A Review of Lithium-Ion Battery State of Health Estimation and Prediction Methods

Abstract

:1. Introduction

2. Lithium-Ion Battery Attenuation Mechanism and SOH Definition

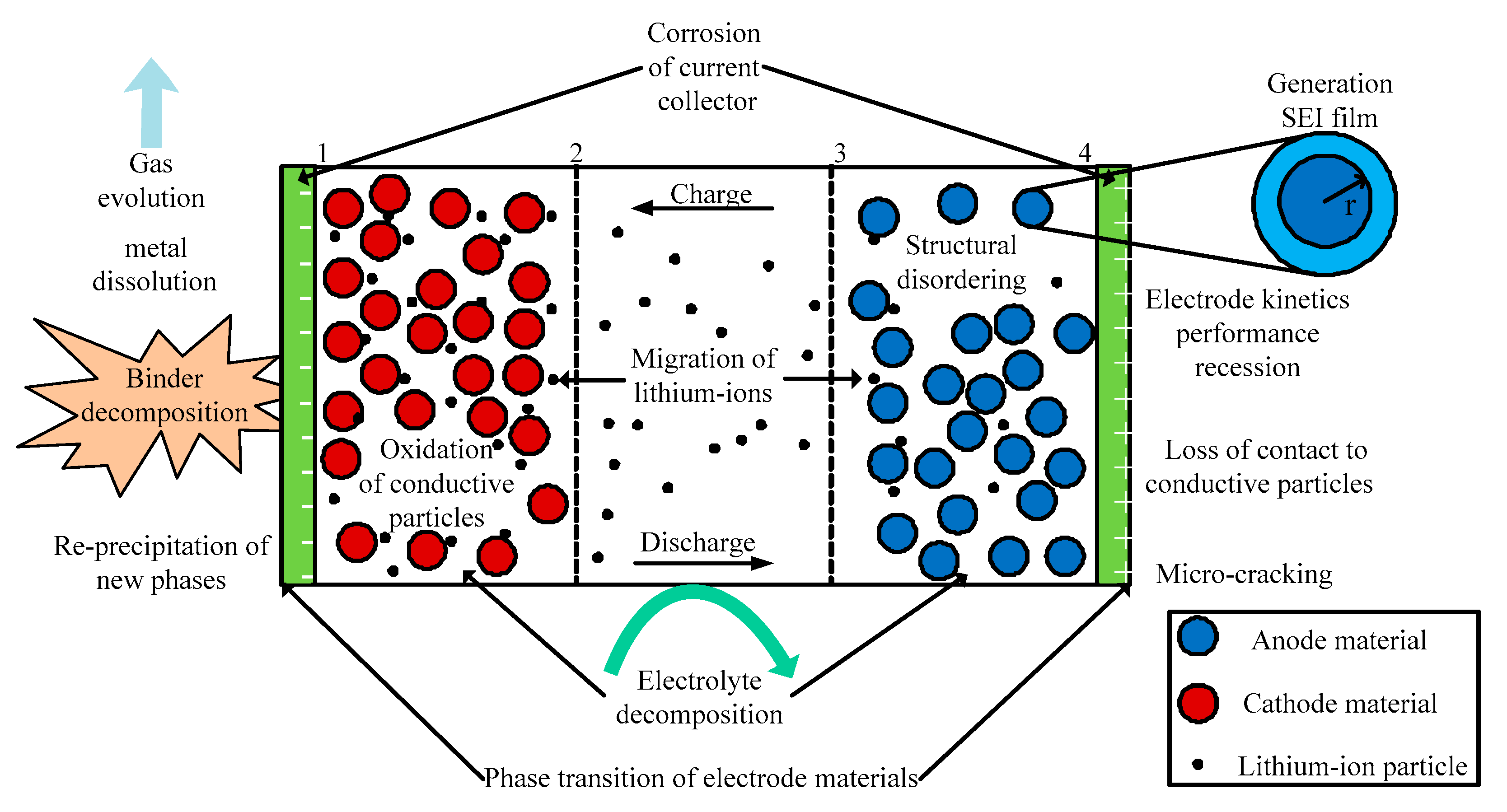

2.1. Fading Mechanism of Lithium-Ion Battery

- Phase transition of electrode materials: Taking lithium manganese oxide battery as an example, its capacity decline is mainly caused by manganese-ions’ dissolution. When manganese-ions are free to the negative electrode, the solid electrolyte interphase (SEI) membrane will be destroyed. In contrast, the interface membrane’s reformation requires the consumption of lithium-ions, resulting in the decrease of available lithium-ions. The experiments in the literature [18] have proved this point of view. Through the study on the aging characteristics of lithium-ion batteries, it is found that the aging degree of lithium-ion batteries will deepen with the increase of the charging and discharging times. During the charge and discharge process, the SEI film resistance increases continuously. The battery’s impedance characteristic is strengthened, and the ion diffusion coefficient at the electrode decreases, resulting in the rapid reduction of discharge voltage and the rapid attenuation of discharge capacity. This is not the case for some batteries, such as lithium titanate batteries, which may not produce an SEI film during operation.

- The electrode kinetics performance of recession: Using inductively coupled plasma emission spectrometer specific capacity, impedance characteristics of the electrode and the polarization characteristics were analyzed [19], and found to be the lithium-ion battery charge and discharge cycle, phase change is negative, ohm resistance, SEI film resistances were significantly increased, anode of lithium-ion is embedded in the reaction, resulting in decreased electrode ion storage capacity, and capacity loss, indicating that the battery capacity loss is negative dynamic performance and is the main cause of the recession.

- The decomposition of electrolyte: in the process of charge and discharge, the electrolyte itself has a certain instability, and the reduction reaction will occur with the carbon-containing electrode, and the reduction reaction will consume the electrolyte and its solvent. Mei [20] et al. used separators to observe lithium-ion batteries’ internal structure and proposed that the decrease of ionic conductivity would lead to electrolyte decomposition, thus reducing the battery capacity.

- The generation of SEI film: the formation of SEI film is the product of the reduction reaction that occurs after the contact between organic solvent and the anode material. The lithium-ion consumed due to the generation of SEI film will change the capacity balance [21,22]. Meanwhile, the SEI film will cause isolation of the electrode and deactivation, resulting in reduced capacity.

2.2. Definition Status of Health of Lithium-Ion Batteries

2.2.1. Capacity Definition

2.2.2. Internal Resistance Definition

2.2.3. The Definition of Capacity Contained in the Electrode

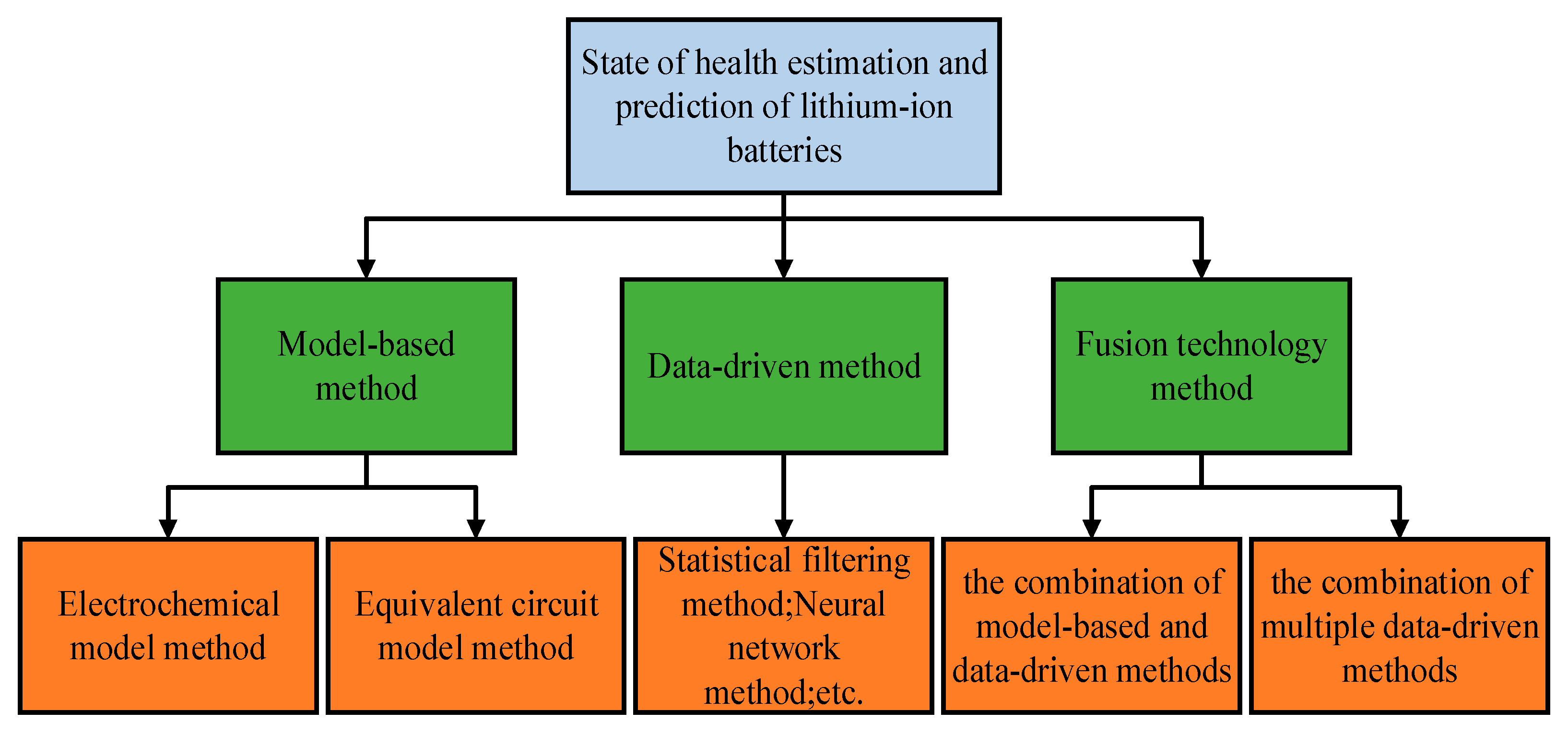

3. Statue of Health Estimation and Prediction of Lithium-Ion Batteries

- Difficulty in measurement: Lithium-ion battery SOH is an internal parameter of batteries, which cannot be directly measured by sensor. Only with voltage, current and temperature, and other relevant parameters can it be obtained by integration, approximate processing, and other methods, increasing the difficulty of accurate identification of SOH parameters.

- Strong time variability: Lithium-ion battery SOH is not only closely related to environmental stresses such as temperature, current and loading mode, but is also affected by internal multi-parameter coupling such as the current internal ion motion state, the ratio of positive and negative active materials, and the intensity of electrochemical reaction.

- Irreversibility: At present, most of the prediction methods adopt irreversible off-line state data for prediction, which is affected by monomers’ differences and has a low repeatability. At the same time, the reliability and timeliness of online identification are poor.

- High nonlinearity: In the actual operation process, the state of health of lithium-ion batteries is cross-coupled by multiple internal and external factors, and its degradation curve is highly nonlinear, which increases the difficulty of accurate identification and reliability of SOH.

3.1. Model-Based Method

3.1.1. Electrochemical Model Method

3.1.2. Equivalent Circuit Model Method

3.2. Data-Driven Method

3.2.1. Statistical Filtering Method

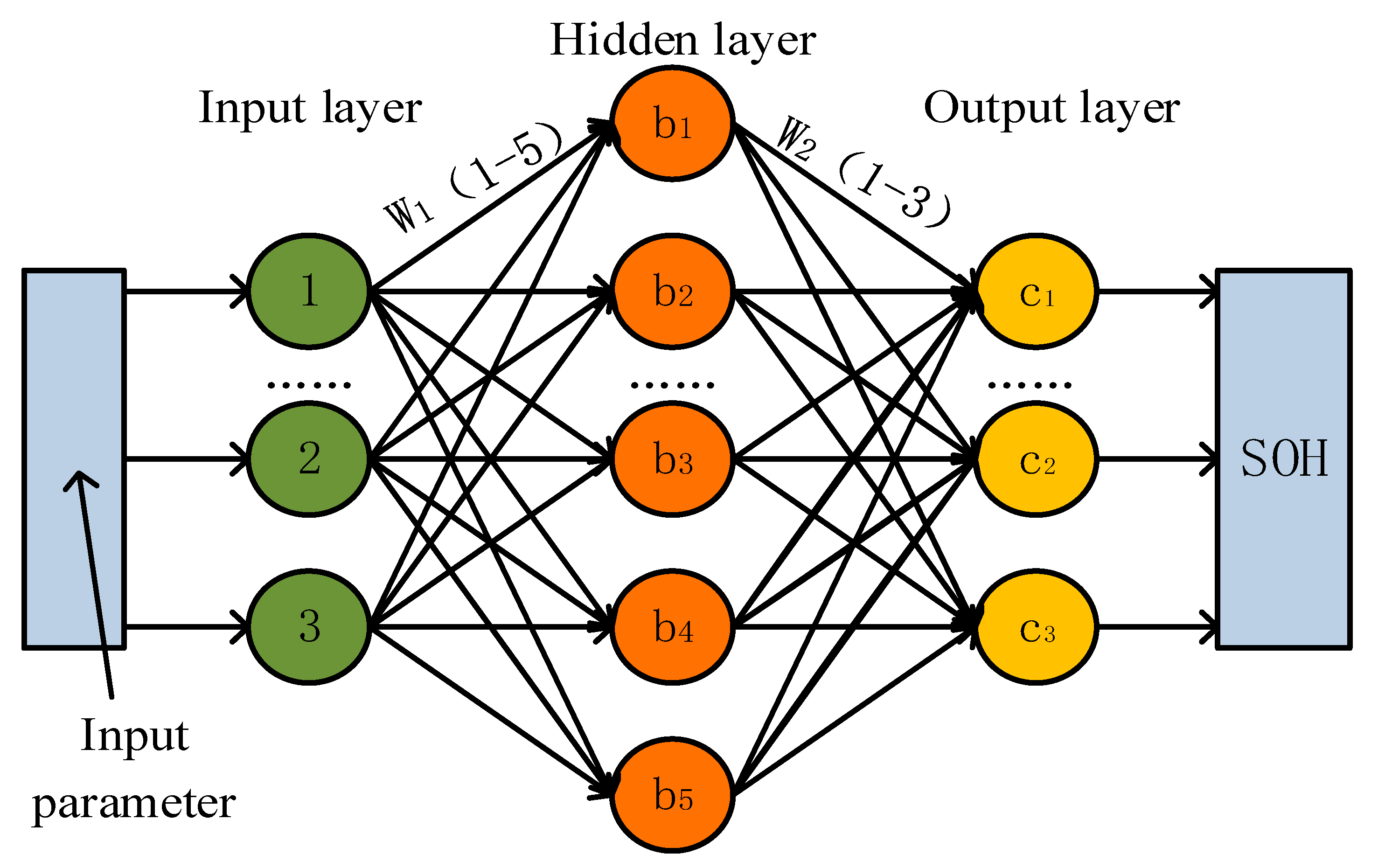

3.2.2. Neural Network Method

3.2.3. Deep Learning Method

3.2.4. Vector Machine Method

3.2.5. Statistical Data Method

- Confirm the function kernel function form;

- Set the initial value of the super parameter;

- A prior model is established in the form of probability distribution;

- The training samples were input into the a prior model for training, and the optimal hyperparameters were obtained to obtain the regression prediction model;

- Using the input regression prediction model of test samples for prediction;

- Output the prediction results, and give the mean and variance of the prediction results with the ability to express uncertainty.

3.3. Fusion Technology Method

- Serial integration algorithm with correlation among individual learners. The adaptive boosting algorithm (AdaBoost) can be individual learning series combined into a strong learning, is the typical representation of the serial integration algorithm, Ma et al. [153], using AdaBoost and the stacking algorithm on multiple SVRs merged into two models, established a lithium battery SOH prediction based on double predictor estimation method, using three kinds of lithium-ion battery the data set was tested. The advantage of AdaBoost is that there are almost no parameters to adjust, and you do not have to worry about overfitting. However, it is sensitive to noise and cannot guarantee the global optimal solution.

- Parallel integration algorithm with no correlation between individual learners. Typical representative is random forests (RF), Li and others [154], measure voltage, current, time of the original signal directly input RF SOH prediction algorithm model, without any pretreatment, and verified by different aging statuses of lithium-ion batteries, and the results show that this algorithm returns low cost, high precision, and root mean square error less than 1.3%. Chen et al. [155] compared the RF, SVM, and least squares support vector machine (LSSVM) estimation ability for lithium-ion battery SOH and concluded that RF was superior to the other two algorithms. The advantages of RF are: high accuracy can be achieved without a large number of parameters; it works for both classification and regression; again, you do not have to worry about over-fitting; no feature selection is required; and several features can be randomly selected for training each time, but the disadvantage is that compared with other algorithms, the operation time is longer.

4. Challenges and Prospects

- Feature parameter extraction of micro/macro coupling mechanism. Under different battery health conditions, parameters such as voltage, current, resistance, and temperature are often used to characterize the degree of battery aging. In other words, the battery is regarded as a black box, and only the relationship between macroscopic inputs and inputs is considered. However, with the deepening of the theoretical research, the macro characterization of the reaction intensity in the battery will become the core of research because it can more reasonably and efficiently determine the battery’s health state.

- Application of multi-algorithm cross fusion technology. Batteries in actual operation are always affected by temperature, loading mode, and the influence of other factors such as coupling interference. Their internal structure is complex, as the charged state and aging properties are different, characterization of parameters are not the same, so a single algorithm can only meet the prediction of the battery’s current specific condition, or characteristic at a certain stage. Many algorithms’ cross fusion technology can play to each algorithm’s advantage, further improving the estimation and prediction accuracy.

- Implementation of new 5G and cloud platform technologies. Using 5G communication technology and the development of cloud platform technology, enables breaking through the limitation of the calculation processing intensity, use of the technology, such as downloading via mobile communication interface, the transmission of online processing results to the battery management system, improving the system of state parameter identification and calculation of strength, and the ability to apply online algorithm.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Abbreviations | |

| SOH | State of health |

| SEI | Solid electrolyte interphase |

| EIS | Electrochemical impedance spectroscopy |

| RC | Resistor-circuit |

| P2D | Pseudo 2 dimensional |

| PNGV | Partnership for a new generation of vehicles |

| HI | Health index |

| KF | Kalman filtering |

| PF | Particle filtering |

| UKF | Unscented Kalman filtering |

| EKF | Extended Kalman filter |

| DEKF | Double extended Kalman filter |

| ANN | Artificial neural network |

| CNN | Convolutional neural network |

| BP | Back propagation neural network |

| SOC | State of Charge |

| DL | Deep Learning |

| GRU-CNN | Gate recursive unity-convolutional neural network |

| SVM | Support vector machine |

| PCA | Principal component analysis |

| RVM | Relevance vector machine |

| WP | Wiener process |

| GPR | Gaussian process regression |

| LSTM | Long-Short Term Memory |

| EL | Ensemble learning |

| AdaBoost | Adaptive boosting algorithm |

| RF | Random forests |

| LSSVM | Least squares support vector machine |

| Notation | |

| Qr | Rated capacity |

| Qm | The current maximum available capacity of the battery |

| R | Internal resistance under the current state |

| Re | Internal resistance of the battery when it reaches the end of life |

| Rn | Internal resistance of the new battery |

| b1-b5 | The threshold of the hidden layer |

| c1–c3 | The threshold of output layer |

| W1(1–5) | Input weights |

| W2(1–3) | Output weights |

| Q | Nominal capacity |

| Q0 | Smaller lithium concentration after multiple cycles |

References

- Yao, L.; Wang, Z. Research on the charging mode of lithium ion power battery. J. Automot. Eng. 2015, 37, 72–77. [Google Scholar]

- Berecibar, M.; Gandiaga, I.; Villarreal, I.; Omar, N.; Mierlo, J.V.; Bossche, P. Critical review of state of health estimation methods of Li-ion batteries for real applications. Renew. Sustain. Energy Rev. 2016, 56, 572–587. [Google Scholar] [CrossRef]

- Salminen, J.; Kallio, T.; Omar, N.; Gualous, H.; Mierlo, J.V. Chapter 14-Transport Energy-Lithium Ion Batteries. In Future Energy, 2nd ed.; Letcher, T.M., Ed.; Elsevier: Amsterdam, The Netherlands, 2014; pp. 291–309. [Google Scholar]

- Andwari, A.M.; Pesiridis, A.; Rajoo, S.; Martinez-Botas, R.; Esfahanian, V. A review of battery electric vehicle technology and readiness levels. Renew. Sustain. Energy Rev. 2017, 78, 414–430. [Google Scholar] [CrossRef]

- Corey, G.P. Batteries for stationary standby and for stationary cycling applications part 6: Alternative electricity storage technologies. In Proceedings of the 2003 IEEE Power Engineering Society General Meeting, Toronto, ON, Canada, 13–17 July 2003. [Google Scholar]

- Hannan, M.A.; Lipu, M.; Hussain, A.; Mohamed, A. A review of lithium-ion battery state of charge estimation and management system in electric vehicle applications: Challenges recommendations. Renew. Sustain. Energy Rev. 2017, 78, 834–854. [Google Scholar] [CrossRef]

- Akhoundzadeh, M.H.; Panchal, S.; Samadani, E.; Raahemifar, K.; Fowler, M.; Fraser, R. Investigation and simulation of electric train utilizing hydrogen fuel cell and lithium-ion battery. Sustain. Energy Technol. Assess. 2021, 46, 101234. [Google Scholar]

- Shang, Y.; Lu, G.; Kang, Y.; Zhou, Z.; Duan, B.; Zhang, C. A multi-fault diagnosis method based on modified sample entropy for lithium-ion battery strings. J. Power Sources 2020, 446, 227275. [Google Scholar] [CrossRef]

- Li, X.; Wang, Z.; Zhang, L.; Zou, C.; Dorrell, D.D. State-of-health estimation for li-ion batteries by combing the incremental capacity analysis method with grey relational analysis. J. Power Sources 2019, 410, 106–114. [Google Scholar] [CrossRef]

- Garche, J.; Jossen, A. Monitoring and safety tests of batteries: From state of charge (SOC) and health (SOH) to misuse, abuse and crash. In Electrochemical Storage Materials: Supply, Processing, Recycling, and Modeling, Proceedings of the 2nd International Freiberg Conference on Electrochemical Storage Materials, Freiberg, Germany, 11–12 June 2015; AIP Conference Proceedings: Freiberg, Germany, 25 August 2016. [Google Scholar]

- Ungurean, L.; Crstoiu, G.; Mihai, V.; Groza, V. Battery state of health estimation: A structured review of models, methods and commercial devices. Int. J. Energy Res. 2016, 41, 151–181. [Google Scholar] [CrossRef]

- Yang, S.; Zhang, C.; Jiang, J.; Zhang, W.; Zhang, L.; Wang, Y. Review on state-of-health of lithium-ion batteries: Characterizations, estimations and applications. J. Clean. Prod. 2021, 314, 128015. [Google Scholar] [CrossRef]

- Li, Y.; Liu, K.; Aoife, M.F.; Zülke, A.; Berecibar, M.; Nanini-Maury, E.; Van Mierlo, J.; Hoster, H.E. Data-driven health estimation and lifetime prediction of lithium-ion batteries: A review. Renew. Sustain. Energy Rev. 2019, 113, 109254. [Google Scholar] [CrossRef]

- Feng, X.; Ouyang, M.; Liu, X.; Lu, L.; Xia, Y.; He, X. Thermal runaway mechanism of lithium ion battery for electric vehicles: A review. Energy Storage Mater. 2018, 10, 246–267. [Google Scholar] [CrossRef]

- Tian, J.; Wang, Y.; Chen, Z. Summary of fault diagnosis for lithium battery energy storage system. In Proceedings of the 19th China Conference on System Simulation Technology and Its Application (19th CCSSTA 2018), Guiyang, China, 12 August 2018. [Google Scholar]

- Tian, J.; Xiong, R.; Shen, W. A review on state of health estimation for lithium ion batteries in photovoltaic systems. ETransportation 2019, 2, 100028. [Google Scholar] [CrossRef]

- Yang, Y.; Okonkwo, E.G.; Huang, G.; Xu, S.; He, Y. On the sustainability of lithium ion battery industry—A review and perspective. Energy Storage Mater. 2021, 36, 186–212. [Google Scholar] [CrossRef]

- Qin, D.; Yao, L.; Hu, M. Rapid determination of failure of lithium-ion batteries. World Sci. Technol. Res. Dev. 2012, 34, 21–24. [Google Scholar]

- Wang, Z.; Li, J.; Wang, K.; Gao, F.; Tian, B. Analysis of degradation mechanism of lithium iron phosphate/graphite power battery. Rare Met. Cem. Carbide 2020, 48, 63–69. [Google Scholar]

- Mei, W.; Zhang, L.; Sun, J.; Wang, Q. Experimental and numerical methods to investigate the overcharge caused lithium plating for lithium ion battery. Energy Storage Mater. 2020, 32, 91–104. [Google Scholar] [CrossRef]

- Peled, E.; Menkin, S. Review—SEI: Past, Present and Future. J. Electrochem. Soc. 2017, 164, A1703–A1719. [Google Scholar] [CrossRef]

- Jie, L.; Ad Ewuyi, K.; Yagin, N.L.; Landers, R.; Park, J. A Single Particle Model with Chemical/Mechanical Degradation Physics for Lithium Ion Battery State of Health (SOH) Estimation. Appl. Energy 2018, 212, 1178–1190. [Google Scholar]

- Shinagawa, C.; Ushiyama, H.; Yamashita, K. Multiscale simulations for lithium-ion batteries: Sei film growth and capacity fading. J. Electrochem. Soc. 2017, 164, A3018–A3024. [Google Scholar] [CrossRef]

- Kim, J.; Ma, H.; Cha, H.; Lee, H.; Sung, J.; Seo, M.; Oh, P.; Pak, M.; Cho, J. A highly stabilized nickel-rich cathode material by nanoscale epitaxy control for high-energy lithium-ion batteries. Energy Environ. Sci. 2018, 11, 1449–1459. [Google Scholar] [CrossRef]

- Sun, Y.; Zhao, Y.; Wang, J.; Liang, J.; Wang, C.; Sun, Q. A Novel Organic ‘Polyurea’ Thin Film for Ultralong-Life Lithium-Metal Anodes via Molecular-Layer Deposition. Adv. Mater. 2019, 31, 1806541. [Google Scholar] [CrossRef] [PubMed]

- Farmann, A.; Waag, W.; Marongiu, A.; Sauer, D.U. Critical review of on-board capacity estimation techniques for lithium-ion batteries in electric and hybrid electric vehicles. J. Power Sources 2015, 281, 114–130. [Google Scholar] [CrossRef]

- Li, R. Study on Evaluation and Estimation Method of Lithium Power Battery Health. Ph.D. Thesis, Harbin University of Science and Technology, Harbin, China, 2016. [Google Scholar]

- Li, G.; Lu, H.; Yuan, J.; Li, B. A Review of Lithium-ion Battery Life Research. Chin. J. Power Sources 2016, 40, 1312–1314. [Google Scholar]

- Andre, D.; Meiler, M.; Steiner, K.; Wirnmer, C.; Soczka-Guth, T.; Sauer, D.U. Characterization of high-power lithium-ion batteries by electrochemical impedance spectroscopy. experimental investigation. J. Power Sources 2011, 196, 5334–5341. [Google Scholar] [CrossRef]

- Tran, N.T.; Khan, A.; Choi, W. State of charge and state of health estimation of agm vrla batteries by employing a dual extended kalman filter and an arx model for online parameter estimation. Energies 2017, 10, 137. [Google Scholar] [CrossRef] [Green Version]

- Lotfi, N.; Li, J.; Landers, R.G.; Park, J. Li-ion Battery State of Health Estimation based on an improved Single Particle model. In Proceedings of the American Control Conference IEEE, Seattle, WA, USA, 24–26 May 2017. [Google Scholar]

- Tan, C.M.; Singh, P.; Chen, C. Accurate real time on-line estimation of state-of-health and remaining useful life of li ion batteries. Appl. Sci. 2020, 10, 7836. [Google Scholar] [CrossRef]

- Lluc, C.C.; Beatriz, A.G. Second-Life Batteries on a Gas Turbine Power Plant to Provide Area Regulation Services. Batteries 2017, 3, 10. [Google Scholar]

- Catton, J.; Walker, S.B.; Mcinnis, P.; Fowler, M.; Gaffney, B. Comparative safety risk and the use of repurposed EV batteries for stationary energy storage. In Proceedings of the 2017 IEEE International Conference on Smart Energy Grid Engineering (SEGE), Oshawa, ON, Canada, 14–17 August 2017. [Google Scholar]

- Andre, D.; Nuhic, A.; Soczka-Guth, T.; Sauer, D.U. Comparative study of a structured neural network and an extended kalman filter for state of health determination of lithium-ion batteries in hybrid electricvehicles. Eng. Appl. Artif. Intell. 2013, 26, 951–961. [Google Scholar] [CrossRef]

- Yun, B.; Dong, W.; Wang, D. Online Internal Resistance Measurement Application in Lithium Ion Battery Capacity and State of Charge Estimation. Energies 2018, 11, 1073. [Google Scholar]

- Akhil, G.; Liu, Y.; Liang, G. Development of recycling strategy for large stacked systems: Experimental and machine learning approach to form reuse battery packs for secondary applications. J. Clean. Prod. 2020, 275, 124152. [Google Scholar]

- Liu, B.; Tang, X.; Gao, F. Joint estimation of battery state-of-charge and state-of-health based on a simplified pseudo-two-dimensional model. Electrochim. Acta 2020, 344, 136098. [Google Scholar] [CrossRef]

- Kumar, B.; Khare, N.; Chaturvedi, P.K. FPGA-based design of advanced BMS implementing SoC/SoH estimators. Microelectron. Reliab. 2018, 84, 66–74. [Google Scholar] [CrossRef]

- Liang, K.; Zhang, Z.; Liu, P.; Wang, Z.; Jiang, S. Data-Driven Ohmic Resistance Estimation of Battery Packs for Electric Vehicles. Energies 2019, 12, 4772. [Google Scholar] [CrossRef] [Green Version]

- Wassiliadis, N.; Adermann, J.; Frericks, A.; Pak, M.; Reiter, C.; Lohmann, B. Revisiting the dual extended kalman filter for battery state-of-charge and state-of-health estimation: A use-case life cycle analysis. J. Energy Storage 2018, 19, 73–87. [Google Scholar] [CrossRef]

- Guha, A.; Patra, A. State of Health Estimation of Lithium-Ion Batteries Using Capacity Fade and Internal Resistance Growth Models. IEEE Trans. Transp. Electrif. 2018, 4, 135–146. [Google Scholar] [CrossRef]

- Ping, S.; Ouyang, M.; Lu, L.; Li, J.; Feng, X. The Co-estimation of State of Charge, State of Health, and State of Function for Lithium-Ion Batteries in Electric Vehicles. IEEE Trans. Veh. Technol. 2017, 67, 92–103. [Google Scholar]

- Cacciato, M.; Nobile, G.; Scarcella, G.; Scelba, G. Real-Time Model-Based Estimation of SOC and SOH for Energy Storage Systems. IEEE Trans. Power Electron. 2016, 32, 794–803. [Google Scholar] [CrossRef]

- Pastor-Fernandez, C.; Uddin, K.; Chouchelamane, G.H.; Widanage, W.D.; Marco, J. Dataset to support: A comparison between electrochemical impedance spectroscopy and incremental capacity-differential voltage as li-ion diagnostic techniques to identify and quantify the effects of degradation modes within battery management systems. J. Power Sources 2017, 360, 301–318. [Google Scholar] [CrossRef]

- Howey, D.A.; Mitcheson, P.D.; Yufit, V.; Offer, G.J.; Brandon, N.P. Online measurement of battery impedance using motor controller excitation. IEEE Trans. Veh. Technol. 2014, 63, 2557–2566. [Google Scholar] [CrossRef]

- Sabet, P.S.; Stahl, G.; Sauer, D.U. Non-invasive investigation of predominant processes in the impedance spectra of high energy lithium-ion batteries with nickel–cobalt–aluminum cathodes. J. Power Sources 2020, 472, 228189. [Google Scholar] [CrossRef]

- Zhang, C.; Li, K.; Deng, J.; Song, S. Improved Realtime State-of-Charge Estimation of LiFePO4 Battery Based on a Novel Thermoelectric Model. IEEE Trans. Ind. Electron. 2017, 64, 654–663. [Google Scholar] [CrossRef] [Green Version]

- Tourani, A.; White, P.; Ivey, P. A multi scale multi-dimensional thermo electrochemical modelling of high capacity lithium-ion cells. J. Power Sources 2014, 255, 360–367. [Google Scholar] [CrossRef]

- Tian, J.; Xu, R.; Wang, Y.; Chen, Z. Capacity attenuation mechanism modeling and health assessment of lithium-ion batteries. Energy 2021, 221, 119682. [Google Scholar] [CrossRef]

- Muratoglu, Y.; Alkaya, A. Unscented kalman filter based state of charge estimation for the equalization of lithium-ion batteries on electrical vehicles. Eng. Technol. Appl. Sci. Res. 2019, 9, 4876–4882. [Google Scholar] [CrossRef]

- Farrier, L.; Bucknall, R. Investigating the performance capability of a lithium-ion battery system when powering future pulsed loads. Energies 2020, 13, 1357. [Google Scholar] [CrossRef] [Green Version]

- Hossain, M.; Saha, S.; Arif, M.T.; Oo, A.; Haque, E. A Parameter Extraction Method for the Li-Ion Batteries with Wide-Range Temperature Compensation. IEEE Trans. Ind. Appl. 2020, 56, 5625–5636. [Google Scholar] [CrossRef]

- Zeng, M.; Zhang, P.; Yang, Y.; Xie, C.; Shi, Y. SOC and SOH Joint Estimation of the Power Batteries Based on Fuzzy Unscented Kalman Filtering Algorithm. Energies 2019, 12, 3122. [Google Scholar] [CrossRef] [Green Version]

- Nejad, S.; Gladwin, D.T.; Stone, D.A. A systematic review of lumped-parameter equivalent circuit models for real-time estimation of lithium-ion battery states. J. Power Sources 2016, 316, 183–196. [Google Scholar] [CrossRef] [Green Version]

- Zuo, Y.; Hu, X.; Ma, H.; Li, S. Combined State of Charge and State of Health estimation over lithium-ion battery cell cycle lifespan for electric vehicles. J. Power Sources 2015, 273, 793–803. [Google Scholar]

- Domenico, D.D.; Fiengo, G.; Stefanopoulou, A. Lithium-Ion Battery State of Charge Estimation with a Kalman Filter Based on an Electrochemical Model. In Proceedings of the 2008 IEEE International Conference on Control Applications, San Antonio, TX, USA, 3–5 September 2008. [Google Scholar]

- Wang, Y.; Tian, J.; Sun, Z.; Wang, L.; Chen, Z. A Comprehensive Review of Battery Modeling and State Estimation Approaches for Advanced Battery Management Systems. Renew. Sustain. Energy Rev. 2020, 131, 110015. [Google Scholar] [CrossRef]

- Huang, M.; Kumar, M. Electrochemical Model-Based Aging Characterization of Lithium-Ion Battery Cell in Electrified Vehicles. In Proceedings of the ASME 2018 Dynamic Systems and Control Conference 2018, Atlanta, GA, USA, 30 September–3 October 2018. [Google Scholar]

- Zhang, Q.; Wang, D.; Yang, B.; Cui, X.; Li, X. Electrochemical model of lithium-ion battery for wide frequency range applications. Electrochim. Acta 2020, 343, 136094. [Google Scholar] [CrossRef]

- Lee, J.L.; Chemistruck, A.; Plett, G.L. One-dimensional physics-based reduced-order model of lithium-ion dynamics. J. Power Sources 2012, 220, 430–448. [Google Scholar] [CrossRef]

- Jie, G.; Barker, D.; Pecht, M. Prognostics implementation of electronics under vibration loading. Microelectron. Reliab. 2007, 47, 1849–1856. [Google Scholar]

- Farmann, A.; Sauer, D.U. Comparative study of reduced order equivalent circuit models for on-board state-of-available-power prediction of lithium-ion batteries in electric vehicles. Appl. Energy 2018, 225, 1102–1122. [Google Scholar] [CrossRef]

- Lai, X.; Wang, S.; Ma, S.; Xie, J.; Zheng, Y. Parameter sensitivity analysis and simplification of equivalent circuit model for the state of charge of lithium-ion batteries—ScienceDirect. Electrochim. Acta 2020, 330, 135239. [Google Scholar] [CrossRef]

- Locorotondo, E.; Pugi, L.; Berzi, L.; Pierini, M.; Lutz Em Berger, G. Online Identification of Thevenin Equivalent Circuit Model Parameters and Estimation State of Charge of Lithium-Ion Batteries. In Proceedings of the 2018 IEEE International Conference on Environment and Electrical Engineering and 2018 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I&CPS Europe), Palermo, Italy, 12–15 June 2018. [Google Scholar]

- Wei, H.; Chen, X.; Lü, Z.; Wang, Z.; Chen, L. Online Estimation of Lithium-Ion Battery State of Health Using Grey Neural Network. Power Syst. Technol. 2017, 41, 4038–4044. [Google Scholar]

- Panchal, S.; Mcgrory, J.; Kong, J.; Fraser, R.; Fowler, M.; Dincer, I.; Agelin-Chaab, M. Cycling degradation testing and analysis of a lifepo4 battery at actual conditions. Int. J. Energy Res. 2017, 41, 2565–2575. [Google Scholar] [CrossRef]

- Liu, X.; Li, W.; Zhou, A. PNGV Equivalent Circuit Model and SOC Estimation Algorithm for Lithium Battery Pack Adopted in AGV Vehicle. IEEE Access 2018, 6, 23639–23647. [Google Scholar] [CrossRef]

- He, H.; Xiong, R.; Guo, H.; Li, S. Comparison study on the battery models used for the energy management of batteries in electric vehicles. Energy Convers. Manag. 2012, 64, 113–121. [Google Scholar] [CrossRef]

- Barcellona, S.; Piegari, L. Lithium Ion Battery Models and Parameter Identification Techniques. Energies 2017, 10, 2007. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Li, M.; Chen, Z. Experimental study of fractional-order models for lithium-ion battery and ultra-capacitor: Modeling, system identification, and validation. Appl. Energy 2020, 278, 115736. [Google Scholar] [CrossRef]

- Vepsäläinen, J.; Ritari, A.; Lajunen, A.; Kivekäs, K.; Tammi, K. Energy uncertainty analysis of electric buses. Energies 2018, 11, 3267. [Google Scholar] [CrossRef] [Green Version]

- Figueroa-Santos, M.A.; Siegel, J.B.; Stefanopoulou, A.G. Leveraging cell expansion sensing in state of charge estimation: Practical considerations. Energies 2020, 13, 2653. [Google Scholar] [CrossRef]

- Deng, Y.; Ying, H.; Jiaqiang, E.; Zhu, H.; Wei, K.; Chen, J. Feature parameter extraction and intelligent estimation of the State-of-Health of lithium-ion batteries. Energy 2019, 176, 91–102. [Google Scholar] [CrossRef]

- Severson, K.A.; Attia, P.M.; Jin, N.; Perkins, N.; Jiang, B.; Yang, Z. Data-driven prediction of battery cycle life before capacity degradation. Nat. Energy 2019, 4, 383–391. [Google Scholar] [CrossRef] [Green Version]

- Mawonou, S.R.; Eddahech, A.; Dumur, D.; Beauvois, D.; Godoy, E. State-of-health estimators coupled to a random forest approach for lithium-ion battery aging factor ranking-sciencedirect. J. Power Sources 2021, 484, 229154. [Google Scholar] [CrossRef]

- Guo, P.; Cheng, Z.; Yang, L. A data-driven remaining capacity estimation approach for lithium-ion batteries based on charging health feature extraction. J. Power Sources 2019, 412, 442–450. [Google Scholar] [CrossRef]

- Wang, S.; Han, X.; Chen, L. Particle Filtering for Lithium-ion Battery Residual Life Prediction. Chin. J. Power Sources 2020, 44, 48–53. [Google Scholar]

- Vidal, C.; Malysz, P.; Kollmeyer, P.; Emadi, A. Machine learning applied to electrified vehicle battery state of charge and state of health estimation: State-of-the-art. IEEE Access 2020, 8, 52796–52814. [Google Scholar] [CrossRef]

- Klass, V.; Behm, M.; Lindbergh, G. A support vector machine-based state-of-health estimation method for lithium-ion batteries under electric vehicle operation. J. Power Sources 2014, 270, 262–272. [Google Scholar] [CrossRef]

- Wei, Z.; Zhao, J.; Ji, D.; Tseng, K.J. A multi-timescale estimator for battery state of charge and capacity dual estimation based on an online identified model. Appl. Energy 2017, 204, 1264–1274. [Google Scholar] [CrossRef]

- Vichard, L.; Ravey, A.; Venet, P.; Harel, F.; Hissel, D. A method to estimate battery soh indicators based on vehicle operating data only. Energy 2021, 225, 120235. [Google Scholar] [CrossRef]

- Topan, P.A.; Ramadan, M.N.; Fathoni, G.; Cahyadi, A.I.; Wahyunggoro, O. State of Charge (SOC) and State of Health (SOH) estimation on lithium polymer battery via Kalman filter. In Proceedings of the 2016 2nd International Conference on Science and Technology-Computer (ICST), Yogyakarta, Indonesia, 27–28 October 2017. [Google Scholar]

- Remmlinger, J.; Buchholz, M.; Soczka-Guth, T.; Dietmayer, K. On-board state-of-health monitoring of lithium-ion batteries using linear parameter-varying models. J. Power Sources 2013, 239, 689–695. [Google Scholar] [CrossRef]

- Zhao, P.C.; Qiu, T.W. The Application of UKF Algorithm for 18650-type Lithium Battery SOH Estimation. Appl. Mech. Mater. 2014, 519, 1079–1084. [Google Scholar]

- Gholizadeh, M.; Yazdizadeh, A. A Systematic Mixed Adaptive Observer and EKF Approach to Estimate the SOC and SOH of a Lithium-Ion Battery. IET Electr. Syst. Transp. 2019, 10, 135–143. [Google Scholar] [CrossRef]

- Fang, L.; Li, J.; Peng, B. Online Estimation and Error Analysis of both SOC and SOH of Lithium-ion Battery based on DEKF Method. Energy Procedia 2019, 158, 3008–3013. [Google Scholar] [CrossRef]

- Li, S.; Fang, H.; Shi, B. Remaining useful life estimation of Lithium-ion battery based on interacting multiple model particle filter and support vector regression. Reliab. Eng. Syst. Saf. 2021, 210, 107542. [Google Scholar] [CrossRef]

- Qu, J.; Liang, H. Fast Adaptive Tracking Based on Fusion Particle Filter Algorithm. In Proceedings of the 2019 2nd International Conference on Mechanical Engineering, Industrial Materials and Industrial Electronics (MEIMIE 2019), Dalian, China, 29 March 2019. [Google Scholar]

- Kim, S.; Park, H.J.; Choi, J.H.; Kwon, D. A novel prognostics approach using shifting kernel particle filter of li-ion batteries under state changes. IEEE Trans. Ind. Electron. 2020, 68, 3485–3493. [Google Scholar] [CrossRef]

- Wang, D.; Tsui, K.L. State Space Models Based Prognostic Methods for Remaining Useful Life Prediction of Rechargeable Batteries; Springer: Singapore, 2017; pp. 307–334. [Google Scholar]

- Guha, A.; Patra, A. Particle filtering based estimation of remaining useful life of lithium-ion batteries employing power fading data. In Proceedings of the 2017 IEEE International Conference on Prognostics and Health Management (ICPHM), Dallas, TX, USA, 19–21 June 2017. [Google Scholar]

- Zhang, J.; Liu, X.; Chen, C.; Simeone, A. An Intelligent Deformation-Based Approach to the State of Health Estimation of Collided Lithium-Ion Batteries for Facilitating Battery Module Safety Evaluation. Energy Technol. 2020, 8, 2000624. [Google Scholar] [CrossRef]

- Fleischer, C.; Waag, W.; Bai, Z.; Sauer, D.U. Adaptive on-line state-of-available-power prediction of lithium-ion batteries. J. Power Electron. 2013, 13, 516–527. [Google Scholar] [CrossRef] [Green Version]

- Xia, Z.; Qahouq, J.A. State-of-charge Balancing of Lithium-ion Batteries with State-of-health Awareness Capability. IEEE Trans. Ind. Appl. 2021, 57, 673–684. [Google Scholar] [CrossRef]

- Zhang, G.; Patuwo, B.E.; Hu, M.Y. Forecasting with artificial neural networks: The state of the art. Int. J. Forecast. 1998, 14, 35–62. [Google Scholar] [CrossRef]

- Naha, A.; Han, S.; Agarwal, S.; Guha, A.; Oh, B. An Incremental Voltage Difference Based Technique for Online State of Health Estimation of Li-ion Batteries. Sci. Rep. 2020, 10, 9526. [Google Scholar] [CrossRef] [PubMed]

- Sarmah, S.B.; Kalita, P.; Das, B.; Garg, A.; Sarma, M. Numerical and experimental investigation of state of health of Li-ion battery. Int. J. Green Energy 2020, 17, 510–520. [Google Scholar] [CrossRef]

- Bonfitto, A. A Method for the Combined Estimation of Battery State of Charge and State of Health Based on Artificial Neural Networks. Energies 2020, 13, 2548. [Google Scholar] [CrossRef]

- Hou, E.; Qiao, X.; Liu, G. Remaining Useful Life Prediction of Power Lithium-Ion Battery based on Artificial Neural Network Model. In Proceedings of the 2017 International Conference on Mechanical, Control and Automation Engineering (MECAE 2017), Wuhan, China, 20 March 2017. [Google Scholar]

- Ungurean, L.; Micea, M.V.; Crstoiu, G. Online state of health prediction method for lithium-ion batteries, based on gated recurrent unit neural networks. Int. J. Energy Res. 2020, 44, 6767–6777. [Google Scholar] [CrossRef]

- Khumprom, P.; Yodo, N. A Data-Driven Predictive Prognostic Model for Lithium-ion Batteries based on a Deep Learning Algorithm. Energies 2019, 12, 660. [Google Scholar] [CrossRef] [Green Version]

- Sterkens, W.; Dillam, D.R.; Goedemé, T.; Dewulf, W.; Jef, R.P. Detection and recognition of batteries on x-ray images of waste electrical and electronic equipment using deep learning-sciencedirect. Resour. Conserv. Recycl. 2021, 168, 105246. [Google Scholar] [CrossRef]

- Khan, N.; Ullah, F.; Afnan, U.A.; Baik, S.W. Batteries State of Health Estimation via Efficient Neural Networks with Multiple Channel Charging Profiles. IEEE Access 2020, 9, 7797–7813. [Google Scholar] [CrossRef]

- Li, D.; Yang, L. Remaining useful life prediction of lithium battery using convolutional neural network with optimized parameters. In Proceedings of the 2020 5th Asia Conference on Power and Electrical Engineering (ACPEE), Chengdu, China, 4–7 June 2020. [Google Scholar]

- Fan, Y.; Xiao, F.; Li, C.; Yang, G.; Tang, X. A novel deep learning framework for state of health estimation of lithium-ion battery. J. Energy Storage 2020, 32, 101741. [Google Scholar] [CrossRef]

- Zhang, Y.; Xiong, R.; He, H.; Pecht, M. Long Short-Term Memory Recurrent Neural Network for Remaining Useful Life Prediction of Lithium-Ion Batteries. IEEE Trans. Veh. Technol. 2018, 67, 5695–5705. [Google Scholar] [CrossRef]

- Ren, L.; Dong, J.; Wang, X.; Meng, Z.; Zhao, L. A data-driven auto-CNN-LSTM prediction model for lithium-ion battery remain useful life. IEEE Trans. Ind. Inform. 2020, 17, 3478–3487. [Google Scholar] [CrossRef]

- Tan, T.; Zhao, G. Transfer Learning With Long Short-Term Memory Network for State-of-Health Prediction of Lithium-Ion Batteries. IEEE Trans. Ind. Electron. 2019, 67, 8723–8731. [Google Scholar] [CrossRef]

- Klass, V.; Behm, M.; Lindbergh, G. Evaluating Real-Life Performance of Lithium-Ion Battery Packs in Electric Vehicles. J. Electrochem. Soc. 2012, 159, A1856. [Google Scholar] [CrossRef]

- Feng, X.; Weng, C.; He, X.; Han, X.; Lu, L.; Ren, D. Online State-of-Health Estimation for Li-Ion Battery Using Partial Charging Segment Based on Support Vector Machine. IEEE Trans. Veh. Technol. 2019, 68, 8583–8592. [Google Scholar] [CrossRef]

- Qin, T.; Zeng, S.; Guo, J.; Skaf, Z. A Rest Time-Based Prognostic Framework for State of Health Estimation of Lithium-Ion Batteries with Regeneration Phenomena. Energies 2016, 9, 896. [Google Scholar] [CrossRef] [Green Version]

- Nuhic, A.; Terzimehic, T.; Soczka-Guth, T.; Buchholz, M.; Dietmayer, K. Health diagnosis and remaining useful life prognostics of lithium-ion batteries using data-driven methods. J. Power Sources 2013, 239, 680–688. [Google Scholar] [CrossRef]

- Song, Z.; Gao, J.; Pan, L.; Xi, J. Lithium-ion battery health status prediction based on principal component analysis and improved support vector machine. Automot. Technol. 2020, 11, 21–27. [Google Scholar]

- Widodoa, A.; Shim, M.; Caesarendra, W.; Yang, B. Intelligent prognostics for battery health monitoring based on sample entropy. Expert Syst. Appl. 2011, 38, 11763–11769. [Google Scholar] [CrossRef]

- Zhang, J.; Lee, J. A review on prognostics and health monitoring of Li-ion battery. J. Power Sources 2011, 195, 6007–6014. [Google Scholar] [CrossRef]

- Zhang, C.; He, Y.; Yuan, L.; Xiang, S.; Wang, J. Prognostics of Lithium-Ion Batteries Based on Wavelet Denoising and DE-RVM. Comput. Intell. Neurosci. 2015, 2015, 918305. [Google Scholar] [CrossRef] [Green Version]

- Liu, D.; Zhou, J.; Pan, D.; Peng, Y.; Peng, X. Lithium-ion battery remaining useful life estimation with an optimized Relevance Vector Machine algorithm with incremental learning. Measurement 2015, 63, 143–151. [Google Scholar] [CrossRef]

- Guo, R.; Liu, Z.; Wei, Y. Remaining useful life prediction for the air turbine starter based on empirical mode decomposition and relevance vector machine. Trans. Inst. Meas. Control 2020, 42, 2578–2588. [Google Scholar] [CrossRef]

- Hao, D. Life Prediction of Satellite Key Components Based on RVM-PF. Ph.D. Thesis, National University of Defense Technology, Changsha, China, 2011. [Google Scholar]

- Qin, X.; Qi, Z.; Zhao, H.; Feng, W.; Guan, X. Prognostics of remaining useful life for lithium-ion batteries based on a feature vector selection and relevance vector machine approach. In Proceedings of the IEEE International Conference on Prognostics & Health Management IEEE, Dallas, TX, USA, 19–21 June 2017. [Google Scholar]

- Shen, S.; Sadoughi, M.; Chen, X.; Hong, M.; Hu, C. A deep learning method for online capacity estimation of lithium-ion batteries. J. Energy Storage 2019, 25, 100817. [Google Scholar] [CrossRef]

- Zhao, L.; Wang, Y.; Cheng, J. A Hybrid Method for Remaining Useful Life Estimation of Lithium-Ion Battery with Regeneration Phenomena. Appl. Sci. 2019, 9, 1890. [Google Scholar] [CrossRef] [Green Version]

- Dong, W.; Qiang, M.; Pecht, M. Prognostics of lithium-ion batteries based on relevance vectors and a conditional three-parameter capacity degradation model. J. Power Sources 2013, 239, 253–264. [Google Scholar]

- Zhou, J. A Method for Predicting the Residual Life of Lithium-Ion Batteries Based on RVM. Ph.D. Thesis, Harbin Institute of Technology, Harbin, China, 2013. [Google Scholar]

- Zhang, Z.; Huang, M.; Chen, Y.; Zhu, S. Prediction of Lithium-ion Battery’s Remaining Useful Life Based on Relevance Vector Machine. SAE Int. J. Altern. Powertrains 2016, 5, 30–40. [Google Scholar] [CrossRef]

- Liu, T.; Sun, Q.; Feng, J.; Pan, Z.; Huangpeng, Q. Residual life estimation under time-varying conditions based on a Wiener process. J. Stat. Comput. Simul. 2017, 87, 211–226. [Google Scholar] [CrossRef]

- Jin, G.; David, E.M.; Zhou, Z. A Bayesian framework for on-line degradation assessment and residual life prediction of secondary batteries inspacecraft. Reliab. Eng. Syst. Saf. 2013, 113, 7–20. [Google Scholar] [CrossRef]

- Feng, J.; Kvam, P.; Tang, Y. Remaining useful lifetime prediction based on the damage-marker bivariate degradation model: A case study on lithium-ion batteries used in electric vehicles. Eng. Fail. Anal. 2016, 70, 323–342. [Google Scholar] [CrossRef]

- Zhai, Q.; Ye, Y. RUL Prediction of Deteriorating Products Using an Adaptive Wiener Process Model. IEEE Trans. Ind. Inform. 2017, 13, 2911–2921. [Google Scholar] [CrossRef]

- Xu, X.; Yu, C.; Tang, S.; Sun, X.; Wu, L. State-of-Health Estimation for Lithium-ion Batteries Based on Wiener Process with Modeling the Relaxation Effect. IEEE Access 2019, 7, 105186–105201. [Google Scholar] [CrossRef]

- Hartikainen, J.; Särkkä, S. Kalman filtering and smoothing solutions to temporal Gaussian process regression models. In Proceedings of the IEEE International Workshop on Machine Learning for Signal Processing, Kittila, Finland, 29 August–1 September 2010. [Google Scholar]

- Yang, D.; Zhang, X.; Pan, R.; Wang, Y.; Chen, Z. A novel Gaussian process regression model for state-of-health estimation of lithium-ion battery using charging curve. J. Power Sources 2018, 384, 387–395. [Google Scholar] [CrossRef]

- He, Y.; Shen, J.; Shen, J.; Ma, Z. State of health estimation of lithium-ion batteries: A multiscale Gaussian process regression modeling approach. AIChE J. 2015, 61, 1589–1600. [Google Scholar] [CrossRef]

- Lu, M. Research on Power Battery SOH Estimation and Fault Prediction Method. Master’s Thesis, Beijing University of Technology, Beijing, China, 2015. [Google Scholar]

- Richardson, R.R.; Osborne, M.A.; Howey, D.A. Gaussian process regression for forecasting battery state of health. J. Power Sources 2017, 357, 209–219. [Google Scholar] [CrossRef]

- Liu, D.; Pang, J.; Zhou, J.; Yu, P.; Pecht, M. Prognostics for state of health estimation of lithium-ion batteries based on combination Gaussian process functional regression. Microelectron. Reliab. 2013, 53, 832–839. [Google Scholar] [CrossRef]

- Fan, T.; Wei, Z. Ensemble of model-based and data-driven prognostic approaches for reliability prediction. In Proceedings of the 2017 Prognostics and System Health Management Conference (PHM-Harbin), Harbin, China, 9–12 July 2017. [Google Scholar]

- Eddahech, A.; Briat, O.; Bertrand, N.; Delétage, J.Y.; Vinassa, J.M. Behavior and State-of-Health Monitoring of Li-ion Batteries Using Impedance Spectroscopy and Recurrent Neural Networks. Int. J. Electr. Power Energy Syst. 2012, 42, 487–494. [Google Scholar] [CrossRef]

- Zhang, H. A New Method for Estimating the SOH of Lithium Batteries Based on IMM. Master’s Thesis, Hefei University of Technology, Hefei, China, 2019. [Google Scholar]

- Wei, J.; Dong, G.; Chen, Z. Remaining Useful Life Prediction and State of Health Diagnosis for Lithium-Ion Batteries Using Particle Filter and Support Vector Regression. IEEE Trans. Ind. Electron. 2018, 65, 5634–5643. [Google Scholar] [CrossRef]

- Wang, Z.; Ma, J.; Zhang, L. State-of-Health Estimation for Lithium-Ion Batteries Based on the Multi-Island Genetic Algorithm and the Gaussian Process Regression. IEEE Access 2017, 5, 21286–21295. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, Y.; Liu, C.; Chen, Z. A novel approach of battery pack state of health estimation using artificial intelligence optimization algorithm. J. Power Sources 2018, 376, 191–199. [Google Scholar] [CrossRef]

- Li, L. A Novel Online Parameter Identification Algorithm for Fractional-Order Equivalent Circuit Model of Lithium-Ion Batteries. Int. J. Electrochem. Sci. 2020, 15, 6863–6879. [Google Scholar] [CrossRef]

- Andre, D.; Appel, C.; Soczka-Guth, T.; Sauer, D.U. Advanced mathematical methods of SOC and SOH estimation for lithium-ion batteries. J. Power Sources 2013, 225, 20–27. [Google Scholar] [CrossRef]

- Tang, X.; Zou, C.; Yao, K.; Chen, G.; Liu, B.; He, Z.; Gao, F. A fast estimation algorithm for lithium-ion battery state of health. J. Power Sources 2018, 396, 453–458. [Google Scholar] [CrossRef]

- Chang, Y.; Fang, H. A hybrid prognostic method for system degradation based on particle filter and relevance vector machine. Reliab. Eng. Syst. Saf. 2019, 186, 51–63. [Google Scholar] [CrossRef]

- Hong, S.; Yue, T.; Liu, H. Vehicle energy system active defense: A health assessment of lithium-ion batteries. Int. J. Intell. Syst. 2020, 1, 1–19. [Google Scholar] [CrossRef]

- Yun, Z.; Qin, W.; Shi, W.; Ping, P. State-of-Health Prediction for Lithium-Ion Batteries Based on a Novel Hybrid Approach. Energies 2020, 13, 4858. [Google Scholar] [CrossRef]

- Krawczyk, B.; Minku, L.L.; Gama, J.; Stefanowski, J.; Woniak, M. Ensemble learning for data stream analysis: A survey. Inf. Fusion 2017, 37, 132–156. [Google Scholar] [CrossRef] [Green Version]

- Sagi, O.; Rokach, L. Ensemble learning: A survey. Wiley Interdiscip. Rev. Data Min. Knowl. Discov. 2018, 8, e1249. [Google Scholar] [CrossRef]

- Gomes, H.M.; Barddal, J.P.; Enembreck, F.; Bifet, A. A Survey on Ensemble Learning for Data Stream Classification. ACM Comput. Surv. 2017, 50, 1–36. [Google Scholar] [CrossRef]

- Ma, C.; Zhai, X.; Wang, Z.; Tian, M.; Yu, Q.; Liu, L. State of health prediction for lithium-ion batteries using multiple- view feature fusion and support vector regression ensemble. Int. J. Mach. Learn. Cybern. 2019, 10, 2269–2282. [Google Scholar] [CrossRef]

- Li, Y.; Zou, C.; Berecibar, M.; Nanini-Maury, E.; Chan, C.W.; Peter, V. Random forest regression for online capacity estimation of lithium-ion batteries. Appl. Energy 2018, 232, 197–210. [Google Scholar] [CrossRef]

- Chen, Z. On-Board State of Health Estimation for Lithium-ion Battery Using Random Forest. In Proceedings of the 2018 IEEE International Conference on Industrial Technology (ICIT), Lyon, France, 20–22 February 2018. [Google Scholar]

| Sequence Number | Recession Reason | Influence | Consequence |

|---|---|---|---|

| 1 | Phase transition of electrode materials | Crystal distortion, internal stress changes. | The capacity decreases |

| 2 | The electrode kinetics performance of recession | The inactivation and disembedment, reactions were difficult to carry out. | The internal resistance increases, the capacity decreases. |

| 3 | The decomposition of electrolyte | Reduction reaction, gas overflow. | The capacity decreases |

| 4 | The generation of SEI film | Lithium-ion depletion and deactivation. | The capacity decreases, power reduction. |

| Method | Advantage | Disadvantage |

|---|---|---|

| Electrochemical model method | High precision, the theory of aging is well supported, the movement law of ions and the change trend of active substances are described. | Model complexity, more parameters, online estimation and prediction ability is weak. |

| Equivalent circuit model method | Model simplicity, methods mature, easy to operate, high engineering application value. | With the development of technology, the accuracy cannot meet the requirements. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yao, L.; Xu, S.; Tang, A.; Zhou, F.; Hou, J.; Xiao, Y.; Fu, Z. A Review of Lithium-Ion Battery State of Health Estimation and Prediction Methods. World Electr. Veh. J. 2021, 12, 113. https://doi.org/10.3390/wevj12030113

Yao L, Xu S, Tang A, Zhou F, Hou J, Xiao Y, Fu Z. A Review of Lithium-Ion Battery State of Health Estimation and Prediction Methods. World Electric Vehicle Journal. 2021; 12(3):113. https://doi.org/10.3390/wevj12030113

Chicago/Turabian StyleYao, Lei, Shiming Xu, Aihua Tang, Fang Zhou, Junjian Hou, Yanqiu Xiao, and Zhijun Fu. 2021. "A Review of Lithium-Ion Battery State of Health Estimation and Prediction Methods" World Electric Vehicle Journal 12, no. 3: 113. https://doi.org/10.3390/wevj12030113

APA StyleYao, L., Xu, S., Tang, A., Zhou, F., Hou, J., Xiao, Y., & Fu, Z. (2021). A Review of Lithium-Ion Battery State of Health Estimation and Prediction Methods. World Electric Vehicle Journal, 12(3), 113. https://doi.org/10.3390/wevj12030113