Adaptive MPC-Based Lateral Path-Tracking Control for Automatic Vehicles

Abstract

1. Introduction

2. Path-Tracking Error Modeling of Vehicles

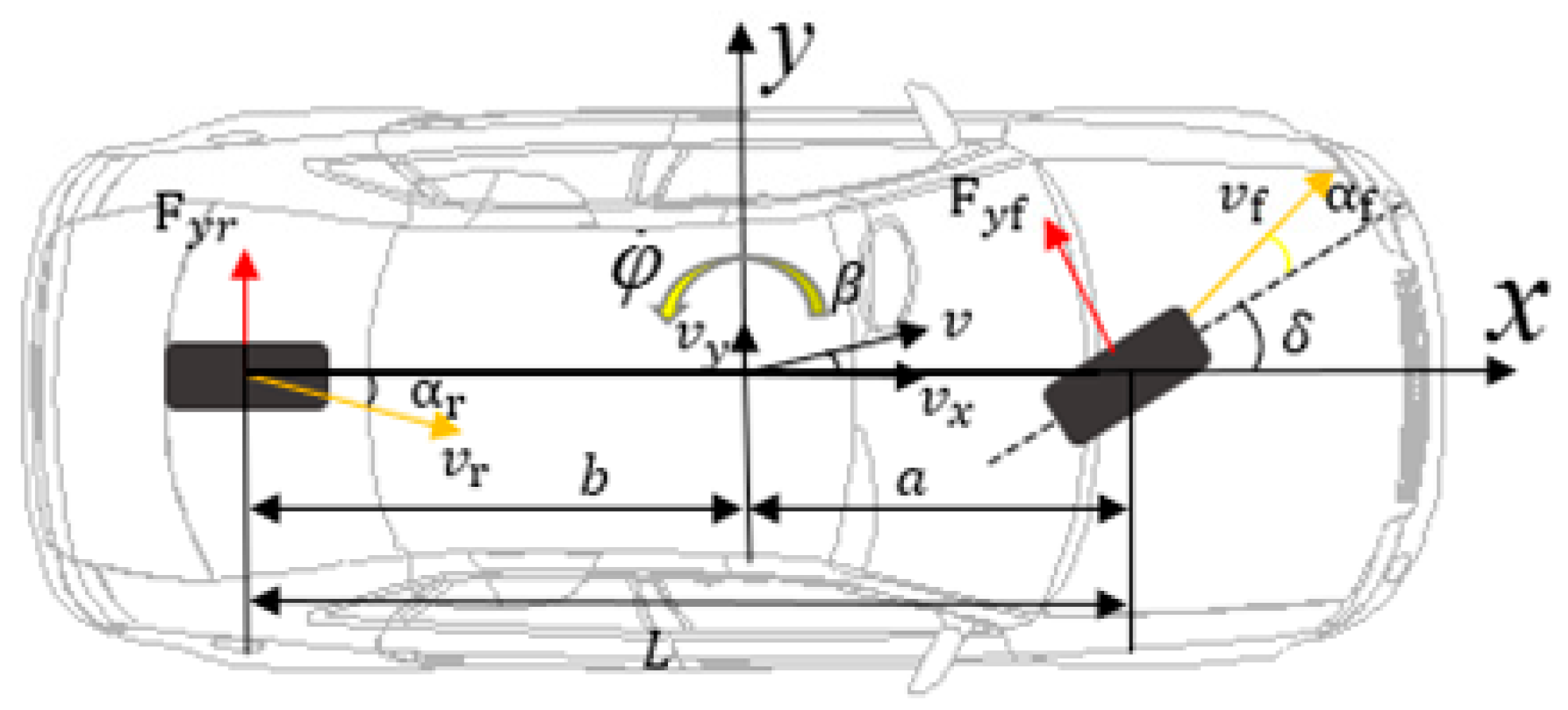

2.1. Vehicle Dynamics Model

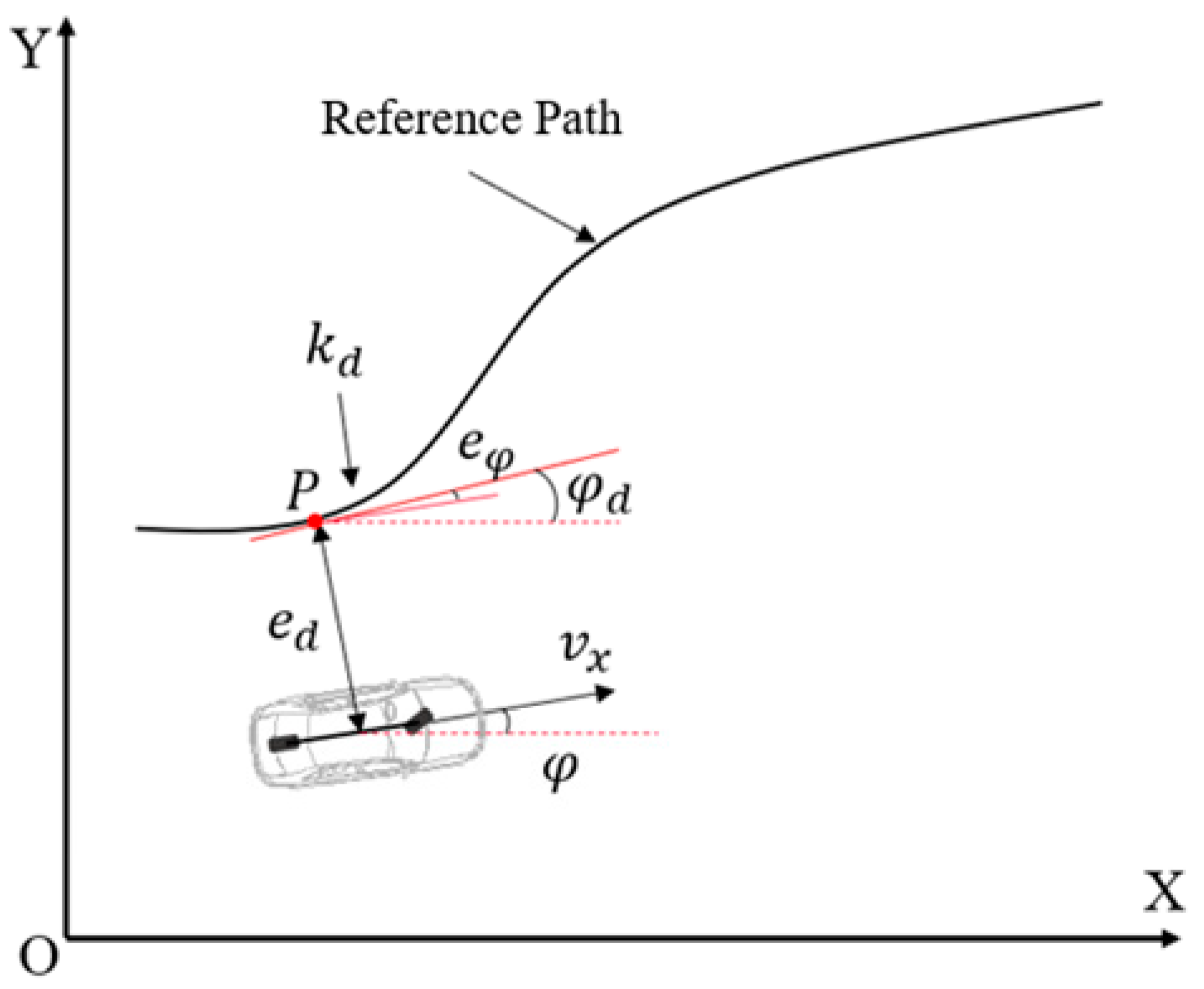

2.2. Tracking Model That Considers Trajectory Curvature

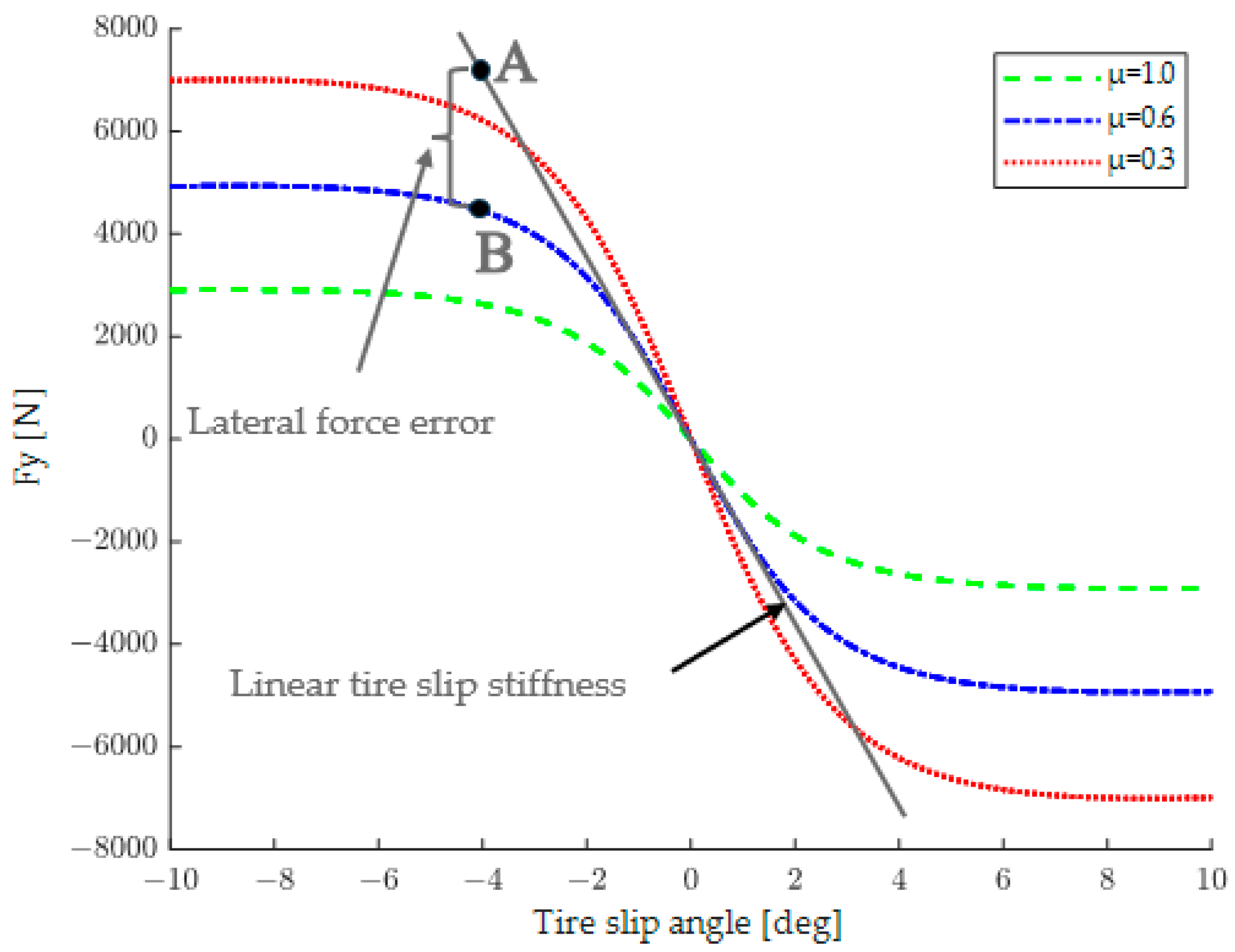

2.3. Tire Model

3. ASRCKF-Based Lateral Force Estimator

3.1. Vehicle System Modeling with ASRCKF Algorithm

- (1)

- Initialization

- (2)

- Time Updates

- (3)

- Measurement Updates

- (4)

- Status Updates

- (5)

- Factor Correction

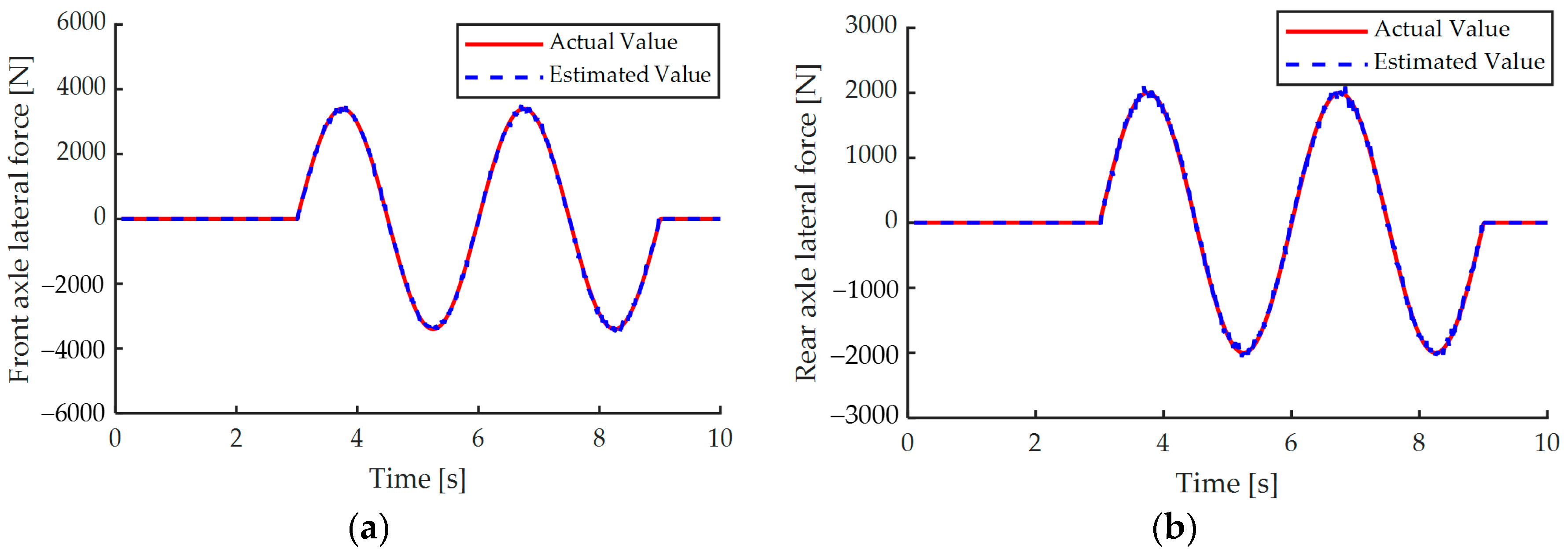

3.2. Validation of the Tire Lateral Force Estimator

4. Path-Tracking Controller Design

4.1. Guidelines for Adjusting Lateral Deflection Stiffness

4.2. Tracking Controller Design

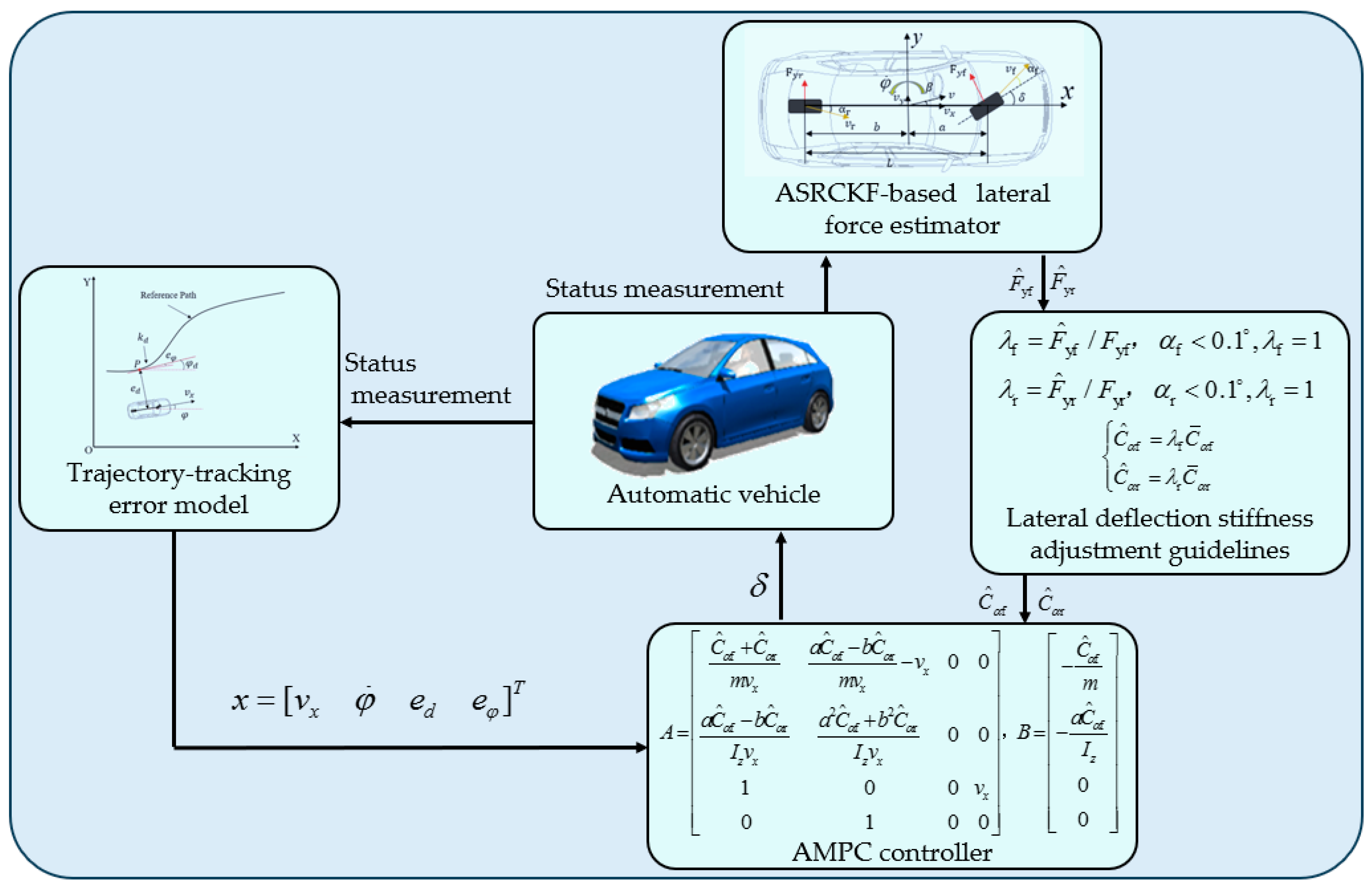

4.3. Adaptive Path-Tracking Control Framework

5. Analysis of Simulation Results

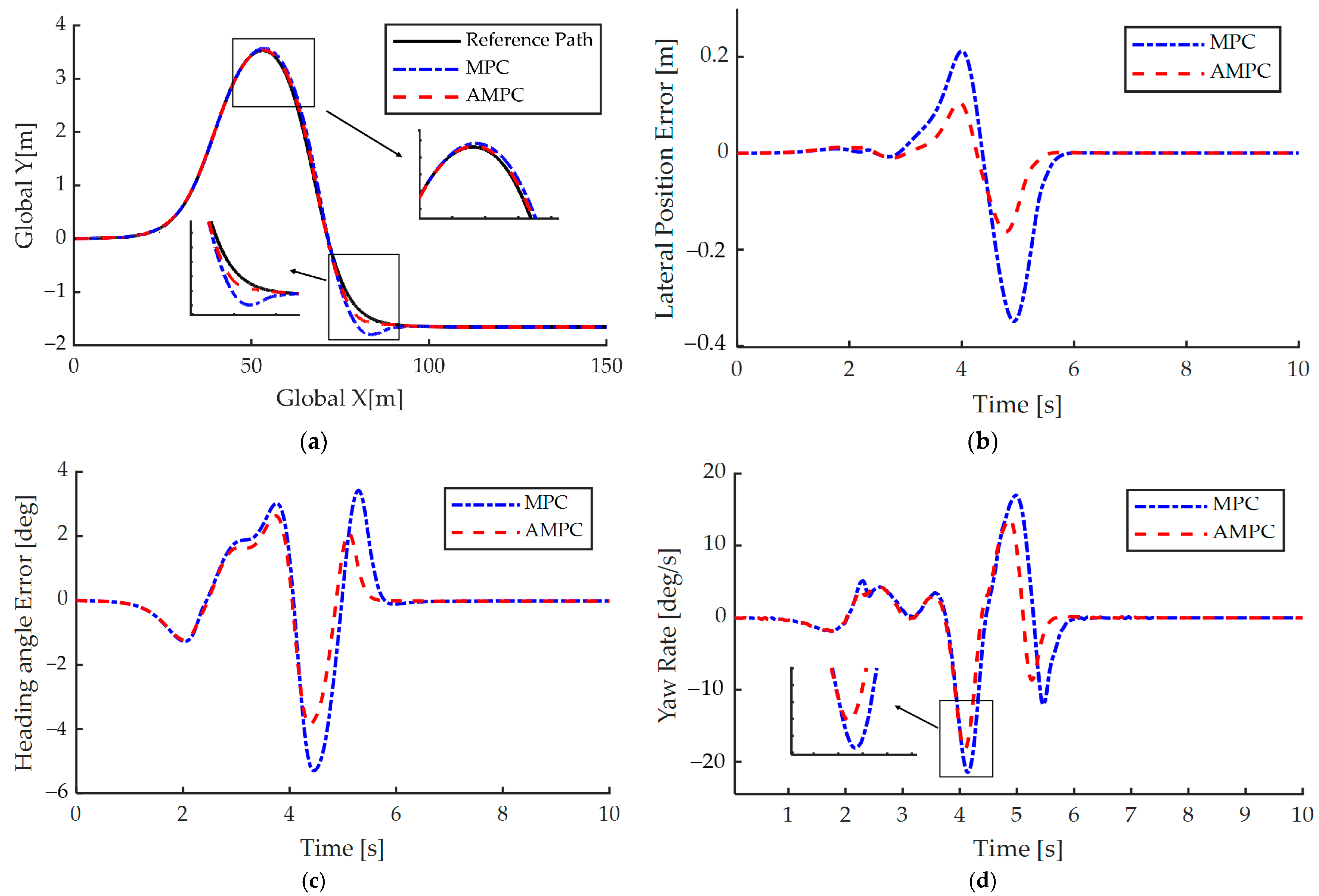

5.1. High-Adhesion Double-Shift Line Condition

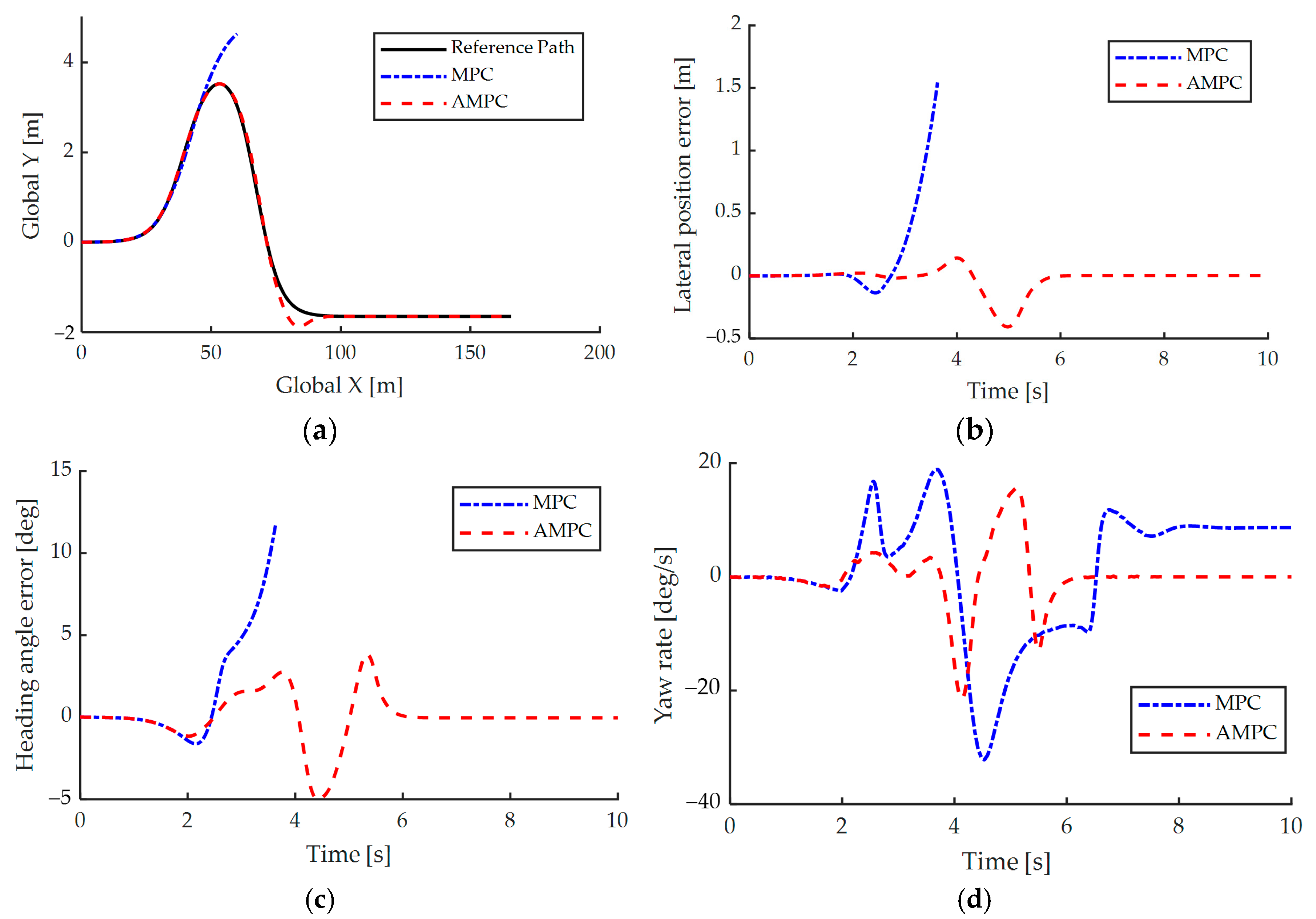

5.2. Low-Adhesion Double-Shift Line Condition

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| Abbreviation | Full Title |

| MPC | Model predictive control |

| AMPC | Adaptive model predictive control |

| PID | Proportional integral derivative |

| LQR | Linear quadratic regulator |

| ASRCKF | Amended square root cubature Kalman filter |

References

- Mu, X.; Gao, W.; Li, X.; Li, G. Coverage Path Planning for UAV Based on Improved Back-and-Forth Mode. IEEE Access 2023, 11, 114840–114854. [Google Scholar] [CrossRef]

- Marino, R.; Scalzi, S.; Netto, M. Nested PID Steering Control for Lane Keeping in Autonomous Vehicles. Control Eng. Pract. 2011, 19, 1459–1467. [Google Scholar] [CrossRef]

- Xu, S.; Peng, H. Design, Analysis, and Experiments of Preview Path Tracking Control for Autonomous Vehicles. IEEE Trans. Intell. Transp. Syst. 2020, 21, 48–58. [Google Scholar] [CrossRef]

- Wang, R.; Li, Y.; Fan, J.; Wang, T.; Chen, X. A Novel Pure Pursuit Algorithm for Autonomous Vehicles Based on Salp Swarm Algorithm and Velocity Controller. IEEE Access 2020, 8, 166525–166540. [Google Scholar] [CrossRef]

- Wang, H.; Wang, Q.; Chen, W.; Zhao, L.; Tan, D. Path Tracking Based on Model Predictive Control with Variable Predictive Horizon. Trans. Inst. Meas. Control 2021, 43, 2676–2688. [Google Scholar] [CrossRef]

- Yakub, F.; Abu, A.; Sarip, S.; Mori, Y. Study of Model Predictive Control for Path-Following Autonomous Ground Vehicle Control under Crosswind Effect. J. Control Sci. Eng. 2016, 2016, 6752671. [Google Scholar] [CrossRef]

- Liu, J.; Jayakumar, P.; Stein, J.L.; Ersal, T. A Study on Model Fidelity for Model Predictive Control-Based Obstacle Avoidance in High-Speed Autonomous Ground Vehicles. Veh. Syst. Dyn. 2016, 54, 1629–1650. [Google Scholar] [CrossRef]

- Aouaouda, S.; Chadli, M.; Boukhnifer, M.; Karimi, H.R. Robust Fault Tolerant Tracking Controller Design for Vehicle Dynamics: A Descriptor Approach. Mechatronics 2015, 30, 316–326. [Google Scholar] [CrossRef]

- Oikonomou, M.G.; Ziakopoulos, A.; Chaudhry, A.; Thomas, P.; Yannis, G. From Conflicts to Crashes: Simulating Macroscopic Connected and Automated Driving Vehicle Safety. Accid. Anal. Prev. 2023, 187, 107087. [Google Scholar] [CrossRef]

- Nie, Z.; Jia, Y.; Wang, W.; Outbib, R. Eco-Co-Optimization Strategy for Connected and Automated Fuel Cell Hybrid Vehicles in Dynamic Urban Traffic Settings. Energy Convers. Manag. 2022, 263, 115690. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, L.; Wang, P.; Chen, H. A Real-Time NMPC Strategy for Electric Vehicle Stability Improvement Combining Torque Vectoring With Rear-Wheel Steering. IEEE Trans. Transp. Electrif. 2022, 8, 3825–3835. [Google Scholar] [CrossRef]

- Stano, P.; Montanaro, U.; Tavernini, D.; Tufo, M.; Fiengo, G.; Novella, L.; Sorniotti, A. Model Predictive Path Tracking Control for Automated Road Vehicles: A Review. Annu. Rev. Control 2022, 55, 194–236. [Google Scholar] [CrossRef]

- Li, H.; Luo, Y. Study on Steering Angle Input during the Automated Lane Change of Electric Vehicle; Technical Paper 2017-01–1962; SAE International: Warrendale, PA, USA, 2017. [Google Scholar] [CrossRef]

- Liang, Y.; Li, Y.; Khajepour, A.; Zheng, L. Multi-Model Adaptive Predictive Control for Path Following of Autonomous Vehicles. IET Intell. Transp. Syst. 2020, 14, 2092–2101. [Google Scholar] [CrossRef]

- Guo, H.; Liu, J.; Cao, D.; Chen, H.; Yu, R.; Lv, C. Dual-Envelop-Oriented Moving Horizon Path Tracking Control for Fully Automated Vehicles. Mechatronics 2018, 50, 422–433. [Google Scholar] [CrossRef]

- Wurts, J.; Stein, J.L.; Ersal, T. Collision Imminent Steering at High Speeds on Curved Roads Using One-Level Nonlinear Model Predictive Control. IEEE Access 2021, 9, 39292–39302. [Google Scholar] [CrossRef]

- Yakub, F.; Mori, Y. Comparative Study of Autonomous Path-Following Vehicle Control via Model Predictive Control and Linear Quadratic Control. Proc. Inst. Mech. Eng. Part J. Automob. Eng. 2015, 229, 1695–1714. [Google Scholar] [CrossRef]

- Ji, J.; Khajepour, A.; Melek, W.W.; Huang, Y. Path Planning and Tracking for Vehicle Collision Avoidance Based on Model Predictive Control with Multiconstraints. IEEE Trans. Veh. Technol. 2017, 66, 952–964. [Google Scholar] [CrossRef]

- Cui, Q.; Ding, R.; Wei, C.; Zhou, B. Path-Tracking and Lateral Stabilisation for Autonomous Vehicles by Using the Steering Angle Envelope. Veh. Syst. Dyn. 2021, 59, 1672–1696. [Google Scholar] [CrossRef]

- Spielberg, N.A.; Brown, M.; Gerdes, J.C. Neural Network Model Predictive Motion Control Applied to Automated Driving with Unknown Friction. IEEE Trans. Control. Syst. Technol. 2022, 30, 1934–1945. [Google Scholar] [CrossRef]

- Piyabongkarn, D.; Rajamani, R.; Grogg, J.A.; Lew, J.Y. Development and Experimental Evaluation of a Slip Angle Estimator for Vehicle Stability Control. IEEE Trans. Control Syst. Technol. 2009, 17, 78–88. [Google Scholar] [CrossRef]

- Xiaoyu, L.; Nan, X.; Konghui, G. Vehicle Sideslip Angle Estimation Based on Fusion of Kinematic Method and Kinematic-geometry Method. J. Mech. Eng. 2020, 56, 121. [Google Scholar] [CrossRef]

- Qi, G.; Yue, M.; Shangguan, J.; Guo, L.; Zhao, J. Integrated Control Method for Path Tracking and Lateral Stability of Distributed Drive Electric Vehicles with Extended Kalman Filter–Based Tire Cornering Stiffness Estimation. 2023. Available online: https://journals.sagepub.com/doi/10.1177/10775463231181635 (accessed on 11 January 2024).

- Li, S.; Yang, Z.; Wang, X. Trajectory Tracking Control of an Intelligent Vehicle Based on T-S Fuzzy Variable Weight MPC. J. Mech. Eng. 2023, 59, 199. [Google Scholar] [CrossRef]

- Teng, S.; Hu, X.; Deng, P.; Li, B.; Li, Y.; Ai, Y.; Yang, D.; Li, L.; Xuanyuan, Z.; Zhu, F.; et al. Motion Planning for Autonomous Driving: The State of the Art and Future Perspectives. IEEE Trans. Intell. Veh. 2023, 8, 3692–3711. [Google Scholar] [CrossRef]

- Liu, J.; Wang, Z.; Zhang, L. Integrated Vehicle-Following Control for Four-Wheel-Independent-Drive Electric Vehicles Against Non-Ideal V2X Communication. IEEE Trans. Veh. Technol. 2022, 71, 3648–3659. [Google Scholar] [CrossRef]

- Pacejka, H. Tire and Vehicle Dynamics; Elsevier: Amsterdam, The Netherlands, 2005. [Google Scholar]

- Han, K.; Choi, M.; Choi, S.B. Estimation of the Tire Cornering Stiffness as a Road Surface Classification Indicator Using Understeering Characteristics. IEEE Trans. Veh. Technol. 2018, 67, 6851–6860. [Google Scholar] [CrossRef]

- Cui, Z.; Xia, X.; Pei, X. A Modified Vehicle Following Control System on the Curved Road Based on Model Predictive Control. In Proceedings of the 2021 33rd Chinese Control and Decision Conference (CCDC), Kunming, China, 22–24 May 2021; pp. 1098–1103. [Google Scholar] [CrossRef]

- Zhe, X.; Hailiang, C.; Ziyu, L.; Enxin, S.; Qi, S.; Shengbo, L. Lateral Trajectory Following for Automated Vehicles at Handling Limits. J. Mech. Eng. 2020, 56, 138. [Google Scholar] [CrossRef]

- Lu, Y.; Zhu, J.; Wang, Z.; Du, N.; Zhang, J. Path Preview Tracking for Autonomous Vehicles Based on Model Predictive Control. In Proceedings of the 2022 IEEE International Conference on Unmanned Systems (ICUS), Guangzhou, China, 28–30 October 2022; pp. 405–410. [Google Scholar] [CrossRef]

- Taghavifar, H.; Shojaei, K. Adaptive Robust Control Algorithm for Enhanced Path-Tracking Performance of Automated Driving in Critical Scenarios. Soft Comput. 2023, 27, 8841–8854. [Google Scholar] [CrossRef]

| Symbol | Meaning | Unit |

|---|---|---|

| A | State-space system matrix | |

| a, b | Front and rear semi-wheelbases | m |

| B | Control action matrix | |

| Linear lateral deflection stiffness of the front tire | N·rad−1 | |

| Linear lateral deflection stiffness of the rear tire | N·rad−1 | |

| Coefficients of the observation vector | ||

| Lateral position error | m | |

| Heading angle error | rad | |

| Lateral force on the front tire | N | |

| Lateral force on the rear tire | N | |

| Unit matrix | ||

| Torque of the vehicle about the axis | kg·m2 | |

| J | Cost function | |

| Road curvature | ||

| Filter gain | ||

| m | Total vehicle mass | kg |

| State transfer matrix | ||

| Number of steps of the control horizon | ||

| Number of steps of the prediction horizon | ||

| Linearized approximation matrix | ||

| Covariance matrix | ||

| Reciprocal covariance matrix | ||

| s | Distance covered along the path | m |

| Square root of the covariance | ||

| Square root of predicted covariance | ||

| Square root of the new interest error covariance matrix | ||

| t | Time | s |

| T | Sampling time | s |

| u | Control action vector | |

| Longitudinal vehicle speed | m·s−1 | |

| Lateral vehicle speed | m·s−1 | |

| Measurement noise | ||

| Process noise | ||

| x | State vector | |

| Initial value | ||

| Volume point | ||

| State prediction | ||

| State estimate | ||

| X, Y | Coordinates in the global reference system | m |

| Weighting matrix | ||

| State estimate | ||

| X, Y | Coordinates in the global reference system | m |

| Weighting matrix | ||

| δ | Front wheel steering angle | rad |

| β | Vehicle sideslip angle | rad |

| Yaw angle | rad | |

| Basic volume point | ||

| Central weighting matrix | ||

| Weighting matrix |

| Parameters | Unit | Value |

|---|---|---|

| kg | 1413 | |

| kg·m2 | 1536.7 | |

| N·rad−1 | −112,600 | |

| N·rad−1 | −80,500 | |

| m | 1.025 | |

| m | 1.885 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, S.; Qian, Y.; Hu, W.; Xu, J.; Sun, H. Adaptive MPC-Based Lateral Path-Tracking Control for Automatic Vehicles. World Electr. Veh. J. 2024, 15, 95. https://doi.org/10.3390/wevj15030095

Yang S, Qian Y, Hu W, Xu J, Sun H. Adaptive MPC-Based Lateral Path-Tracking Control for Automatic Vehicles. World Electric Vehicle Journal. 2024; 15(3):95. https://doi.org/10.3390/wevj15030095

Chicago/Turabian StyleYang, Shaobo, Yubin Qian, Wenhao Hu, Jiejie Xu, and Hongtao Sun. 2024. "Adaptive MPC-Based Lateral Path-Tracking Control for Automatic Vehicles" World Electric Vehicle Journal 15, no. 3: 95. https://doi.org/10.3390/wevj15030095

APA StyleYang, S., Qian, Y., Hu, W., Xu, J., & Sun, H. (2024). Adaptive MPC-Based Lateral Path-Tracking Control for Automatic Vehicles. World Electric Vehicle Journal, 15(3), 95. https://doi.org/10.3390/wevj15030095