CLAMT Shifting Strategy with Dog Clutch and Active Synchronization for Electrified Tractors

Abstract

1. Introduction

1.1. Literature Review

1.1.1. AMT-Based Shifting Control Systems

1.1.2. CVT-Based Shifting Control Systems

1.1.3. Actuation Methods for Shifting

1.2. Background

1.3. Objective

1.4. Project Scope

2. Preliminaries

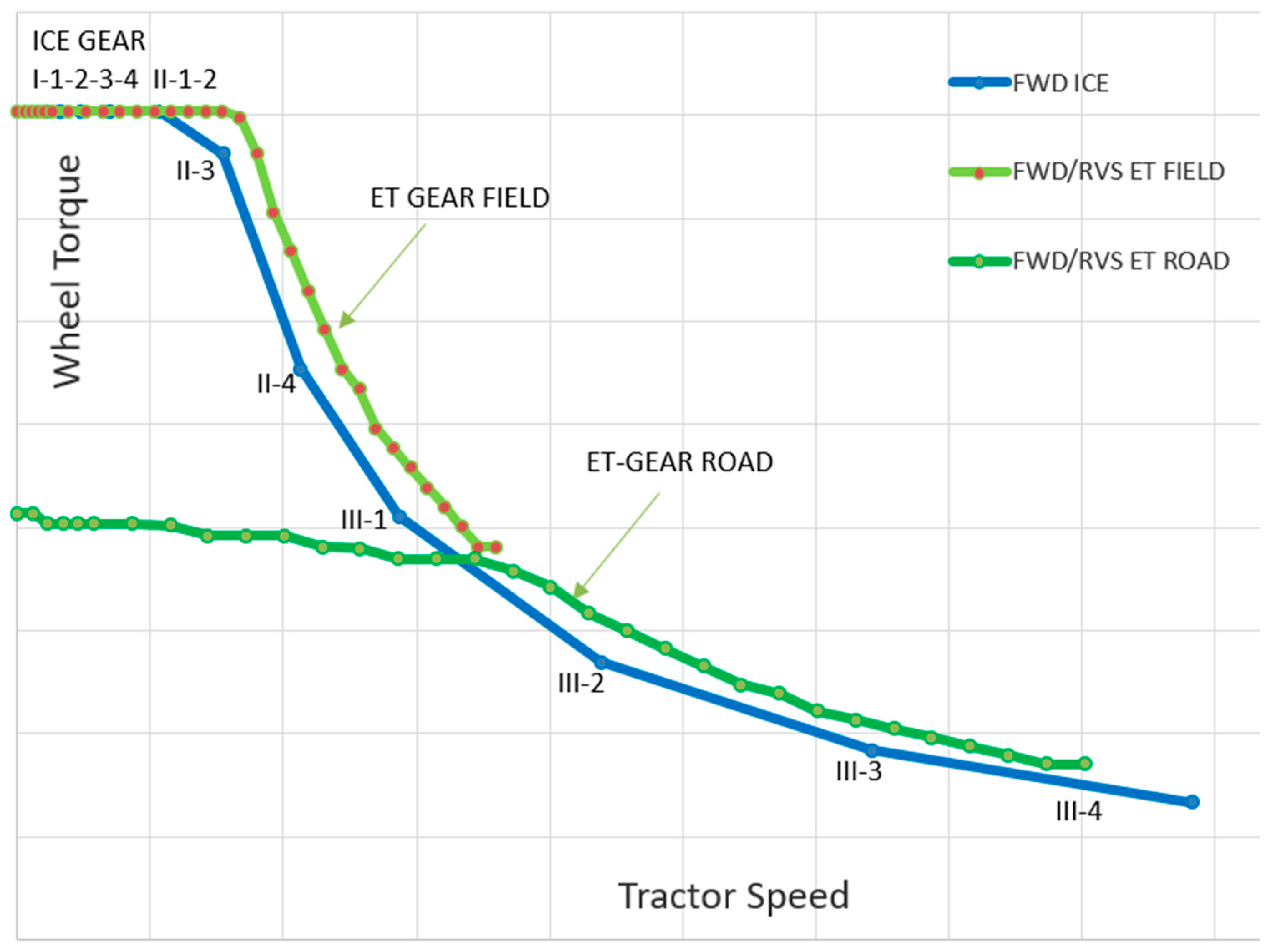

2.1. Motivation and Problem

2.2. Essential Components

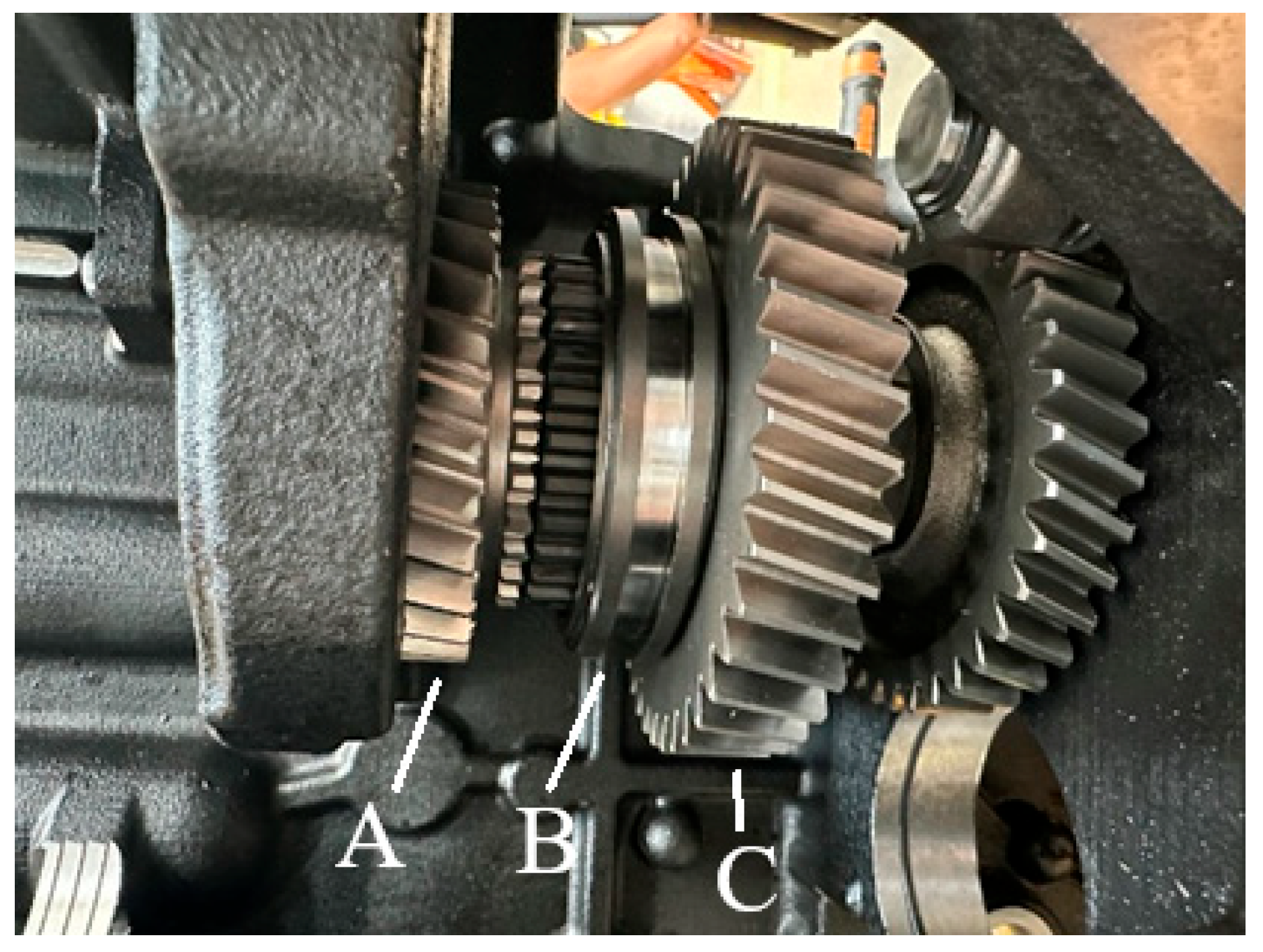

2.2.1. Mounted Dog Clutch

2.2.2. Gearbox Design

2.2.3. Proportional Valves

3. Proposed Work

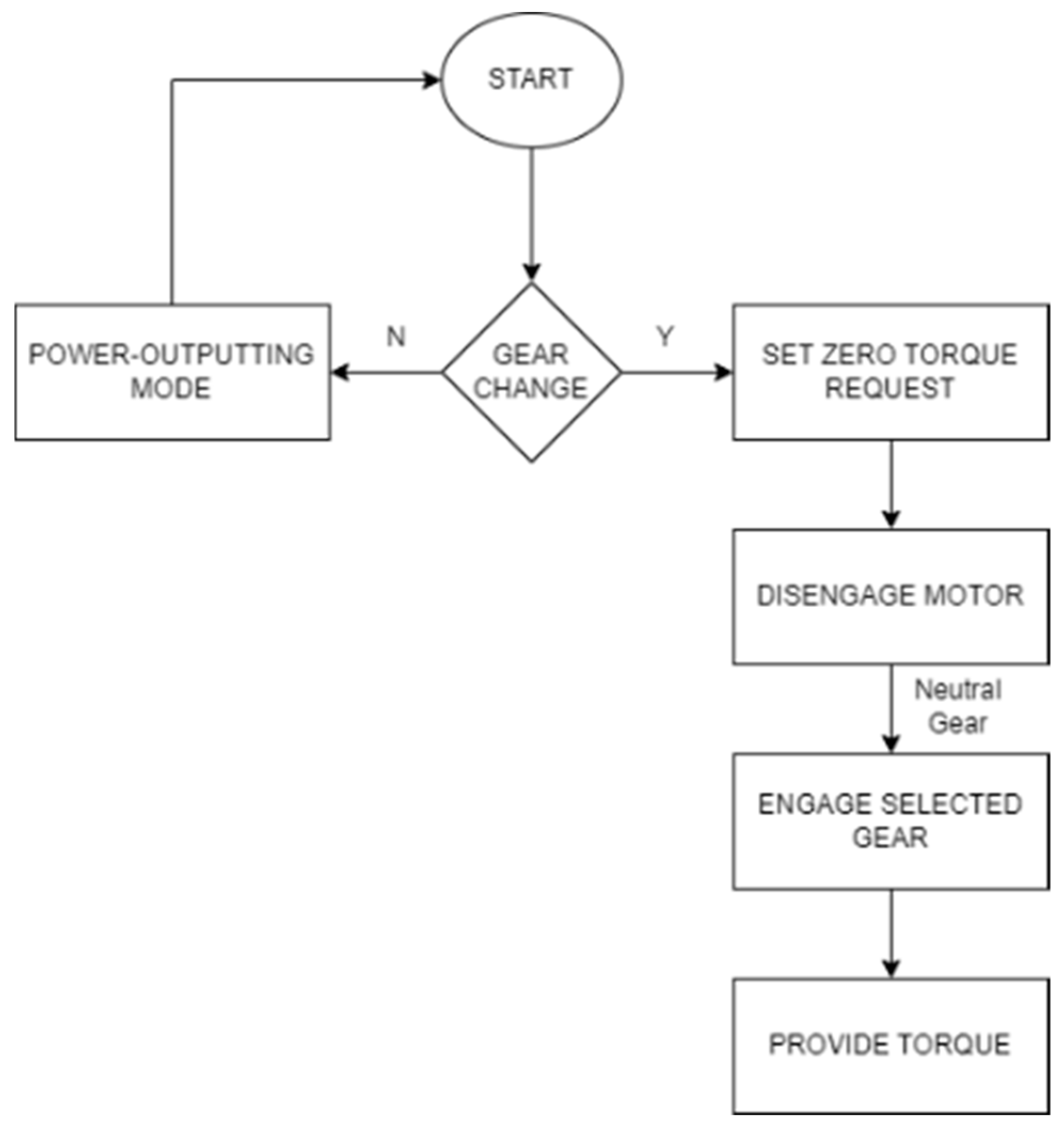

3.1. Gear-Shifting Algorithms

3.1.1. Gear-Shifting Algorithm Without Speed Synchronization

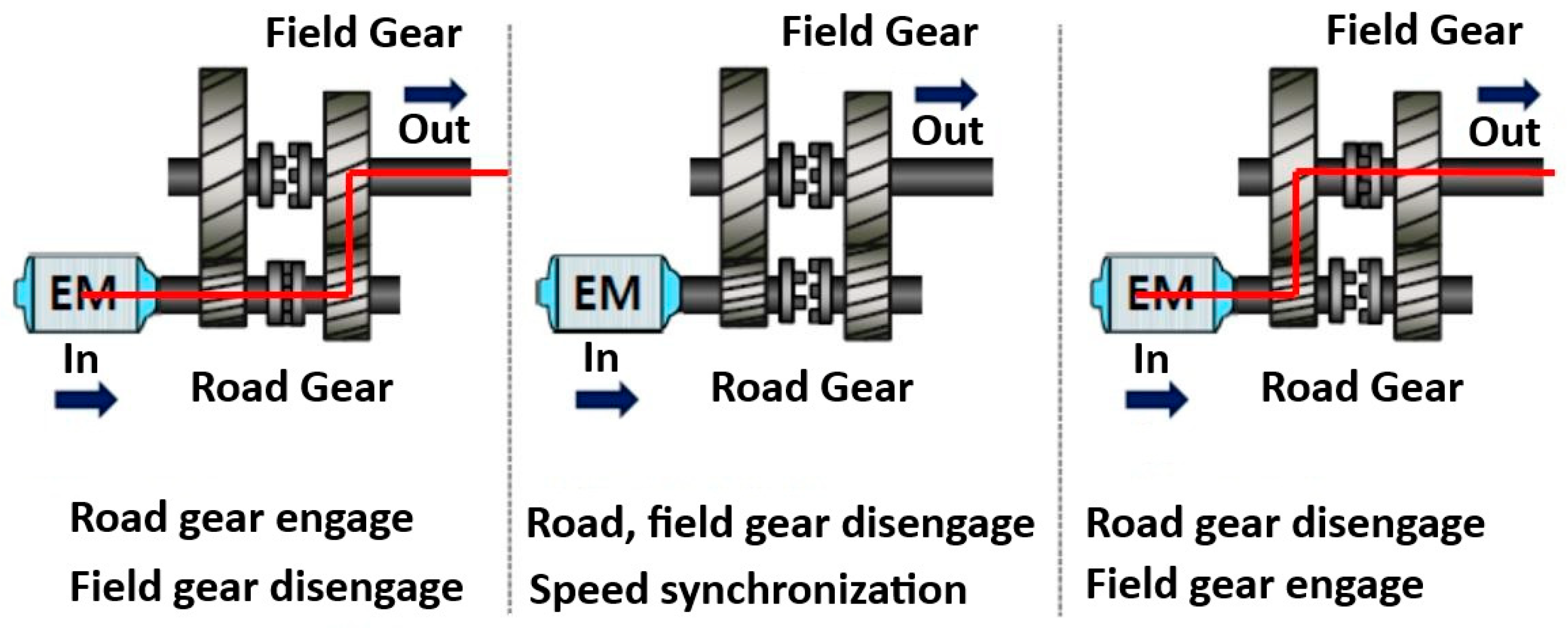

3.1.2. Gear-Shifting Algorithm with Speed Synchronization

3.2. System Architecture

3.3. Shifting Strategy

4. Experimentation

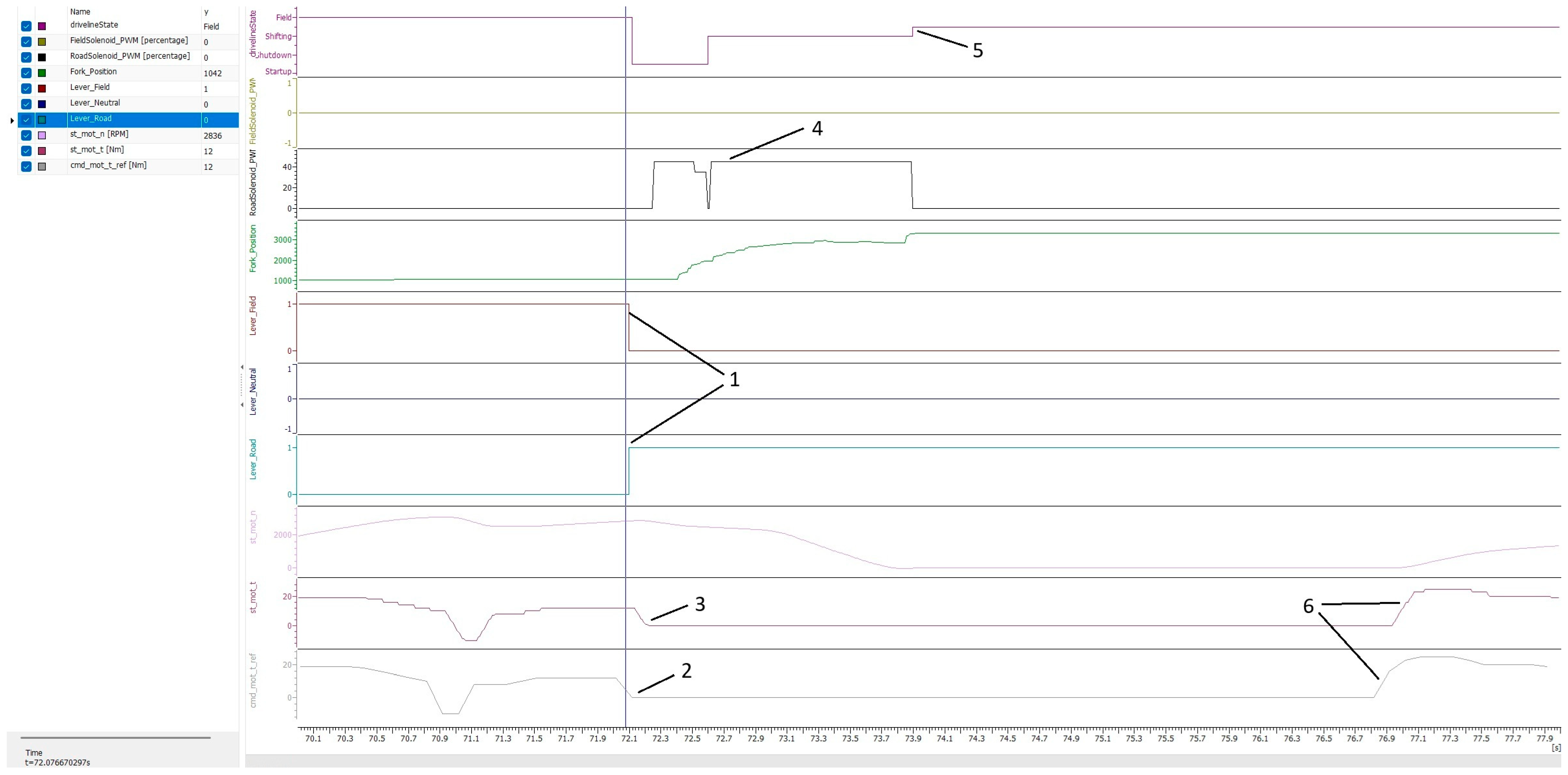

4.1. Testing System Without Speed Synchronization

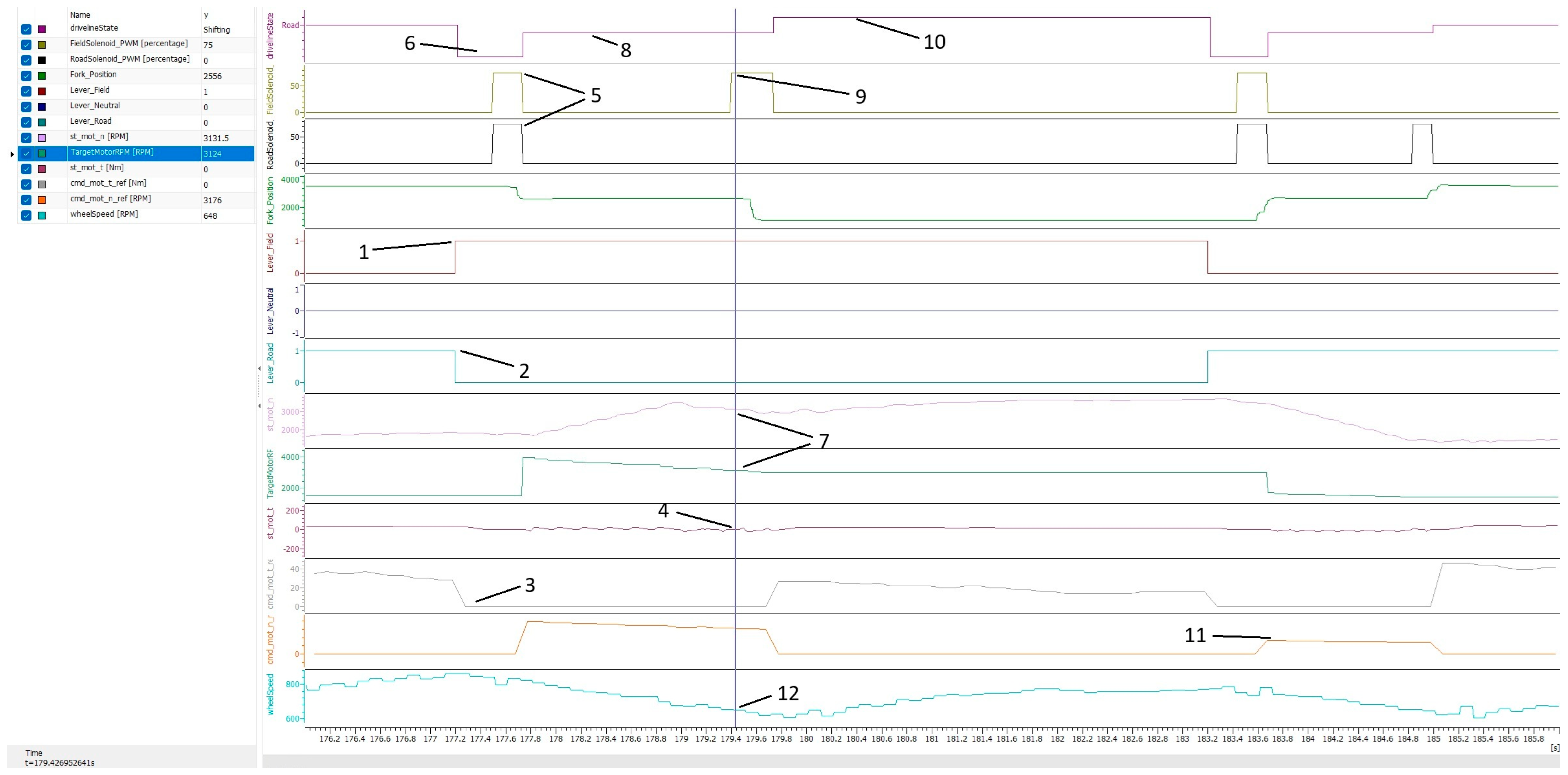

4.2. Testing System with Speed Synchronization

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CLAMT | Clutchless Automated-Manual Transmission |

| VMU | Vehicle Management Unit |

| RPM | Revolutions Per Minute |

| AMT | Automated-Manual Transmission |

| CVT | Continuously Variable Transmission |

| PTO | Power Take-Off |

| IC | Internal Combustion |

| PWM | Pulse Width Modulation |

| CAN | Controller Area Network |

| PMSM | Permanent Magnet Synchronous Motor |

References

- Khan, R.; Alabsi, A.A.N.; Muda, I. Comparing the effects of agricultural intensification on CO2 emissions and energy consumption in developing and developed countries. Front. Environ. Sci. 2023, 10, 1065634. [Google Scholar] [CrossRef]

- Tseng, C.-Y.; Yu, C.-H. Advanced shifting control of synchronizer mechanisms for clutchless automatic manual transmission in an electric vehicle. Mech. Mach. Theory 2015, 84, 37–56. [Google Scholar] [CrossRef]

- Gündoğdu, M.; Ersarı, M. Tractor transmission gear ratio optimization. Eng. Perspect. 2024, 4, 95–99. [Google Scholar] [CrossRef]

- Scolaro, E.; Beligoj, M.; Perez Estevez, M.; Alberti, L.; Renzi, M.; Mattetti, M. Electrification of agricultural machinery: A review. IEEE Access 2021, 9, 164520–164541. [Google Scholar] [CrossRef]

- Lu, Z.; Tian, G.; Onori, S. Time-optimal coordination control for the gear-shifting process in electric-driven mechanical transmission (dog clutch) without impacts. SAE Int. J. Electrified Veh. 2020, 9, 155–168. [Google Scholar] [CrossRef]

- Tian, Y.; Yang, H.; Mo, W.; Zhou, S.; Zhang, N.; Walker, P.D. Optimal coordinating gearshift control of a two-speed transmission for battery electric vehicles. Mech. Syst. Signal Process. 2020, 136, 106521. [Google Scholar] [CrossRef]

- El Morsy, M.; Achtenova, G.; Pakosta, J. Smoothness of Maybach dog clutch shift in the automotive gearbox. In Proceedings of the 13th International CTI Symposium, Berlin, Germany, 8–11 December 2014. [Google Scholar]

- Taguchi, Y.; Soga, Y.; Mineno, A.; Kuzuya, H.; Horiuchi, I.; Ueda, Y.; Miyazaki, T. Development of an automated manual transmission system based on robust design. SAE Tech. Pap. 2003, 9. [Google Scholar] [CrossRef]

- Zhong, Z.; Kong, G.; Yu, Z.; Xin, X.; Chen, X. Shifting control of an automated mechanical transmission without using the clutch. Int. J. Automot. Technol. 2012, 13, 487–496. [Google Scholar] [CrossRef]

- Yamaha Motor Co. Ltd. Easy-to-Use CVT-Equipped Engines. Available online: https://global.yamaha-motor.com/design_technology/technology/spread/003/ (accessed on 4 April 2025).

- Jensen, T.A.; Antille, D.L.; Tullberg, J.N. Improving on-farm energy use efficiency by optimizing machinery operations and management: A review. Agric. Res. 2024, 14, 15–33. [Google Scholar] [CrossRef]

- Pustavrh, J.; Hočevar, M.; Podržaj, P.; Trajkovski, A.; Majdič, F. Comparison of hydraulic, pneumatic and electric linear actuation systems. Sci. Rep. 2023, 13, 20938. [Google Scholar] [CrossRef] [PubMed]

- Rajagopalan, A.; Washington, G.; Rizzoni, G.; Guezennec, Y. Development of Fuzzy Logic and Neural Network Control and Advanced Emissions Modeling for Parallel Hybrid Vehicles; National Renewable Energy Laboratory: Golden, CO, USA, 2003. [Google Scholar]

- Tecnord. Datasheet. Available online: https://www.tecnord.com/cartridge-valves/proportional-controls/pressure-reducing-relieving/ (accessed on 11 April 2025).

- Lei, Y.; Hu, J.; Fu, Y.; Sun, S.; Li, X.; Chen, W.; Hou, L.; Zhang, Y. Control strategy of automated manual transmission based on active synchronization of driving motor in electric bus. Adv. Mech. Eng. 2019, 11, 1–17. [Google Scholar] [CrossRef]

- Li, L.; Wang, X.; He, K.; Liu, Y.; Liu, C. Position and force switching control for gear engagement of automated manual transmission gear-shift process. J. Dyn. Syst. Meas. Control. 2018, 140, 081010. [Google Scholar] [CrossRef]

- Xu, X.; Luo, Y. Modeling and analysis of gear shifting process of non-synchronizer AMT based on collision model. IEEE Access 2021, 9, 13354–13367. [Google Scholar] [CrossRef]

- Yu, C.-H.; Tseng, C.-Y. Research on gear-change control technology for the clutchless automatic-manual transmission of an electric vehicle. J. Automob. Eng. 2013, 227, 1446–1458. [Google Scholar] [CrossRef]

| Shift Time (s) | Power Interruption Time (s) | |||

|---|---|---|---|---|

| Gear Change | Releasing Clutch | Without Releasing Clutch | Releasing Clutch | Without Releasing Clutch |

| 1->2 | 1.7 | 1.20 | 0.72 | 1.10 |

| 2->3 | 1.63 | 1.00 | 1.12 | 1.04 |

| 3->4 | 1.50 | 0.67 | 0.88 | 0.80 |

| 4->5 | 1.52 | 0.97 | 0.79 | 0.65 |

| 5->4 | 1.44 | 0.93 | 0.75 | 0.65 |

| 4->3 | 1.19 | 0.69 | 0.66 | 0.58 |

| 3->2 | 1.55 | 1.02 | 0.75 | 0.62 |

| 2->1 | 1.38 | 1.10 | 0.78 | 0.64 |

| Indicator | Hydraulic | Pneumatic | Electric |

|---|---|---|---|

| Displacement | 10 | 7 | 4 |

| Velocity | 6 | 8 | 5 |

| Acceleration | 4 | 5 | 9 |

| Compressive force | 9 | 6 | 7 |

| Tensile force | 9 | 8 | 8 |

| Output power | 9 | 4 | 2 |

| Electric consumption | 3 | 1 | 6 |

| Weight | 1 | 9 | 8 |

| Hydraulic oil temperature (°C) | 85 |

| Hydraulic pressure (bar) | 190 |

| Pressure output of proportional valves (bar) | 18.5 |

| Supply voltage (V) | 14.4 |

| Sensor’s supply voltage (V) | 5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Published by MDPI on behalf of the World Electric Vehicle Association. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bingol, B.; Gunes, E.O.; Gundogdu, M. CLAMT Shifting Strategy with Dog Clutch and Active Synchronization for Electrified Tractors. World Electr. Veh. J. 2025, 16, 622. https://doi.org/10.3390/wevj16110622

Bingol B, Gunes EO, Gundogdu M. CLAMT Shifting Strategy with Dog Clutch and Active Synchronization for Electrified Tractors. World Electric Vehicle Journal. 2025; 16(11):622. https://doi.org/10.3390/wevj16110622

Chicago/Turabian StyleBingol, Bertug, Ece Olcay Gunes, and Murat Gundogdu. 2025. "CLAMT Shifting Strategy with Dog Clutch and Active Synchronization for Electrified Tractors" World Electric Vehicle Journal 16, no. 11: 622. https://doi.org/10.3390/wevj16110622

APA StyleBingol, B., Gunes, E. O., & Gundogdu, M. (2025). CLAMT Shifting Strategy with Dog Clutch and Active Synchronization for Electrified Tractors. World Electric Vehicle Journal, 16(11), 622. https://doi.org/10.3390/wevj16110622