Modeling and Technical-Economic Analysis of a Hydrogen Transport Network for France

Abstract

1. Introduction

- What will be the total demand for hydrogen in France in 2035 for the road transport sector, considering that only car users who drive long distances (more than 20,000 km/year) will switch to fuel cell electrical vehicles?

- Will the energy supply of wind origin be available for the production of green hydrogen for road transport?

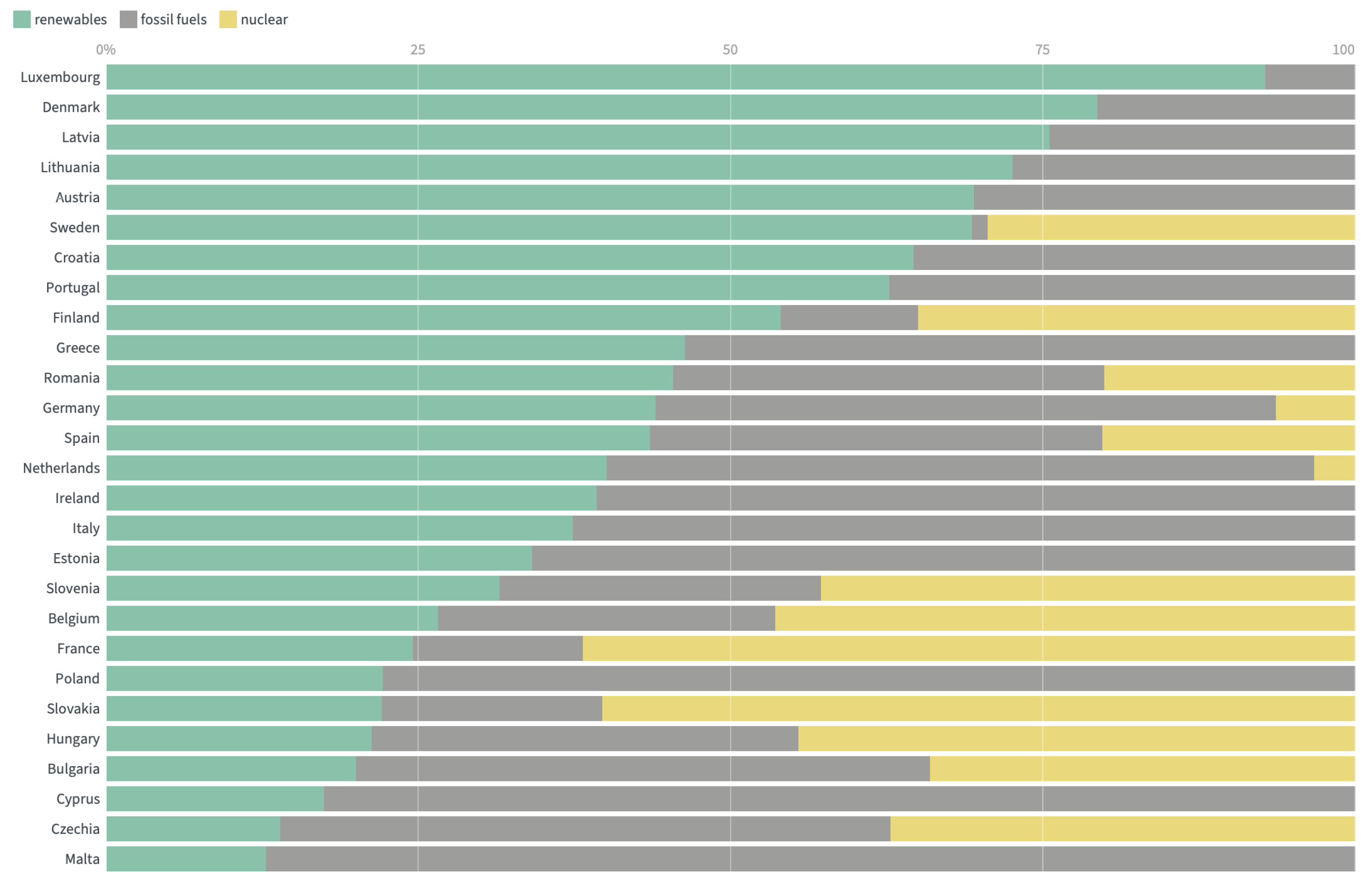

- Will the energy supply from nuclear power plants be available for the production of hydrogen with low-carbon emission?

- What is the cost of the considered hydrogen transport network?

- Is centralized or decentralized hydrogen production better economically?

2. Demand and Supply

2.1. Demand of Hydrogen

- The proportions of drivers driving more than 20,000 km per year are currently well known by region in France. It is assumed that these proportions will remain the same in 2035 (see Table 1).

- It is assumed that it is necessary to have 1 kg of hydrogen to travel 100 km for a fuel cell electrical vehicle (see Maruta [12]).

- It is necessary to have 60.9 kWh of electricity, which includes the following (see Pierre [13]):

- 56 kWh of electricity per kg of H2 for electrolysis of water;

- 4.9 kWh of electricity per kg of H2 to compress at 900 bars (necessary because it needs 700 bars in the car).

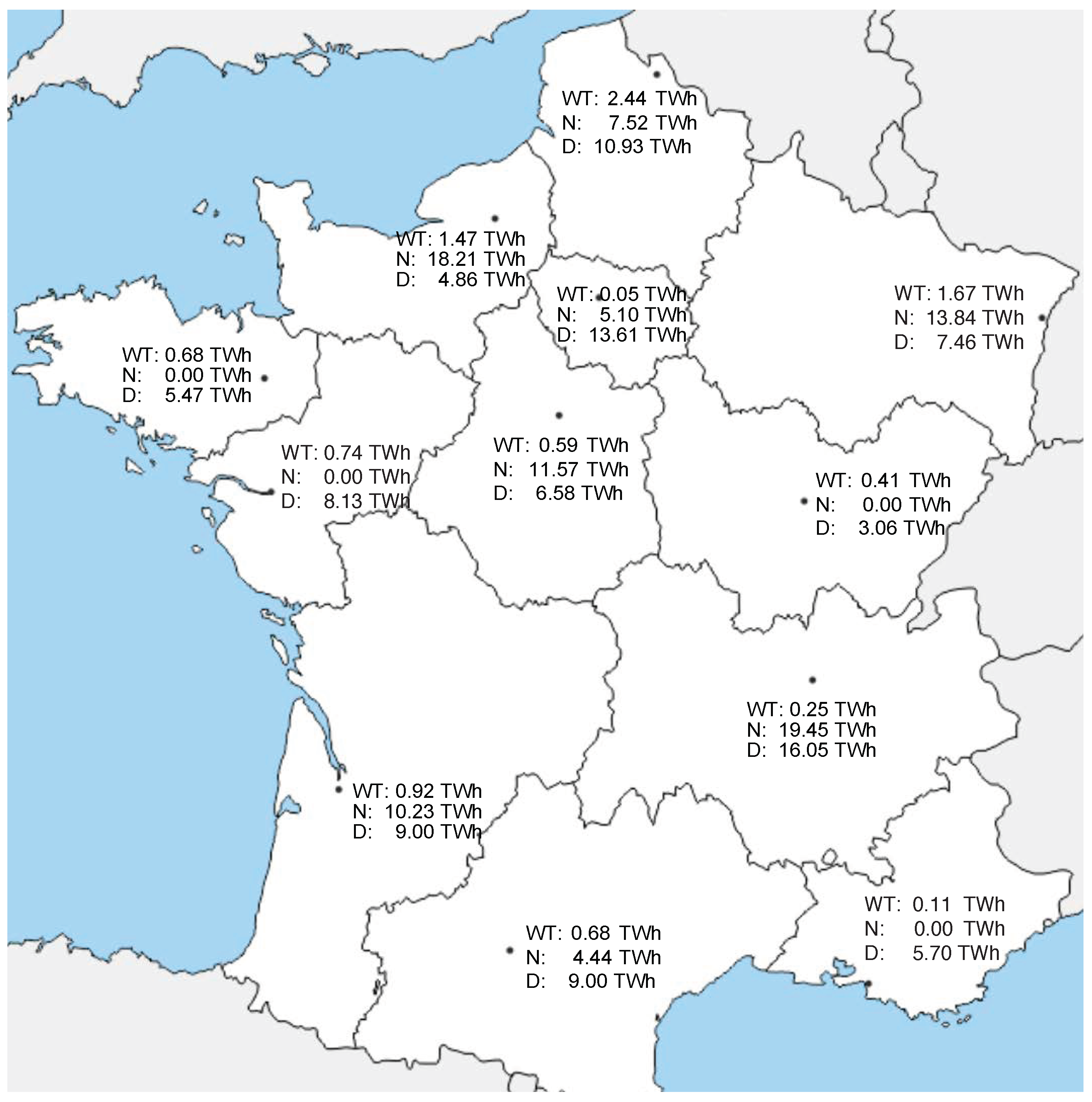

2.2. Wind Electricity Surplus for Hydrogen

- Tlili et al. [19] determined that 7.9 TWh per year was produced in surplus by renewable energies in France in 2017. In 2017, France produced 84.26 TWh of electrical energy, thanks to these renewable sources. Therefore, a good estimate of the percentage of renewable energy allocable to hydrogen production is 9.38%. We assume that this factor will be used and applied only to wind energy in our case.

2.3. Surplus Nuclear Electricity for Hydrogen

- The efficiency of nuclear plants, namely, the average production divided by the nominal power, is 85%.

- The annual production of nuclear plants in France in 2017 is 379.1 TWh (see Ministère du Développement Durable [20]). We know that the nominal capacity of the parks is 61.4 GW, corresponding to a theoretical maximum annual production of 553.02 TWh. The actual excess production of nuclear plants France is thus:We suppose that the same proportion will remain available in 2035.

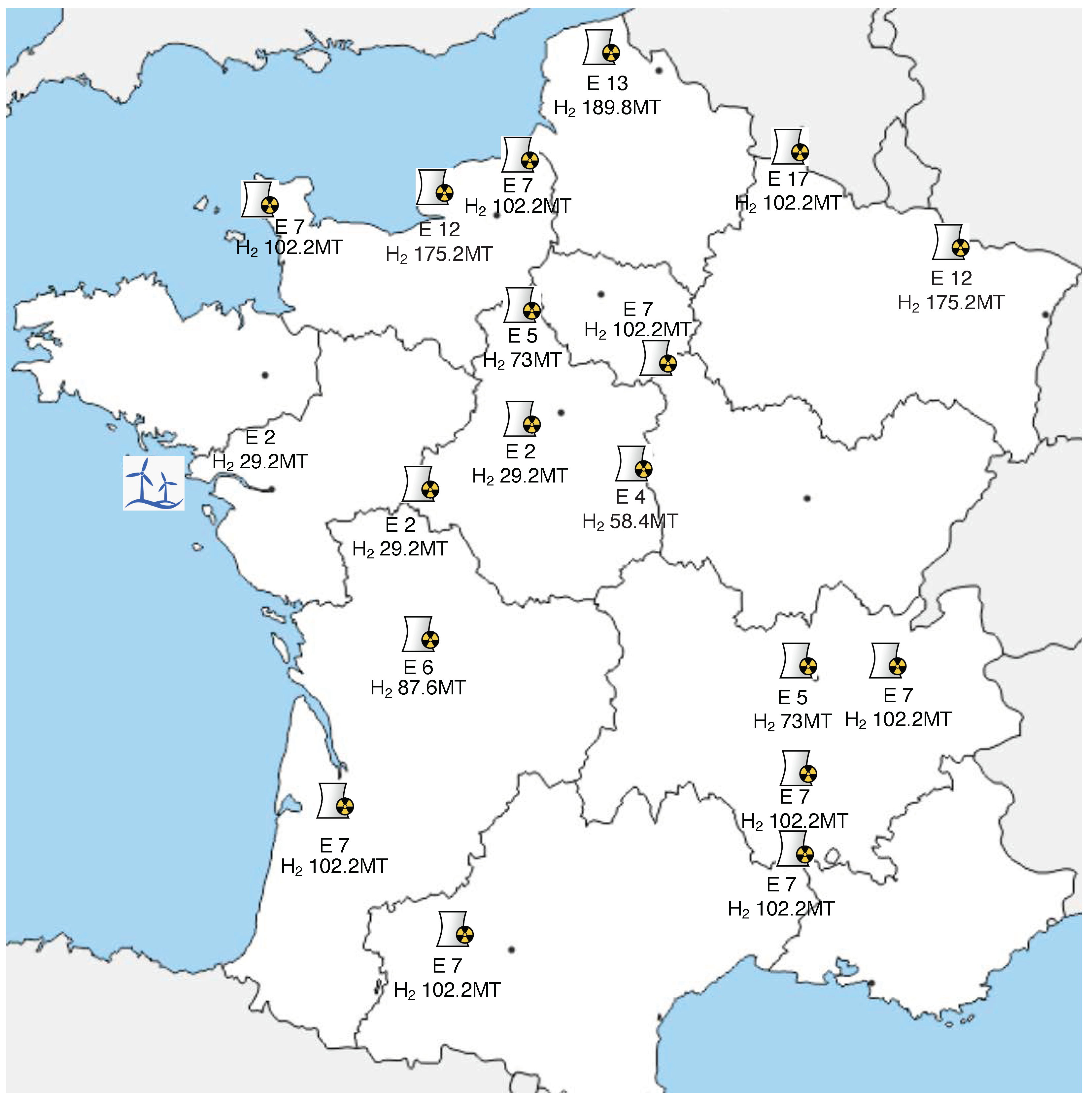

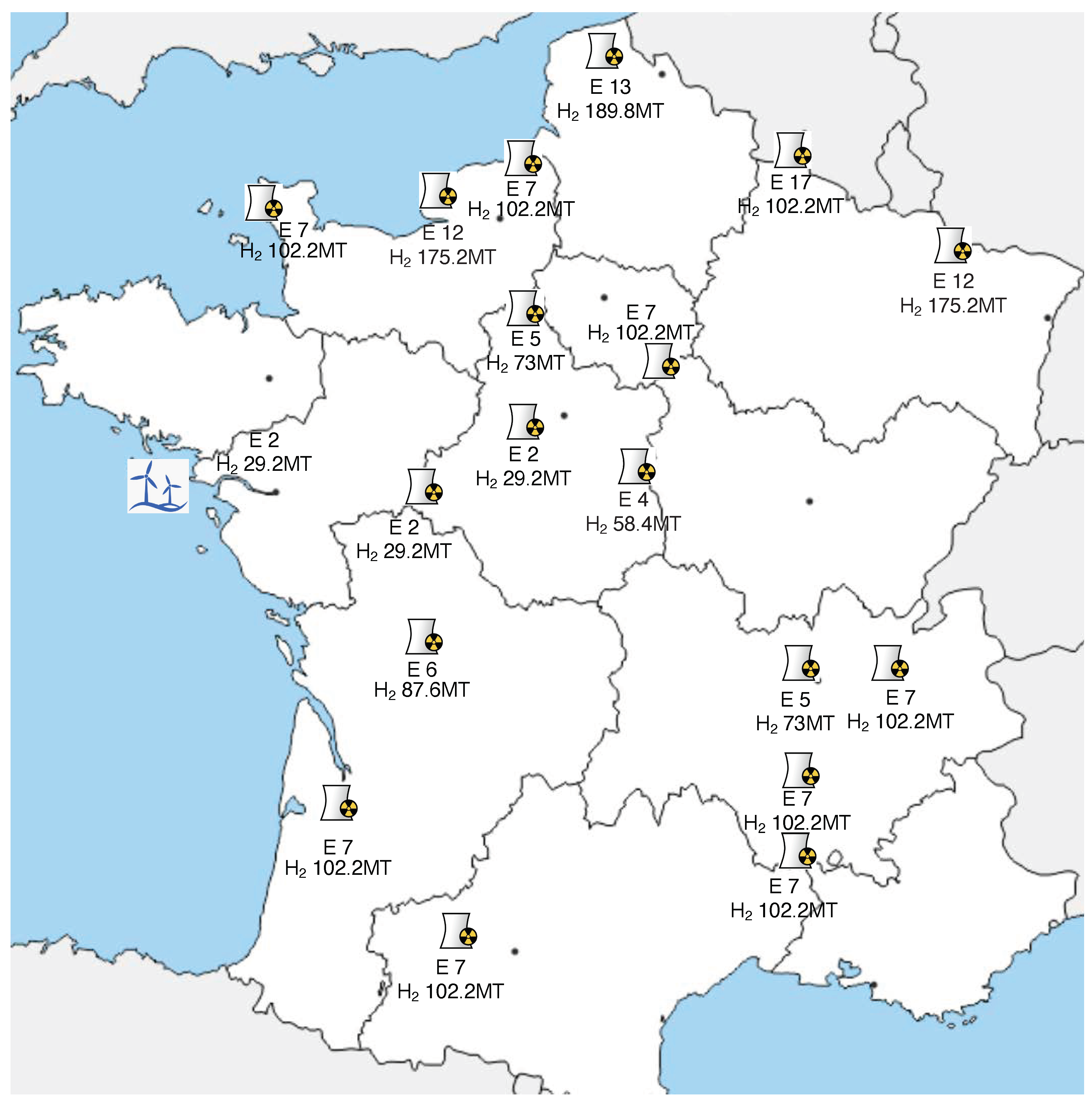

2.4. Location and Number of Electrolyzers

- For electrolyzers using nuclear electricity, we assume a location close to the source, namely, close to the nuclear plants (see Figure 2).

- For electrolyzers using onshore wind electricity, since onshore wind turbines are disseminated all over France, we assume a location close to nuclear plants, and we use the grid to transport electricity from the supply point (the wind turbine) to the production point (the electrolyzer).

- For electrolyzers using offshore wind electricity, we assume a location close to the important wind farm of Saint-Nazaire (see Figure 2).

3. Network Design

- The demand of each region is assumed to be located in the largest city of the region, thus in one point for each region.

- Hydrogen is transported by truck with hydrogen in gaseous form for distances shorter than 130 km and in liquid form for longer distances (see Reuß et al. [7]).

- The transportation cost is assumed to be proportional to the traveled distance and to the quantities of hydrogen transported.

- For each supply point, the total quantity of hydrogen for all demand regions cannot exceed the total supply of hydrogen, as follows:where is the total supply of hydrogen of e.

- For each demand point, the total quantity of hydrogen coming from all sources must satisfy the demand of the region, as follows:where is the total demand of hydrogen of the region r.

- They are, of course, also the non-negativity constraints on all variables, as follows:

4. Network Cost

- For a distance of less than 130 km, it is more advantageous in terms of costs to transport hydrogen in gaseous form.

- For a distance of more than 130 km, the liquid form is preferred.

- The initial investment for the tractor and trailer;

- The salary of drivers during the year;

- The fuel consumption of trucks;

- The cost of operating and maintaining equipment;

- The cost of French highways for trucks (class 4 vehicle).

4.1. The German Case

- They consider 15 sources of hydrogen production by water electrolysis, all located in the north of Germany.

- They consider 96,083 hydrogen recharging stations scattered throughout the country.

- The transport of hydrogen is done by trucks with H2 in gaseous form for a distance of less than 130 km and by trucks H2 in liquid form for a greater distance.

- On the one hand, a total transport price of EUR 0.73 per kilo of hydrogen transported is computed by dividing the total cost of the network by the total H2 transported per year.

- On the other hand, the average distance traveled between the supply points and the charging station is 430 km.

4.2. The Case of France

- We consider 19 sources of hydrogen production by electrolysis (located near wind turbines farm or near nuclear power plants) distributed across the different regions in France (see Figure 4).

- We consider 13 demand points, one per region situated in the biggest city of the region.

- Hydrogen is transported by trucks with H2 in gaseous form for distances less than 130 km and in liquid form for greater distances.

- On the one hand, we computed a total transport price of EUR 0.31 per kilo of hydrogen transported.

- On the other hand, we computed an average distance traveled between the supply points and the centers of the regions of 160 km.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kim, M.; Kim, J. An integrated decision support model for design and operation of a wind-based hydrogen supply system. Int. J. Hydrogen Energy 2017, 42, 3899–3915. [Google Scholar] [CrossRef]

- Al-Ghussain, L.; Ahmad, A.D.; Abubaker, A.M.; Hassan, M.A. Exploring the feasibility of green hydrogen production using excess energy from a country-scale 100% solar-wind renewable energy system. Int. J. Hydrogen Energy 2022, 47, 21613–21633. [Google Scholar] [CrossRef]

- De Wolf, D.; Smeers, Y. Comparison of battery electric vehicles and fuel cell vehicles. World Electr. Veh. J. 2023, 14, 262. [Google Scholar] [CrossRef]

- Galimova, T.; Fasihi, M.; Bogdanov, D.; Breyer, C. Impact of international transportation chains on cost of green e-hydrogen: Global cost of hydrogen and consequences for Germany and Finland. Appl. Energy 2023, 347, 121369. [Google Scholar] [CrossRef]

- André, J.; Auray, S.; Brac, J.; Wolf, D.D.; Maisonnier, G.; Ould-Sidi, M.; Simonnet, A. Design and dimensioning of hydrogen transmission pipeline networks. Eur. J. Oper. Res. 2013, 229, 239–251. [Google Scholar] [CrossRef]

- André, J.; Auray, S.; Wolf, D.D.; Ould-Sidi, M.; Simonnet, A. Time development of new hydrogen transmission. Int. J. Hydrogen Energy 2014, 39, 10323–10337. [Google Scholar] [CrossRef]

- Reuß, M.; Dimos, P.; Léon, A.; Grube, T.; Robinius, M.; Stolten, D. Hydrogen Road Transport Analysis in the Energy System: A Case Study for Germany through 2050. Energies 2021, 14, 3166. [Google Scholar] [CrossRef]

- Rieraa, J.A.; Lima, R.M.; Knio, O.M. A review of hydrogen production and supply chain modeling and optimization. Int. J. Hydrogen Energy 2023, 48, 1373–13755. [Google Scholar] [CrossRef]

- Akyuza, E.S.; Tellia, E.; Farsak, M. Hydrogen generation electrolyzers: Paving the way for sustainable energy. Int. J. Hydrogen Energy 2024, 81, 1338–1362. [Google Scholar] [CrossRef]

- Kato, T.; Kubota, M.; Kobayashi, N.; Suzuoki, Y. Effective utilization of by-product oxygen from electrolysis hydrogen production. Energy 2005, 30, 2580–2595. [Google Scholar] [CrossRef]

- Capgemini France, Observatoire de l’éolien, Analyse des Emplois et des Enjeux de l’éolien en France, September 2020. pp. 1–188. Available online: https://www.connaissancedesenergies.org/sites/connaissancedesenergies.org/files/pdf-actualites/obseol2020_web_light_v2.pdf (accessed on 4 February 2025).

- Maruta, A. Economics of Hydrogen for Transportation. In Hydrogen Science and Engineering: Materials, Processes, Systems and Technology; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2016; pp. 831–848. [Google Scholar]

- Pierre, S. Rendement de la Chaîne Hydrogène. Available online: https://www.connaissancedesenergies.org/sites/connaissancedesenergies.org/files/pdf-pt-vue/rendement-chaine-h2_fiche-technique-02-2020.pdf (accessed on 10 May 2024).

- Ramirez, K.; Weiss, T.; Kirk, T.; Gamage, C. Hydrogen Reality Check: Distilling Green Hydrogen’s Water Consumption. Available online: https://rmi.org/hydrogen-reality-check-distilling-green-hydrogens-water-consumption/ (accessed on 4 February 2025).

- Torregrossa, M. Hydrogène Vert: Quel Impact sur la Consommation d’eau? Available online: https://www.h2-mobile.fr/actus/non-production-hydrogene-vert-impactera-ressources-eau/ (accessed on 4 February 2025).

- Ministère de la Transition Écologique et de la cohésion des Territoires, L’eau en France: Ressource et Utilisation—Synthèse des Connaissances en 2023. Available online: https://www.statistiques.developpement-durable.gouv.fr/leau-en-france-ressource-et-utilisation-synthese-des-connaissances-en-2023 (accessed on 4 February 2025).

- Alterna Energie, Energie, Décryptage du Rendement d’une éolienne. Available online: https://www.alterna-energie.fr/blog-article/a-la-conquete-du-vent-decryptage-du-rendement-eolien-pour-une-energie-verte-maximale (accessed on 24 March 2024).

- Le Figaro, Eoliennes en Mer: Bataille de Chiffres sur la Production du Parc au Large de Saint-Nazaire. Available online: https://www.lefigaro.fr/nantes/eoliennes-en-mer-bataille-de-chiffres-sur-la-production-du-parc-au-large-de-saint-nazaire-20230317 (accessed on 24 March 2024).

- Tlili, O.; Mansilla, C.; Robinius, M.; Syranidis, K.; Reuss, M.; Linssen, J.; André, J.; Perez, Y.; Stolten, D. Role of electricity interconnections and impact of the geographical scale on the French potential of producing hydrogen via electricity surplus by 2035. Energy 2019, 172, 977–990. [Google Scholar] [CrossRef]

- Ministère du Développement Durable, Bilan Énergétique de la France Pour 2017, Données Et études Statistiques. Available online: https://www.statistiques.developpement-durable.gouv.fr/bilan-energetique-de-la-france-pour-2017 (accessed on 30 March 2024).

- Van der Meulen, S.; Grijspaardt, T.; Mars, W.; Van der Gees, W.V.; Roest-Crollius, A.; Kiel, J. Cost Figures for Freight Transport—Final Report, Netherlands Institute for Transport Policy Analysis, Zoetermeer, January 2023. pp. 1–86. Available online: https://www.kimnet.nl (accessed on 5 February 2025).

- Sophanna, S. An in Depth Comparison Between the Different Methods of Hydrogen Transportation. 11 March 2024. Available online: https://www.divigas.com/blog/transportation-of-hydrogen (accessed on 5 February 2025).

- Yang, M.; Hunger, R.; Berrettoni, S.; Sprecher, B.; Wang, B. A review of hydrogen storage and transport technologies. Clean Energy 2023, 7, 190–216. [Google Scholar] [CrossRef]

- GAMS Development Corporation. General Algebraic Modeling System (GAMS) Release 47.1.0. Fairfax, VA, USA, 2024. Available online: https://www.gams.com/download/ (accessed on 5 February 2025).

- Wang, W.; Wu, Y. Is uncertainty always bad for the performance of transportation systems? Commun. Transp. Res. 2021, 1, 100021. [Google Scholar] [CrossRef]

- Vickerman, R. The transport problem: The need for consistent policies on pricing and investment. Transp. Policy 2024, 149, 49–58. [Google Scholar] [CrossRef]

- Institut National de la Statistique et des Études Économiques, Prix Moyens Mensuels de Vente au détail en métropole-Gazole (1L). Available online: https://www.insee.fr/fr/statistiques/serie/000442588 (accessed on 8 May 2024).

- Levret, A.; Mohammadioun, B. Determination of seismic reference motion for nuclear sites in France. Eng. Geol. 1984, 20, 25–38. [Google Scholar] [CrossRef]

- Institut de Radioprotection et de Sûreté Nucléaire. Suites de l’accident nucléaire de Fukushima Daiichi en mars 2011, March 2016. pp. 1–163. Available online: https://www.irsn.fr/sites/default/files/documents/connaissances/installations_nucleaires/les-accidents-nucleaires/accident-fukushima-2011/fukushima-2016/IRSN-Fukushima-2016.pdf (accessed on 5 February 2025).

- European Council. How Is EU Electricity Produced and Sold? Available online: https://www.consilium.europa.eu/en/infographics/how-is-eu-electricity-produced-and-sold/ (accessed on 5 February 2025).

| Region | Population (Residents) | Proportion >20.000 km | 106 Km | H2 [103T] | Electricity [TWh] |

|---|---|---|---|---|---|

| Corse | 355,528 | 12% | 853 | 9 | 0.520 |

| Bourgogne-Franche-Comté | 2,791,719 | 9% | 5025 | 50 | 3.060 |

| Normandie | 3,327,077 | 12% | 7985 | 80 | 4.863 |

| Bretagne | 3,453,023 | 13% | 8978 | 90 | 5.468 |

| Provence-Alpes-Côte d’Azur | 5,198,011 | 9% | 9356 | 94 | 5.698 |

| Centre-Val de Loire | 2,573,295 | 21% | 10,808 | 108 | 6.582 |

| Grand Est | 5,568,711 | 11% | 12,251 | 123 | 7.461 |

| Pays de la Loire | 3,926,389 | 17% | 13,350 | 133 | 8.130 |

| Occitanie | 6,154,729 | 12% | 14,771 | 148 | 8996 |

| Nouvelle-Aquitaine | 6,154,772 | 12% | 14,771 | 148 | 8.996 |

| Hauts-de-France | 5,983,823 | 15% | 17,951 | 180 | 10.932 |

| Ile-de-France | 12,419,961 | 9% | 22,356 | 224 | 13.615 |

| Auvergne-Rhône-Alpes | 8,235,923 | 16% | 26,355 | 264 | 16.050 |

| France métropolitaine | 66,142,961 | 12% | 164,812 | 1648 | 100.37 |

| Region | Onshore [TWh] | Offshore [TWh] | Total [TWh] |

|---|---|---|---|

| Hauts-de-France | 2.27 | 0.17 | 2.44 |

| Grand Est | 1.67 | 1.67 | |

| Occitanie | 0.59 | 0.09 | 0.68 |

| Bretagne | 0.47 | 0.21 | 0.68 |

| Pays de la Loire | 0.47 | 0.27 | 0.74 |

| Nouvelle-Aquitaine | 0.64 | 0.28 | 0.92 |

| PACA | 0.03 | 0.08 | 0.11 |

| Auvergne-Rhône-Alpes | 0.25 | 0.25 | |

| Bourgogne-Franche-Comté | 0.41 | 0.41 | |

| Normandie | 0.37 | 1.10 | 1.47 |

| Corse | 0.01 | 0.01 | |

| Centre-Val de Loire | 0.59 | 0.59 | |

| Ile-de-France | 0.05 | 0.05 | |

| France | 7.82 | 2.19 | 10.1 |

| Region | Surplus 2035 [TWh] | Used 2035 [TWh] |

|---|---|---|

| Hauts-de-France | 10.63 | 7.52 |

| Grand Est | 19.57 | 13.84 |

| Occitanie | 6.28 | 4.44 |

| Bretagne | 0.00 | 0.00 |

| Pays de la Loire | 0.00 | 0.00 |

| Nouvelle-Aquitaine | 14.46 | 10.23 |

| PACA | 0.00 | 0.00 |

| Auvergne-Rhône-Alpes | 27.50 | 19.45 |

| Bourgogne-Franche-Comté | 0.00 | 0.00 |

| Normandie | 25.75 | 18.21 |

| Corse | 0.00 | 0.00 |

| Centre-Val de Loire | 16.36 | 11.57 |

| Ile-de-France | 7.22 | 5.10 |

| France | 127.77 | 90.36 |

| (kT) | Rouen | Lille | Strasb. | Paris | Orléans | Bord. | Lyon | Montp. | Nantes | Rennes | Mars. | Dijon |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Flamanville | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 89.78 | 0 | 0 | |

| Paluel | 79.85 | 0 | 0 | 95.35 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Penly | 0 | 0 | 0 | 26.01 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Gravelines | 0 | 179.52 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Chooz | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Cattenom | 0 | 0 | 122.51 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 20.75 |

| Nogent | 0 | 0 | 0 | 102.2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Saint-Laurent | 0 | 0 | 0 | 0 | 29.2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Dampierre | 0 | 0 | 0 | 0 | 73 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Belleville | 0 | 0 | 0 | 0 | 5.88 | 0 | 23.02 | 0 | 0 | 0 | 0 | 29.5 |

| Chinon | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 73 | 0 | 0 | 0 |

| Civaux | 0 | 0 | 0 | 0 | 0 | 45.52 | 0 | 0 | 31.3 | 0 | 0 | 0 |

| Le Blayais | 0 | 0 | 0 | 0 | 0 | 102.2 | 0 | 0 | 0 | 0 | 0 | 0 |

| Bugey | 0 | 0 | 0 | 0 | 0 | 0 | 102.2 | 0 | 0 | 0 | 0 | 0 |

| Saint-Alban | 0 | 0 | 0 | 0 | 0 | 0 | 73 | 0 | 0 | 0 | 0 | 0 |

| Cruas | 0 | 0 | 0 | 0 | 0 | 0 | 65.33 | 0 | 0 | 0 | 36.87 | 0 |

| Tricastin | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 45.51 | 0 | 0 | 56.69 | 0 |

| Golfech | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 102.2 | 0 | 0 | 0 | 0 |

| Saint-Nazaire | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 29.2 | 0 | 0 | 0 |

| Parameter | Unit | Unitary Cost |

|---|---|---|

| Tractor investment | € | 120,000 |

| H2 gas trailer investment | € | 1,000,000 |

| Liquid H2 trailer investment | € | 860,000 |

| Average usage time | h/year | 2000 |

| Driver’s salary | €/h | 35 |

| Operation and maintenance | €/year*truck | 14,400 |

| Consumption | l/100 km | 35.5 |

| Price of diesel | € | 1.75 |

| Average speed of truck | km/h | 60 |

| Average distance | km/truck*year | 120,000 |

| Average price per km of motorway | €/km | 0.37 |

| Trailer capacity for gaseous H2 | kg | 1000 |

| Trailer capacity for liquid H2 | kg | 4300 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Published by MDPI on behalf of the World Electric Vehicle Association. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

De Wolf, D.; Magidson, C.; Sigot, J. Modeling and Technical-Economic Analysis of a Hydrogen Transport Network for France. World Electr. Veh. J. 2025, 16, 109. https://doi.org/10.3390/wevj16020109

De Wolf D, Magidson C, Sigot J. Modeling and Technical-Economic Analysis of a Hydrogen Transport Network for France. World Electric Vehicle Journal. 2025; 16(2):109. https://doi.org/10.3390/wevj16020109

Chicago/Turabian StyleDe Wolf, Daniel, Christophe Magidson, and Jules Sigot. 2025. "Modeling and Technical-Economic Analysis of a Hydrogen Transport Network for France" World Electric Vehicle Journal 16, no. 2: 109. https://doi.org/10.3390/wevj16020109

APA StyleDe Wolf, D., Magidson, C., & Sigot, J. (2025). Modeling and Technical-Economic Analysis of a Hydrogen Transport Network for France. World Electric Vehicle Journal, 16(2), 109. https://doi.org/10.3390/wevj16020109