Machine-Learning-Based Optimization of Energy Management in a Novel Hybrid Powertrain of Concrete Truck Mixers

Abstract

:1. Introduction

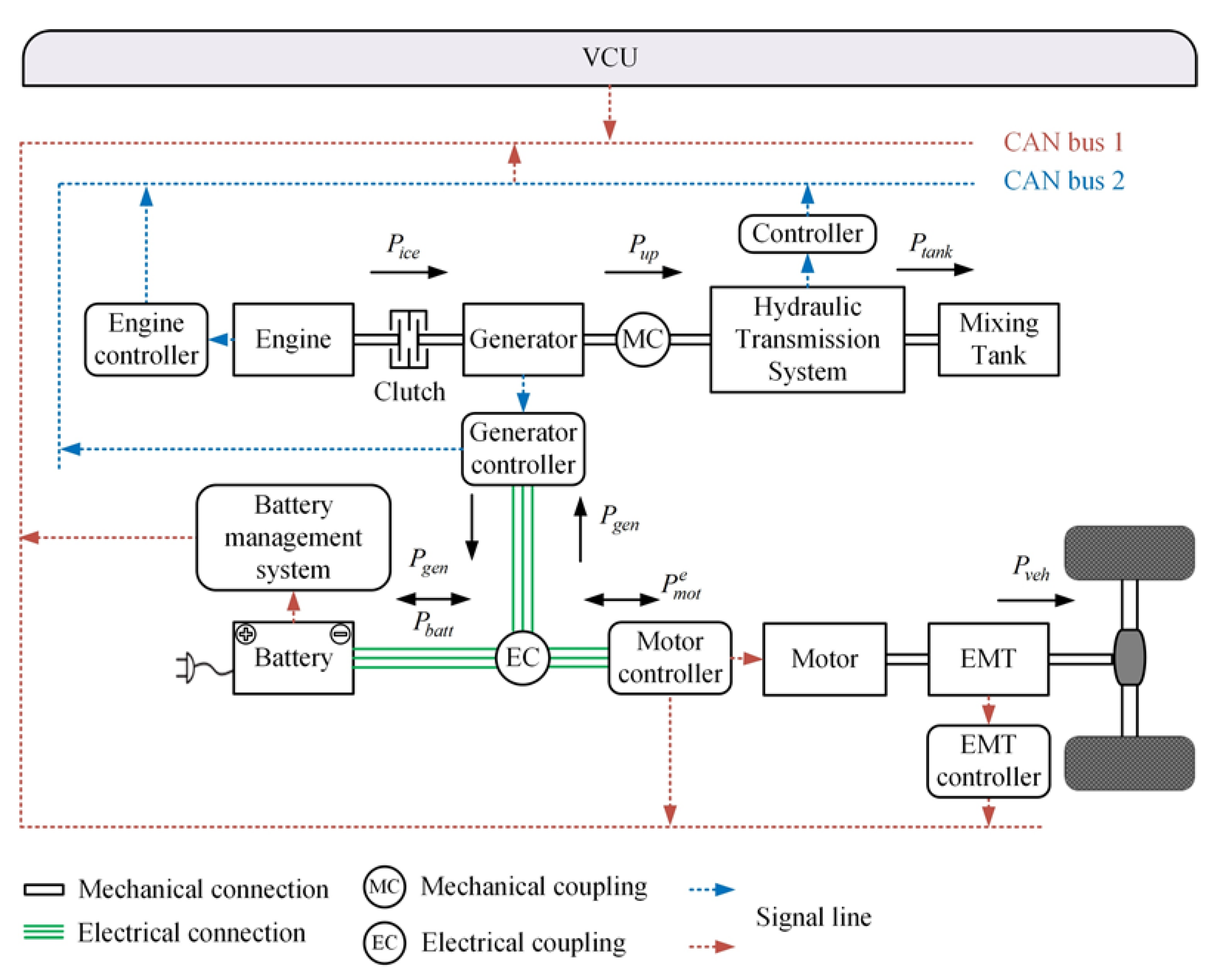

2. Powertrain Configuration and Model

2.1. Powertrain Specification and System Modeling

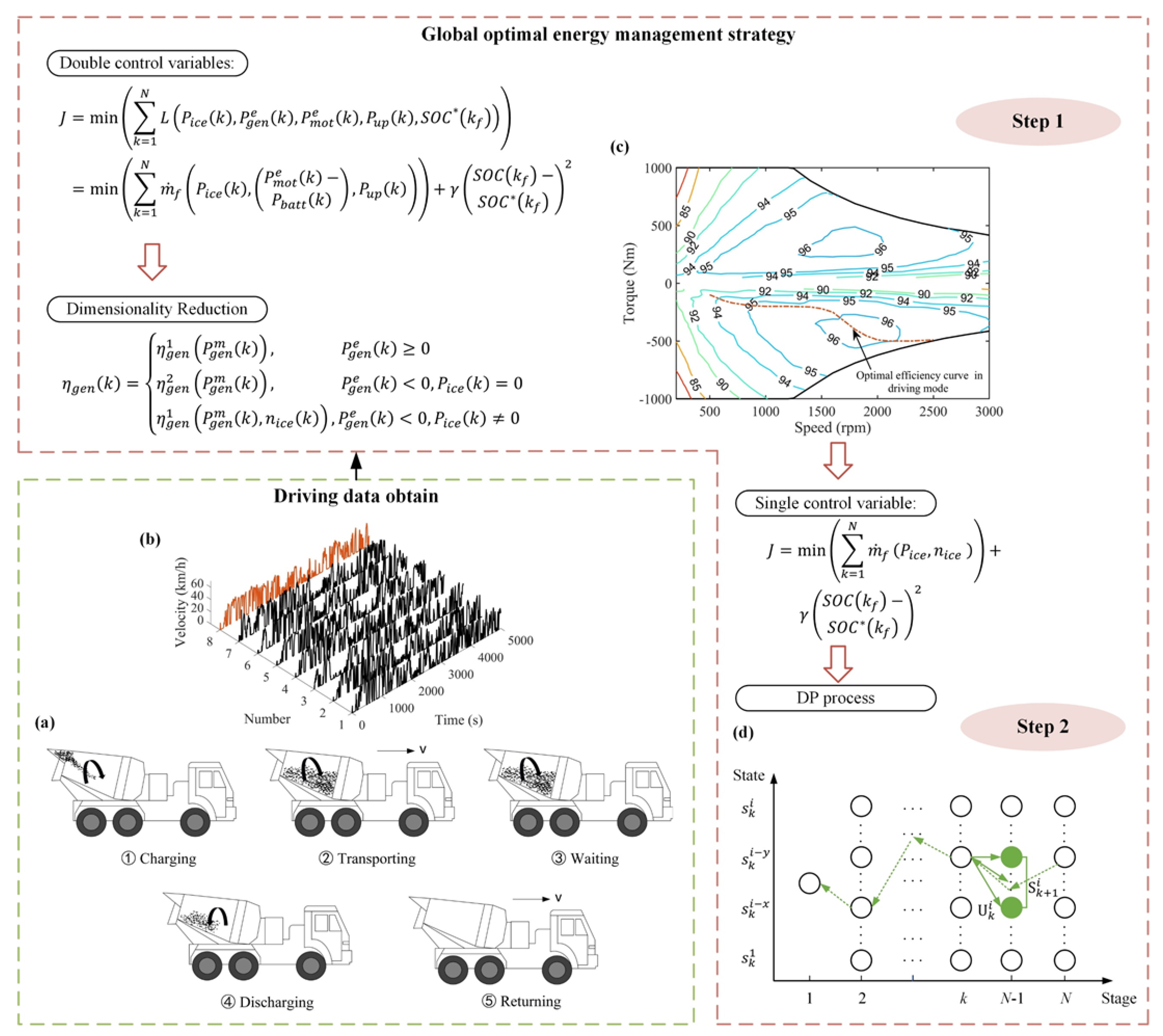

2.2. Energy Optimal Problem Formulation

3. Global Optimal Energy Management Strategy

3.1. Driving Data Obtain

3.2. Dynamic Programming to Solve the Optimization Problem

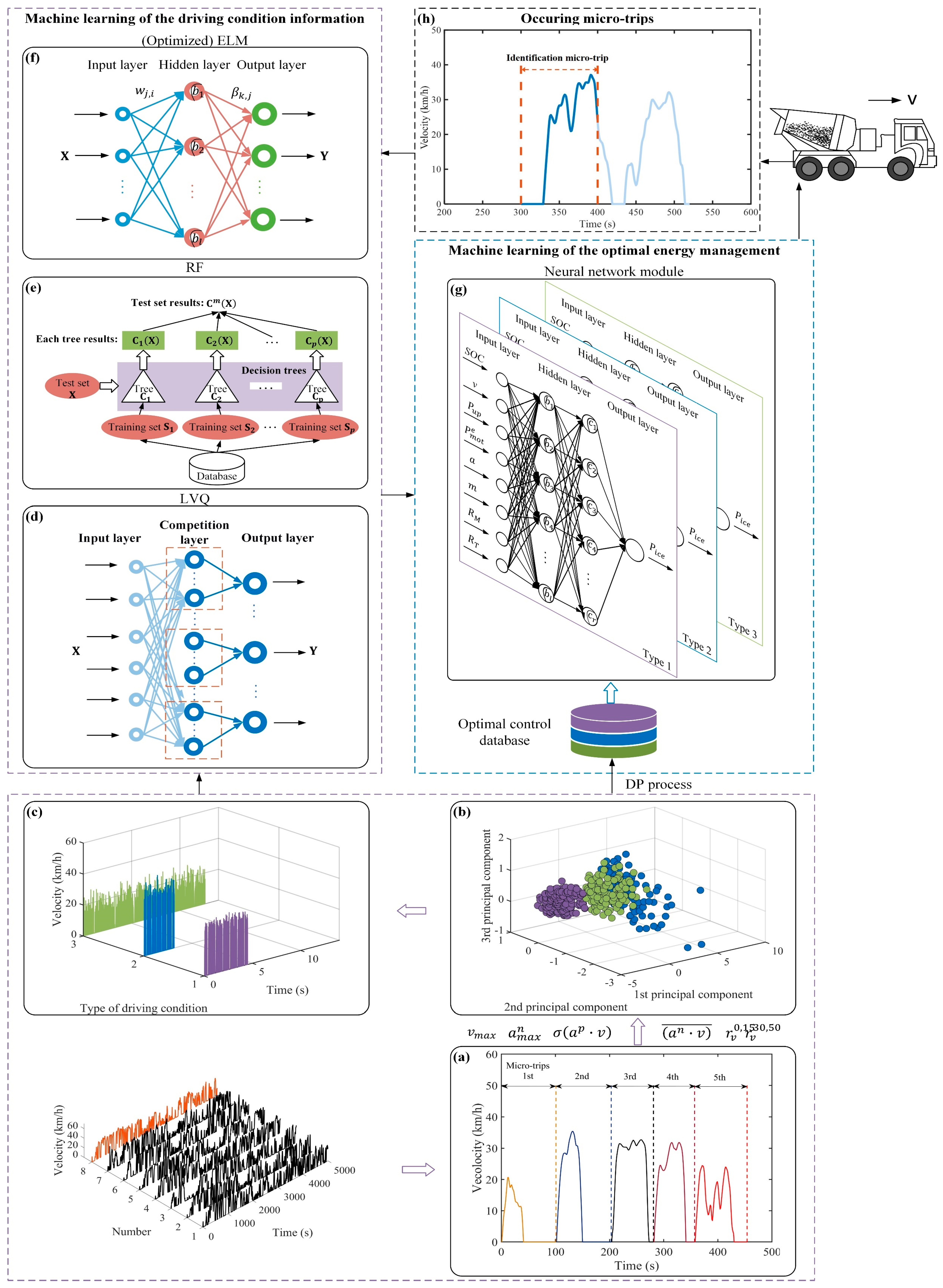

4. Approximate Optimal Energy Management Design Based on Machine Learning

4.1. Machine Learning of the Trip Information

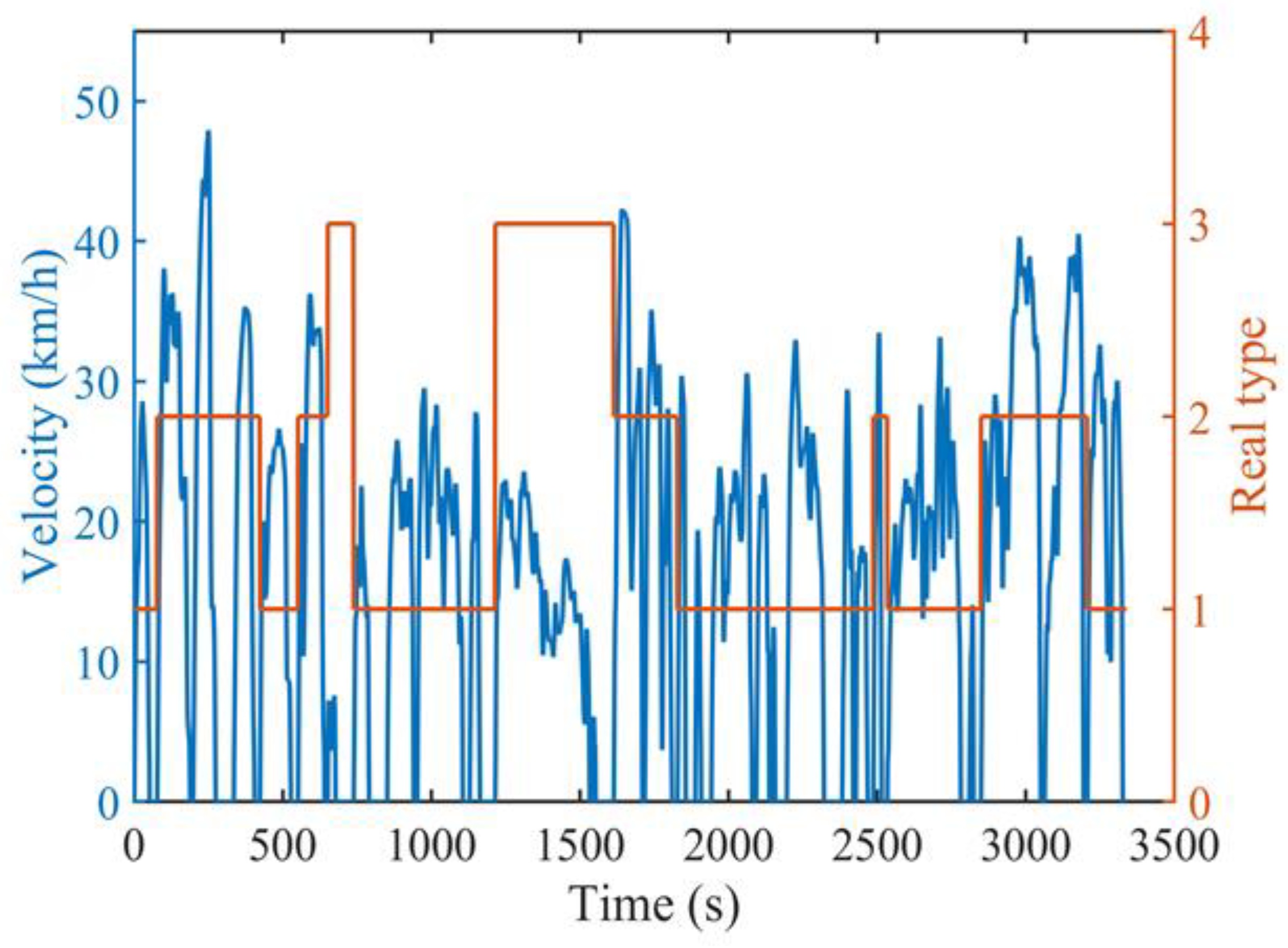

4.1.1. Typical Driving Conditions Construction Based on Unsupervised Learning

4.1.2. Development of Driving Condition Identifier Based on Supervised Learning

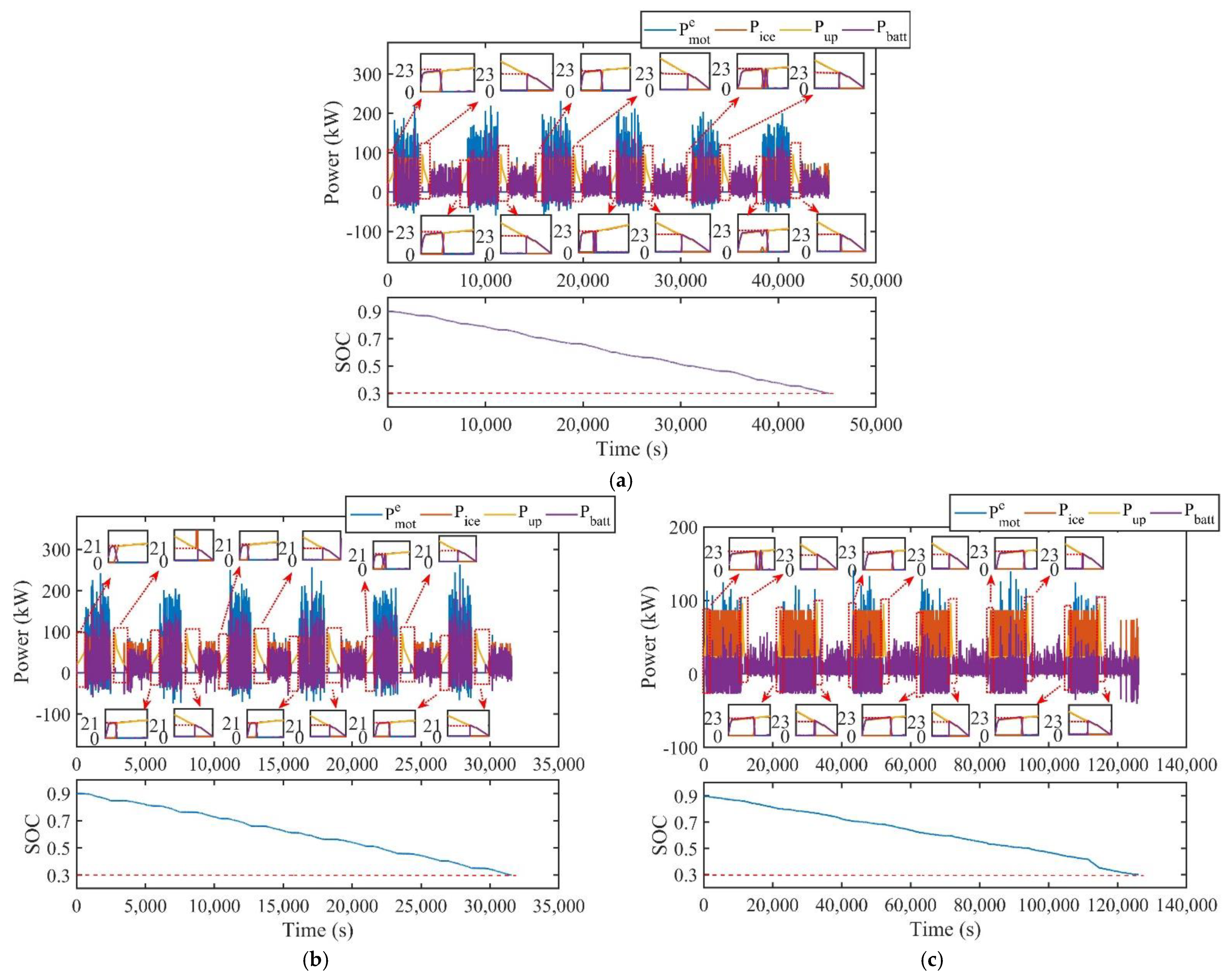

4.2. Machine Learning of the Optimal Energy Management

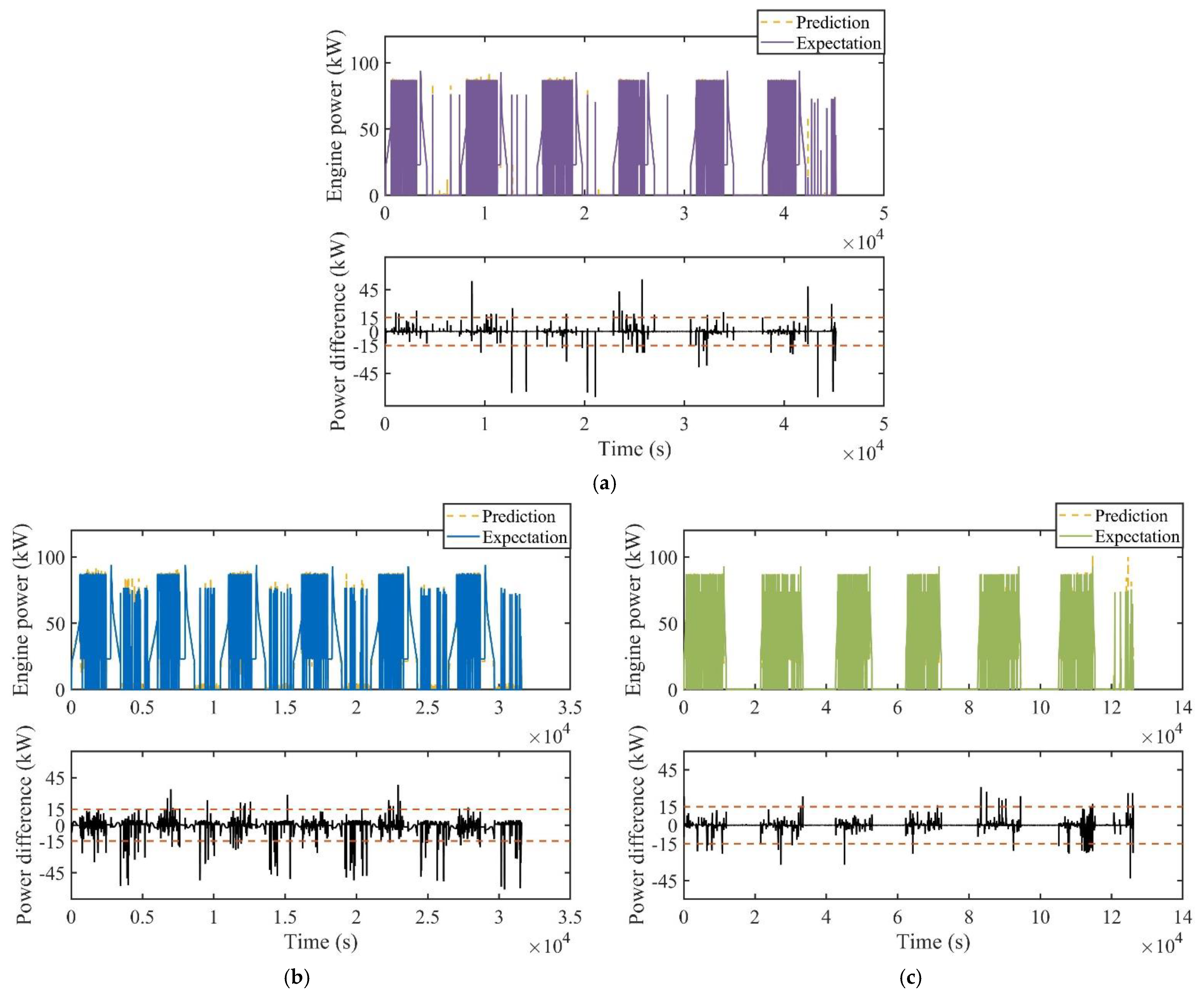

4.2.1. Neural Network Structure Determination

4.2.2. Neural Network Training and Verification

5. Conclusions

- For the CTMs equipped with a proposed novel hybrid powertrain, a global optimization algorithm based on DP was proposed to solve the two-point boundary value problem in the finite time domain, which has the characteristics of constrained time-varying and double control variables. By designing an optimal efficiency curve of the generator in driving mode and establish the generator efficiency model, the complexity of solving the energy optimization problem can be reduced;

- An optimal control database can be obtained based on the ML and data-driven method; different ML-based driving condition identifiers were constructed and compared. Simulation results showed that the total performance of ELM is superior to the RF and LVQ through the comparison of kappa coefficient, identification time, and identification accuracy. An optimized ELM identifier based on genetic algorithm was presented, which can further promote online identification performance;

- For the E-RE-CTM, a vehicle mass and power demand of an upper-part system based novel neural network energy management strategy was designed based on a constructed optimal control database. Simulation results showed that the designed neural network is reasonable and feasible.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Feng, Y.; Dong, Z. Optimal energy management with balanced fuel economy and battery life for large hybrid electric mining truck. J. Power Sources 2020, 454, 227948. [Google Scholar] [CrossRef]

- Kosowski, M.; Dunckley, J.; Bowermaster, D. Results of plug-in hybrid medium-duty truck demonstration and evaluation program. World Electr. Veh. J. 2016, 8, 57–68. [Google Scholar] [CrossRef] [Green Version]

- Zhuang, W.; Eben, S.L.; Zhang, X.; Kum, D.; Song, Z.; Yin, G.; Ju, F. A survey of powertrain configuration studies on hybrid electric vehicles. Appl. Energy 2020, 262, 114553. [Google Scholar] [CrossRef]

- Zhao, J.; Liu, X.; Xin, Z.; Han, Y. Research on the energy-saving technology of concrete mixer truck. In Proceedings of the 2009 4th IEEE Conference on Industrial Electronics and Applications, Xi’an, China, 25–27 May 2009. [Google Scholar]

- Gadner, S.; Pifko, A.; Brehmer, U.; Stockbauer-Muhr, D. Electric Truck Mixer for the Future Urban Construction Site. ATZheavy Duty Worldw. 2019, 12, 14–21. [Google Scholar] [CrossRef]

- Peng, J.; He, H.; Xiong, R. Rule based energy management strategy for a series–Parallel plug-in hybrid electric bus optimized by dynamic programming. Appl. Energy 2017, 185, 1633–1643. [Google Scholar] [CrossRef]

- Yu, Y.; Jiang, J.; Min, Z.; Wang, P.; Shen, W. Research on energy management strategies of extended-range electric vehicles based on driving characteristics. World Electr. Veh. J. 2020, 11, 54. [Google Scholar] [CrossRef]

- Xie, H. Energy Management Strategy for Extended-Range Electric City Buses Based on Driving Condition Adaptation. Ph.D. Thesis, Tsinghua University, Beijing, China, 2017. [Google Scholar]

- Zhang, F.; Hu, X.; Xu, K.; Tang, X.; Cui, Y. Current Status and Prospects for Model Predictive Energy Management in Hybrid Electric Vehicles. J. Mech. Eng. 2019, 55, 86–108. [Google Scholar] [CrossRef] [Green Version]

- Liu, T.; Tang, X.; Wang, H.; Yu, H.; Hu, X. Adaptive Hierarchical energy management design for a plug-in hybrid electric vehicle. IEEE Trans. Veh. Technol. 2019, 68, 11513–11522. [Google Scholar] [CrossRef]

- Tian, Y.; Liu, J.; Yao, Q.; Liu, K. Optimal control strategy for parallel plug-in hybrid electric vehicles based on dynamic pro-gramming. World Electr. Veh. J. 2021, 12, 85. [Google Scholar] [CrossRef]

- Murphey, Y.L.; Park, J.; Kiliaris, L.; Kuang, M.L.; Masrur, M.A.; Phillips, A.M.; Wang, Q. Intelligent hybrid vehicle power con-trol—Part II: Online intelligent energy management. IEEE Trans. Veh. Technol. 2013, 62, 69–79. [Google Scholar] [CrossRef]

- Tian, H.; Li, S.E.; Wang, X.; Huang, Y.; Tian, G. Data-driven hierarchical control for online energy management of plug-in hybrid electric city bus. Energy 2018, 142, 55–67. [Google Scholar] [CrossRef]

- Zhang, J.; Chu, L.; Wang, X.; Guo, C.; Fu, Z.; Zhao, D. Optimal energy management strategy for plug-in hybrid electric vehicles based on a combined clustering analysis. Appl. Math. Model. 2021, 94, 49–67. [Google Scholar] [CrossRef]

- Tsinghua, H.S. Self-Learning Online Energy Management Strategy for Plug-in Hybrid Electric Bus. Ph.D. Thesis, Tsinghua University, Beijing, China, 2018. [Google Scholar]

- Chen, Z.; Mi, C.; Xu, J.; Gong, X.; You, C. Energy Management for a Power-Split Plug-in Hybrid Electric Vehicle Based on Dynamic Programming and Neural Networks. IEEE Trans. Veh. Technol. 2014, 63, 1567–1580. [Google Scholar] [CrossRef]

- Xie, S.; Hu, X.; Qi, S.; Lang, K.; Tian, G. An artificial neural network-enhanced energy management strategy for plug-in hybrid electric vehicles. Energy 2018, 163, 837–848. [Google Scholar] [CrossRef] [Green Version]

- Tian, H.; Lu, Z.; Wang, X.; Zhang, X.; Huang, Y.; Tian, G. A length ratio based neural network energy management strategy for online control of plug-in hybrid electric city bus. Appl. Energy 2016, 177, 71–80. [Google Scholar] [CrossRef]

- Hu, J.; Liu, D.; Du, C.; Yan, F.; Lv, C. Intelligent energy management strategy of hybrid energy storage system for electric vehicle based on driving pattern recognition. Energy 2020, 198, 117298. [Google Scholar] [CrossRef]

- Zhang, J.; Xu, F.; Zhang, Y.; Shen, T. ELM-based driver torque demand prediction and real-time optimal energy management strategy for HEVs. Neural Comput. Appl. 2020, 32, 14411–14429. [Google Scholar] [CrossRef]

- Song, K.; Li, F.; Hu, X.; He, L.; Niu, W.; Lu, S.; Zhang, T. Multi-mode energy management strategy for fuel cell electric vehicles based on driving pattern identification using learning vector quantization neural network algorithm. J. Power Sources 2018, 389, 230–239. [Google Scholar] [CrossRef]

- Liu, T.; Tan, W.; Tang, X.; Zhang, J.; Xing, Y.; Cao, D. Driving conditions-driven energy management strategies for hybrid electric vehicles: A review. Renew. Sustain. Energy Rev. 2021, 151, 111521. [Google Scholar] [CrossRef]

- Huang, Y.; Jiang, F.; Xie, H. Adaptive hierarchical energy management design for a novel hybrid powertrain of concrete truck mixers. J. Power Sources 2021, 509, 230325. [Google Scholar] [CrossRef]

- Simona, O. Hybrid Electric Vehicles Energy Management Strategies; Springer: Berlin/Heidelberg, Germany, 2015. [Google Scholar]

- Liu, J.; Chen, Y.; Zhan, J.; Shang, F. Heuristic dynamic programming based online energy management strategy for plug-in hybrid electric vehicles. IEEE Trans. Veh. Technol. 2019, 68, 4479–4493. [Google Scholar] [CrossRef]

- Wang, X.; He, H.; Sun, F.; Zhang, J. Application study on the dynamic programming algorithm for energy management of plug-in hybrid electric vehicles. Energies 2015, 8, 3225–3244. [Google Scholar] [CrossRef] [Green Version]

- Xie, H.; Tian, G.; Chen, H.; Wang, J.; Huang, Y. A distribution density-based methodology for driving data cluster analysis: A case study for an extended-range electric city bus. Pattern Recognit. 2018, 73, 131–143. [Google Scholar] [CrossRef]

- Arthur, D.; Vassilvitskii, S. k-means++: The advantages of careful seeding. In Proceedings of the Eighteenth Annual ACM-SIAM Symposium on Discrete Algorithms SODA ’07, Society for Industrial and Applied Mathematics, Philadelphia, PA, USA, 7–9 January 2007; pp. 1027–1035. [Google Scholar]

- Zahra, S.; Ghazanfar, M.A.; Khalid, A.; Azam, M.A.; Naeem, U.; Prugel-Bennett, A. Novel centroid selection approaches for KMeans-clustering based recommender systems. Inf. Sci. 2015, 320, 156–189. [Google Scholar] [CrossRef]

- Pham, D.T.; Otri, S.; Ghanbarzadeh, A.; Koc, E. Application of the Bees Algorithm to the training of learning vector quanti-sation networks for control chart pattern recognition. In Proceedings of the International Conference on Information & Communication Technologies, Damascus, Syria, 24–28 April 2006. [Google Scholar]

- He, H.; Sun, C.; Zhang, X. A Method for Identification of Driving Patterns in Hybrid Electric Vehicles Based on a LVQ Neural Network. Energies 2012, 5, 3363–3380. [Google Scholar] [CrossRef]

- Breiman, L. Random Forests. Mach. Learn. 2001, 45, 5–32. [Google Scholar] [CrossRef] [Green Version]

- Lahouar, A.; Ben Hadj Slama, J. Hour-ahead wind power forecast based on random forests. Renew. Energy 2017, 109, 529–541. [Google Scholar] [CrossRef]

- Pritiesh, M.; Neagu, D.; Paul, R.T.; Jonathan, D.V. Using random forest and decision tree models for a new vehicle prediction approach in computational toxicology. Soft Comput. 2016, 20, 2967–2979. [Google Scholar]

- Huang, G.-B.; Zhu, Q.-Y.; Siew, C.-K. Extreme learning machine: Theory and applications. Neurocomputing 2006, 70, 489–501. [Google Scholar] [CrossRef]

- Cohen, J. A Coefficient of Agreement for Nominal Scales. Educ. Psychol. Meas. 1960, 20, 37–46. [Google Scholar] [CrossRef]

- Landis, J.R.; Koch, G.G. The Measurement of Observer Agreement for Categorical Data. Biometrics 1977, 33, 159–174. [Google Scholar] [CrossRef] [Green Version]

- Murphey, Y.L.; Park, J.; Chen, Z.; Kuang, M.L.; Masrur, M.A.; Phillips, A.M. Intelligent Hybrid Vehicle Power Control—Part I: Machine Learning of Optimal Vehicle Power. IEEE Trans. Veh. Technol. 2012, 61, 3519–3530. [Google Scholar] [CrossRef]

| Item | Value |

|---|---|

| E-RE-CTM non-load mass (kg) | 15,000 |

| E-RE-CTM full-load mass (kg) | 40,500 |

| Li-ion battery pack capacity (Ah) | 300 |

| Driving motor maximum power (kW) | 350 |

| Hydraulic pump maximum displacement (cm3/r) | 90 |

| Hydraulic pump/motor maximum pressure (bar) | 420 |

| Generator maximum power (kW) | 130 |

| Engine maximum power (kW) | 125 |

| Symbol | Description | Unit |

|---|---|---|

| Maximum vehicle speed | km/h | |

| Maximum negative acceleration | m/s2 | |

| The standard deviation of the product of positive acceleration and speed | m2/s3 | |

| Mean value of the product of negative acceleration and speed | m2/s3 | |

| The ratio between 0 and 15 of vehicle speed | - | |

| The ratio between 30 and 50 of vehicle speed | - |

| Evaluation Index | |||||||

|---|---|---|---|---|---|---|---|

| LVQ | RF | ELM | Optimized ELM | LVQ | RF | ELM | |

| κ | 0.52 | 0.59 | 0.63 | 0.65 | 0.61 | 0.53 | 0.56 |

| 0.73 | 0.76 | 0.78 | 0.79 | 0.78 | 0.71 | 0.73 | |

| 15.30 | 11.94 | 0.52 | 0.45 | 17.91 | 12.32 | 0.47 | |

| Type | MSE |

|---|---|

| 1 | 0.00032 |

| 2 | 0.0020 |

| 3 | 0.00021 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, Y.; Jiang, F.; Xie, H. Machine-Learning-Based Optimization of Energy Management in a Novel Hybrid Powertrain of Concrete Truck Mixers. World Electr. Veh. J. 2021, 12, 175. https://doi.org/10.3390/wevj12040175

Huang Y, Jiang F, Xie H. Machine-Learning-Based Optimization of Energy Management in a Novel Hybrid Powertrain of Concrete Truck Mixers. World Electric Vehicle Journal. 2021; 12(4):175. https://doi.org/10.3390/wevj12040175

Chicago/Turabian StyleHuang, Ying, Fachao Jiang, and Haiming Xie. 2021. "Machine-Learning-Based Optimization of Energy Management in a Novel Hybrid Powertrain of Concrete Truck Mixers" World Electric Vehicle Journal 12, no. 4: 175. https://doi.org/10.3390/wevj12040175

APA StyleHuang, Y., Jiang, F., & Xie, H. (2021). Machine-Learning-Based Optimization of Energy Management in a Novel Hybrid Powertrain of Concrete Truck Mixers. World Electric Vehicle Journal, 12(4), 175. https://doi.org/10.3390/wevj12040175