/Work | MAE (%) | MSE (%) | R2 | Cell Type Tested |

|---|---|---|---|---|

| Proposed LSTM model | 0.43 | 0.23 | 0.99 | LG 18650HG2 |

| Obuli et al. (GPR) [38] | - | 0.60 | - | LG 18650HG2 |

| Sadiqa et al. (ETR) [39] | 0.09 | 0.39 | 0.99 | LG 18650HG2 |

| Sreekumar and Lekshmi (XGBoost) [40] | 0.68 | 0.01 | 0.99 | LG 18650HG2 |

| RamParakash and Sivraj (GRU) [41] | 0.90 | - | - | US06, eVTOL, BMW i3 |

| Hannan et al. (Transformer) [42] | 0.44 | - | 0.99 | LG 18650HG2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Published by MDPI on behalf of the World Electric Vehicle Association. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Benallal, A.; Cheggaga, N.; Hebib, A.; Ilinca, A. LSTM-Based State-of-Charge Estimation and User Interface Development for Lithium-Ion Battery Management. World Electr. Veh. J. 2025, 16, 168. https://doi.org/10.3390/wevj16030168

Benallal A, Cheggaga N, Hebib A, Ilinca A. LSTM-Based State-of-Charge Estimation and User Interface Development for Lithium-Ion Battery Management. World Electric Vehicle Journal. 2025; 16(3):168. https://doi.org/10.3390/wevj16030168

Chicago/Turabian StyleBenallal, Abdellah, Nawal Cheggaga, Amine Hebib, and Adrian Ilinca. 2025. "LSTM-Based State-of-Charge Estimation and User Interface Development for Lithium-Ion Battery Management" World Electric Vehicle Journal 16, no. 3: 168. https://doi.org/10.3390/wevj16030168

APA StyleBenallal, A., Cheggaga, N., Hebib, A., & Ilinca, A. (2025). LSTM-Based State-of-Charge Estimation and User Interface Development for Lithium-Ion Battery Management. World Electric Vehicle Journal, 16(3), 168. https://doi.org/10.3390/wevj16030168